warning light MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 22 of 2103

GENERAL before Service

PRECAUTIONS BEFORE SERVICE.

SUPPLEMENTAL RESTRAINT SYSTEM

1. to follow when servicing SRS

(1) Be sure to read GROUP Supplemental Restraint System

For safe operations, please follow the directions a nd heed all

(2) Always use the designated special tools and tes t equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before” further work;

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the bat tery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components (SRS-ECU air bag module and

clock spring). If faulty, replace it.

(5) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

Sun visor

l Glove box

. S R S - E C U

l Steering wheel

l Air bag module

l Clock spring

l Steering gear and linkage clamp

(6) Store components removed from the SRS

a clean and dry place.

The air bag module should be stored on a flat surfa ce and placed so that the pad surface is’

facing upward.

Do not place anything on top of it.

(7) Be sure to deploy the air bag before disposing of the air bag’module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP

Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the

check the SRS warning light operation to make sure

that the system functions properly.

2.Observe the following when carrying out operations on places where SRS components are installed,’

.,

including operations not directly related to the SR S air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over so remove the SRS compo-

nents before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lig ht operation to make sure that the system

functions properly.

SERVICING THE ELECTRICAL SYSTEM

1. Note the following before proceeding with work o n the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that co uld result

in a fire in the vehicle.

2.When servicing the electrical system, disconnect th e nega-

tive cable terminal from the battery.

Page 53 of 2103

GENERAL Maintenance

21 SYSTEM component

damage, to wiring,

harness, etc.)

Certification labelManufacture dateI

SRSlight

Insulating tape

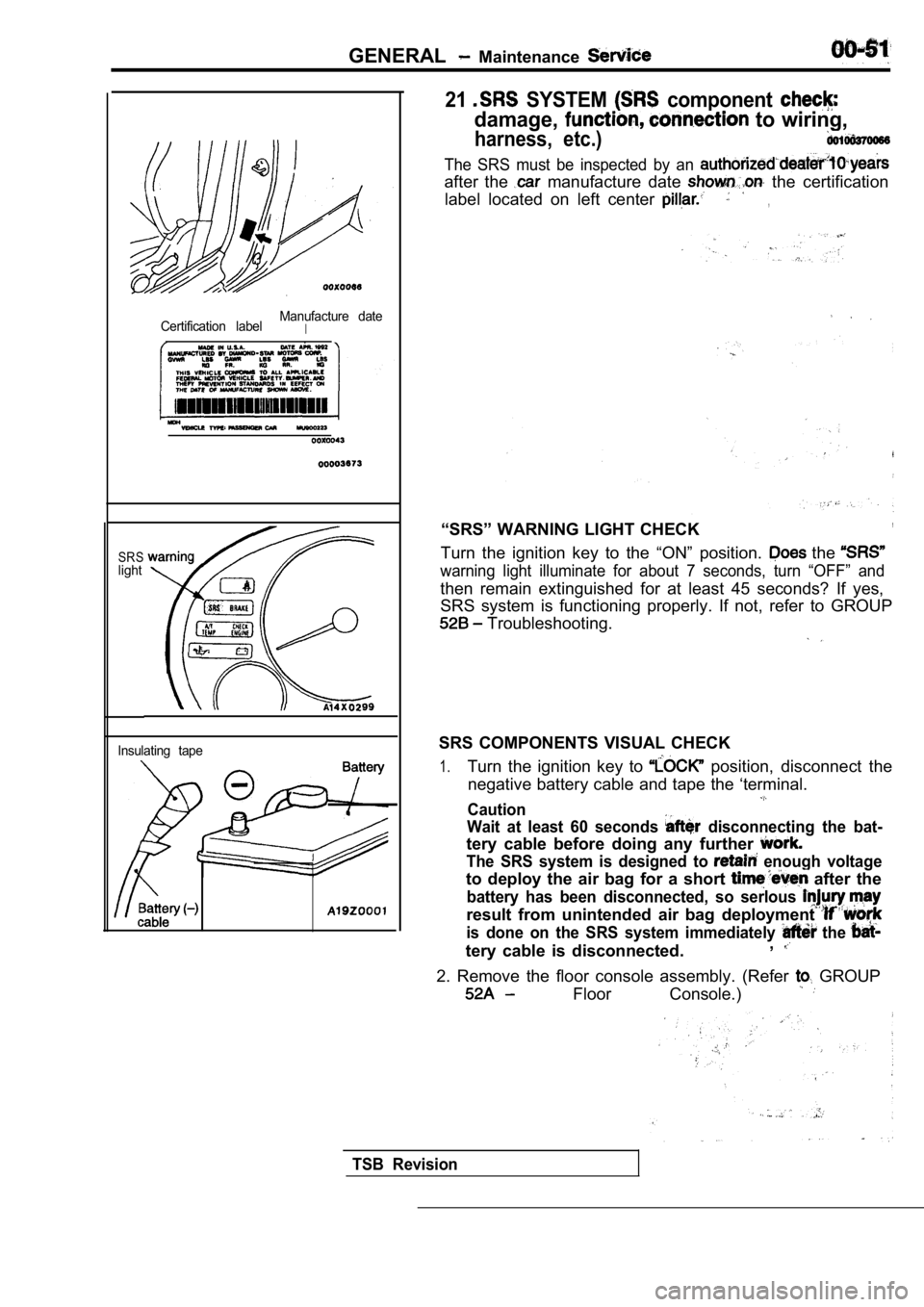

The SRS must be inspected by an

after the manufacture date the certification

label located on left center

,

“SRS” WARNING LIGHT CHECK,

Turn the ignition key to the “ON” position. the

warning light illuminate for about 7 seconds, turn “OFF” and

then remain extinguished for at least 45 seconds? I f yes,

SRS system is functioning properly. If not, refer t o GROUP

Troubleshooting.

SRS COMPONENTS VISUAL CHECK

1.Turn the ignition key to position, disconnect the

negative battery cable and tape the ‘terminal.

Caution

Wait at least 60 seconds

disconnecting the bat-

tery cable before doing any further

The SRS system is designed to enough voltage

to deploy the air bag for a short after the

battery has been disconnected, so serlous

result from unintended air bag deployment

is done on the SRS system immediately the

tery cable is disconnected. ,

2. Remove the floor console assembly. (Refer GROUP

Floor Console.)

TSB Revision

Page 519 of 2103

ENGINE (TURBO)

ENGINE>

DIAGNOSTIC TEST MODEl When an abnormality is detected in one

of the sensors or actuators related to emis-

sion control, the CHECK

FUNCTION INDICATOR LAMP illuminates

as a warning to the driver.

l When an abnormality is detected in one

of the’ sensors or actuators, a

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Compressor Clutch Relay Control Turns the A/C compressor clutch ON and

OFF.

3. Fan Relay Control

The radiator fan and condenser fan speeds

are controlled in response to the engine

coolant temperature and vehicle speed.

4. Fuel

Control

Supplies current to fuel pressure solenoid

coil to raise the fuel pressure so that the

fuel does not vaporize when the engine

is started while it is warm.

trouble code ‘the,,

normality is output.

lThe RAM data inside the that

to the sensors and actuators can be read’

by

scan’ tool.

addition, the actuators can be controlled

under certain

5. Charge Control

Controls the intake charge pressure by con-

trolling the duty of the turbocharger

gate solenoid!

6. Intake Pressure Gauge’ Control Indicates the intake charge pressure on

the

7. Generator Output Current Control

Prevents generator output current from in-

creasing idle speed from

dropping at times such as when the head-

lights are turned on.

8.Evaporative Emission Purge Solenoid Con-

trol Engine (TURBO)>

Refer to

17.

Evaporative Emission Purge Solenoid Con-

trol GROUP 17.

9. EGR Solenoid’ Control

Refer to GROUP

,,

,

TSB Revision

Page 741 of 2103

CONTENTS

AUTO-CRUISE CONTROL SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

AUTO-CRUISE CONTROL* . . . . . . . . . . . . . . 40

GENERAL INFORMATION . . . . . . . . . . . . . . . . 7

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . 33

Auto-cruise Control Cable Check and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Auto-cruise Control Component Check . . . . . 37

Auto-cruise Control System Operation Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

SERVICE SPECIFICATIONS . . . . . . . . . . . . . 8

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING

ENGINE (NON-TURBO)> . . . . . . . . . . . 9

TROUBLESHOOTING

(TURBO) AND ENGINE> . . . . .

EMISSION CONTROL’ SYSTEM

. . . . .

CATALYTIC . . . . . . . . . . . . . .

General Information . . . . . . . . . . . . . . . . . . 57

EVAPORATIVE EMISSION .

SYSTEM. . . . . . . . . . . . . . . .

Air Conditioning . . . . . . . . . . . . . . . . . . . 52

Component Location

. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor

Intake Air Temperature Sensor . . . . . . . . . . . . 52

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRA INT SYSTEM (SRS) EQUIPPED

WARNING!

(1) Improper serviceor maintenance of any component of the or any SRS-related can to injuryorcleathtoservicepersonnel (from inadvertentfiring the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly rev iew this manual, and especially its GROUP

Restraint System (SRS) and GROUP 00 Maintenance Service, before any service or maintenance of any

componentof the SRS or any SRS-related component.

NOTEJhe includes the following components: warning light, air bag module, clock components (that may have to be removed/installed in connection with or areIndicated in the table of contents by an asterisk

Page 819 of 2103

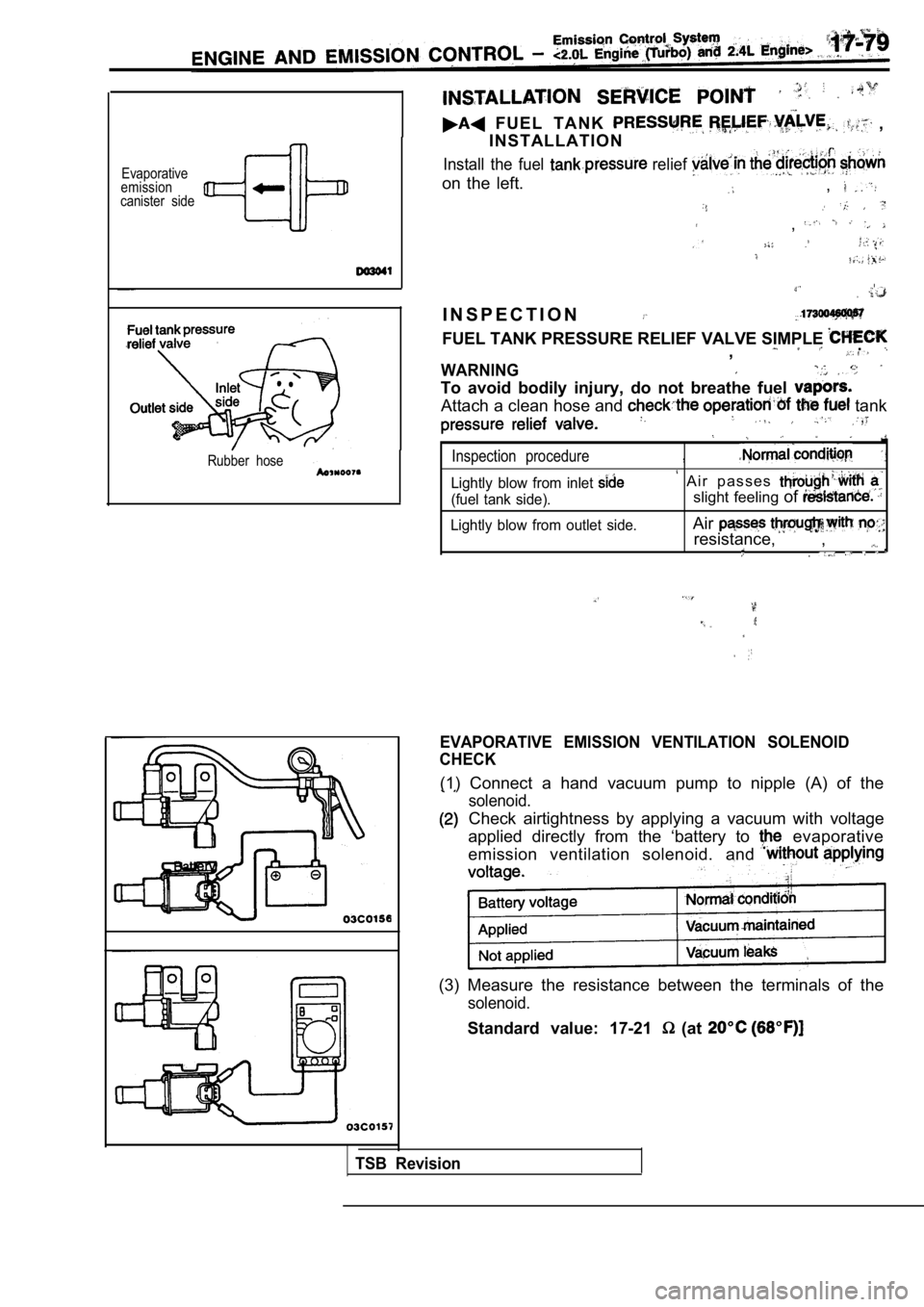

Evaporative

emission

canister side

Rubber hose

F U E L T A N K ,

I N S T A L L A T I O N

Install the fuel relief

on the left.,

,

I..- ,

I N S P E C T I O N

FUEL TANK PRESSURE RELIEF VALVE SIMPLE .,

WARNING

To avoid bodily injury, do not breathe fuel

Attach a clean hose and tank

Inspection procedure,

Lightly blow from inlet A i r p a s s e s

(fuel tank side).slight feeling of

Lightly blow from outlet side.Air

resistance, , .

EVAPORATIVE EMISSION VENTILATION SOLENOID

CHECK

(1) Connect a hand vacuum pump to nipple (A) of the

solenoid.

Check airtightness by applying a vacuum with voltag e

applied directly from the ‘battery to

evaporative

emission ventilation solenoid. and

(3) Measure the resistance between the terminals of the

solenoid.

Standard value: 17-21 (at

TSB Revision

Page 859 of 2103

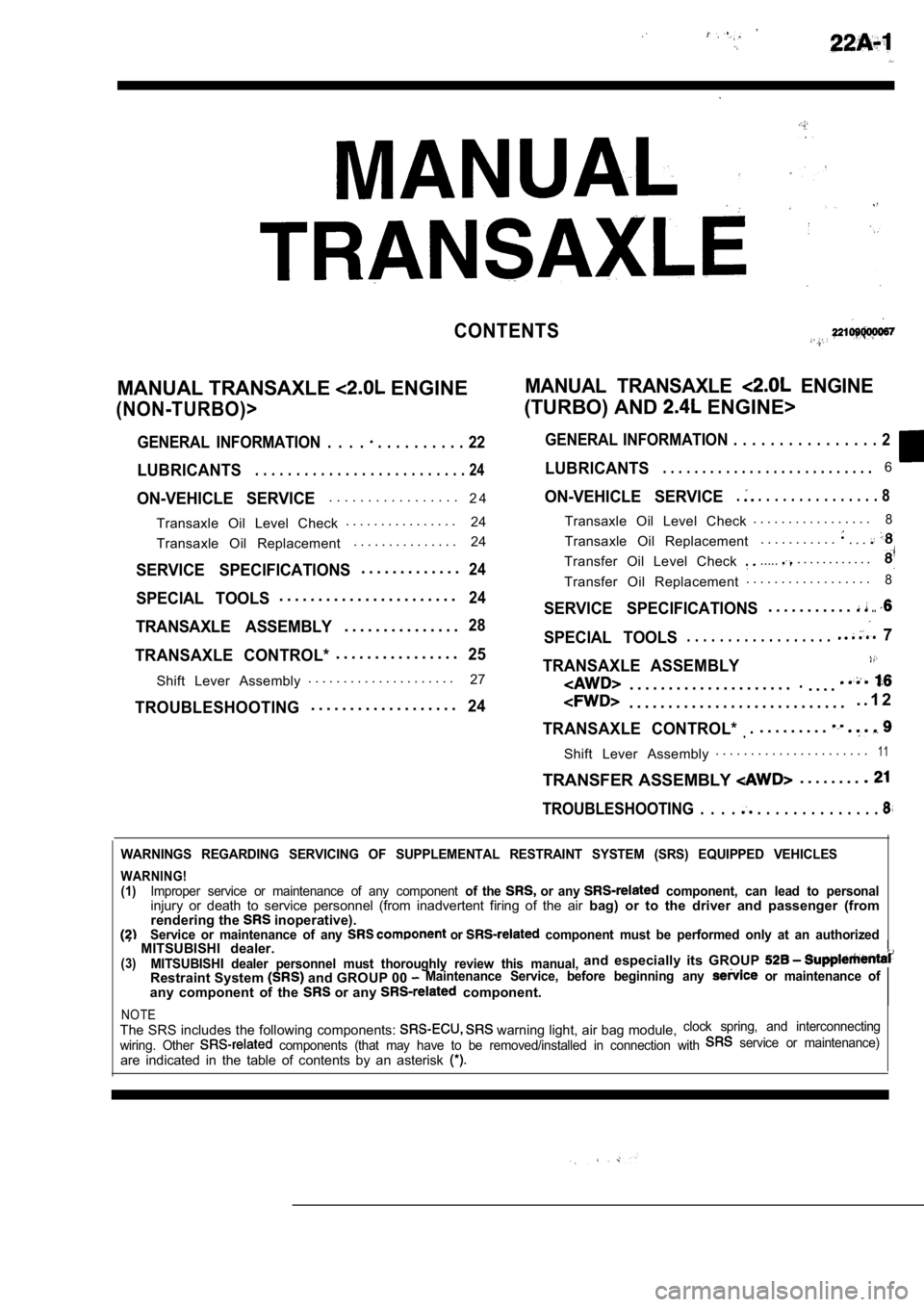

CONTENTS

MANUAL TRANSAXLE ENGINEMANUAL TRANSAXLE ENGINE

(NON-TURBO)>(TURBO) AND ENGINE>

GENERAL INFORMATION . . . . . . . . . . . . . . 22GENERAL INFORMATION . . . . . . . . . . . . . . . .

2

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . 24LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . .6

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . .

2 4

Transaxle Oil Level Check . . . . . . . . . . . . . . . .

24

Transaxle Oil Replacement . . . . . . . . . . . . . . .

24

SERVICE SPECIFICATIONS. . . . . . . . . . . . .24

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . .24

TRANSAXLE ASSEMBLY. . . . . . . . . . . . . . .28

TRANSAXLE CONTROL*. . . . . . . . . . . . . . . .25ON-VEHICLE SERVICE

. . . . . . . . . . . . . . . . 8

Shift Lever Assembly

. . . . . . . . . . . . . . . . . . . . .

27

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . .24

Transaxle Oil Level Check . . . . . . . . . . . . . . . . .8

Transaxle Oil Replacement

. . . . . . . . . . .. . .

Transfer Oil Level Check ...... . . . . . . . . . . .

Transfer Oil Replacement. . . . . . . . . . . . . . . . . .8

SERVICE SPECIFICATIONS. . . . . . . . . . ...

SPECIAL TOOLS 7. . . . . . . . . . . . . . . . . .

TRANSAXLE ASSEMBLY

. . . . . . . . . . . . . . . . . . . . ... . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 1 2

TRANSAXLE CONTROL*... . . . . . . . .

Shift Lever Assembly. . . . . . . . . . . . . . . . . . . . . .1 1

TRANSFER ASSEMBLY . . . . . . . .

TROUBLESHOOTING . . . . . . . . . . . . . . . . . .

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRA

INT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1)Improper service or maintenance of any component of the or any component, can lead to personalinjury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from

rendering the inoperative).Service or maintenance of any or component must be performed only at an authorized MITSUBISHI dealer.(3)MITSUBISHI dealer personnel must thoroughly review this manual,and especially its GROUP

Restraint System and GROUP 00 Maintenance Service, before beginning any or maintenance of

any component of the or any component.

NOTEThe SRS includes the following components: warning light, air bag module,clock spring, and interconnecting

wiring. Other

components (that may have to be removed/installed in connection with service or maintenance)

are indicated in the table of contents by an asterisk

Page 1009 of 2103

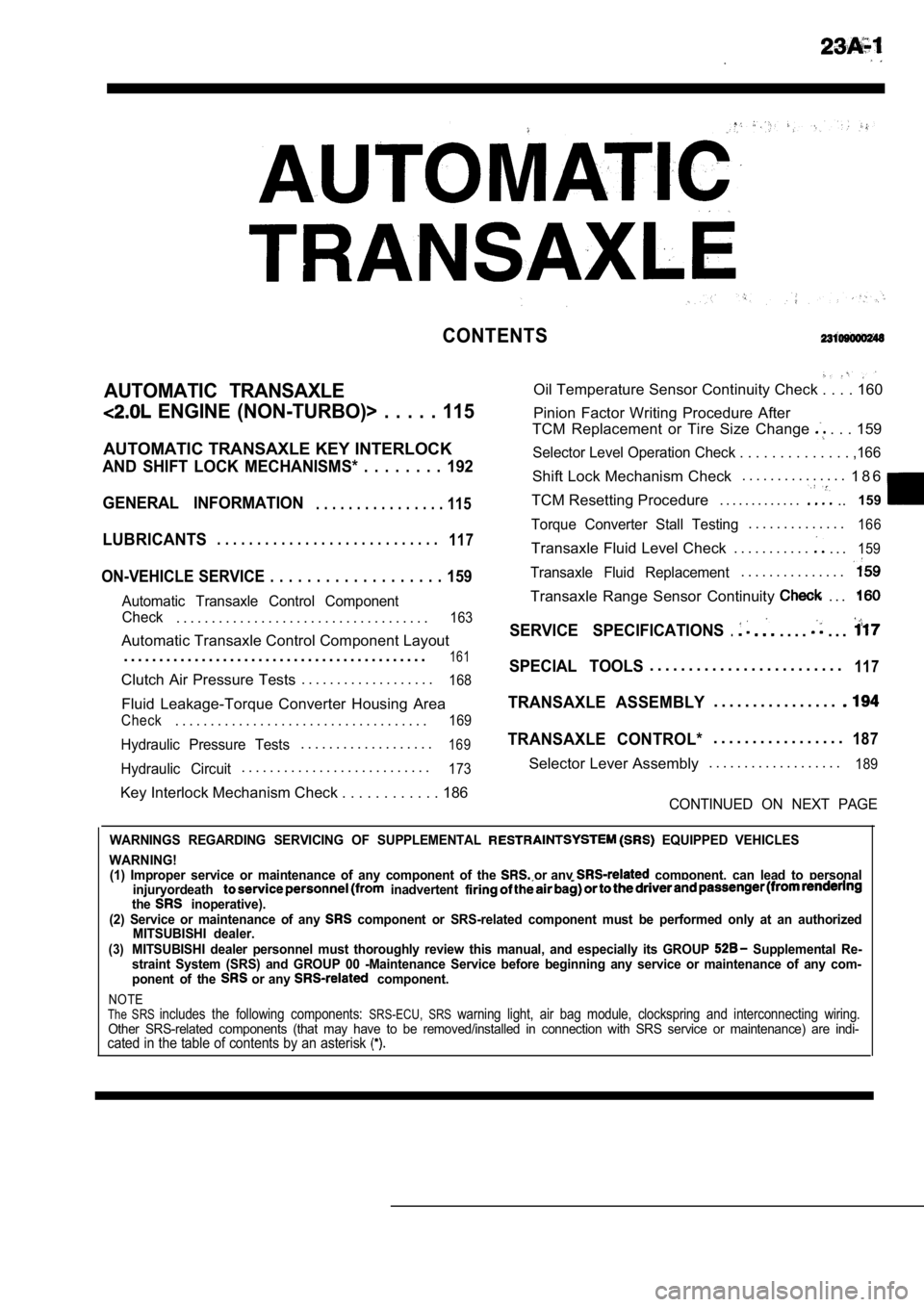

CONTENTS

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> . . . . . 115

AUTOMATIC TRANSAXLE KEY INTERLOCK

AND SHIFT LOCK MECHANISMS* . . . . . . . . 192

GENERAL INFORMATION

. . . . . . . . . . . . . . . . 115

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . .117

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . 159

Automatic Transaxle Control Component

Oil Temperature Sensor Continuity Check . . . . 160

Pinion Factor Writing Procedure After

TCM Replacement or Tire Size Change

. . . 159

Selector Level Operation Check . . . . . . . . . . . . . . ,166

Shift Lock Mechanism Check. . . . . . . . . . . . . . .

1 8 6

TCM Resetting Procedure . . . . . . . . . . . . .

..159

Torque Converter Stall Testing. . . . . . . . . . . . . .166

Transaxle Fluid Level Check . . . . . . . . . . .. . .159

Transaxle Fluid Replacement. . . . . . . . . . . . . . .

Transaxle Range Sensor Continuity . . .

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163SERVICE SPECIFICATIONS.. . . .. . .Automatic Transaxle Control Component Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . .117Clutch Air Pressure Tests . . . . . . . . . . . . . . . . . . .168

Fluid Leakage-Torque Converter Housing Area

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Hydraulic Pressure Tests. . . . . . . . . . . . . . . . . . .169

Hydraulic Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . .173

TRANSAXLE ASSEMBLY. . . . . . . . . . . . . . . .

TRANSAXLE CONTROL*. . . . . . . . . . . . . . . . .187

Selector Lever Assembly. . . . . . . . . . . . . . . . . . .189

Key Interlock Mechanism Check . . . . . . . . . . .

. 186CONTINUED ON NEXT PAGE

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL EQUIPPED VEHICLES

WARNING! (1) Improper service or maintenance of any componen t of the

or any component, can lead to personal

injuryordeath inadvertent the inoperative).

(2) Service or maintenance of any component or SRS-related component must be perform ed only at an authorized

MITSUBISHI dealer.

(3)MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP Supplemental Re-

straint System (SRS) and GROUP 00 -Maintenance Serv ice before beginning any service or maintenance of any com-

ponent of the

or any component.

NOTEThe SRS includes the following components: SRS-ECU, SRS warning light, air bag module, clockspring and inte rconnecting wiring.Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are indi-cated in the table of contents by an asterisk

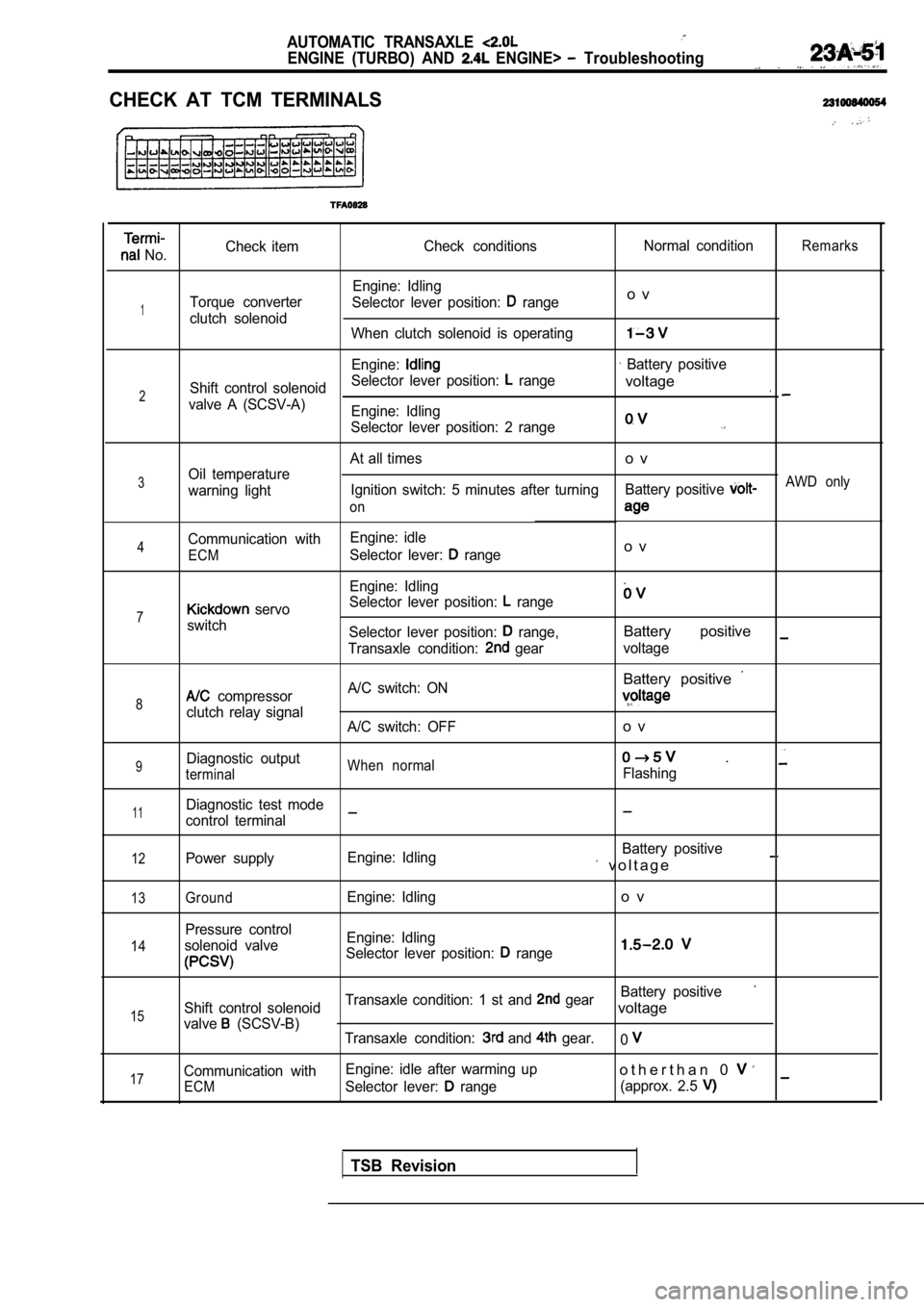

Page 1059 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

CHECK AT TCM TERMINALS

No.Check item

Check conditions Normal conditionRemarks

Engine: Idling

Torque converter Selector lever position:

rangeo v

1clutch solenoid

When clutch solenoid is operating

Engine: Battery positive

Shift control solenoid Selector lever position:

range

2voltage

valve A (SCSV-A)

Engine: Idling

Selector lever position: 2 range

At all timeso v

3Oil temperature

warning light Ignition switch: 5 minutes after turning

Battery positive AWD only

on

Communication with Engine: idle4Selector lever: rangeo vECM

Engine: Idling

Selector lever position:

range7 servo

switch Selector lever position:

range,Battery positive

Transaxle condition: gearvoltage

Battery positive

8 compressor A/C switch: ON

clutch relay signal

A/C switch: OFFo v

9Diagnostic outputWhen normal .

terminalFlashing

11Diagnostic test mode

control terminal

12Power supply Engine: Idling Battery positive v o l t a g e

13

14

15

17

GroundEngine: Idlingo v

Pressure control

solenoid valve Engine: Idling

Selector lever position:

range

Battery positive

Shift control solenoid Transaxle condition: 1 st and gearvoltage

valve (SCSV-B)

Transaxle condition: and gear.0

Communication with Engine: idle after warming upo t h e r t h a n 0

ECMSelector lever: range

(approx. 2.5

TSB Revision

Page 1148 of 2103

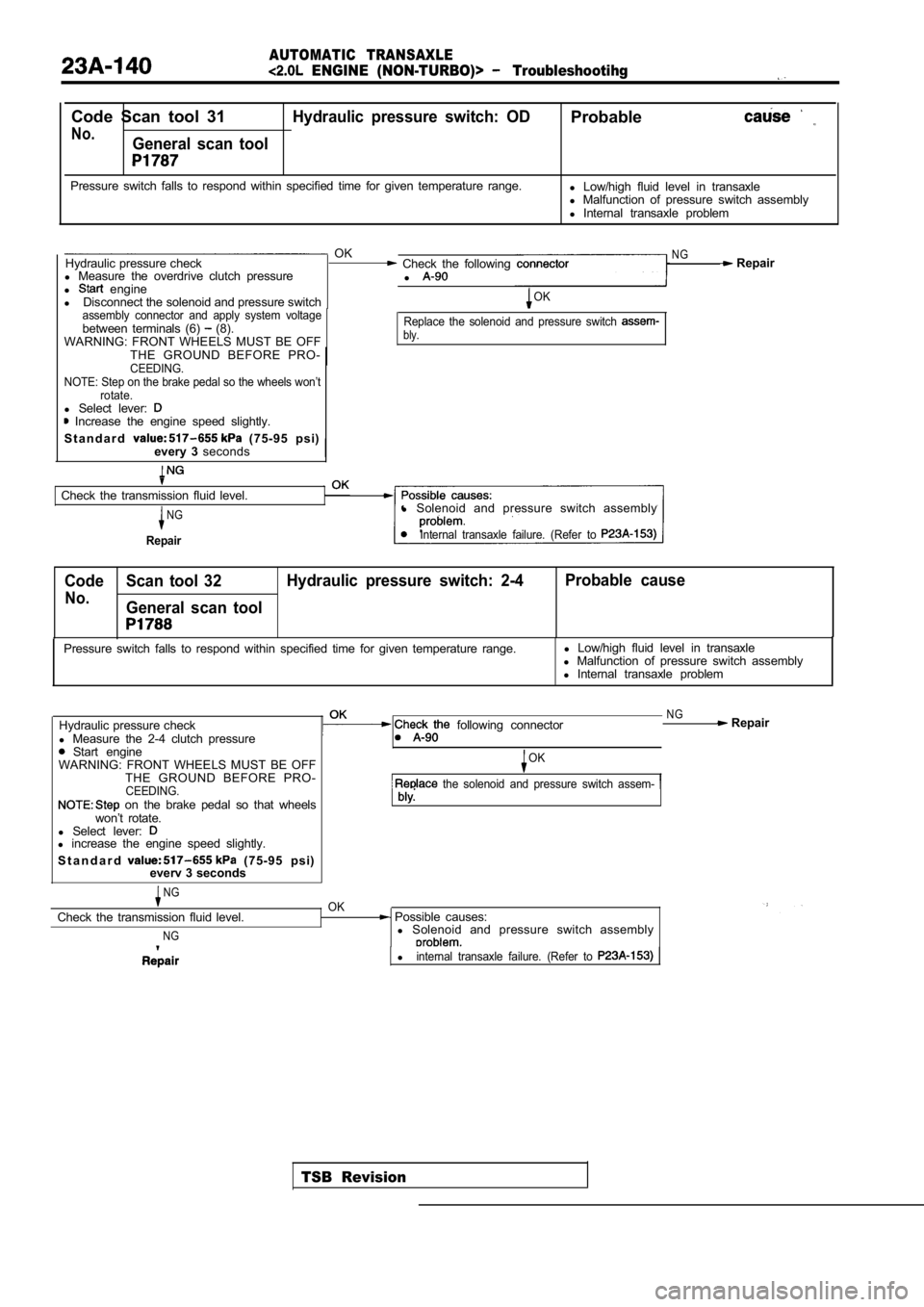

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshootihg

Code Scan tool 31Hydraulic pressure switch: ODProbable

No.General scan tool

Pressure switch falls to respond within specified time for given temperature range.

l Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

OKNGHydraulic pressure check Check the following Repair

l Measure the overdrive clutch pressure

l

l engine

l Disconnect the solenoid and pressure switchOK

assembly connector and apply system voltage

between terminals (6) (8).

WARNING: FRONT WHEELS MUST BE OFFReplace the solenoid and pressure switch bly.

THE GROUND BEFORE PRO-CEEDING.

NOTE: Step on the brake pedal so the wheels won’t rotate.

l Select lever: Increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

every 3 seconds

Check the transmission fluid level.

NG

Repair

l Solenoid and pressure switch assembly

Internal transaxle failure. (Refer to

Code Scan tool 32 Hydraulic pressure switch: 2-4 Probable cause

No.General scan tool

TSB Revision

Pressure switch falls to respond within specified t

ime for given temperature range.l

Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

Hydraulic pressure check

l Measure the 2-4 clutch pressure

Start engine

following connector

WARNING: FRONT WHEELS MUST BE OFF THE GROUND BEFORE PRO-

CEEDING. on the brake pedal so that wheels

won’t rotate.

l Select lever:

l increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

everv 3 seconds

NGOK

NG Repair

OK

the solenoid and pressure switch assem-

Check the transmission fluid level.

NG

Possible causes:

l Solenoid and pressure switch assembly

linternal transaxle failure. (Refer to

Page 1174 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> On-vehicle Service

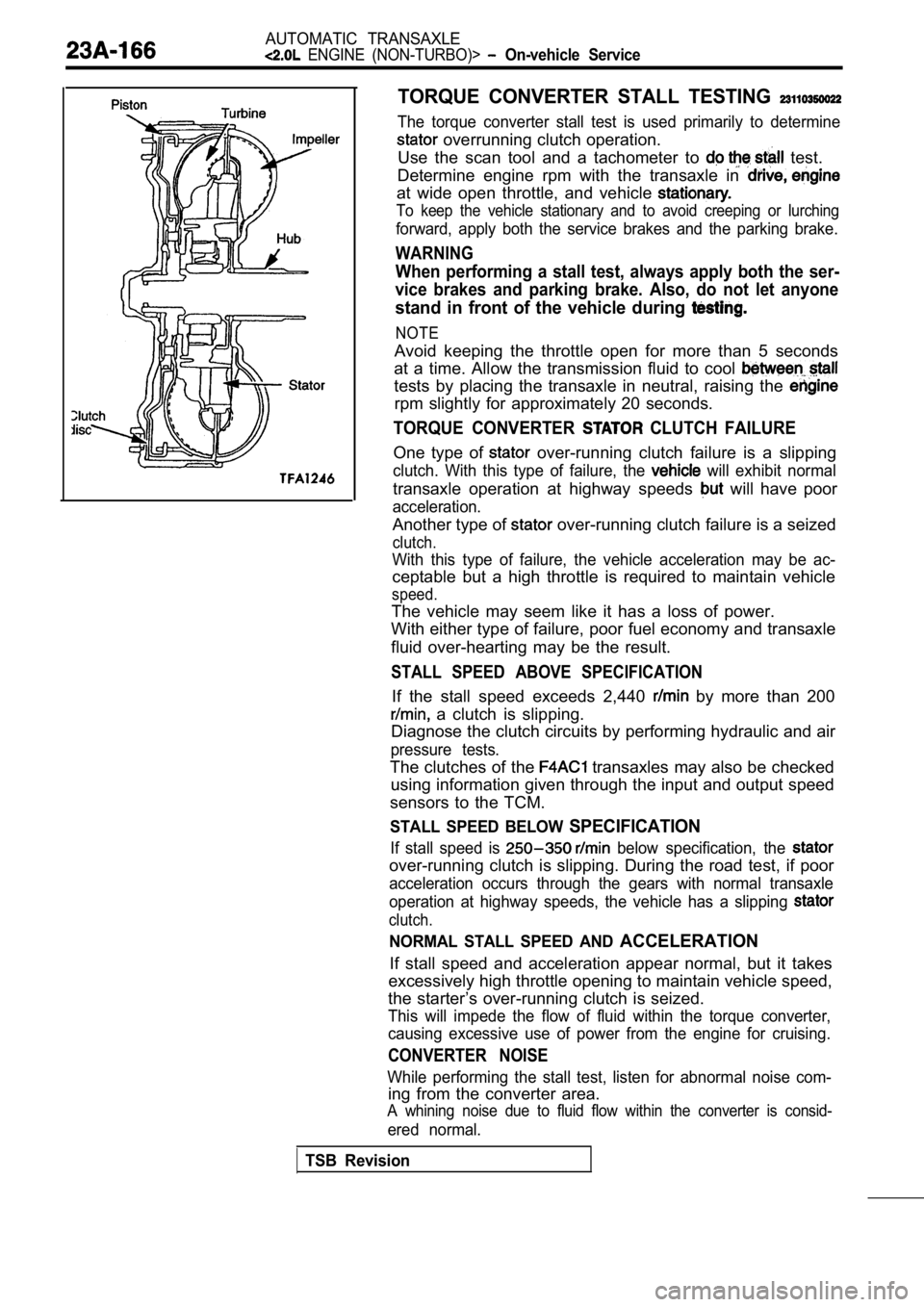

TORQUE CONVERTER STALL TESTING

The torque converter stall test is used primarily to determine

overrunning clutch operation.

Use the scan tool and a tachometer to

test.

Determine engine rpm with the transaxle in

at wide open throttle, and vehicle

To keep the vehicle stationary and to avoid creepin g or lurching

forward, apply both the service brakes and the parking brake.

WARNING

When performing a stall test, always apply both the ser-

vice brakes and parking brake. Also, do not let any one

stand in front of the vehicle during

NOTE

Avoid keeping the throttle open for more than 5 seconds

at a time. Allow the transmission fluid to cool

tests by placing the transaxle in neutral, raising the

rpm slightly for approximately 20 seconds.

TORQUE CONVERTER CLUTCH FAILURE

One type of over-running clutch failure is a slipping

clutch. With this type of failure, the will exhibit normal

transaxle operation at highway speeds will have poor

acceleration.

Another type of over-running clutch failure is a seized

clutch.

With this type of failure, the vehicle acceleration may be ac-

ceptable but a high throttle is required to maintai n vehicle

speed.

The vehicle may seem like it has a loss of power.

With either type of failure, poor fuel economy and transaxle

fluid over-hearting may be the result.

STALL SPEED ABOVE SPECIFICATION

If the stall speed exceeds 2,440 by more than 200

a clutch is slipping.

Diagnose the clutch circuits by performing hydrauli c and air

pressure tests.

The clutches of the transaxles may also be checked

using information given through the input and outpu t speed

sensors to the TCM.

STALL SPEED BELOW SPECIFICATION

If stall speed is below specification, the

over-running clutch is slipping. During the road te st, if poor

acceleration occurs through the gears with normal t ransaxle

operation at highway speeds, the vehicle has a slip ping

clutch.

NORMAL STALL SPEED AND ACCELERATION

If stall speed and acceleration appear normal, but it takes

excessively high throttle opening to maintain vehic le speed,

the starter’s over-running clutch is seized.

This will impede the flow of fluid within the torqu e converter,

causing excessive use of power from the engine for cruising.

CONVERTER NOISE

While performing the stall test, listen for abnormal noise com-

ing from the converter area.

A whining noise due to fluid flow within the conver ter is consid-

ered normal.

TSB Revision