air bleeding MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 74 of 2103

ENGINE On-vehicle Service

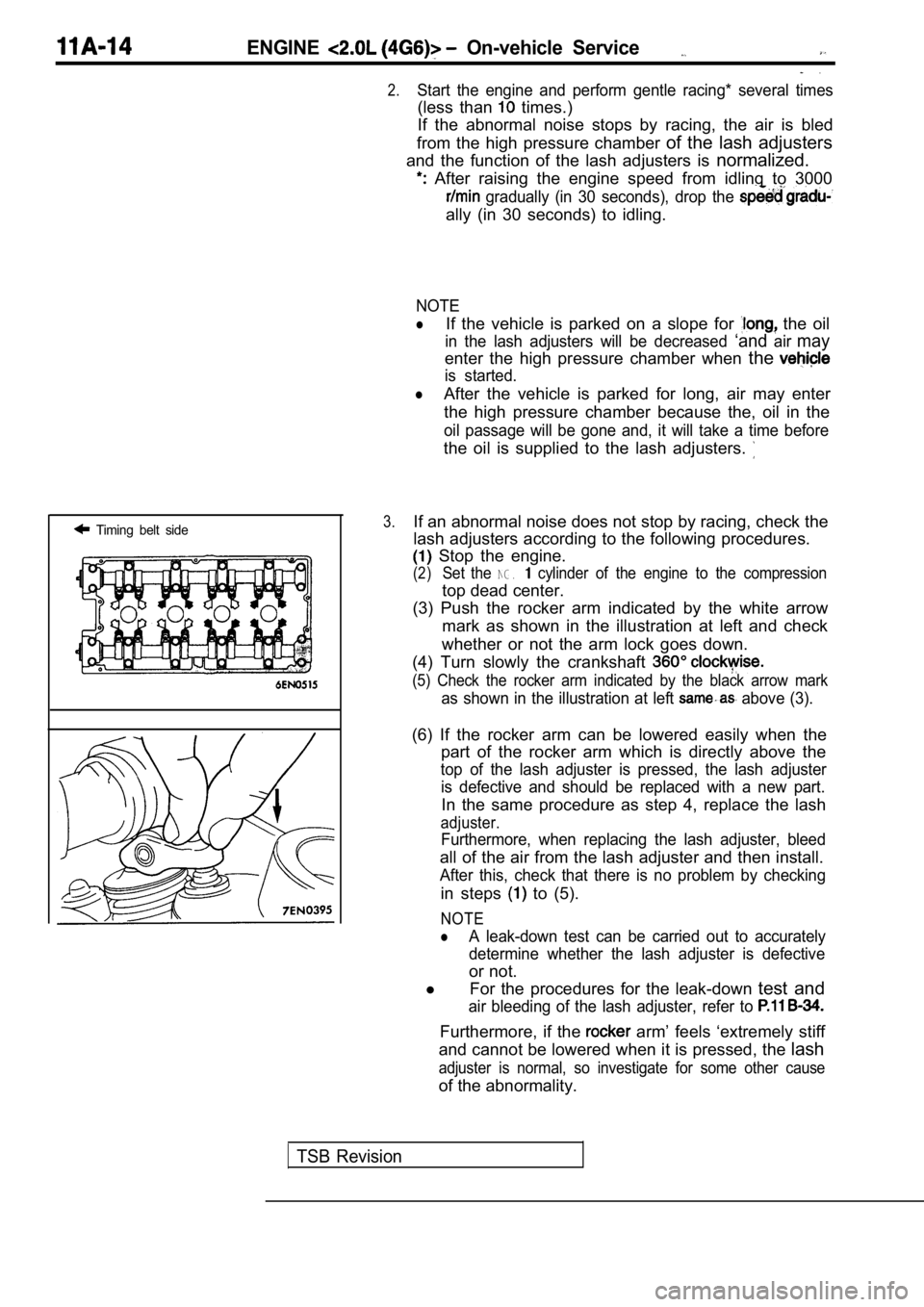

Timing belt side

.

2.Start the engine and perform gentle racing* several times

(less than times.)

If the abnormal noise stops by racing, the air is b led

from the high pressure chamber of the lash adjusters

and the function of the lash adjusters is normalized.

After raising the engine speed from idling to 3000

gradually (in 30 seconds), drop the

ally (in 30 seconds) to idling.

NOTE

lIf the vehicle is parked on a slope for the oil

in the lash adjusters will be decreased ‘andairmay

enter the high pressure chamber when the

is started.

lAfter the vehicle is parked for long, air may enter

the high pressure chamber because the, oil in the

oil passage will be gone and, it will take a time b efore

the oil is supplied to the lash adjusters.

3.If an abnormal noise does not stop by racing, check the

lash adjusters according to the following procedure s.

Stop the engine.

(2)Set the NG. cylinder of the engine to the compression

top dead center.

(3) Push the rocker arm indicated by the white arro w

mark as shown in the illustration at left and check

whether or not the arm lock goes down.

(4) Turn slowly the crankshaft

(5) Check the rocker arm indicated by the black arr ow mark

as shown in the illustration at left above (3).

(6) If the rocker arm can be lowered easily when th e

part of the rocker arm which is directly above the

top of the lash adjuster is pressed, the lash adjus ter

is defective and should be replaced with a new part .

In the same procedure as step 4, replace the lash

adjuster.

Furthermore, when replacing the lash adjuster, bleed

all of the air from the lash adjuster and then install.

After this, check that there is no problem by check ing

in steps to (5).

NOTE

lA leak-down test can be carried out to accurately

determine whether the lash adjuster is defective

or not.

l For the procedures for the leak-down test and

air bleeding of the lash adjuster, refer to

Furthermore, if the arm’ feels ‘extremely stiff

and cannot be lowered when it is pressed, the lash

adjuster is normal, so investigate for some other c ause

of the abnormality.

TSB Revision

Page 138 of 2103

11 ENGINE OVERHAUL Rocker

.

INSPECTION

CAMSHAFT

(1) Measure the cam height.

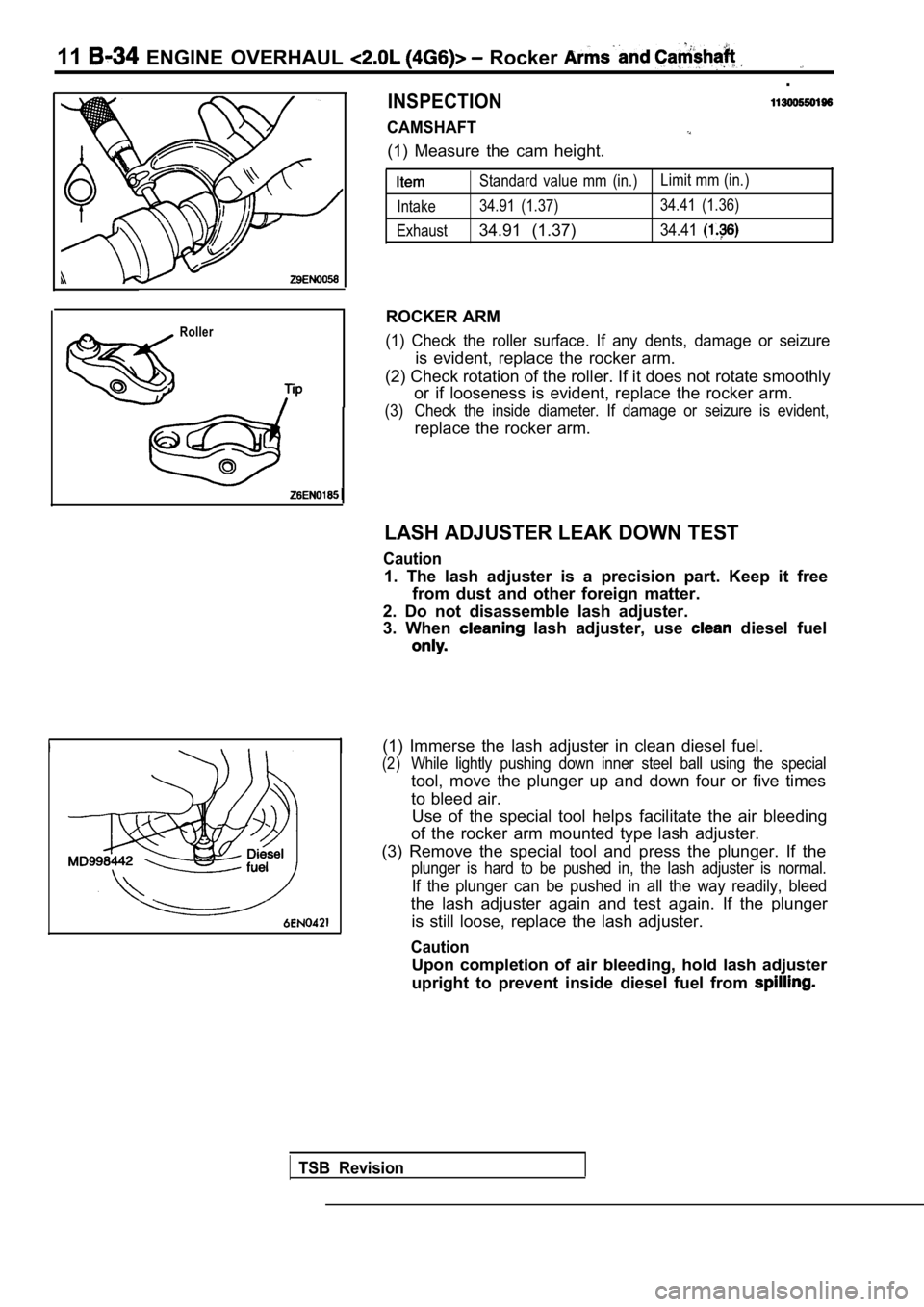

Roller

Standard value mm (in.)Limit mm (in.)

Intake 34.91 (1.37) 34.41 (1.36)

Exhaust

34.91 (1.37)34.41

ROCKER ARM

(1) Check the roller surface. If any dents, damage or seizure

is evident, replace the rocker arm.

(2) Check rotation of the roller. If it does not ro tate smoothly

or if looseness is evident, replace the rocker arm.

(3) Check the inside diameter. If damage or seizure is evident,

replace the rocker arm.

LASH ADJUSTER LEAK DOWN TEST

Caution

1. The lash adjuster is a precision part. Keep it f ree

from dust and other foreign matter.

2. Do not disassemble lash adjuster.

3. When

lash adjuster, use diesel fuel

(1) Immerse the lash adjuster in clean diesel fuel.

(2)While lightly pushing down inner steel ball using t he special

tool, move the plunger up and down four or five tim es

to bleed air. Use of the special tool helps facilitate the air bl eeding

of the rocker arm mounted type lash adjuster.

(3) Remove the special tool and press the plunger. If the

plunger is hard to be pushed in, the lash adjuster is normal.

If the plunger can be pushed in all the way readily, bleed

the lash adjuster again and test again. If the plun ger

is still loose, replace the lash adjuster.

Caution

Upon completion of air bleeding, hold lash adjuster

upright to prevent inside diesel fuel from

TSB Revision

Page 139 of 2103

ENGINE OVERHAUL Rocker Arms and

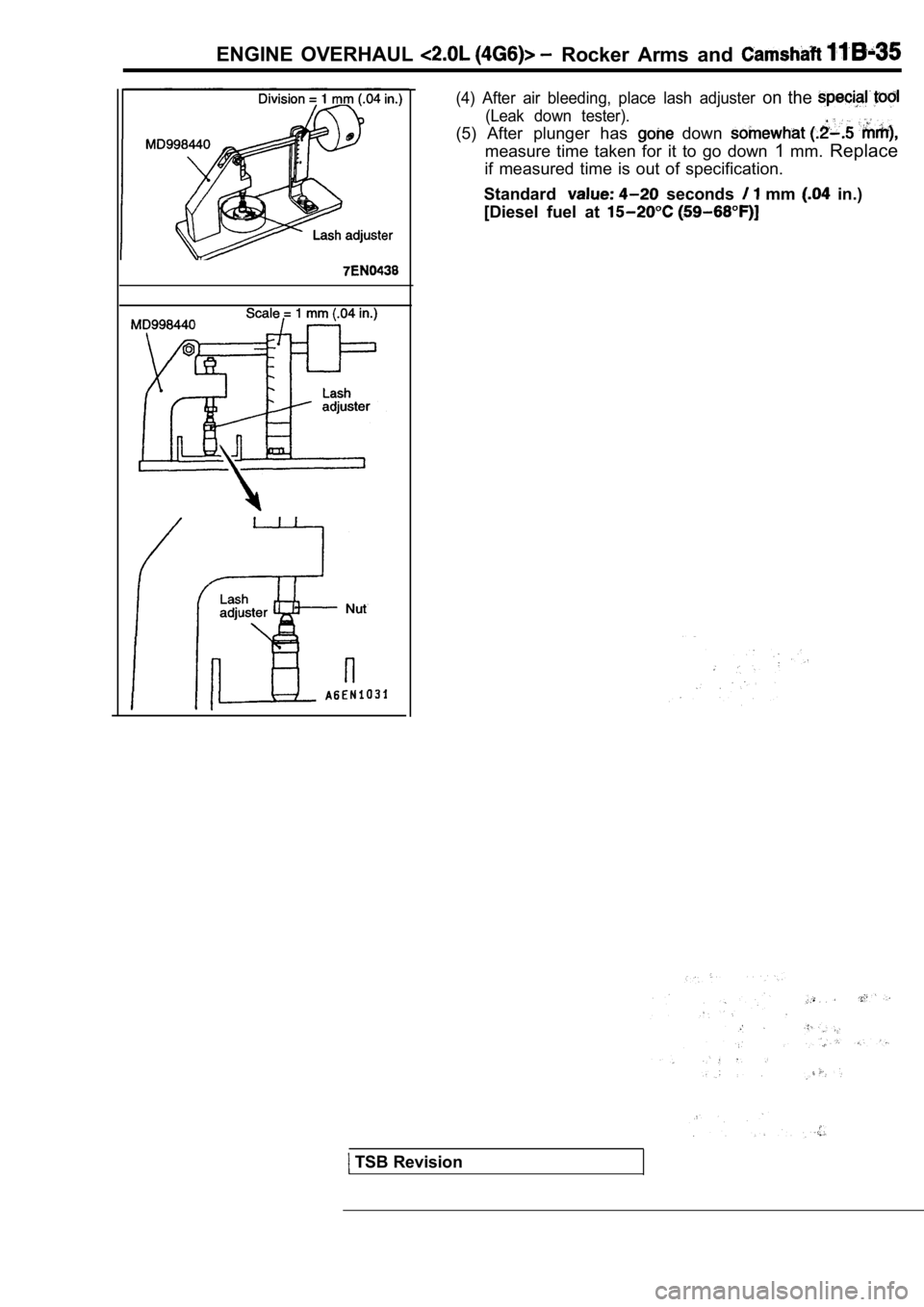

(4) After air bleeding, place lash adjuster on the

(Leak down tester).

(5) After plunger has down

measure time taken for it to go down 1mm. Replace

if measured time is out of specification.

Standard

seconds mm in.)

[Diesel fuel at

TSB Revision

Page 282 of 2103

ENGINE On-vehicle

NOTE

lIf the vehicle is parked on a slope for long, oil

in the lash adjusters will

and ‘air may

enter the high-pressure’ chamber when the vehicle

i s s t a r t e d .

lAfter the vehicle is parked for long, air may enter the high-pressure

because, the oil in the

oil passage will be gone it take a time before

the oil is supplied to the

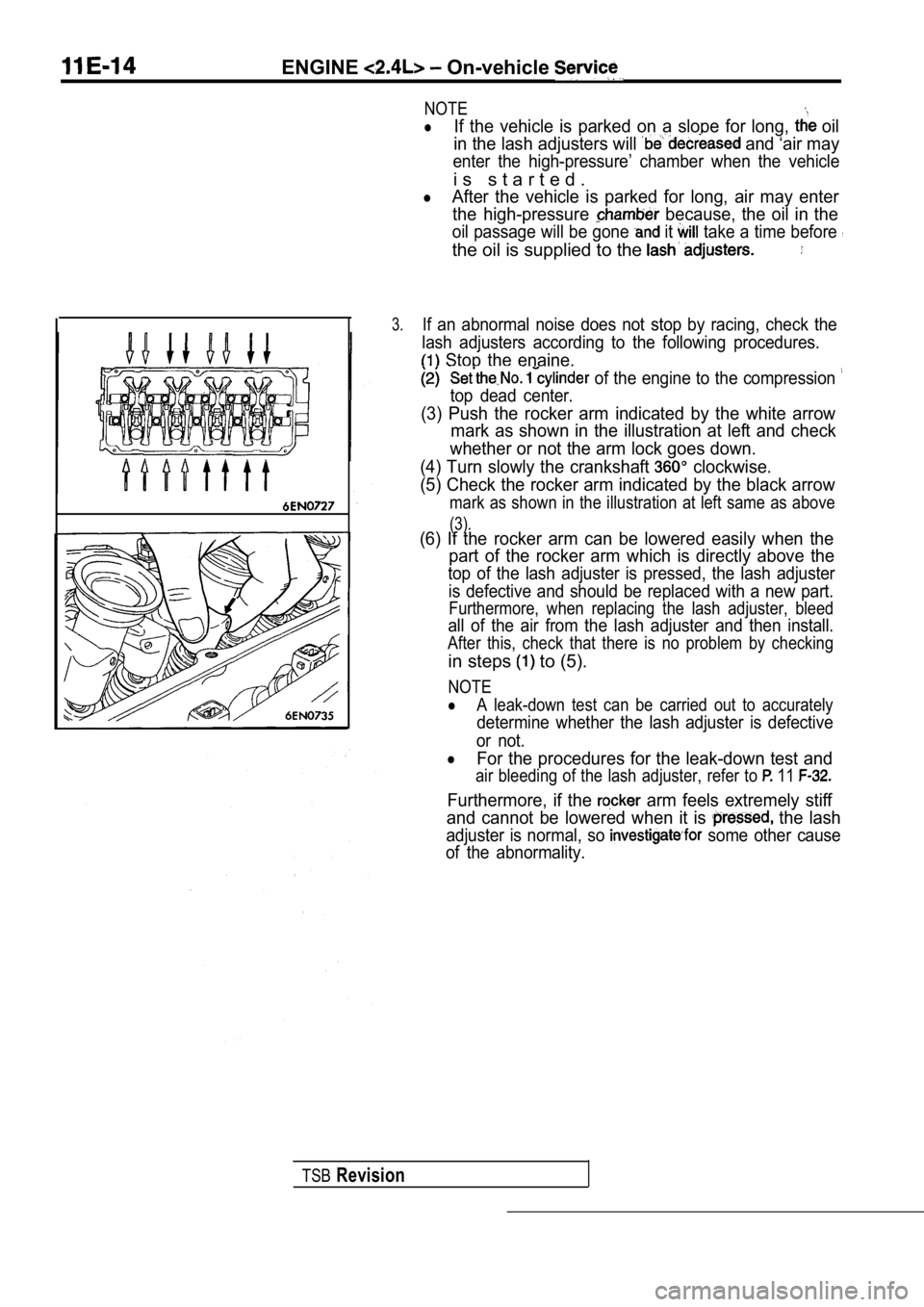

3.If an abnormal noise does not stop by racing, check the

lash adjusters according to the following procedure s.

Stop the enaine.

of the engine to the compression

top dead center.

(3) Push the rocker arm indicated by the white arrow

mark as shown in the illustration at left and check

whether or not the arm lock goes down.

(4) Turn slowly the crankshaft

clockwise.

(5) Check the rocker arm indicated by the black arr ow

mark as shown in the illustration at left same as above

(3).(6) If the rocker arm can be lowered easily when th e

part of the rocker arm which is directly above the

top of the lash adjuster is pressed, the lash adjus ter

is defective and should be replaced with a new part .

Furthermore, when replacing the lash adjuster, blee d

all of the air from the lash adjuster and then install.

After this, check that there is no problem by check ing

in steps to (5).

NOTE

lA leak-down test can be carried out to accurately

determine whether the lash adjuster is defective

or not.

lFor the procedures for the leak-down test and

air bleeding of the lash adjuster, refer to 11

Furthermore, if the arm feels extremely stiff

and cannot be lowered when it is

the lash

adjuster is normal, so some other cause

of the abnormality.

TSBRevision

Page 342 of 2103

ENGINE OVERHAUL Rocker Arms Camshaft

I

INSPECTION

CAMSHAFT.

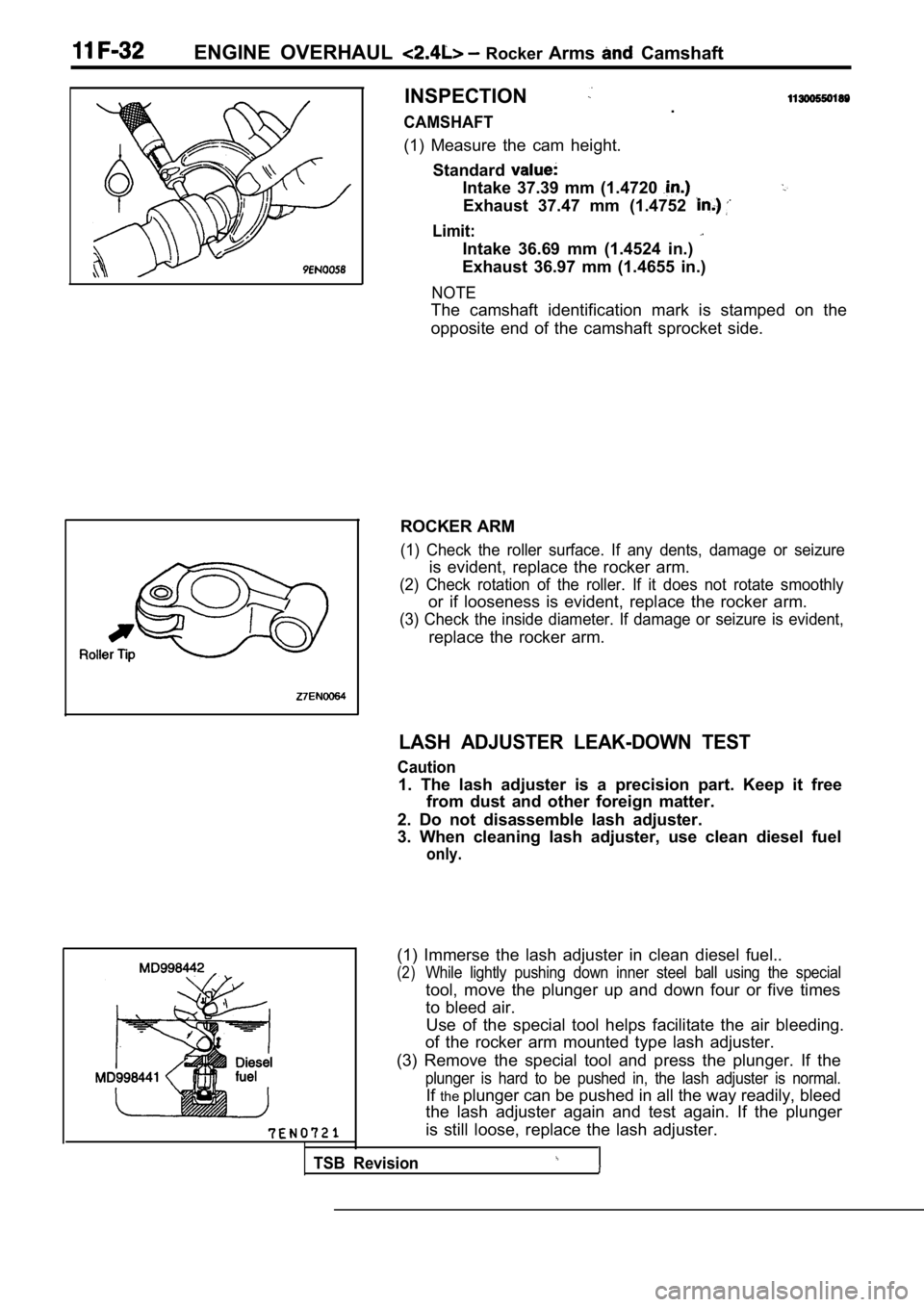

(1) Measure the cam height. Standard

Intake 37.39 mm (1.4720

Exhaust 37.47 mm (1.4752

Limit:

Intake 36.69 mm (1.4524 in.)

Exhaust 36.97 mm (1.4655 in.)

NOTE

The camshaft identification mark is stamped on the

opposite end of the camshaft sprocket side.

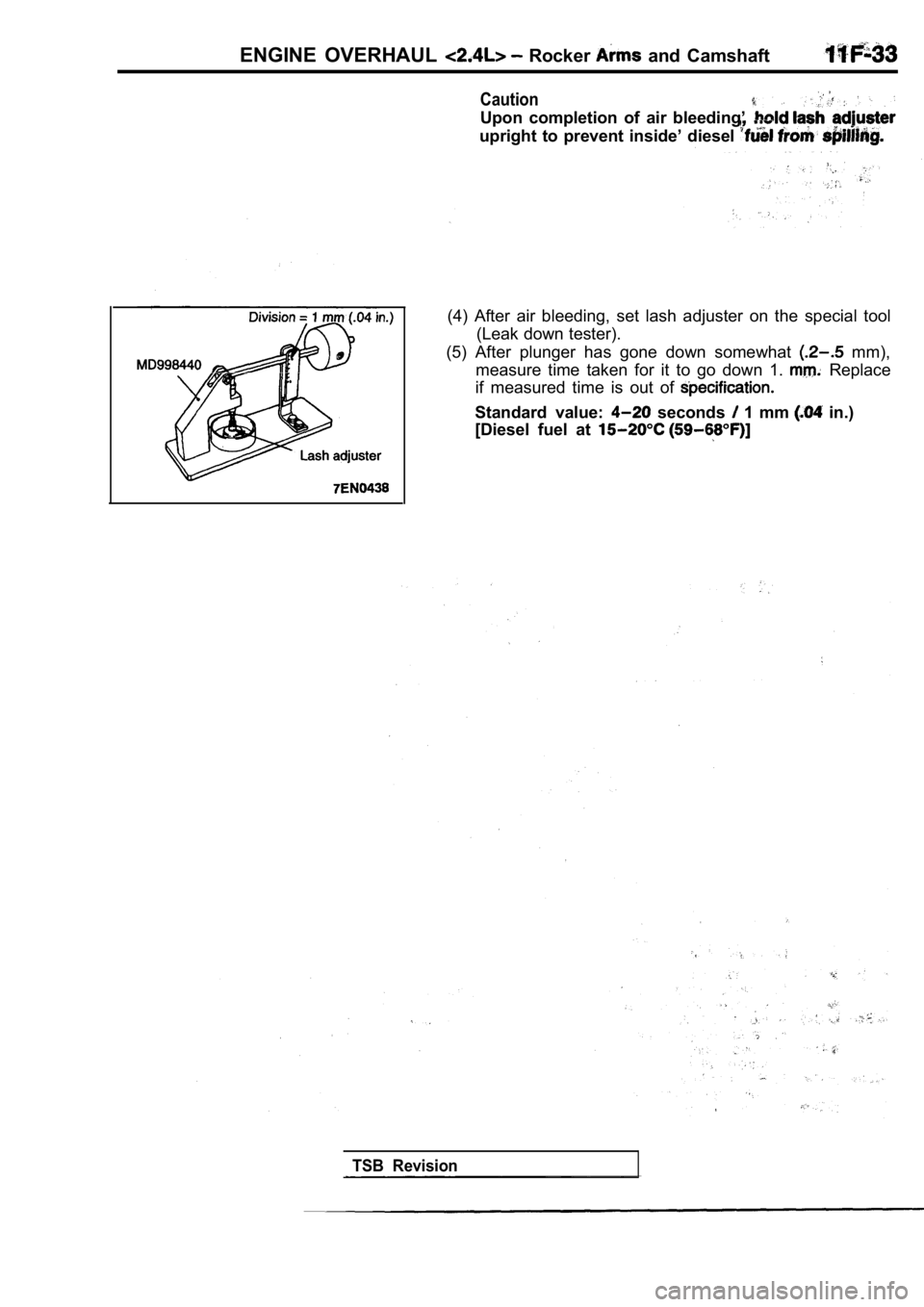

ROCKER ARM

(1) Check the roller surface. If any dents, damage or seizure

is evident, replace the rocker arm.

(2) Check rotation of the roller. If it does not rotate smoothly

or if looseness is evident, replace the rocker arm.

(3) Check the inside diameter. If damage or seizure is evident,

replace the rocker arm.

LASH ADJUSTER LEAK-DOWN TEST

Caution

1. The lash adjuster is a precision part. Keep it f ree

from dust and other foreign matter.

2. Do not disassemble lash adjuster.

3. When cleaning lash adjuster, use clean diesel fu el

only.

Use of the special tool helps facilitate the air bleeding.

of the rocker arm mounted type lash adjuster.

(3) Remove the special tool and press the plunger. If the

plunger is hard to be pushed in, the lash adjuster is normal.

Ifthe plunger can be pushed in all the way readily, bleed

the lash adjuster again and test again. If the plun ger

is still loose, replace the lash adjuster.

TSB Revision

(1) Immerse the lash adjuster in clean diesel fuel. .

(2)While lightly pushing down inner steel ball using t he special

tool, move the plunger up and down four or five tim es

to bleed air.

Page 343 of 2103

ENGINE OVERHAUL Rocker and Camshaft

Caution

Upon completion of air bleeding’

upright to prevent inside’ diesel

(4) After air bleeding, set lash adjuster on the special tool

(Leak down tester).

(5) After plunger has gone down somewhat

mm),

measure time taken for it to go down 1.

Replace

if measured time is out of

Standard value: seconds 1 mm in.)

[Diesel fuel at

TSB Revision

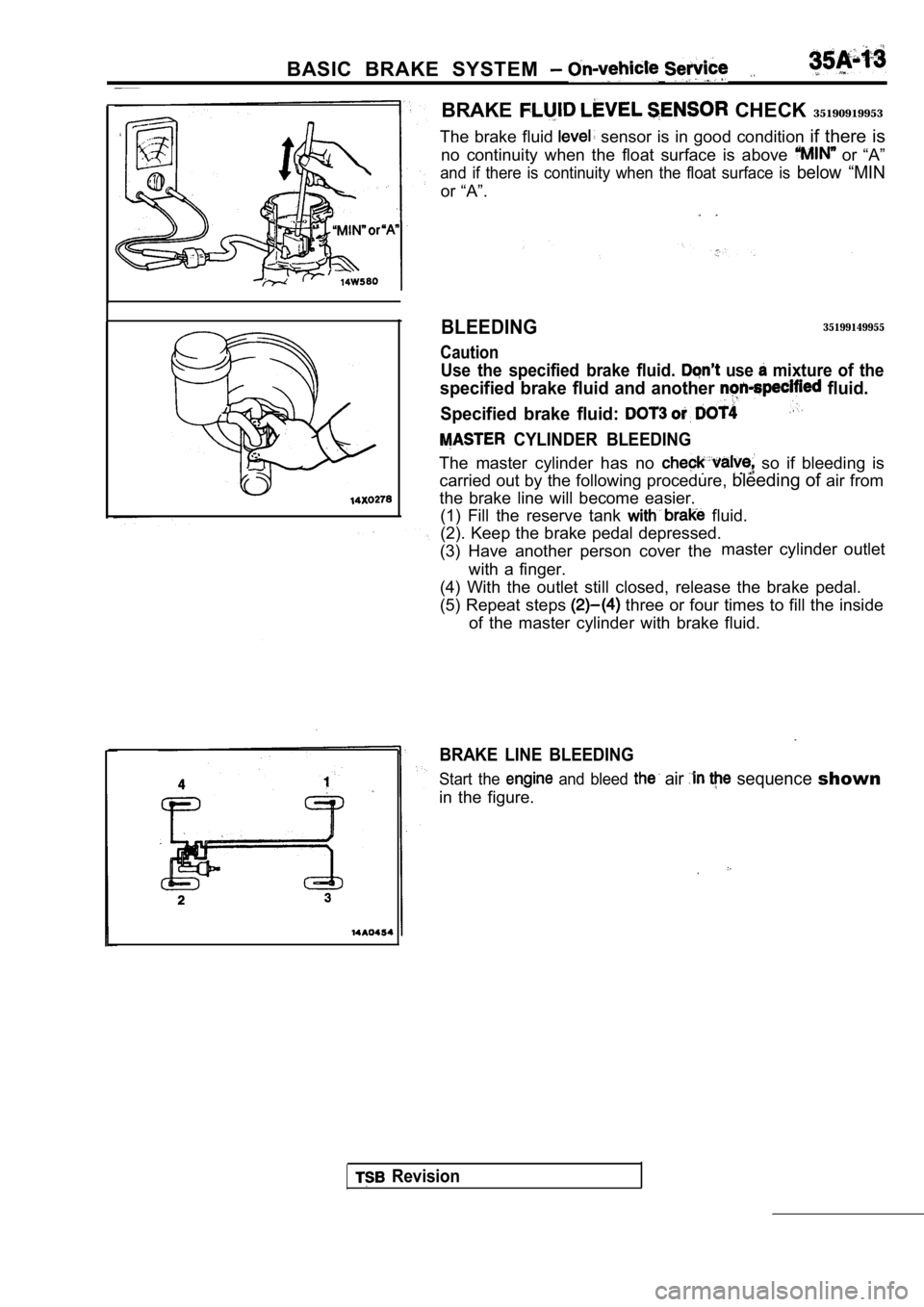

Page 1651 of 2103

BASIC BRAKE SYSTEM

BRAKE CHECK 35190919953

The brake fluid

sensor is in good condition if there is

no continuity when the float surface is above

or “A”

and if there is continuity when the float surface i s below “MIN

or “A”.

BLEEDING

Caution

35199149955

Use the specified brake fluid. use mixture of the

specified brake fluid and another fluid.

Specified brake fluid:

CYLINDER BLEEDING

The master cylinder has no so if bleeding is

carried out by the following procedure, bleeding of air from

the brake line will become easier. (1) Fill the reserve tank

fluid.

(2). Keep the brake pedal depressed.

(3) Have another person cover the master cylinder outlet

with a finger.

(4) With the outlet still closed, release the brake pedal.

(5) Repeat steps

three or four times to fill the inside

of the master cylinder with brake fluid.

BRAKE LINE BLEEDING

Start the and bleed air sequence shown

in the figure.

Revision

Page 1663 of 2103

BASIC BRAKE SYSTEM Master Cylinder and Brake Booster

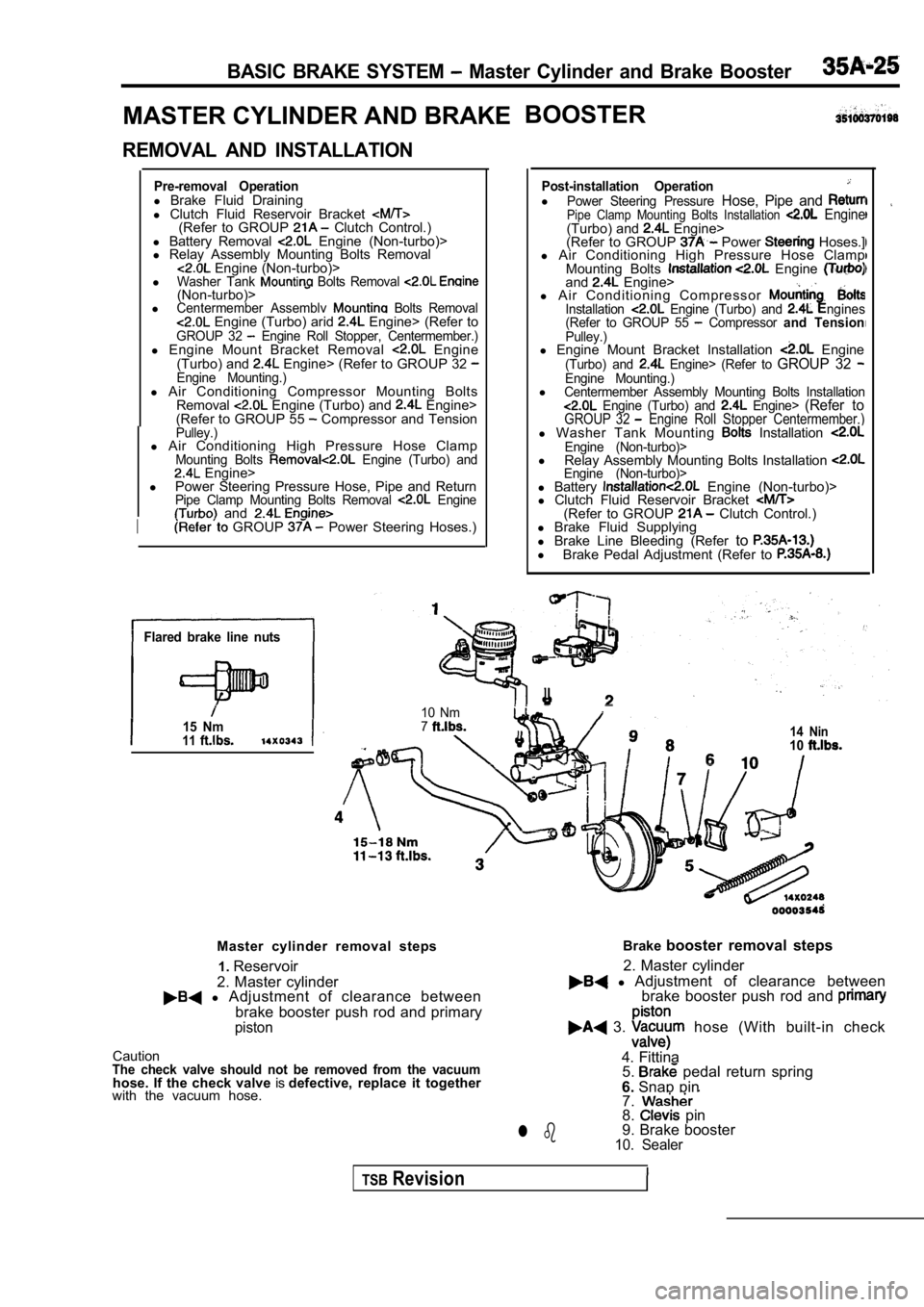

MASTER CYLINDER AND BRAKEBOOSTER

REMOVAL AND INSTALLATION

Pre-removal Operationl

Brake Fluid Draining

l Clutch Fluid Reservoir Bracket

(Refer to GROUP Clutch Control.)

l Battery Removal Engine (Non-turbo)>

l Relay Assembly Mounting Bolts Removal

Engine (Non-turbo)>

lWasher Tank Bolts Removal (Non-turbo)>lCentermember Assemblv Bolts Removal Engine (Turbo) arid Engine> (Refer toGROUP 32 Engine Roll Stopper, Centermember.)l Engine Mount Bracket Removal Engine

(Turbo) and Engine> (Refer to GROUP 32 Engine Mounting.)l Air Conditioning Compressor Mounting Bolts

Removal Engine (Turbo) and Engine>

(Refer to GROUP 55 Compressor and TensionPulley.)l Air Conditioning High Pressure Hose ClampMounting Bolts Engine (Turbo) and Engine>

l Power Steering Pressure Hose, Pipe and Return

Pipe Clamp Mounting Bolts Removal Engine and

I GROUP Power Steering Hoses.)

Flared brake line nuts

15 Nm11

Post-installation OperationlPower Steering Pressure Hose, Pipe and Pipe Clamp Mounting Bolts Installation Engine(Turbo) and Engine>

(Refer to GROUP Power Hoses.]

l Air Conditioning High Pressure Hose Clamp

Mounting Bolts

Engine and Engine>

l A i r C o n d i t i o n i n g C o m p r e s s o r

Installation Engine (Turbo) and ngines

(Refer to GROUP 55 Compressor and TensionPulley.)l Engine Mount Bracket Installation Engine(Turbo) and Engine> (Refer to GROUP 32 Engine Mounting.)lCentermember Assembly Mounting Bolts Installation Engine (Turbo) and Engine> (Refer toGROUP 32 Engine Roll Stopper Centermember.)l Washer Tank Mounting Installation Engine (Non-turbo)>l

Relay Assembly Mounting Bolts Installation Engine (Non-turbo)>l Battery Engine (Non-turbo)>

l Clutch Fluid Reservoir Bracket

(Refer to GROUP Clutch Control.)

l Brake Fluid Supplying

l Brake Line Bleeding (Refer to

l

Brake Pedal Adjustment (Refer to

I

10 Nm714 Nin10

Master cylinder removal steps

2. Master cylinder1.

Reservoir

l Adjustment of clearance between

brake booster push rod and primary

piston

CautionThe check valve should not be removed from the vacu umhose. If the check valve isdefective, replace it together

with the vacuum hose. Brake

booster removal steps

l Adjustment of clearance between

2. Master cylinder

brake booster push rod and

3. hose (With built-in check

4. Fittina 5.

pedal return spring

6. Snap pin

7.

8. pin

9. Brake booster

10. Sealerl b

TSBRevision

Page 1678 of 2103

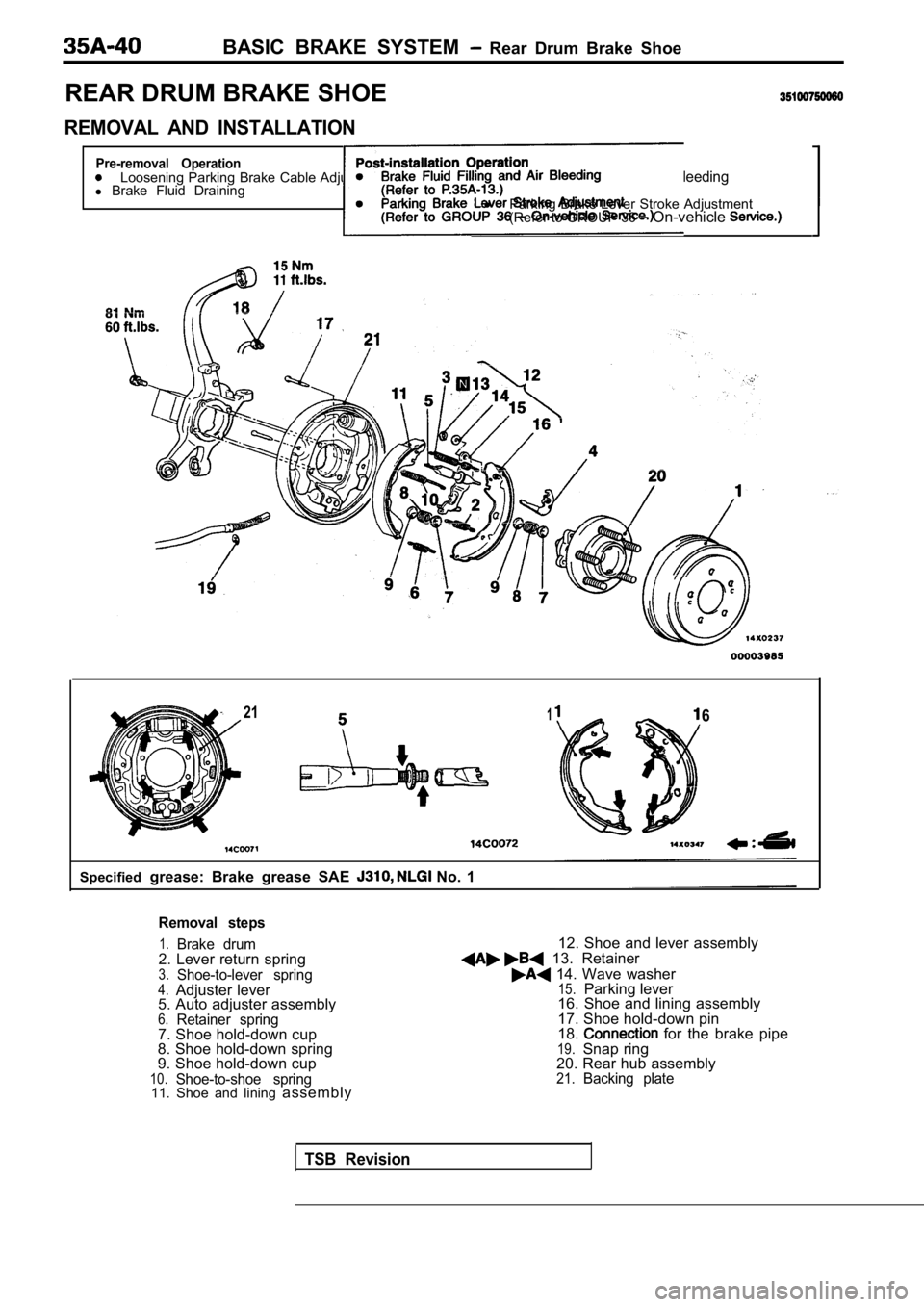

BASIC BRAKE SYSTEM Rear Drum Brake Shoe

REAR DRUM BRAKE SHOE

REMOVAL AND INSTALLATION

Pre-removal OperationLoosening Parking Brake Cable Adjusting Nut. lBrake Fluid Filling and Air Bleedingl

Brake Fluid Drainingl

Parking Brake Lever Stroke Adjustment

(Refer to GROUP 36 On-vehicle

2116

Specified grease: Brake grease SAE No. 1

Removal steps

1.Brake drum2. Lever return spring3.Shoe-to-lever spring4.Adjuster lever

5. Auto adjuster assembly

6.Retainer spring7. Shoe hold-down cup

8. Shoe hold-down spring

9. Shoe hold-down cup

10.Shoe-to-shoe spring11. Shoe and lining assembly 12. Shoe and lever assembly

13. Retainer

14. Wave washer15.Parking lever

16. Shoe and lining assembly

17. Shoe hold-down pin

18.

for the brake pipe19.Snap ring

20. Rear hub assembly

21.Backing plate

TSB Revision

Page 1724 of 2103

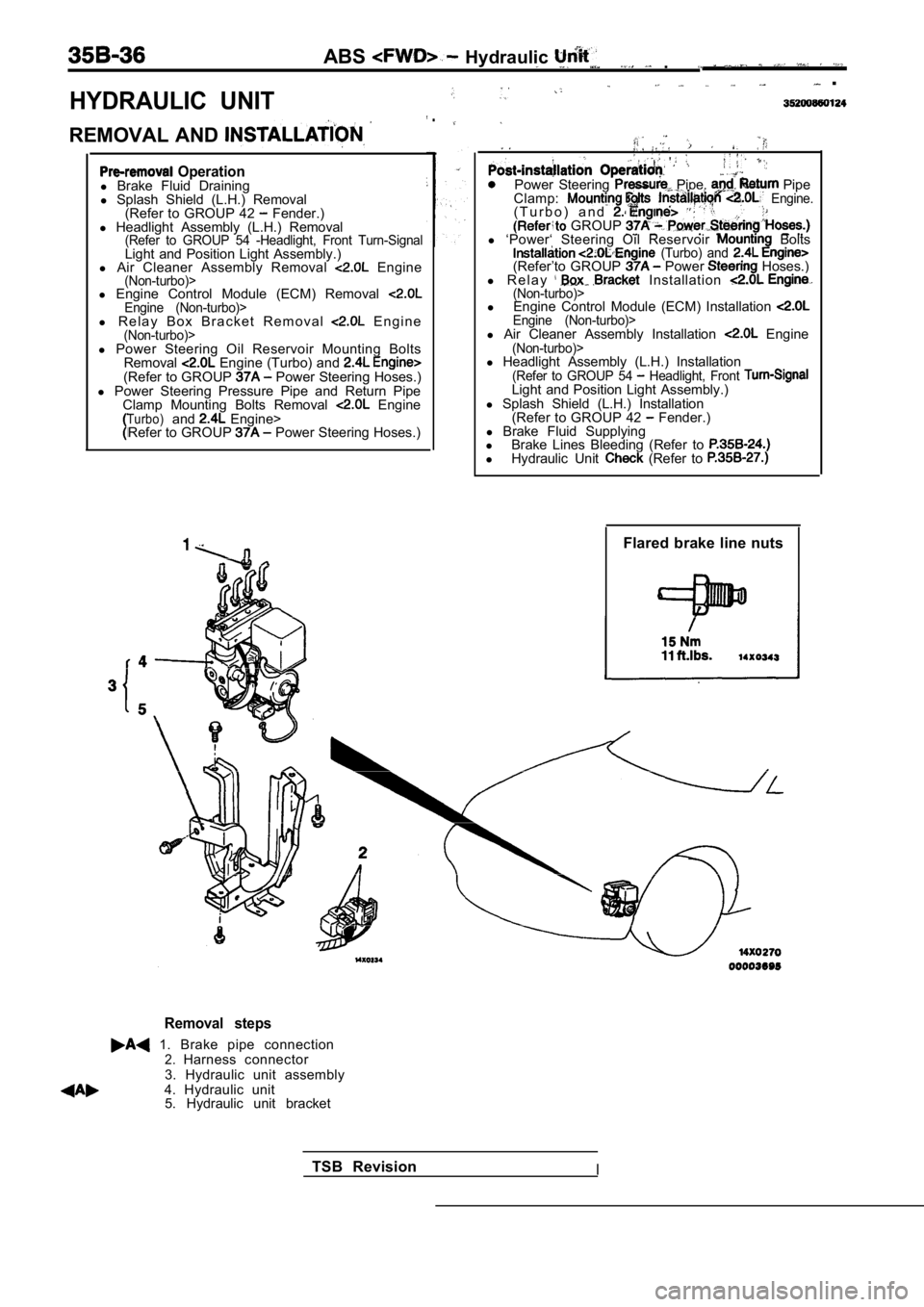

HYDRAULIC UNIT

ABS Hydraulic .

.

REMOVAL AND

.

Operationl Brake Fluid Draining

l Splash Shield (L.H.) Removal

(Refer to GROUP 42

Fender.)

l Headlight Assembly (L.H.) Removal

(Refer to GROUP 54 -Headlight, Front Turn-SignalLight and Position Light Assembly.)

l Air Cleaner Assembly Removal Engine(Non-turbo)>l Engine Control Module (ECM) Removal Engine (Non-turbo)>l R e l a y B o x B r a c k e t R e m o v a l E n g i n e(Non-turbo)>

Power Steering Pipe, Pipe

Clamp: Engine.( T u r b o ) a n d . GROUP l ‘Power‘ Steering Oil Reservoir Bolts (Turbo) and (Refer’to GROUP Power Hoses.)

l R e l a y Installation (Non-turbo)>l Engine Control Module (ECM) Installation Engine (Non-turbo)>l Air Cleaner Assembly Installation Engine(Non-turbo)>l Power Steering Oil Reservoir Mounting Bolts

Removal Engine (Turbo) and (Refer to GROUP Power Steering Hoses.)

l Power Steering Pressure Pipe and Return Pipe

Clamp Mounting Bolts Removal

EngineTurbo)and Engine>

Refer to GROUP Power Steering Hoses.) l

Headlight Assembly (L.H.) Installation

(Refer to GROUP 54 Headlight, Front Light and Position Light Assembly.)

l Splash Shield (L.H.) Installation

(Refer to GROUP 42

Fender.)

l Brake Fluid Supplying

l Brake Lines Bleeding (Refer to

lHydraulic Unit (Refer to

Flared brake line nuts

Removal steps

1. Brake pipe connection2.Harness connector

3. Hydraulic unit assembly

4. Hydraulic unit 5. Hydraulic unit bracket

TSB Revision

I