roof MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 11 of 2103

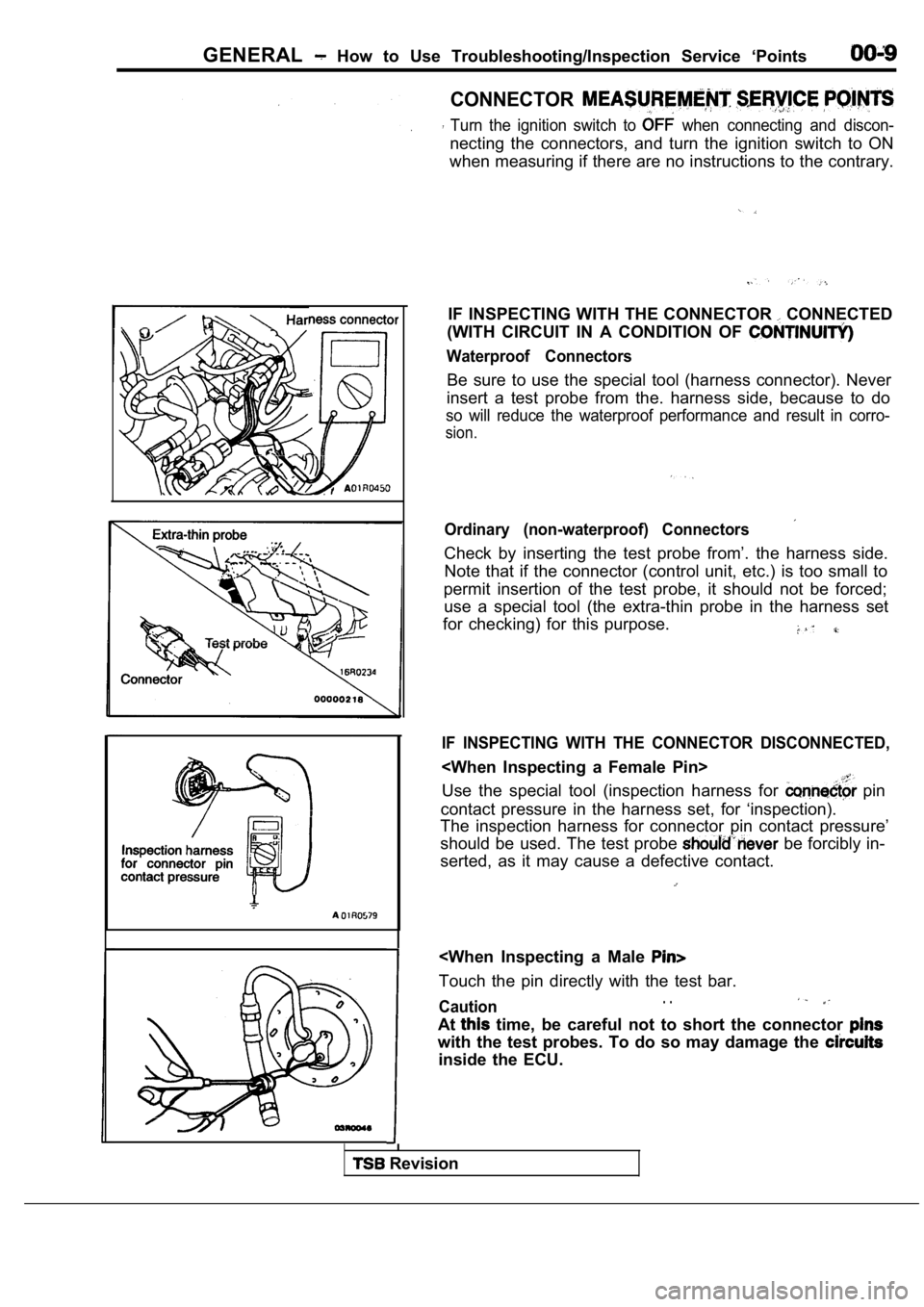

GENERAL How to Use Troubleshooting/Inspection Service ‘Points

CONNECTOR

Turn the ignition switch to when connecting and discon-

necting the connectors, and turn the ignition switch to ON

when measuring if there are no instructions to the contrary.

IF INSPECTING WITH THE CONNECTOR

CONNECTED

(WITH CIRCUIT IN A CONDITION OF

Waterproof Connectors

Be sure to use the special tool (harness connector) . Never

insert a test probe from the. harness side, because to do

so will reduce the waterproof performance and result in corro-

sion.

Ordinary (non-waterproof) Connectors

Check by inserting the test probe from’. the harness side.

Note that if the connector (control unit, etc.) is too small to

permit insertion of the test probe, it should not b e forced;

use a special tool (the extra-thin probe in the har ness set

for checking) for this purpose.

IF INSPECTING WITH THE CONNECTOR DISCONNECTED,

Use the special tool (inspection harness for

pin

contact pressure in the harness set, for ‘inspectio n).

The inspection harness for connector pin contact pr essure’

should be used. The test probe

be forcibly in-

serted, as it may cause a defective contact.

Caution. .

At time, be careful not to short the connector

with the test probes. To do so may damage the

inside the ECU.

Revision

Page 57 of 2103

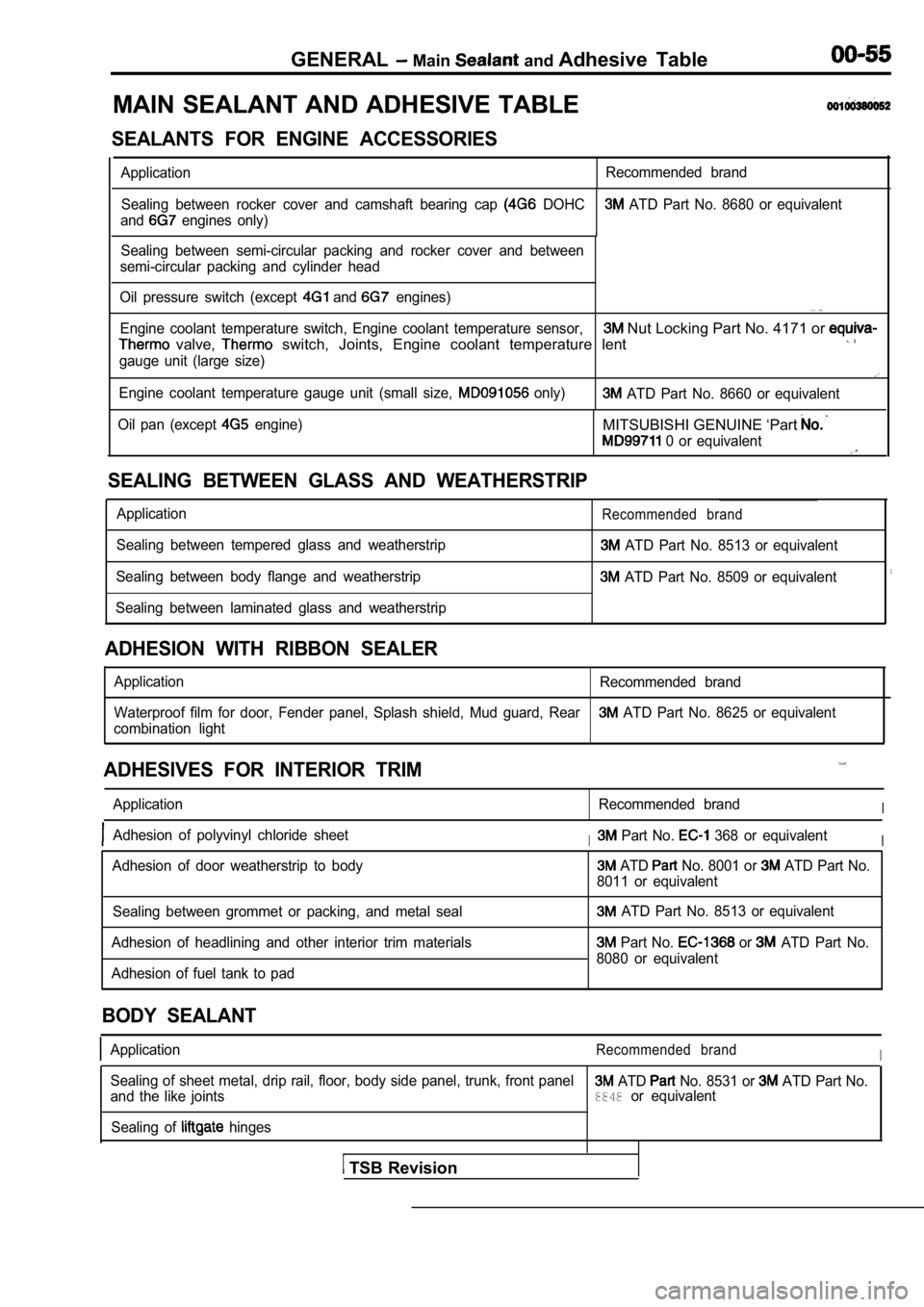

GENERAL Main and Adhesive Table

MAIN SEALANT AND ADHESIVE TABLE

SEALANTS FOR ENGINE ACCESSORIES

Application Recommended brand

Sealing between rocker cover and camshaft bearing c ap

DOHC ATD Part No. 8680 or equivalent

and

engines only)

1Sealing between semi-circular packing and rocker co ver and between

semi-circular packing and cylinder head

Oil pressure switch (except

and engines). . .

Engine coolant temperature switch, Engine coolant t emperature sensor, Nut Locking Part No. 4171 or

valve, switch, Joints, Engine coolant temperature lent

gauge unit (large size)

Engine coolant temperature gauge unit (small size, only) ATD Part No. 8660 or equivalent

Oil pan (except

engine)MITSUBISHI GENUINE ‘Part

0 or equivalent

SEALING BETWEEN GLASS AND WEATHERSTRIP

Application

Sealing between tempered glass and weatherstrip

Sealing between body flange and weatherstrip

Sealing between laminated glass and weatherstripRecommended brand

ATD Part No. 8513 or equivalent

ATD Part No. 8509 or equivalent

ADHESION WITH RIBBON SEALER

Application Recommended brand

Waterproof film for door, Fender panel, Splash shie ld, Mud guard, Rear

ATD Part No. 8625 or equivalent

combination light

ADHESIVES FOR INTERIOR TRIM

Application Recommended brandI

Adhesion of polyvinyl chloride sheetI Part No. 368 or equivalentI

Adhesion of door weatherstrip to body ATD No. 8001 or ATD Part No.

8011 or equivalent

Sealing between grommet or packing, and metal seal

Adhesion of headlining and other interior trim mate rials

Adhesion of fuel tank to pad

ATD Part No. 8513 or equivalent

Part No. or ATD Part No.

8080 or equivalent

BODY SEALANT

ApplicationRecommended brandI

Sealing of sheet metal, drip rail, floor, body side panel, trunk, front panel ATD No. 8531 or ATD Part No.

and the like joints8848or equivalent

Sealing of

hinges

TSB Revision

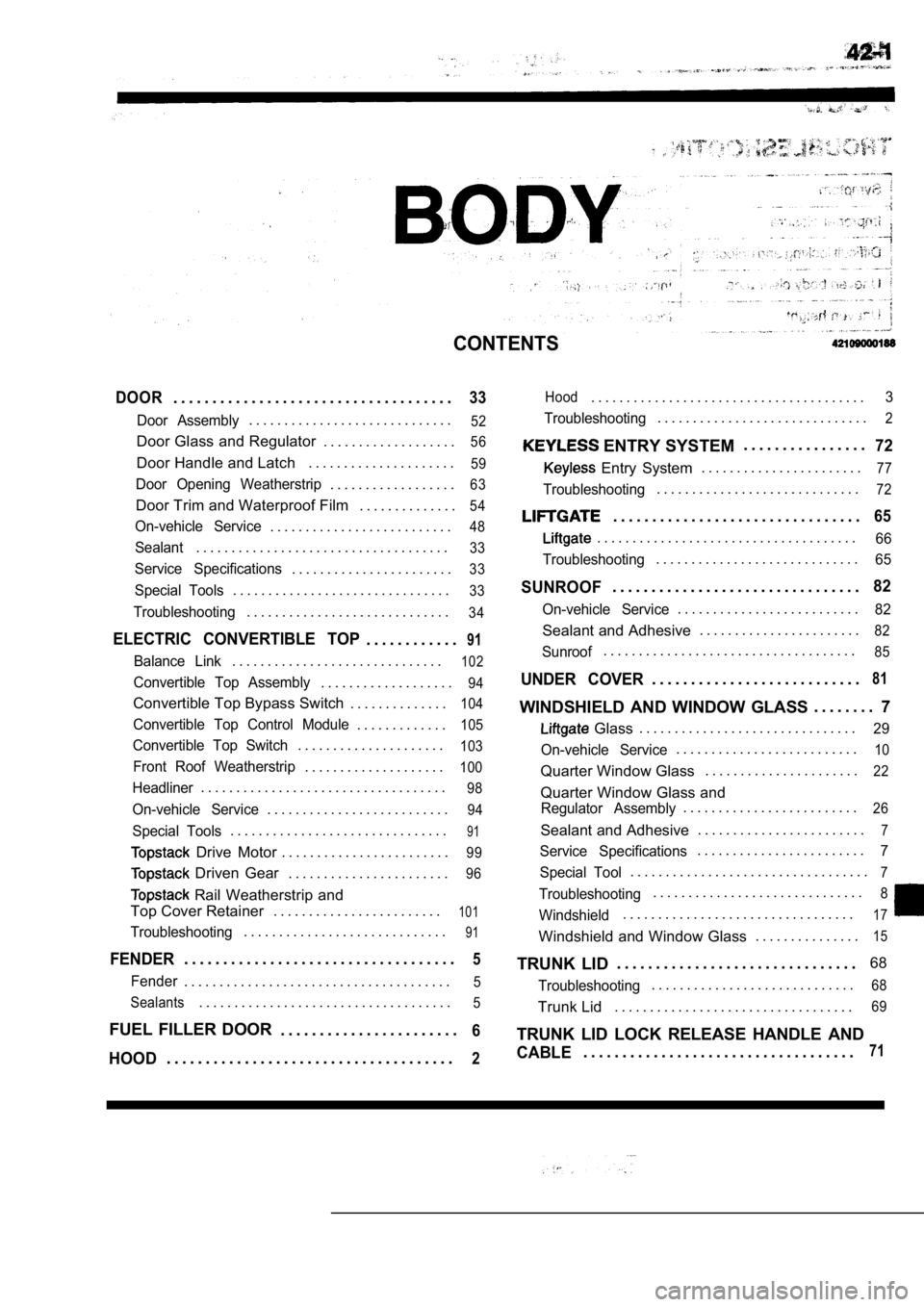

Page 1825 of 2103

CONTENTS

DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Door Glass and Regulator . . . . . . . . . . . . . . . . . . .56

Door Handle and Latch. . . . . . . . . . . . . . . . . . . . .59

Door Opening Weatherstrip. . . . . . . . . . . . . . . . . .63

Door Trim and Waterproof Film . . . . . . . . . . . . . .54

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .48

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Service Specifications. . . . . . . . . . . . . . . . . . . . . . .33

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

ELECTRIC CONVERTIBLE TOP. . . . . . . . . . . .91

Balance Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Convertible Top Assembly. . . . . . . . . . . . . . . . . . .94

Convertible Top Bypass Switch . . . . . . . . . . . . . .104

Convertible Top Control Module. . . . . . . . . . . . .105

Convertible Top Switch. . . . . . . . . . . . . . . . . . . . .103

Front Roof Weatherstrip. . . . . . . . . . . . . . . . . . . .100

Headliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .94

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Drive Motor. . . . . . . . . . . . . . . . . . . . . . . .99

Driven Gear . . . . . . . . . . . . . . . . . . . . . . .96

Rail Weatherstrip and

Top Cover Retainer . . . . . . . . . . . . . . . . . . . . . . . .

101

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

FENDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sealants

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUEL FILLER DOOR . . . . . . . . . . . . . . . . . . . . . . .6

HOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ENTRY SYSTEM . . . . . . . . . . . . . . . .72

Entry System

. . . . . . . . . . . . . . . . . . . . . . .77

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

SUNROOF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .82

Sealant and Adhesive . . . . . . . . . . . . . . . . . . . . . . .82

Sunroof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

UNDER COVER. . . . . . . . . . . . . . . . . . . . . . . . . . .81

WINDSHIELD AND WINDOW GLASS . . . . . . . .

7

Glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

On-vehicle Service

. . . . . . . . . . . . . . . . . . . . . . . . . .10

Quarter Window Glass . . . . . . . . . . . . . . . . . . . . . .22

Quarter Window Glass and

Regulator Assembly. . . . . . . . . . . . . . . . . . . . . . . . .26

Sealant and Adhesive. . . . . . . . . . . . . . . . . . . . . . . .7

Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .7

Special Tool

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Windshield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Windshield and Window Glass . . . . . . . . . . . . . . .15

TRUNK LID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Trunk Lid

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

TRUNK LID LOCK RELEASE HANDLE AND

CABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

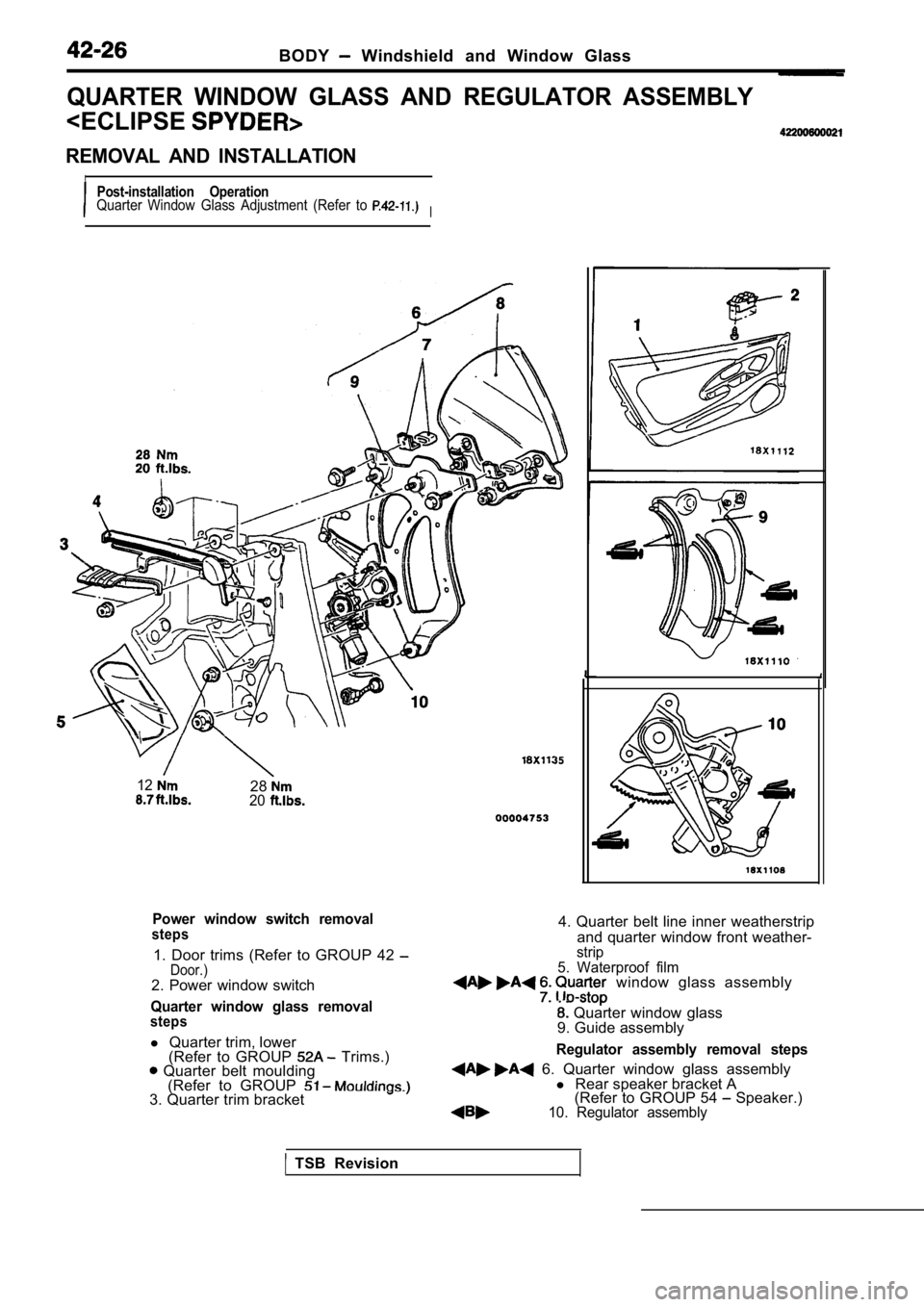

Page 1850 of 2103

BODY Windshield and Window Glass

QUARTER WINDOW GLASS AND REGULATOR ASSEMBLY

IPost-installation OperationQuarter Window Glass Adjustment (Refer to I

122820

Power window switch removalsteps

1. Door trims (Refer to GROUP 42 Door.)2. Power window switch

Quarter window glass removalsteps

l Quarter trim, lower

(Refer to GROUP Trims.) Quarter belt moulding (Refer to GROUP

3. Quarter trim bracket

4. Quarter belt line inner weatherstrip

and quarter window front weather-

strip

5. Waterproof film

window glass assembly

Quarter window glass

9. Guide assembly

Regulator assembly removal steps

6. Quarter window glass assembly l Rear speaker bracket A

(Refer to GROUP 54 Speaker.)10. Regulator assembly

TSB Revision

Page 1851 of 2103

BODY Windshield Window

Section A A

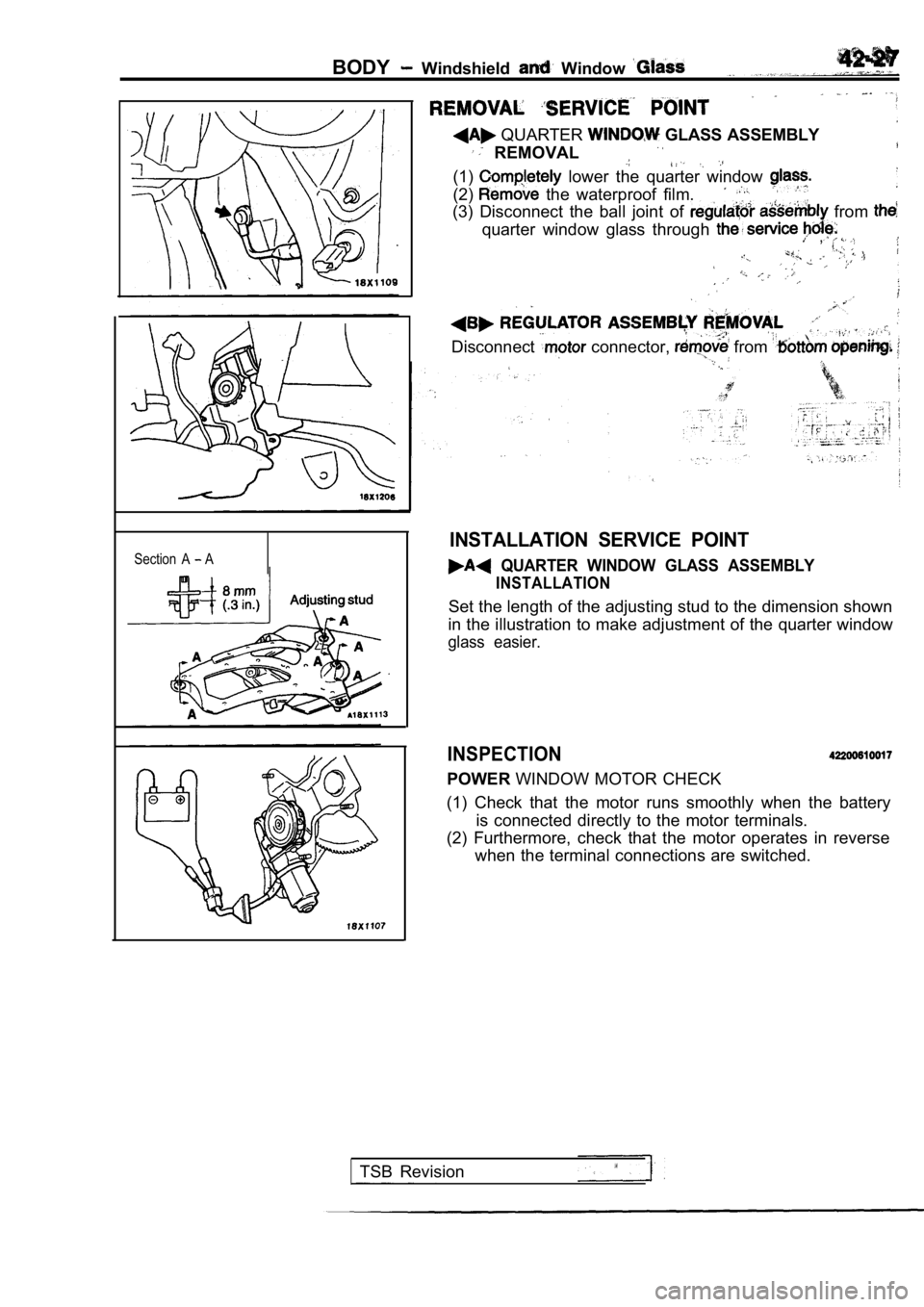

QUARTER GLASS ASSEMBLY

REMOVAL

(1) lower the quarter window

(2) the waterproof film.

(3) Disconnect the ball joint of from

quarter window glass through ,

Disconnect connector, from

INSTALLATION SERVICE POINT

QUARTER WINDOW GLASS ASSEMBLY

INSTALLATION

Set the length of the adjusting stud to the dimension shown

in the illustration to make adjustment of the quart er window

glass easier.

INSPECTION

POWERWINDOW MOTOR CHECK

(1) Check that the motor runs smoothly when the bat tery

is connected directly to the motor terminals.

(2) Furthermore, check that the motor operates in r everse

when the terminal connections are switched.

TSB Revision

Page 1857 of 2103

BODY,

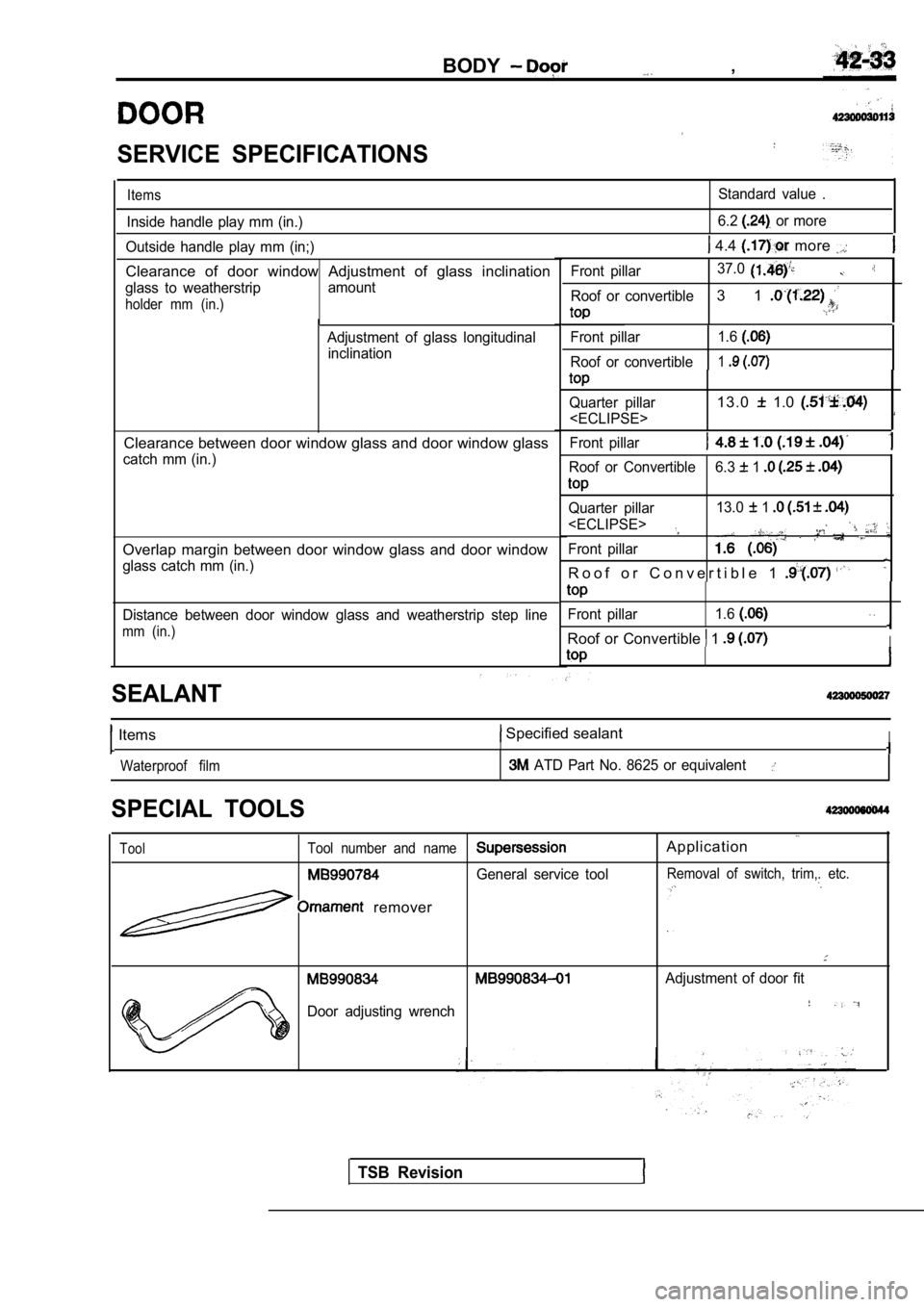

SERVICE SPECIFICATIONS

Items

Inside handle play mm (in.)Standard value .

6.2 or more

Outside handle play mm (in;)

Clearance of door window Adjustment of glass inclin ation

glass to weatherstripamount

holder mm (in.)

Adjustment of glass longitudinal

inclination

Clearance between door window glass and door window glass

catch mm (in.)

Overlap margin between door window glass and door w indow

glass catch mm (in.)

Distance between door window glass and weatherstrip step line

mm (in.)

4.4 more

Front pillar37.0

Roof or convertible3 1

Front pillar

1.6

Roof or convertible1

Quarter pillar

Front pillar

SEALANT

Roof or Convertible 6.3 1

Quarter pillar 13.0 1

Front pillar

R o o f o r C o n v e r t i b l e 1

Front pillar

1.6

Roof or Convertible 1 I

Items Specified sealantII

Waterproof film ATD Part No. 8625 or equivalent

SPECIAL TOOLS

ToolTool number and nameApplication

General service toolRemoval of switch, trim,. etc.

remover

Adjustment of door fit

Door adjusting wrench

TSB Revision

Page 1870 of 2103

BODY Door

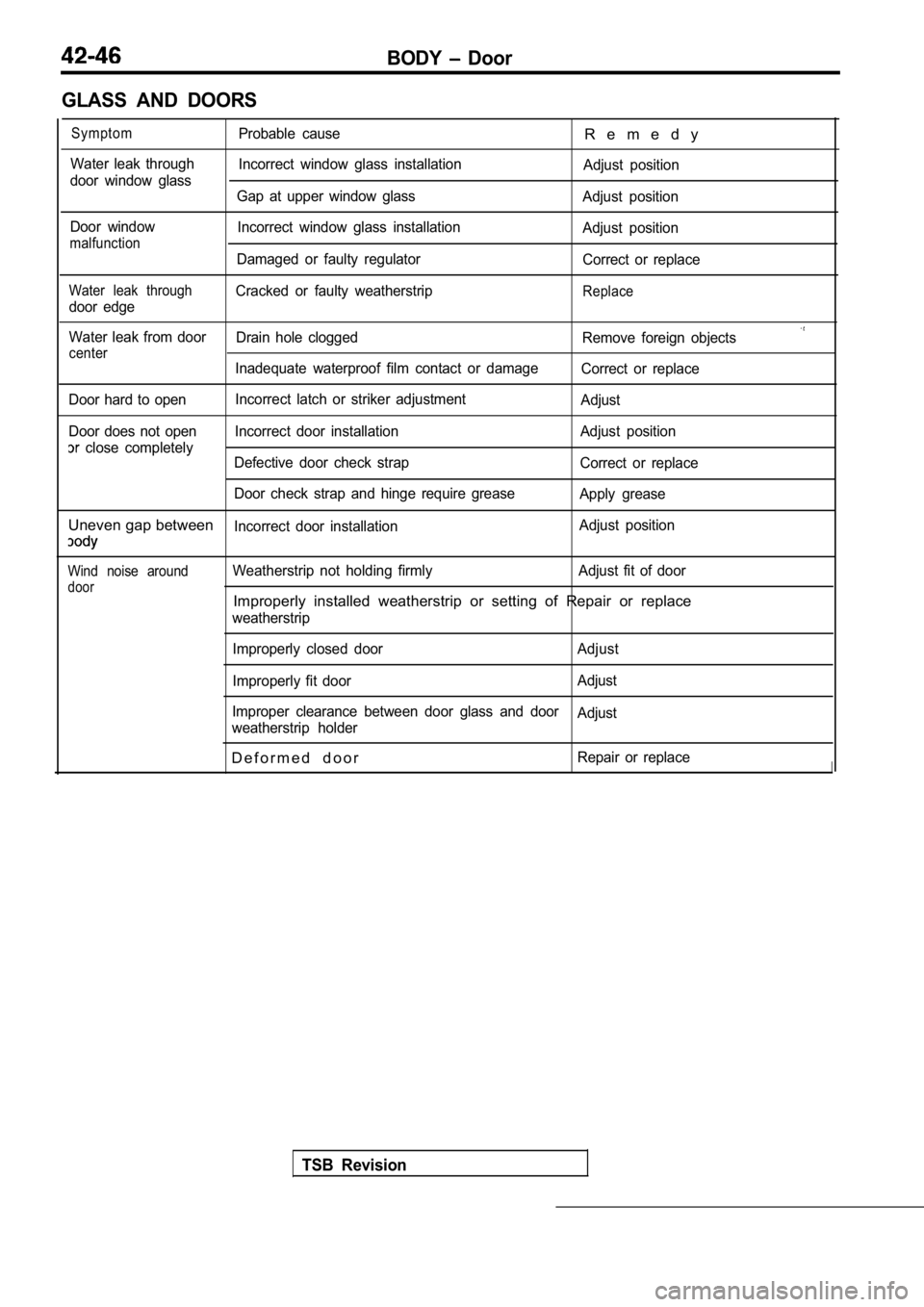

GLASS AND DOORS

SymptomProbable causeR e m e d y

Water leak through Incorrect window glass installation

Adjust position

door window glass Gap at upper window glass Adjust position

Door window Incorrect window glass installation

Adjust position

malfunction

Damaged or faulty regulator Correct or replace

Water leak throughCracked or faulty weatherstripReplace

door edge

Water leak from doorDrain hole clogged

Remove foreign objects

centerInadequate waterproof film contact or damageCorrect or replace

Door hard to open Incorrect latch or striker adjustment

Adjust

Door does not open Incorrect door installation Adjust position

close completely

Defective door check strap Correct or replace

Door check strap and hinge require grease Apply grease

Uneven gap betweenIncorrect door installationAdjust position

Wind noise around

door

Weatherstrip not holding firmly Adjust fit of door

Improperly installed weatherstrip or setting of Rep

air or replace

weatherstrip

Improperly closed door Adjust

Improperly fit door Adjust

Improper clearance between door glass and door Adjust

weatherstrip holder

D e f o r m e d d o o rRepair or replaceI

TSB Revision

Page 1872 of 2103

42-48BODY Door

Delta sashInner stabilizer

track

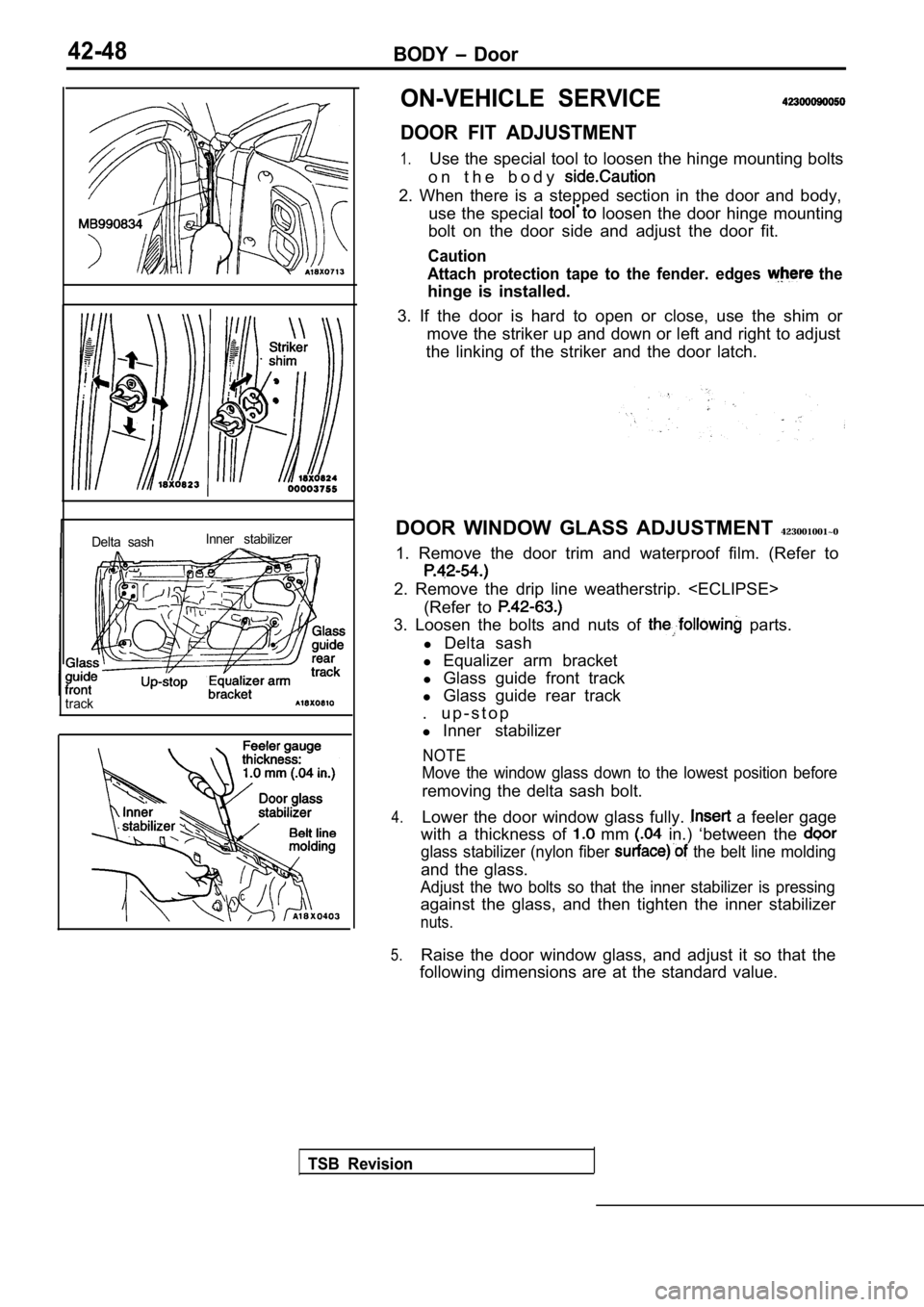

ON-VEHICLE SERVICE

DOOR FIT ADJUSTMENT

1.Use the special tool to loosen the hinge mounting b

olts

o n t h e b o d y

2. When there is a stepped section in the door and body,

use the special

loosen the door hinge mounting

bolt on the door side and adjust the door fit.

Caution

Attach protection tape to the fender. edges

the

hinge is installed.

3. If the door is hard to open or close, use the sh im or

move the striker up and down or left and right to a djust

the linking of the striker and the door latch.

DOOR WINDOW GLASS ADJUSTMENT 423001001~0

1. Remove the door trim and waterproof film. (Refer to

2. Remove the drip line weatherstrip.

(Refer to

3. Loosen the bolts and nuts of parts.

l Delta sash

l Equalizer arm bracket

l Glass guide front track

l Glass guide rear track

. u p - s t o p

l Inner stabilizer

NOTE

Move the window glass down to the lowest position b efore

removing the delta sash bolt.

4.Lower the door window glass fully. a feeler gage

with a thickness of

mm in.) ‘between the

glass stabilizer (nylon fiber the belt line molding

and the glass.

Adjust the two bolts so that the inner stabilizer i s pressing

against the glass, and then tighten the inner stabi lizer

nuts.

5.Raise the door window glass, and adjust it so that the

following dimensions are at the standard value.

TSB Revision

Page 1875 of 2103

B O D Y Door

U P

Section A-A

0 0 0 0 0 1 4 5

D O W N

6 9 8 0 0 4 6

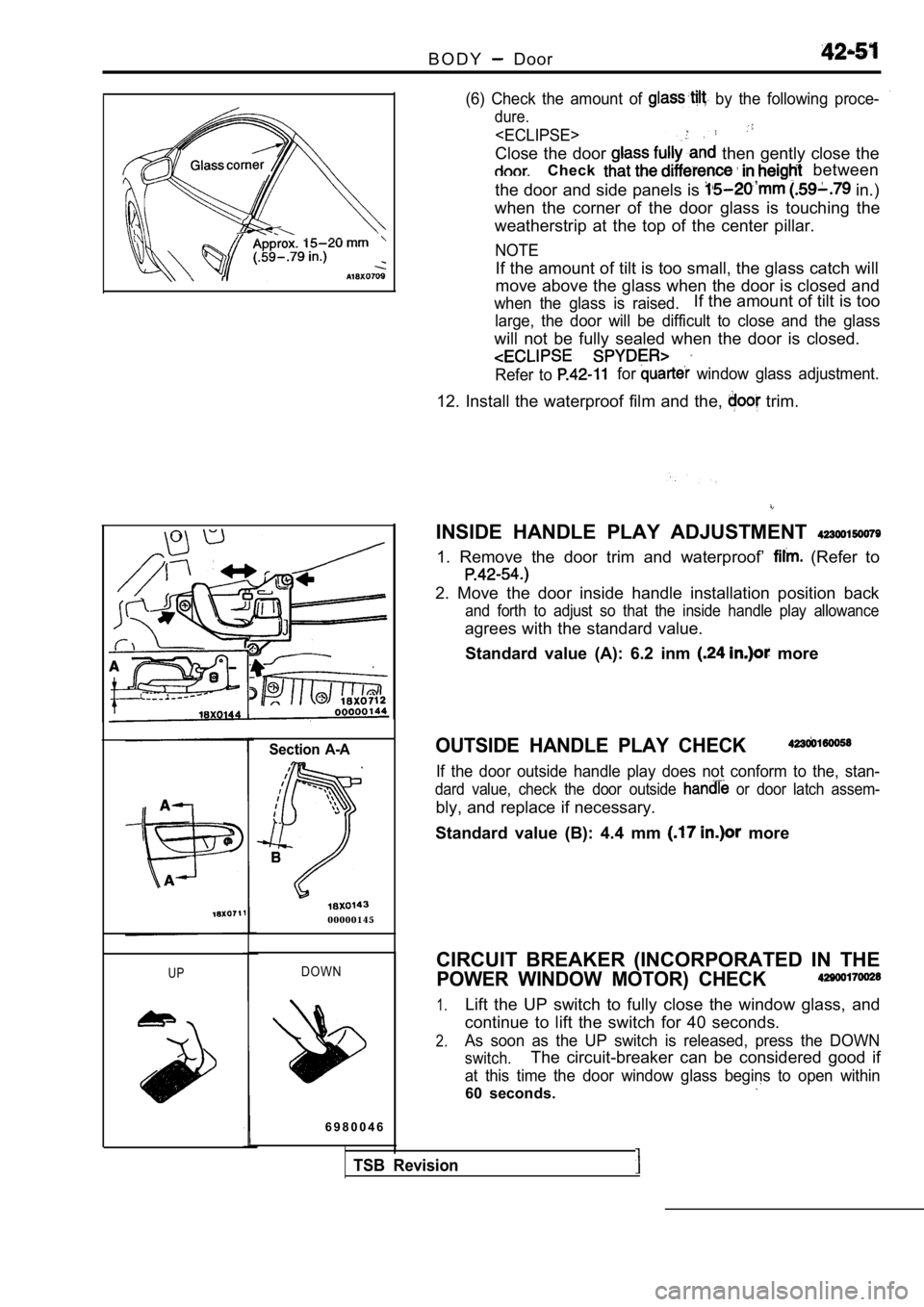

(6) Check the amount of by the following proce-

dure.

Close the door then gently close the

Check between

the door and side panels is

in.)

when the corner of the door glass is touching the

weatherstrip at the top of the center pillar.

NOTE

If the amount of tilt is too small, the glass catch will

move above the glass when the door is closed and

when the glass is raised.If the amount of tilt is too

large, the door will be difficult to close and the glass

will not be fully sealed when the door is closed.

Refer to for window glass adjustment.

12. Install the waterproof film and the, trim.

INSIDE HANDLE PLAY ADJUSTMENT

1. Remove the door trim and waterproof’ (Refer to

2. Move the door inside handle installation positio n back

and forth to adjust so that the inside handle play allowance

agrees with the standard value.

Standard value (A): 6.2 inm

more

OUTSIDE HANDLE PLAY CHECK

If the door outside handle play does not conform to the, stan-

dard value, check the door outside or door latch assem-

bly, and replace if necessary.

Standard value (B): 4.4 mm

more

TSB Revision

CIRCUIT BREAKER (INCORPORATED IN THE

POWER WINDOW MOTOR) CHECK

1.Lift the UP switch to fully close the window glass, and

continue to lift the switch for 40 seconds.

2.As soon as the UP switch is released, press the DOW N

switch.The circuit-breaker can be considered good if

at this time the door window glass begins to open within

60 seconds.

Page 1876 of 2103

42-52BODY Door

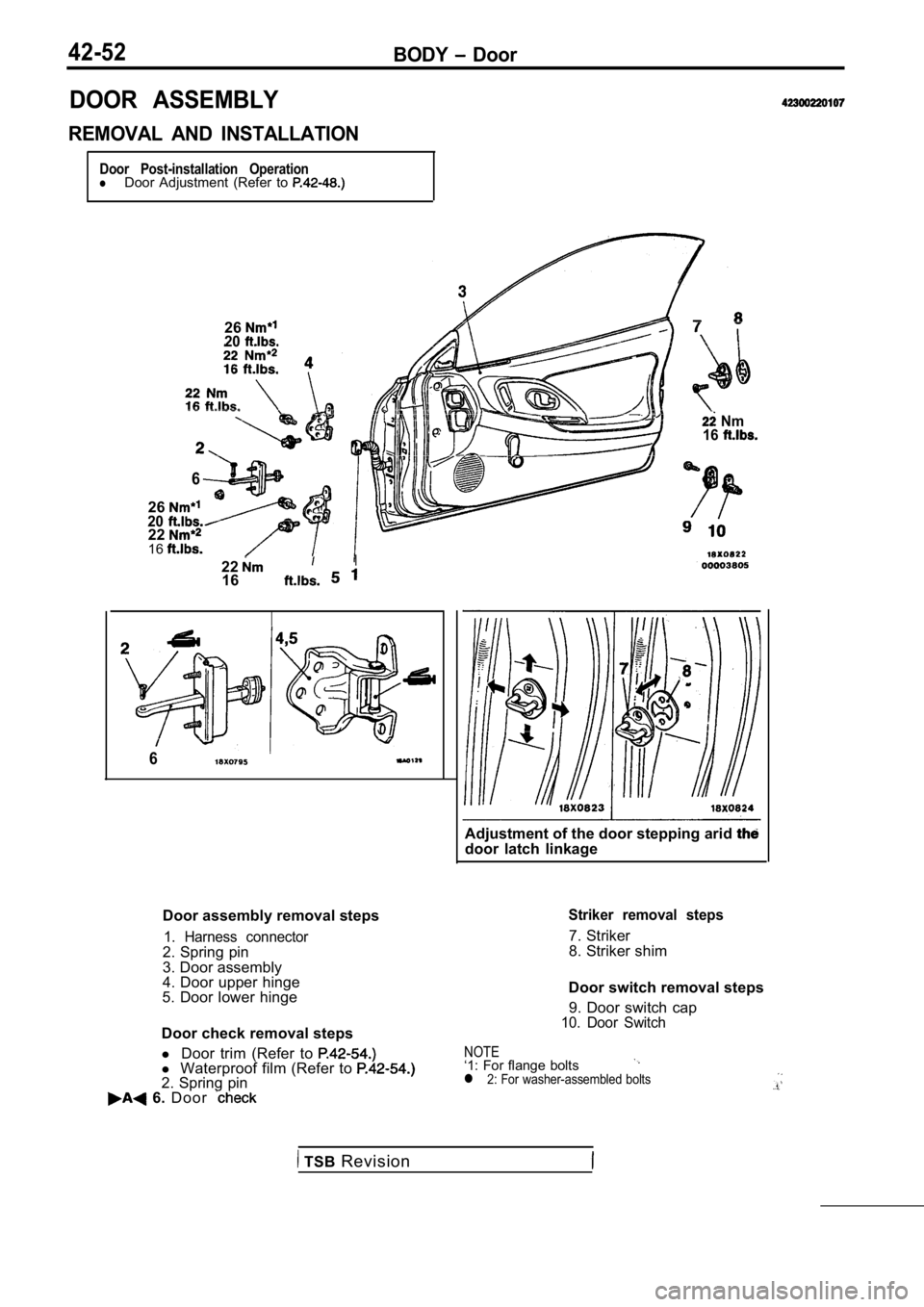

DOOR ASSEMBLY

REMOVAL AND INSTALLATION

Door Post-installation OperationlDoor Adjustment (Refer to

2620

6

26202216

22I

16

6

Door assembly removal steps

1. Harness connector2. Spring pin

3. Door assembly

4. Door upper hinge

5. Door lower hinge

Door check removal steps

l Door trim (Refer to

l Waterproof film (Refer to 2. Spring pin 6. D o o r

Nm

16

Adjustment of the door stepping arid door latch linkage

Striker removal steps

7. Striker

8. Striker shim

Door switch removal steps 9. Door switch cap

10. Door Switch

NOTE‘1: For flange boltsl 2: For washer-assembled bolts

TSB Revision