boot MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 42 of 2103

GENERAL Maintenance

Incorrect Correct

5. SPARK PLUGS

1.Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission

Therefore, they should be periodically with new

ones.

2. The new plugs should be checked gap.

Spark plug gap:, . .

Engine (Turbo)>’

mm

Engine (Non-turbo)> ,

1.22-1.35 mm

in.)

Engine> .

in.)

3. Install the spark plug and tighten to the

Tightening torque:

Engine (Turbo) and Engine>

25 Nm (18

E n g i n e ( N o n - t u r b o ) >

28 Nm (20

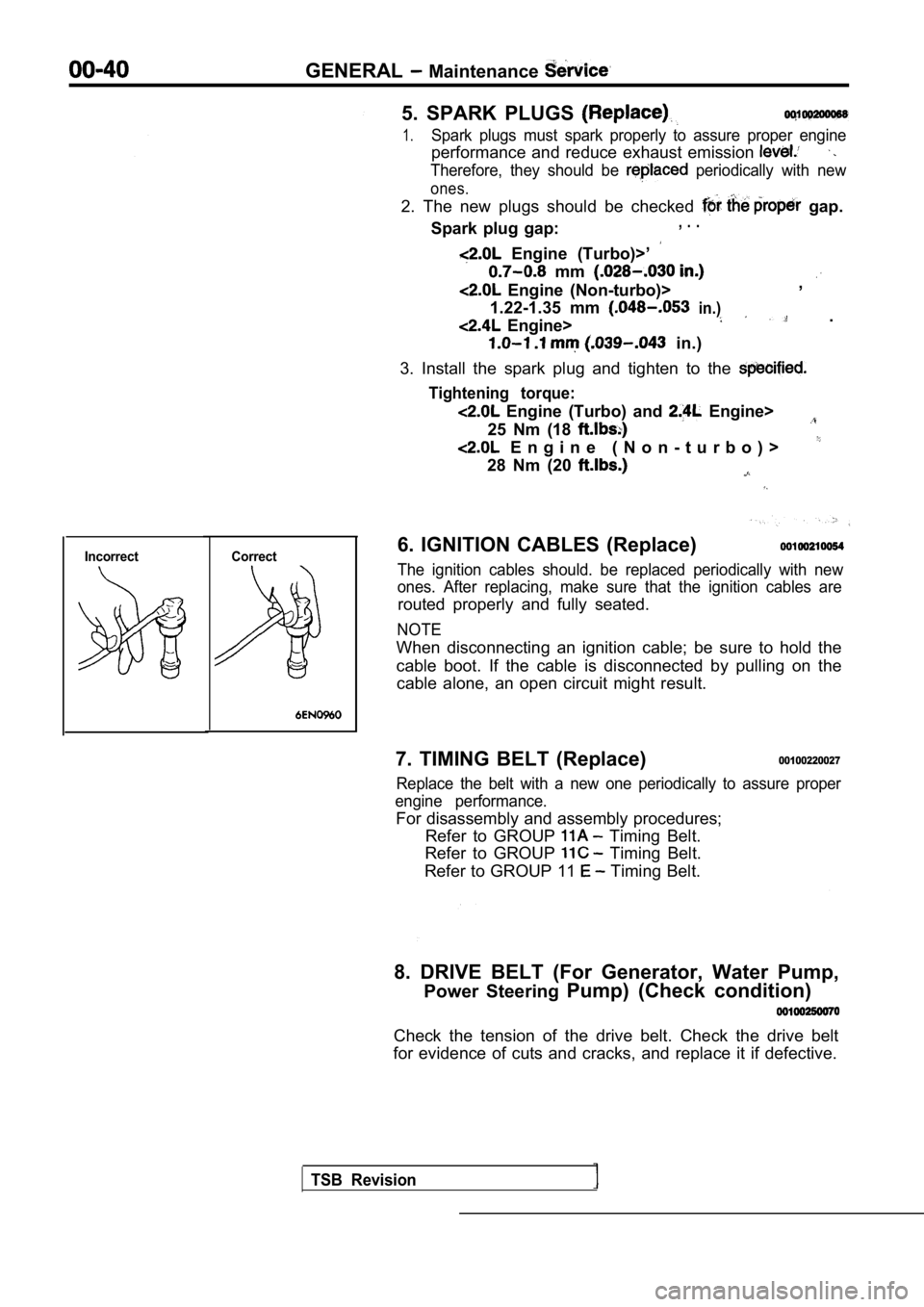

6. IGNITION CABLES (Replace)

The ignition cables should. be replaced periodicall y with new

ones. After replacing, make sure that the ignition cables are

routed properly and fully seated.

NOTE

When disconnecting an ignition cable; be sure to ho ld the

cable boot. If the cable is disconnected by pulling on the

cable alone, an open circuit might result.

7. TIMING BELT (Replace)

00100220027

Replace the belt with a new one periodically to ass ure proper

engine performance.

For disassembly and assembly procedures; Refer to GROUP

Timing Belt.

Refer to GROUP

Timing Belt.

Refer to GROUP 11

Timing Belt.

8. DRIVE BELT (For Generator, Water Pump, Power Steering Pump) (Check condition)

Check the tension of the drive belt. Check the driv e belt

for evidence of cuts and cracks, and replace it if defective.

TSB Revision

Page 52 of 2103

GENERAL Maintenance Service

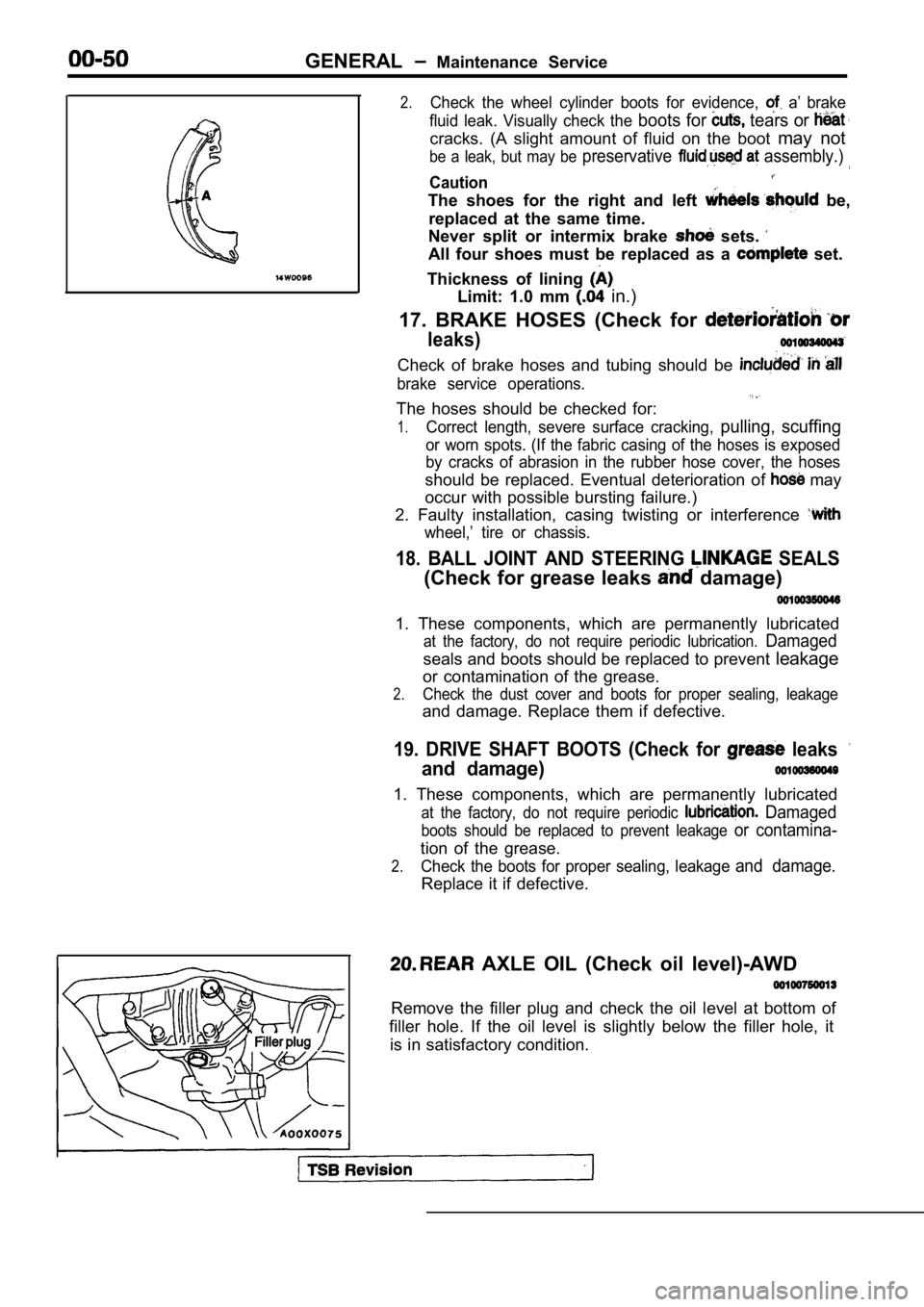

2.Check the wheel cylinder boots for evidence, a’ brake

fluid leak. Visually check the

boots for tears or

cracks. (A slight amount of fluid on the boot may not

be a leak, but may be preservative assembly.)

Caution

The shoes for the right and left be,

replaced at the same time.

Never split or intermix brake

sets.

All four shoes must be replaced as a set.

Thickness of lining

Limit: 1.0 mm in.)

17. BRAKE HOSES (Check for

leaks)

Check of brake hoses and tubing should be

brake service operations.

The hoses should be checked for:

1.Correct length, severe surface cracking, pulling, scuffing

or worn spots. (If the fabric casing of the hoses i s exposed

by cracks of abrasion in the rubber hose cover, the hoses

should be replaced. Eventual deterioration of may

occur with possible bursting failure.)

2. Faulty installation, casing twisting or interfer ence

wheel,’ tire or chassis.

18. BALL JOINT AND STEERING SEALS

(Check for grease leaks damage)

1. These components, which are permanently lubricat ed

at the factory, do not require periodic lubrication. Damaged

seals and boots should be replaced to prevent leakage

or contamination of the grease.

2.Check the dust cover and boots for proper sealing, leakage

and damage. Replace them if defective.

19. DRIVE SHAFT BOOTS (Check for leaks

and damage)

1. These components, which are permanently lubricat ed

at the factory, do not require periodic Damaged

boots should be replaced to prevent leakage or contamina-

tion of the grease.

2.Check the boots for proper sealing, leakage and damage.

Replace it if defective.

AXLE OIL (Check oil level)-AWD

Remove the filler plug and check the oil level at bottom of

filler hole. If the oil level is slightly below the filler hole, it

is in satisfactory condition.

Page 833 of 2103

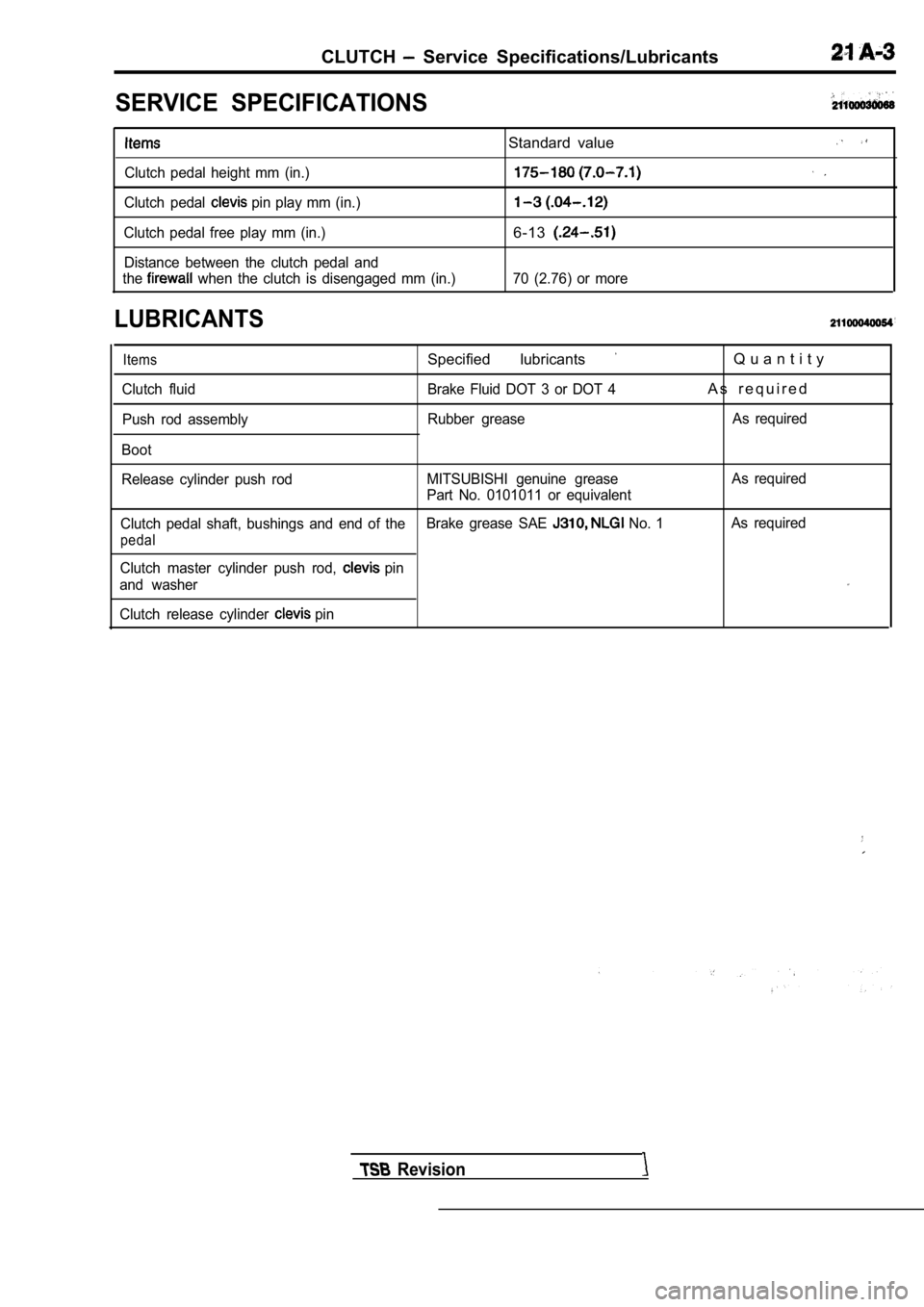

CLUTCH Service Specifications/Lubricants

SERVICE SPECIFICATIONS

Clutch pedal height mm (in.)

Clutch pedal

pin play mm (in.)

Clutch pedal free play mm (in.) Distance between the clutch pedal and

the

when the clutch is disengaged mm (in.)

LUBRICANTS

Standard value

6-13

70 (2.76) or more

Items

Clutch fluid

Push rod assembly

Boot

Specified lubricants

Brake Fluid DOT 3 or DOT 4

Rubber grease

Q u a n t i t y

A s r e q u i r e d

As required

Release cylinder push rod MITSUBISHI genuine grease

Part No. 0101011 or equivalentAs required

Clutch pedal shaft, bushings and end of the Brake grease SAE

No. 1As required

pedal

Clutch master cylinder push rod, pin

and washer

Clutch release cylinder

pin

Revision

Page 848 of 2103

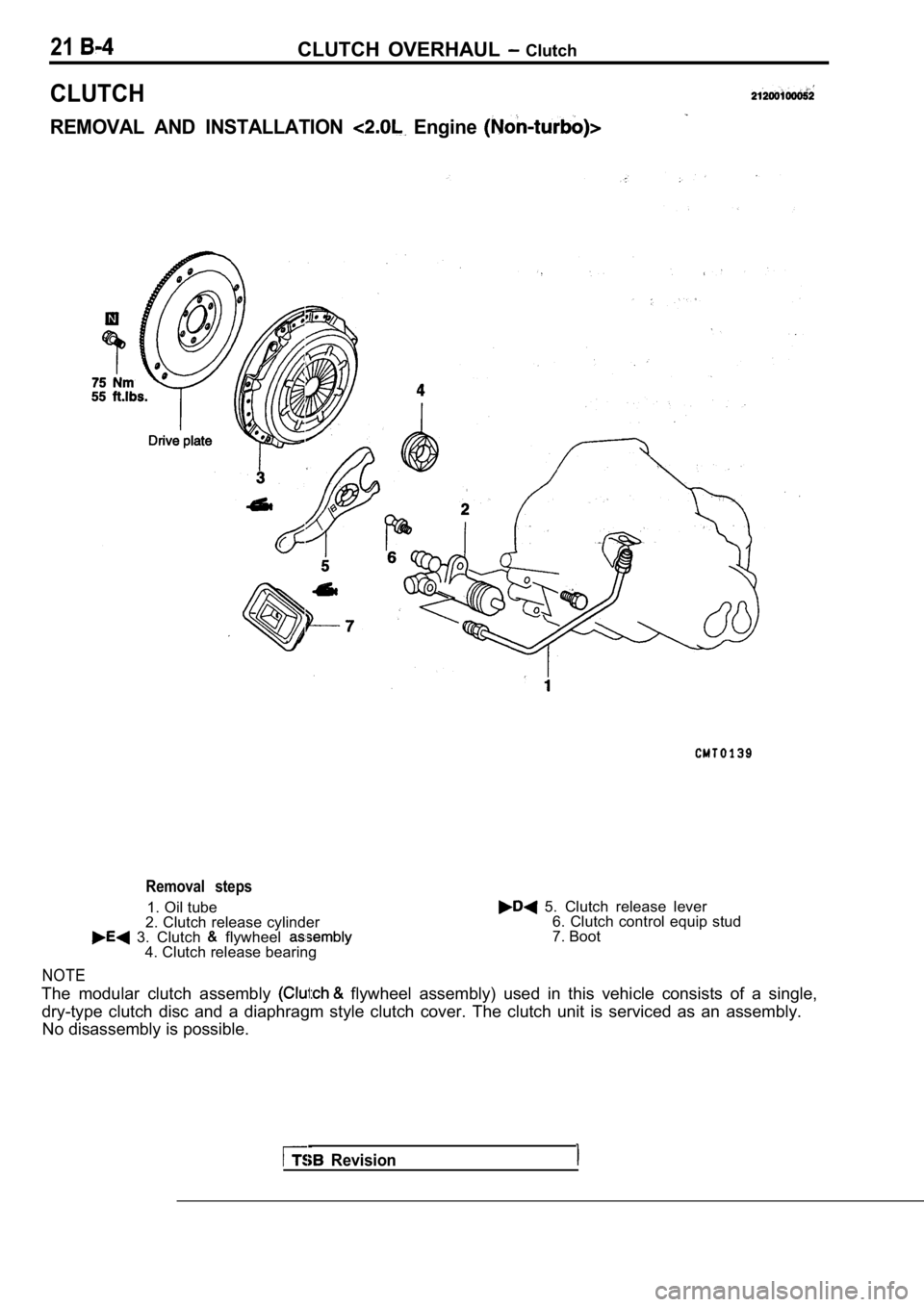

21CLUTCH OVERHAUL Clutch

CLUTCH

REMOVAL AND INSTALLATION Engine

Removal steps

1. Oil tube

2. Clutch release cylinder 5. Clutch release lever

3. Clutch flywheel

6. Clutch control equip stud

7. Boot

4. Clutch release bearing

NOTE

The modular clutch assembly flywheel assembly) used in this vehicle consists o f a single,

dry-type clutch disc and a diaphragm style clutch c over. The clutch unit is serviced as an assembly.

No disassembly is possible.

Revision

Page 854 of 2103

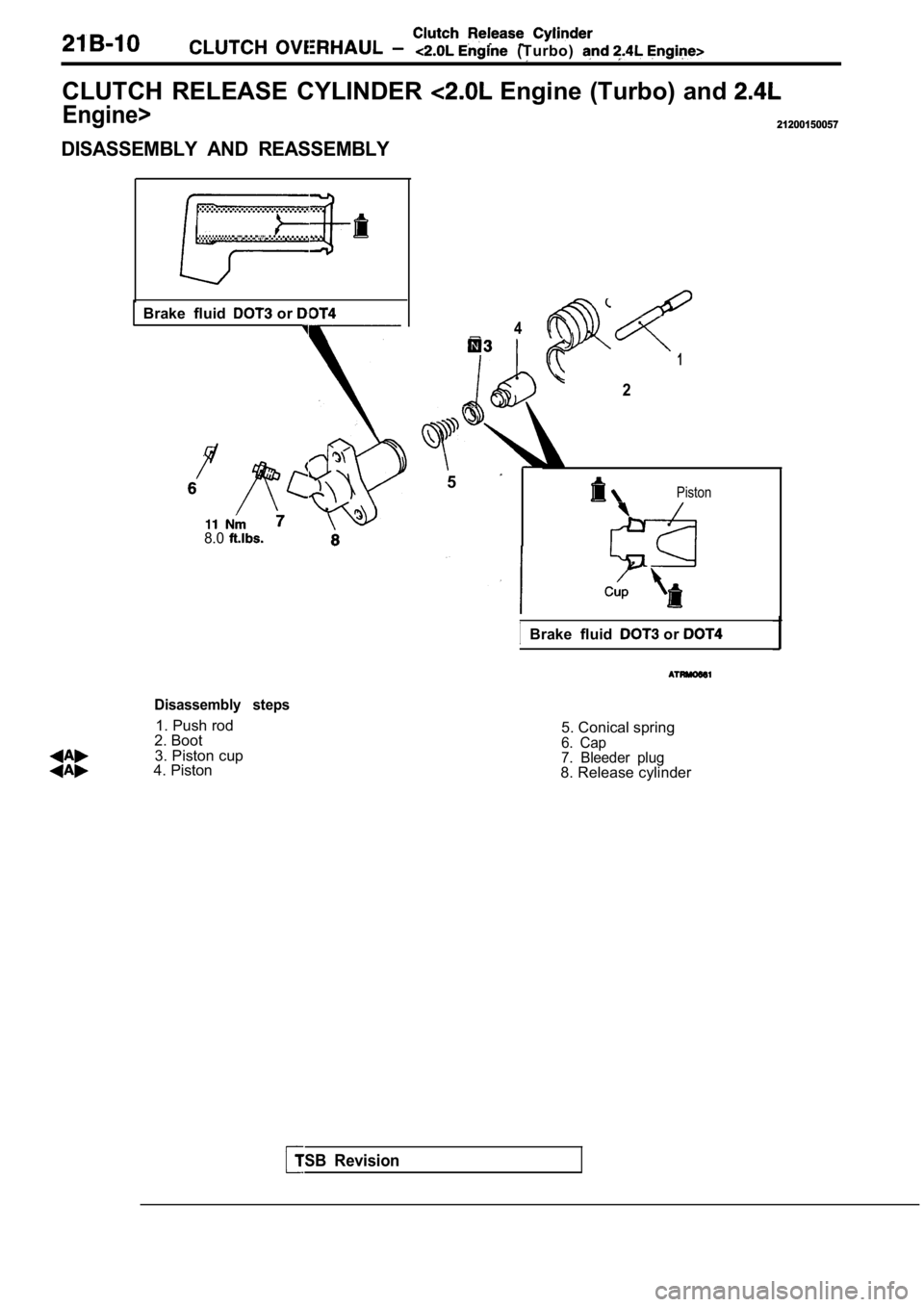

(Turbo)

CLUTCH RELEASE CYLINDER Engine (Turbo) and

Engine>

DISASSEMBLY AND REASSEMBLY

21200150057

Brake fluid or

8.0

TSB Revision

Disassembly steps

1. Push rod

2. Boot

3. Piston cup

4. Piston

4

q31

2

5Piston

IBrake fluid or

5. Conical spring6. Cap

7. Bleeder plug

8. Release cylinder

Page 955 of 2103

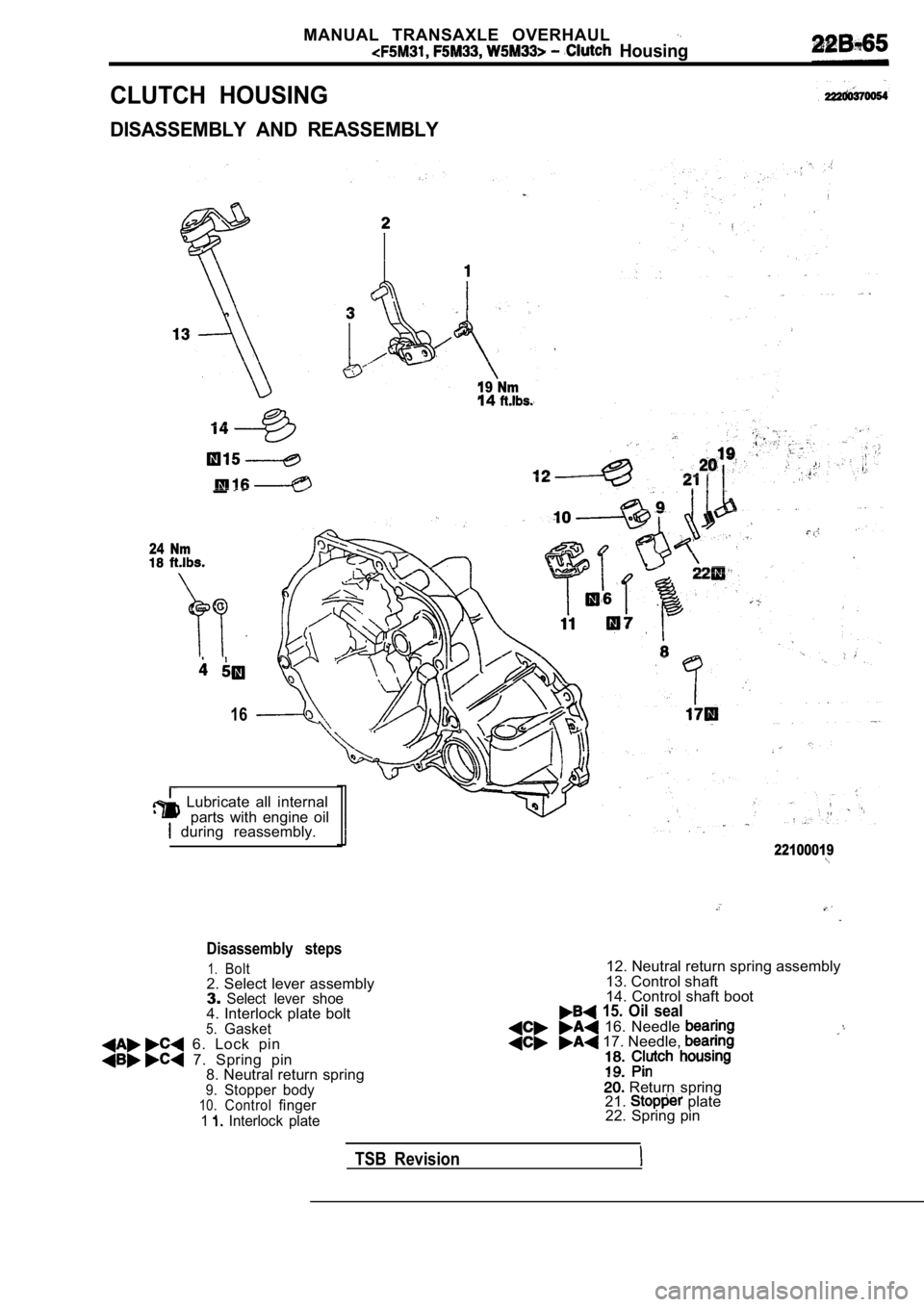

MANUAL TRANSAXLE OVERHAUL

Housing

CLUTCH HOUSING

DISASSEMBLY AND REASSEMBLY

19 Nm14

24 Nm

16

Lubricate all internalparts with engine oil

during reassembly.

22100019

Disassembly steps

1.Bolt2. Select lever assembly3.Select lever shoe4. Interlock plate bolt5.Gasket 6. Lock pin

7. Spring pin 8. Neutral return spring

9.Stopper body10.Controlfinger

1

Interlock plate

12. Neutral return spring assembly

13. Control shaft

14. Control shaft boot

15. Oil seal 16. Needle 17. Needle,

Return spring

21. plate

22. Spring pin

TSB Revision

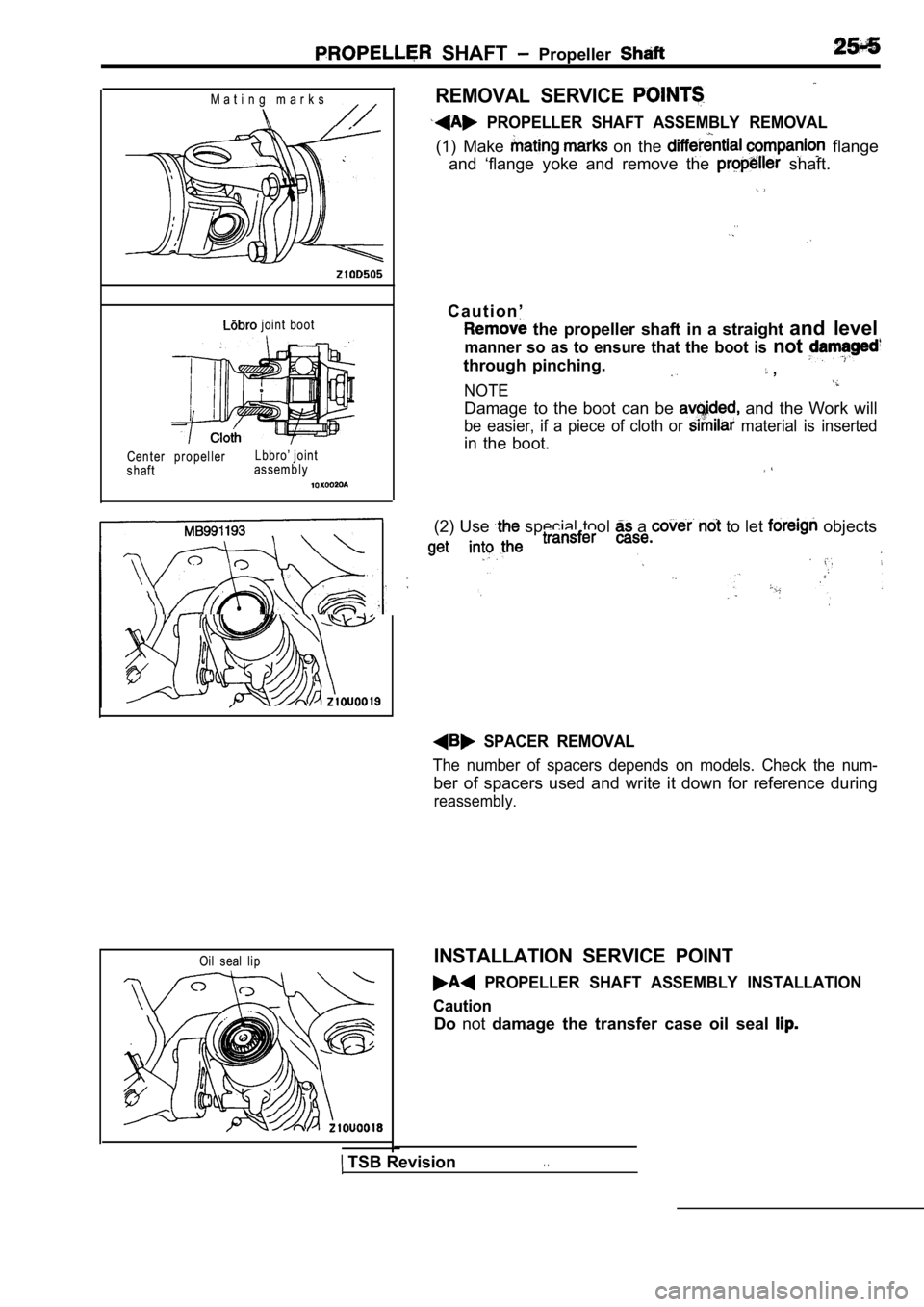

Page 1495 of 2103

SHAFT Propeller

M a t i n g m a r k s

joint boot

Center propeller

shaft Lbbro’ joint

assembly

REMOVAL SERVICE

PROPELLER SHAFT ASSEMBLY REMOVAL

(1) Make on the flange

and ‘flange yoke and remove the

shaft.

. .

C a u t i o n ’

the propeller shaft in a straight and level

manner so as to ensure that the boot is not

through pinching. ,

NOTE

Damage to the boot can be and the Work will

be easier, if a piece of cloth or material is inserted

in the boot.

(2) Use special tool a to let objects

SPACER REMOVAL

The number of spacers depends on models. Check the num-

ber of spacers used and write it down for reference during

reassembly.

Oil seal lipINSTALLATION SERVICE POINT

PROPELLER SHAFT ASSEMBLY INSTALLATION

Caution

Do not damage the transfer case oil seal

TSB Revision. .

Page 1497 of 2103

PROPELLER SHAFT Propeller Shaft

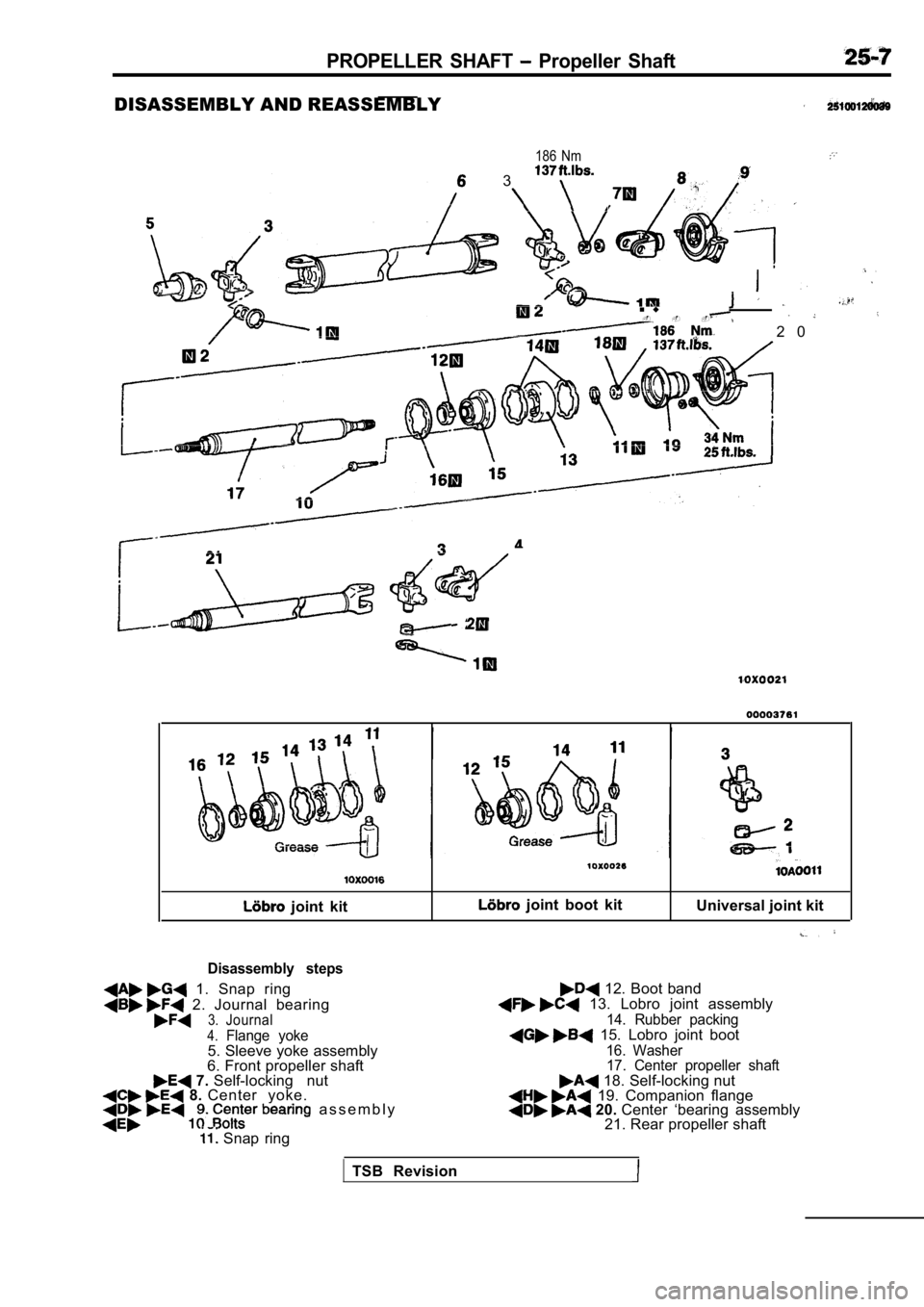

DISASSEMBLY AND REASSEMBLY

186 Nm

3

n u- - -

2 0

21

joint kit joint boot kitUniversal joint kit

Disassembly steps

1. Snap ring

2. Journal bearing3.Journal

4.Flange yoke5. Sleeve yoke assembly

6. Front propeller shaft

7. Self-locking nut 8. Center yoke. a s s e m b l y

Snap ring

12. Boot band 13. Lobro joint assembly

14. Rubber packing 15. Lobro joint boot

16. Washer

17. Center propeller shaft

18. Self-locking nut 19. Companion flange 20. Center ‘bearing assembly

21. Rear propeller shaft

TSB Revision

Page 1500 of 2103

PROPELLER SHAFT Shaft

Mat i n g m ar k s

Inner race

Cag e

Cag e

Lbbro ioint

Plastic

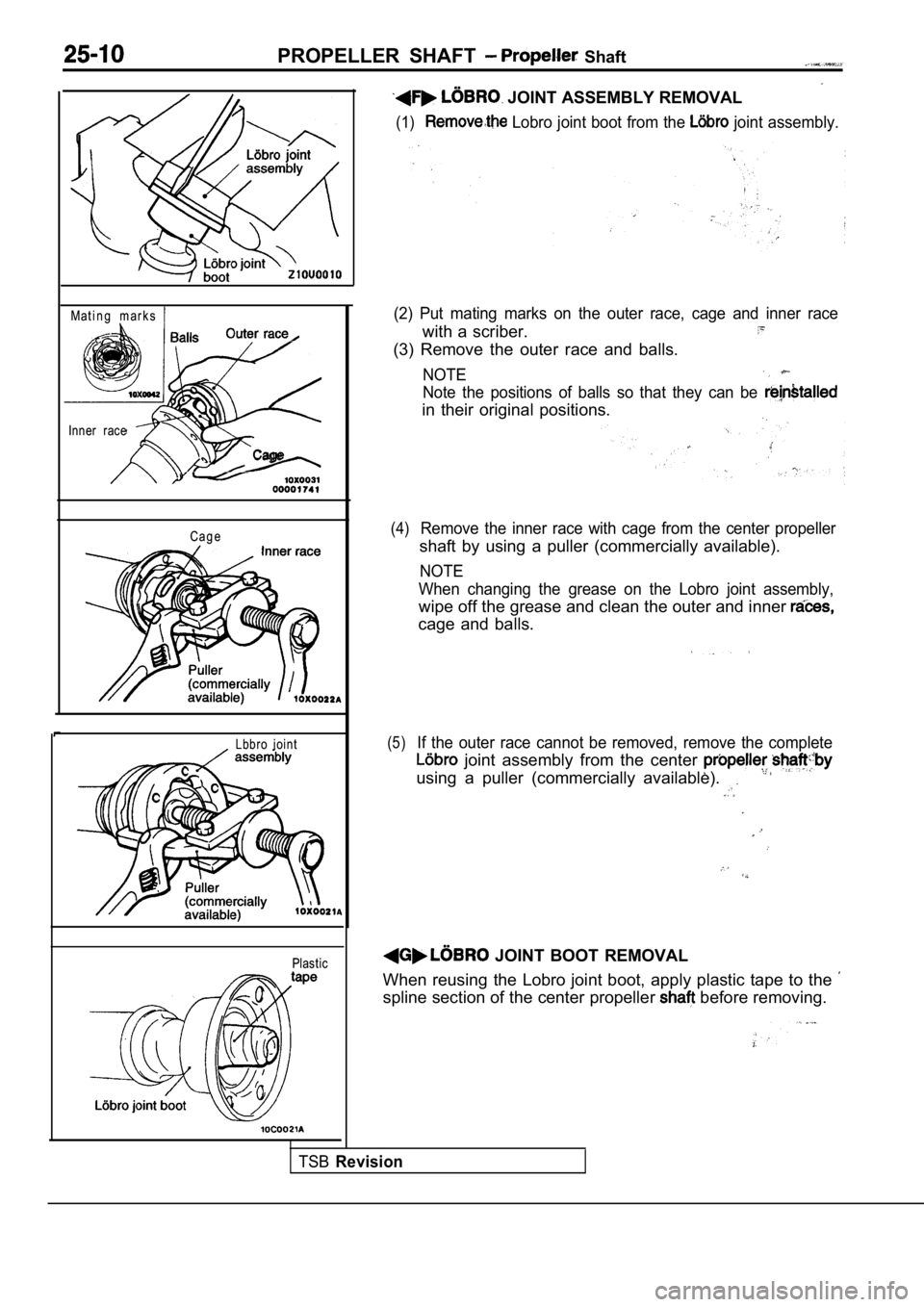

JOINT ASSEMBLY REMOVAL

(1) Lobro joint boot from the joint assembly.

(2) Put mating marks on the outer race, cage and in ner race

with a scriber.

(3) Remove the outer race and balls.

NOTE

Note the positions of balls so that they can be

in their original positions.

(4)Remove the inner race with cage from the center propeller

shaft by using a puller (commercially available).

NOTE

When changing the grease on the Lobro joint assembl y,

wipe off the grease and clean the outer and inner

cage and balls.

(5)If the outer race cannot be removed, remove the complete

joint assembly from the center

using a puller (commercially available).

JOINT BOOT REMOVAL

When reusing the Lobro joint boot, apply plastic ta pe to the

spline section of the center propeller before removing.

TSBRevision