engine MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 108 of 2103

![MITSUBISHI SPYDER 1990 Service Manual PDF ENGINE OVERHAUL

Items Standard value

Piston ring end gap mm (in.)

Piston pin O.D. mm (in.)

0 . 8

Oil 9 . 8

21

Piston pin press-in load (Ibs.)

[Room temperature]

Crankshaft pin MITSUBISHI SPYDER 1990 Service Manual PDF ENGINE OVERHAUL

Items Standard value

Piston ring end gap mm (in.)

Piston pin O.D. mm (in.)

0 . 8

Oil 9 . 8

21

Piston pin press-in load (Ibs.)

[Room temperature]

Crankshaft pin](/img/19/57345/w960_57345-107.png)

ENGINE OVERHAUL

Items Standard value

Piston ring end gap mm (in.)

Piston pin O.D. mm (in.)

0 . 8

Oil 9 . 8

21

Piston pin press-in load (Ibs.)

[Room temperature]

Crankshaft pin oil clearance mm (in.) 17,500

Connecting rod big end side clearance mm (in.)

Crankshaft, flywheel and drive plate

Bearing cap bolt shank length mm (in.)

0 . 4

Crankshaft end play mm (in.)

Crankshaft journal O.D. mm (in.) 0 . 2 5

57 (2.24)

pin O.D. mm (in.) 42 (1.77)

Crankshaft journal oil clearance mm (in.)

to cylinder clearance mm (in.)

0 . 1

block flatness of gasket surface mm (in.) 0.05 0.1

block grinding limit of gasket surface mm (in.)l 0.2‘Total resurfacing depth of both cylinder head and cylinder block

block overall height mm (in.)283.9-284.1

(11.177-11.185)

block I.D. mm (in.) 85.0 (3.35)

TSBRevision

REWORK DIMENSIONS

Items

Cylinder head and valve

Oversize rework dimensions of valve guide0.05 O.S.

hole (both intake and exhaust) mm (in.) 0.25 O.S.

0.50

Intake oversize rework 0.3

dimensions of valve seat hole mm (in.)

0.6 O.S.

Exhaust oversize rework dimensions of valve 0.3 O.S.

seat hole

mm (in.)0.6 O.S.

Crankshaft, flywheel and drive plate

Crankshaft out of roundness and taper of journal an d pin mm (in.)

Standard value

12.25-12.27 ,

,

Max. 0.01

NOTE

O.D.: Outer diameter

I.D.: Inner diameter

Oversize diameter

Page 109 of 2103

ENGINE OVERHAUL

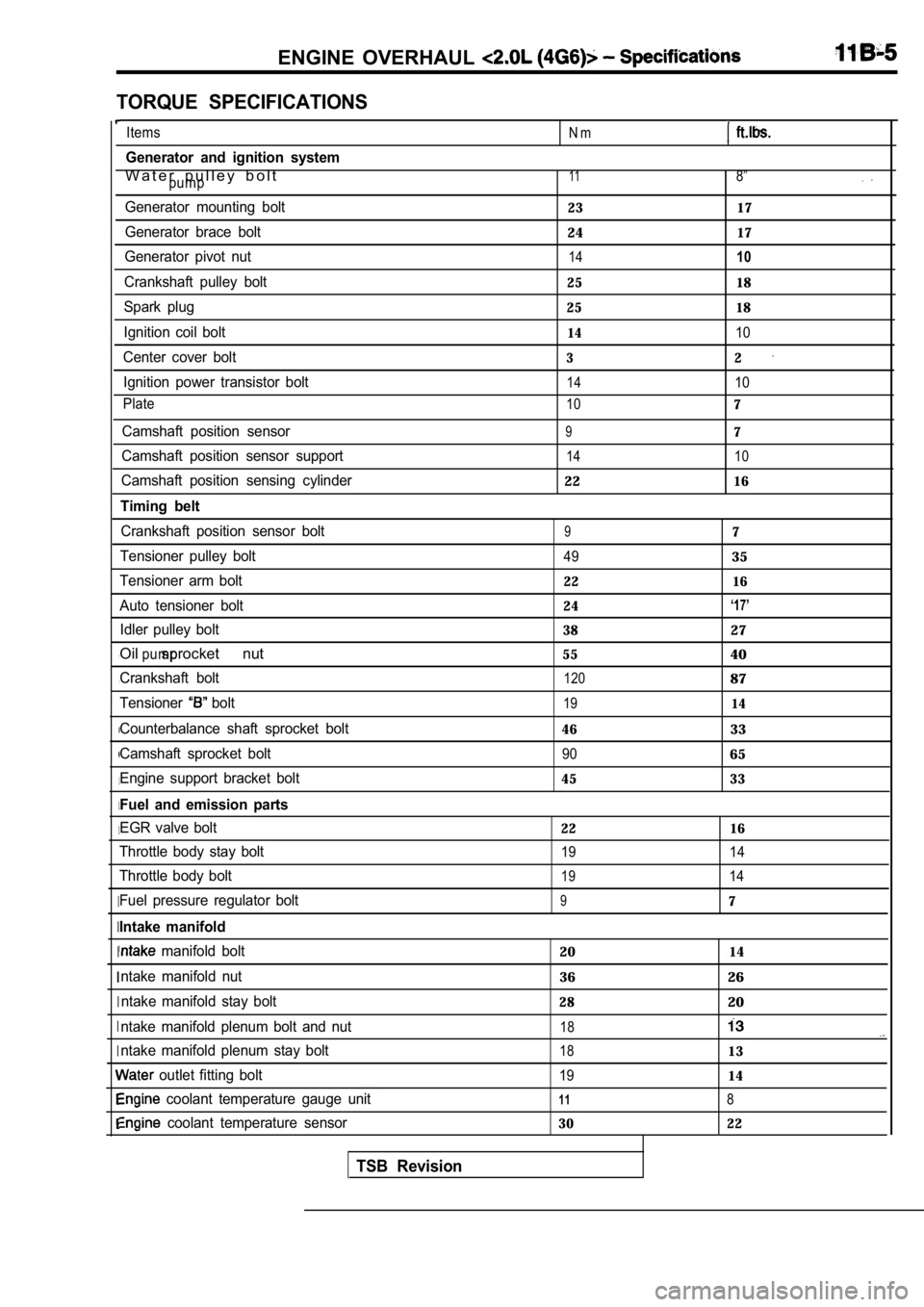

TORQUE SPECIFICATIONS

, ,

I

I I

I

I I

I

I

I I

Items

Generator and ignition system

W a t e r p u l l e y b o l tpump

Generator mounting bolt

Generator brace bolt

Generator pivot nut

Crankshaft pulley bolt

Spark plug

Ignition coil bolt

Center cover bolt Ignition power transistor bolt

Plate

Camshaft position sensor

Camshaft position sensor support

Camshaft position sensing cylinder

Timing belt

Crankshaft position sensor bolt

Tensioner pulley bolt

Tensioner arm bolt

Auto tensioner bolt Idler pulley bolt

Oil sprocket nutpump

Crankshaft bolt

Tensioner

bolt

Counterbalance shaft sprocket bolt

Camshaft sprocket bolt

Engine support bracket bolt

Fuel and emission parts

EGR valve bolt

Throttle body stay bolt

Throttle body bolt

Fuel pressure regulator bolt

Intake manifold

manifold bolt

ntake manifold nut ntake manifold stay bolt

ntake manifold plenum bolt and nut

ntake manifold plenum stay bolt

outlet fitting bolt

coolant temperature gauge unit

coolant temperature sensor

TSB Revision

N m

118”

23 17

2417

1410

25 18

25 18

1410

32

1410

107

97

14 10

2216

97

4935

22 16

24

‘17’

3827

5540

12087

1914

4633

9065

45 33

22 16

19 14

1914

97

2014

3626

2820

18

1813

1914

118

30 22

Page 111 of 2103

ENGINE OVERHAUL

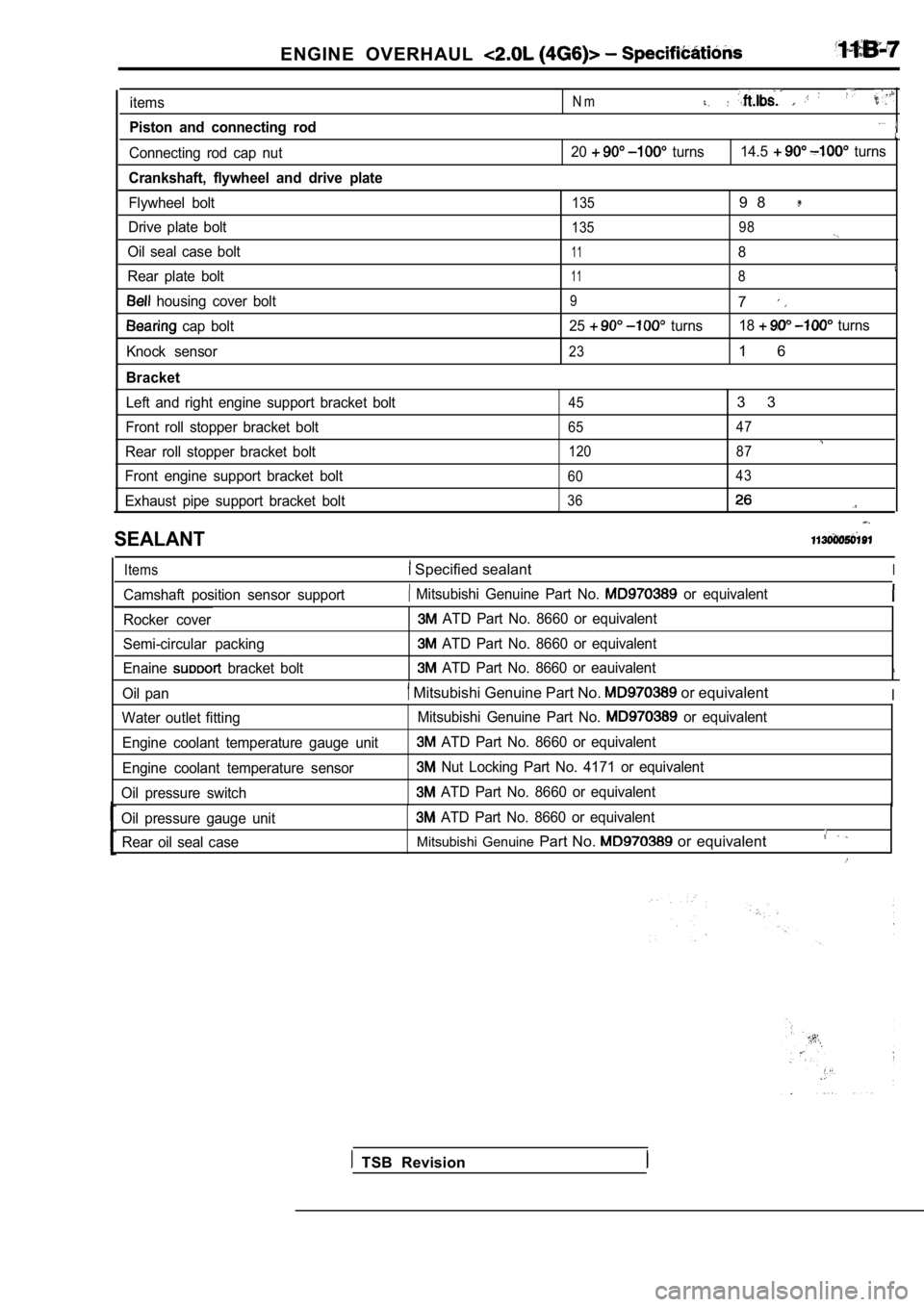

items

Piston and connecting rod

Connecting rod cap nut

Crankshaft, flywheel and drive plate

Flywheel bolt

Drive plate bolt

Oil seal case bolt

Rear plate bolt

housing cover bolt

cap bolt

Knock sensor

Bracket

Left and right engine support bracket bolt

Front roll stopper bracket bolt

Rear roll stopper bracket bolt

Front engine support bracket bolt

Exhaust pipe support bracket bolt

N m

20 turns 14.5 turns

1359 8

135 98

118

118

97

25 turns18 turns

231 6

453 3

65 47

120 87

60 43

36

SEALANT

Items Specified sealantI

Camshaft position sensor support Mitsubishi Genuine Part No. or equivalent

Rocker cover

Semi-circular packing

Enaine

bracket bolt

ATD Part No. 8660 or equivalent

ATD Part No. 8660 or equivalent

ATD Part No. 8660 or eauivalent

Oil pan Mitsubishi Genuine Part No. or equivalentI

Water outlet fitting

Engine coolant temperature gauge unit

Engine coolant temperature sensor

Oil pressure switch Mitsubishi Genuine Part No. or equivalent

ATD Part No. 8660 or equivalent

Nut Locking Part No. 4171 or equivalent

ATD Part No. 8660 or equivalent

Oil pressure gauge unit

ATD Part No. 8660 or equivalent

Rear oil seal case

Mitsubishi Genuine Part No. or equivalent

TSB Revision

Page 112 of 2103

ENGINE OVERHAUL ,

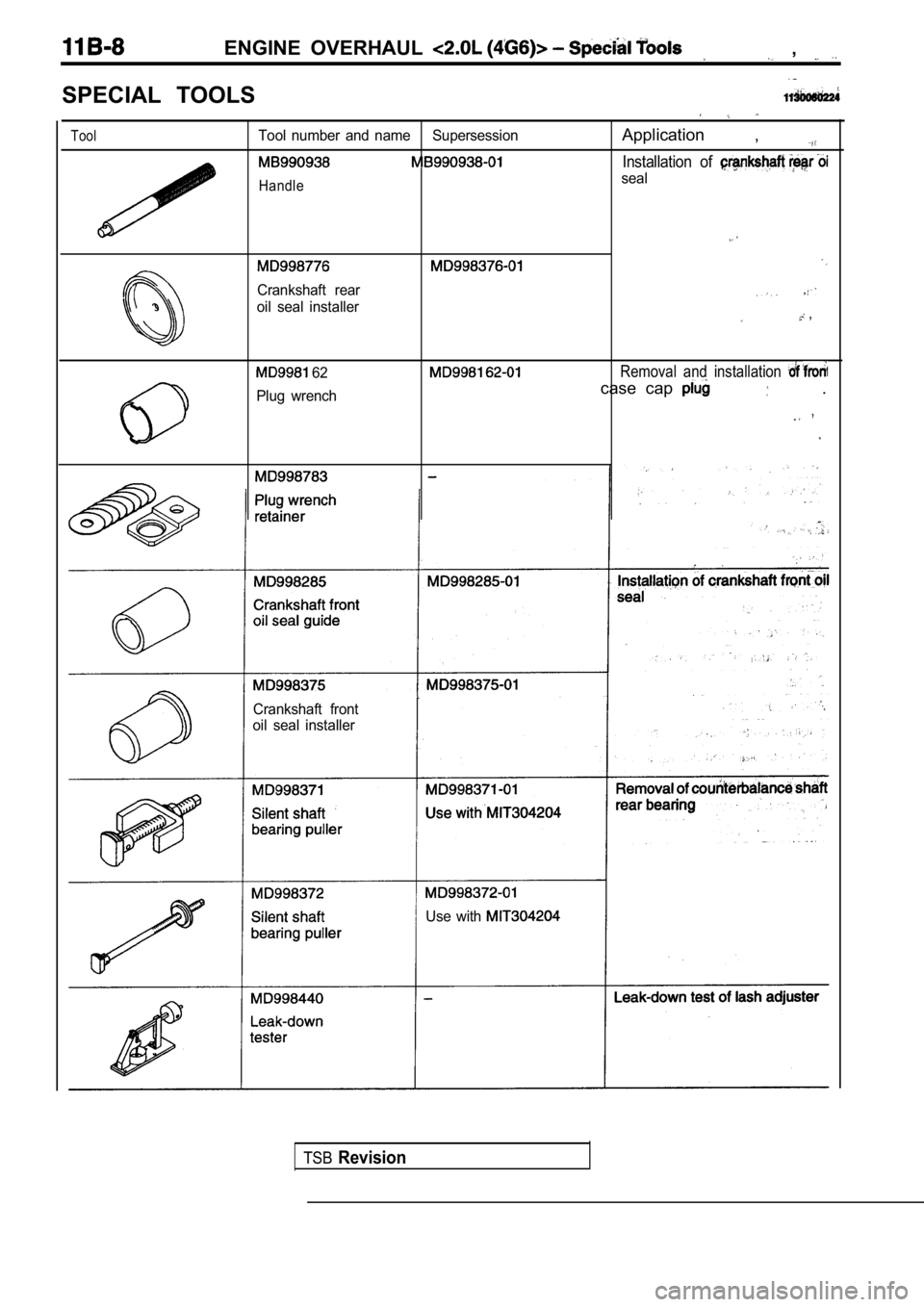

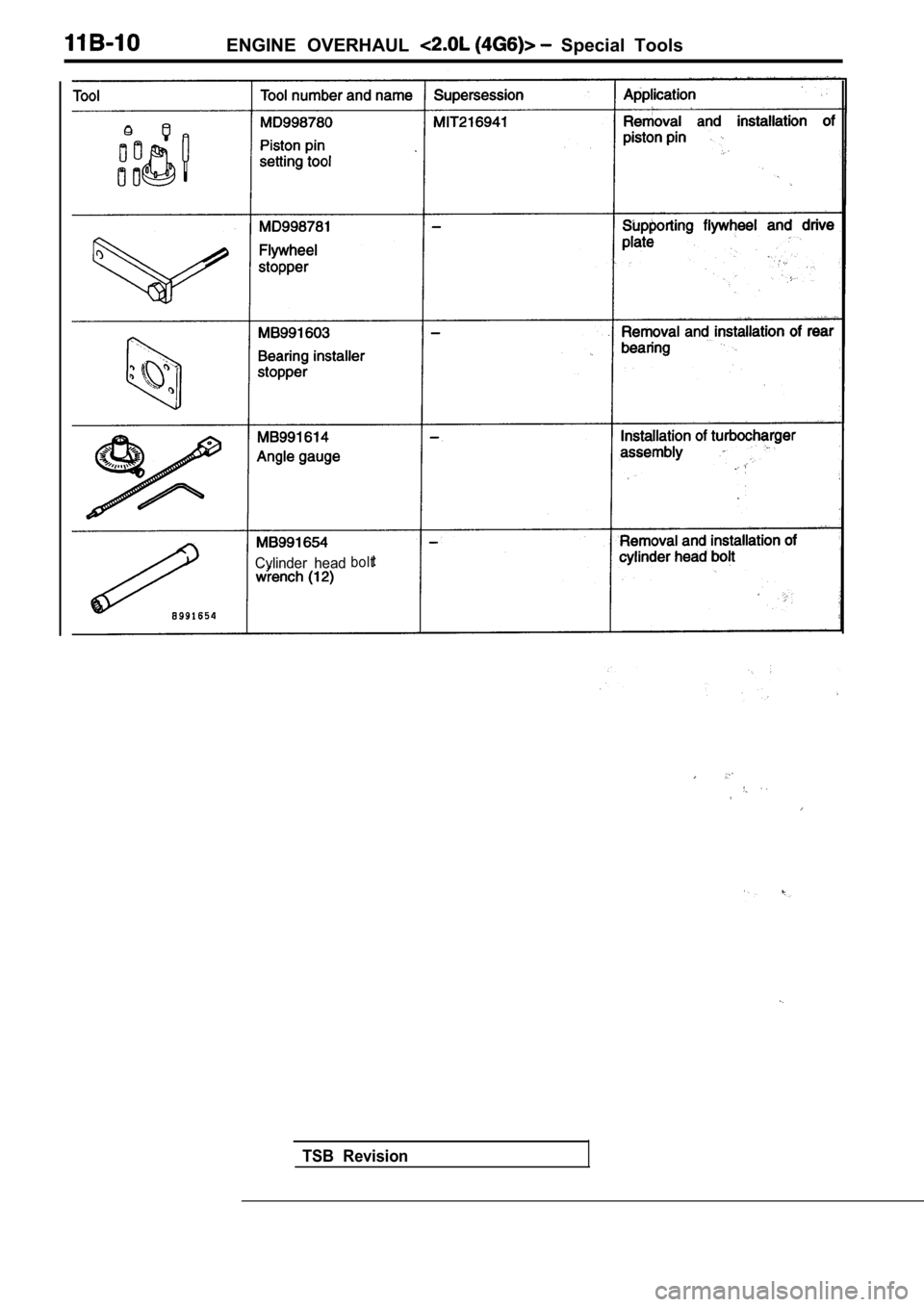

SPECIAL TOOLS

ToolTool number and name SupersessionApplication ,

Installation of

Handleseal

Crankshaft rear

oil seal installer ,

62Removal and installation

Plug wrenchcase cap .

Crankshaft front

oil seal installer

Use with

TSBRevision

Page 113 of 2103

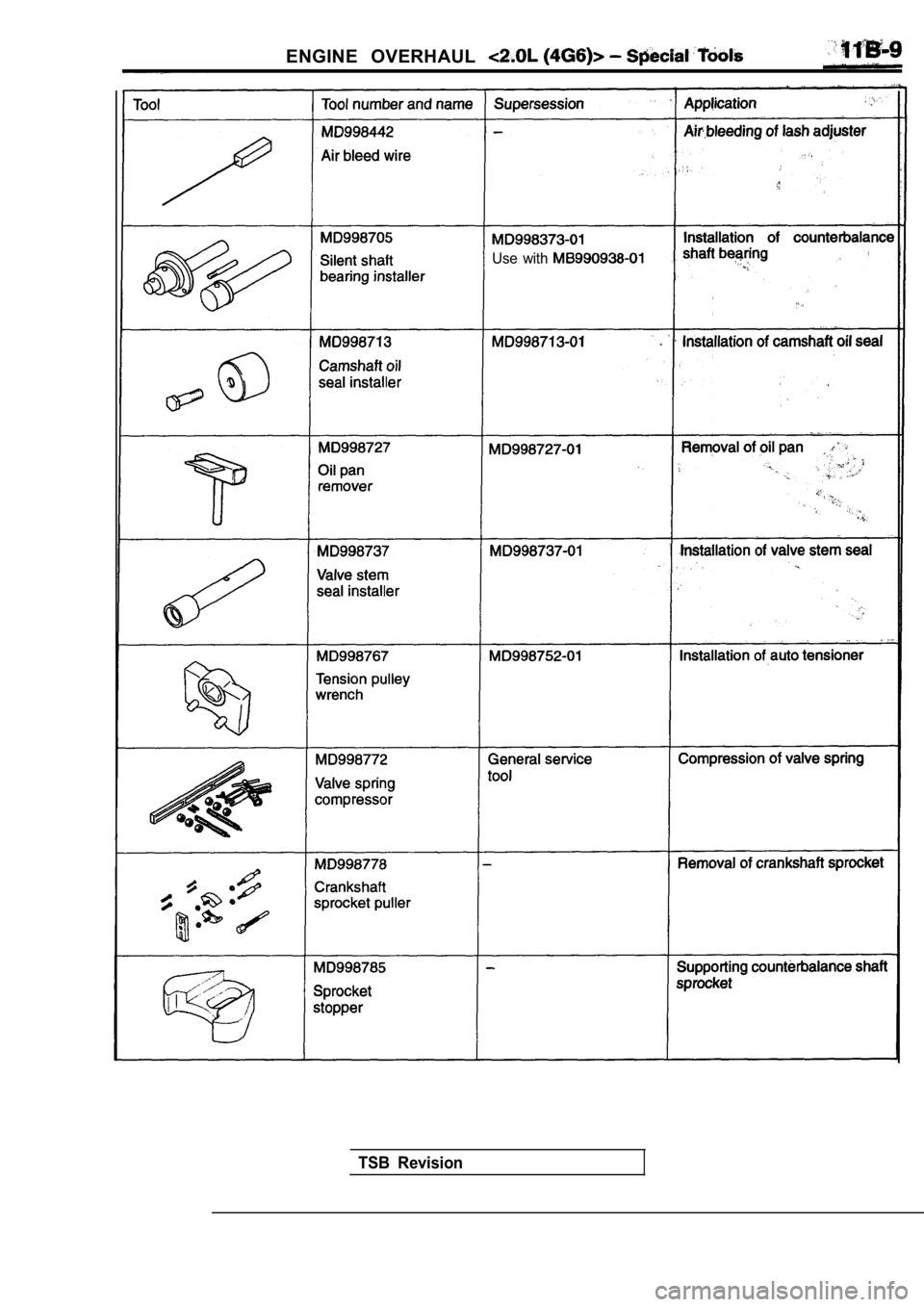

ENGINE OVERHAUL

Use with

TSB Revision

Page 114 of 2103

ENGINE OVERHAUL Special Tools

Cylinder headbolt

TSB Revision

Page 115 of 2103

ENGINE OVERHAUL and 11

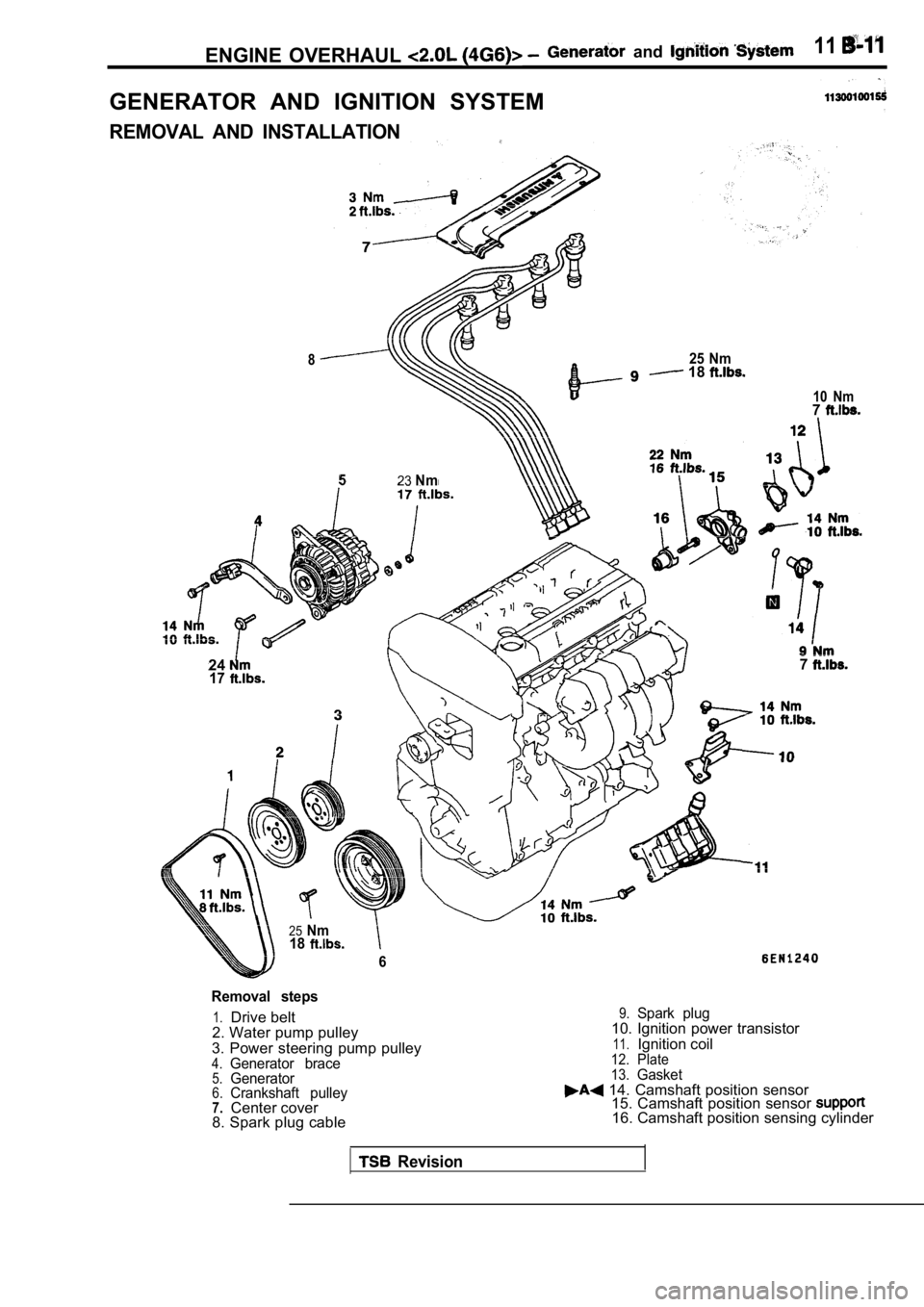

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

825 Nm 18

523Nm

24177

25Nm18

6

10 Nm7

Removal steps

1.Drive belt

2. Water pump pulley

3. Power steering pump pulley

4.Generator brace5.Generator6.Crankshaft pulley7.Center cover

8. Spark plug cable

9.Spark plug10. Ignition power transistor

11.Ignition coil12. Plate

13.Gasket 14. Camshaft position sensor 15. Camshaft position sensor

16. Camshaft position sensing cylinder

Revision

Page 116 of 2103

ENGINE OVERHAUL Generator and

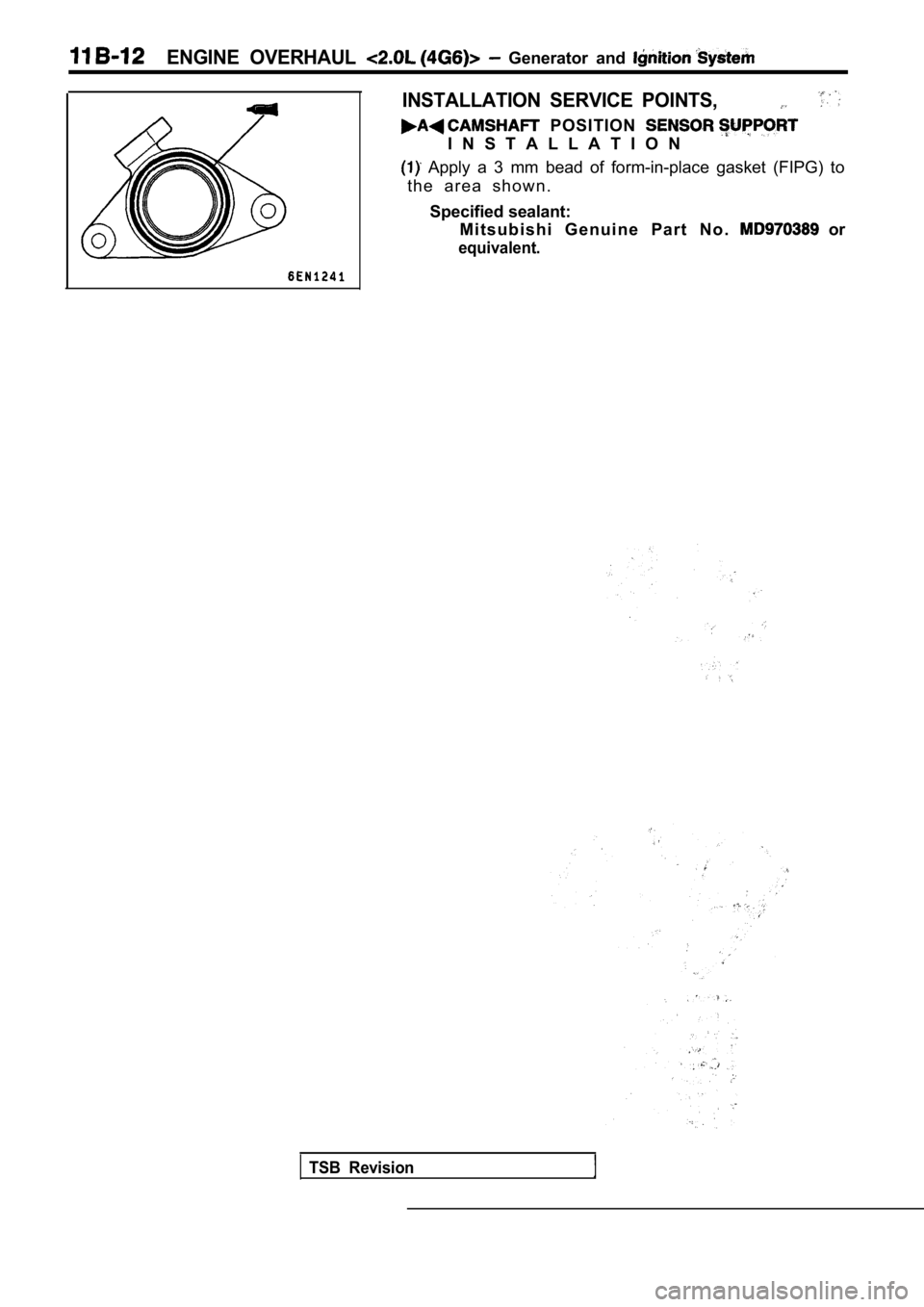

INSTALLATION SERVICE POINTS,

POSITION

I N S T A L L A T I O N

Apply a 3 mm bead of form-in-place gasket (FIPG) to

t h e a r e a s h o w n .

Specified sealant: M i t s u b i s h i G e n u i n e P a r t N o .

or

equivalent.

TSB Revision

Page 117 of 2103

ENGINE OVERHAUL

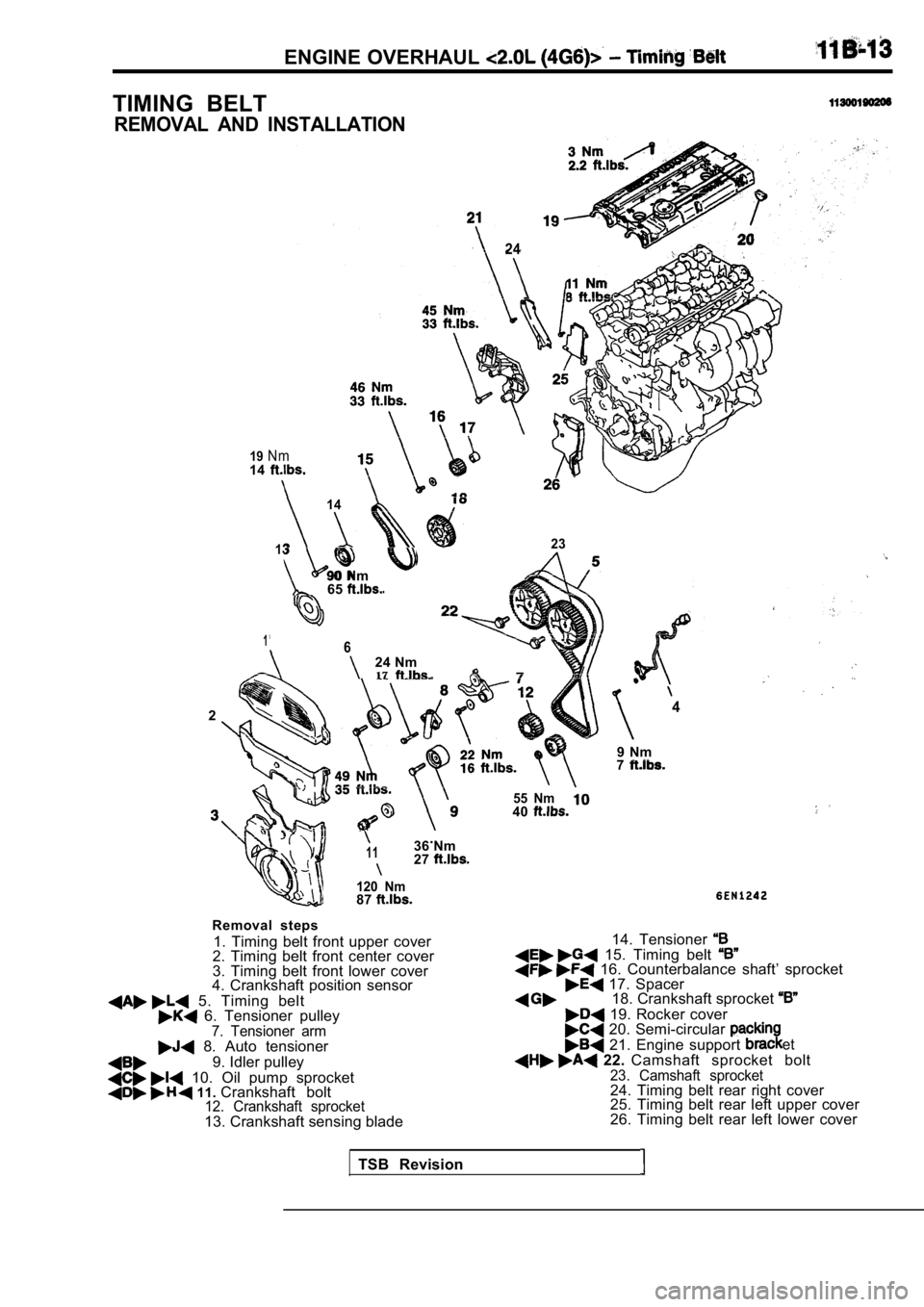

TIMING BELT

REMOVAL AND INSTALLATION

19N m

24

14

14

13

90 Nm65

23

1624 Nm17

24

9 Nm7

.1136 Nm27

120 Nm87

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Crankshaft position sensor

5. Timing belt 6. Tensioner pulley7. Tensioner arm 8. Auto tensioner

9. Idler pulley

10. Oil pump sprocket 11. Crankshaft bolt12. Crankshaft sprocket13. Crankshaft sensing blade

55 Nm40

14. Tensioner 15. Timing belt 16. Counterbalance shaft’ sprocket 17. Spacer18. Crankshaft sprocket

19. Rocker cover 20. Semi-circular

21. Engine support et

22. Camshaft sprocket bolt23. Camshaft sprocket24. Timing belt rear right cover

25. Timing belt rear left upper cover

26. Timing belt rear left lower cover

TSB Revision

Page 120 of 2103

ENGINE OVERHAUL Timing Belt,

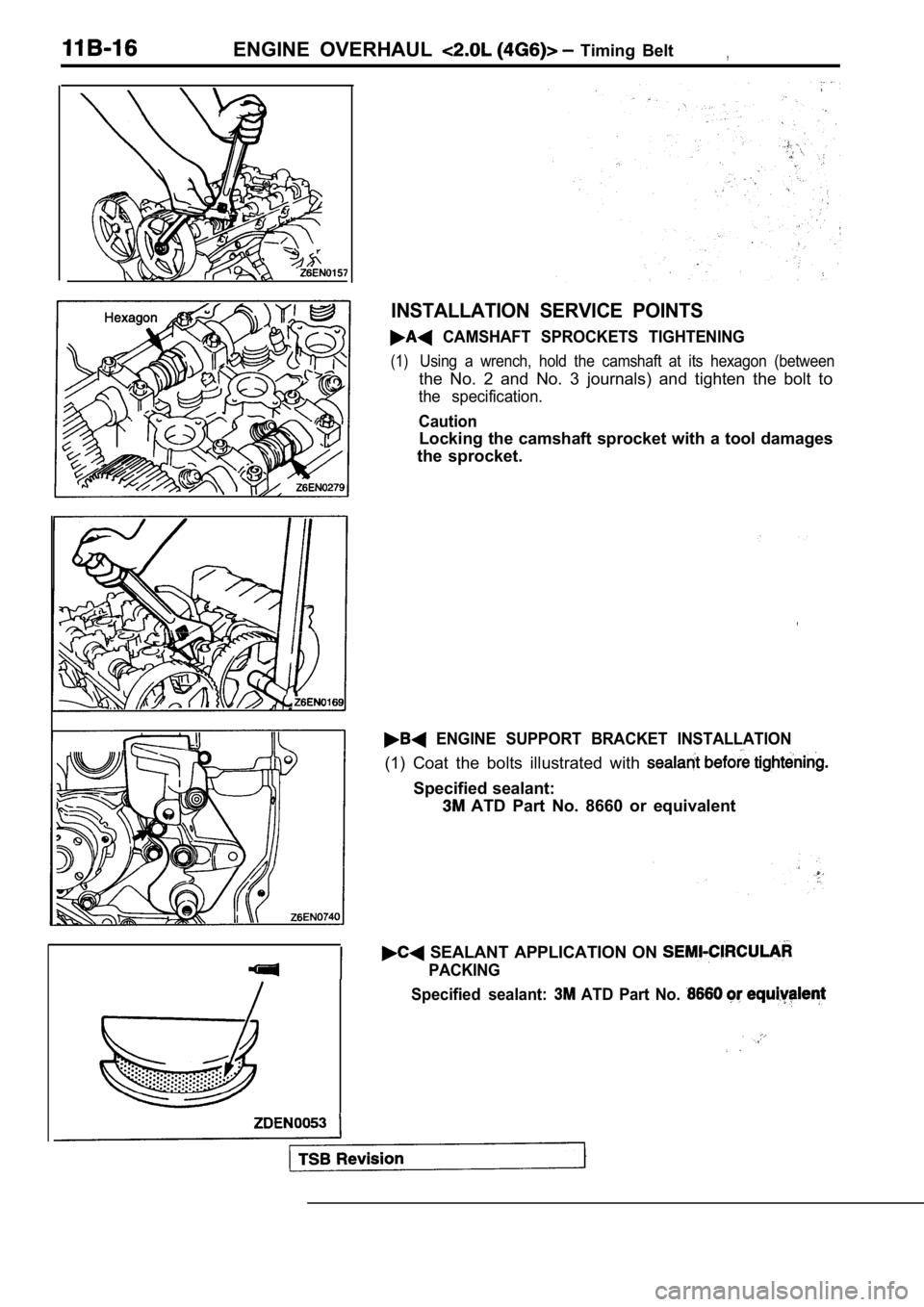

INSTALLATION SERVICE POINTS

CAMSHAFT SPROCKETS TIGHTENING

(1)Using a wrench, hold the camshaft at its hexagon (between

the No. 2 and No. 3 journals) and tighten the bolt to

the specification.

Caution

Locking the camshaft sprocket with a tool damages

the sprocket.

ENGINE SUPPORT BRACKET INSTALLATION

(1) Coat the bolts illustrated with

Specified sealant:

ATD Part No. 8660 or equivalent

SEALANT APPLICATION ON

PACKING

Specified sealant:

ATD Part No.