engine MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 152 of 2103

Front Case, ENGINE OVERHAUL Shaft and. Pan

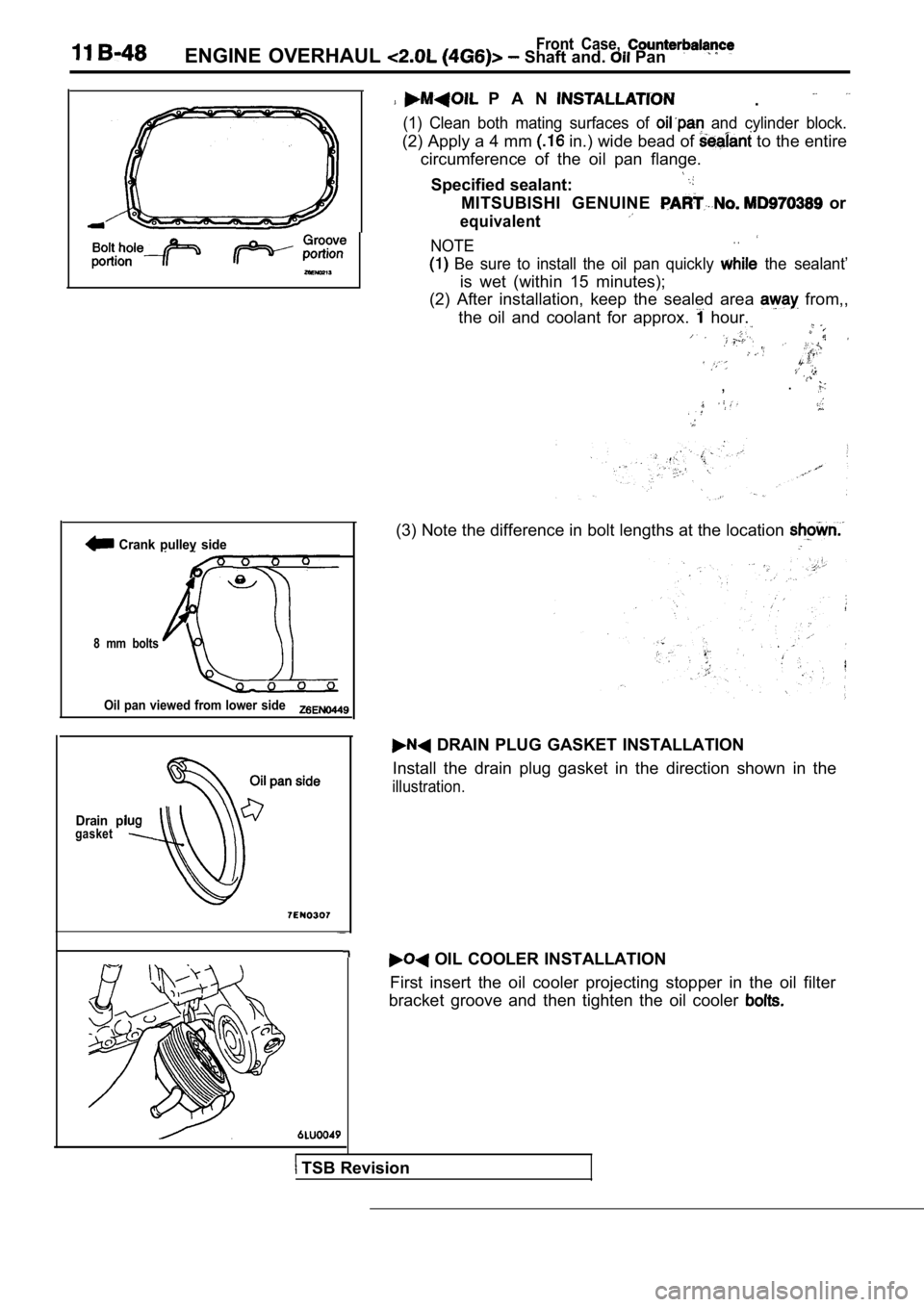

Crank pulley side

8 mm bolts

Oil pan viewed from lower side

Drain pigasket

P A N .

(1) Clean both mating surfaces of and cylinder block.

(2) Apply a 4 mm in.) wide bead of to the entire

circumference of the oil pan flange.

Specified sealant:

MITSUBISHI GENUINE or

equivalent

NOTE. .

Be sure to install the oil pan quickly the sealant’

is wet (within 15 minutes);

(2) After installation, keep the sealed area

from,,

the oil and coolant for approx.

hour.

, .

(3) Note the difference in bolt lengths at the loca

tion

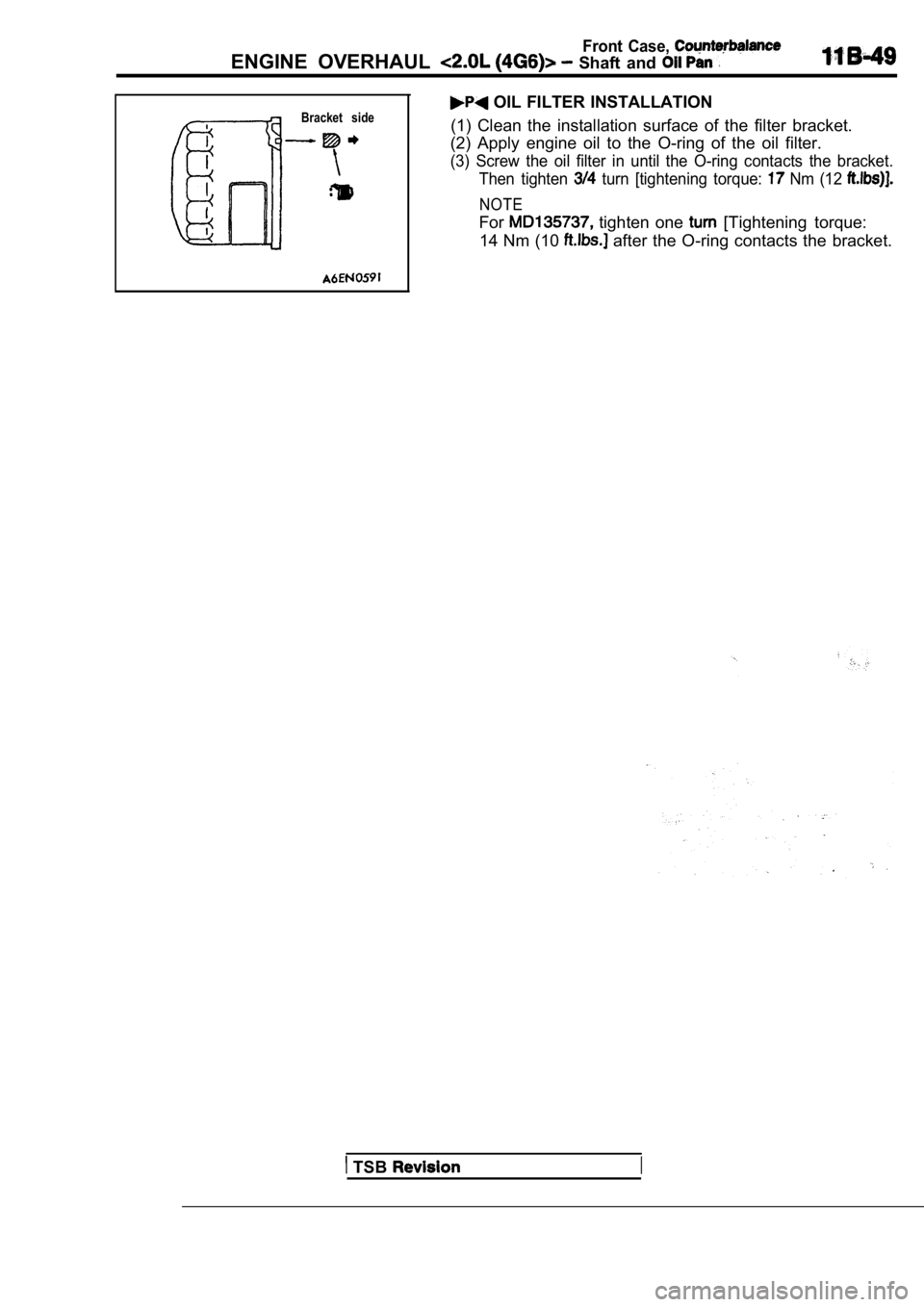

DRAIN PLUG GASKET INSTALLATION

Install the drain plug gasket in the direction show n in the

illustration.

OIL COOLER INSTALLATION

First insert the oil cooler projecting stopper in t he oil filter

bracket groove and then tighten the oil cooler

TSB Revision

Page 153 of 2103

Front Case,

ENGINE OVERHAUL Shaft and

Bracket side OIL FILTER INSTALLATION

(1) Clean the installation surface of the filter br acket.

(2) Apply engine oil to the O-ring of the oil filte r.

(3) Screw the oil filter in until the O-ring contacts the bracket.

Then tighten

turn [tightening torque: Nm (12

NOTE

For tighten one [Tightening torque:

14 Nm (10

after the O-ring contacts the bracket.

TSB I

Page 154 of 2103

Front Case, Counterbalance

ENGINE Shaft and

INSPECTION

FRONT CASE

(1) Check oil holes for clogging and if necessary.

(2)’ Check left counterbalance shaft front bearing

for

Wear, damage and seizure. If there is anything wron g’

with the section, replace the front

(3) Check the front case for cracks and other damag e.

place cracked or damaged front case.

OIL SEAL

(1) Check the oil seal lip for wear and damage. Rep lace

oil seal if necessary.

(2) Check the oil seal lip for deterioration. Repla ce oil seal

if necessary.

I

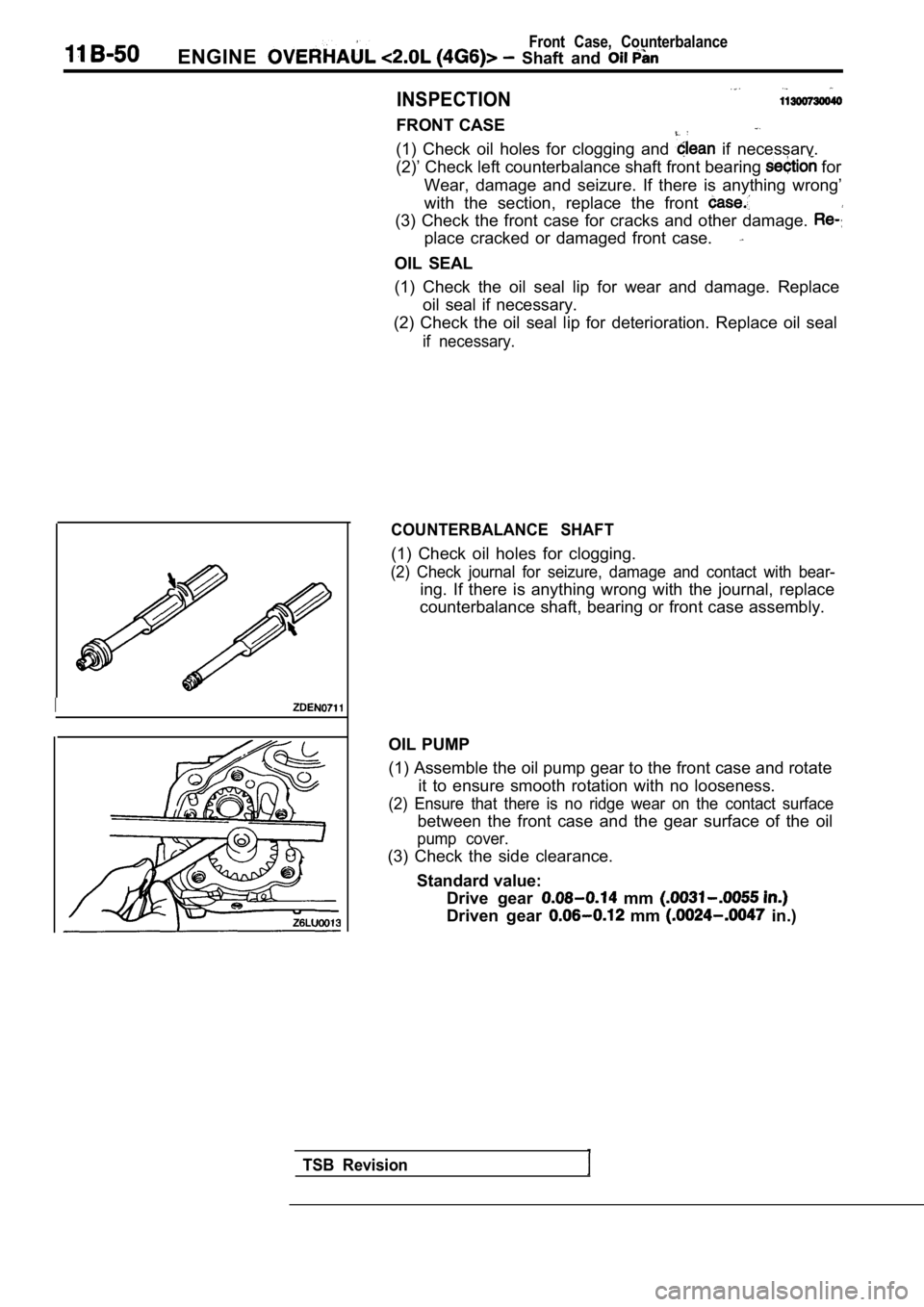

COUNTERBALANCE SHAFT

(1) Check oil holes for clogging.

(2) Check journal for seizure, damage and contact w ith bear-

ing. If there is anything wrong with the journal, replace

counterbalance shaft, bearing or front case assembl y.

OIL PUMP

(1) Assemble the oil pump gear to the front case an d rotate

it to ensure smooth rotation with no looseness.

(2) Ensure that there is no ridge wear on the conta ct surface

between the front case and the gear surface of the oil

pump cover.

(3) Check the side clearance.

Standard value: Drive gear

mm

Driven gear mm in.)

TSB Revision

Page 155 of 2103

ENGINE OVERHAUL Piston and Connecting 1

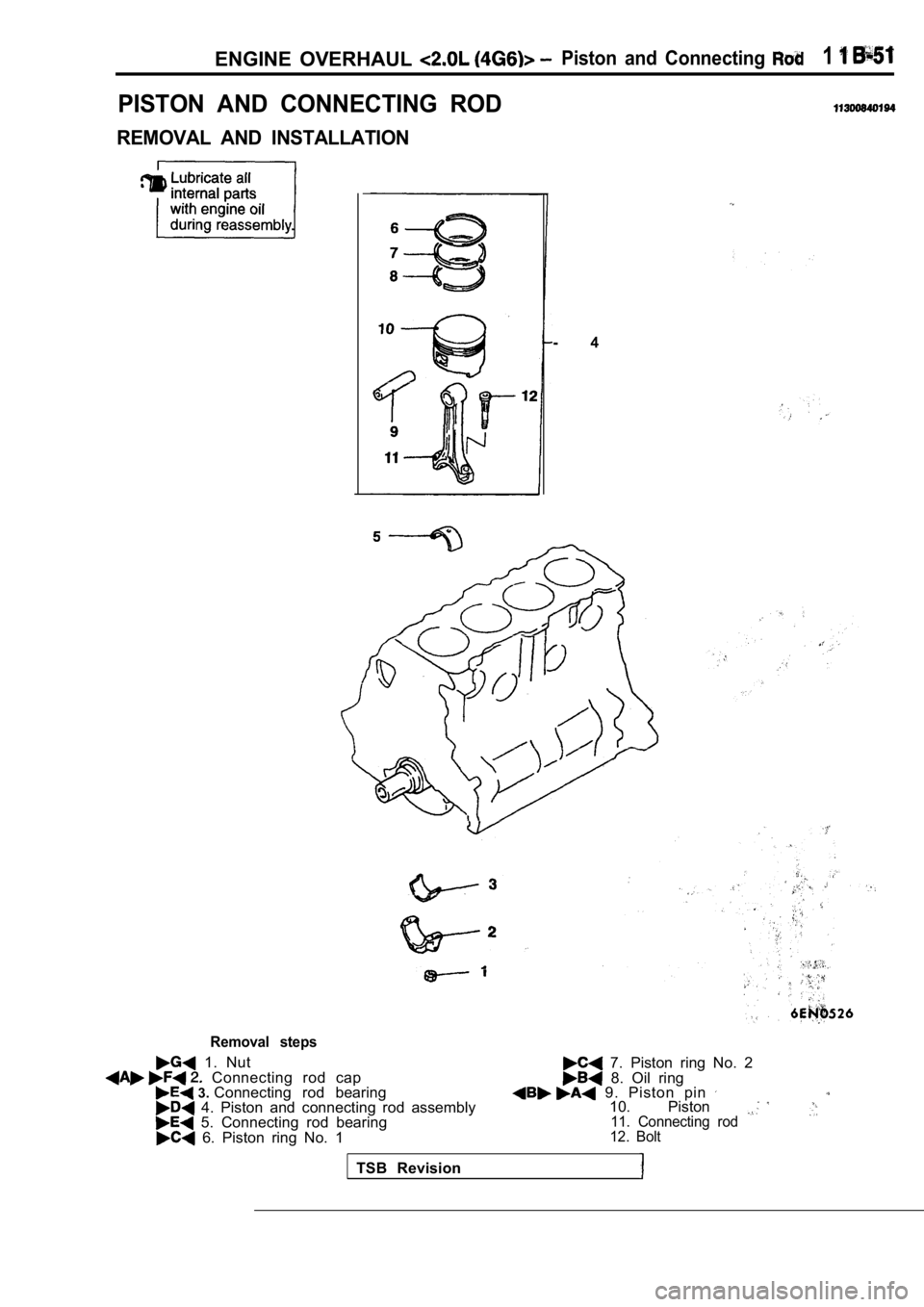

PISTON AND CONNECTING ROD

REMOVAL AND INSTALLATION

- 4

Removal steps

1. Nut Connecting rod cap 3. Connecting rod bearing 4. Piston and connecting rod assembly 5. Connecting rod bearing 6. Piston ring No. 1

7. Piston ring No. 2 8. Oil ring 9. Piston pin 10. Piston 11. Connecting rod

12. Bolt

TSB Revision

Page 156 of 2103

11 ENGINE OVERHAUL Piston and Rod

Piston pin settingtool 6941

11

Presspin

Piston pinFront mark

Connecting rod

guide pin

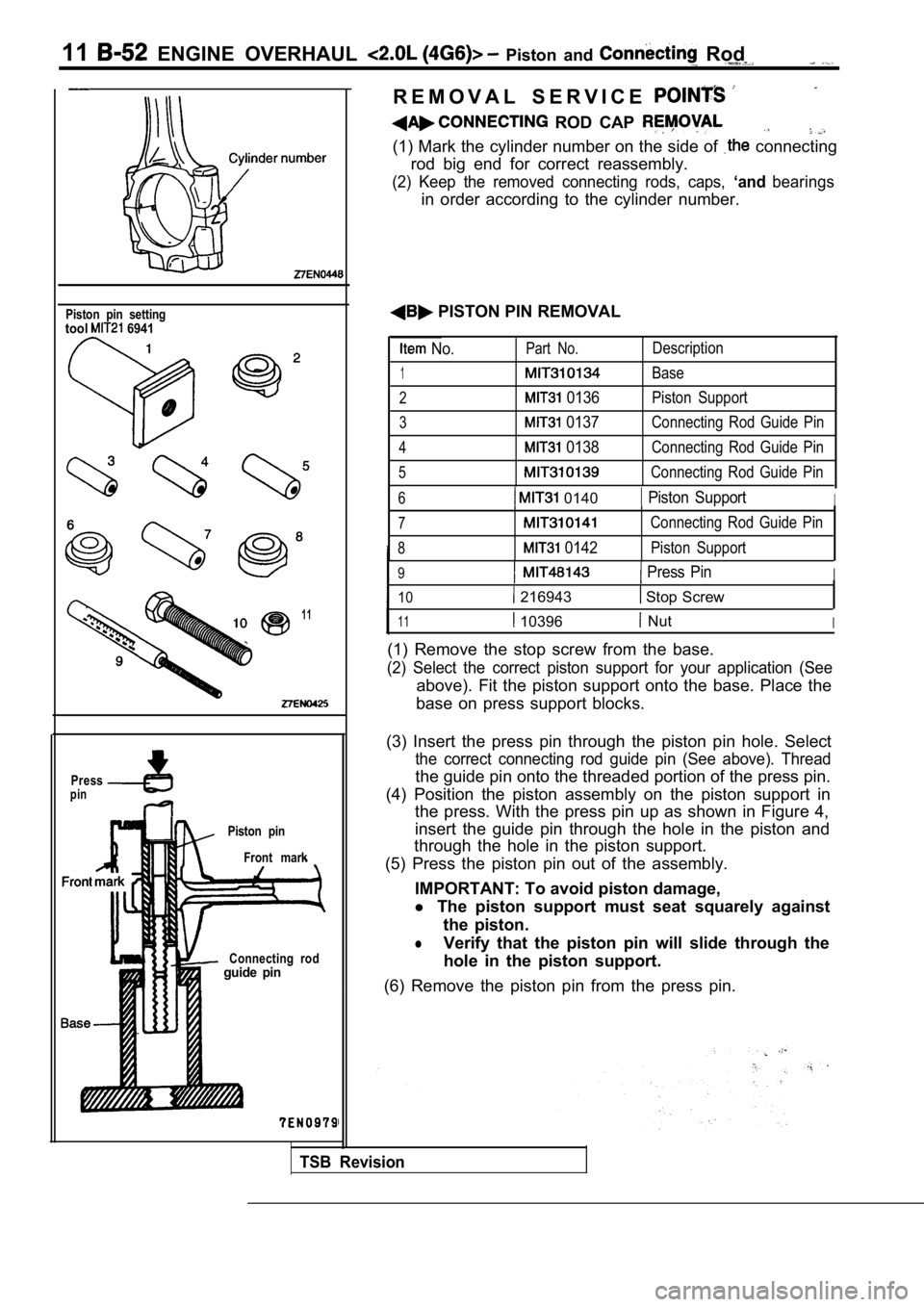

R E M O V A L S E R V I C E

ROD CAP

(1) Mark the cylinder number on the side of connecting

rod big end for correct reassembly.

(2) Keep the removed connecting rods, caps, ‘andbearings

in order according to the cylinder number.

PISTON PIN REMOVAL

No.Part No.

1

2 0136

3 0137

4 0138

5

Description

Base

Piston Support

Connecting Rod Guide Pin

Connecting Rod Guide Pin

Connecting Rod Guide Pin

6 0140 Piston SupportI

7

8 0142

Connecting Rod Guide Pin

Piston Support

9 Press PinI

10 216943 Stop Screw

11 10396 NutI

(1) Remove the stop screw from the base.

(2) Select the correct piston support for your appl ication (See

above). Fit the piston support onto the base. Place the

base on press support blocks.

TSB Revision

(3) Insert the press pin through the piston pin hol e. Select

the correct connecting rod guide pin (See above). T hread

the guide pin onto the threaded portion of the press pin.

(4) Position the piston assembly on the piston supp ort in

the press. With the press pin up as shown in Figure 4,

insert the guide pin through the hole in the piston and

through the hole in the piston support.

(5) Press the piston pin out of the assembly.

IMPORTANT: To avoid piston damage,

l The piston support must seat squarely against

the piston.

lVerify that the piston pin will slide through the

hole in the piston support.

(6) Remove the piston pin from the press pin.

Page 157 of 2103

ENGINE OVERHAUL Piston and Connecting Rod

Piston pin

Base

Front

Base

Connecting rod

guide pin

StopLock nut

1

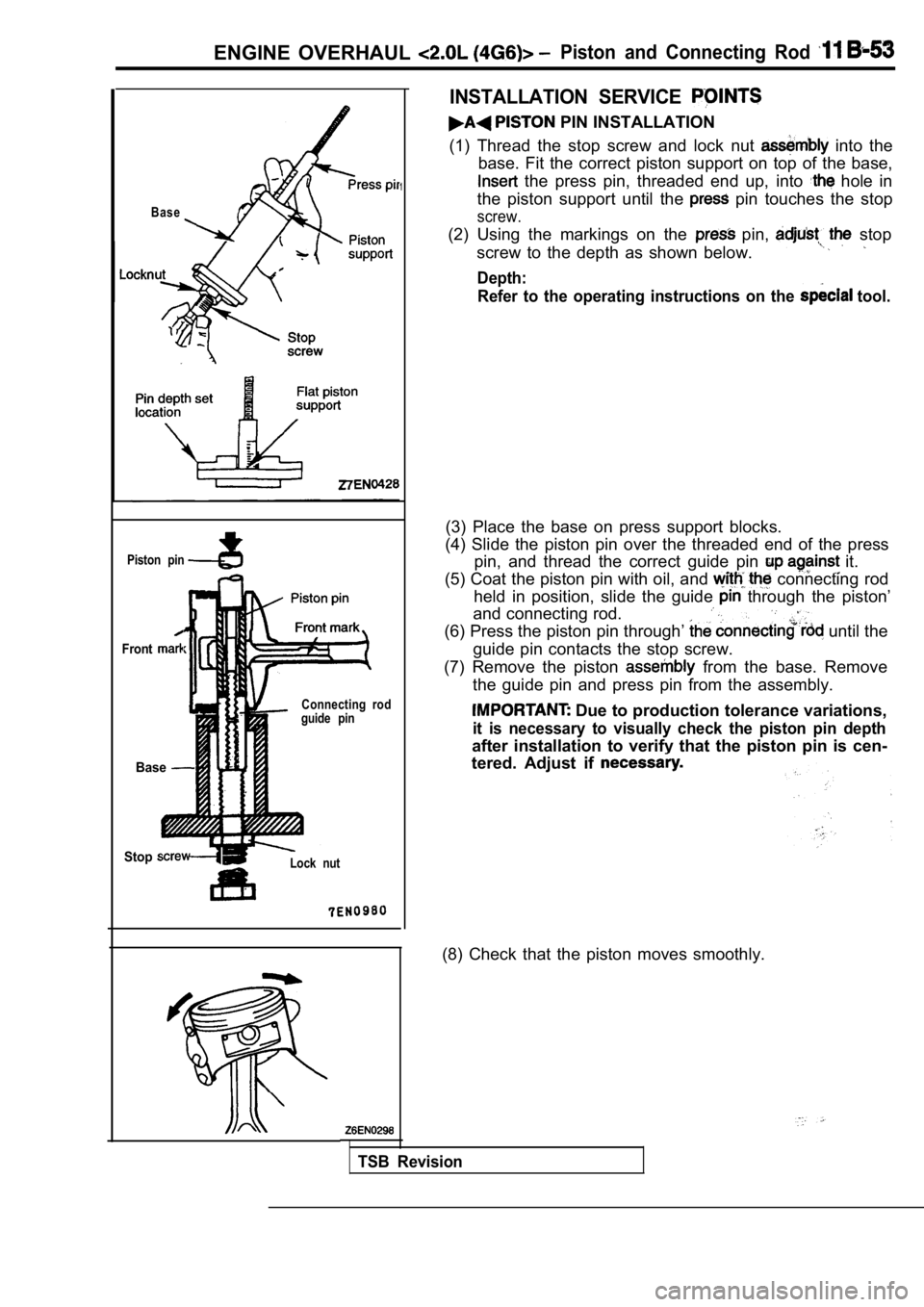

INSTALLATION SERVICE

PIN INSTALLATION

(1) Thread the stop screw and lock nut

into the

base. Fit the correct piston support on top of the base,

the press pin, threaded end up, into hole in

the piston support until the

pin touches the stop

screw.

(2) Using the markings on the pin, stop

screw to the depth as shown below.

Depth: Refer to the operating instructions on the

tool.

(3) Place the base on press support blocks.

(4) Slide the piston pin over the threaded end of t he press

pin, and thread the correct guide pin

it.

(5) Coat the piston pin with oil, and

connecting rod

held in position, slide the guide

through the piston’

and connecting rod.

(6) Press the piston pin through’ until the

guide pin contacts the stop screw.

(7) Remove the piston

from the base. Remove

the guide pin and press pin from the assembly.

Due to production tolerance variations,

it is necessary to visually check the piston pin de pth

after installation to verify that the piston pin is cen-

tered. Adjust if

(8) Check that the piston moves smoothly.

TSB Revision

Page 159 of 2103

ENGINE OVERHAUL and

CrankshaftUpper side

side

ring gap and spacer gaprail

Timing belt side

Front mark

Identification mark

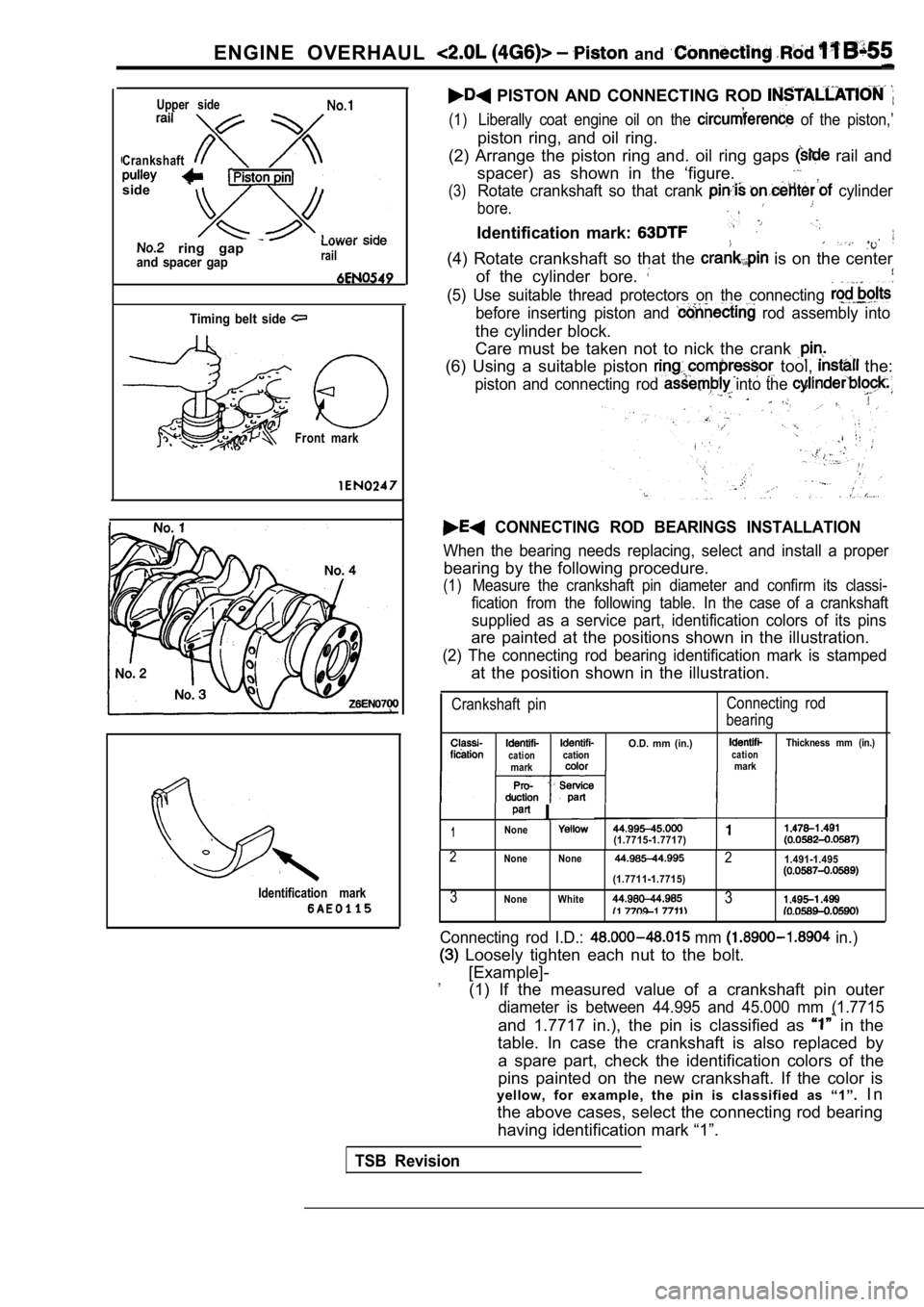

PISTON AND CONNECTING ROD

(1)Liberally coat engine oil on the of the piston,’

piston ring, and oil ring.

(2) Arrange the piston ring and. oil ring gaps

rail and

spacer) as shown in the ‘figure.

(3)Rotate crankshaft so that crank cylinder

bore.

Identification mark:

(4) Rotate crankshaft so that the is on the center

of the cylinder bore.

(5) Use suitable thread protectors on the connectin g

before inserting piston and rod assembly into

the cylinder block.

Care must be taken not to nick the crank

(6) Using a suitable piston tool, the:

piston and connecting rod into the ,

CONNECTING ROD BEARINGS INSTALLATION

When the bearing needs replacing, select and instal l a proper

bearing by the following procedure.

(1)Measure the crankshaft pin diameter and confirm its classi-

fication from the following table. In the case of a crankshaft

supplied as a service part, identification colors of its pins

are painted at the positions shown in the illustrat ion.

(2) The connecting rod bearing identification mark is stamped

at the position shown in the illustration.

Crankshaft pinConnecting rod

bearing

O.D. mm (in.)Thickness mm (in.)cationcationcationmarkmark

I

1None(1.7715-1.7717)

2None None21.491-1.495

(1.7711-1.7715)

3None White3

Connecting rod I.D.: mm in.)

Loosely tighten each nut to the bolt.

[Example]-

”(1) If the measured value of a crankshaft pin outer

diameter is between 44.995 and 45.000 mm (1.7715

and 1.7717 in.), the pin is classified as in the

table. In case the crankshaft is also replaced by

a spare part, check the identification colors of th e

pins painted on the new crankshaft. If the color is

yellow, for example, the pin is classified as “1”. I n

the above cases, select the connecting rod bearing having identification mark “1”.

TSB Revision

Page 160 of 2103

11ENGINE OVERHAUL Piston and

No.

Notch

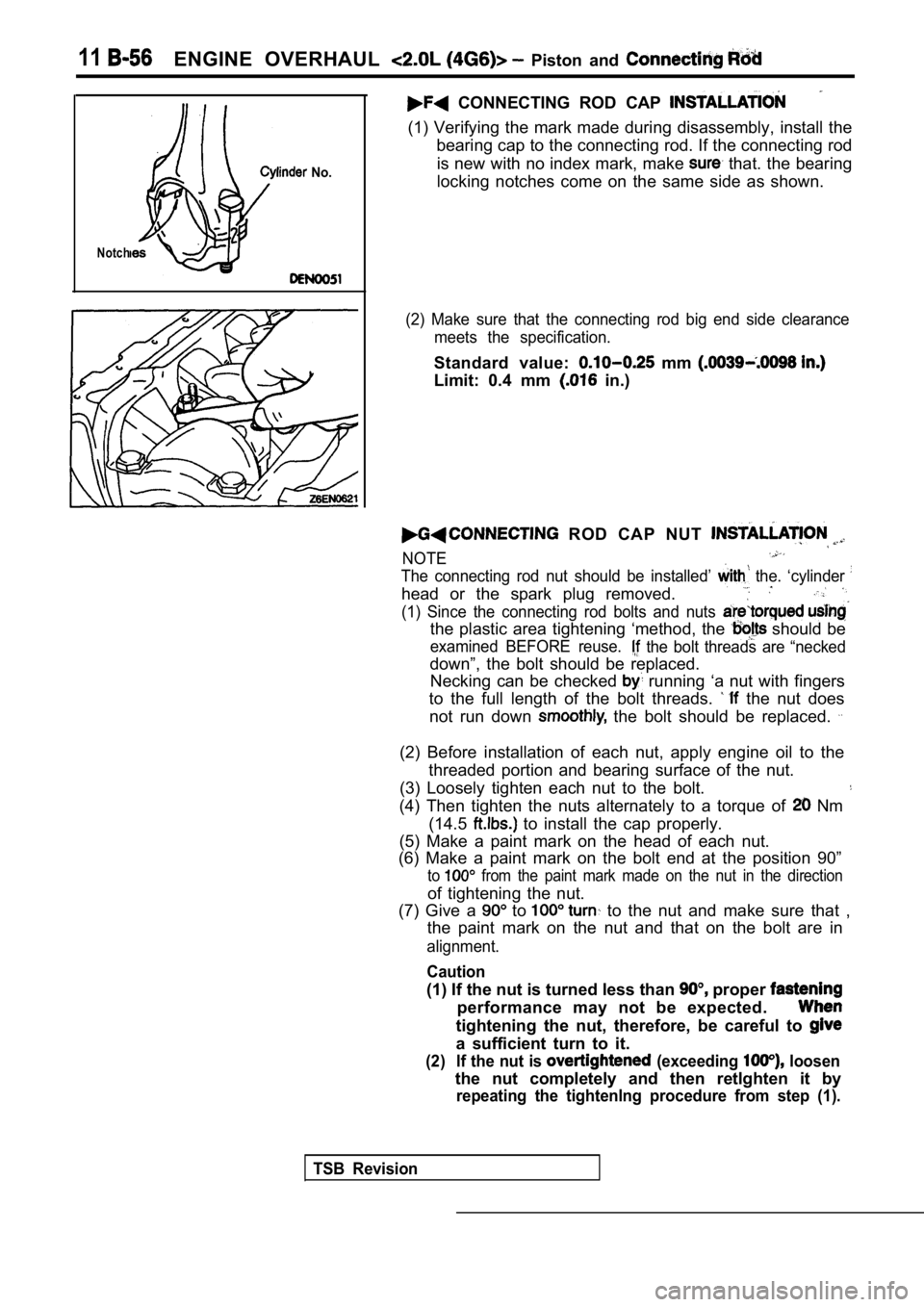

CONNECTING ROD CAP

(1) Verifying the mark made during disassembly, install the

bearing cap to the connecting rod. If the connectin g rod

is new with no index mark, make

that. the bearing

locking notches come on the same side as shown.

(2) Make sure that the connecting rod big end side clearance

meets the specification.

Standard value: mm

Limit: 0.4 mm in.)

ROD CAP NUT

NOTE

The connecting rod nut should be installed’ the. ‘cylinder

head or the spark plug removed.

(1) Since the connecting rod bolts and nuts

the plastic area tightening ‘method, the should be

examined BEFORE reuse. the bolt threads are “necked

down”, the bolt should be replaced. Necking can be checked

running ‘a nut with fingers

to the full length of the bolt threads.

the nut does

not run down

the bolt should be replaced.

(2) Before installation of each nut, apply engine o il to the

threaded portion and bearing surface of the nut.

(3) Loosely tighten each nut to the bolt.

(4) Then tighten the nuts alternately to a torque o f Nm

(14.5

to install the cap properly.

(5) Make a paint mark on the head of each nut.

(6) Make a paint mark on the bolt end at the positi on 90”

to from the paint mark made on the nut in the direction

of tightening the nut.

(7) Give a

to to the nut and make sure that ,

the paint mark on the nut and that on the bolt are in

alignment.

Caution

(1) If the nut is turned less than proper

performance may not be expected.

tightening the nut, therefore, be careful to

a sufficient turn to it.

(2) If the nut is (exceeding loosen

the nut completely and then retlghten it by

repeating the tightenlng procedure from step (1).

TSB Revision

Page 161 of 2103

ENGINE OVERHAUL

11300850104

(1) Replace piston ii or seizure is evident

its surfaces (especially surface). Replace the

piston if it is cracked.

PISTON PIN

(1) the piston pin the pin hole a

You should feel a slight resistance. the

pin if it can be easily inserted or there ‘is .

(2) The piston and piston pin must be replaced

bly.

PISTON RING

(1) Check ‘the ring for

and replace if defects are evident: piston

has been replaced with a

one, the piston

also be replaced with new ones.

(2) Check for the clearance

the piston ring and

ring groove. If the limit is exceeded, replace the

or piston, or both.

Item

No. 1 ring

ring

Limit: 0.1 mm

in.)

-Standard value mm (in.)

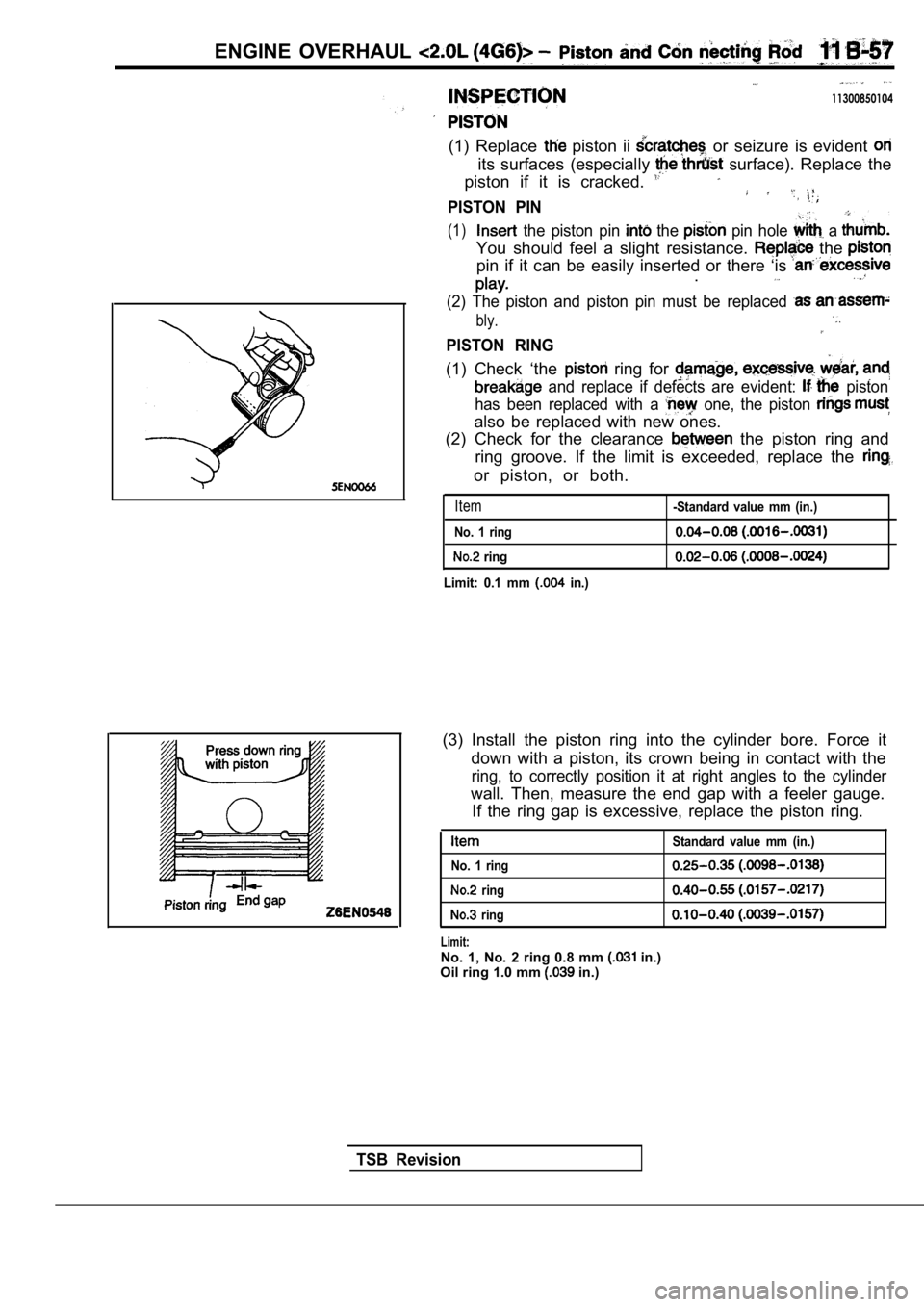

(3) Install the piston ring into the cylinder bore. Force it

down with a piston, its crown being in contact with the

ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a feeler gauge .

If the ring gap is excessive, replace the piston ri ng.

Standard value mm (in.)

No. 1 ring

ring

ring

Limit:No. 1, No. 2 ring 0.8 mm in.)

Oil ring 1.0 mm in.)

TSB Revision

Page 162 of 2103

ENGINE OVERHAUL Piston Rod

1I

PIN OIL CLEARANCE

(PLASTIGAGE METHOD)

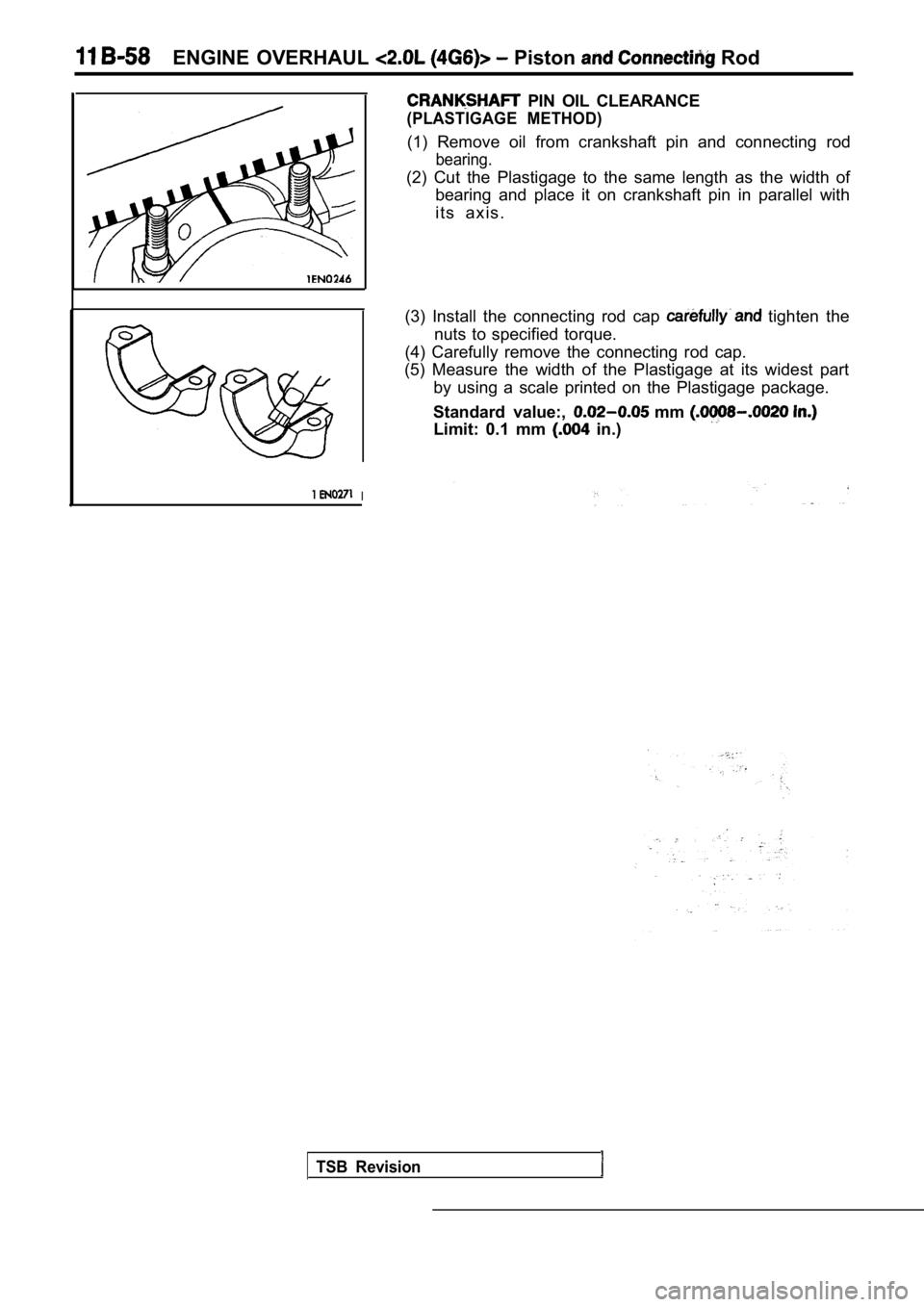

(1) Remove oil from crankshaft pin and connecting rod

bearing.

(2) Cut the Plastigage to the same length as the width of

bearing and place it on crankshaft pin in parallel with

i t s a x i s .

(3) Install the connecting rod cap

tighten the

nuts to specified torque.

(4) Carefully remove the connecting rod cap.

(5) Measure the width of the Plastigage at its wide st part

by using a scale printed on the Plastigage package.

Standard value:,

mm

Limit: 0.1 mm in.)

TSB Revision