wheel alignment MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 55 of 2103

G E N E R A L Maintenance

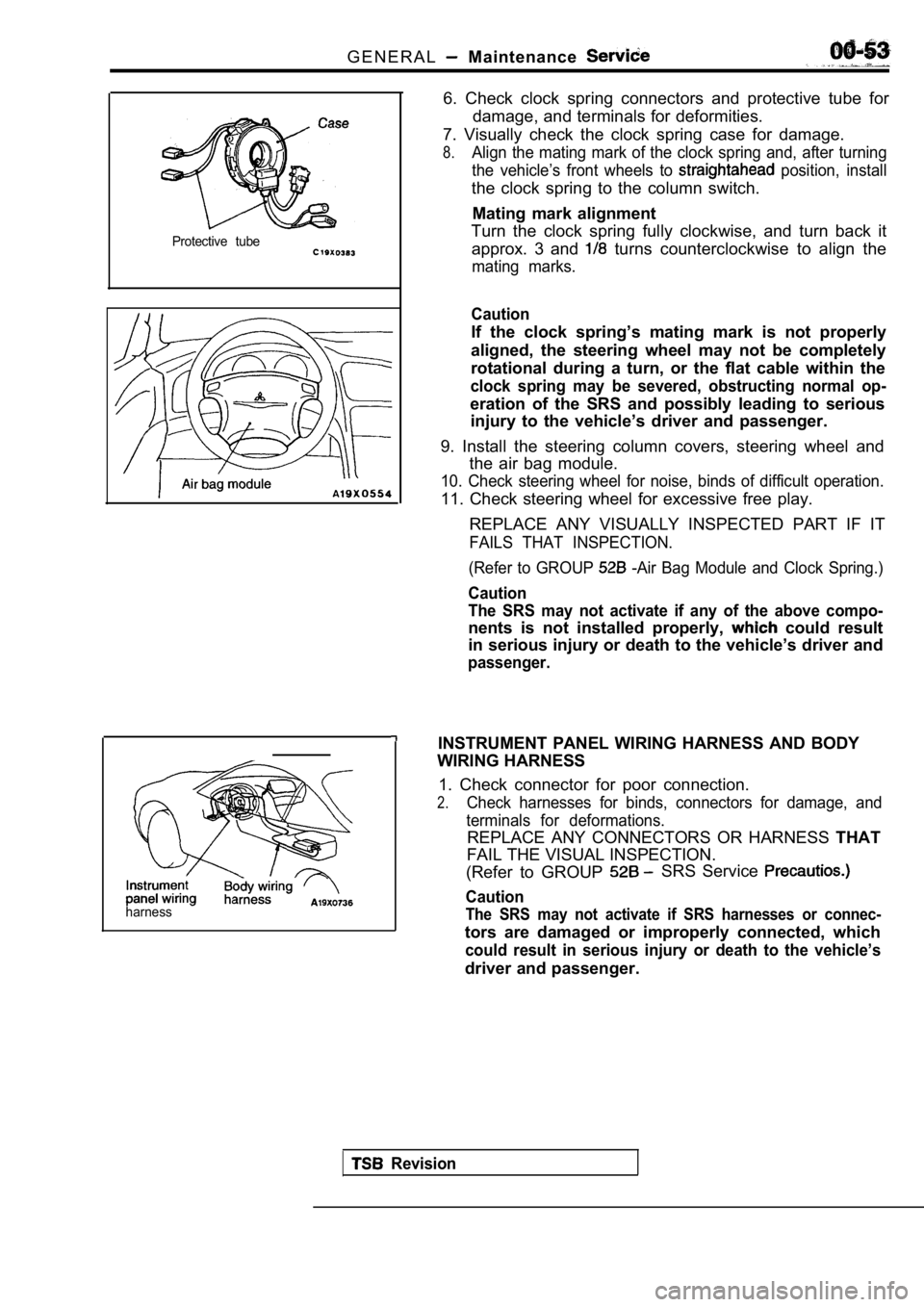

Protective tube

harness

6. Check clock spring connectors and protective tube for

damage, and terminals for deformities.

7. Visually check the clock spring case for damage.

8.Align the mating mark of the clock spring and, afte r turning

the vehicle’s front wheels to

position, install

the clock spring to the column switch.

Mating mark alignment

Turn the clock spring fully clockwise, and turn bac k it

approx. 3 and

turns counterclockwise to align the

mating marks.

Caution

If the clock spring’s mating mark is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal op-

eration of the SRS and possibly leading to serious

injury to the vehicle’s driver and passenger.

9. Install the steering column covers, steering whe el and

the air bag module.

10. Check steering wheel for noise, binds of diffic ult operation.

11. Check steering wheel for excessive free play.

REPLACE ANY VISUALLY INSPECTED PART IF IT

FAILS THAT INSPECTION.

(Refer to GROUP

-Air Bag Module and Clock Spring.)

Caution

The SRS may not activate if any of the above compo-

nents is not installed properly, could result

in serious injury or death to the vehicle’s driver and

passenger.

INSTRUMENT PANEL WIRING HARNESS AND BODY

WIRING HARNESS

1. Check connector for poor connection.

2.Check harnesses for binds, connectors for damage, a nd

terminals for deformations.

REPLACE ANY CONNECTORS OR HARNESS THAT

FAIL THE VISUAL INSPECTION.

(Refer to GROUP

SRS Service

Caution

The SRS may not activate if SRS harnesses or connec -

tors are damaged or improperly connected, which

could result in serious injury or death to the vehicle’s

driver and passenger.

Revision

Page 369 of 2103

E N G I N E O V E R H A U L Flywheel

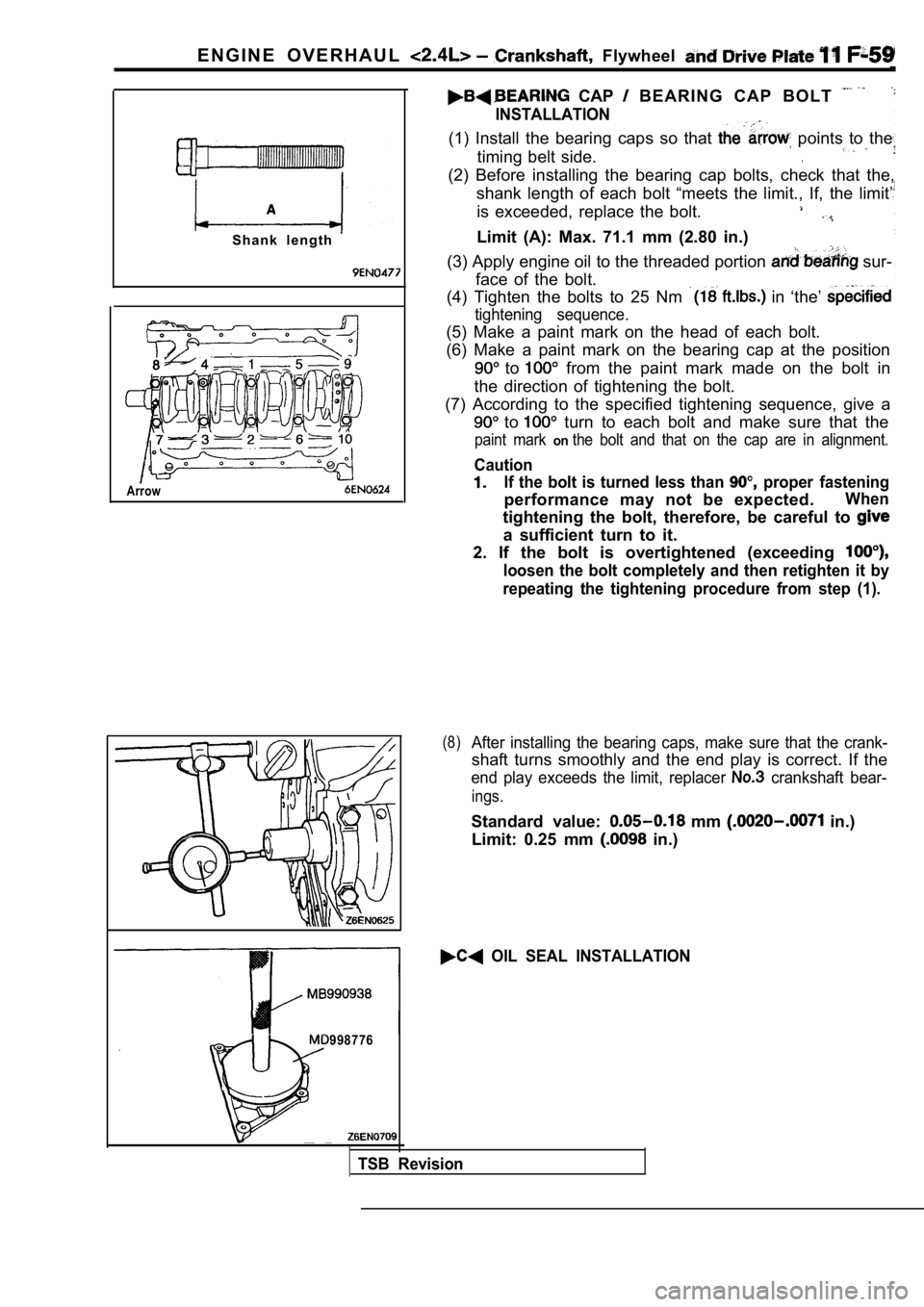

S h a n k l e n g t h

Arrow

CAP B E A R I N G C A P B O L T

INSTALLATION

(1) Install the bearing caps so that points to the

timing belt side.

(2) Before installing the bearing cap bolts, check that the,

shank length of each bolt “meets the limit., If, th e limit’

is exceeded, replace the bolt.

Limit (A): Max. 71.1 mm (2.80 in.)

(3) Apply engine oil to the threaded portion

sur-

face of the bolt.

(4) Tighten the bolts to 25 Nm

in ‘the’

tightening sequence.

(5) Make a paint mark on the head of each bolt.

(6) Make a paint mark on the bearing cap at the pos ition

to from the paint mark made on the bolt in

the direction of tightening the bolt.

(7) According to the specified tightening sequence, give a

to turn to each bolt and make sure that the

paint mark onthe bolt and that on the cap are in alignment.

Caution

If the bolt is turned less than proper fastening

performance may not be expected.When

tightening the bolt, therefore, be careful to

a sufficient turn to it.

2. If the bolt is overtightened (exceeding

loosen the bolt completely and then retighten it by

repeating the tightening procedure from step (1).

(8)After installing the bearing caps, make sure that t he crank-

shaft turns smoothly and the end play is correct. I f the

end play exceeds the limit, replacer crankshaft bear-

ings.

Standard value: mm in.)

Limit: 0.25 mm

in.)

OIL SEAL INSTALLATION

998776

TSB Revision

Page 734 of 2103

INTAKE AND EXHAUST Exhaust Manifold ENGINE (Turbo)>

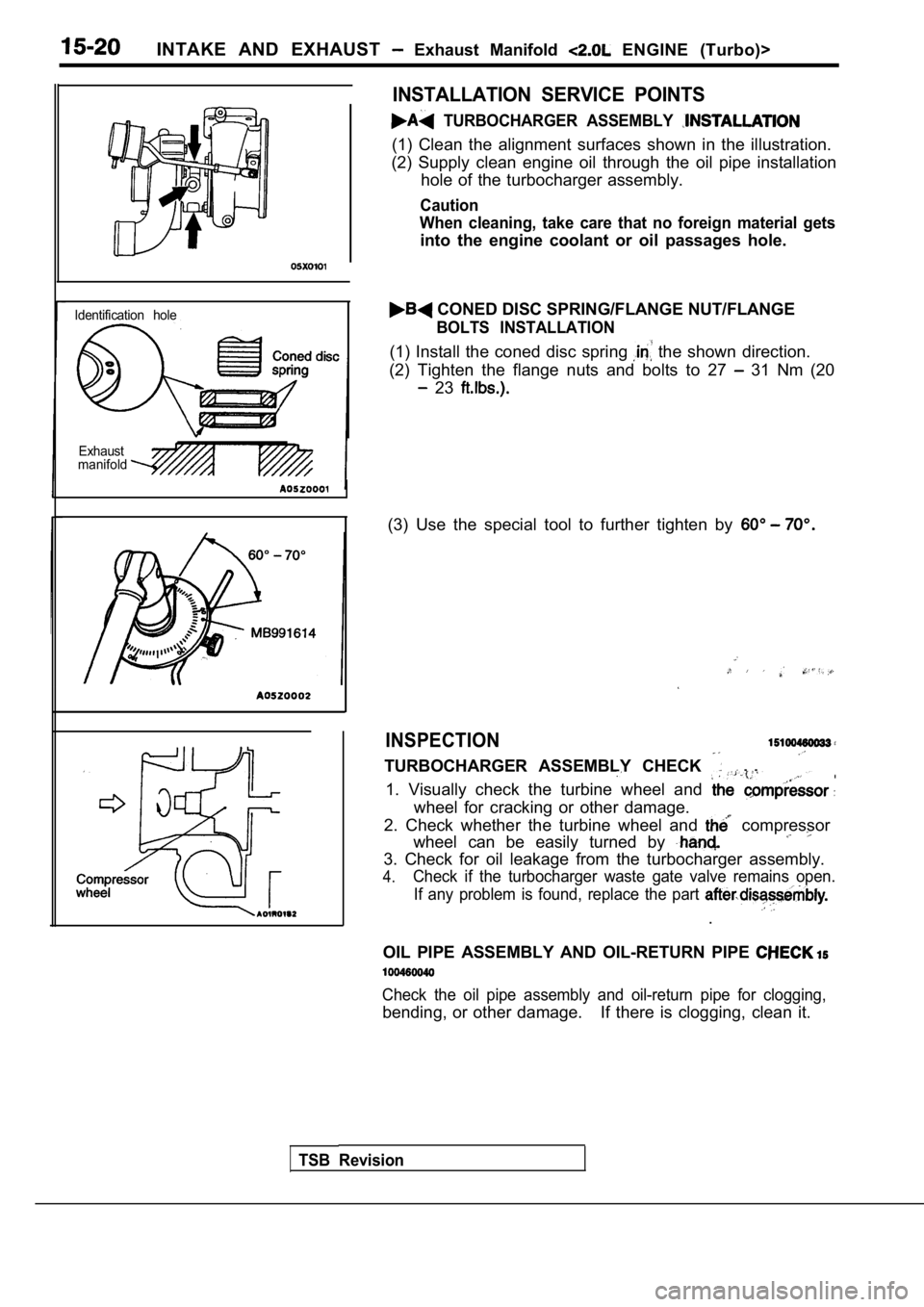

Identification holeExhaust

manifold

INSTALLATION SERVICE POINTS

TURBOCHARGER ASSEMBLY

(1) Clean the alignment surfaces shown in the illus tration.

(2) Supply clean engine oil through the oil pipe in stallation

hole of the turbocharger assembly.

Caution

When cleaning, take care that no foreign material g ets

into the engine coolant or oil passages hole.

CONED DISC SPRING/FLANGE NUT/FLANGE

BOLTS INSTALLATION

(1) Install the coned disc spring the shown direction.

(2) Tighten the flange nuts and bolts to 27

31 Nm (20

23

(3) Use the special tool to further tighten by

INSPECTION

TURBOCHARGER ASSEMBLY CHECK . .

1. Visually check the turbine wheel and

wheel for cracking or other damage.

2. Check whether the turbine wheel and

compressor

wheel can be easily turned by

3. Check for oil leakage from the turbocharger asse mbly.

4.Check if the turbocharger waste gate valve remains open.

If any problem is found, replace the part

.

OIL PIPE ASSEMBLY AND OIL-RETURN PIPE

Check the oil pipe assembly and oil-return pipe for clogging,

bending, or other damage. If there is clogging, clea n it.

TSB Revision

Page 1159 of 2103

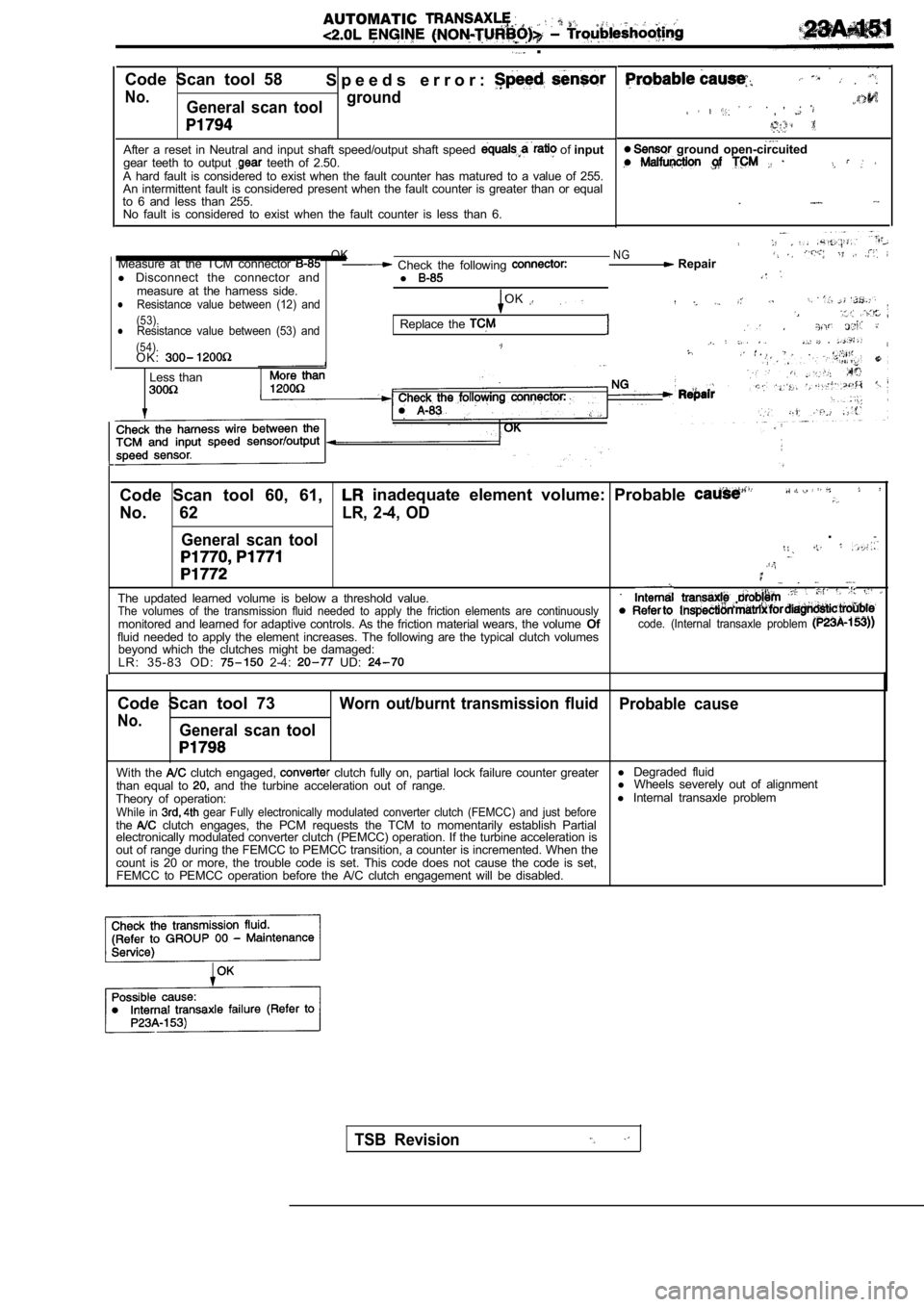

AUTOMATIC .

.

Code Scan tool 58 S p e e d s e r r o r :

No.General scan toolground

After a reset in Neutral and input shaft speed/outp

ut shaft speed of input

gear teeth to output teeth of 2.50.

A hard fault is considered to exist when the fault counter has matured to a value of 255.

An intermittent fault is considered present when th e fault counter is greater than or equal

to 6 and less than 255. No fault is considered to exist when the fault coun ter is less than 6.

.

. , ,

. .

ground open-circuited

OKNGMeasure at the TCM connector Check the following Repair

l Disconnect the connector and

l

measure at the harness side.Resistance value between (12) andOKl

(53).lResistance value between (53) andReplace the . (54).O K :.

Less than

Code Scan tool 60, 61, inadequate element volume: Probable

No. 62LR, 2-4, OD

General scan tool

.

The updated learned volume is below a threshold val ue..The volumes of the transmission fluid needed to app

ly the friction elements are continuouslymonitored and learned for adaptive controls. As the friction material wears, the volume Ofcode. (Internal transaxle problem fluid needed to apply the element increases. The fo llowing are the typical clutch volumes

beyond which the clutches might be damaged:

L R : 3 5 - 8 3 O D :

2-4: UD:

Code Scan tool 73Worn out/burnt transmission fluid Probable cause

No.General scan tool

With the clutch engaged, clutch fully on, partial lock failure counter greaterl

Degraded fluid

than equal to and the turbine acceleration out of range. l

Wheels severely out of alignment

Theory of operation: l

Internal transaxle problem

While in gear Fully electronically modulated converter clut ch (FEMCC) and just beforethe clutch engages, the PCM requests the TCM to moment arily establish Partial

electronically modulated converter clutch (PEMCC) o peration. If the turbine acceleration is

out of range during the FEMCC to PEMCC transition, a counter is incremented. When the

count is 20 or more, the trouble code is set. This code does not cause the code is set,

FEMCC to PEMCC operation before the A/C clutch enga gement will be disabled.

TSB Revision

Page 1551 of 2103

REAR AXLE On-vehicle Service

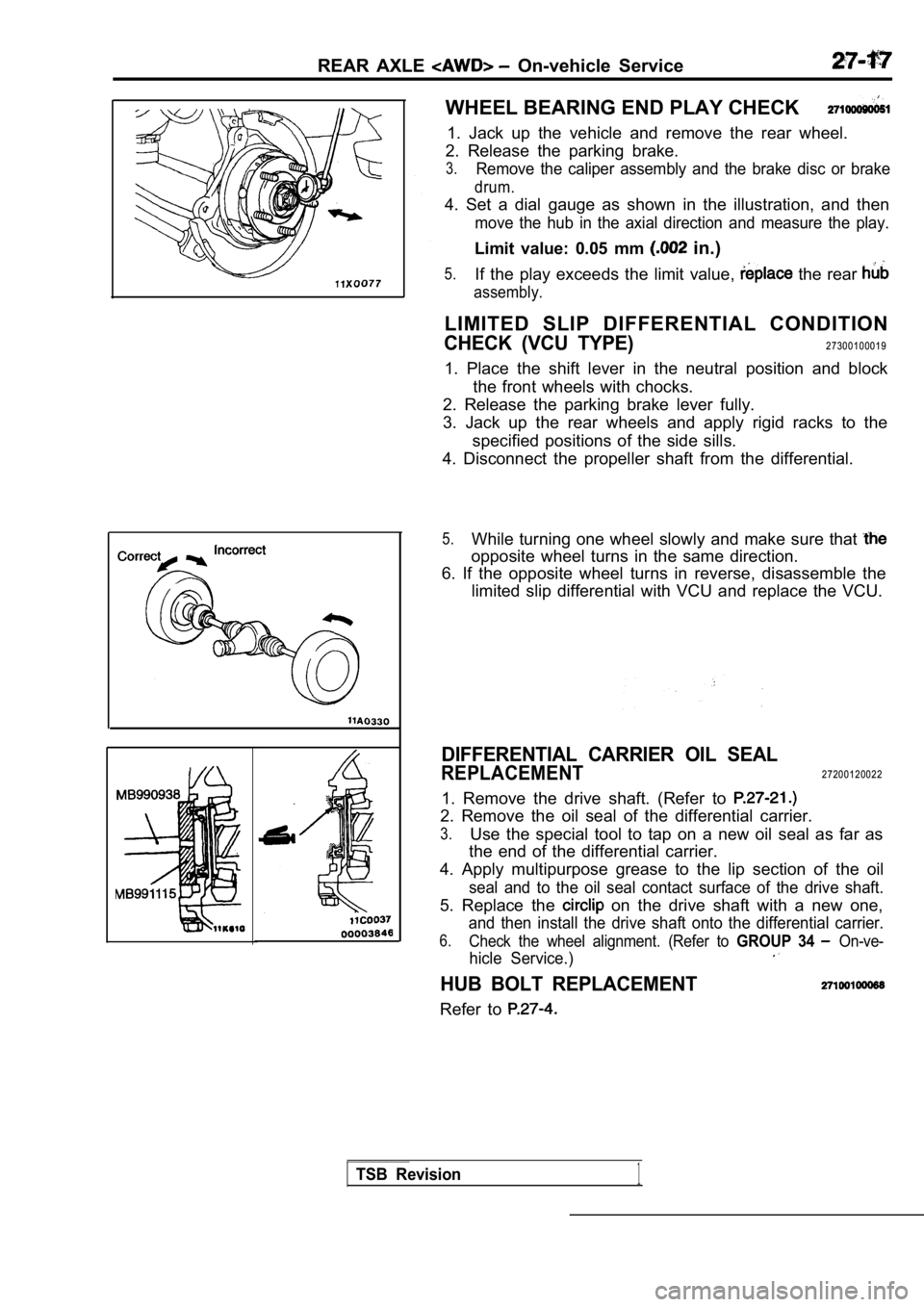

WHEEL BEARING END PLAY CHECK

1. Jack up the vehicle and remove the rear wheel.

2. Release the parking brake.

3.Remove the caliper assembly and the brake disc or b rake

drum.

4. Set a dial gauge as shown in the illustration, and then

move the hub in the axial direction and measure the play.

Limit value: 0.05 mm in.)

5.If the play exceeds the limit value, the rear

assembly.

LIMITED SLIP DIFFERENTIAL CONDITION

CHECK (VCU TYPE)27300100019

1. Place the shift lever in the neutral position an d block

the front wheels with chocks.

2. Release the parking brake lever fully.

3. Jack up the rear wheels and apply rigid racks to the

specified positions of the side sills.

4. Disconnect the propeller shaft from the differen tial.

5.While turning one wheel slowly and make sure that

opposite wheel turns in the same direction.

6. If the opposite wheel turns in reverse, disassem ble the

limited slip differential with VCU and replace the VCU.

DIFFERENTIAL CARRIER OIL SEAL

REPLACEMENT27200120022

1. Remove the drive shaft. (Refer to

2. Remove the oil seal of the differential carrier.

3.Use the special tool to tap on a new oil seal as fa r as

the end of the differential carrier.

4. Apply multipurpose grease to the lip section of the oil

seal and to the oil seal contact surface of the drive shaft.

5. Replace the on the drive shaft with a new one,

and then install the drive shaft onto the differential carrier.

6.Check the wheel alignment. (Refer to GROUP 34 On-ve-

hicle Service.)

HUB BOLT REPLACEMENT

Refer to

TSB Revision1

Page 1588 of 2103

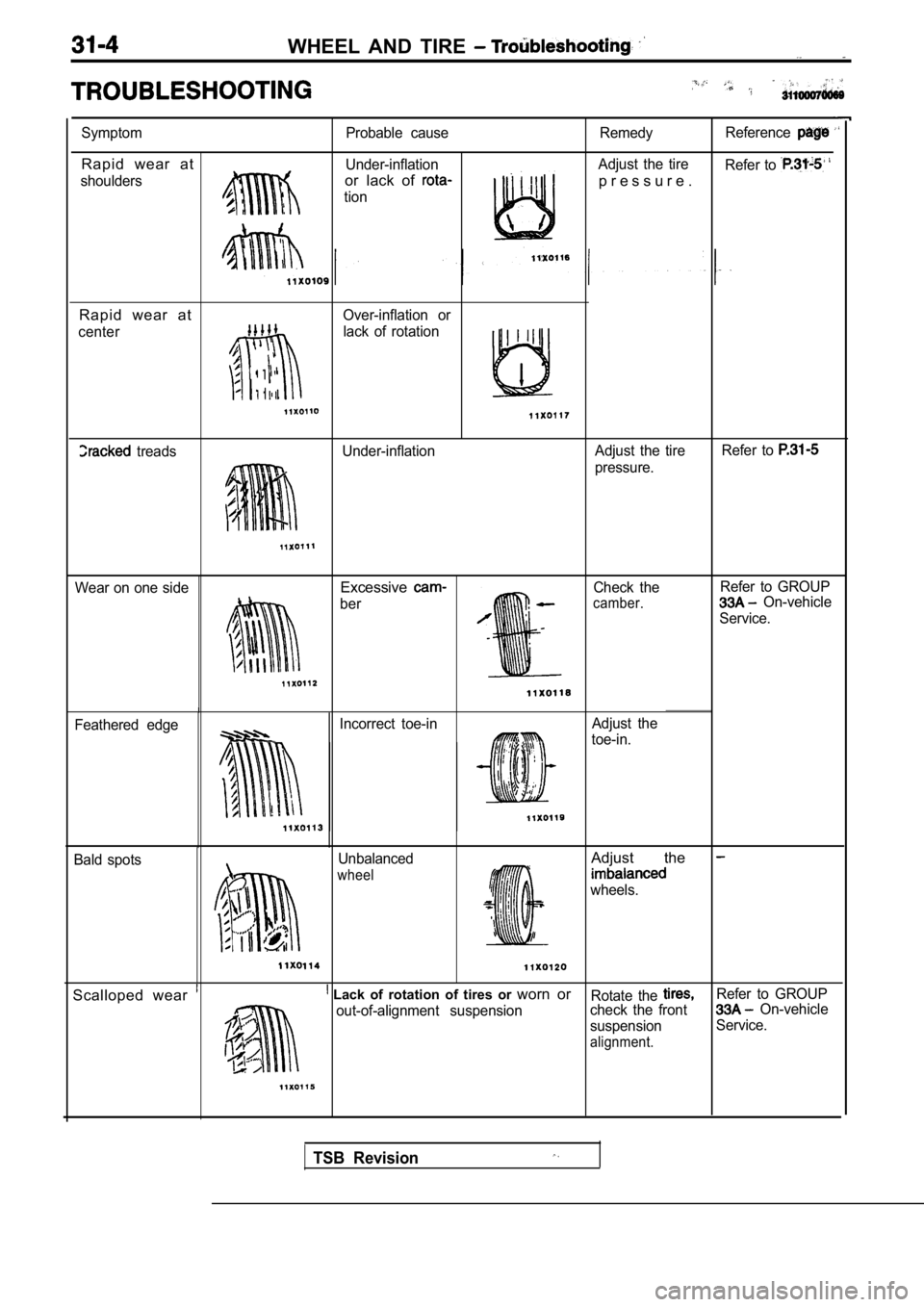

WHEEL AND TIRE

Symptom

Rapid wear at

shouldersProbable cause

Under-inflationor lack of

tion

Remedy Reference

Adjust the tire

Refer to

p r e s s u r e .

Rapid wear at

Over-inflation or

center

lack of rotation

I

treads Under-inflation Adjust the tireRefer to

pressure.

Wear on one side

Excessive

ber Check thecamber.

Refer to GROUP On-vehicle

Service.

Feathered edge Incorrect toe-in

Adjust the

toe-in.

Bald spots Unbalanced

wheel

Adjust the

wheels.

Scalloped wear Lack of rotation of tires or

worn orRotate the Refer to GROUP

out-of-alignment suspension check the front On-vehicle

suspension Service.

alignment.

TSB Revision

Page 1601 of 2103

FRONT

CONTENTS

COMPRESSION LOWER ARM ANDSHOCK ABSORBER ASSEMBLY.. . . . . . . . 8

LATERAL LOWER ARM ASSEMBLIES . . . . . 11

SPECIAL TOOLS3

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

STABILIZER BAR. . . . . . . . . . . . . . . ..*.......14

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 4

Front Wheel Alignment CheckTROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 4

and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4UPPER ARM ASSEMBLY . . . . . . . . . . . . . . . .

. . . 6

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 3

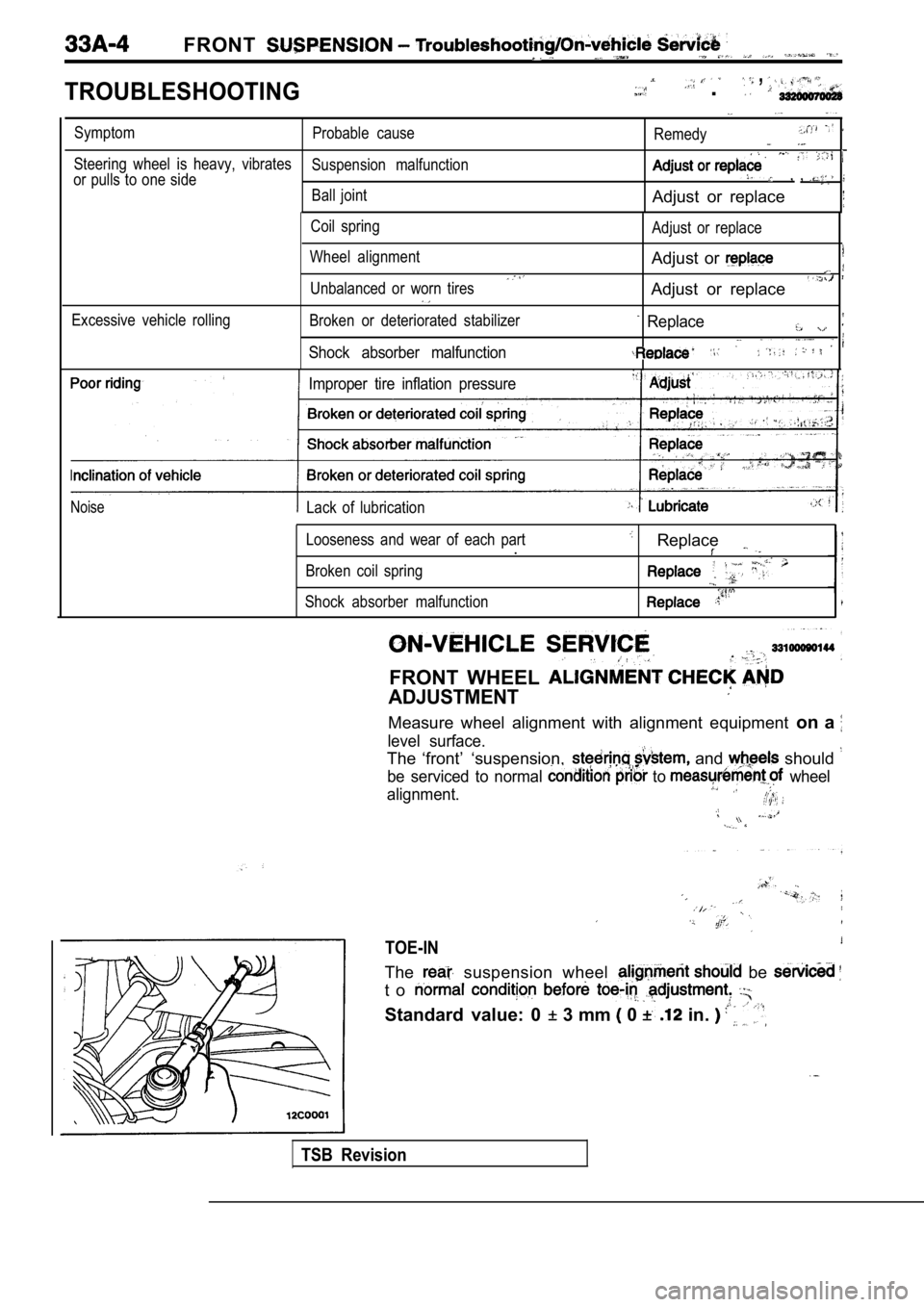

Page 1604 of 2103

FRONT __

TROUBLESHOOTING

, .

SymptomProbable cause

Remedy

Steering wheel is heavy, vibratesSuspension malfunction

or pulls to one side, ,

Ball jointAdjust or replace

Coil spring

Wheel alignment

Unbalanced or worn tires Adjust or replace

Adjust or

Adjust or replace

Excessive vehicle rollingBroken or deteriorated stabilizer

Shock absorber malfunction

Replace

Improper tire inflation pressure

NoiseLack of lubrication

Looseness and wear of each part

.

Broken coil spring

Shock absorber malfunction

Replace

FRONT WHEEL

ADJUSTMENT

Measure wheel alignment with alignment equipment on a

level surface.

The ‘front’ ‘suspension, and should

be serviced to normal to wheel

alignment.

TOE-IN

The suspension wheel be

t o

Standard value: 0 3 mm 0 in.

TSB Revision

Page 1606 of 2103

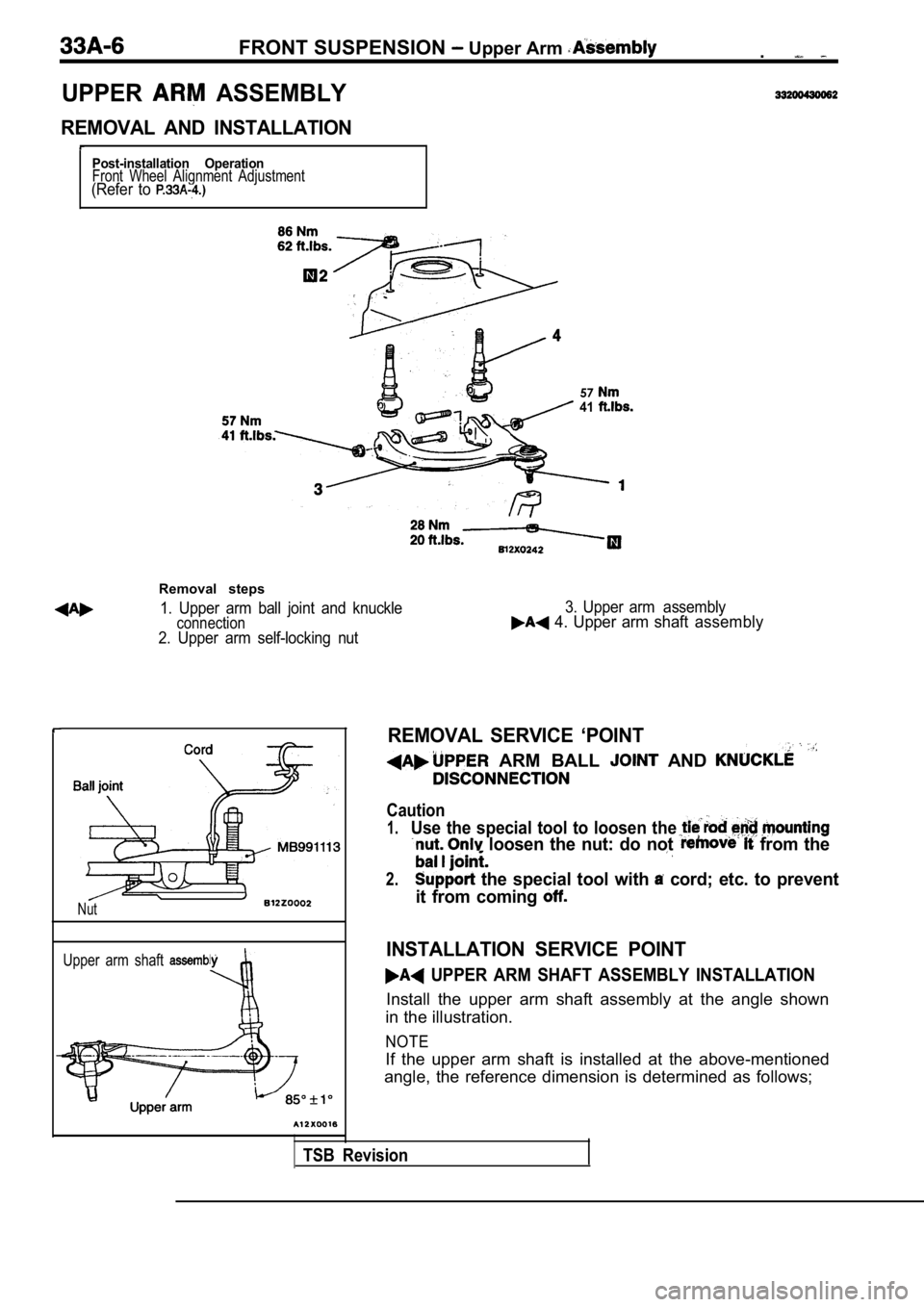

FRONT SUSPENSION Upper Arm .

UPPER ASSEMBLY

REMOVAL AND INSTALLATION

Post-installation OperationFront Wheel Alignment Adjustment(Refer to

5741

Removal steps

1. Upper arm ball joint and knuckleconnection2. Upper arm self-locking nut3. Upper arm assembly

4. Upper arm shaft assembly

Nut

Upper arm shaft

REMOVAL SERVICE ‘POINT

ARM BALL AND

Caution

1.Use the special tool to loosen the

loosen the nut: do not from the

2. the special tool with cord; etc. to prevent

it from coming

INSTALLATION SERVICE POINT

UPPER ARM SHAFT ASSEMBLY INSTALLATION

Install the upper arm shaft assembly at the angle s hown

in the illustration.

NOTE

If the upper arm shaft is installed at the above-me ntioned

angle, the reference dimension is determined as fol lows;

TSB Revision

Page 1608 of 2103

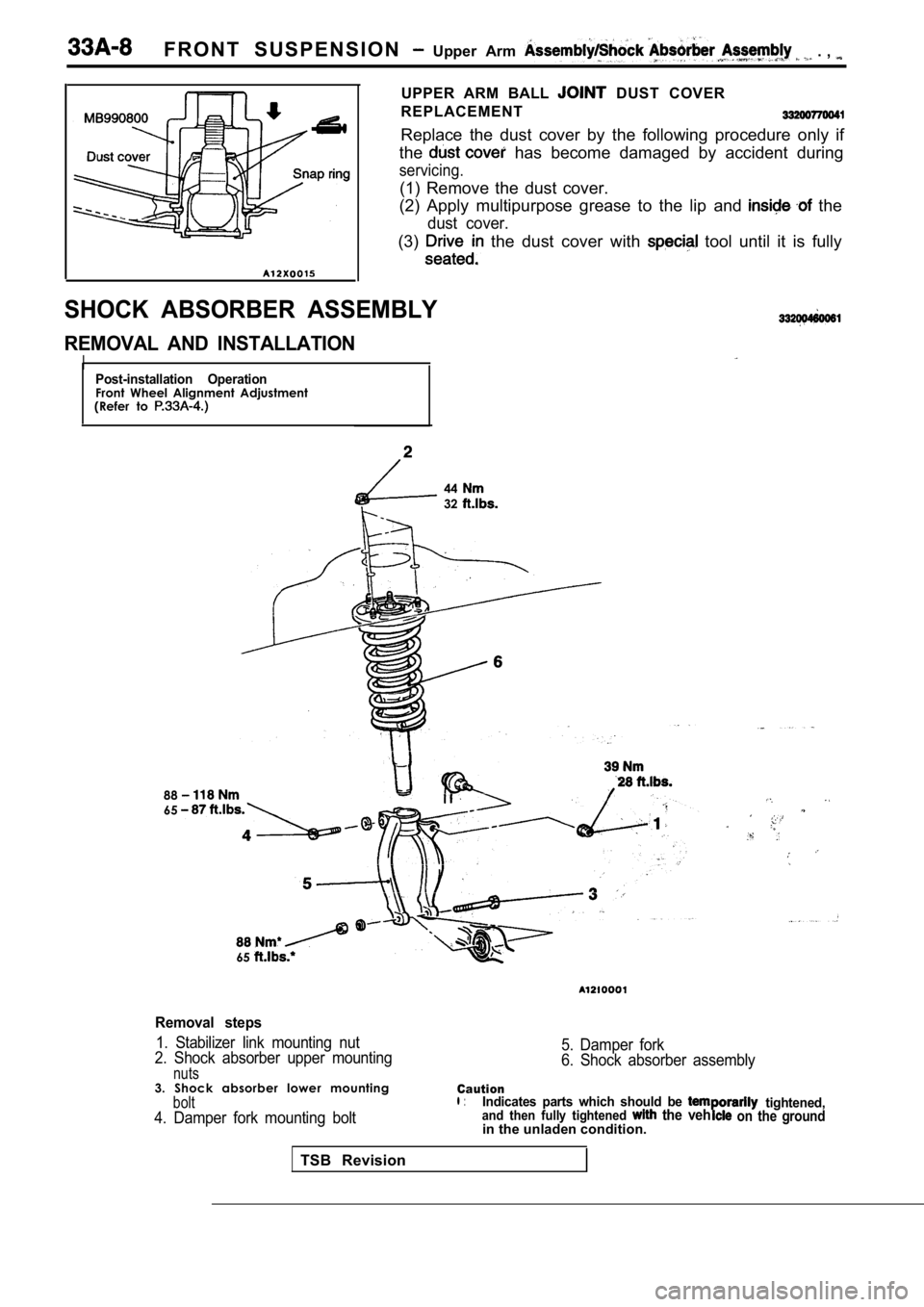

F R O N T S U S P E N S I O N Upper Arm . ,

UPPER ARM BALL DUST COVER

REPLACEMENT

Replace the dust cover by the following procedure o nly if

the

has become damaged by accident during

servicing.

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and

the

dust cover.

(3) the dust cover with tool until it is fully

.

SHOCK ABSORBER ASSEMBLY

REMOVAL AND INSTALLATION

I,Post-installation OperationFront Wheel Alignment Adjustment

(Refer to

8865

4432

65

Removal steps

1. Stabilizer link mounting nut

2. Shock absorber upper mounting

nuts

5. Damper fork

6. Shock absorber assembly

3. Shock absorber lower mounting

bolt4. Damper fork mounting bolt

Cautionl :Indicates parts which should be tightened,and then fully tightened the veh on the groundin the unladen condition.

TSB Revision