differential MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 36 of 2103

Lubrication and

GENERAL Lubricants and Lubricant Capacities Table

Use of fuels containing alcohol is not recommended

unless the nature of the blend can be determined

as being satisfactory.

Gasohol

A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used in your

car.

If problems are experienced as a result

of using gasohol, it is recommended that the car

be operated on gasoline.

Methanol Do not use gasolines containing

methanol (wood alcohol). Use of this type of alcohol

can result in vehicle performance deterioration and

damage critical parts in the fuel system compo-

nents. Fuel system damage and performance prob-

lems, resulting from the use of gasolines containin g

methanol, may not be covered by the new car war-

ranty.

Gasolines containing

Ether)

Unleaded gasoline containing 15% or

may be used in car. Fuel containing MTBE

over 15% vol. may cause reduced engine perfor-

mance and produce vapor lock or hard starting.

MATERIALS

TO FUEL

Indiscriminate use of fuel system -cleaning’

should be avoided. Many of these materials in-

tended for gum and varnish removal

highly active solvents or similar ingredients that

can be harmful to gasket and diaphragm materials

used in fuel system component

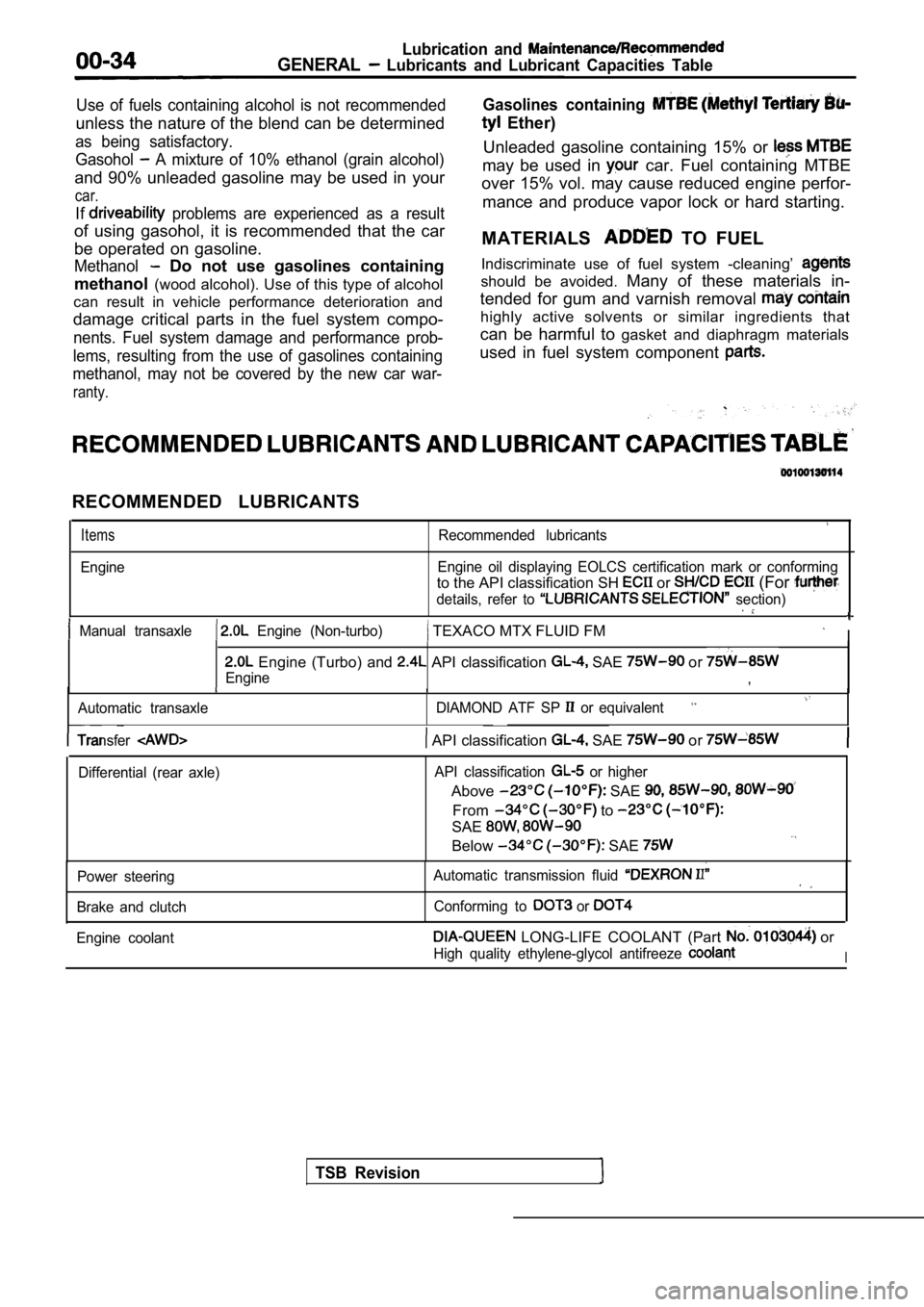

RECOMMENDED LUBRICANTS

Items

Engine

Recommended lubricants

Engine oil displaying EOLCS certification mark or c onforming

to the API classification SH or (For

details, refer to section)

Manual transaxle Engine (Non-turbo) TEXACO MTX FLUID FM I

Engine (Turbo) and API classification SAE or

Engine,

Automatic transaxle DIAMOND ATF SP or equivalent

TSB Revision

Transfer API classification SAE or

Differential (rear axle)API classification or higher

Above SAE

From to

SAE

Below SAE

Power steering

Brake and clutch Automatic transmission fluid

Conforming to or

Engine coolant LONG-LIFE COOLANT (Part or

High quality ethylene-glycol antifreeze I

Page 37 of 2103

GENERAL Recommended Lubricants and Lubricant Table

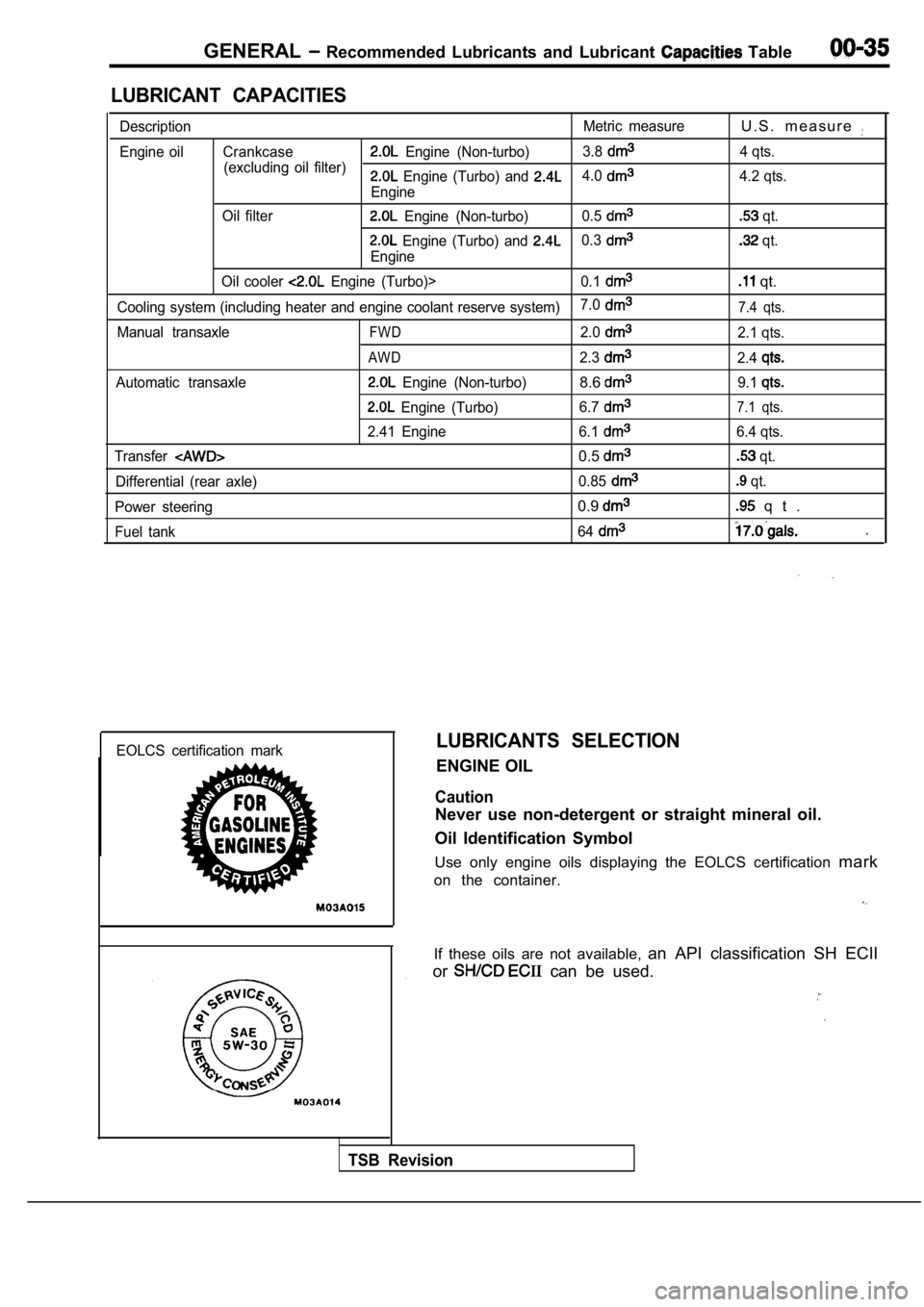

LUBRICANT CAPACITIES

DescriptionMetric measureU . S . m e a s u r e

Engine oil Crankcase Engine (Non-turbo)3.8

(excluding oil filter) 4 qts. Engine (Turbo) and 4.0

Engine4.2 qts.

Oil filter

Engine (Non-turbo) 0.5 qt.

Engine (Turbo) and 0.3

Engine

qt.

Oil cooler

Engine (Turbo)> 0.1 qt.

Cooling system (including heater and engine coolant reserve system)7.07.4 qts.

Manual transaxleFWD2.02.1 qts.

AWD2.32.4

Automatic transaxle Engine (Non-turbo)8.69.1

Engine (Turbo)

6.77.1 qts.

2.41 Engine 6.16.4 qts.

Transfer

0.5 qt.

Differential (rear axle) 0.85

qt.

Power steering

0.9 q t .

Fuel tank 64

EOLCS certification markLUBRICANTS SELECTION

ENGINE OIL

Caution

Never use non-detergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

If these oils are not available, an API classification SH ECII

or

can be used.

TSB Revision

Page 58 of 2103

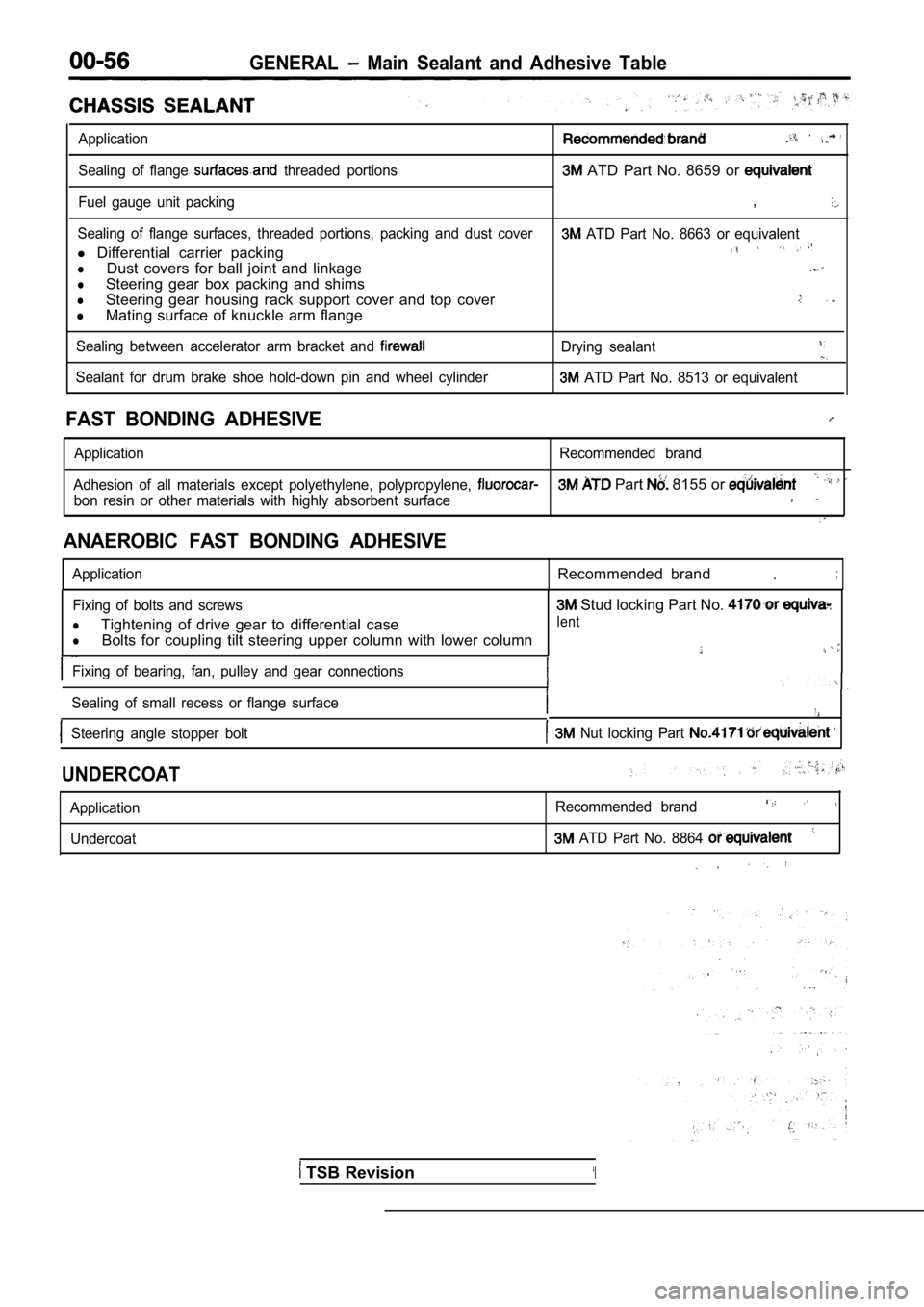

GENERAL Main Sealant and Adhesive Table

Application

Sealing of flange threaded portions ATD Part No. 8659 or

Fuel gauge unit packing,

Sealing of flange surfaces, threaded portions, packing and dust cover ATD Part No. 8663 or equivalent

l Differential carrier packing

lDust covers for ball joint and linkage

lSteering gear box packing and shims

lSteering gear housing rack support cover and top co ver

lMating surface of knuckle arm flange

Sealing between accelerator arm bracket and Drying sealant

Sealant for drum brake shoe hold-down pin and wheel cylinder ATD Part No. 8513 or equivalent

FAST BONDING ADHESIVE

Application Recommended brand

Adhesion of all materials except polyethylene, poly propylene,

Part 8155 or

bon resin or other materials with highly absorbent surface,

ANAEROBIC FAST BONDING ADHESIVE

ApplicationRecommended brand.

Fixing of bolts and screws

lTightening of drive gear to differential case

lBolts for coupling tilt steering upper column with lower column

Fixing of bearing, fan, pulley and gear connections

Sealing of small recess or flange surface

Steering angle stopper bolt Nut locking Part

Stud locking Part No.

lent

UNDERCOAT

Application Undercoat Recommended brand

ATD Part No. 8864

TSB Revision‘I

Page 77 of 2103

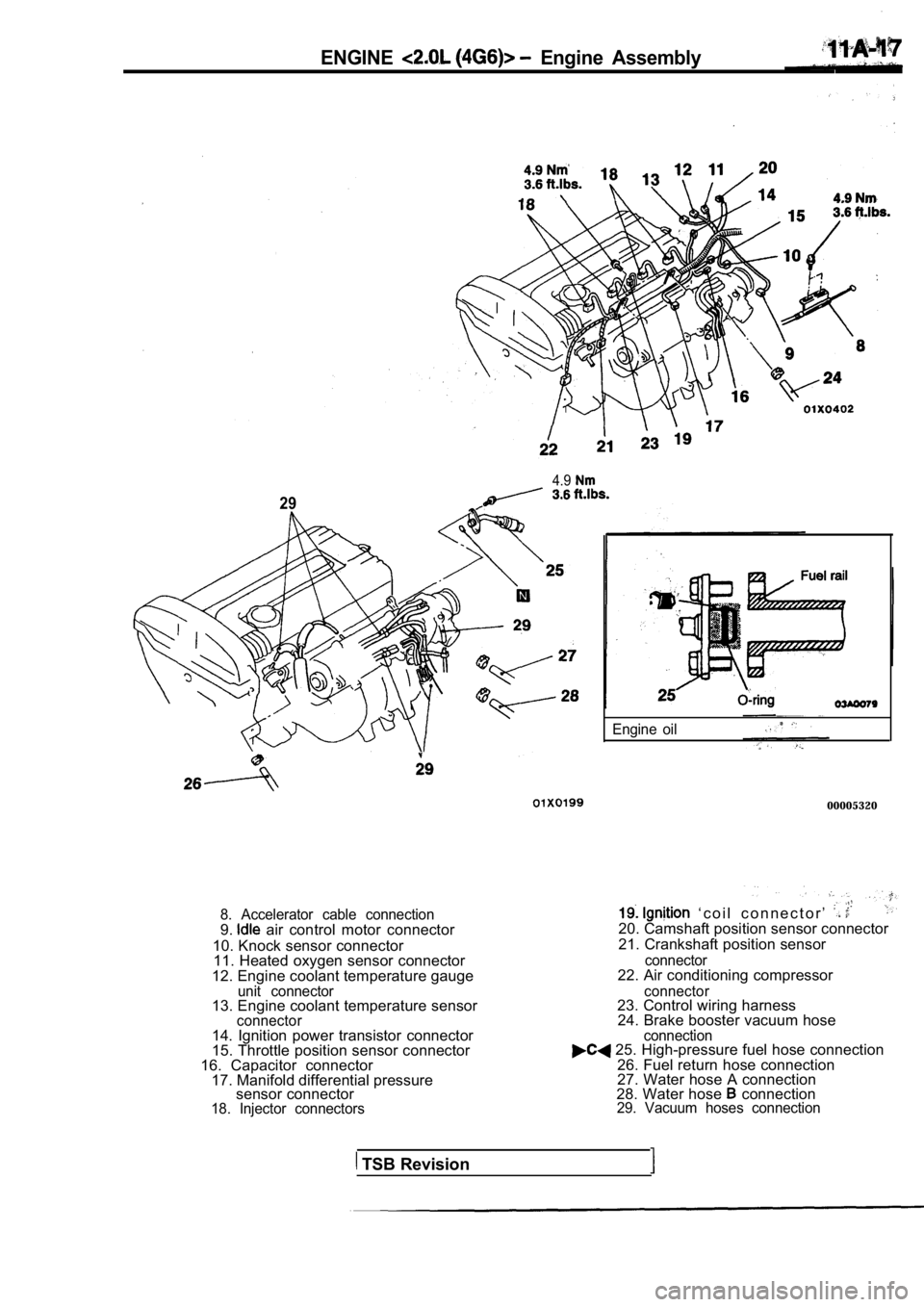

ENGINE Engine Assembly

4.9

29

8. Accelerator cable connection9. air control motor connector

10. Knock sensor connector 11. Heated oxygen sensor connector

12. Engine coolant temperature gauge

unit connector13. Engine coolant temperature sensorconnector

Engine oil

00005320

‘ c o i l c o n n e c t o r ’ 20. Camshaft position sensor connector

21. Crankshaft position sensor

connector22. Air conditioning compressor

connector23. Control wiring harness 24. Brake booster vacuum hose .

14. Ignition power transistor connector

15. Throttle position sensor connector

16. Capacitor connector 17. Manifold differential pressure sensor connector

18. Injector connectors connection

25. High-pressure fuel hose connection

26. Fuel return hose connection

27. Water hose A connection

28. Water hose

connection29. Vacuum hoses connection

TSB Revision

Page 91 of 2103

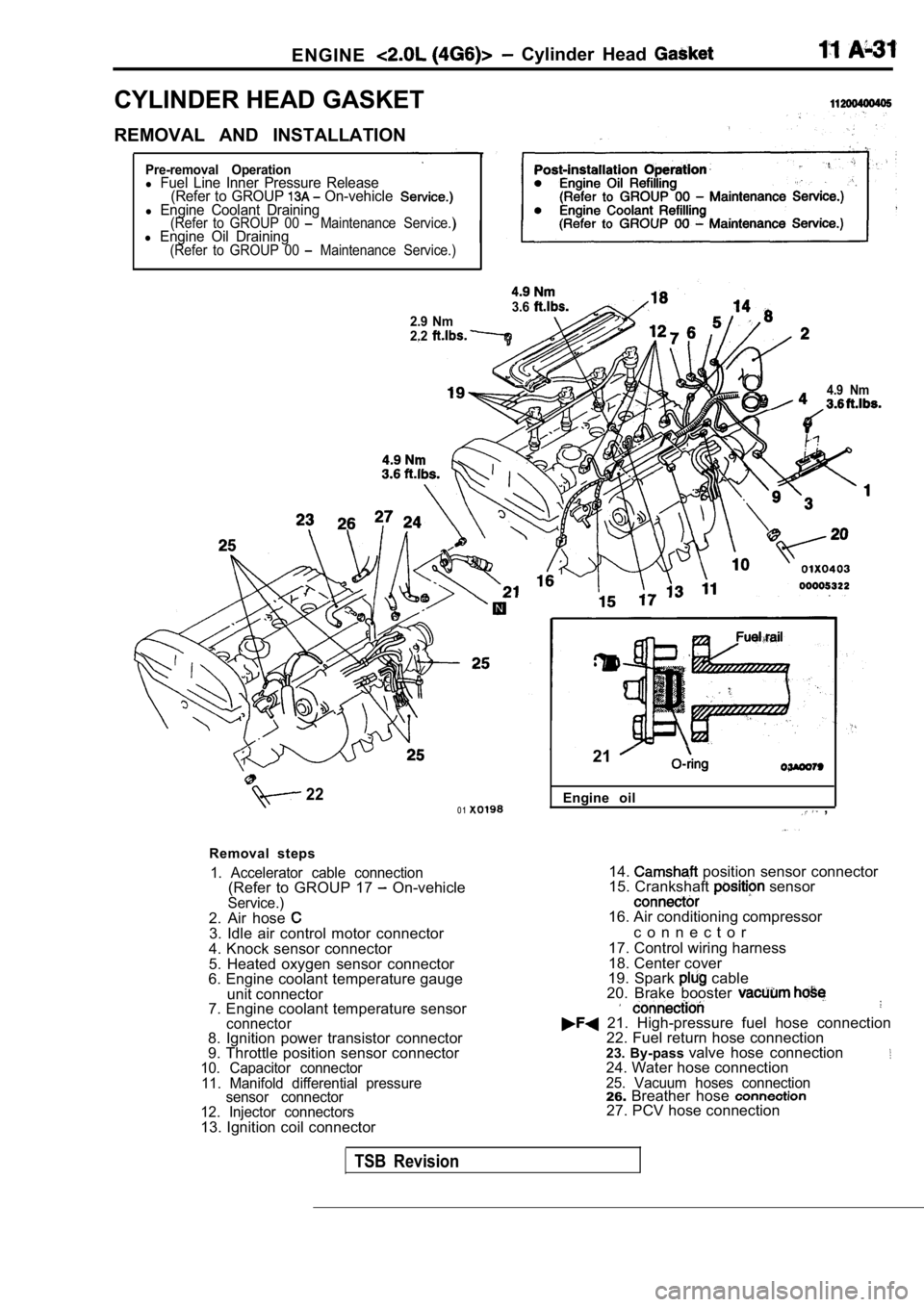

ENGINE Cylinder Head

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal Operationl Fuel Line Inner Pressure Release(Refer to GROUP On-vehiclel Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)l Engine Oil Draining(Refer to GROUP 00 Maintenance Service.)

3.62.9 Nm

2.2

4.9 Nm

220 1

Removal steps

1. Accelerator cable connection(Refer to GROUP 17 On-vehicleService.)2. Air hose 3. Idle air control motor connector

4. Knock sensor connector

5. Heated oxygen sensor connector

6. Engine coolant temperature gauge

unit connector

7. Engine coolant temperature sensor

connector8. Ignition power transistor connector

9. Throttle position sensor connector

10. Capacitor connector

11. Manifold differential pressure sensor connector

12. Injector connectors

13. Ignition coil connector Engine oil

,

21

14. position sensor connector

15. Crankshaft sensor

16. Air conditioning compressor

c o n n e c t o r

17. Control wiring harness

18. Center cover

19. Spark

cable

20. Brake booster

21. High-pressure fuel hose connection 22. Fuel return hose connection

23. By-pass valve hose connection

24. Water hose connection25. Vacuum hoses connection26.Breather hose 27. PCV hose connection

TSB Revision

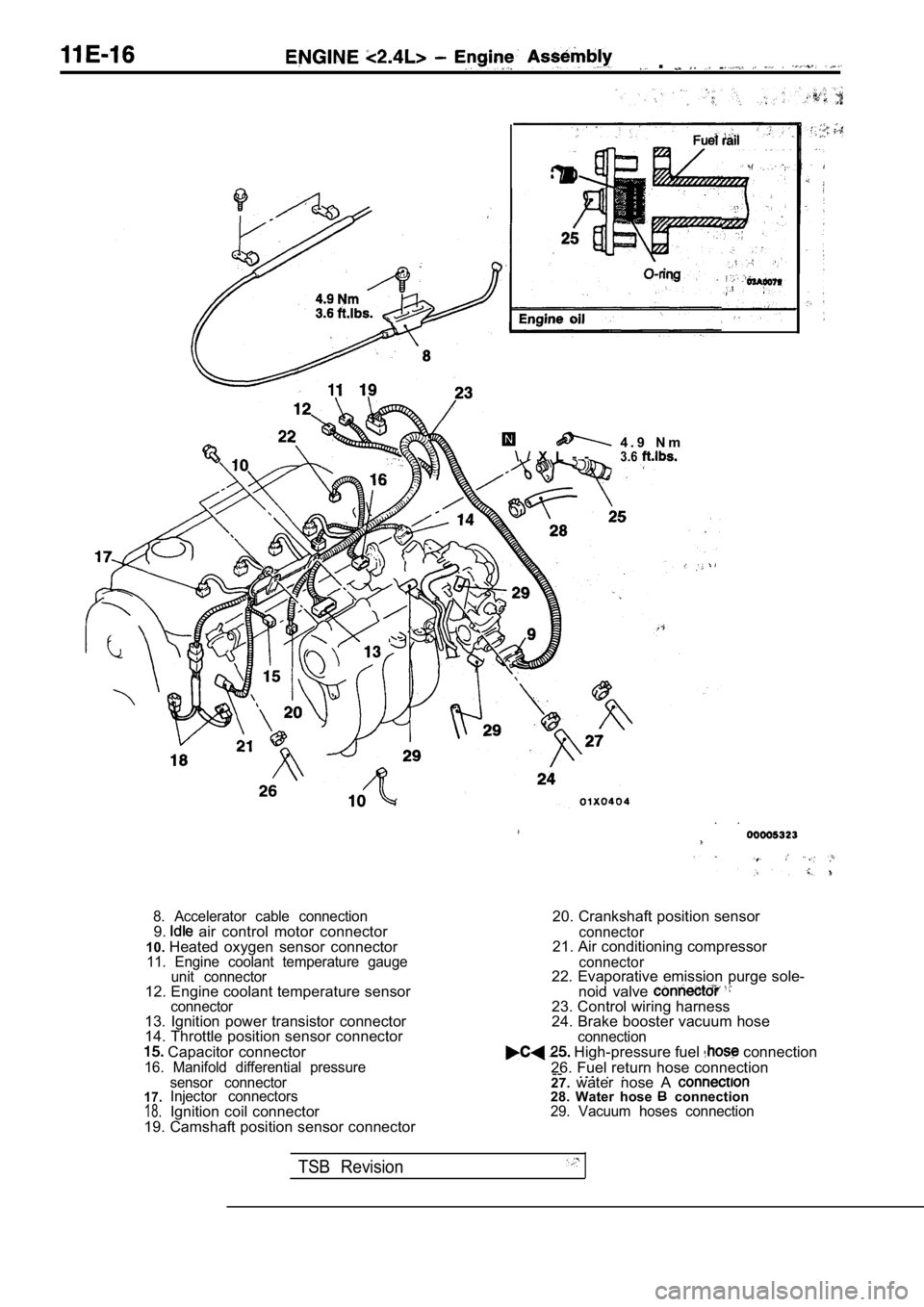

Page 284 of 2103

.

4 . 9 N m

\ / X L - -3.6

. .

8. Accelerator cable connection9. air control motor connector

10. Heated oxygen sensor connector

11. Engine coolant temperature gauge

unit connector

12. Engine coolant temperature sensorconnector13. Ignition power transistor connector

14. Throttle position sensor connector

Capacitor connector16. Manifold differential pressure

20. Crankshaft position sensor

connector21. Air conditioning compressor

connector22. Evaporative emission purge sole-

noid valve

23. Control wiring harness

24. Brake booster vacuum hose

connection High-pressure fuel connection

26. Fuel return hose connection --

. .. .

17.18.

sensor connector

Injector connectors

Ignition coil connector

19. Camshaft position sensor connector 27.

water nose A 28. Water hose connection29. Vacuum hoses connection

TSB Revision

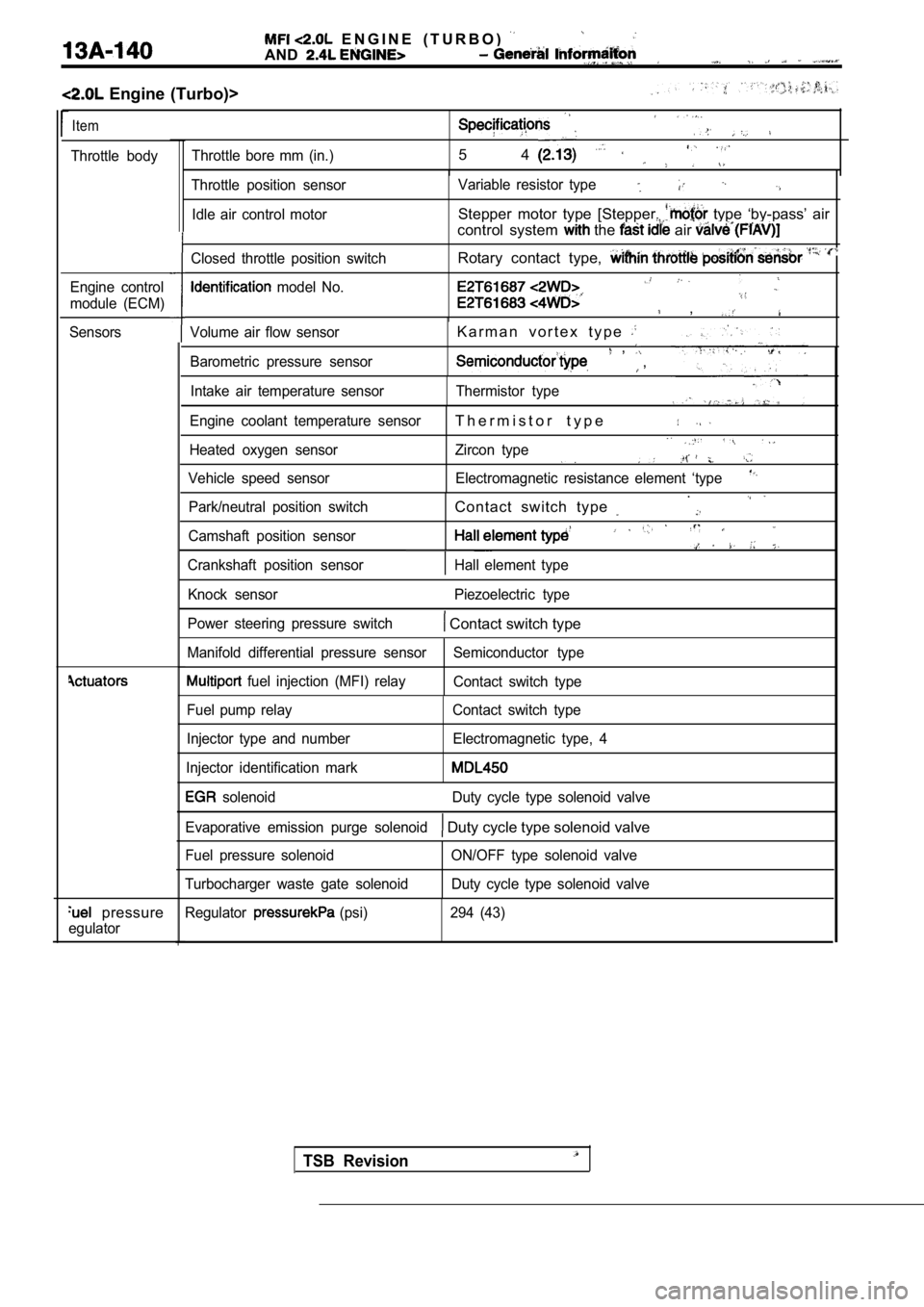

Page 520 of 2103

E N G I N E ( T U R B O )

AND

Engine (Turbo)>

Item

Throttle bodyThrottle bore mm (in.)5 4

Engine control

module (ECM)

Sensors

pressure

egulator

Volume air flow sensor

Barometric pressure sensorK a r m a n v o r t e x t y p e , ,

Intake air temperature sensor Thermistor type

Engine coolant temperature sensor

T h e r m i s t o r t y p e

Heated oxygen sensor Zircon type

Vehicle speed sensor Electromagnetic resistance elem ent ‘type

Park/neutral position switchContact switch type .

Camshaft position sensor

Crankshaft position sensorHall element type

Throttle position sensor

Idle air control motor Variable resistor type

Stepper motor type [Stepper. type ‘by-pass’ air

control system

the air

Closed throttle position switch

model No.

Rotary contact type,

,

Knock sensor Piezoelectric type

Power steering pressure switch

Contact switch type

Manifold differential pressure sensor Semiconductor type

fuel injection (MFI) relay

Contact switch type

Fuel pump relay

Injector type and number

Injector identification mark Contact switch type

Electromagnetic type, 4

solenoid Duty cycle type solenoid valve

Evaporative emission purge solenoid

Duty cycle type solenoid valve

Fuel pressure solenoid

Turbocharger waste gate solenoid ON/OFF type solenoid valve

Duty cycle type solenoid valve

Regulator

(psi) 294 (43)

TSB Revision

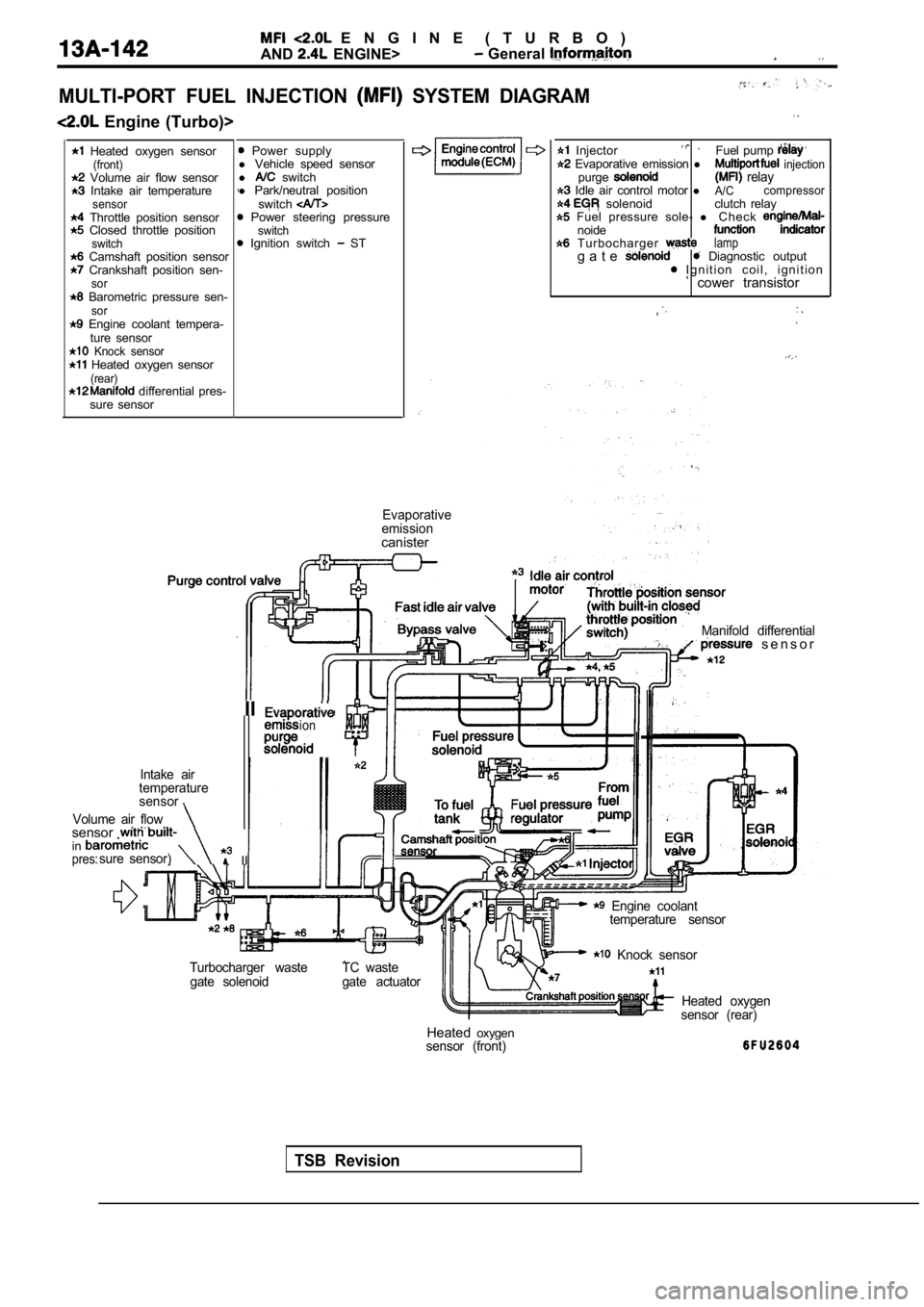

Page 522 of 2103

E N G I N E ( T U R B O )

AND

ENGINE> General . .

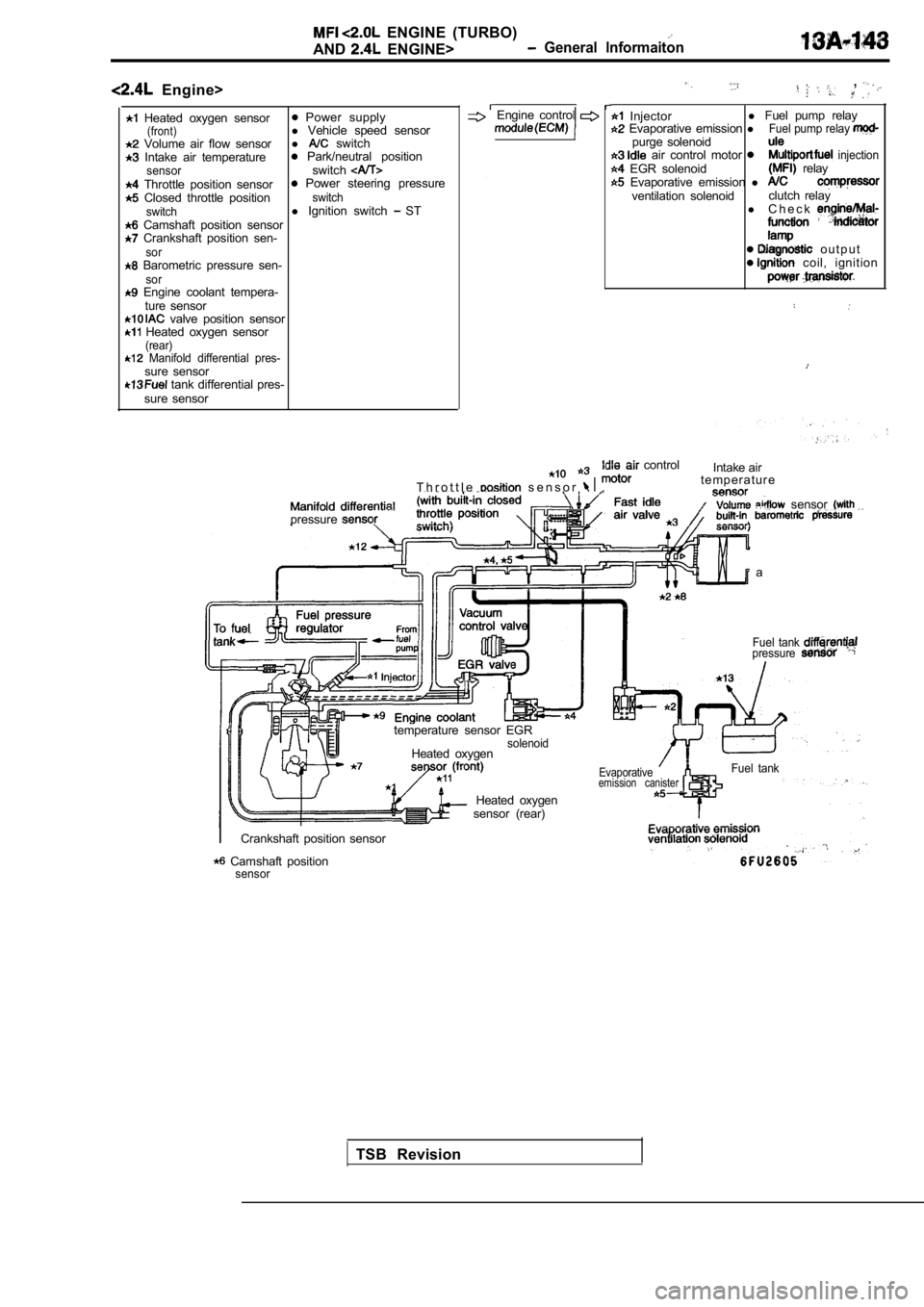

MULTI-PORT FUEL INJECTION SYSTEM DIAGRAM

Engine (Turbo)>

Heated oxygen sensor(front) Volume air flow sensor Intake air temperaturesensor Throttle position sensor Closed throttle positionswitch Camshaft position sensor Crankshaft position sen-sor Barometric pressure sen-sor Engine coolant tempera- ture sensor

Knock sensor Heated oxygen sensor(rear) differential pres-

sure sensor

Power supply

l Vehicle speed sensor

l

switch

l Park/neutral position

switch

Power steering pressureswitch Ignition switch ST

Enginecontrol Injector . Fuel pump

Evaporative emission l injectionpurge relay Idle air control motor lA/Ccompressor solenoid clutch relay Fuel pressure sole-

l C h e c knoide T u r b o c h a r g e r lampg a t e Diagnostic output I g n i t i o n c o i l , i g n i t i o n cower transistor

,

Evaporative

emission

canister

TSB Revision

Manifold differential s e n s o r

IIion. .

Intake air

temperature

sensor

Volume air flow

sensor . insure sensor) IIpres:

Engine coolant temperature sensor

Turbocharger waste gate solenoid TC waste

gate actuator

Knock sensor

Heated oxygen

sensor (rear)

Heated oxygensensor (front)

Page 523 of 2103

ENGINE (TURBO)

AND ENGINE> General lnformaiton

Engine>

Heated oxygen sensor Power supply(front)l Vehicle speed sensor Volume air flow sensor l switch Intake air temperature Park/neutral positionsensorswitch Throttle position sensor Power steering pressure Closed throttle positionswitch

switchl Ignition switch ST Camshaft position sensor Crankshaft position sen-sor Barometric pressure sen-sor Engine coolant tempera-

ture sensor

valve position sensor Heated oxygen sensor(rear) Manifold differential pres-sure sensor tank differential pres-

sure sensor

,

Engine control Injector l

Fuel pump relay Evaporative emission lFuel pump relay purge solenoid air control motor injection EGR solenoid relay Evaporative emission l ventilation solenoid clutch relay

l C h e c k

o u t p u t coil, ignition

T h r o t t l e s e n s o r ,

control

Intake air

t e m p e r a t u r e

. . . sensor pressure

a

temperature sensor EGR

solenoidHeated oxygen

Fuel tank pressure

sensor (rear) Heated oxygen

Evaporativeemission canisterFuel tank

Crankshaft position sensor

Camshaft positionsensor

TSB Revision

Page 528 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

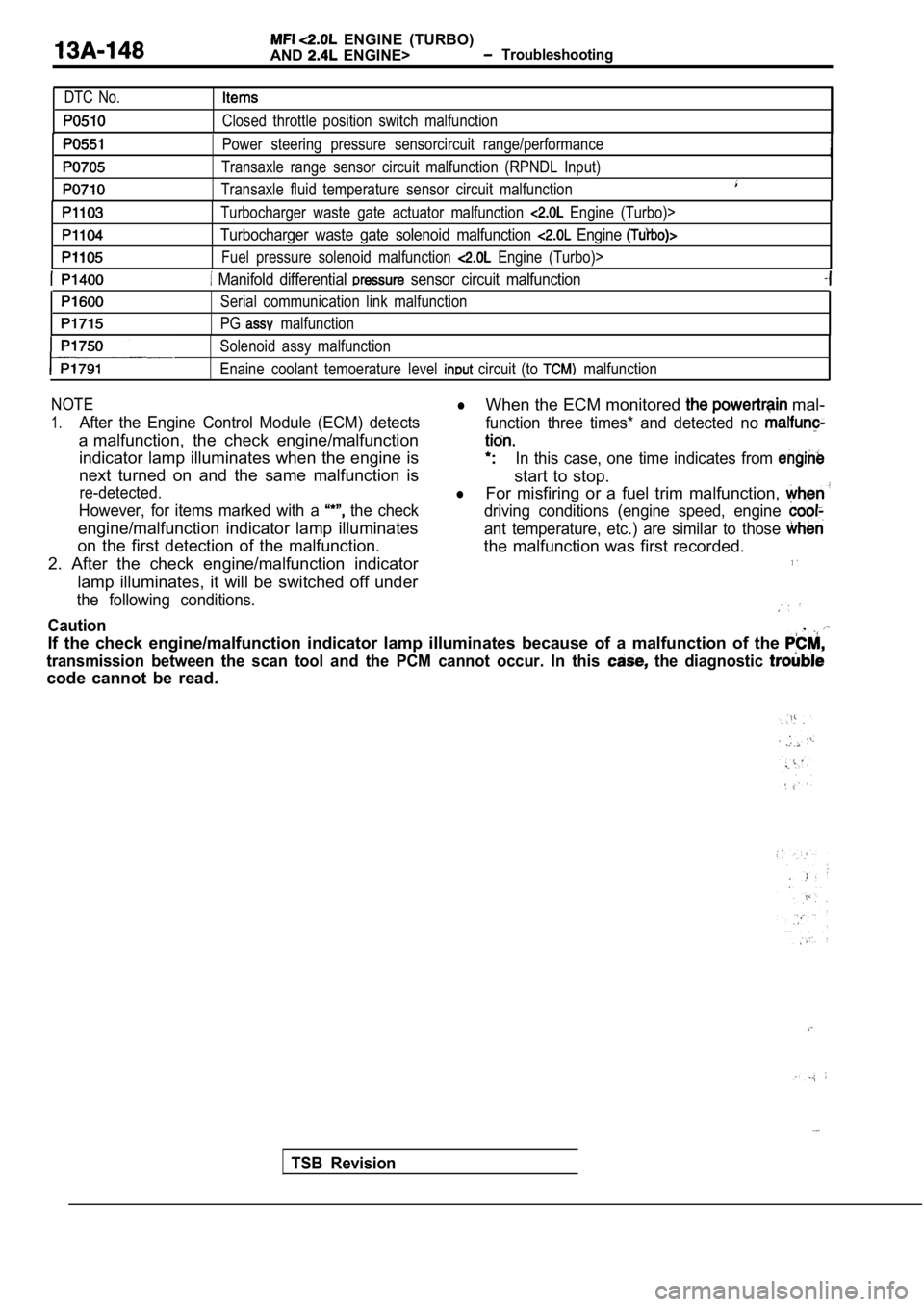

DTC No.

Closed throttle position switch malfunction

Power steering pressure sensorcircuit range/perfor mance

Transaxle range sensor circuit malfunction (RPNDL Input)

Transaxle fluid temperature sensor circuit malfunct ion

Turbocharger waste gate actuator malfunction Engine (Turbo)>

Turbocharger waste gate solenoid malfunction Engine

Fuel pressure solenoid malfunction Engine (Turbo)>

Manifold differential sensor circuit malfunction

Serial communication link malfunction

PG

malfunction

Solenoid assy malfunction

Enaine coolant temoerature level

circuit (to malfunction

NOTElWhen the ECM monitored mal-

1.After the Engine Control Module (ECM) detects function three times* and detected no

a malfunction, the check engine/malfunction

indicator lamp illuminates when the engine isIn this case, one time indicates from

next turned on and the same malfunction is

start to stop.

re-detected.lFor misfiring or a fuel trim malfunction,

However, for items marked with a the checkdriving conditions (engine speed, engine

engine/malfunction indicator lamp illuminatesant temperature, etc.) are similar to those

on the first detection of the malfunction. the malfunction was first recorded.

2. After the check engine/malfunction indicator

lamp illuminates, it will be switched off under

the following conditions.

Caution,

If the check engine/malfunction indicator lamp illu minates because of a malfunction of the

transmission between the scan tool and the PCM cann ot occur. In this the diagnostic

code cannot be read.

TSB Revision