engine coolant MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 470 of 2103

![MITSUBISHI SPYDER 1990 Service Manual PDF E N G I N E

INSPECTION PROCEDURE 9

Idle speed is high. (Improper idle speed)

[Comment] lIn such cases as the above, the cause is probably that the intake air volume during MITSUBISHI SPYDER 1990 Service Manual PDF E N G I N E

INSPECTION PROCEDURE 9

Idle speed is high. (Improper idle speed)

[Comment] lIn such cases as the above, the cause is probably that the intake air volume during](/img/19/57345/w960_57345-469.png)

E N G I N E

INSPECTION PROCEDURE 9

Idle speed is high. (Improper idle speed)

[Comment] lIn such cases as the above, the cause is probably that the intake air volume during idle is’ ltoo great. Intake manifold vacuum leak b o d y

SCAN TOOL DTC

Are diagnostic trouble codes output

NO

07 motor (Refer to

NG

Refer to INSPECTION CHART FOR DIAGNOSTICTROUBLE CODES.

Checktheidleaircontrolmotorcircuit.PROCEDURE FOR DIAGNOSTIC TROUBLE

OK

SCAN TOOLSpecial function

“Reset

Check trouble symptoms.

NG

SCAN TOOL SENSOR NGCheck the engine coolant temperature circuit.(Refer to INSPECTION

OK

SCAN TOOL OUTPUT clutch relay (Refer to

OK

NGCheck the switch and compressor clutch relay to INSPECTION PROCEDURE 26.)

Check the throttle body minimum air flow.

(Refer to

INSPECTION PROCEDURE 10

Idle speed is low. (Improper idle speed) Probable ca use

,

[Comment]l control motor In cases such as the above, the cause is probably that the intake air volume during idling is l

Malfunction of the’ throttle body

too small.

SCAN TOOL DTC

YESRefer to INSPECTION CHART FOR DIAGNOSTIC

Are diagnostic troublecodesoutputTROUBLE CODES.

SCAN TOOL Actuator test

07 motor. (Refer to

OK

NG

PROCEDURE FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL Special function

“Reset

Check trouble

OK

Check the engine coolant temperature circuit. (Refer to INSPECTION PROCEDURE 36.)

SCAN TOOL INPUT STATE TESTS

list) position switch (transaxle range switch)

(Refer to

OK Checktransaxle range sensorcircuit.

INSPECTION

PROCEDURE 25.)

Check the throttle body minimum air flow.

(Refer to

TSB Revision

Page 481 of 2103

ENGINE (NON-TURBO)>

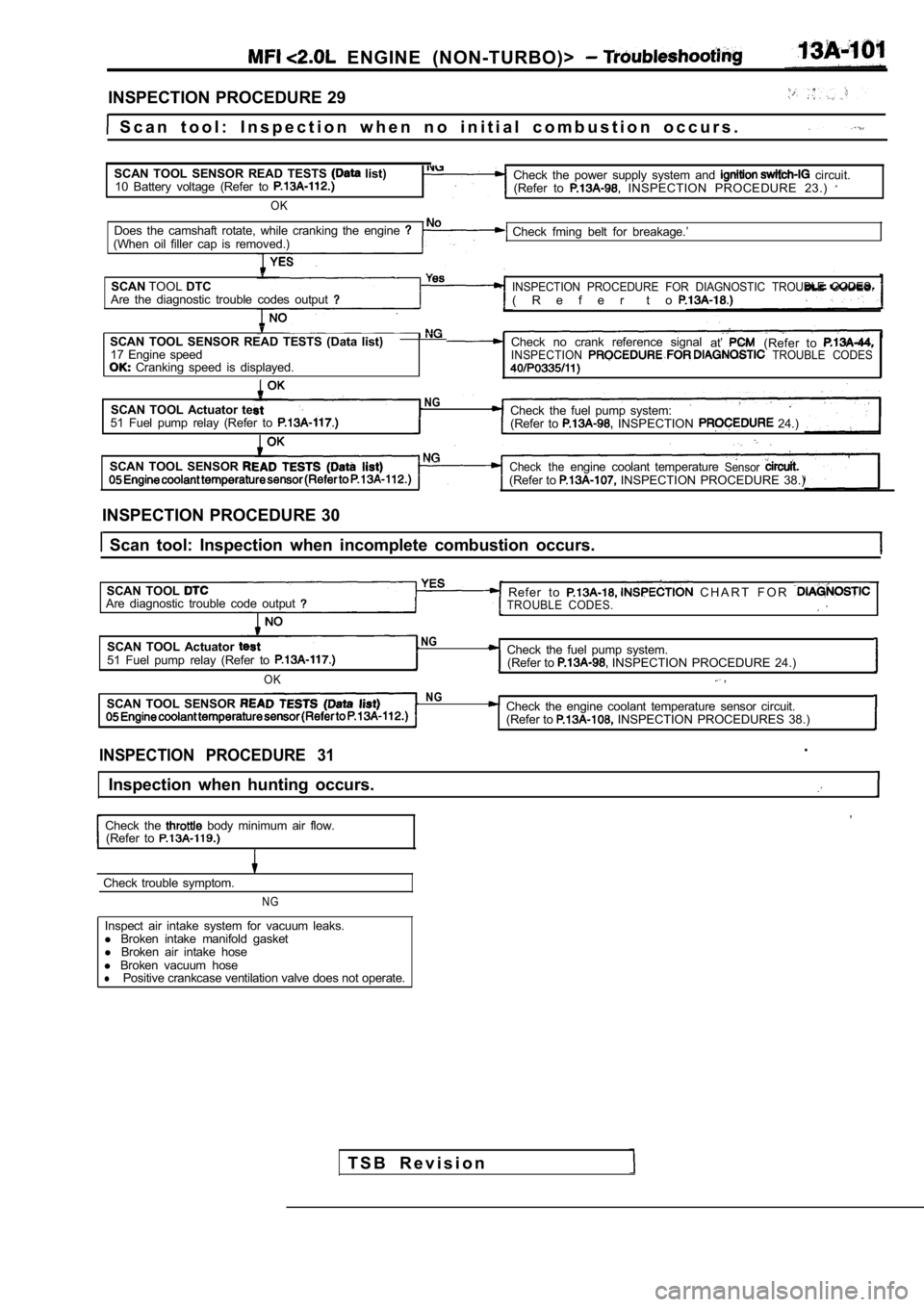

INSPECTION PROCEDURE 29

S c a n t o o l : I n s p e c t i o n w h e n n o i n i t i a l c o m b u s t i o n oc c u r s .

SCAN TOOL SENSOR READ TESTS

list)

10 Battery voltage (Refer to

OK

Check the power supply system and circuit.

(Refer to INSPECTION PROCEDURE 23.)

Does the camshaft rotate, while cranking the engine (When oil filler cap is removed.) Check fming belt for breakage.’

SCAN TOOLDTC

INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODES.Are the diagnostic trouble codes output( R e f e r t o

SCAN TOOL SENSOR READ TESTS (Data list) Check no crank reference signal

at’(Refer to 17 Engine speedINSPECTION TROUBLE CODES Cranking speed is displayed.

SCAN TOOL Actuator teNGCheck the fuel pump system:51 Fuel pump relay (Refer to (Refer to INSPECTION 24.)

SCAN TOOL SENSOR

Check theengine coolant temperatureSensor(Refer to INSPECTION PROCEDURE 38.)

INSPECTION PROCEDURE 30

Scan tool: Inspection when incomplete combustion o ccurs.

SCAN TOOL

Refer to C H A R T F O R Are diagnostic trouble code outputTROUBLE CODES.

SCAN TOOL Actuator NG

51 Fuel pump relay (Refer to Check the fuel pump system. (Refer to INSPECTION PROCEDURE 24.)

OK ,

SCAN TOOL SENSOR NGCheck the engine coolant temperature sensor circuit .

(Refer to INSPECTION PROCEDURES 38.)

INSPECTION PROCEDURE 31.

Inspection when hunting occurs.

,

Check the body minimum air flow.

(Refer to

Check trouble symptom.

NG

Inspect air intake system for vacuum leaks.

l Broken intake manifold gasket

l Broken air intake hose

l Broken vacuum hose

lPositive crankcase ventilation valve does not opera te.

T S B R e v i s i o n

Page 482 of 2103

ENGINE (NON-TURBO)>

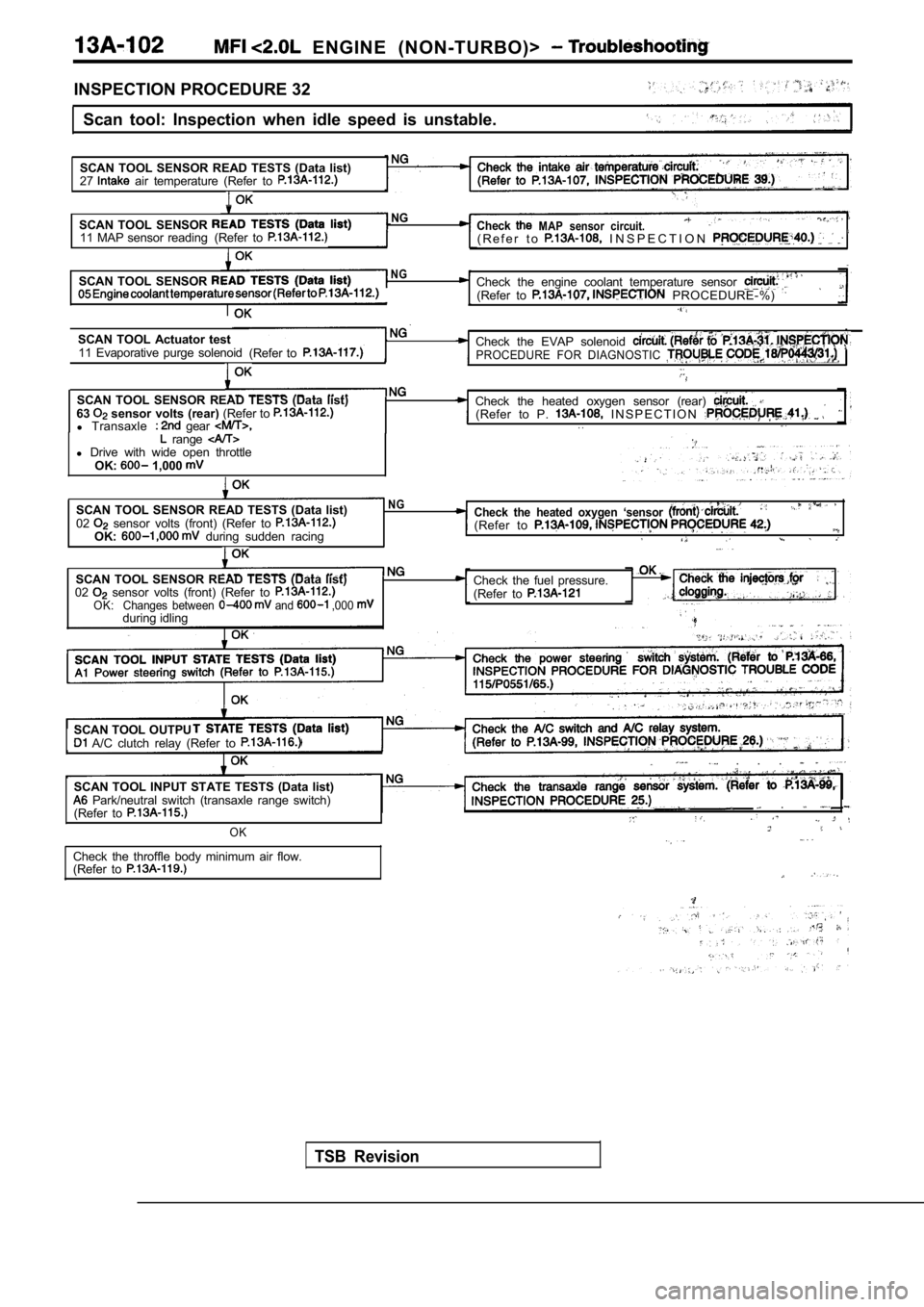

INSPECTION PROCEDURE 32Scan tool: Inspection when idle speed is unstable.

SCAN TOOL SENSOR READ TESTS (Data list)

27

air temperature (Refer to . .

SCAN TOOL SENSOR 11 MAP sensor reading (Refer to

NG CheckMAP sensor circuit.( R e f e r t o I N S P E C T I O N

SCAN TOOL SENSOR NGCheck the engine coolant temperature sensor (Refer to PROCEDURE-%)

SCAN TOOL Actuator test11 Evaporative purge solenoid (Refer toCheck the EVAP solenoid PROCEDURE FOR DIAGNOSTIC

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear

Check the heated oxygen sensor (rear) (Refer to P. I N S P E C T I O N . . range l Drive with wide open throttle

OK: 1,000

SCAN TOOL SENSOR READ TESTS (Data list)NG

02 sensor volts (front) (Refer to Check the heated oxygen ‘sensor

OK: during sudden racing (Refer to

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to Changes between and ,000 OK:during idling Check the fuel pressure.

(Refer to

SCAN TOOL OUTPU A/C clutch relay (Refer to

SCAN TOOL INPUT STATE TESTS (Data list) Park/neutral switch (transaxle range switch)

(Refer to

OK

Check the throffle body minimum air flow.

(Refer to

. . .

. .

TSB Revision

Page 483 of 2103

(NON-TURBO)> .

INSPECTION PROCEDURE 33

Scan tool: Inspection when engine. stalls when, engine warm

SCAN TOOL SENSOR READ TESTS (Data list)

27 air temperature sensor (Refer to

.

SCAN TOOL SENSOR N G ’ Check the MAP sensor circuit

11 MAP sensor reading (Refer to

(Refer to INSPECTION

SCAN TOOL SENSOR Check the engine coolant temperature sensor circuit . (Refer to INSPECTION PROCEDURE 38.) .

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear range l with wide open throttle

OK: 1,000

OK

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between 1,000 during sudden

racing

OK Check the heated oxygen sensor (rear) circuit.

(Refer to

INSPECTION ,

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between and 1,000 during idling

SCAN TOOL INPUT STATE TESTS (Data

list)Al Power steering switch (Refer to

Check the fuel pressure. (Refer to

,

Check the power steering switch (Refer INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODE

.

SCAN TOOL OUTPUT

A/C clutch relay (Refer to

OK

NGCheck the switch and ( R e f e r t o .

SCAN TOOL INPUT STATE TESTS (Data list) Park/neutral switch (transaxle range switch)

(Refer to (Refer toINSPECTION PROCEDURE 25.)

OK

Check the throttle body minimum air flow. to I

TSB

Page 485 of 2103

E N G I N E

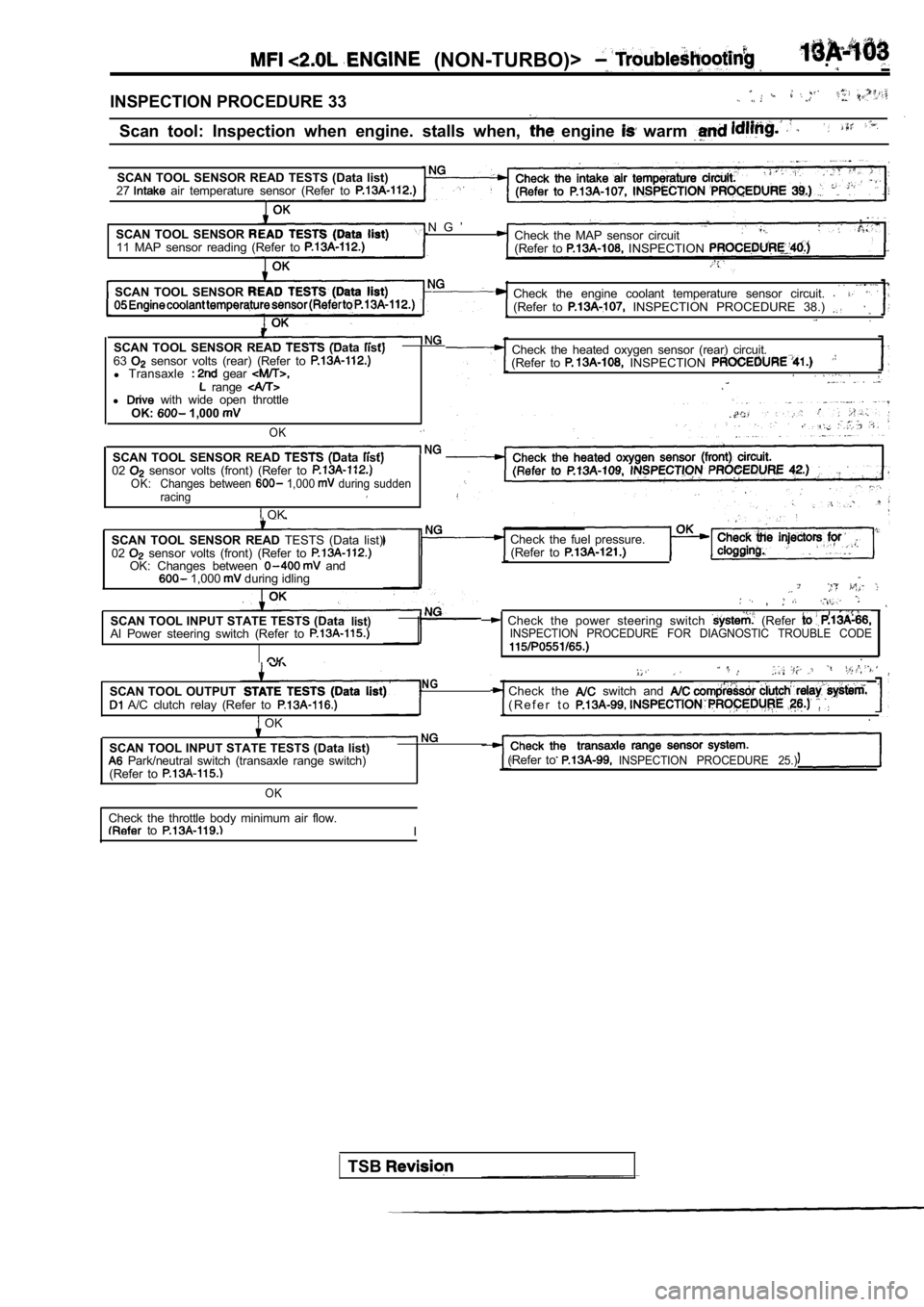

INSPECTION PROCEDURE 35

Scan tool: Inspection when surge occurs.

SCAN TOOL SENSOR READ TESTS (Data list)

27 Intake air temperature sensor (Refer to

Check the intake air’ (Refer to INSPECTION. PROCEDURE 39.)

SCAN TOOL SENSOR 11 MAP sensor reading (Refer to

OK NG

Check the MAP sensor it.(Refer to INSPECTION PROCEDURE 40.)

SCAN TOOL SENSOR READ

N GCheck the engine coolant temperature sensor circuit

.

(Refer to INSPECTION PROCEDURE 38.)

SCAN TOOL SENSOR NGCheck the position circuit.

07 Throttle position sensor (Refer to(Refer to INSPECTION PROCEDURE 43.)

SCAN TOOL Actuator test

16 EGR solenoid (Refer to

OK Check the EGR solenoid circuit- (Refer to

INSPECTIONPROCEDURE FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear range l with wide open throttle

OK:

NG

(Refer to INSPECTION PROCEDURE 41.)

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between 1,000 during sudden

racing

Check the heated oxygen sensor (front) (Refer to PROCEDURE 42.)

SCAN TOOL SENSOR 02 sensor (front) (Refer toOK: Changes between and during idling Check the fuel pressure.

(Refer to

INSPECTION PROCEDURE 36

Check the fuel pump circuit.

Measure at the fuel pump connector

Check the harness wire between fuel pump-and lDisconnect the connector and measure at the harness necessary.

side.

l Continuity between 2 and ground

O K :

OK

Check the following connectNG Repair

OK

Check trouble symptom.

NG

Check the harness wirerelay and fuel pumpconnector.

OK

N G Repair

Replace the fuel pump.

TSB Revision

Page 487 of 2103

E N G I N E

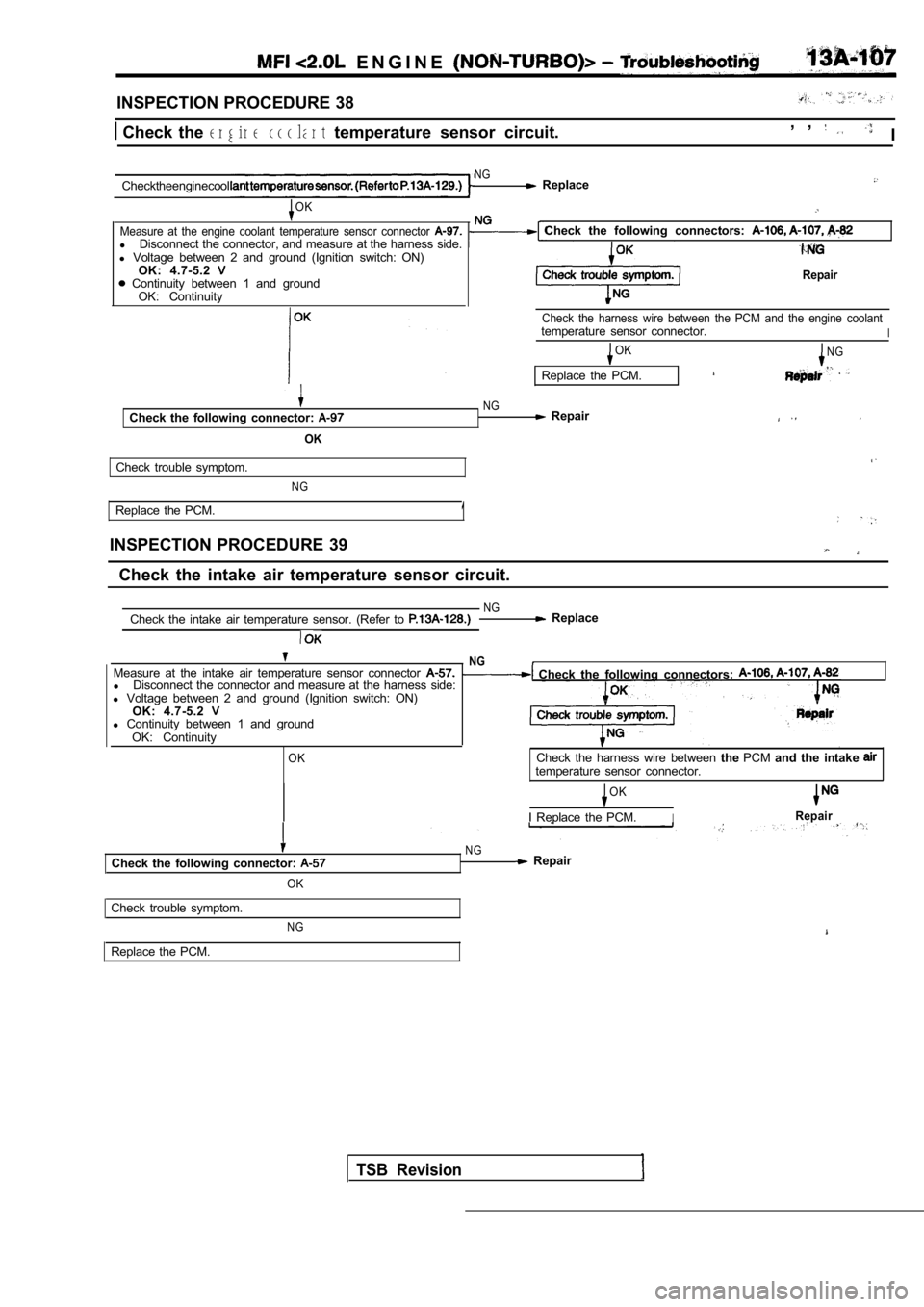

INSPECTION PROCEDURE 38

Check the engine coolant temperature sensor circuit. , , I

Checktheenginecool

NG Replace

OK

Measure at the engine coolant temperature sensor co nnector

lDisconnect the connector, and measure at the harnes s side.

l Voltage between 2 and ground (Ignition switch: ON)

OK: 4.7-5.2

Continuity between 1 and ground OK: Continuity

Check the following connectors:

Repair

Check the harness wire between the PCM and the engi ne coolanttemperature sensor connector.I

Check the following connector:

OK

OKN G

Replace the PCM.

NG Repair

Check trouble symptom.

N G

Replace the PCM.

INSPECTION PROCEDURE 391

Check the intake air temperature sensor circuit.

NGCheck the intake air temperature sensor. (Refer to Replace

NGMeasure at the intake air temperature sensor connec tor Check the following connectors: lDisconnect the connector and measure at the harness side:

l Voltage between 2 and ground (Ignition switch: ON)

OK: 4.7-5.2

l Continuity between 1 and ground

OK: Continuity

OKCheck the harness wire between thePCM and the intake temperature sensor connector.

OK

I Replace the PCM.IRepair

Check the following connector:

OK

NG Repair

Check trouble symptom.

Replace the PCM.

NG

TSB Revision

Page 492 of 2103

ENGINE (NON-TURBO)> Troubleshooting

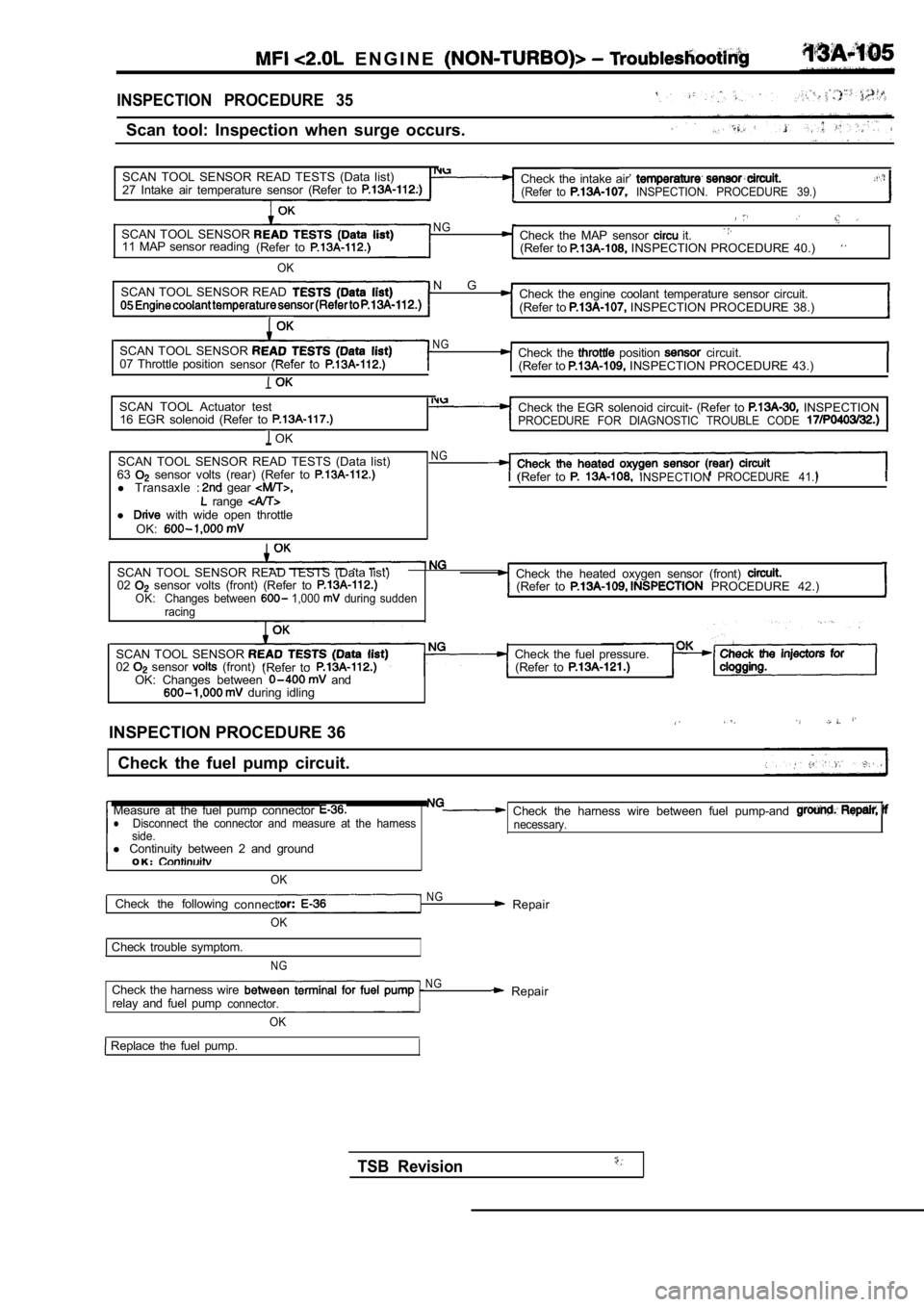

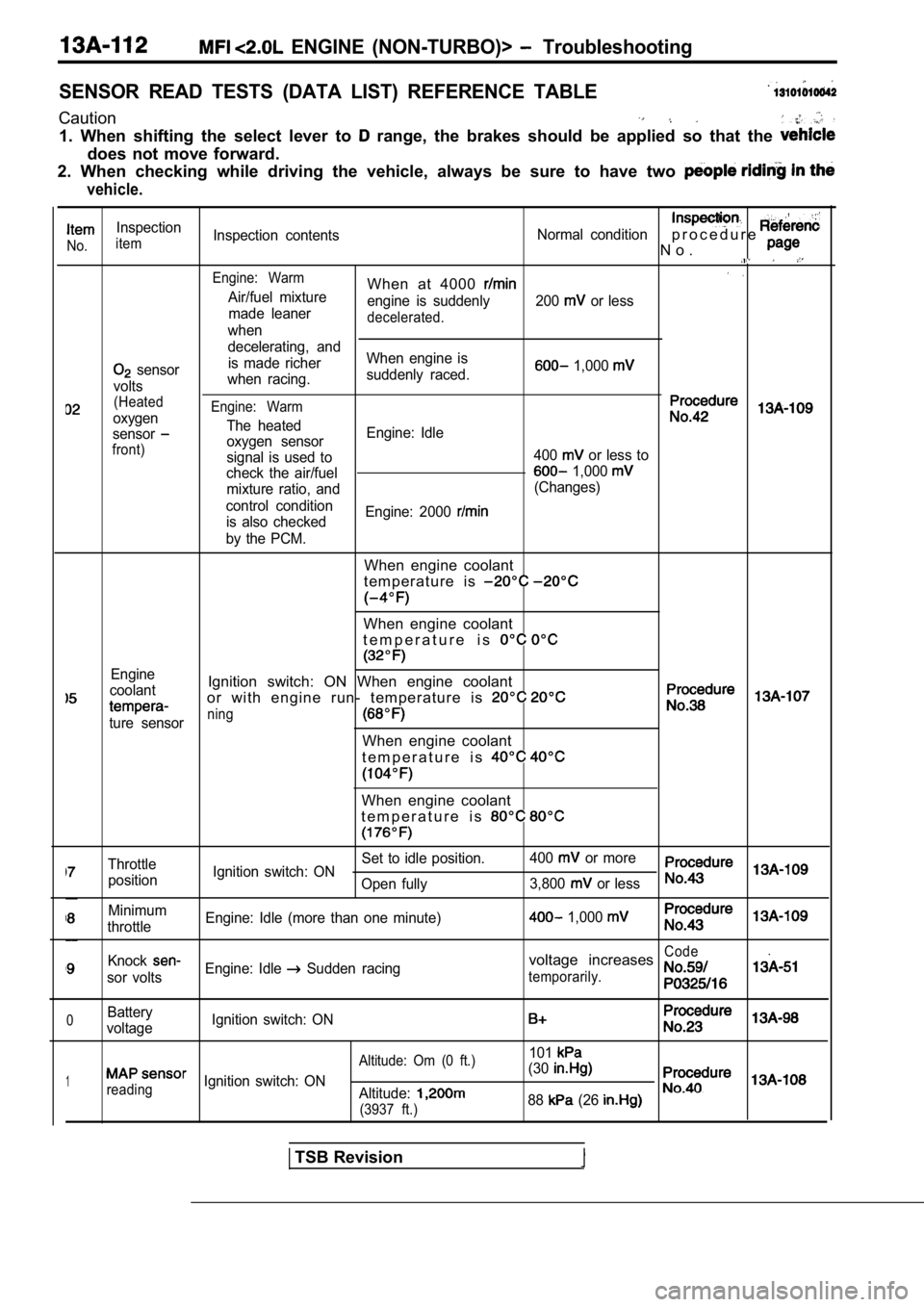

SENSOR READ TESTS (DATA LIST) REFERENCE TABLE

Caution

1. When shifting the select lever to range, the brakes should be applied so that the

does not move forward.

2. When checking while driving the vehicle, always be sure to have two

vehicle.

Inspection

No.itemInspection contents

Normal conditionp r o c e d u r e

N o .

Engine: WarmWhen at 4000 Air/fuel mixture

engine is suddenly 200 or less

made leaner

decelerated.when

decelerating, and

sensor is made richer

When engine is 1,000

voltswhen racing.

suddenly raced.

(Heated

oxygenEngine: Warm

The heatedsensoroxygen sensor Engine: Idlefront)signal is used to

400 or less to

check the air/fuel

1,000

mixture ratio, and (Changes)

control condition is also checked Engine: 2000

by the PCM.

When engine coolant

t e m p e r a t u r e i s

When engine coolant

t e m p e r a t u r e i s

Engine

coolantIgnition switch: ON When engine coolant

or with engine run- temperature is

ture sensorning

When engine coolant

t e m p e r a t u r e i s

When engine coolant

t e m p e r a t u r e i s

Throttle Set to idle position.

400 or more

position Ignition switch: ON

Open fully 3,800

or less

Minimum

throttle Engine: Idle (more than one minute) 1,000

KnockCode

sor voltsEngine: Idle Sudden racingvoltage increases

temporarily.

0Battery

voltage Ignition switch: ON

101

1

Altitude: Om (0 ft.)

reading

Ignition switch: ON (30Altitude:

(3937 ft.)88 (26

TSB Revision

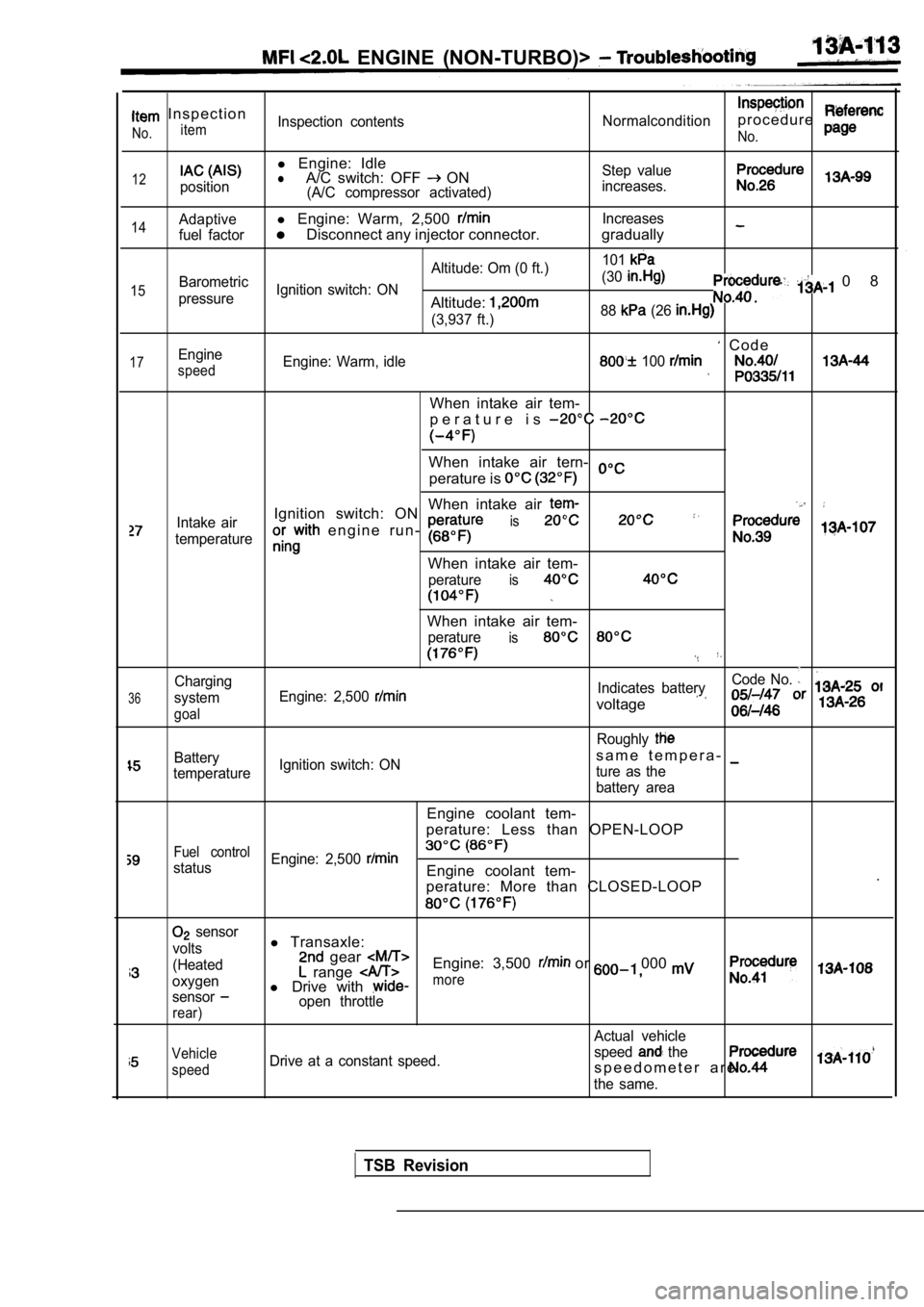

Page 493 of 2103

ENGINE (NON-TURBO)>

I n s p e c t i o n

itemNo.Inspection contentsNormalconditionp r o c e d u r e

No.

12position

l Engine: IdlelA/C switch: OFF ON(A/C compressor activated) Step value

increases.

14

15

17

Adaptivel Engine: Warm, 2,500 Increases

fuel factor

Disconnect any injector connector. gradually

Altitude: Om (0 ft.) 101Barometric

Ignition switch: ON (30

pressureAltitude:

0 8

(3,937 ft.)

88 (26

C o d eEngine

speedEngine: Warm, idle 100

When intake air tem-

p e r a t u r e i s

When intake air tern-

perature is

When intake air

Intake airIgnition switch: ON

e n g i n e r u n - is

temperature

When intake air tem-

peratureis

36

Charging

system

goal

When intake air tem-

peratureis

Code No.

Engine: 2,500 Indicates battery

voltage

Roughly

Batterys a m e t e m p e r a -

temperature Ignition switch: ON

ture as the

battery area

Engine coolant tem-

perature: Less than OPEN-LOOP

Fuel control

status Engine: 2,500 Engine coolant tem-

.

perature: More than CLOSED-LOOP

sensor

volts

(Heated

oxygen

sensor

rear)

l Transaxle: gear Engine: 3,500 or 000 range l Drive with more

open throttle

Actual vehicle

Vehicle

speedDrive at a constant speed. speed the

s p e e d o m e t e r a r e .

the same.

TSB Revision

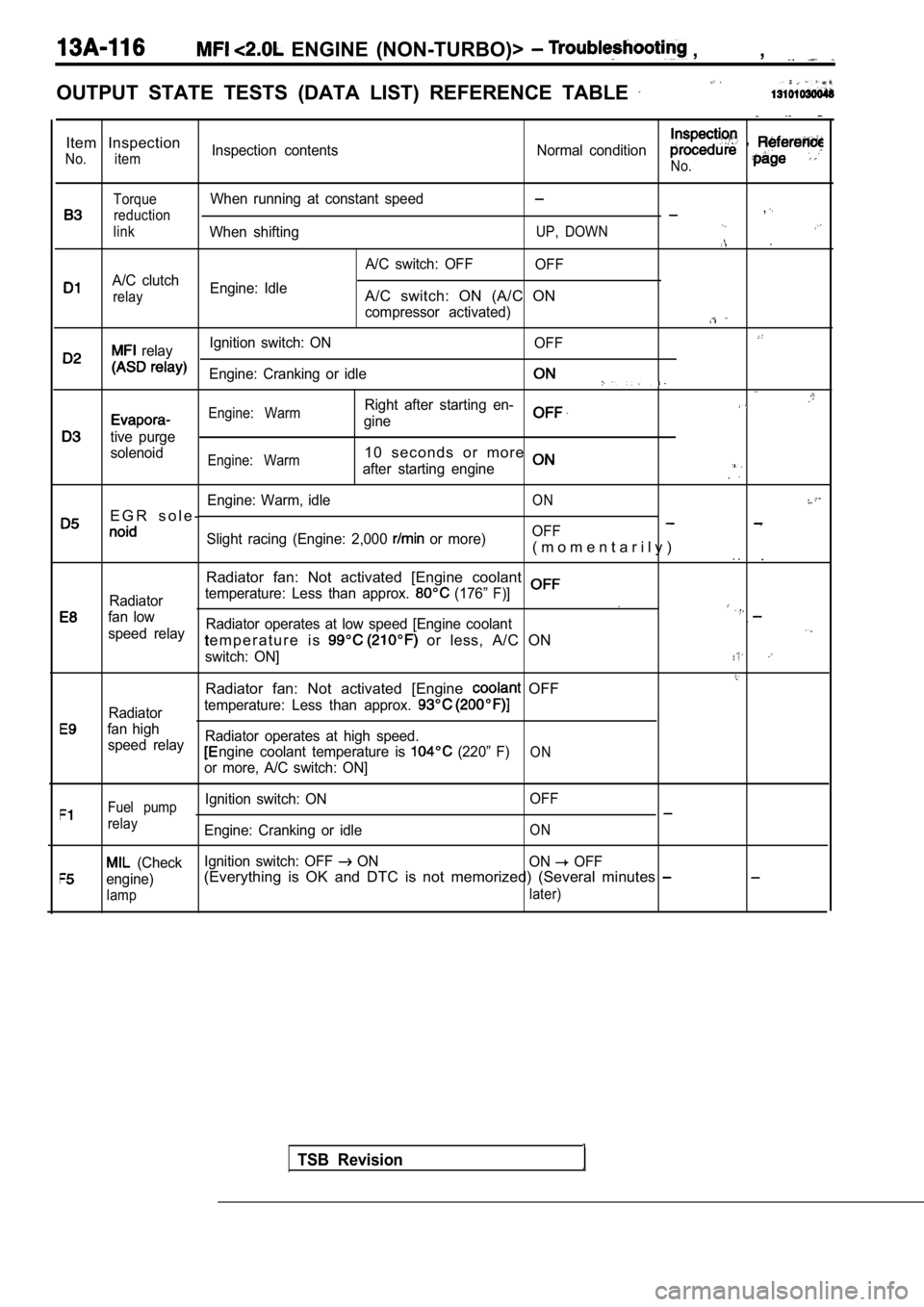

Page 496 of 2103

ENGINE (NON-TURBO)> , ,

OUTPUT STATE TESTS (DATA LIST) REFERENCE TABLE

Item Inspection

No. itemInspection contentsNormal condition ,

No.

TorqueWhen running at constant speed

reduction,

linkWhen shiftingUP, DOWN

A/C switch: OFFOFF

A/C clutch

relayEngine: IdleA/C switch: ON (A/C ON

compressor activated)

relayIgnition switch: ON

OFF

Engine: Cranking or idle

Engine: WarmRight after starting en-

gine

tive purge

solenoid

Engine: Warm1 0 s e c o n d s o r m o r e

after starting engine

Engine: Warm, idleON

E G R s o l e -OFFSlight racing (Engine: 2,000 or more)( m o m e n t a r i l y ). ..

Radiator fan: Not activated [Engine coolant

Radiator temperature: Less than approx. (176” F)]

fan lowRadiator operates at low speed [Engine coolantspeed relaye m p e r a t u r e i s or less, A/C ON

switch: ON]

Radiator fan: Not activated [Engine OFF

Radiatortemperature: Less than approx.

fan high

speed relay Radiator operates at high speed.

ngine coolant temperature is (220” F)ON

or more, A/C switch: ON]

Fuel pumpIgnition switch: ON

OFF

relayEngine: Cranking or idleON

(CheckIgnition switch: OFF ON

ON OFF

engine)(Everything is OK and DTC is not memorized) (Severa l minutes

lamp later)

TSB Revision

Page 509 of 2103

On-vehicle Inspection of

ENGINE

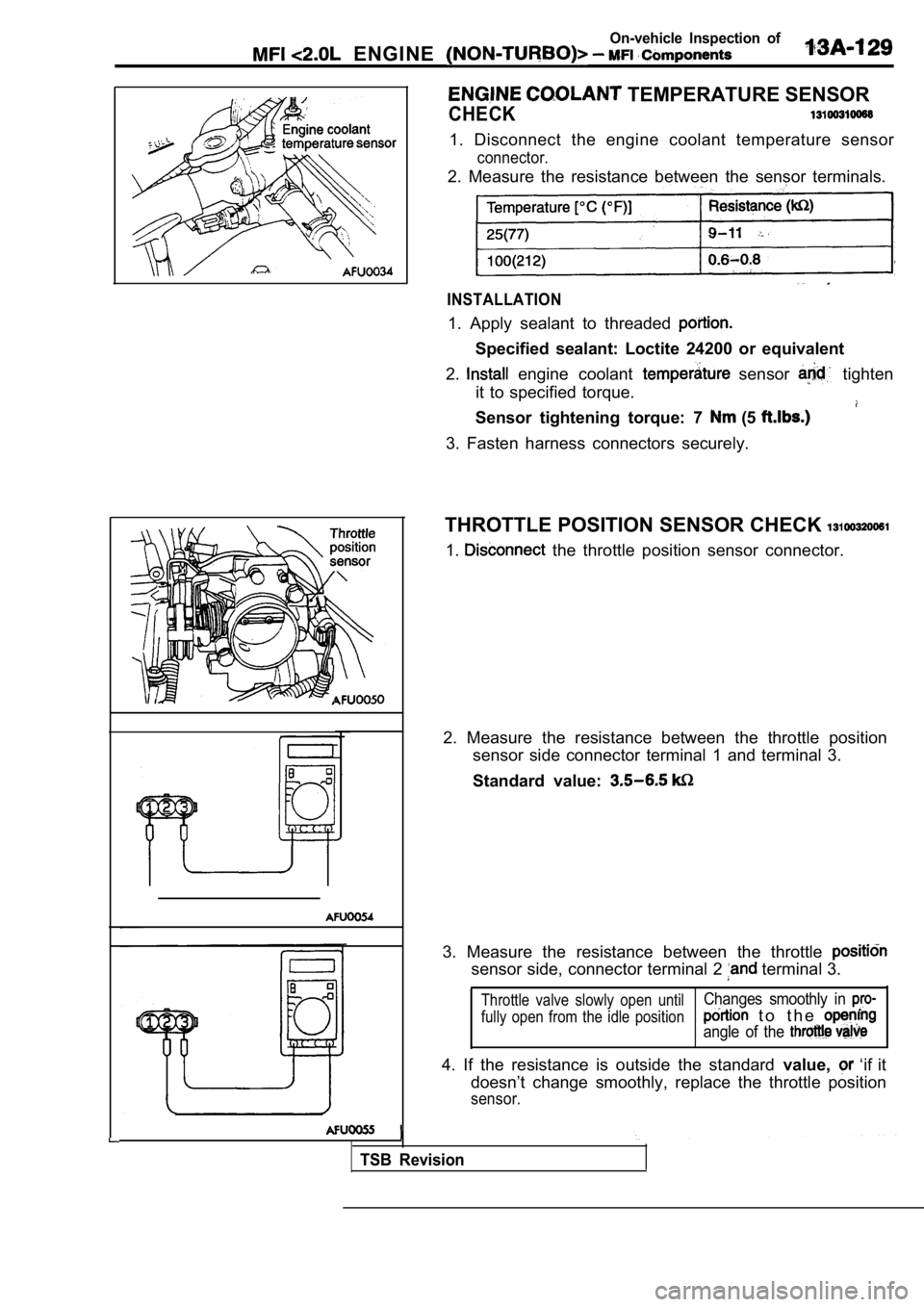

TEMPERATURE SENSOR

CHECK

1. Disconnect the engine coolant temperature sensor

connector.

2. Measure the resistance between the sensor terminals.

INSTALLATION

1. Apply sealant to threaded

Specified sealant: Loctite 24200 or equivalent

2.

engine coolant sensor tighten

it to specified torque.

Sensor tightening torque: 7 (5

3. Fasten harness connectors securely.

THROTTLE POSITION SENSOR CHECK

1. the throttle position sensor connector.

2. Measure the resistance between the throttle posi tion

sensor side connector terminal 1 and terminal 3.

Standard value:

3. Measure the resistance between the throttle

sensor side, connector terminal 2 terminal 3.

Throttle valve slowly open until

fully open from the idle positionChanges smoothly in

t o t h e

angle of the

4. If the resistance is outside the standard value, ‘if it

doesn’t change smoothly, replace the throttle posit ion

sensor.

TSB Revision