brake pads MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 51 of 2103

GENERAL Maintenance

a

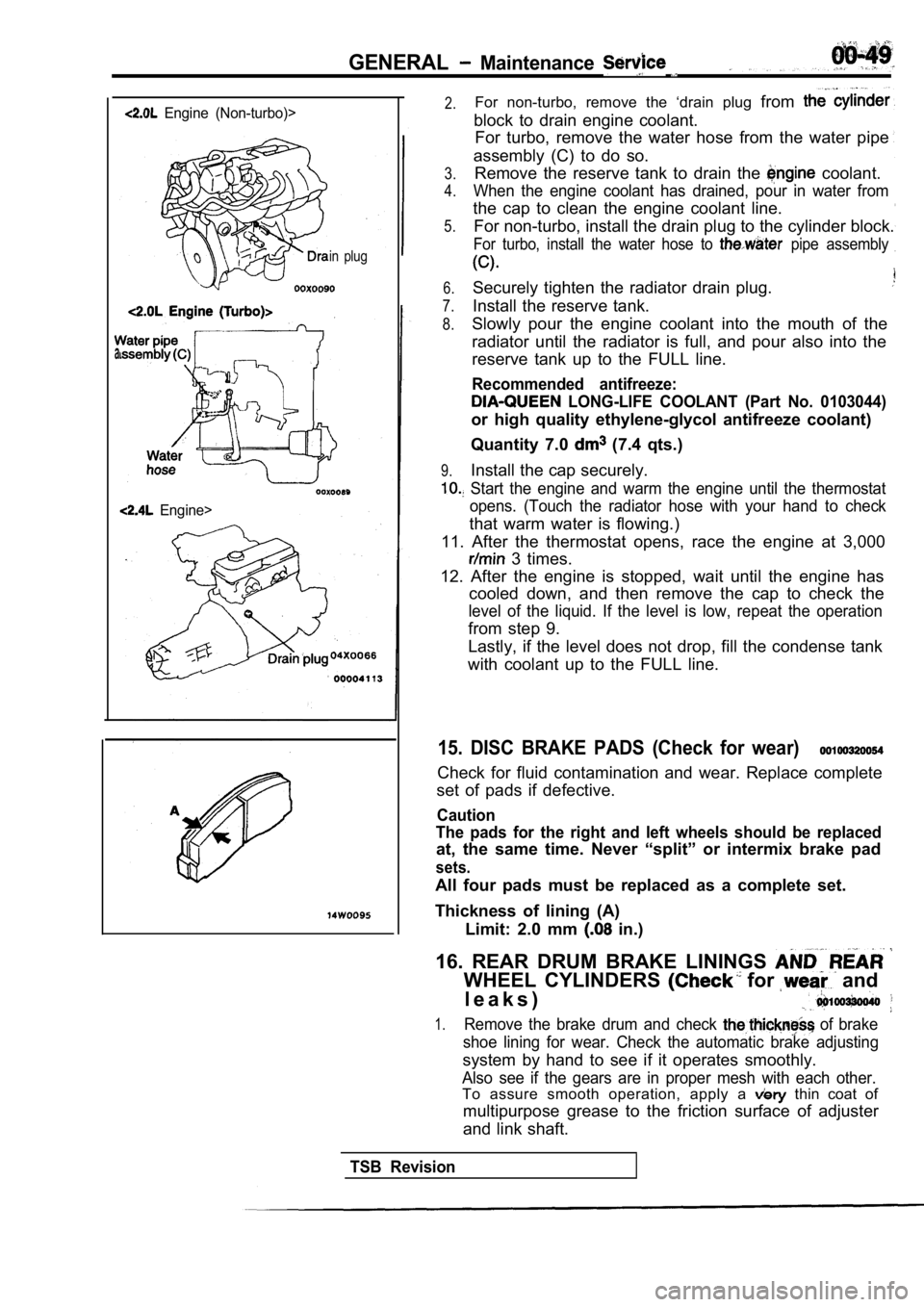

Engine (Non-turbo)>

in plug

Engine>

2.For non-turbo, remove the ‘drain plug from

block to drain engine coolant.

For turbo, remove the water hose from the water pip e

assembly (C) to do so.

3.

4.

5.Remove the reserve tank to drain the coolant.

When the engine coolant has drained, pour in water from

the cap to clean the engine coolant line.

For non-turbo, install the drain plug to the cylind er block.

For turbo, install the water hose to pipe assembly

6.

7.

8.

Securely tighten the radiator drain plug.

Install the reserve tank.

9.

Slowly pour the engine coolant into the mouth of th e

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended antifreeze:

LONG-LIFE COOLANT (Part No. 0103044)

or high quality ethylene-glycol antifreeze coolant)

Quantity 7.0

(7.4 qts.)

Install the cap securely.

Start the engine and warm the engine until the the rmostat

opens. (Touch the radiator hose with your hand to c heck

that warm water is flowing.)

11. After the thermostat opens, race the engine at 3,000

3 times.

12. After the engine is stopped, wait until the eng ine has

cooled down, and then remove the cap to check the

level of the liquid. If the level is low, repeat th e operation

from step 9.

Lastly, if the level does not drop, fill the conden se tank

with coolant up to the FULL line.

15. DISC BRAKE PADS (Check for wear)

Check for fluid contamination and wear. Replace com plete

set of pads if defective.

Caution

The pads for the right and left wheels should be re placed

at, the same time. Never “split” or intermix brake pad

sets.

All four pads must be replaced as a complete set.

Thickness of lining (A) Limit: 2.0 mm

in.)

16. REAR DRUM BRAKE LININGS

WHEEL CYLINDERS for and

l e a k s )

1.Remove the brake drum and check of brake

shoe lining for wear. Check the automatic brake adj usting

system by hand to see if it operates smoothly.

Also see if the gears are in proper mesh with each other.

To assure smooth operation, apply a thin coat of

multipurpose grease to the friction surface of adju ster

and link shaft.

TSB Revision

Page 1644 of 2103

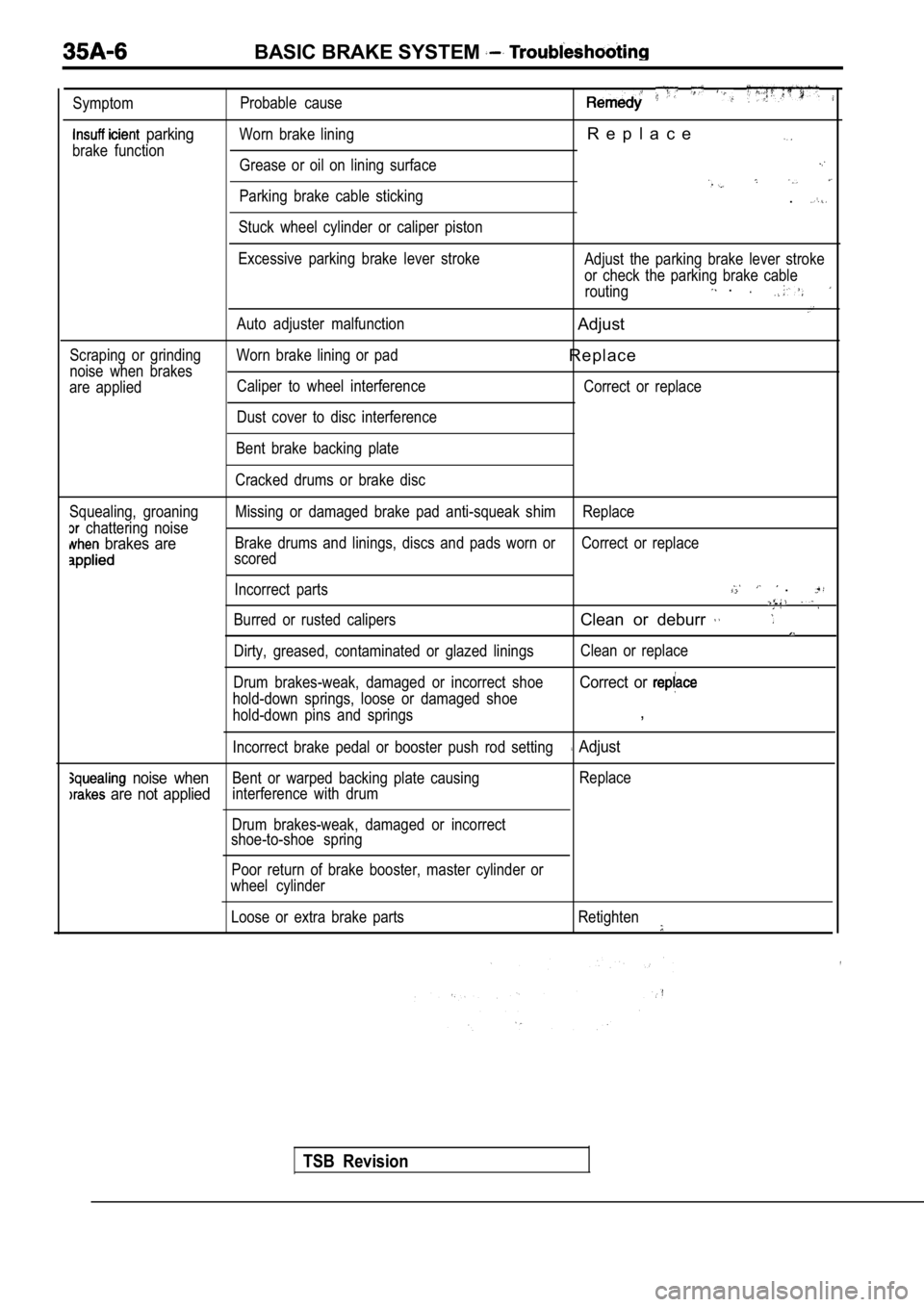

BASIC BRAKE SYSTEM

Symptom

parking

brake functionProbable cause

Worn brake lining

R e p l a c e

Grease or oil on lining surface

Parking brake cable sticking

Stuck wheel cylinder or caliper piston.

Scraping or grinding

noise when brakes

are applied Excessive parking brake lever stroke

Auto adjuster malfunction

Worn brake lining or pad Caliper to wheel interference

Dust cover to disc interference Adjust the parking brake lever stroke

or check the parking brake cable

routing

.

Adjust

R e p l a c e

Correct or replace

Bent brake backing plate

Cracked drums or brake disc

Squealing, groaning

chattering noise

brakes are

Missing or damaged brake pad anti-squeak shim Replac e

Brake drums and linings, discs and pads worn or Corr ect or replace

scored

Incorrect parts

.

Burred or rusted calipersClean or deburr

Dirty, greased, contaminated or glazed linings Clean or replace

Drum brakes-weak, damaged or incorrect shoe

hold-down springs, loose or damaged shoe

Correct or

hold-down pins and springs,

Incorrect brake pedal or booster push rod setting Adjust

noise whenBent or warped backing plate causing Replace

are not appliedinterference with drum

Drum brakes-weak, damaged or incorrect

shoe-to-shoe spring

Poor return of brake booster, master cylinder or

wheel cylinder

Loose or extra brake parts Retighten

TSB Revision

Page 1645 of 2103

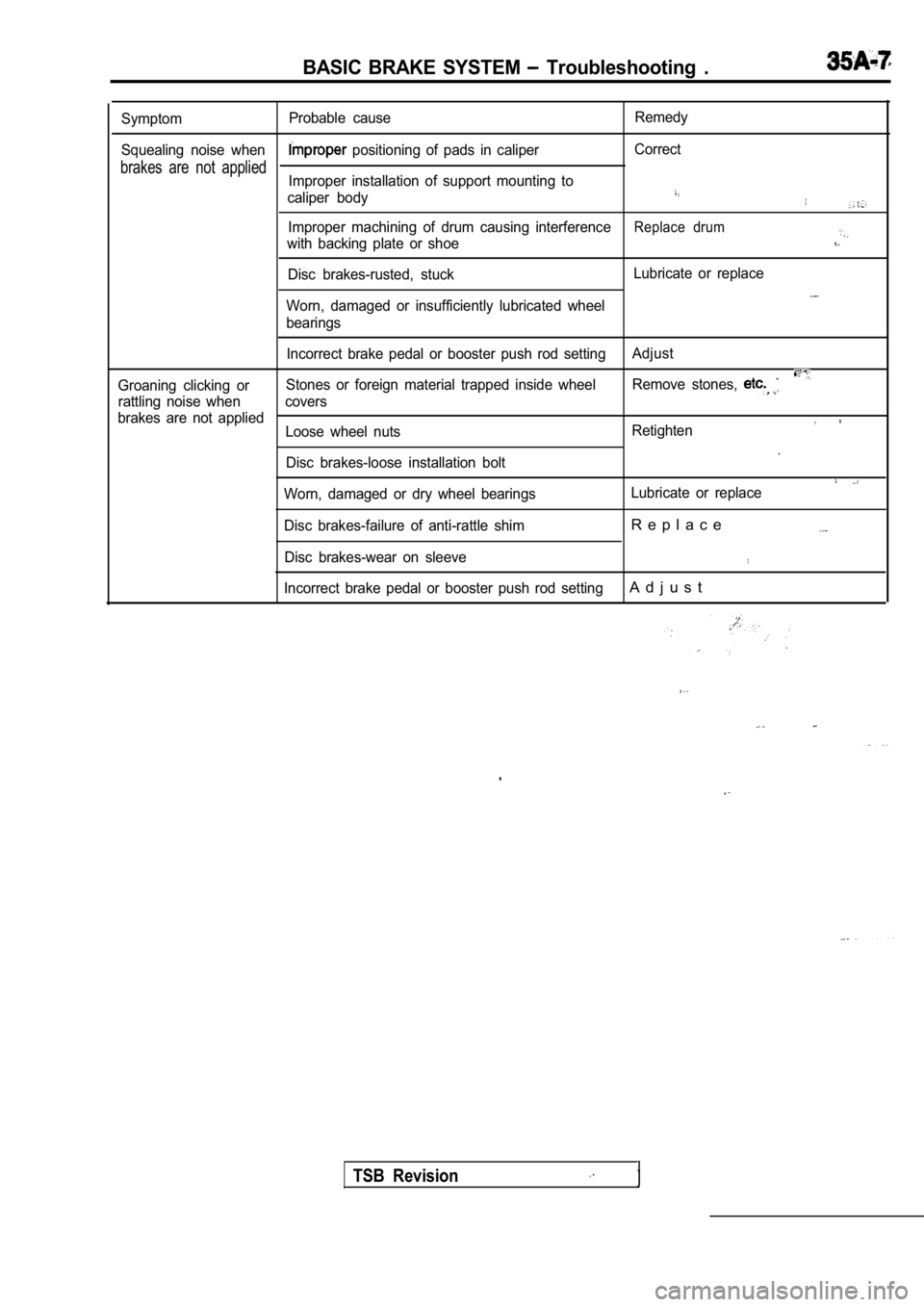

BASIC BRAKE SYSTEM Troubleshooting .

SymptomProbable cause Remedy

Squealing noise when

positioning of pads in caliper Correct

brakes are not appliedImproper installation of support mounting to

caliper body

Improper machining of drum causing interferenceReplace drum

with backing plate or shoe

Disc brakes-rusted, stuck Lubricate or replace

Worn, damaged or insufficiently lubricated wheel

bearings

Incorrect brake pedal or booster push rod setting Adjust

Groaning clicking orStones or foreign material trapped inside wheel

Remove stones,

rattling noise when covers

brakes are not applied

Loose wheel nuts Retighten

Disc brakes-loose installation bolt

Worn, damaged or dry wheel bearings Lubricate or replace

Disc brakes-failure of anti-rattle shim

R e p l a c e

Disc brakes-wear on sleeve

Incorrect brake pedal or booster push rod settingA d j u s t

,

TSB Revision

Page 1652 of 2103

4 SYSTEM Service

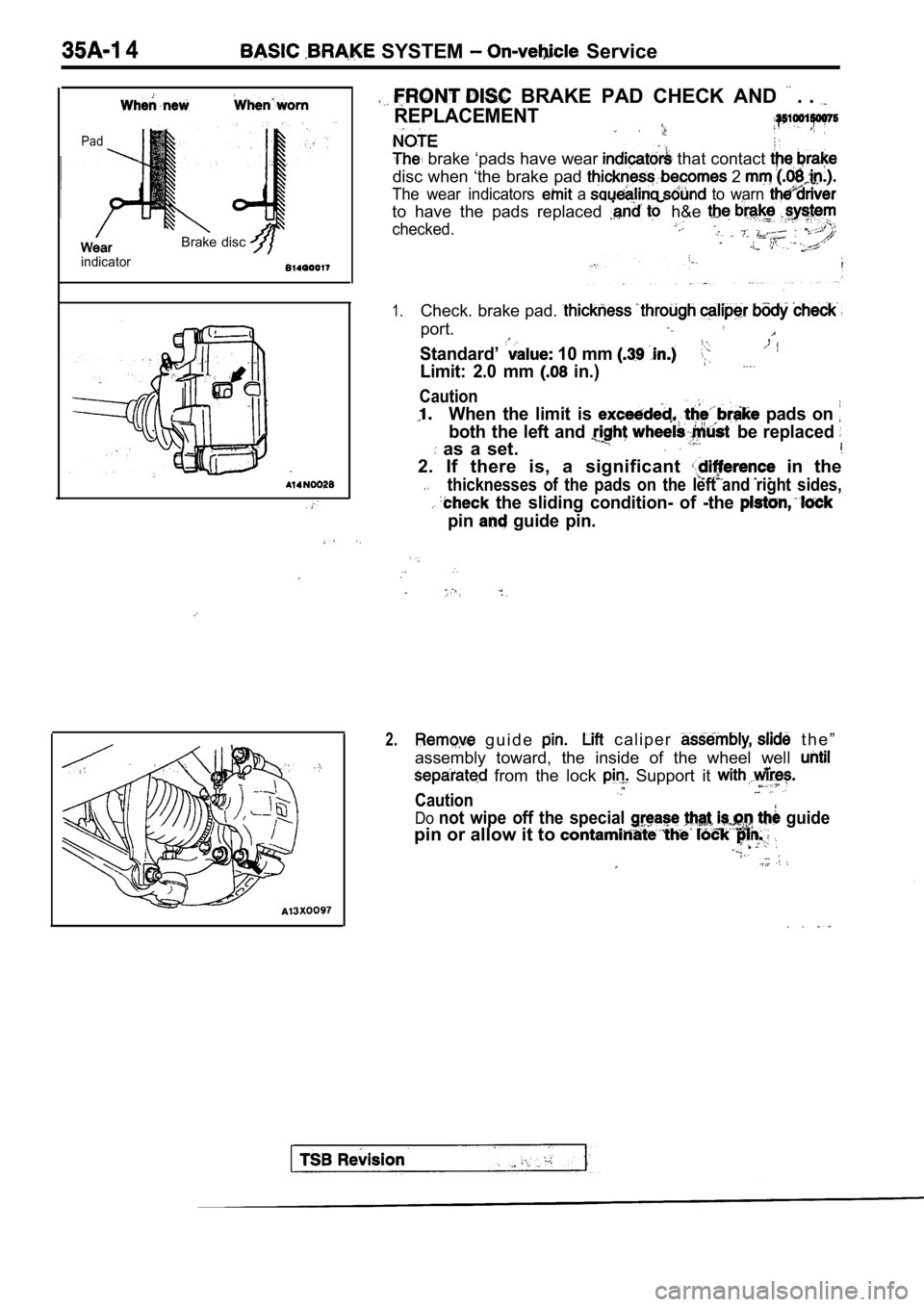

Pad

indicator

Brake disc

BRAKE PAD CHECK AND . .

REPLACEMENT

brake ‘pads have wear that contact

disc when ‘the brake pad 2

The wear indicators a to warn

to have the pads replaced h&e

checked.

1.Check. brake pad.

port.

Standard’ 10 mm

,

Limit: 2.0 mm in.)

Caution

When the limit is pads on

both the left and be replaced

as a set.

2. If there is, a significant in the

thicknesses of the pads on the left and right sides,

the sliding condition- of -the

pin guide pin.

2. g u i d e c a l i p e r t h e ”

assembly toward, the inside of the wheel well

from the lock Support it

Caution

Donot wipe off the special guide

pin or allow it to

Page 1653 of 2103

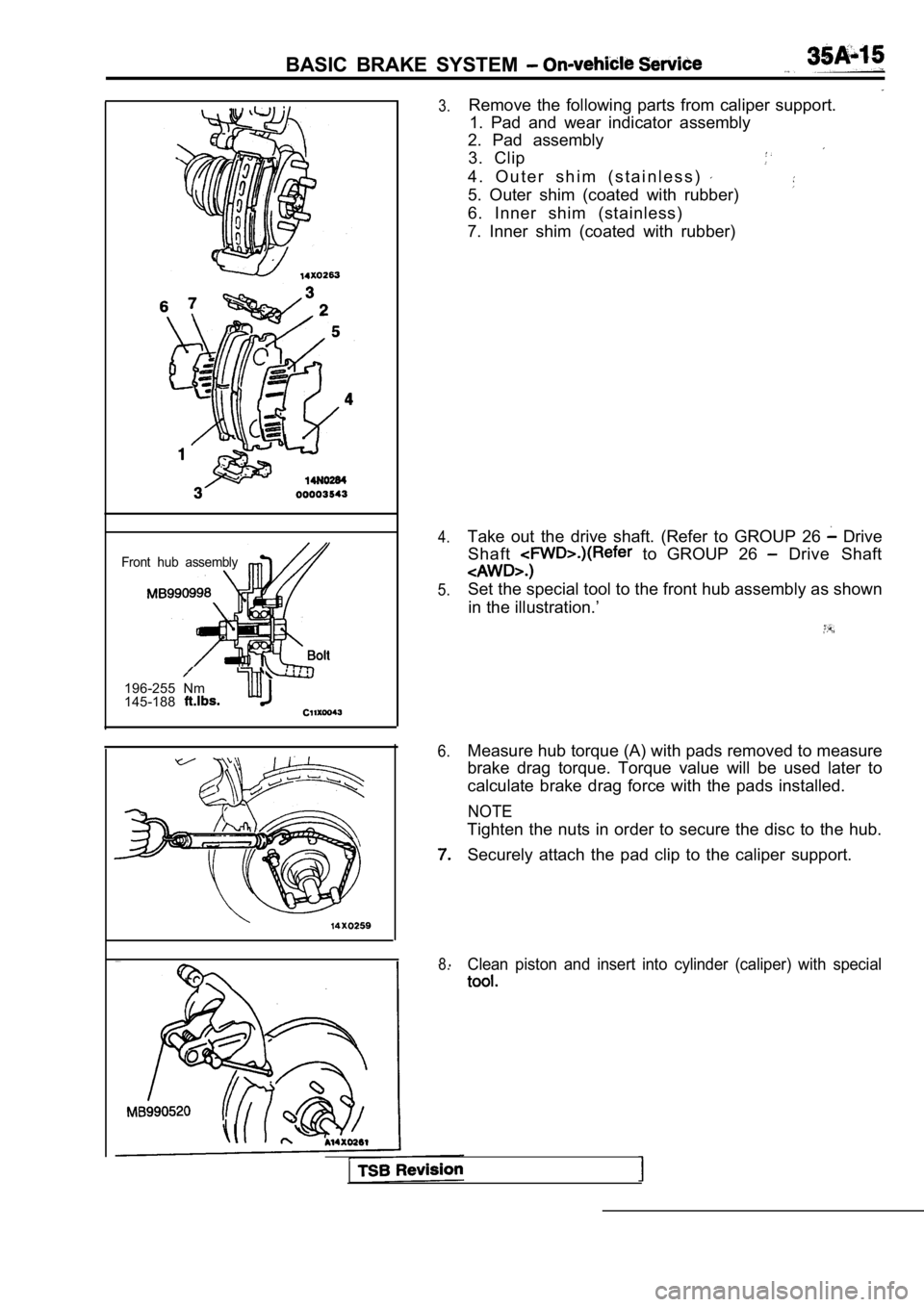

BASIC BRAKE SYSTEM

Front hub assembly

196-255 Nm

145-188

3.

4.

5.

6.

8.

Remove the following parts from caliper support. 1. Pad and wear indicator assembly

2. Pad assembly

3. Clip

4 . O u t e r s h i m ( s t a i n l e s s )

5. Outer shim (coated with rubber)

6. Inner shim (stainless)

7. Inner shim (coated with rubber)

Take out the drive shaft. (Refer to GROUP 26

Drive

Shaft

to GROUP 26 Drive Shaft

Set the special tool to the front hub assembly as s hown

in the illustration.’

Measure hub torque (A) with pads removed to measure

brake drag torque. Torque value will be used later to

calculate brake drag force with the pads installed.

NOTE

Tighten the nuts in order to secure the disc to the hub.

Securely attach the pad clip to the caliper support .

Clean piston and insert into cylinder (caliper) with special

Page 1659 of 2103

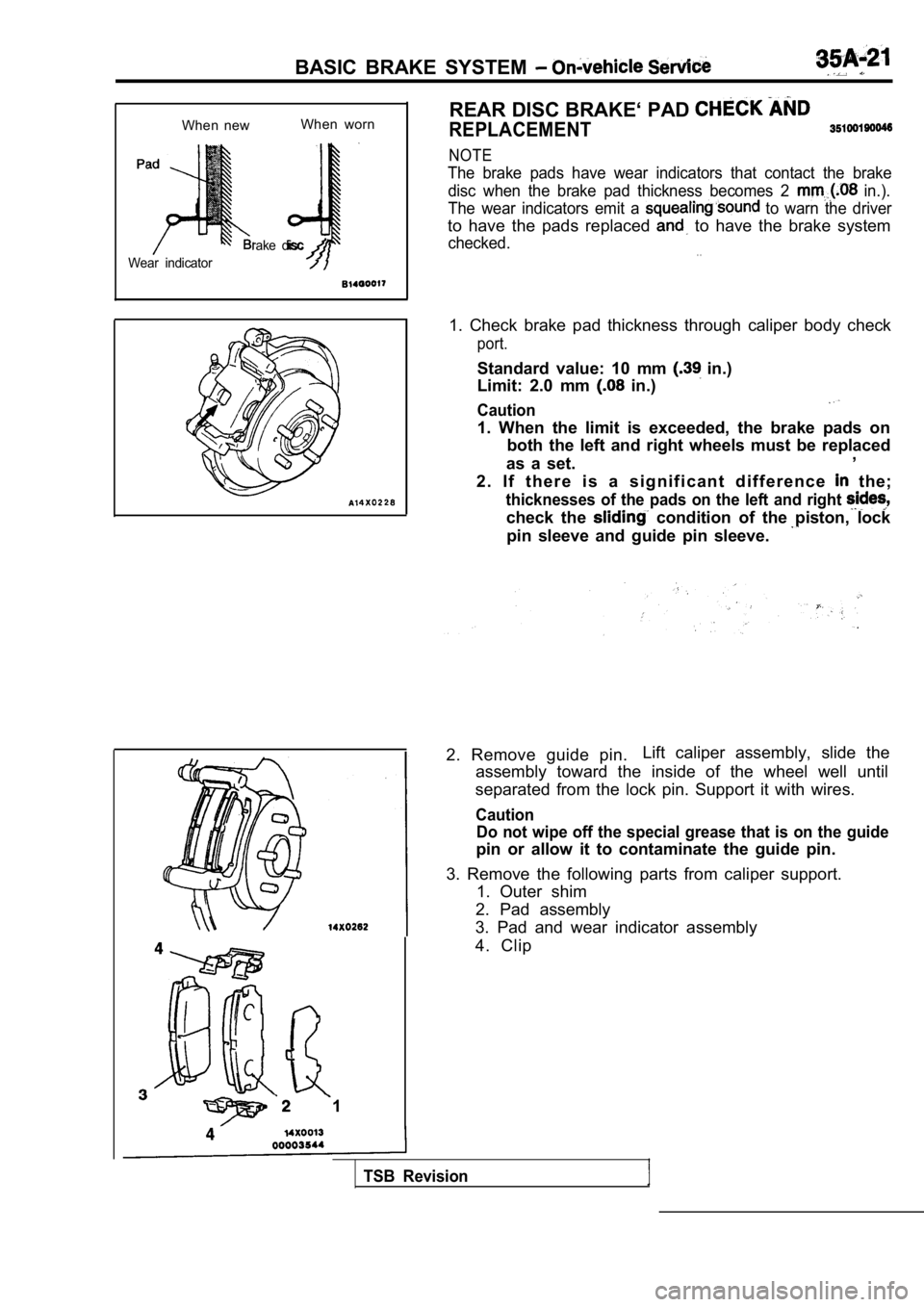

BASIC BRAKE SYSTEM

When newWhen worn

rake disc

Wear indicator

1 REAR DISC BRAKE‘ PAD

REPLACEMENT

NOTE

The brake pads have wear indicators that contact th

e brake

disc when the brake pad thickness becomes 2

in.).

The wear indicators emit a

to warn the driver

to have the pads replaced to have the brake system

checked.. .

1. Check brake pad thickness through caliper body c heck

port.

Standard value: 10 mm in.)

Limit: 2.0 mm

in.)

Caution

1. When the limit is exceeded, the brake pads on

both the left and right wheels must be replaced

as a set. ,

2 . I f t h e r e i s a s i g n i f i c a n t d i f f e r e n c e

the;

thicknesses of the pads on the left and right

check the condition of the piston, lock

pin sleeve and guide pin sleeve.

2. Remove guide pin. Lift caliper assembly, slide the

assembly toward the inside of the wheel well until

separated from the lock pin. Support it with wires.

Caution Do not wipe off the special grease that is on the g uide

pin or allow it to contaminate the guide pin.

3. Remove the following parts from caliper support. 1. Outer shim

2. Pad assembly

3. Pad and wear indicator assembly

4. Clip

TSB Revision

Page 1660 of 2103

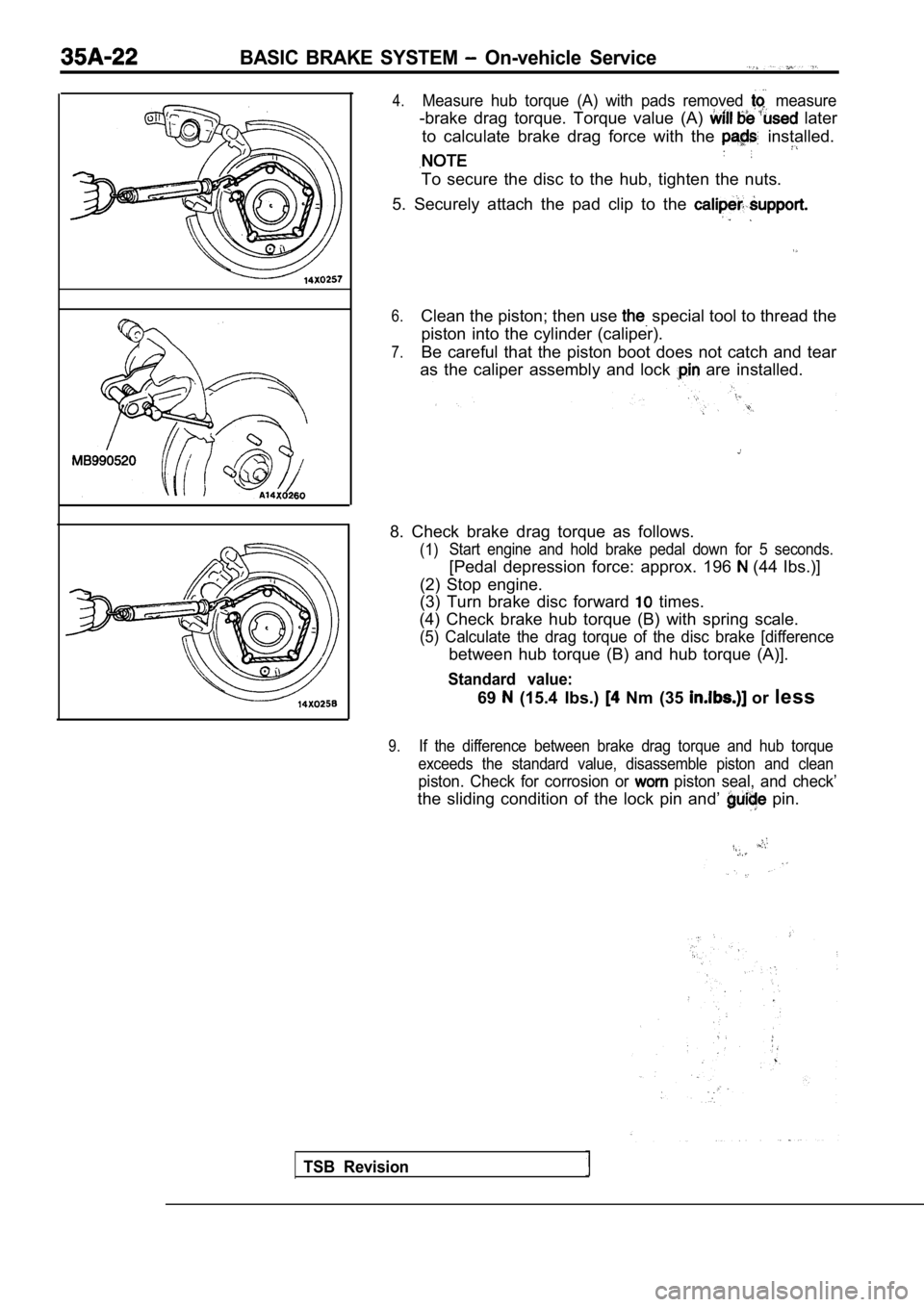

BASIC BRAKE SYSTEM On-vehicle Service

TSB Revision

4.Measure hub torque (A) with pads removed measure

-brake drag torque. Torque value (A) later

to calculate brake drag force with the

installed.

To secure the disc to the hub, tighten the nuts.

5. Securely attach the pad clip to the

6.Clean the piston; then use special tool to thread the

piston into the cylinder (caliper).

7.Be careful that the piston boot does not catch and tear

as the caliper assembly and lock

are installed.

8. Check brake drag torque as follows.

(1) Start engine and hold brake pedal down for 5 second

s.

[Pedal depression force: approx. 196 (44 Ibs.)]

(2) Stop engine.

(3) Turn brake disc forward

times.

(4) Check brake hub torque (B) with spring scale.

(5) Calculate the drag torque of the disc brake [di fference

between hub torque (B) and hub torque (A)].

Standard value:

69 (15.4 Ibs.) Nm (35 or less

9.If the difference between brake drag torque and hub torque

exceeds the standard value, disassemble piston and clean

piston. Check for corrosion or piston seal, and check’

the sliding condition of the lock pin and’ pin.

Page 1673 of 2103

BRAKE SYSTEM Front Disc

INSPECTION

lCheck cylinder for wear, rust.

lCheck piston surface for wear, damage or rust.

lCheck caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less tha n the

limit value.

Standard value: 10 mm in.)

L i m i t

value: 2.0 m m in.)

Caution

1.When the limit is exceeded, the brake pads on both

the left and right wheels must be replaced as a set .

2.If there is a significant difference in the thicknesses

of the pads on the left and right

check the

sliding condition of the piston, lock pin and guide

pin.

TSB Revision

Page 1677 of 2103

BASIC BRAKE SYSTEM Front Disc

INSPECTION

lCheck cylinder for wear, damage or rust.

lCheck piston surface for wear, damage or rust:

lCheck caliper body or sleeve for wear.

l Check pad for damage or adhesion of

check

backing metal for damage.

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly when pad thickness is less tha n the

limit value.

Standard value: 10 mm in.)

Limit value: 2.0 mm

in.)

Caution

1. When the limit is exceeded, the brake pads on bo th

the left and right wheels must be replaced as a set .

2.If there is a significant difference the thicknesses

of the pads on the left and right sides, check

sliding condition of the piston, lock pin and

pin.

TSB Revision