oil reset MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 123 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde](/img/19/57345/w960_57345-122.png)

ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinder block to block the left counterbalance sha ft.

(2)

the oil pump sprocket. .

(3) Apply a proper amount of engine oil-to the bearing

of the nuts.

(4) Tighten the nuts to the specified‘ torque.

AUTO TENSIONER INSTALLATION

(1) If the auto tensioner rod is in its fully exten ded position,

reset it as follows.

(2) Clamp the auto-tensioner in the vise

jaws.

(3) Push in the rod little by little with the vise the

hole A in the rod is aligned with the hole in the

(4) a wire mm in.) diameter] into the

(5) Unclamp the auto tensioner from the vise.

.

,

the auto tensioner to front case and tighten.

the specified torque.

Caution

Leave the wire installed the

,

. .

,

TSB Revision

Page 327 of 2103

ENGINE OVERHAUL Timing Belt

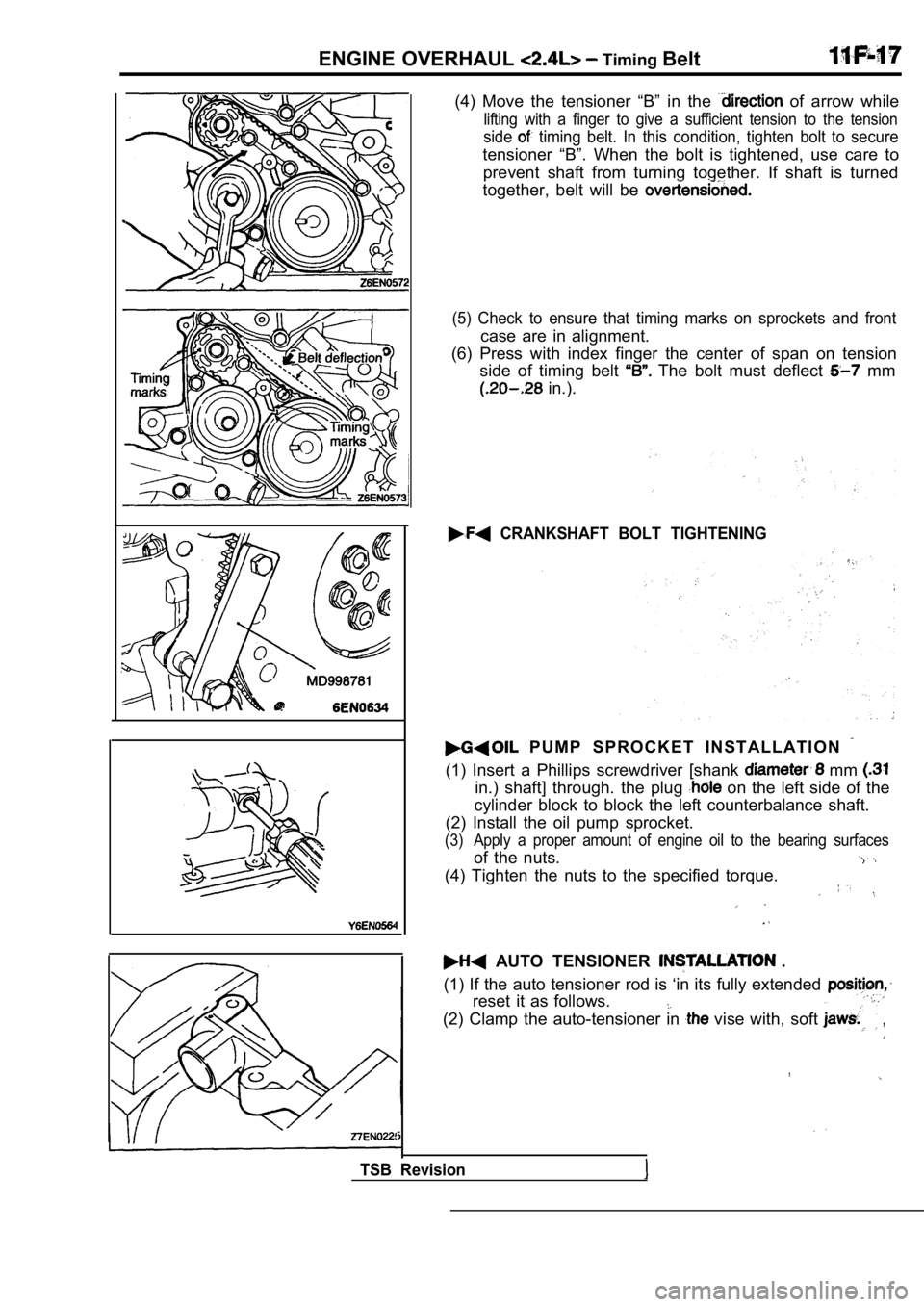

(4) Move the tensioner “B” in the of arrow while

lifting with a finger to give a sufficient tension to the tension

side timing belt. In this condition, tighten bolt to secure

tensioner “B”. When the bolt is tightened, use care to

prevent shaft from turning together. If shaft is tu rned

together, belt will be

(5) Check to ensure that timing marks on sprockets and front

case are in alignment.

(6) Press with index finger the center of span on t ension

side of timing belt

The bolt must deflect mm

in.).

CRANKSHAFT BOLT TIGHTENING

P U M P S P R O C K E T I N S T A L L A T I O N

(1) Insert a Phillips screwdriver [shank mm

in.) shaft] through. the plug on the left side of the

cylinder block to block the left counterbalance sha ft.

(2) Install the oil pump sprocket.

(3) Apply a proper amount of engine oil to the beari ng surfaces

of the nuts.

(4) Tighten the nuts to the specified torque.

AUTO TENSIONER .

(1) If the auto tensioner rod is ‘in its fully exte nded

reset it as follows.

(2) Clamp the auto-tensioner in vise with, soft ,

TSB Revision

Page 469 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)> Troubleshooting

INSPECTION PROCEDURE 8

Unstable idle (Rough idle, hunting)Probable cause

[Comment] Malfunction of the ignition system

In cases such as the abo MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)> Troubleshooting

INSPECTION PROCEDURE 8

Unstable idle (Rough idle, hunting)Probable cause

[Comment] Malfunction of the ignition system

In cases such as the abo](/img/19/57345/w960_57345-468.png)

ENGINE (NON-TURBO)> Troubleshooting

INSPECTION PROCEDURE 8

Unstable idle (Rough idle, hunting)Probable cause

[Comment] Malfunction of the ignition system

In cases such as the above, the cause is probably t hat the ignition system,l Malfunction of air-fuel ratio system

idle air control motor or compression pressure is d efective.

l Malfunction of the system

Because the range of possible causes is broad, insp ection is narrowed down to simple items.

l Malfunction of the evaporative emission

purge solenoid system

l Malfunction of the EGR system

l Poor compression

l Drawing air into exhaust system

W ere the battery terminals disconnected recently?

SCAN TOOL DTC

Are diagnostic trouble codes output

NO Refer to

INSPECTION CHART FOR DIAGNOSTICTROUBLE CODES.

YES

Inspection when hunting occurs.

(Refer to INSPECTION PROCEDURE 31.)

SCANTOOL Actuator test

07 motor (Refer to

OK

NG Check the idle air control motor (Refer to P. INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL Specialfunction

“Reset

I

Check trouble symptoms.

OK

Scan tool: Inspection when idle speed is unstable. (Refer

to INSPECTION PROCEDURE 32.)

OK

Check the injector control circuit: (Carry out pro cedures 19, 20, 21, in “INSPECTION PROCEDURE

FOR DIAGNOSTIC TROUBLE CODES”.)

Check the following items. l Check the ignition coil, spark plugs, spark plug ca bles.

l Check the purge control system.

l Check the EGR svstem.

l Check the compression pressure.

l Check if foreign materials (water, alcohol, etc.) g ot into fuel.

TSB Revision

Page 471 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE,

INSPECTION PROCEDURE 11When the engine is cold, it stalls at idle. (Die ou t)

[Comment]lMalfunction of the idle air control

In such cases as the above, the cause is pro MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE,

INSPECTION PROCEDURE 11When the engine is cold, it stalls at idle. (Die ou t)

[Comment]lMalfunction of the idle air control

In such cases as the above, the cause is pro](/img/19/57345/w960_57345-470.png)

ENGINE,

INSPECTION PROCEDURE 11When the engine is cold, it stalls at idle. (Die ou t)

[Comment]lMalfunction of the idle air control

In such cases as the above, the cause is probably t hat the air/fuel mixture is inappropriate when l Malfunction of the fhroffle body the engine is cold, or that the intake air volume i s insufficient..l Malfunction of the injector System l Malfunction: system

W ere the battery terminals disconnected recently?

NO

SCAN TOOL DTC

.After warming-up, let the engine run at idling for 10 minutes.I

,

Are diagnostic trouble codes output?TROUBLE CODES

N OI -.: .

Does the engine stall right after the accelerator p

edal is

Check the throffle body minimum air (Refer to released

NO . . . N O Check for unstable idle (Rough hunting)Is engine-idling stable after the warming-up?

YES(Refer to INSPECTION 8.)

SCAN TOOL Actuator test

07 motor (Refer to

OK NG

Check the idle air control motor circuit. (Refer t

o INSPECTION PROCEDURE FOR TROUBLE CODE

SCAN TOOL Special function

“Reset

Check trouble symptoms.

NG

OK

.

Check the injector control circuit. Carry procedures 19, in “INSPECTION PROCEDUREFOR DIAGNOSTIC TROUBLE

Check the fuel pressure. (Refer to

Check the following items.

l Check the ignition coil, spark plugs, spark plug ca bles.

l Check the compression pressure.

l Check the engine oil viscosity.

TSB Revision

Page 472 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 12 , .

. .

When the engine is hot, it stalls at idle. (Die out )

[Comment]l Malfunction of the ignition In cases such as the above, the caus MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 12 , .

. .

When the engine is hot, it stalls at idle. (Die out )

[Comment]l Malfunction of the ignition In cases such as the above, the caus](/img/19/57345/w960_57345-471.png)

E N G I N E

INSPECTION PROCEDURE 12 , .

. .

When the engine is hot, it stalls at idle. (Die out )

[Comment]l Malfunction of the ignition In cases such as the above, the cause is probably t hat ignition system, mixture, idle l

air control motor or compression pressure is defect ive.Malfunction control M a l f u n c t i o n o f t h e s y s t e m In addition, if the engine stalls, the cause

mayalso be a defective connector contact.l into intake system

l Improper connector contact

W ere the battery terminals disconnected recently

NO

YES After warming-up, let the engine run at idling for 10 minutes.

SCAN TOOL DTC

Are diagnostic trouble codes output?

NO

SCAN TOOL Actuator test

07 motor. (Refer to

OK YES

N G

Refer to INSPECTION CHART FOR DIAGNOSTICTROUBLE CODES.

Checktheidleaircontrolmotorcircuit. INSPECTIONPROCEDURE FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL Special function

“Reset

Check trouble symptoms.

NG

Check the injector for operation sound.

(Refer to Check the injector control circuit. Carry out proc edures 20, in “INSPECTION PROCEDURE

FOR DIAGNOSTIC TROUBLE CODES”.

Does the engine stall right

released

NO.

Does the engine stall easily again

YES

Scan tool: Inspection when engine stalls when the e ngine

is warm and idling (Refer to INSPECTIONPROCEDURE 33.)

OK

Check the throttle body minimum air flow (Refer to

While carrying out an intermittent malfunction simulation test (Refer

to GROUP 00 How to Cope with Intermittent Malfunctions), check

for sudden changes in the signals shown below.

l Crankshaft position sensor and

l MAP sensor signal Fuel pump signall Injector drive signal l power supply voltage

Check the following items.

l

Check the ignition coil, spark plugs, spark plug ca bles.

l Clean the injectors.

l Check the compression pressure.

l Check if foreign materials (water, alcohol, etc.) g ot into fuel.

INSPECTION PROCEDURE 13

The engine stalls when accelerating. (Pass out) Probable cause

[Comment]l

Injectors failedIn cases such as the above, the cause is probably m isfiring due to a weak spark, or an inappropriatelMalfunction of the ignition system

air/fuel mixture when the accelerator is depressed.

YESRefer to INSPECTION CHART FORDIAGNOSTIC

Arediagnostic trouble codes outputTROUBLE CODES.

NO

Check the following items.

l Check the ignition coil, spark plugs, spark plug ca bles.

l Clogged injectors

Page 474 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak ac MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak ac](/img/19/57345/w960_57345-473.png)

E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak accompanyinglthe increase in the spark plug demand voltage durin g acceleration.Improper control of reduction stiifting.

Are diagnostic trouble codes output

NO YES

Refer to INSPECTION CHART D I A G N O S T I CTROUBLE CODES.

Check the following items.

l

Check the ignition coil, spark plugs, spark plug ca bles.

l Check for occurrence of ignition leak.

l Check the torque reduction link (wire) between the PCM and TCM.

INSPECTION PROCEDURE 17

Deceleration shock Probable cause

[Comment]Malfunction of the system is suspected.l Malfunction of ‘system

III

Are diagnostic trouble codes output

NO

YESR e f e r t o C H A R T F O R TROUBLE CODES.

SCAN TOOL Actuator test

07 motor. (Refer to PROCEDURE FOR DIAGNOSTIC TROUBLE CODES

SCAN TOOL Special function“Reset

Check trouble I

N G

TSB Revision

Check the throttle body minimum air flow.

(Refer to

SCAN TOOL SENS

07 Throttle position (Refer to NGl Check the throttle position sensor

(Refer to INSPECTION PROCEDURE 43.)

Page 1009 of 2103

CONTENTS

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> . . . . . 115

AUTOMATIC TRANSAXLE KEY INTERLOCK

AND SHIFT LOCK MECHANISMS* . . . . . . . . 192

GENERAL INFORMATION

. . . . . . . . . . . . . . . . 115

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . .117

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . 159

Automatic Transaxle Control Component

Oil Temperature Sensor Continuity Check . . . . 160

Pinion Factor Writing Procedure After

TCM Replacement or Tire Size Change

. . . 159

Selector Level Operation Check . . . . . . . . . . . . . . ,166

Shift Lock Mechanism Check. . . . . . . . . . . . . . .

1 8 6

TCM Resetting Procedure . . . . . . . . . . . . .

..159

Torque Converter Stall Testing. . . . . . . . . . . . . .166

Transaxle Fluid Level Check . . . . . . . . . . .. . .159

Transaxle Fluid Replacement. . . . . . . . . . . . . . .

Transaxle Range Sensor Continuity . . .

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163SERVICE SPECIFICATIONS.. . . .. . .Automatic Transaxle Control Component Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . .117Clutch Air Pressure Tests . . . . . . . . . . . . . . . . . . .168

Fluid Leakage-Torque Converter Housing Area

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Hydraulic Pressure Tests. . . . . . . . . . . . . . . . . . .169

Hydraulic Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . .173

TRANSAXLE ASSEMBLY. . . . . . . . . . . . . . . .

TRANSAXLE CONTROL*. . . . . . . . . . . . . . . . .187

Selector Lever Assembly. . . . . . . . . . . . . . . . . . .189

Key Interlock Mechanism Check . . . . . . . . . . .

. 186CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL EQUIPPED VEHICLES

WARNING! (1) Improper service or maintenance of any componen t of the

or any component, can lead to personal

injuryordeath inadvertent the inoperative).

(2) Service or maintenance of any component or SRS-related component must be perform ed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP Supplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Serv ice before beginning any service or maintenance of any com-

ponent of the

or any component.

NOTEThe SRS includes the following components: SRS-ECU, SRS warning light, air bag module, clockspring and inte rconnecting wiring.Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are indi-cated in the table of contents by an asterisk

Page 1177 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> On-vehicle .

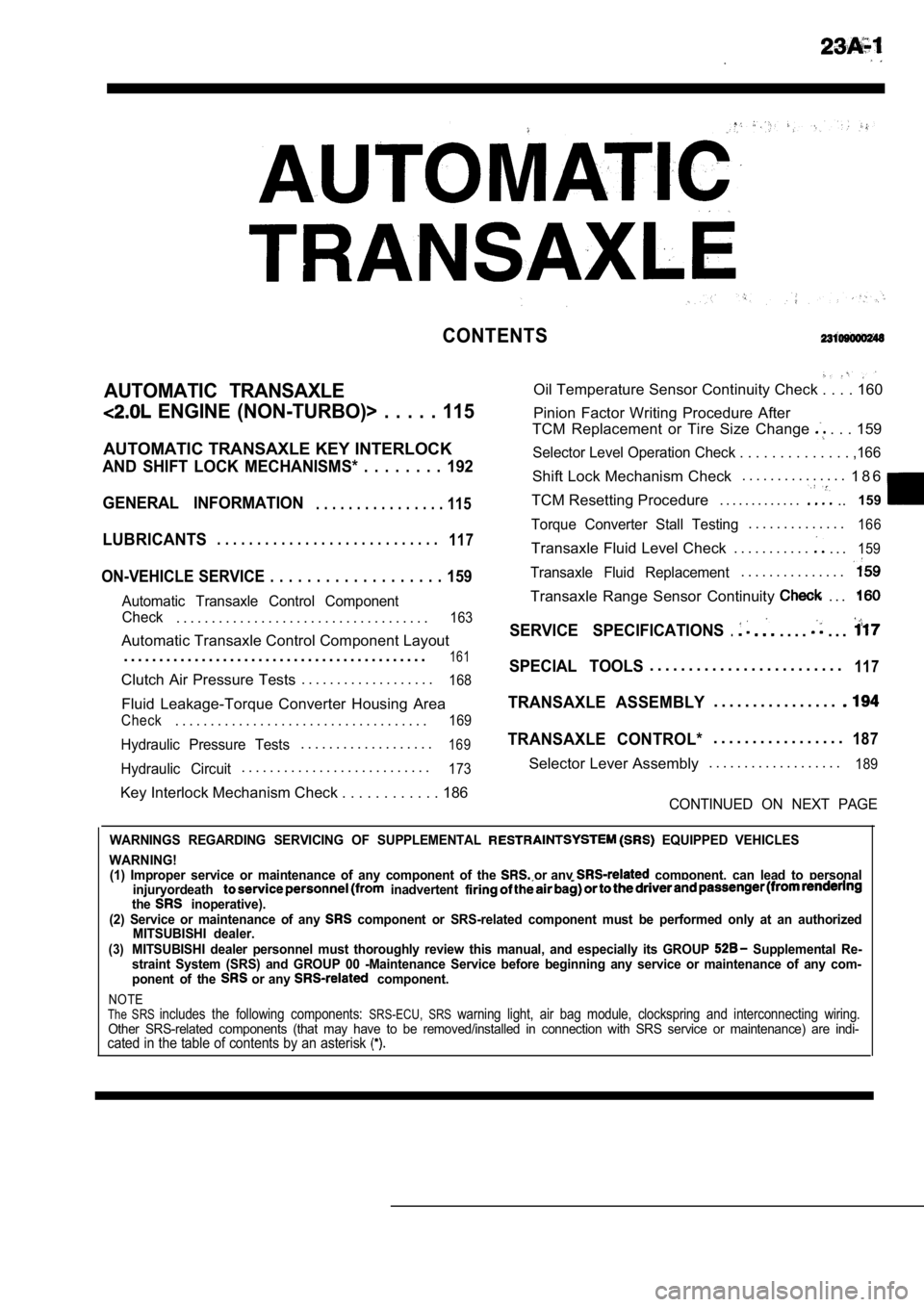

FLUID LEAKAGE-TORQUE CONVERTER

HOUSING AREA CHECK

(1) Check for source of leakage.Since fluid leakage at or around the torque convert er

area may originate from an engine oil leak, the area should

be examined closely, Factory fill fluid is dyed red and,

therefore, can be distinguished from engine oil.

(2) Before removing the transaxle, perform the foll owing

checks:

When leakage is determined to originate from the tr ans-

axle, check fluid level before removal of the transaxle

and torque converter.

High oil level can result in oil leakage out the vent in

the manual shaft. If the fluid level is high, adjust to

proper level.

After fluid is at the proper level, check for leakage. If

a leak

perform the following operation on the

to determine if it is the torque converter or tran saxle

that is, leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

(2) Torque converter weld leaks at the out side (pe ripheral)

weld. Torque converter hub weld.

(3) Hub

inside and not visible. Do not attempt to

repair.

Replace torque converter.

If the torque converter must be replaced, refer to Torque

Converter Clutch Break-in Procedure in this section . This

procedure’ will reset the transaxle control module break-in

status. Failure to perform this procedure may cause transaxle

shutter.

Clutch

HYDRAULIC PRESSURE TESTS

Pressure testing is a very important step in the diagnostic

procedure. These tests usually reveal the cause of most

transaxle problems.

Before performing pressure tests, be certain that fluid level

and condition, and shift cable adjustments have bee n checked

and approved.Fluid must be at operating temperature

(150 to

1. Install an engine tachometer.

2.Raise vehicle on hoist which allows front wheels to

turn,

and position tachometer so it can be read.

3. Attach 1,000

(140 psi) gauge and special tool

to ports required for test being conducted.

A 3,000 (400 psi) gauge and special tool

are required for reverse pressure test. Test port l ocations

are shown in illustration.

TSB Revision