oil MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 23 of 2103

GENERAL Precautions before Service . .

Caution

1.Before connecting or disconnecting the negative

be sure to turn off the ignition and

the lighting switch.

(if this is not done, the possibility semi-

conductor parts being damaged.)

2.After completion of the work steps [when the bat-

tery’s negative terminal is connected], warm

up the engine and allow it for approximately

five minutes under the conditions be-

low, in order to stabilize the engine condi-

tions, and then check to be sure that idling’ is

satisfactory.

Engine temperature:

Lights, electric fans, accessories: OFF

Transaxle: Neutral position

(A/T models: “N” or “P”)

Steering

neutral (center) position

mm (in.)

Scan tool

ROM pack

VEHICLE WASHING

If high-pressure car-washing equipment or steam car -washing

equipment is used to wash the vehicle, be maintain

the spray nozzle at a distance of at ‘least 300 mm (12 in.)

from any plastic parts and all opening parts (doors , luggage

compartment, etc.).

APPLYING ANTI-CORROSION

OTHER UNDERCOAT AGENTS.,

Be careful not to adhere oil or grease to the heate d oxygen

sensor. If adhered, the sensor may malfunction.

Protect the heated oxygen sensor with a cover befor e applying

anti-corrosion agent, etc.

SCAN TOOL

To operate the scan tool, refer to the “MUT-II OPER ATING

INSTRUCTIONS”.

Caution

Turn the ignition switch off befoie connecting and discon-

necting the scan tool.

Page 24 of 2103

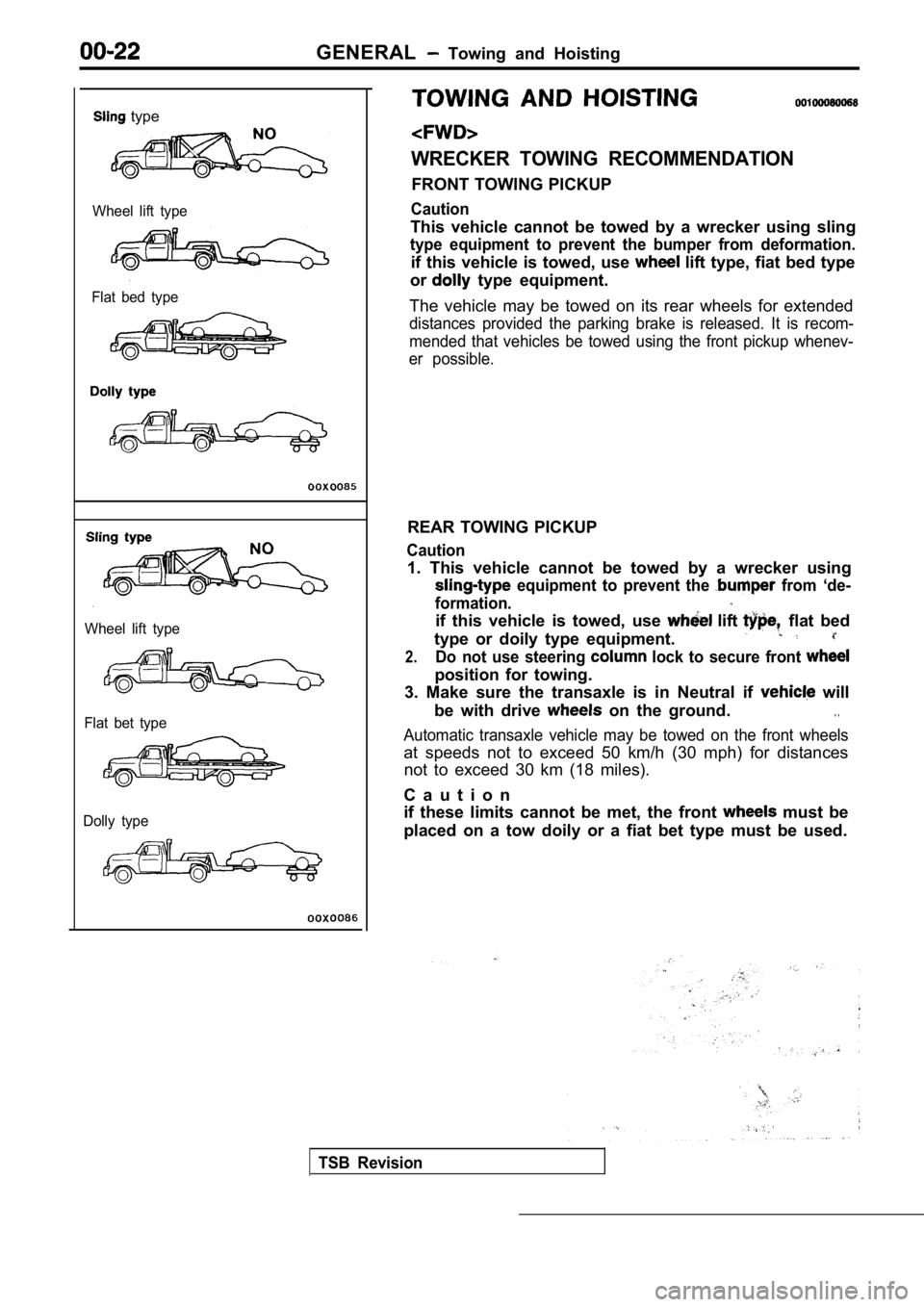

GENERAL Towing and Hoisting

type

Wheel lift type

Flat bed type

Wheel lift type

Flat bet type

Dolly type

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sli ng

type equipment to prevent the bumper from deformati on.

if this vehicle is towed, use lift type, fiat bed type

or

type equipment.

The vehicle may be towed on its rear wheels for ext ended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front picku p whenev-

er possible.

REAR TOWING PICKUP

Caution

1. This vehicle cannot be towed by a wrecker using

equipment to prevent the from ‘de-

formation.

if this vehicle is towed, use lift flat bed

type or doily type equipment.

2.Do not use steering lock to secure front

position for towing.

3. Make sure the transaxle is in Neutral if

will

be with drive

on the ground.. .

Automatic transaxle vehicle may be towed on the fro nt wheels

at speeds not to exceed 50 km/h (30 mph) for distan ces

not to exceed 30 km (18 miles).

C a u t i o n

if these limits cannot be met, the front

must be

placed on a tow doily or a fiat bet type must be us ed.

TSB Revision

Page 25 of 2103

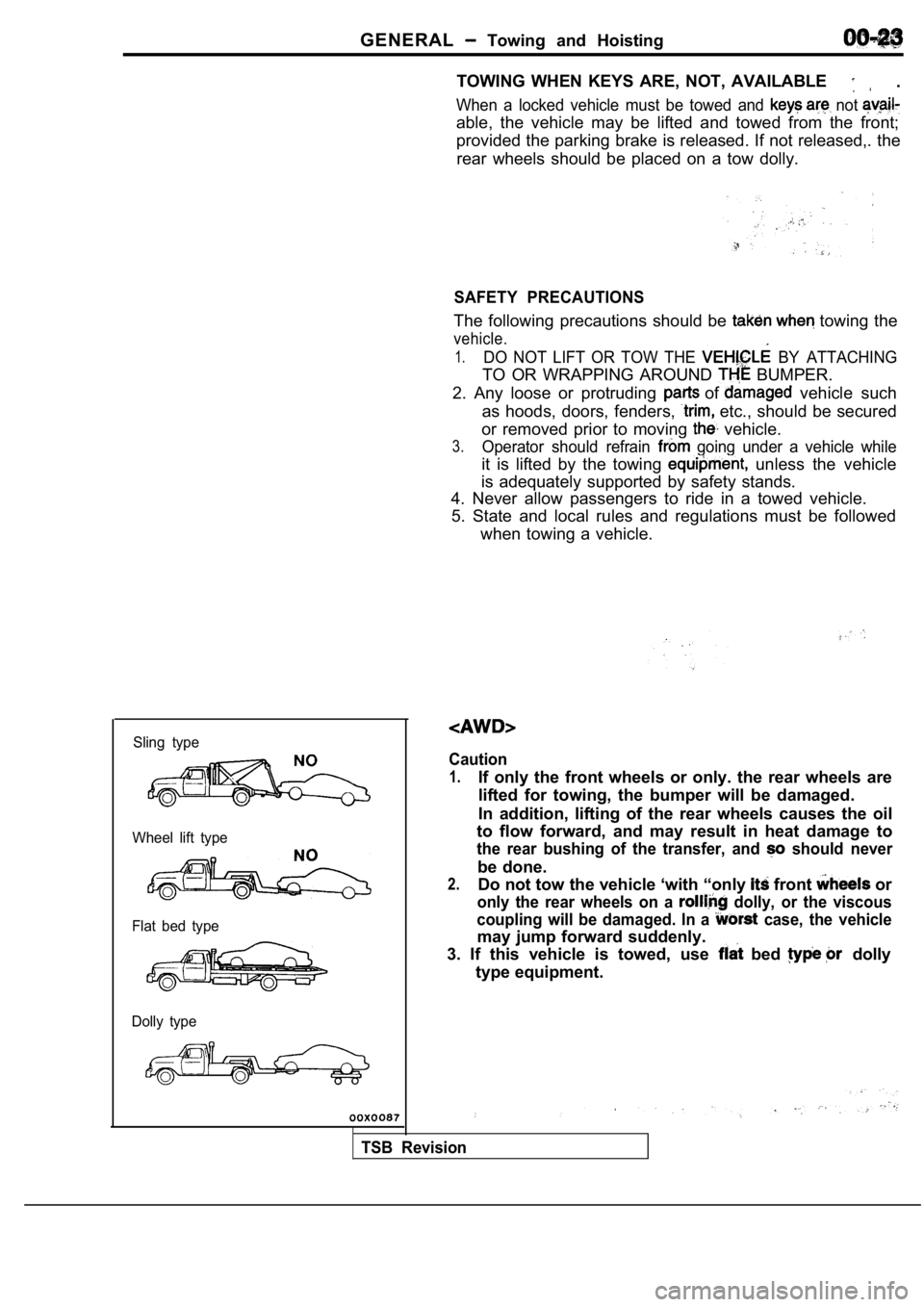

GENERAL Towing and Hoisting

Sling type

Wheel lift type

Flat bed type

Dolly type

TOWING WHEN KEYS ARE, NOT, AVAILABLE .

When a locked vehicle must be towed and not

able, the vehicle may be lifted and towed from the front;

provided the parking brake is released. If not rele ased,. the

rear wheels should be placed on a tow dolly.

SAFETY PRECAUTIONS

The following precautions should be towing the

vehicle.

1.DO NOT LIFT OR TOW THE BY ATTACHING

TO OR WRAPPING AROUND BUMPER.

2. Any loose or protruding

of vehicle such

as hoods, doors, fenders,

etc., should be secured

or removed prior to moving

vehicle.

3.Operator should refrain going under a vehicle while

it is lifted by the towing unless the vehicle

is adequately supported by safety stands.

4. Never allow passengers to ride in a towed vehicl e.

5. State and local rules and regulations must be fo llowed

when towing a vehicle.

Caution

1.If only the front wheels or only. the rear wheels a re

lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes the oil

to flow forward, and may result in heat damage to

the rear bushing of the transfer, and should never

be done.

2.Do not tow the vehicle ‘with “only front or

only the rear wheels on a dolly, or the viscous

coupling will be damaged. In a

case, the vehicle

may jump forward suddenly.

3. If this vehicle is towed, use

bed dolly

type equipment.

TSB Revision

Page 35 of 2103

GENERAL Lubrication arid Maintenance,

00100120067

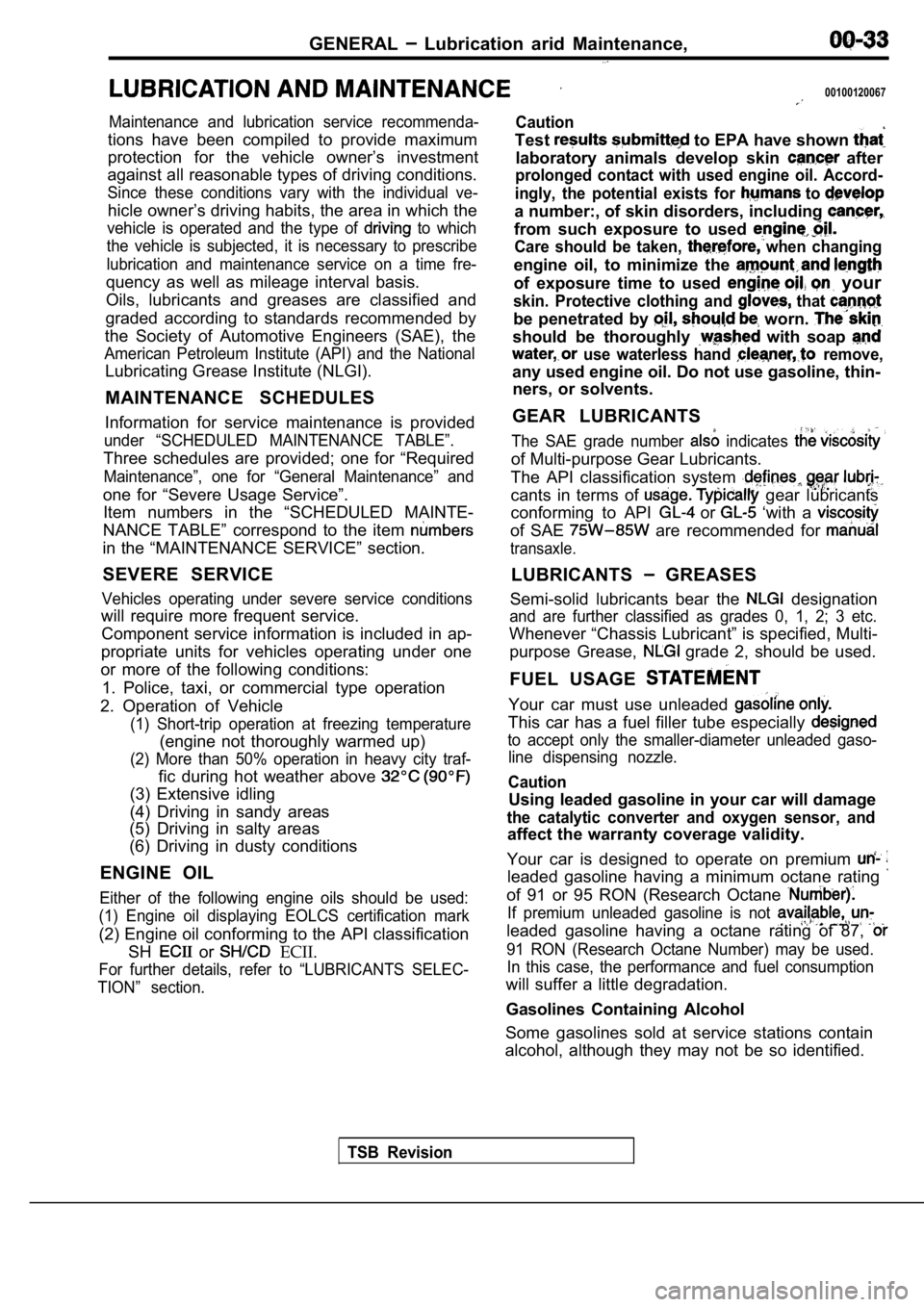

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual ve-

hicle owner’s driving habits, the area in which the

vehicle is operated and the type of to which

the vehicle is subjected, it is necessary to prescr ibe

lubrication and maintenance service on a time fre-

quency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by

the Society of Automotive Engineers (SAE), the

American Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”. Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item

in the “MAINTENANCE SERVICE” section.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information is included in ap-

propriate units for vehicles operating under one

or more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traf-

fic during hot weather above

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

Either of the following engine oils should be used:

(1) Engine oil displaying EOLCS certification mark

(2) Engine oil conforming to the API classification SH

or ECII.

For further details, refer to “LUBRICANTS SELEC-

TION” section.

Caution

Test to EPA have shown

laboratory animals develop skin after

prolonged contact with used engine oil. Accord-

ingly, the potential exists for

to

a number:, of skin disorders, including

from such exposure to used

Care should be taken, when changing

engine oil, to minimize the

of exposure time to used your

skin. Protective clothing and that

be penetrated by worn.

should be thoroughly with soap

use waterless hand remove,

any used engine oil. Do not use gasoline, thin- ners, or solvents.

GEAR LUBRICANTS

The SAE grade number indicates

of Multi-purpose Gear Lubricants.

The API classification system

cants in terms of gear lubricants

conforming to API

or ‘with a

of SAE are recommended for

transaxle.

LUBRICANTS GREASES

Semi-solid lubricants bear the

designation

and are further classified as grades 0, 1, 2; 3 etc .

Whenever “Chassis Lubricant” is specified, Multi-

purpose Grease,

grade 2, should be used.

FUEL USAGE

Your car must use unleaded

This car has a fuel filler tube especially

to accept only the smaller-diameter unleaded gaso- line dispensing nozzle.

Caution

Using leaded gasoline in your car will damage

the catalytic converter and oxygen sensor, and

affect the warranty coverage validity.

Your car is designed to operate on premium

leaded gasoline having a minimum octane rating

of 91 or 95 RON (Research Octane

If premium unleaded gasoline is not

leaded gasoline having a octane rating of 87,

91 RON (Research Octane Number) may be used. In this case, the performance and fuel consumption

will suffer a little degradation.

Gasolines Containing Alcohol

Some gasolines sold at service stations contain

alcohol, although they may not be so identified.

TSB Revision

Page 36 of 2103

Lubrication and

GENERAL Lubricants and Lubricant Capacities Table

Use of fuels containing alcohol is not recommended

unless the nature of the blend can be determined

as being satisfactory.

Gasohol

A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used in your

car.

If problems are experienced as a result

of using gasohol, it is recommended that the car

be operated on gasoline.

Methanol Do not use gasolines containing

methanol (wood alcohol). Use of this type of alcohol

can result in vehicle performance deterioration and

damage critical parts in the fuel system compo-

nents. Fuel system damage and performance prob-

lems, resulting from the use of gasolines containin g

methanol, may not be covered by the new car war-

ranty.

Gasolines containing

Ether)

Unleaded gasoline containing 15% or

may be used in car. Fuel containing MTBE

over 15% vol. may cause reduced engine perfor-

mance and produce vapor lock or hard starting.

MATERIALS

TO FUEL

Indiscriminate use of fuel system -cleaning’

should be avoided. Many of these materials in-

tended for gum and varnish removal

highly active solvents or similar ingredients that

can be harmful to gasket and diaphragm materials

used in fuel system component

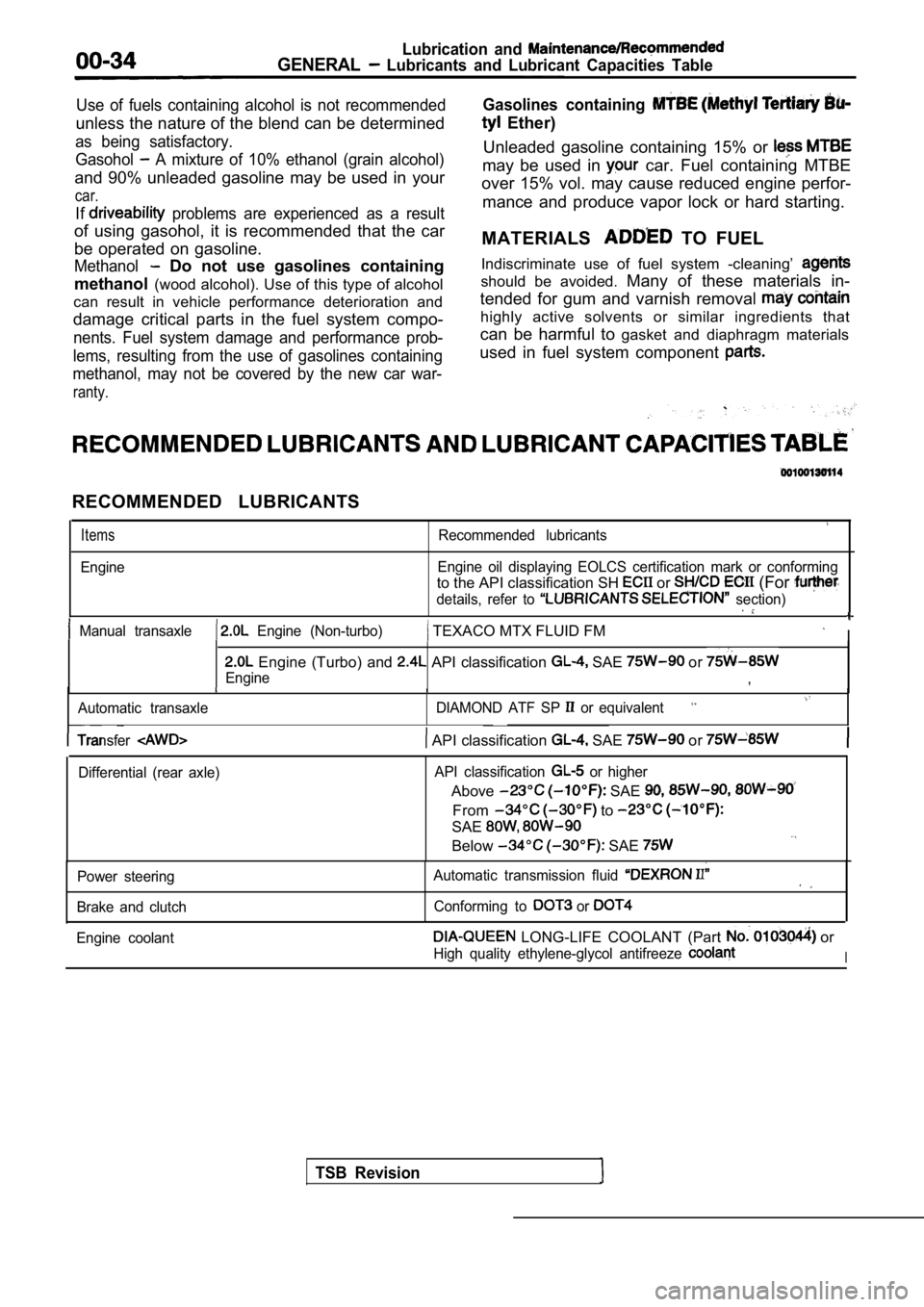

RECOMMENDED LUBRICANTS

Items

Engine

Recommended lubricants

Engine oil displaying EOLCS certification mark or c onforming

to the API classification SH or (For

details, refer to section)

Manual transaxle Engine (Non-turbo) TEXACO MTX FLUID FM I

Engine (Turbo) and API classification SAE or

Engine,

Automatic transaxle DIAMOND ATF SP or equivalent

TSB Revision

Transfer API classification SAE or

Differential (rear axle)API classification or higher

Above SAE

From to

SAE

Below SAE

Power steering

Brake and clutch Automatic transmission fluid

Conforming to or

Engine coolant LONG-LIFE COOLANT (Part or

High quality ethylene-glycol antifreeze I

Page 37 of 2103

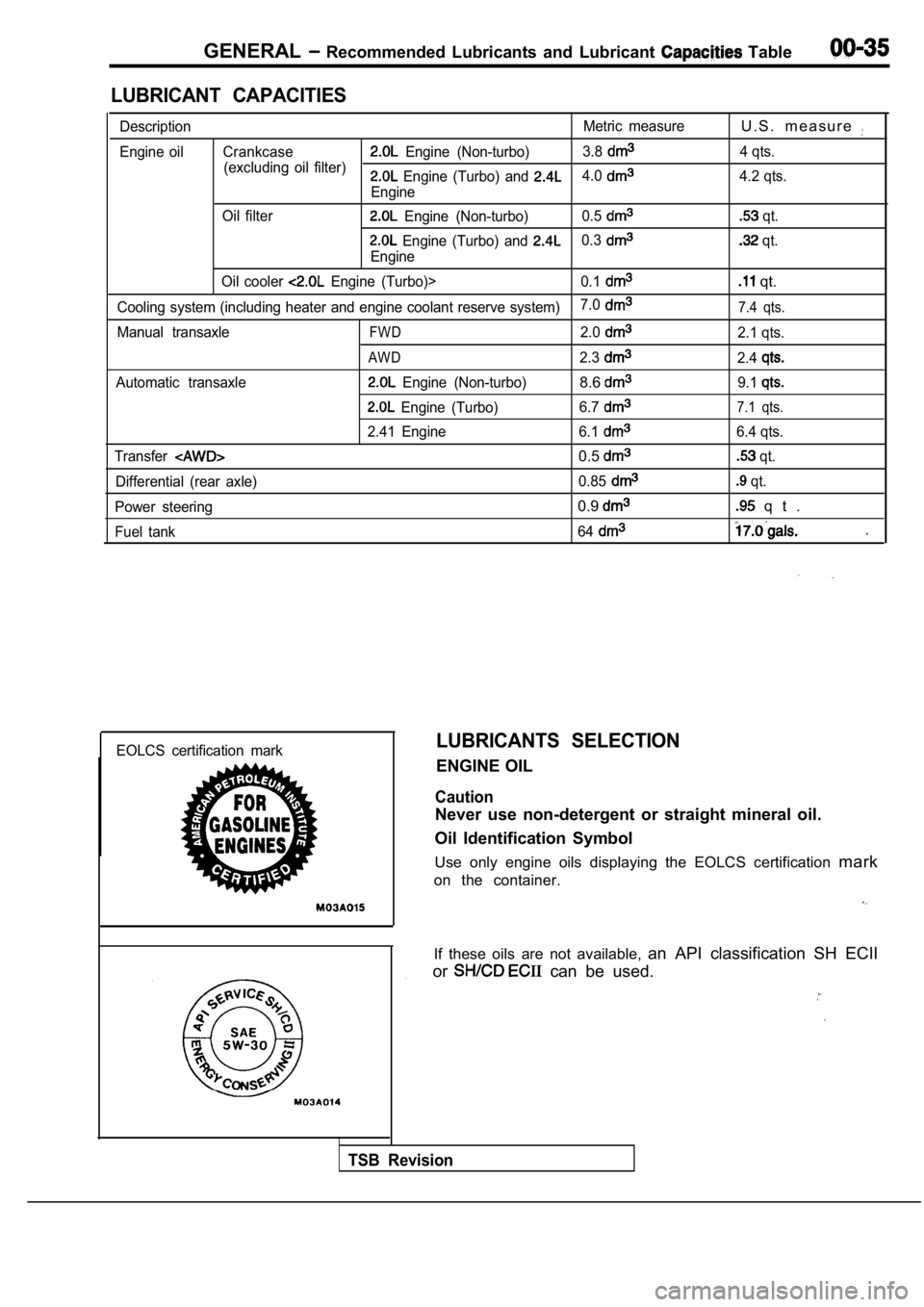

GENERAL Recommended Lubricants and Lubricant Table

LUBRICANT CAPACITIES

DescriptionMetric measureU . S . m e a s u r e

Engine oil Crankcase Engine (Non-turbo)3.8

(excluding oil filter) 4 qts. Engine (Turbo) and 4.0

Engine4.2 qts.

Oil filter

Engine (Non-turbo) 0.5 qt.

Engine (Turbo) and 0.3

Engine

qt.

Oil cooler

Engine (Turbo)> 0.1 qt.

Cooling system (including heater and engine coolant reserve system)7.07.4 qts.

Manual transaxleFWD2.02.1 qts.

AWD2.32.4

Automatic transaxle Engine (Non-turbo)8.69.1

Engine (Turbo)

6.77.1 qts.

2.41 Engine 6.16.4 qts.

Transfer

0.5 qt.

Differential (rear axle) 0.85

qt.

Power steering

0.9 q t .

Fuel tank 64

EOLCS certification markLUBRICANTS SELECTION

ENGINE OIL

Caution

Never use non-detergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

If these oils are not available, an API classification SH ECII

or

can be used.

TSB Revision

Page 38 of 2103

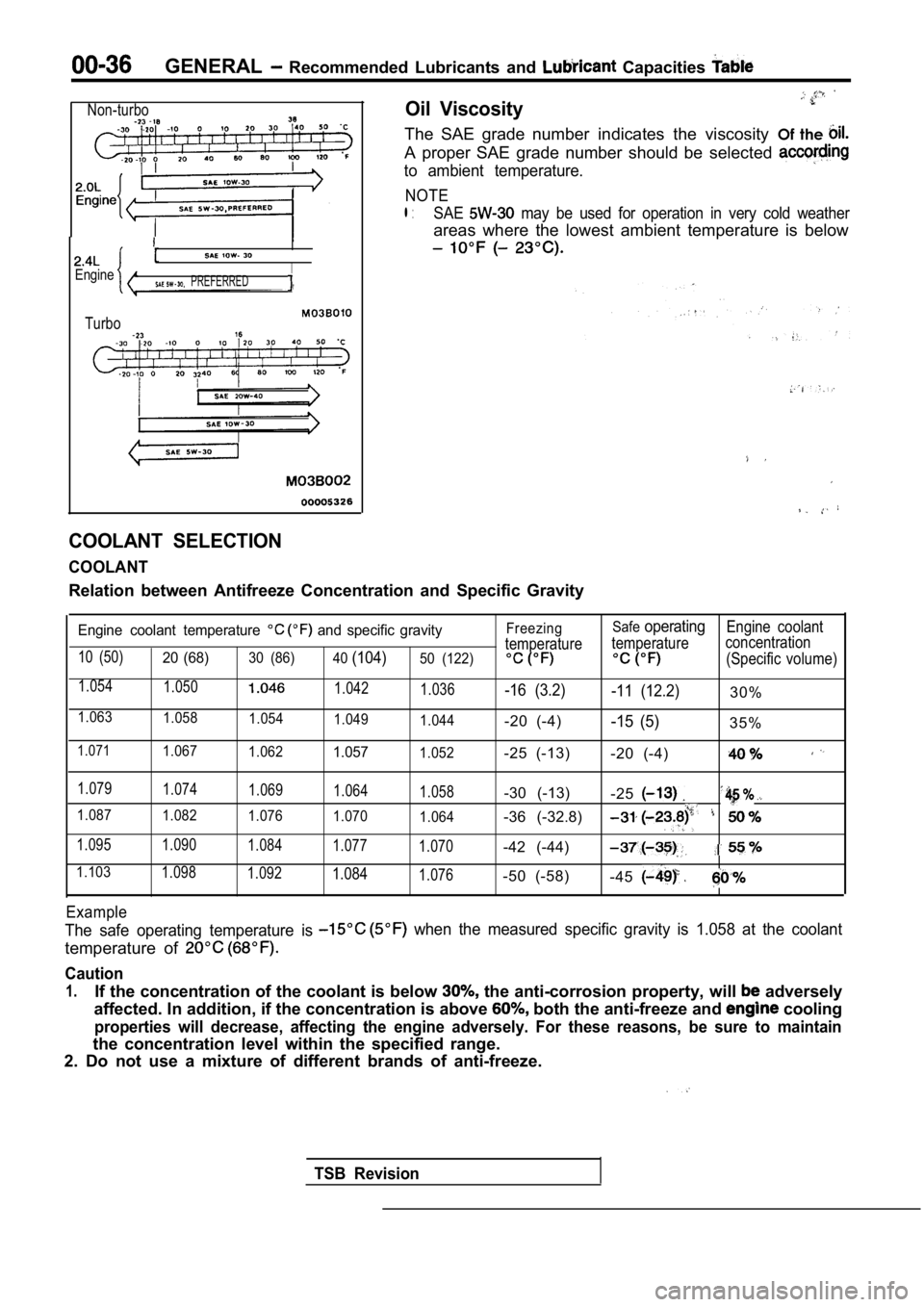

GENERAL Recommended Lubricants and Capacities

Non-turbo

I

EngineI PREFERRED

Turbo

Oil Viscosity

The SAE grade number indicates the viscosity Of the

A proper SAE grade number should be selected

to ambient temperature.

NOTE

l :SAE may be used for operation in very cold weather

areas where the lowest ambient temperature is below

COOLANT SELECTION

COOLANT

Relation between Antifreeze Concentration and Speci fic Gravity

Engine coolant temperature and specific gravity

10 (50)20 (68)30 (86)

40(104)50 (122)

1.054

1.0501.042

1.036

1.0631.058 1.0541.049

1.044

1.0711.0671.0621.0571.052 Freezing

Safe

operatingEngine coolant

temperature temperature concentration

(Specific volume)

-16 (3.2)

-11 (12.2)30%

-20 (-4)

-15 (5)35%

-25 (-13) -20 (-4)

1.079

1.074 1.0691.064

1.058-30 (-13)-25

1.0871.082 1.0761.070

1.064-36 (-32.8)

1.095 1.090 1.0841.077

1.070-42 (-44)

1.1031.0981.0921.0841.076-50 (-58)-45

Example

The safe operating temperature is when the measured specific gravity is 1.058 at the coolant

temperature of

Caution

1.If the concentration of the coolant is below the anti-corrosion property, will adversely

affected. In addition, if the concentration is abov e

both the anti-freeze and cooling

properties will decrease, affecting the engine adve rsely. For these reasons, be sure to maintain

the concentration level within the specified range.

2. Do not use a mixture of different brands of anti -freeze.

TSB Revision

Page 44 of 2103

GENERALMaintenanceService

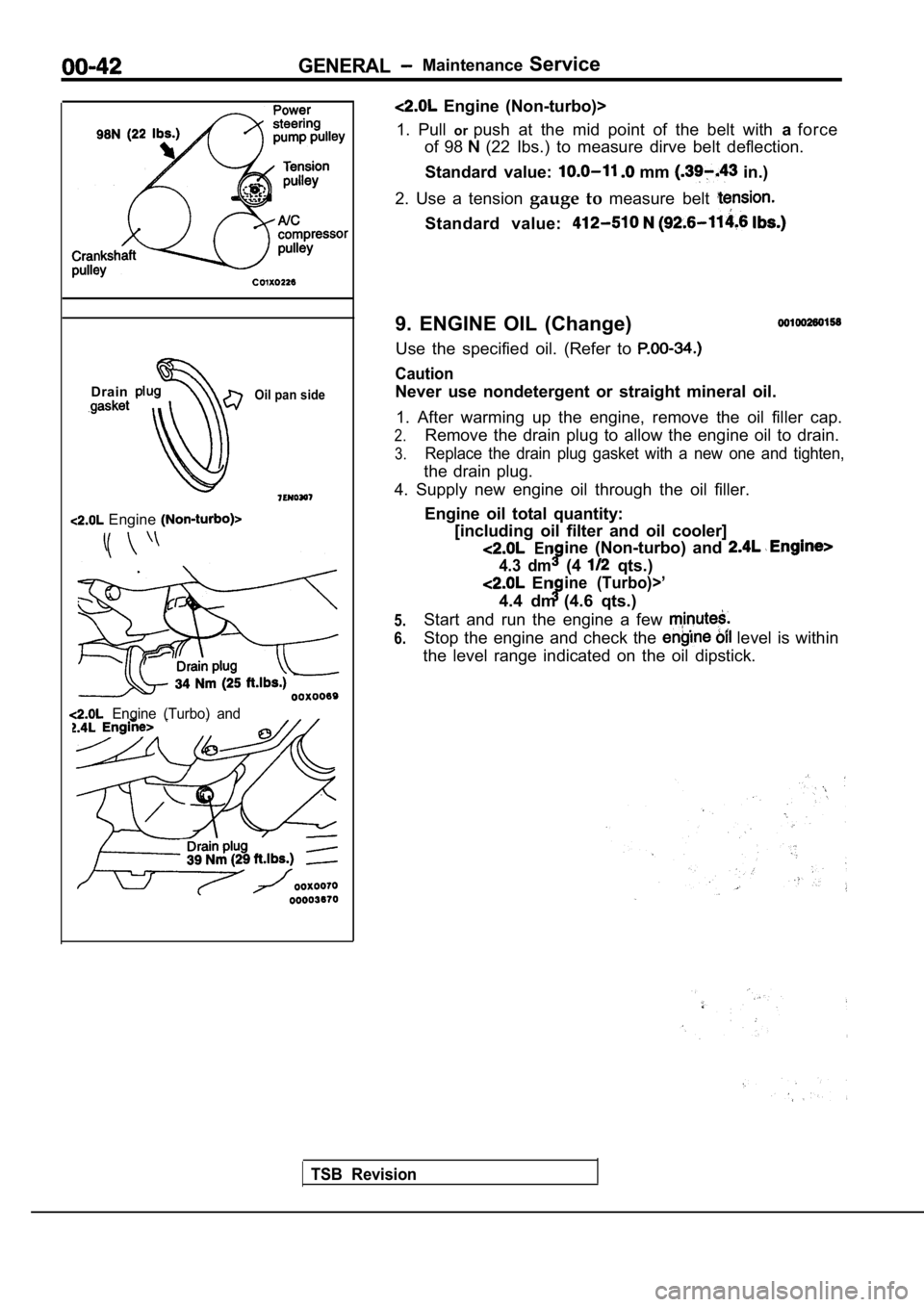

Drain

Oil pan side

Engine

Engine (Turbo) and

TSB Revision

Engine (Non-turbo)>

1. Pull orpush at the mid point of the belt with aforce

of 98

(22 Ibs.) to measure dirve belt deflection.

Standard value:

mm in.)

2. Use a tension gauge to measure belt

Standard value:

9. ENGINE OIL (Change)

Use the specified oil. (Refer to

Caution

Never use nondetergent or straight mineral oil.

1. After warming up the engine, remove the oil fill er cap.

2.Remove the drain plug to allow the engine oil to drain.

3.Replace the drain plug gasket with a new one and ti ghten,

the drain plug.

4. Supply new engine oil through the oil filler.

Engine oil total quantity:[including oil filter and oil cooler]

Enine (Non-turbo) and

4.3 dm(4 qts.)

Enine (Turbo)>’

4.4 dm (4.6 qts.)

Start and run the engine a few

Stop the engine and check the level is within

the level range indicated on the oil dipstick.

5.

6.

Page 45 of 2103

GENERAL Maintenance Service

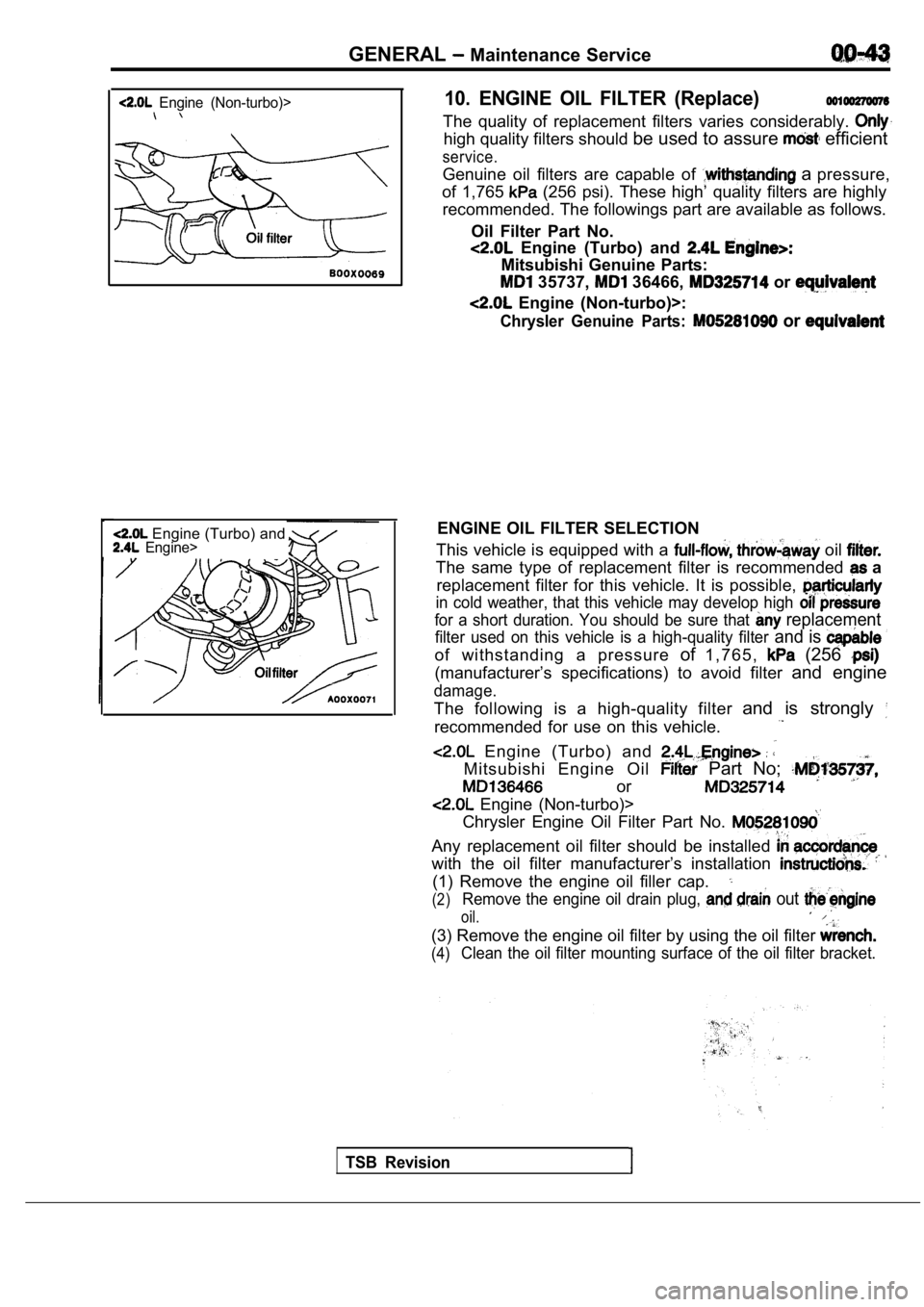

Engine (Non-turbo)>

Engine (Turbo) and Engine>

10. ENGINE OIL FILTER (Replace)

The quality of replacement filters varies considerably.

high quality filters should be used to assure efficient

service.

Genuine oil filters are capable of a pressure,

of 1,765

(256 psi). These high’ quality filters are highly

recommended. The followings part are available as f ollows.

Oil Filter Part No.

Engine (Turbo) and

Mitsubishi Genuine Parts:

35737, 36466, or

Engine (Non-turbo)>:

Chrysler Genuine Parts: or

ENGINE OIL FILTER SELECTION

This vehicle is equipped with a

oil

The same type of replacement filter is recommended a

replacement filter for this vehicle. It is possible ,

in cold weather, that this vehicle may develop high

for a short duration. You should be sure that replacement

filter used on this vehicle is a high-quality filter and is

of withstanding a pressure of1 , 7 6 5 , (256

(manufacturer’s specifications) to avoid filter and engine

damage.

The following is a high-quality filter and is strongly

recommended for use on this vehicle.

Engine (Turbo) and

Mitsubishi Engine Oil Part No;

or

Engine (Non-turbo)>

Chrysler Engine Oil Filter Part No.

Any replacement oil filter should be installed

with the oil filter manufacturer’s installation

(1) Remove the engine oil filler cap.

(2)Remove the engine oil drain plug, out

oil.

(3) Remove the engine oil filter by using the oil f ilter

(4)Clean the oil filter mounting surface of the oil filter bracket.

TSB Revision