coolant level MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 38 of 2103

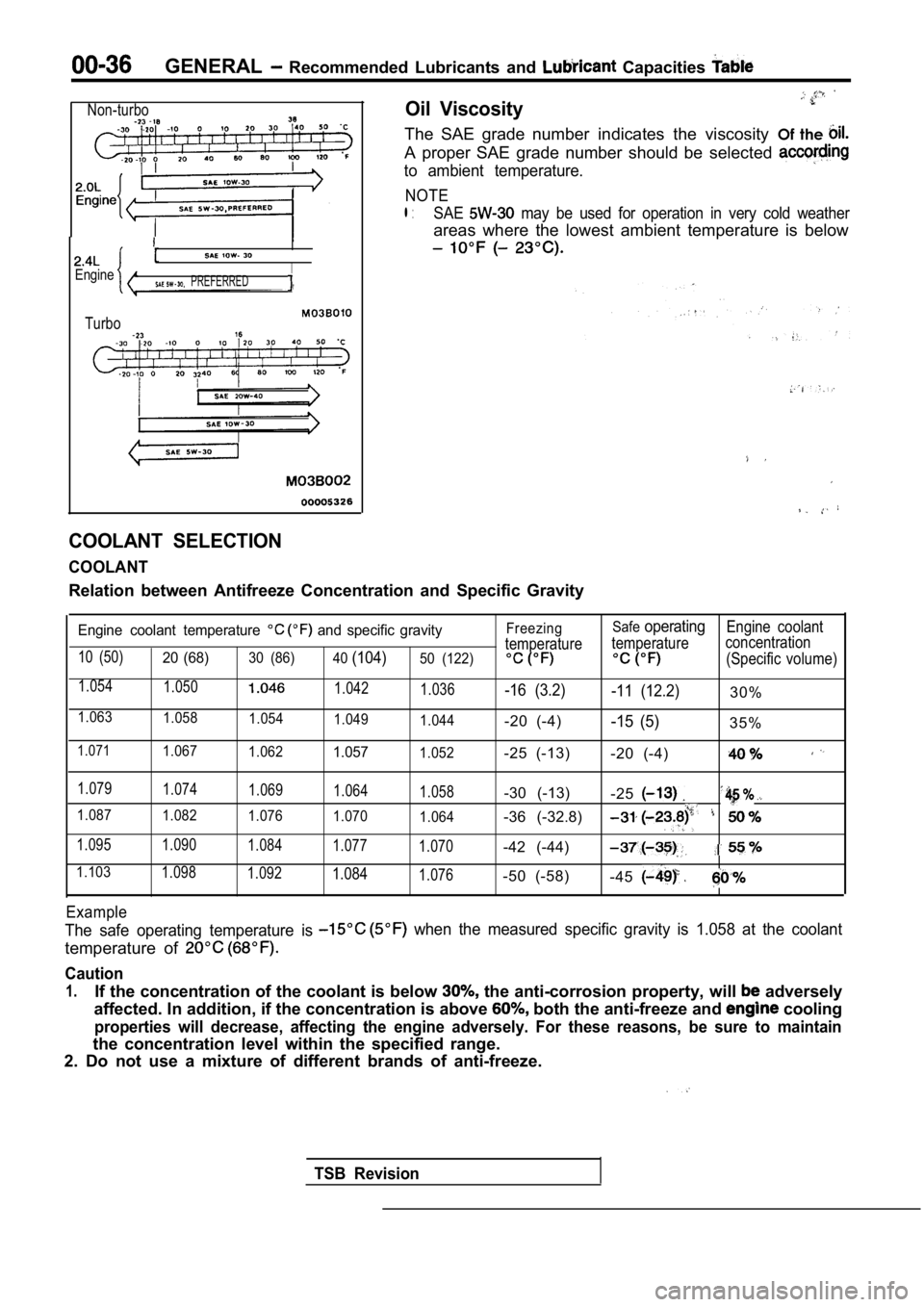

GENERAL Recommended Lubricants and Capacities

Non-turbo

I

EngineI PREFERRED

Turbo

Oil Viscosity

The SAE grade number indicates the viscosity Of the

A proper SAE grade number should be selected

to ambient temperature.

NOTE

l :SAE may be used for operation in very cold weather

areas where the lowest ambient temperature is below

COOLANT SELECTION

COOLANT

Relation between Antifreeze Concentration and Speci fic Gravity

Engine coolant temperature and specific gravity

10 (50)20 (68)30 (86)

40(104)50 (122)

1.054

1.0501.042

1.036

1.0631.058 1.0541.049

1.044

1.0711.0671.0621.0571.052 Freezing

Safe

operatingEngine coolant

temperature temperature concentration

(Specific volume)

-16 (3.2)

-11 (12.2)30%

-20 (-4)

-15 (5)35%

-25 (-13) -20 (-4)

1.079

1.074 1.0691.064

1.058-30 (-13)-25

1.0871.082 1.0761.070

1.064-36 (-32.8)

1.095 1.090 1.0841.077

1.070-42 (-44)

1.1031.0981.0921.0841.076-50 (-58)-45

Example

The safe operating temperature is when the measured specific gravity is 1.058 at the coolant

temperature of

Caution

1.If the concentration of the coolant is below the anti-corrosion property, will adversely

affected. In addition, if the concentration is abov e

both the anti-freeze and cooling

properties will decrease, affecting the engine adve rsely. For these reasons, be sure to maintain

the concentration level within the specified range.

2. Do not use a mixture of different brands of anti -freeze.

TSB Revision

Page 50 of 2103

GENERAL Maintenance Service

,

Revision

Drain Plug

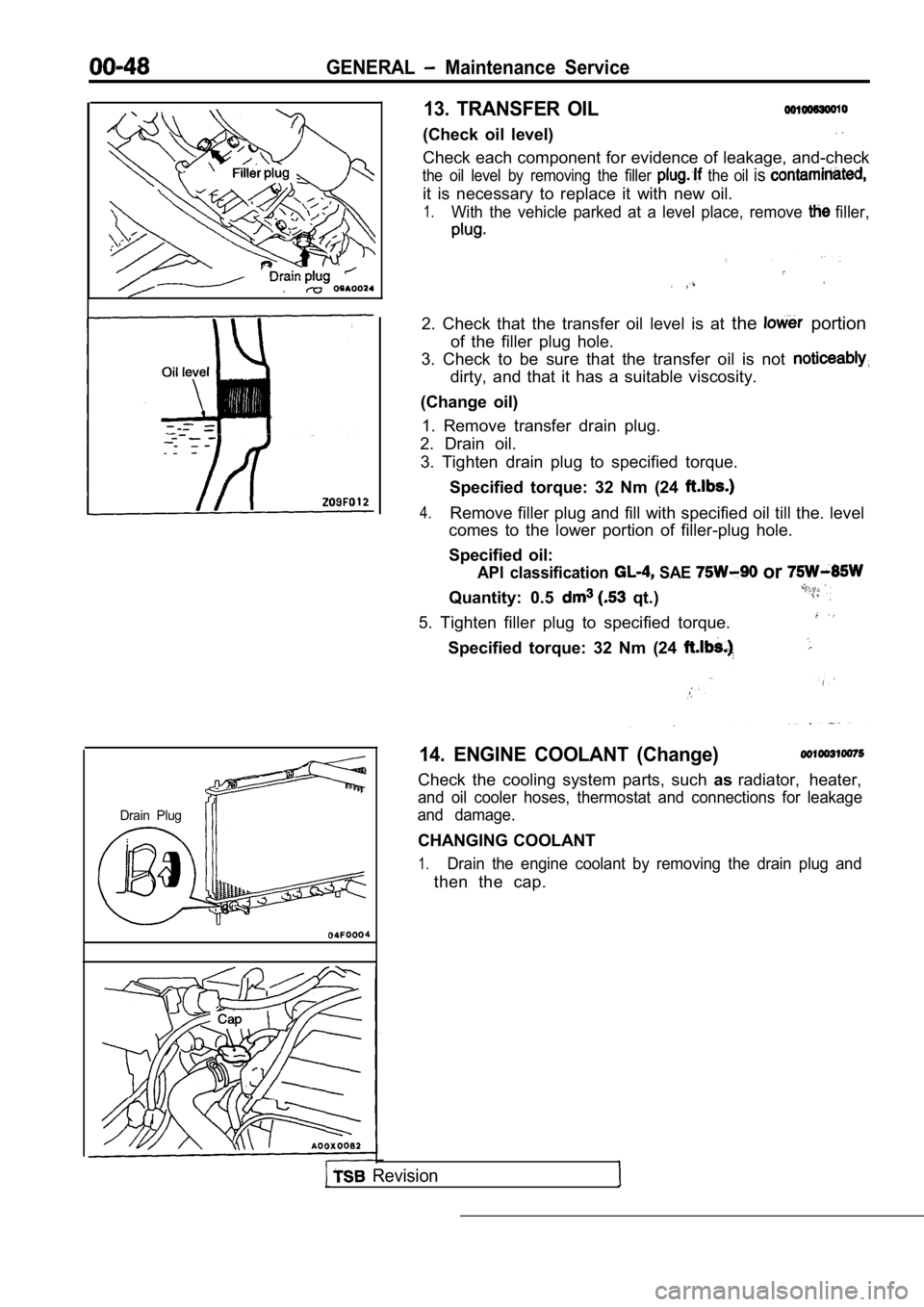

13. TRANSFER OIL

(Check oil level)

Check each component for evidence of leakage, and-check

the oil level by removing the filler the oil is

it is necessary to replace it with new oil.

1.With the vehicle parked at a level place, remove filler,

2. Check that the transfer oil level is at the portion

of the filler plug hole.

3. Check to be sure that the transfer oil is not

dirty, and that it has a suitable viscosity.

(Change oil) 1. Remove transfer drain plug.

2. Drain oil.

3. Tighten drain plug to specified torque.

Specified torque: 32 Nm (24

4.Remove filler plug and fill with specified oil till the. level

comes to the lower portion of filler-plug hole.

Specified oil:

API classification SAE or

Quantity: 0.5 qt.)

5. Tighten filler plug to specified torque.

Specified torque: 32 Nm (24

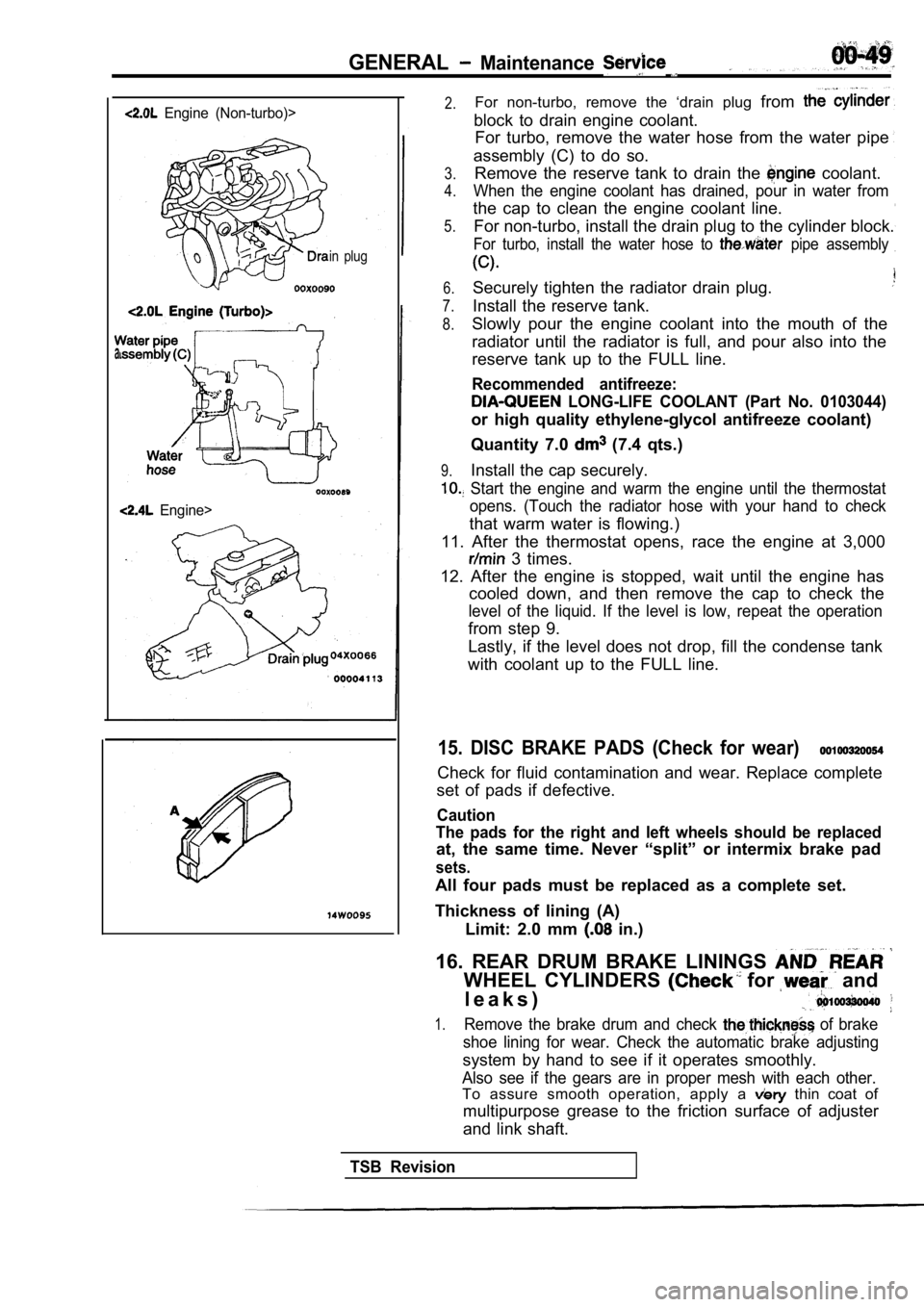

14. ENGINE COOLANT (Change)

Check the cooling system parts, such asradiator, heater,

and oil cooler hoses, thermostat and connections fo r leakage

and damage.

CHANGING COOLANT

1.Drain the engine coolant by removing the drain plug and

then the cap.

Page 51 of 2103

GENERAL Maintenance

a

Engine (Non-turbo)>

in plug

Engine>

2.For non-turbo, remove the ‘drain plug from

block to drain engine coolant.

For turbo, remove the water hose from the water pip e

assembly (C) to do so.

3.

4.

5.Remove the reserve tank to drain the coolant.

When the engine coolant has drained, pour in water from

the cap to clean the engine coolant line.

For non-turbo, install the drain plug to the cylind er block.

For turbo, install the water hose to pipe assembly

6.

7.

8.

Securely tighten the radiator drain plug.

Install the reserve tank.

9.

Slowly pour the engine coolant into the mouth of th e

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended antifreeze:

LONG-LIFE COOLANT (Part No. 0103044)

or high quality ethylene-glycol antifreeze coolant)

Quantity 7.0

(7.4 qts.)

Install the cap securely.

Start the engine and warm the engine until the the rmostat

opens. (Touch the radiator hose with your hand to c heck

that warm water is flowing.)

11. After the thermostat opens, race the engine at 3,000

3 times.

12. After the engine is stopped, wait until the eng ine has

cooled down, and then remove the cap to check the

level of the liquid. If the level is low, repeat th e operation

from step 9.

Lastly, if the level does not drop, fill the conden se tank

with coolant up to the FULL line.

15. DISC BRAKE PADS (Check for wear)

Check for fluid contamination and wear. Replace com plete

set of pads if defective.

Caution

The pads for the right and left wheels should be re placed

at, the same time. Never “split” or intermix brake pad

sets.

All four pads must be replaced as a complete set.

Thickness of lining (A) Limit: 2.0 mm

in.)

16. REAR DRUM BRAKE LININGS

WHEEL CYLINDERS for and

l e a k s )

1.Remove the brake drum and check of brake

shoe lining for wear. Check the automatic brake adj usting

system by hand to see if it operates smoothly.

Also see if the gears are in proper mesh with each other.

To assure smooth operation, apply a thin coat of

multipurpose grease to the friction surface of adju ster

and link shaft.

TSB Revision

Page 183 of 2103

ENGINE On-vehicle.’

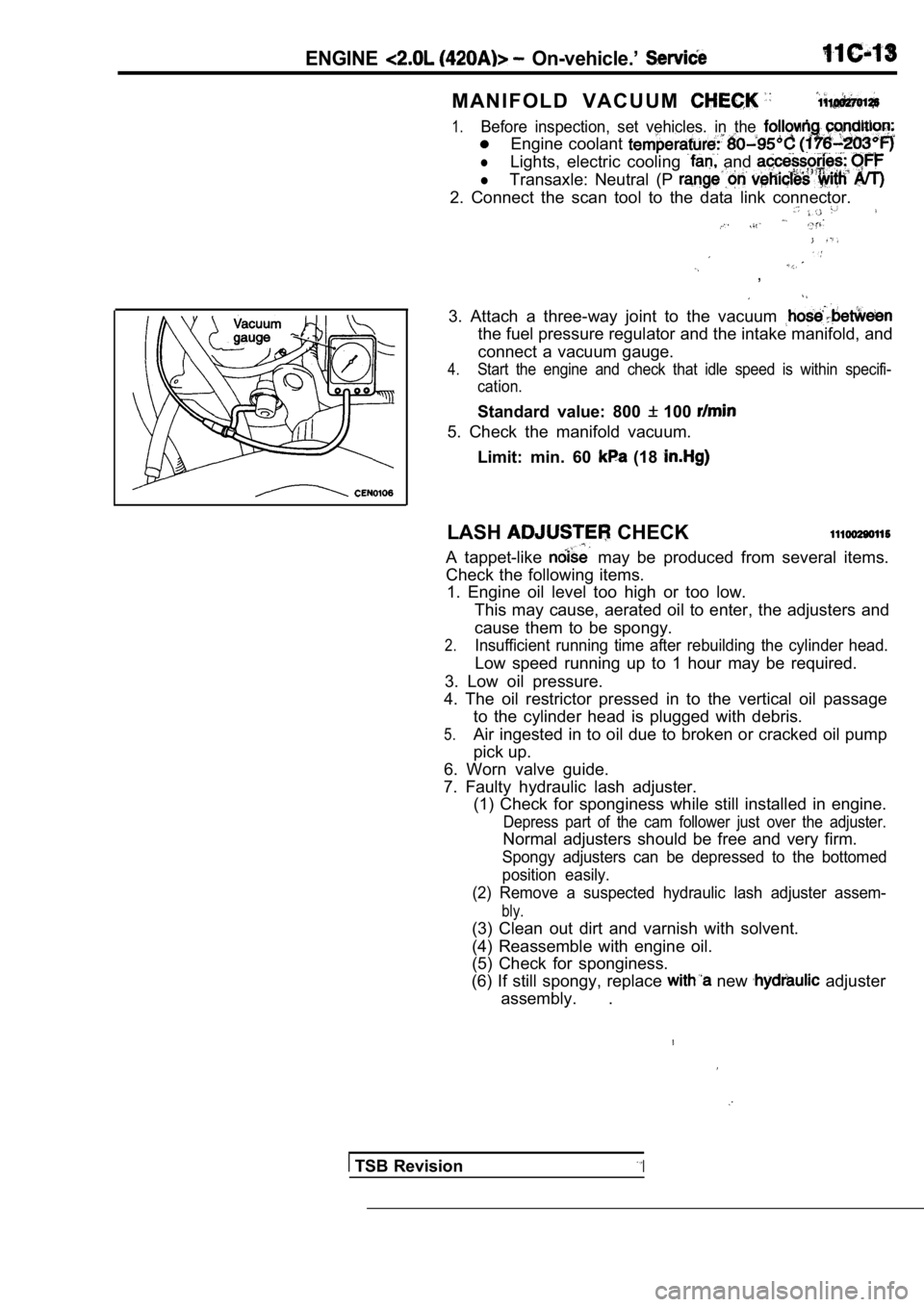

M A N I F O L D V A C U U M

1.Before inspection, set vehicles. in the condition:

Engine coolant

lLights, electric cooling and

lTransaxle: Neutral (P

2. Connect the scan tool to the data link connector.

,

3. Attach a three-way joint to the vacuum

the fuel pressure regulator and the intake manifold, and

connect a vacuum gauge.

4.Start the engine and check that idle speed is withi n specifi-

cation.

Standard value: 800 100

5. Check the manifold vacuum.

Limit: min. 60

(18

LASH CHECK

A tappet-like may be produced from several items.

Check the following items. 1. Engine oil level too high or too low.

This may cause, aerated oil to enter, the adjusters and

cause them to be spongy.

2.Insufficient running time after rebuilding the cyli nder head.

Low speed running up to 1 hour may be required.

3. Low oil pressure.

4. The oil restrictor pressed in to the vertical oi l passage

to the cylinder head is plugged with debris.

5.Air ingested in to oil due to broken or cracked oil pump

pick up.

6. Worn valve guide.

7. Faulty hydraulic lash adjuster. (1) Check for sponginess while still installed in e ngine.

Depress part of the cam follower just over the adju ster.

Normal adjusters should be free and very firm.

Spongy adjusters can be depressed to the bottomed

position easily.

(2) Remove a suspected hydraulic lash adjuster asse m-

bly.

(3) Clean out dirt and varnish with solvent.

(4) Reassemble with engine oil.

(5) Check for sponginess.

(6) If still spongy, replace

new adjuster

assembly. .

TSB RevisionI

Page 227 of 2103

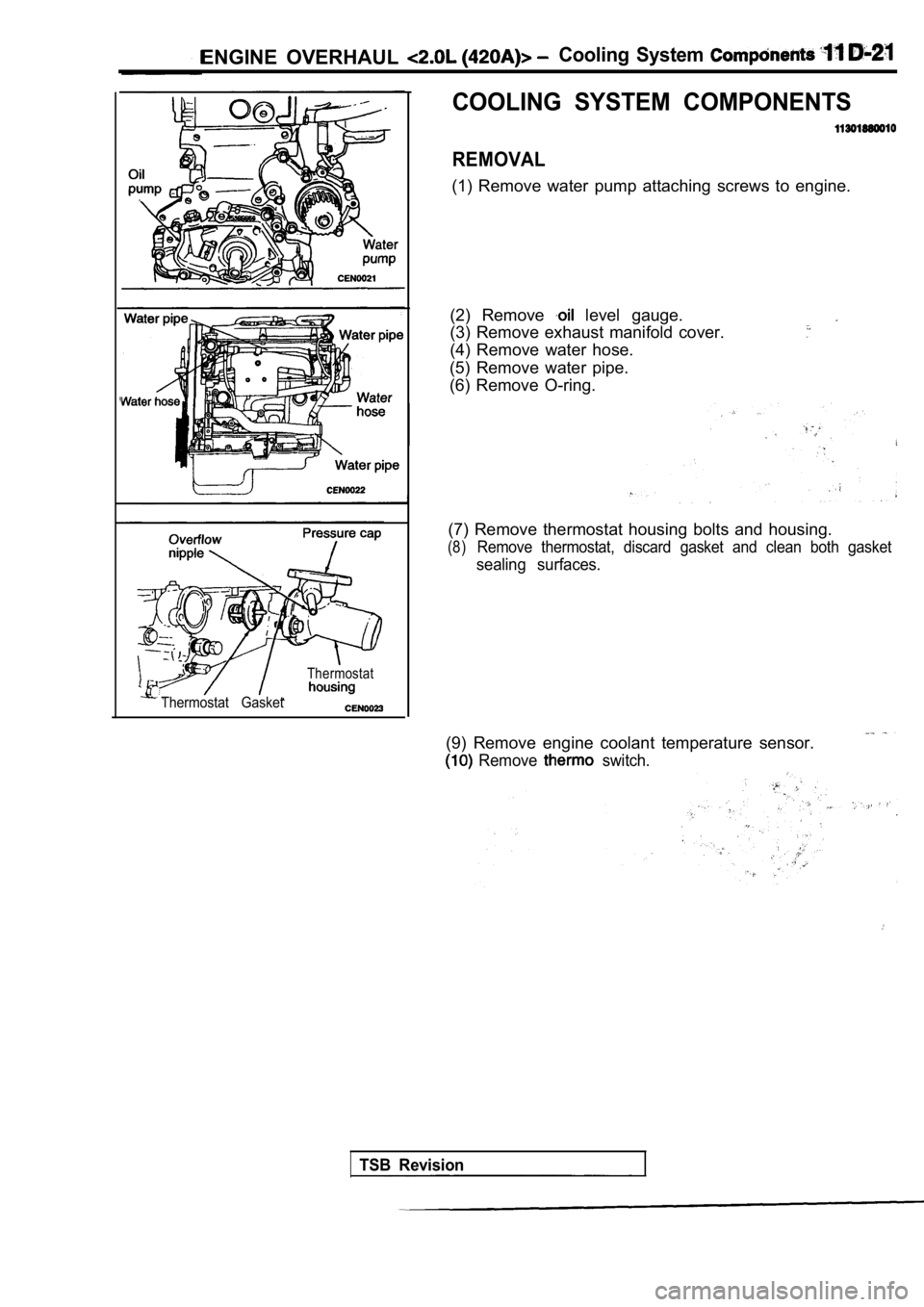

ENGINE OVERHAUL Cooling System

COOLING SYSTEM COMPONENTS

REMOVAL

(1) Remove water pump attaching screws to engine.

Thermostat

Thermostat Gasket

(2) Remove level gauge.

(3) Remove exhaust manifold cover.

(4) Remove water hose.

(5) Remove water pipe.

(6) Remove O-ring.

(7) Remove thermostat housing bolts and housing.

(8)Remove thermostat, discard gasket and clean both ga sket

sealing surfaces.

(9) Remove engine coolant temperature sensor.

Remove switch.

TSB Revision

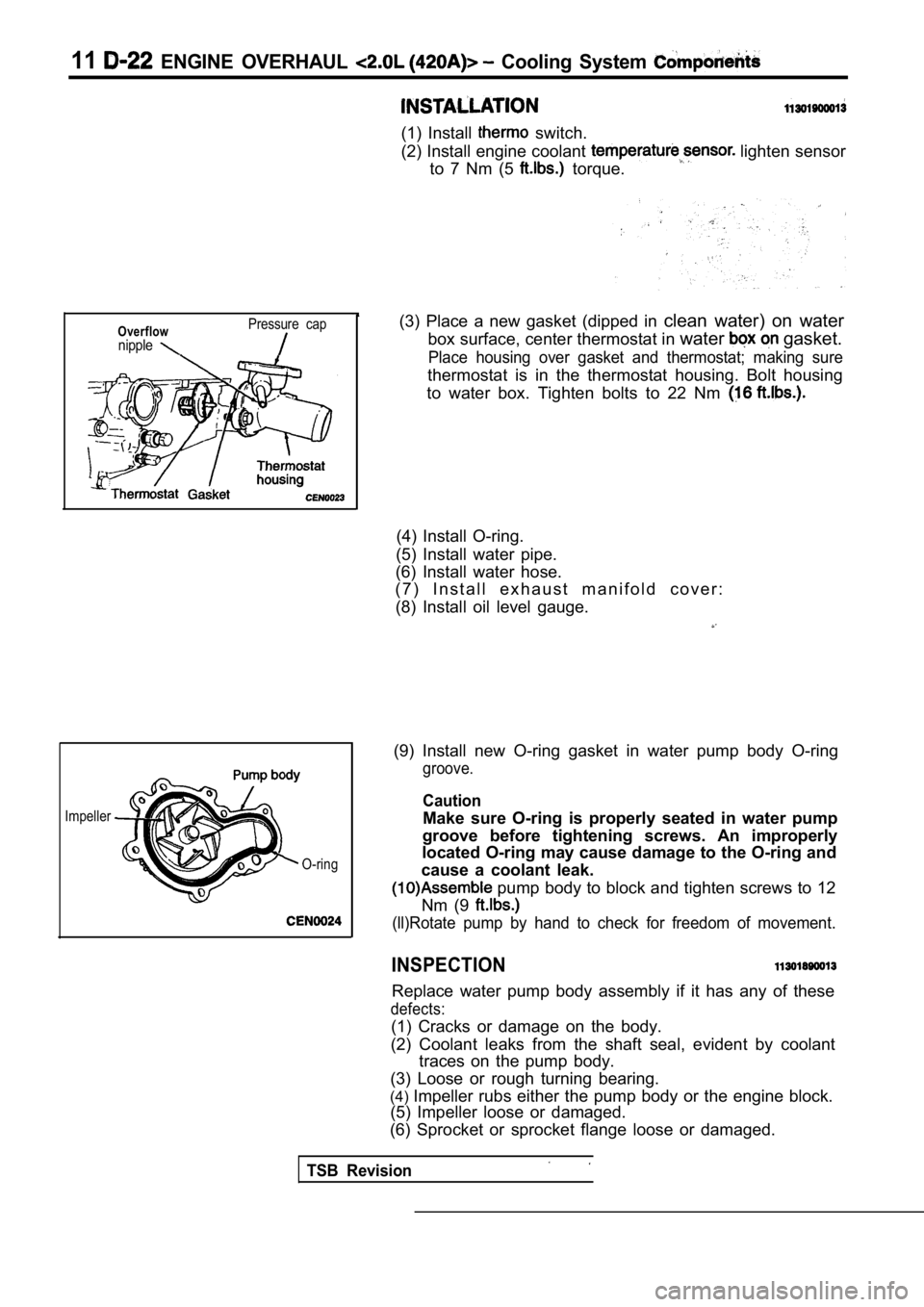

Page 228 of 2103

11 ENGINE OVERHAUL Cooling System

(1) Install switch.

(2) Install engine coolant

lighten sensor

to 7 Nm (5

torque.

Overflownipple

Pressure cap

Impeller

TSB Revision

O-ring

(3) Place a new gasket (dipped in clean water) on water

box surface, center thermostat in water

gasket.

Place housing over gasket and thermostat; making su re

thermostat is in the thermostat housing. Bolt housing

to water box. Tighten bolts to 22 Nm

(4) Install O-ring.

(5) Install water pipe.

(6) Install water hose.

( 7 ) I n s t a l l e x h a u s t m a n i f o l d c o v e r :

(8) Install oil level gauge.

(9) Install new O-ring gasket in water pump body O- ring

groove.

Caution

Make sure O-ring is properly seated in water pump

groove before tightening screws. An improperly

located O-ring may cause damage to the O-ring and

cause a coolant leak.

pump body to block and tighten screws to 12

Nm (9

(ll)Rotate pump by hand to check for freedom of mov ement.

INSPECTION

Replace water pump body assembly if it has any of these

defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by c oolant

traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the engine bl ock.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

Page 459 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen MITSUBISHI SPYDER 1990 Service Repair Manual ,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen](/img/19/57345/w960_57345-458.png)

,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen the heated oxygen sensor temperature is low, t he sensor has the same electrical

l PCM failed characteristics as an insulator.lThe heated oxygen sensor output signal line is That is is approx. when the heated oxygen sensor temperature is low.If the heated oxygen sensor output signal line is g rounded, will become lRange of checkl Engine coolant temperature when the engine starts: or lessl Within three seconds after the engine starts

Set Conditions

The heated oxygen sensor output signal line is

or less.

NGCheck the harness I .oxygen sensor connector.. , ,

OK

Replace the PCM.

11

[Comment]Background , connectedlAfter the engine has been started, the PCM maintain s an expected camshaft port l position

Scan tool 157,General scan toolIntermittent Loss of CMP CKP Probable cause

value. connectedlAt every crankshaft leading edge, this value is updated to reflect the expected

.Camshaft position sensor change in the cam level.

l lAt every crankshaft trailing edge, this value is compared to the true port level. sensor improperly lIf there is a disagreement between two values, then the diagnostic code isset.l sensor

Range of Check

l Engine: running

Set Condition

l Cam and crank signals have been out of sync, than times.

N GCheck the following connectors:. A-l 06

OK

__Check no cam sync. signal at PCM. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

CODE.

Check no crank reference signal at PCM. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

TSB Revision

Page 528 of 2103

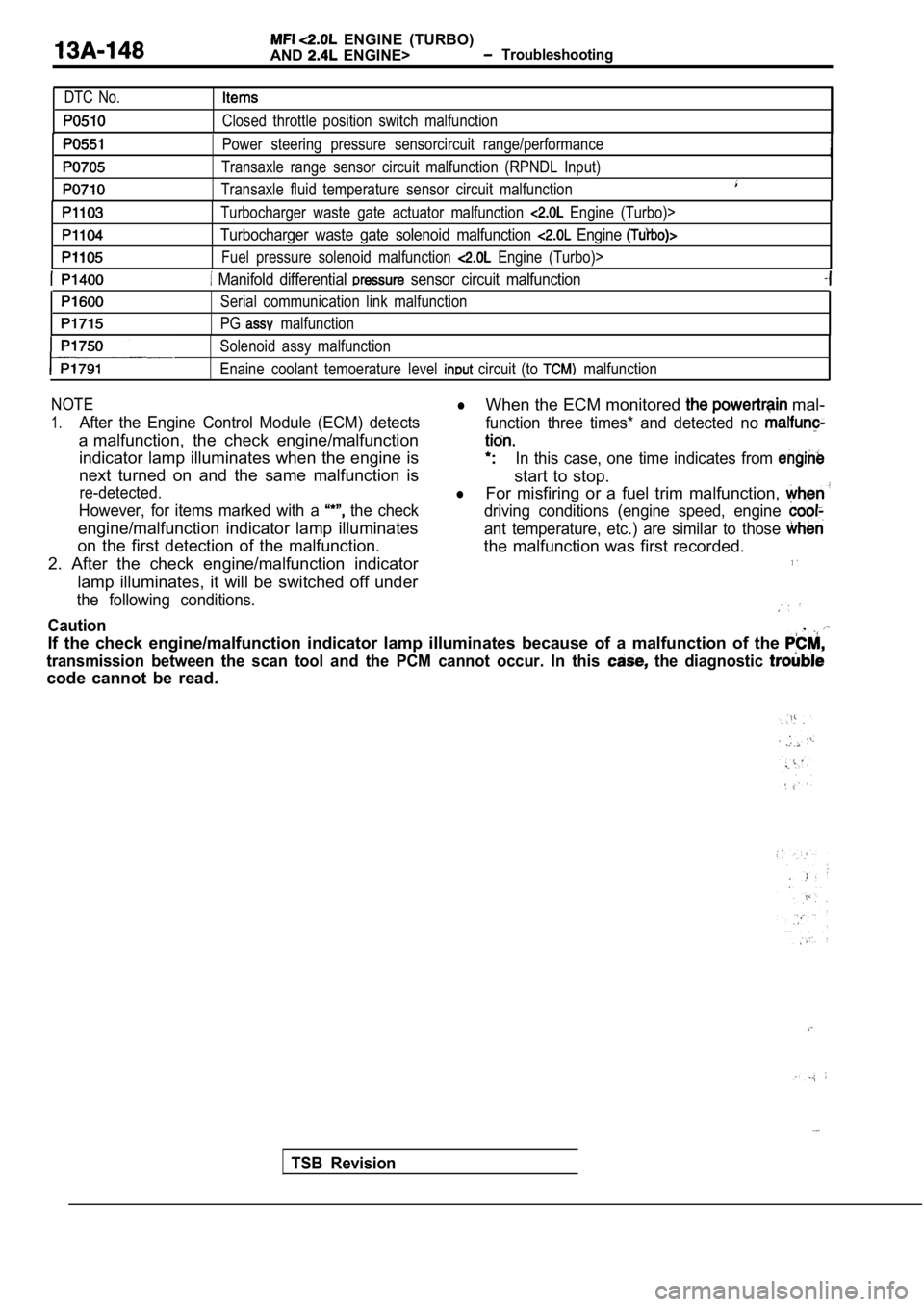

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

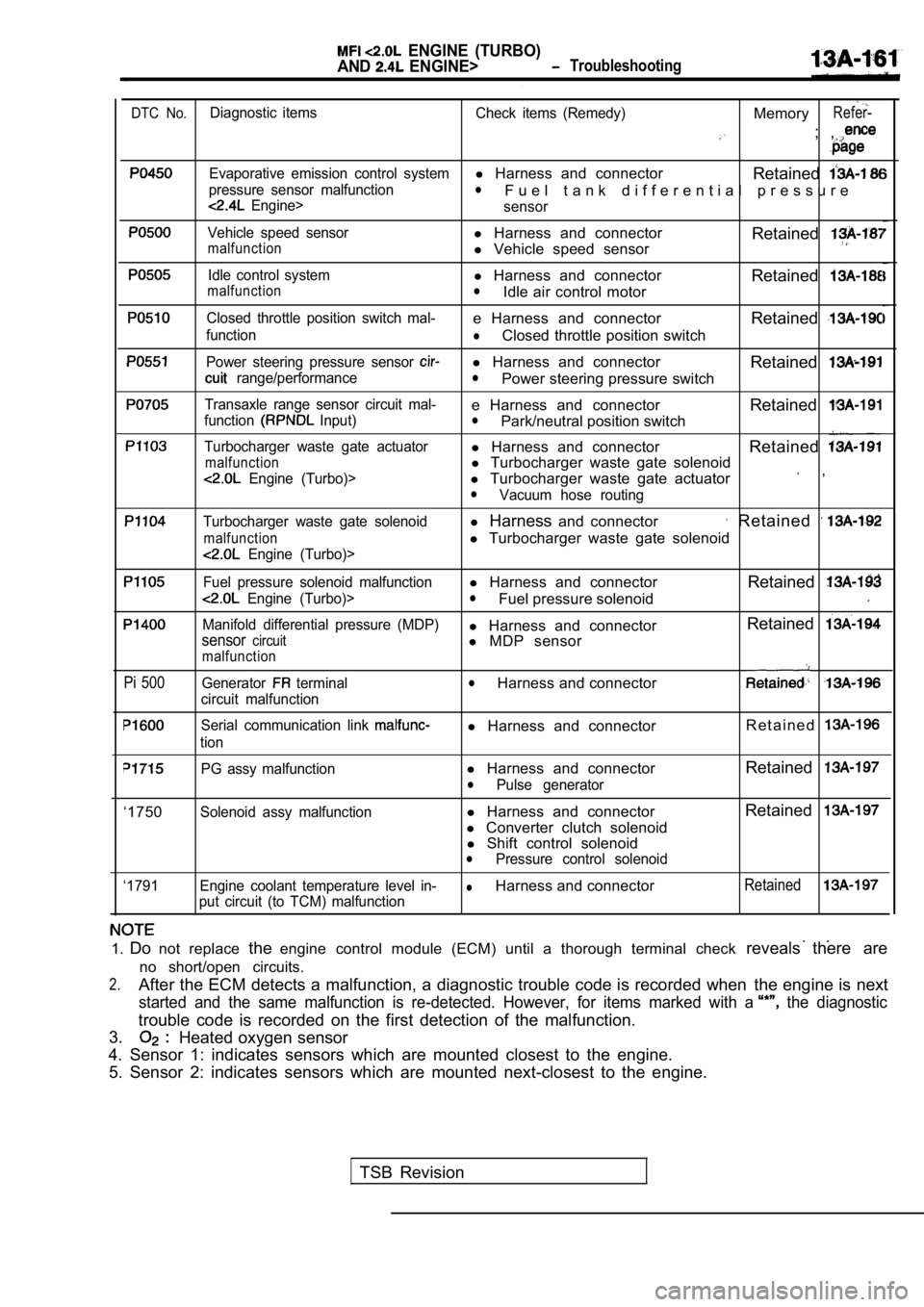

DTC No.

Closed throttle position switch malfunction

Power steering pressure sensorcircuit range/perfor mance

Transaxle range sensor circuit malfunction (RPNDL Input)

Transaxle fluid temperature sensor circuit malfunct ion

Turbocharger waste gate actuator malfunction Engine (Turbo)>

Turbocharger waste gate solenoid malfunction Engine

Fuel pressure solenoid malfunction Engine (Turbo)>

Manifold differential sensor circuit malfunction

Serial communication link malfunction

PG

malfunction

Solenoid assy malfunction

Enaine coolant temoerature level

circuit (to malfunction

NOTElWhen the ECM monitored mal-

1.After the Engine Control Module (ECM) detects function three times* and detected no

a malfunction, the check engine/malfunction

indicator lamp illuminates when the engine isIn this case, one time indicates from

next turned on and the same malfunction is

start to stop.

re-detected.lFor misfiring or a fuel trim malfunction,

However, for items marked with a the checkdriving conditions (engine speed, engine

engine/malfunction indicator lamp illuminatesant temperature, etc.) are similar to those

on the first detection of the malfunction. the malfunction was first recorded.

2. After the check engine/malfunction indicator

lamp illuminates, it will be switched off under

the following conditions.

Caution,

If the check engine/malfunction indicator lamp illu minates because of a malfunction of the

transmission between the scan tool and the PCM cann ot occur. In this the diagnostic

code cannot be read.

TSB Revision

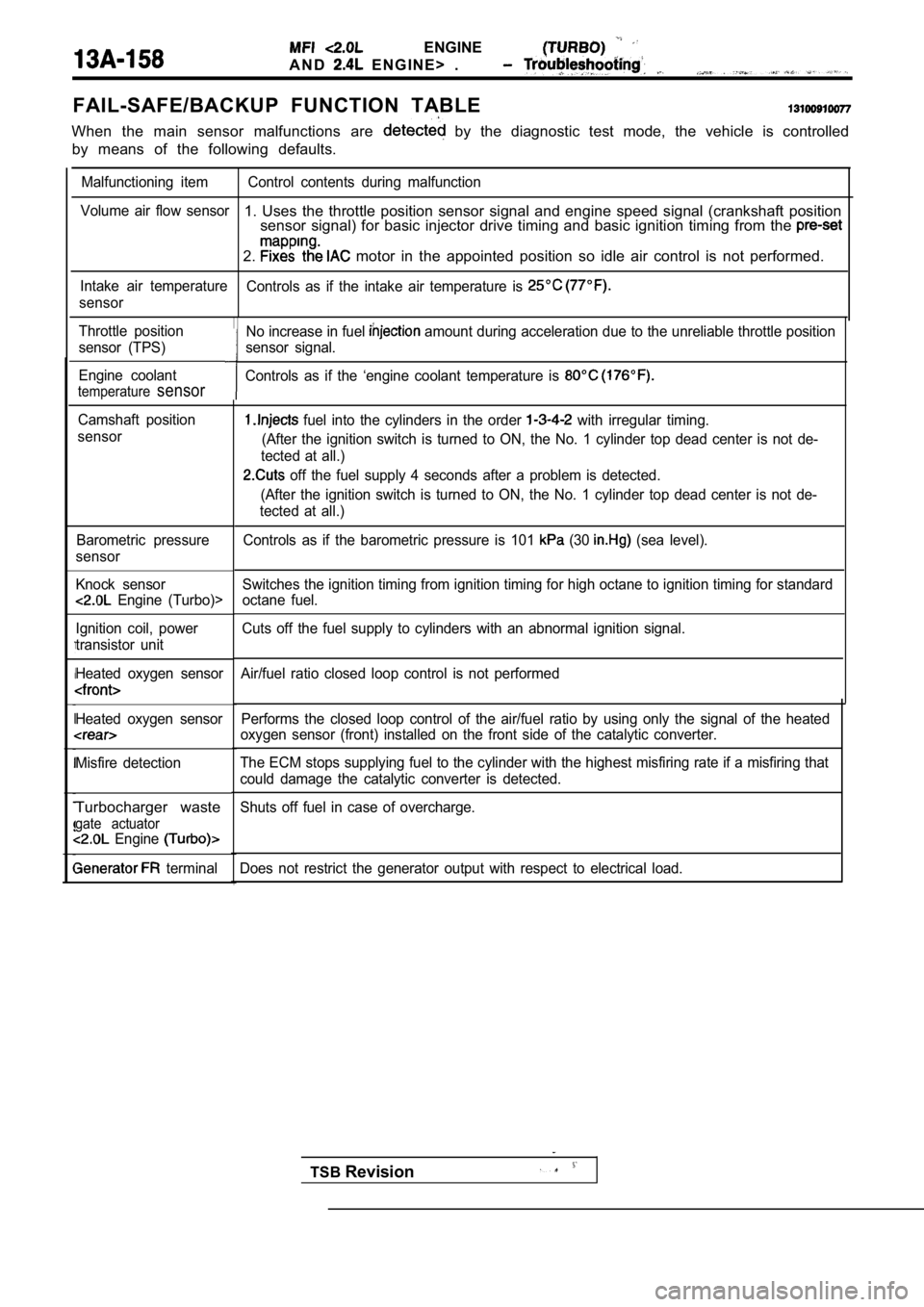

Page 538 of 2103

ENGINE

A N D E N G I N E > .

FAIL-SAFE/BACKUP FUNCTION TABLE

When the main sensor malfunctions are by the diagnostic test mode, the vehicle is controlled

by means of the following defaults.

Malfunctioning item Control contents during malfunct ion

Volume air flow sensor

1. Uses the throttle position sensor signal and eng ine speed signal (crankshaft position

sensor signal) for basic injector drive timing and basic ignition timing from the

2. motor in the appointed position so idle air contro l is not performed.

Intake air temperature

Controls as if the intake air temperature is

sensor

Throttle position

sensor (TPS)

Engine coolant

temperaturesensor

Camshaft position

sensor

Barometric pressure

sensor

Knock sensor

Engine (Turbo)>

Ignition coil, power

transistor unit

Heated oxygen sensor

Heated oxygen sensor

Misfire detection

Turbocharger waste

gate actuator Engine

terminal Performs the closed loop control of the air/fuel ra

tio by using only the signal of the heated

oxygen sensor (front) installed on the front side o f the catalytic converter.

The ECM stops supplying fuel to the cylinder with t he highest misfiring rate if a misfiring that

could damage the catalytic converter is detected.

Shuts off fuel in case of overcharge.

Does not restrict the generator output with respect to electrical load.

No increase in fuel amount during acceleration due to the unreliable throttle position

sensor signal.

Controls as if the ‘engine coolant temperature is

fuel into the cylinders in the order with irregular timing.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

off the fuel supply 4 seconds after a problem is d etected.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

Controls as if the barometric pressure is 101

(30 (sea level).

Switches the ignition timing from ignition timing f or high octane to ignition timing for standard

octane fuel.

Cuts off the fuel supply to cylinders with an abnor mal ignition signal.

Air/fuel ratio closed loop control is not performed

TSB Revision

Page 541 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

DTC No.Diagnostic items Check items (Remedy)MemoryRefer-

; ,

Evaporative emission control systeml Harness and connector

Retained

pressure sensor malfunctionl

Engine>F u e l t a n k d i f f e r e n t i a l p r e s s u r e

sensor

Vehicle speed sensorl Harness and connectormalfunctionl Vehicle speed sensor Retained

Idle control systeml

Harness and connector

RetainedmalfunctionlIdle air control motor

Closed throttle position switch mal-e Harness and connector Retained

functionlClosed throttle position switch

Power steering pressure sensor l Harness and connector

Retained

range/performancelPower steering pressure switch

Transaxle range sensor circuit mal-e Harness and connector Retainedfunction Input)lPark/neutral position switch

Turbocharger waste gate actuatorl Harness and connector

Retained

malfunctionl Turbocharger waste gate solenoid

Engine (Turbo)>l Turbocharger waste gate actuator ,

lVacuum hose routing

Turbocharger waste gate solenoidl Harness and connector Retained

malfunctionl Turbocharger waste gate solenoid

Engine (Turbo)>

Fuel pressure solenoid malfunctionl Harness and connector

Retained

Engine (Turbo)>lFuel pressure solenoid

Manifold differential pressure (MDP)l Harness and connector Retainedsensorcircuitl

MDP sensormalfunction

Pi 500Generator terminal

circuit malfunctionlHarness and connector

Serial communication link

tion

l Harness and connector R e t a i n e d

‘1750

‘1791PG assy malfunction

l

Harness and connector RetainedlPulse generator

Solenoid assy malfunction

l Harness and connector Retained

l

Converter clutch solenoid

l Shift control solenoid

lPressure control solenoid

Engine coolant temperature level in-

lHarness and connectorRetained

put circuit (to TCM) malfunction

1. Do not replace theengine control module (ECM) until a thorough termin al check reveals there are

no short/open circuits.

2.After the ECM detects a malfunction, a diagnostic t rouble code is recorded when the engine is next

started and the same malfunction is re-detected. Ho wever, for items marked with a the diagnostic

trouble code is recorded on the first detection of the malfunction.

3.

Heated oxygen sensor

4. Sensor 1: indicates sensors which are mounted cl osest to the engine.

5. Sensor 2: indicates sensors which are mounted ne xt-closest to the engine.

TSB Revision