key MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 25 of 2103

GENERAL Towing and Hoisting

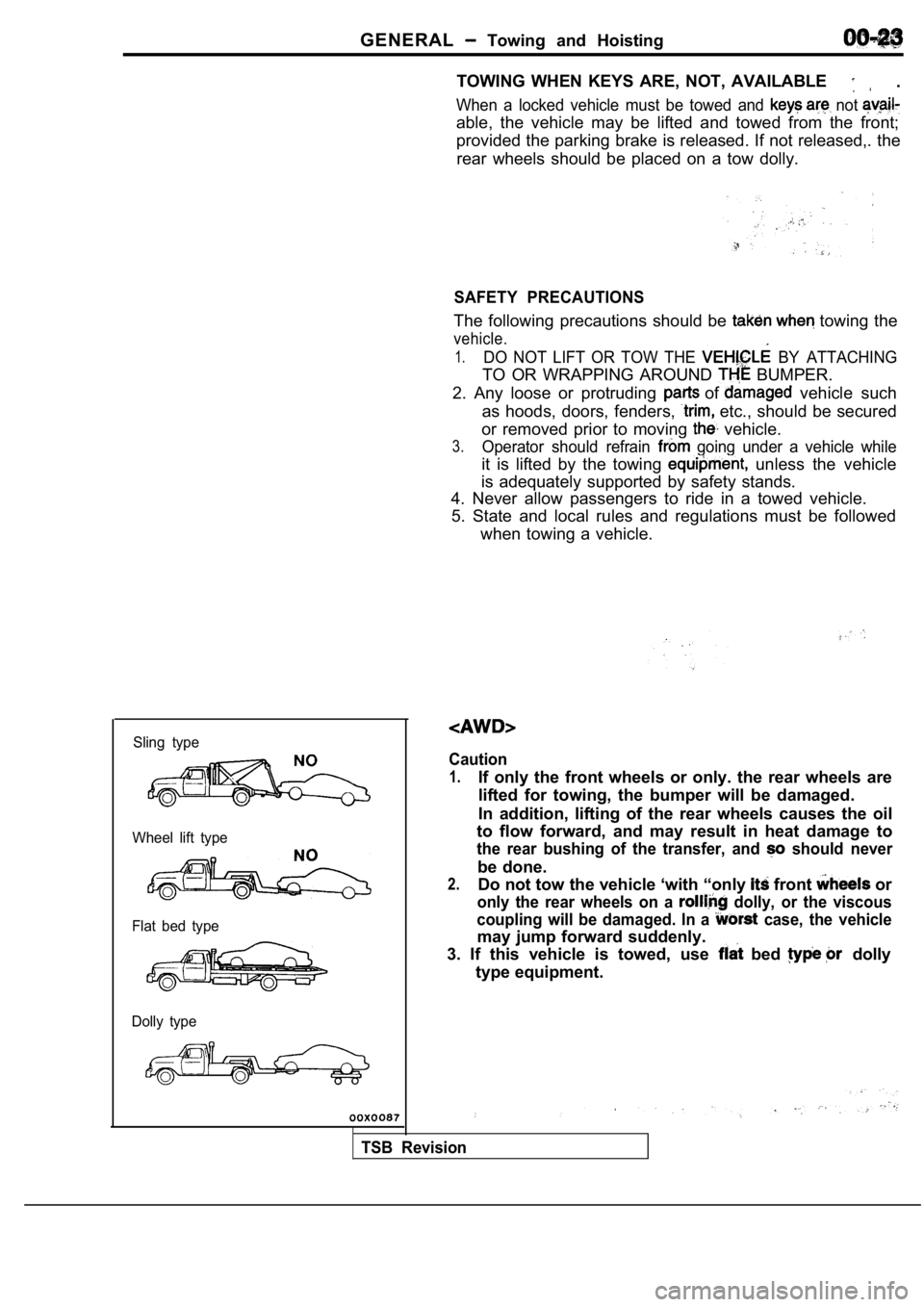

Sling type

Wheel lift type

Flat bed type

Dolly type

TOWING WHEN KEYS ARE, NOT, AVAILABLE .

When a locked vehicle must be towed and not

able, the vehicle may be lifted and towed from the front;

provided the parking brake is released. If not rele ased,. the

rear wheels should be placed on a tow dolly.

SAFETY PRECAUTIONS

The following precautions should be towing the

vehicle.

1.DO NOT LIFT OR TOW THE BY ATTACHING

TO OR WRAPPING AROUND BUMPER.

2. Any loose or protruding

of vehicle such

as hoods, doors, fenders,

etc., should be secured

or removed prior to moving

vehicle.

3.Operator should refrain going under a vehicle while

it is lifted by the towing unless the vehicle

is adequately supported by safety stands.

4. Never allow passengers to ride in a towed vehicl e.

5. State and local rules and regulations must be fo llowed

when towing a vehicle.

Caution

1.If only the front wheels or only. the rear wheels a re

lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes the oil

to flow forward, and may result in heat damage to

the rear bushing of the transfer, and should never

be done.

2.Do not tow the vehicle ‘with “only front or

only the rear wheels on a dolly, or the viscous

coupling will be damaged. In a

case, the vehicle

may jump forward suddenly.

3. If this vehicle is towed, use

bed dolly

type equipment.

TSB Revision

Page 53 of 2103

GENERAL Maintenance

21 SYSTEM component

damage, to wiring,

harness, etc.)

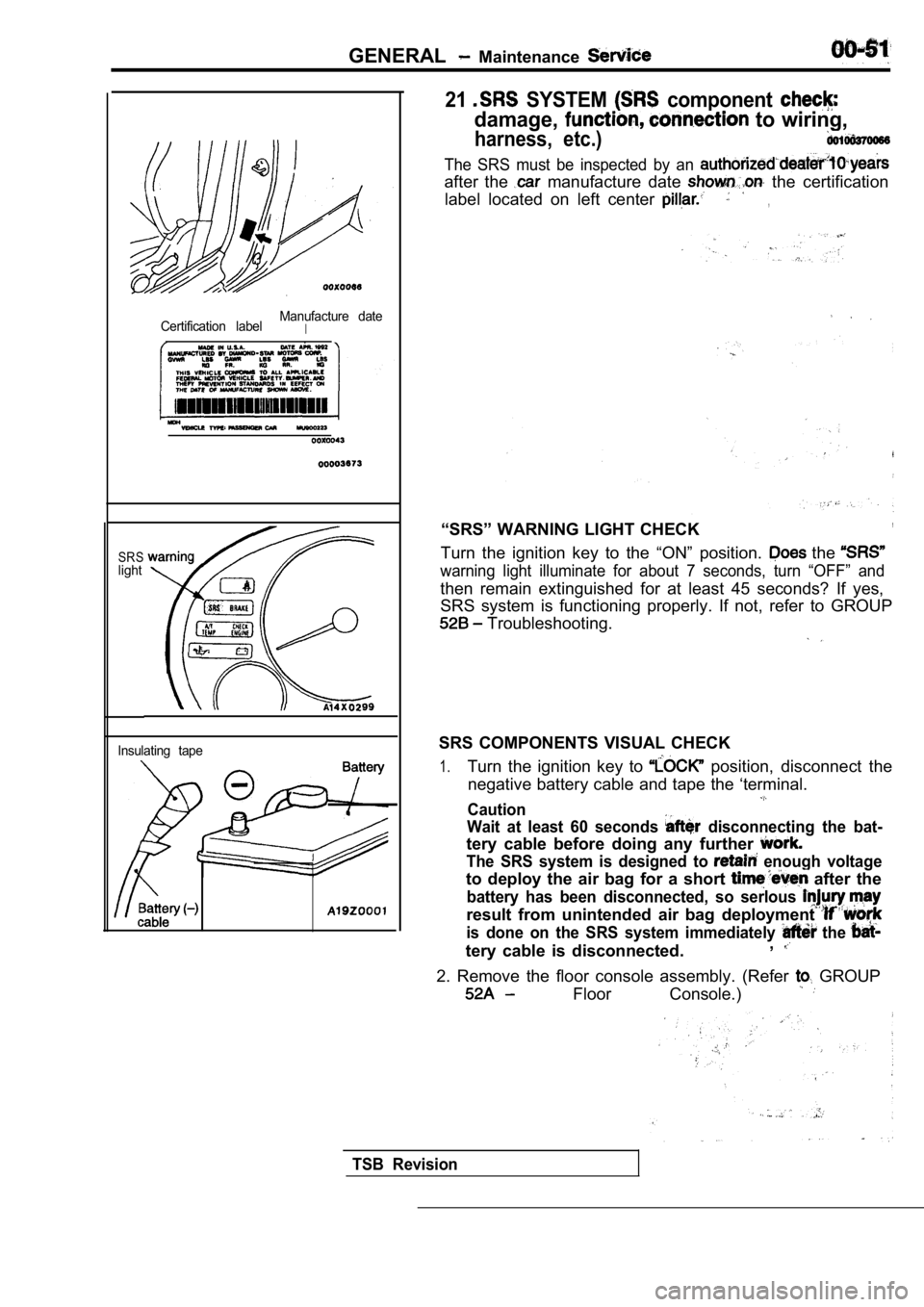

Certification labelManufacture dateI

SRSlight

Insulating tape

The SRS must be inspected by an

after the manufacture date the certification

label located on left center

,

“SRS” WARNING LIGHT CHECK,

Turn the ignition key to the “ON” position. the

warning light illuminate for about 7 seconds, turn “OFF” and

then remain extinguished for at least 45 seconds? I f yes,

SRS system is functioning properly. If not, refer t o GROUP

Troubleshooting.

SRS COMPONENTS VISUAL CHECK

1.Turn the ignition key to position, disconnect the

negative battery cable and tape the ‘terminal.

Caution

Wait at least 60 seconds

disconnecting the bat-

tery cable before doing any further

The SRS system is designed to enough voltage

to deploy the air bag for a short after the

battery has been disconnected, so serlous

result from unintended air bag deployment

is done on the SRS system immediately the

tery cable is disconnected. ,

2. Remove the floor console assembly. (Refer GROUP

Floor Console.)

TSB Revision

Page 69 of 2103

ENGINE On-vehicle

A/C COMPRESSOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt tension with adjusting bolt B.

Standard value:

Items

Tension

(Ibs.)

Deflection

When a new belt isWhen a used belt is

installedinstalled

382-411255-333

6.5-7.5

3. Tighten fixing nut A.

Tightening torque: 23-26 Nm

4.Check the belt deflection and readjust if neces-

sary.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

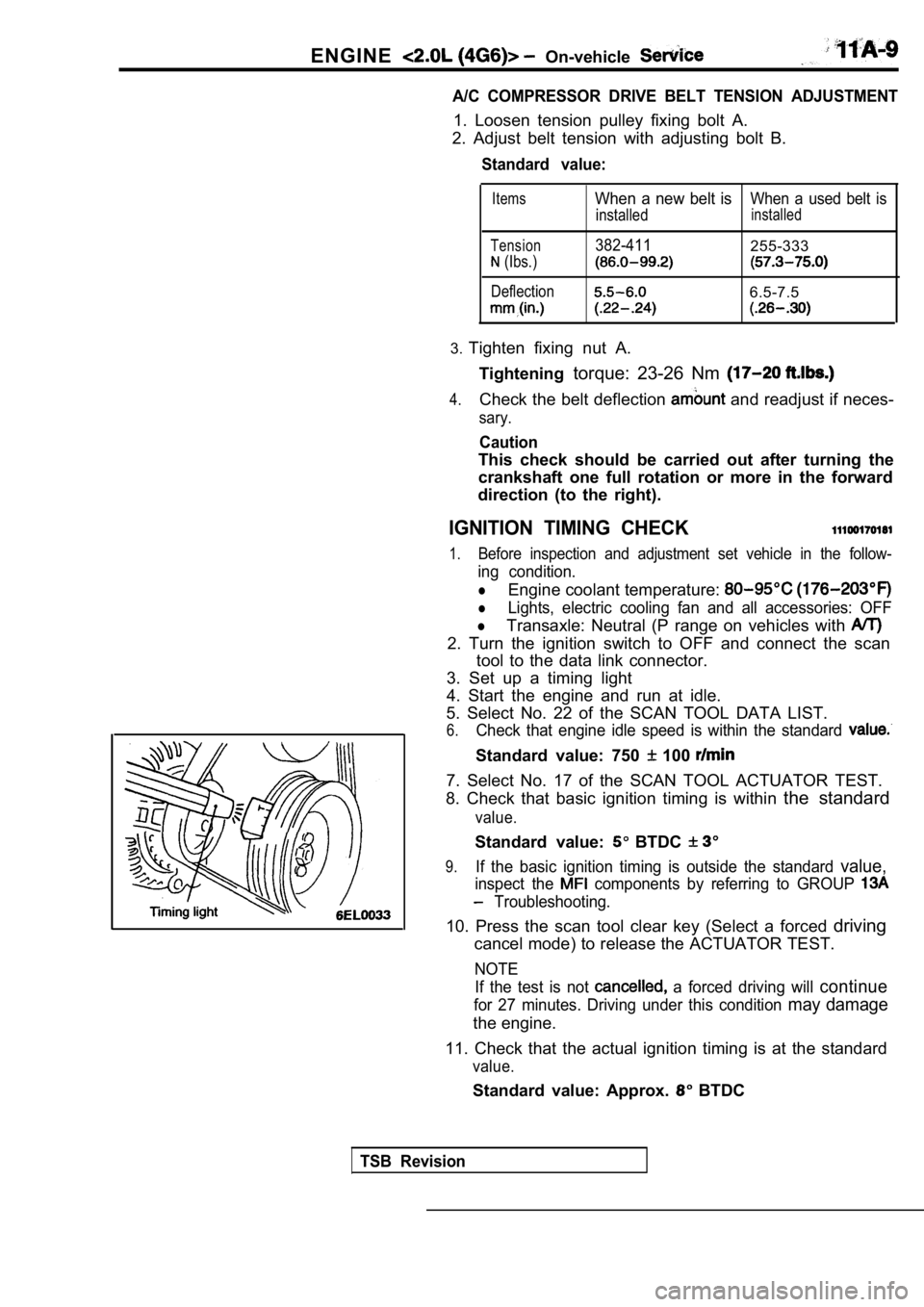

IGNITION TIMING CHECK

1.Before inspection and adjustment set vehicle in the follow-

ing condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Set up a timing light

4. Start the engine and run at idle.

5. Select No. 22 of the SCAN TOOL DATA LIST.

6.Check that engine idle speed is within the standard

Standard value: 750 100

7. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

8. Check that basic ignition timing is within the standard

value.

Standard value: BTDC

9.If the basic ignition timing is outside the standar d value,

inspect the components by referring to GROUP

Troubleshooting.

10. Press the scan tool clear key (Select a forced driving

cancel mode) to release the ACTUATOR TEST.

NOTE

If the test is not

a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

11. Check that the actual ignition timing is at the standard

value.

Standard value: Approx. BTDC

TSB Revision

Page 278 of 2103

ENGINE O n - v e h i c l e

Press the scan tool clear key (select aforced driving

cancel mode) to release the ACTUATOR TEST

NOTE

If the test is not a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

Check that the actual ignition timing is at the st andard

value.

Standard value: Approx. BTDC

NOTE

Ignition timing is variable within about even under

normal operating.

2. And it is automatically further advanced by abou t

from BTDC at higher altitudes.

CURB IDLE SPEED CHECK

Before inspection and adjustment, set vehicles in the

following condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with A/T)

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST

4. Check the basic ignition timing.

Standard value: BTDC

5. Run the engine at idle for 2 minutes.

6. Select No. 22 of the SCAN TOOL DATA LIST.

7. Check the curb idle speed.

Standard value: 750 100

NOTE

The idle speed is controlled automatically by the i dle air

control system.

8. If the idle speed is outside the standard value, check

the components by referring to GROUP Trou-

bleshooting.

IDLE MIXTURE CHECK

Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

4.Check that the basic ignition timing is within the standard

value..

Standard value:

TSB Revision

Page 389 of 2103

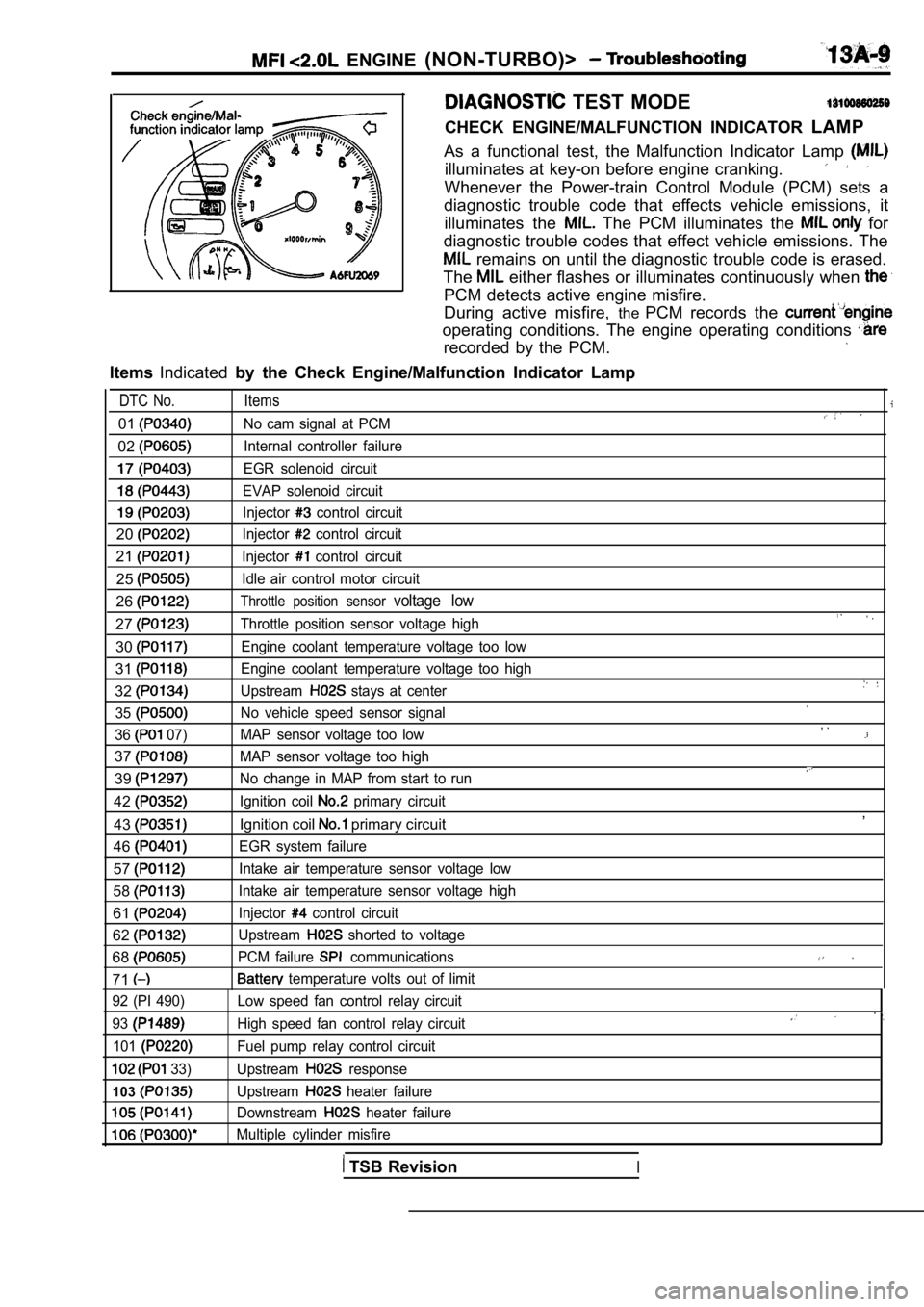

ENGINE (NON-TURBO)>

TEST MODE

CHECK ENGINE/MALFUNCTION INDICATOR LAMP

As a functional test, the Malfunction Indicator Lam p

illuminates at key-on before engine cranking.

Whenever the Power-train Control Module (PCM) sets a

diagnostic trouble code that effects vehicle emissi ons, it

illuminates the

The PCM illuminates the for

diagnostic trouble codes that effect vehicle emissi ons. The

remains on until the diagnostic trouble code is erased.

The

either flashes or illuminates continuously when

PCM detects active engine misfire.

During active misfire, thePCM records the

operating conditions. The engine operating conditio ns

recorded by the PCM.

ItemsIndicated by the Check Engine/Malfunction Indicator Lamp

DTC No. Items

01No cam signal at PCM

02Internal controller failure

EGR solenoid circuit

EVAP solenoid circuit

Injector control circuit

20Injector control circuit

21Injector control circuit

25Idle air control motor circuit

26Throttle position sensor voltage low

27Throttle position sensor voltage high

30Engine coolant temperature voltage too low

31Engine coolant temperature voltage too high

32Upstream stays at center

35

No vehicle speed sensor signal

36

07) MAP sensor voltage too low

37MAP sensor voltage too high

39No change in MAP from start to run

42Ignition coil primary circuit

43Ignition coil primary circuit

46

EGR system failure

57Intake air temperature sensor voltage low

58Intake air temperature sensor voltage high

61Injector control circuit

62Upstream shorted to voltage

68PCM failure communications

71 temperature volts out of limit

, .

,

92 (PI 490)

93

101

33)

103

Low speed fan control relay circuit

High speed fan control relay circuit

Fuel pump relay control circuit

Upstream

response

Upstream

heater failure

Downstream

heater failure

Multiple cylinder misfire

TSB RevisionI

Page 393 of 2103

ENGINE (NON-TURBO)> Troubleshooting 3

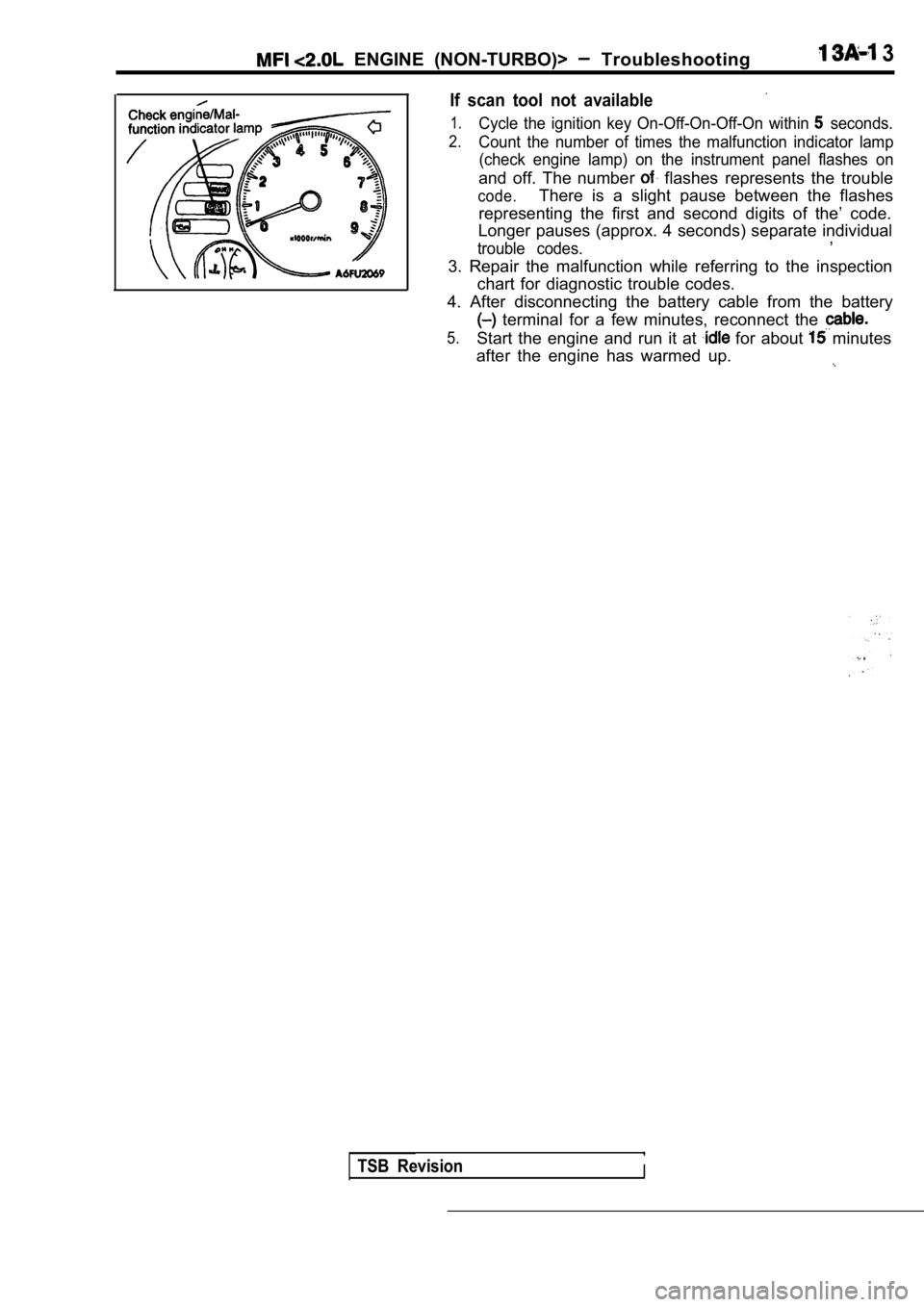

If scan tool not available

1.Cycle the ignition key On-Off-On-Off-On within seconds.

2.Count the number of times the malfunction indicator lamp

(check engine lamp) on the instrument panel flashes on

and off. The number flashes represents the trouble

code.There is a slight pause between the flashes

representing the first and second digits of the’ co de.

Longer pauses (approx. 4 seconds) separate individu al

,

trouble codes.

3. Repair the malfunction while referring to the in spection

chart for diagnostic trouble codes.

4. After disconnecting the battery cable from the b attery

terminal for a few minutes, reconnect the

5.Start the engine and run it at for about minutes

after the engine has warmed up.

TSB RevisionI

Page 423 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

General scan toolNo Change in MAP From Start to

[Comment]

Background

l The MAP sensor is mounted to intake manifold vacuum .

lThis information provides a MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

General scan toolNo Change in MAP From Start to

[Comment]

Background

l The MAP sensor is mounted to intake manifold vacuum .

lThis information provides a](/img/19/57345/w960_57345-422.png)

ENGINE Troubleshooting

General scan toolNo Change in MAP From Start to

[Comment]

Background

l The MAP sensor is mounted to intake manifold vacuum .

lThis information provides an important PCM input fo r determining fuel injector pulse wide.lThe sensor should measure a difference in manifold pressure between key ON and after

the engine is running.

Range of Check

l Vehicle is not moving

l

Engine: The engine idle speed is almost identical t o the target idle speed while the engineis idling.

Set Condition

l Diagnostic trouble code (DTC) memory is not deleted even after the ignition switch is

turned off.

l The difference between the two following MAP values is small.

The value immediately after the ignition switch is turned to ON.

The value while the

is at idle for two seconds.

Ice in sensorl Sensor failedl . failed

Measure at the MAP sensor connector l

Disconnect the connector, and measure at the harnes s side.

l Continuity between and ground.

OK: Continuitv

Check the

Check the harness wire between the PCM and the MAP sensor

connector. if

Check the following connectors: Repair

OK

Check trouble symptom.

N G N G

Check the harness wire between the PCM and the MAP

connector.

OK

.

Replace the MAP sensor.

TSB Revision

Page 439 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 103

Code General scan tool

No.Upstream Failure

21

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 103

Code General scan tool

No.Upstream Failure

21

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM](/img/19/57345/w960_57345-438.png)

ENGINE (NON-TURBO)>

Scan tool 103

Code General scan tool

No.Upstream Failure

21

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM waits some periods to allow the heated oxyg en sensors to cool.

l Once the PCM calculates that the heated oxygen sens or is cooled, it energizes the

relay (ASD relay) and tests for the heated oxygen sensor operation.

Range of Check

5 seconds or more after turning the ignition switch to OFF. Battery positive voltage: or morelThe heated oxygen sensor output line voltage rises by 0.49 or more within 144 secondsafter turning the ignition switch to OFF. The initial rise of the output line voltage is less than 1.57 V.Set ConditionHeated oxygen sensor’s circuit does not show the ap propriate decrease of voltage the test.

l Heated oxygen sensor heater open l harness and connectors ,

Measure at the heated oxygen sensor (front) connect or l

Disconnect the connector, and measure at the harnes s side.

SCAN TOOL Actuator test

relay (ASD relay) Check the following connector: everyapprox. 1. Voltage between 4 and ground

[Measure with the relay (ASD relay) on]

OK: Battery positive voltage Check the harness wire between the and

2. Continuity between 3 and ground the heated oxygen sensor connector. if

OK: Continuity

2. NG Check the harness wire between the heated oxygen sensor and

OKthe ground. Repair, if necessary.

NGCheck the followingconnect Repair

OK

Check trouble symptom.

NG

Replace the heated oxygen sensor (front).

TSB Revision

Page 440 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM waits some periods to allow the heated oxyg en sensors to cool. MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM waits some periods to allow the heated oxyg en sensors to cool.](/img/19/57345/w960_57345-439.png)

E N G I N E

[Comment]

Background

l The PCM continues to monitor this system after the key is OFF.

l The PCM waits some periods to allow the heated oxyg en sensors to cool.

l Once the PCM calculates that the heated oxygen sens or is cooled, it energizes the

relay relay) and tests for the heated oxygen sensor operation.

Range of Check

l 5 seconds or more after turning the ignition switch to OFF.

l Battery positive voltage: 10

or morelThe heated oxygen sensor output line voltage rises by 0.49 or more within 144 secondsafter turning the ignition switch to OFF. The initial of the output line voltage is less than 1.57 V.Set ConditionHeated oxygen sensor’s circuit does not show the ap propriate decrease of voltage the test.

1. NG

Measure at the heated oxygen sensor (rear) connecto r

lDisconnect the connector, and measure at the harnes s side.

SCAN TOOL Actuator test 10

relay (ASD relay) everyapprox. 1. Voltage between 3 and ground [Measure with the relay

(ASD relay) on]

OK: Battery positive voltage

2. Continuity between 4 and ground

OK: Continuity

OK

2. NG l

Heated oxygen sensor heater

l harness and

. .

Check the harness wire between (ASP the heated oxygen sensor

Check the harness wire between the heated oxygen s ensor and

the ground. Repair, if necessary.

NG Repair

Check trouble symptom.

OK

NG

Replace the heated oxygen sensor (rear).

TSB Revision

Page 501 of 2103

E N G I N E ,

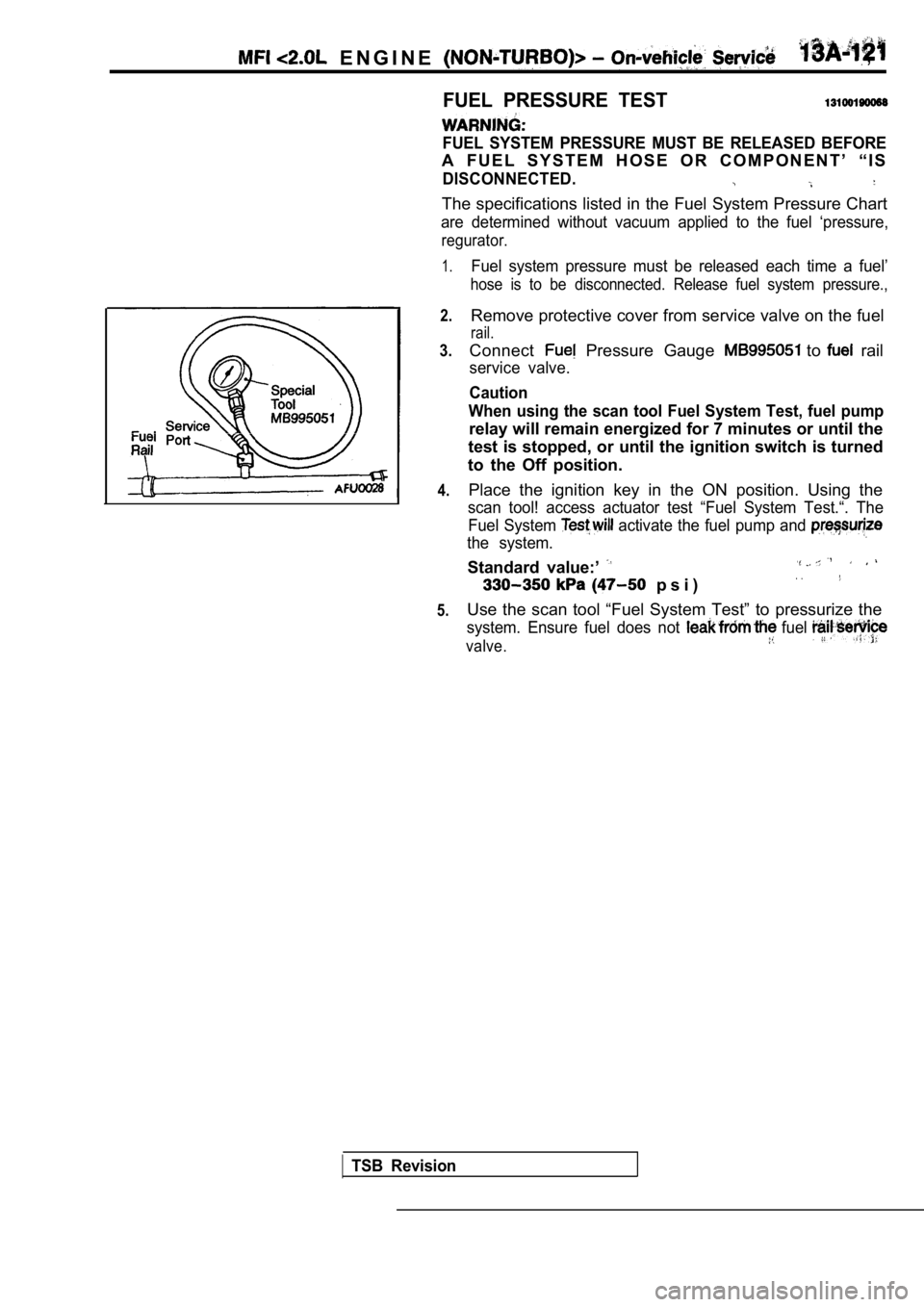

FUEL PRESSURE TEST

FUEL SYSTEM PRESSURE MUST BE RELEASED BEFORE

A F U E L S Y S T E M H O S E O R C O M P O N E N T ’ “ I S

DISCONNECTED.

The specifications listed in the Fuel System Pressure Chart

are determined without vacuum applied to the fuel ‘ pressure,

regurator.

1.

2.

3.

4.

5.

Fuel system pressure must be released each time a f uel’

hose is to be disconnected. Release fuel system pre ssure.,

Remove protective cover from service valve on the fuel

rail.

Connect Pressure Gauge to rail

service valve.

Caution

When using the scan tool Fuel System Test, fuel pum p

relay will remain energized for 7 minutes or until the

test is stopped, or until the ignition switch is tu rned

to the Off position.

Place the ignition key in the ON position. Using th e

scan tool! access actuator test “Fuel System Test.“. The

Fuel System

activate the fuel pump and

the system.

Standard value:’

p s i )

Use the scan tool “Fuel System Test” to pressurize the

system. Ensure fuel does not fuel

valve.

TSB Revision