water pump MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 42 of 2103

GENERAL Maintenance

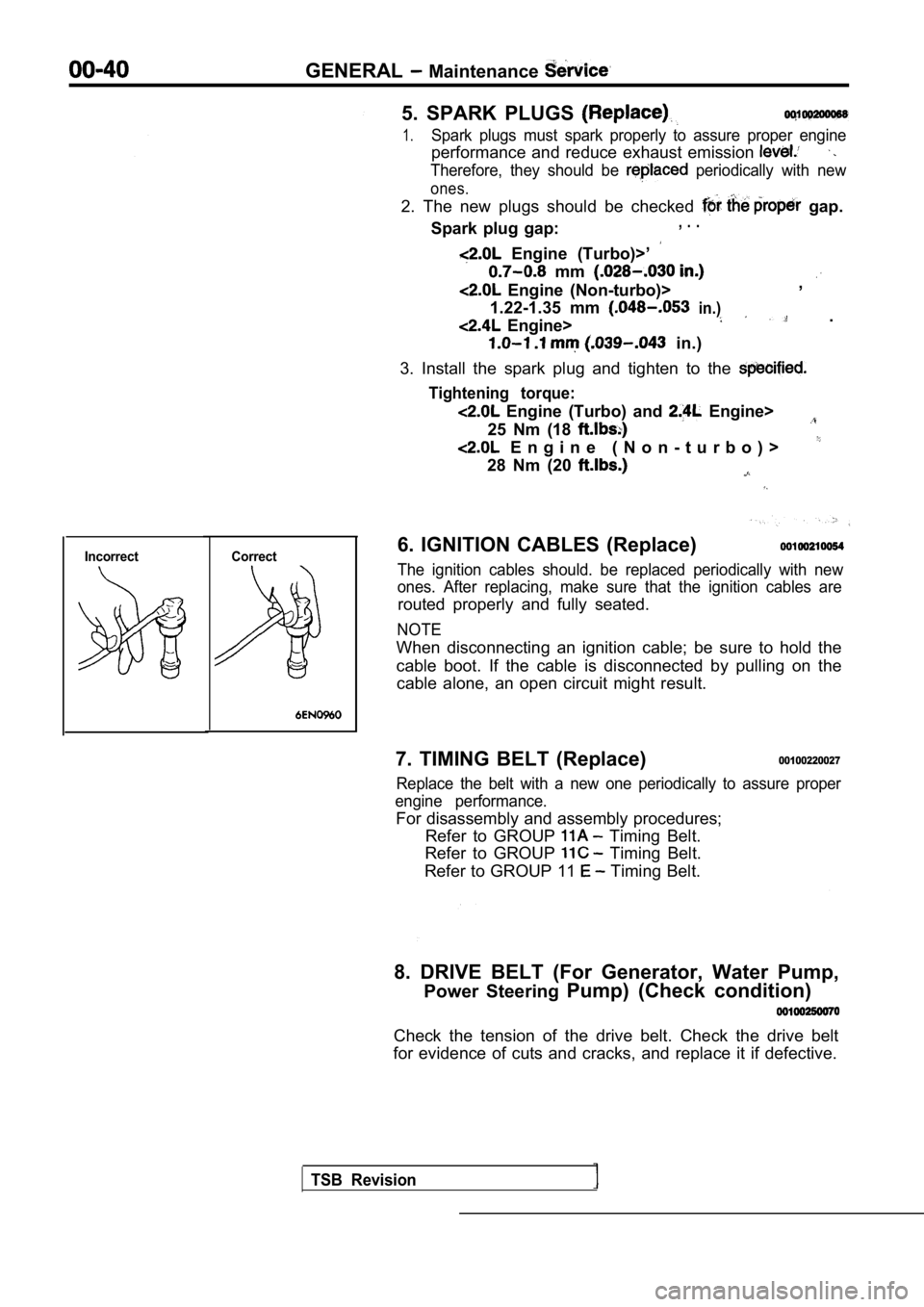

Incorrect Correct

5. SPARK PLUGS

1.Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission

Therefore, they should be periodically with new

ones.

2. The new plugs should be checked gap.

Spark plug gap:, . .

Engine (Turbo)>’

mm

Engine (Non-turbo)> ,

1.22-1.35 mm

in.)

Engine> .

in.)

3. Install the spark plug and tighten to the

Tightening torque:

Engine (Turbo) and Engine>

25 Nm (18

E n g i n e ( N o n - t u r b o ) >

28 Nm (20

6. IGNITION CABLES (Replace)

The ignition cables should. be replaced periodicall y with new

ones. After replacing, make sure that the ignition cables are

routed properly and fully seated.

NOTE

When disconnecting an ignition cable; be sure to ho ld the

cable boot. If the cable is disconnected by pulling on the

cable alone, an open circuit might result.

7. TIMING BELT (Replace)

00100220027

Replace the belt with a new one periodically to ass ure proper

engine performance.

For disassembly and assembly procedures; Refer to GROUP

Timing Belt.

Refer to GROUP

Timing Belt.

Refer to GROUP 11

Timing Belt.

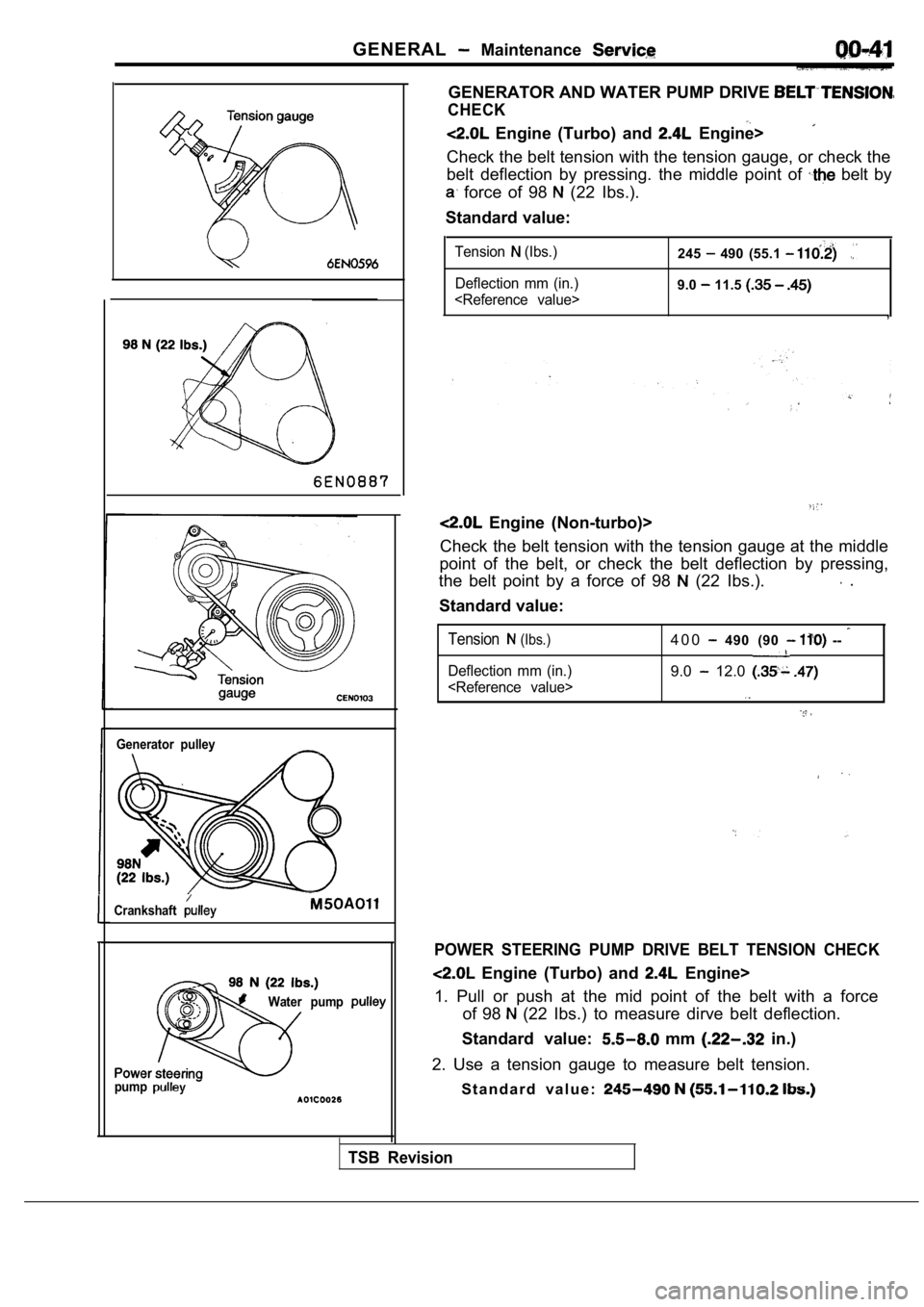

8. DRIVE BELT (For Generator, Water Pump, Power Steering Pump) (Check condition)

Check the tension of the drive belt. Check the driv e belt

for evidence of cuts and cracks, and replace it if defective.

TSB Revision

Page 43 of 2103

GENERAL Maintenance

Generator pulley

Crankshaft

Water pump

pump

GENERATOR AND WATER PUMP DRIVE

CHECK

Engine (Turbo) and Engine>

Check the belt tension with the tension gauge, or c heck the

belt deflection by pressing. the middle point of

belt by

force of 98 (22 Ibs.).

Standard value:

Tension (Ibs.)

Deflection mm (in.)

9.0 11.5

,

Engine (Non-turbo)>

Check the belt tension with the tension gauge at th e middle

point of the belt, or check the belt deflection by pressing,

the belt point by a force of 98

(22 Ibs.). .

Standard value:

Tension (Ibs.)

Deflection mm (in.)

4 0 0 490 (90 --

9.0 12.0

POWER STEERING PUMP DRIVE BELT TENSION CHECK

Engine (Turbo) and Engine>

1. Pull or push at the mid point of the belt with a force

of 98

(22 Ibs.) to measure dirve belt deflection.

Standard value:

mm in.)

2. Use a tension gauge to measure belt tension. S t a n d a r d v a l u e :

TSB Revision

Page 92 of 2103

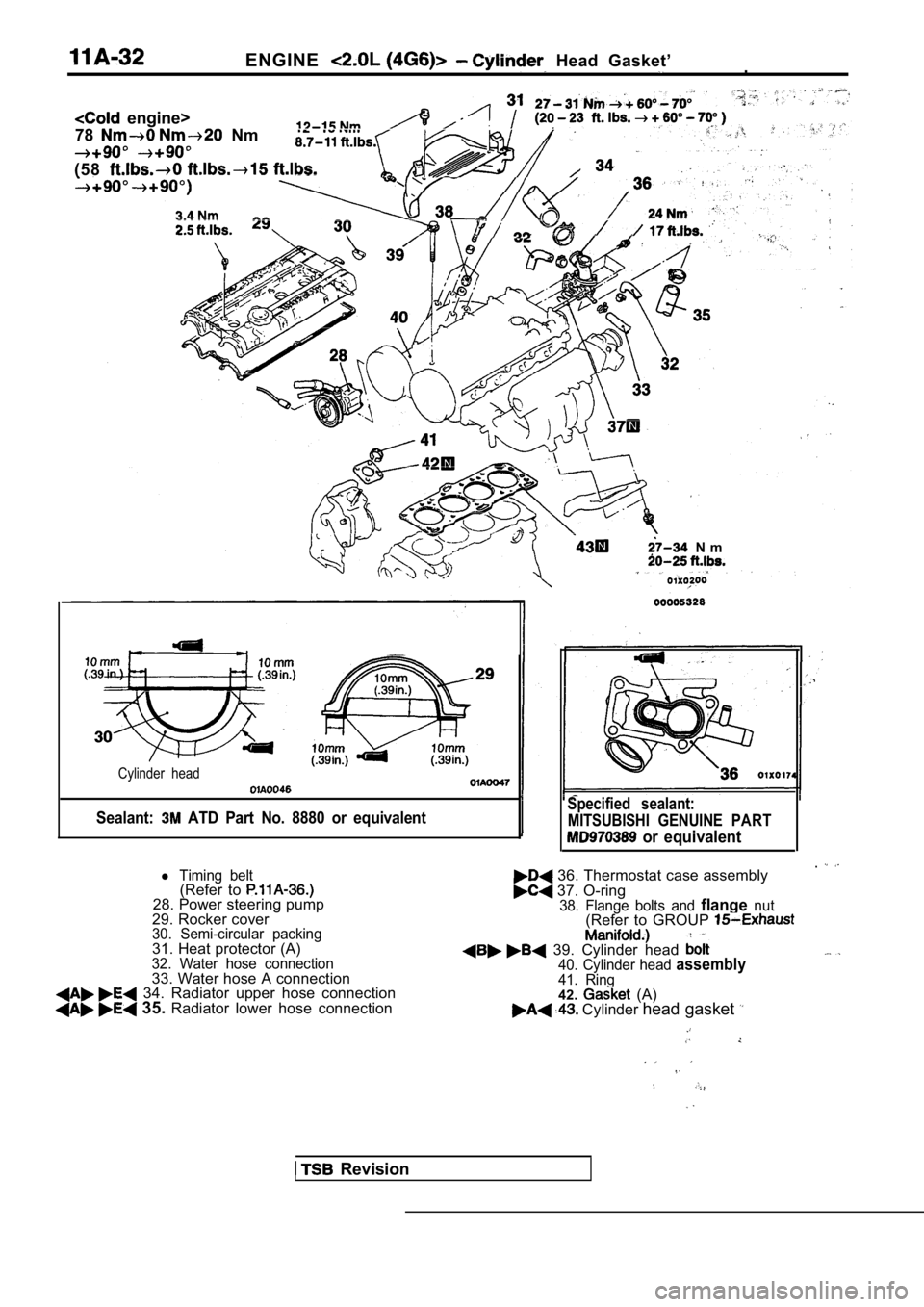

ENGINE Head Gasket’.

engine>

78

Nm

(58

N m

Cylinder head

Sealant: ATD Part No. 8880 or equivalent

Revision

Specified sealant: MITSUBISHI GENUINE PART

or equivalent

36. Thermostat case assembly 37. O-ring38. Flange bolts and flangenut(Refer to GROUP

39. Cylinder head 40. Cylinder head assembly41. Ring42. (A) Cylinder head gasket

l Timing belt(Refer to 28. Power steering pump

29. Rocker cover

30. Semi-circular packing31. Heat protector (A)32. Water hose connection33. Water hose A connection 34. Radiator upper hose connection 35. Radiator lower hose connection

Page 94 of 2103

ENGINE H e a d

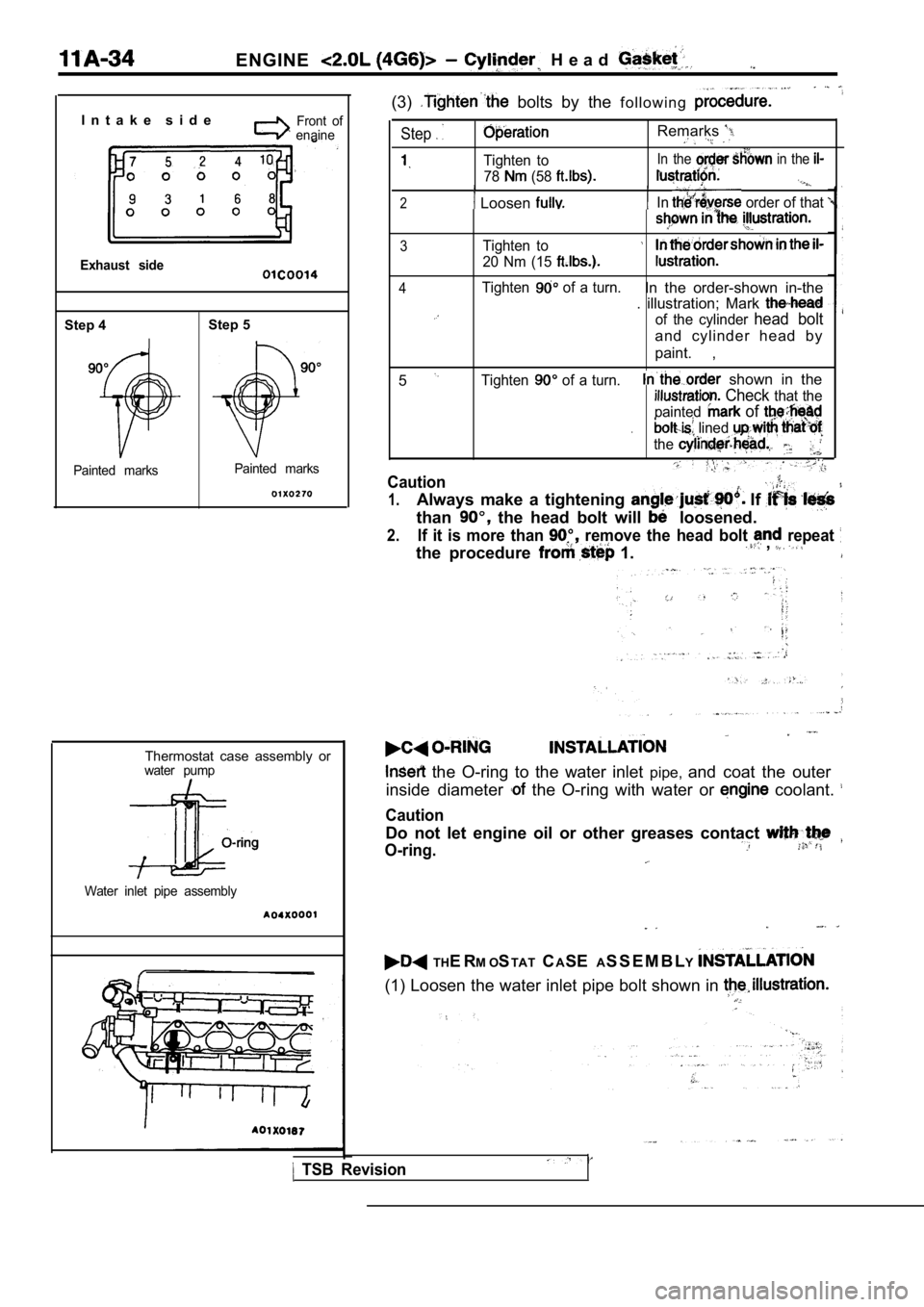

I n t a k e s i d eFront of

enaine

Exhaust side

Step 4

I

Painted marks

Step 5

Painted marks

Thermostat case assembly orwater pump

Water inlet pipe assembly

(3) bolts by the f o l l o w i n g

Step

Tighten to

78

(58

Remarks

In the in the

2 Loosen In order of that

3Tighten to

20 Nm (15

4Tighten of a turn.In the order-shown in-the

. illustration; Mark

of the cylinder head bolt

and cylinder head by

paint. ,

5

Tighten of a turn. shown in the

Check that the

painted

of

. lined

the

Caution

1.Always make a tightening If

than the head bolt will loosened.

2.If it is more than remove the head bolt repeat

the procedure 1. ,

the O-ring to the water inlet pipe,and coat the outer

inside diameter

the O-ring with water or coolant.

Caution

Do not let engine oil or other greases contact

O-ring.

TH E R M OSTAT CASE AS S E M B L Y

(1) Loosen the water inlet pipe bolt shown in

TSB Revision

Page 96 of 2103

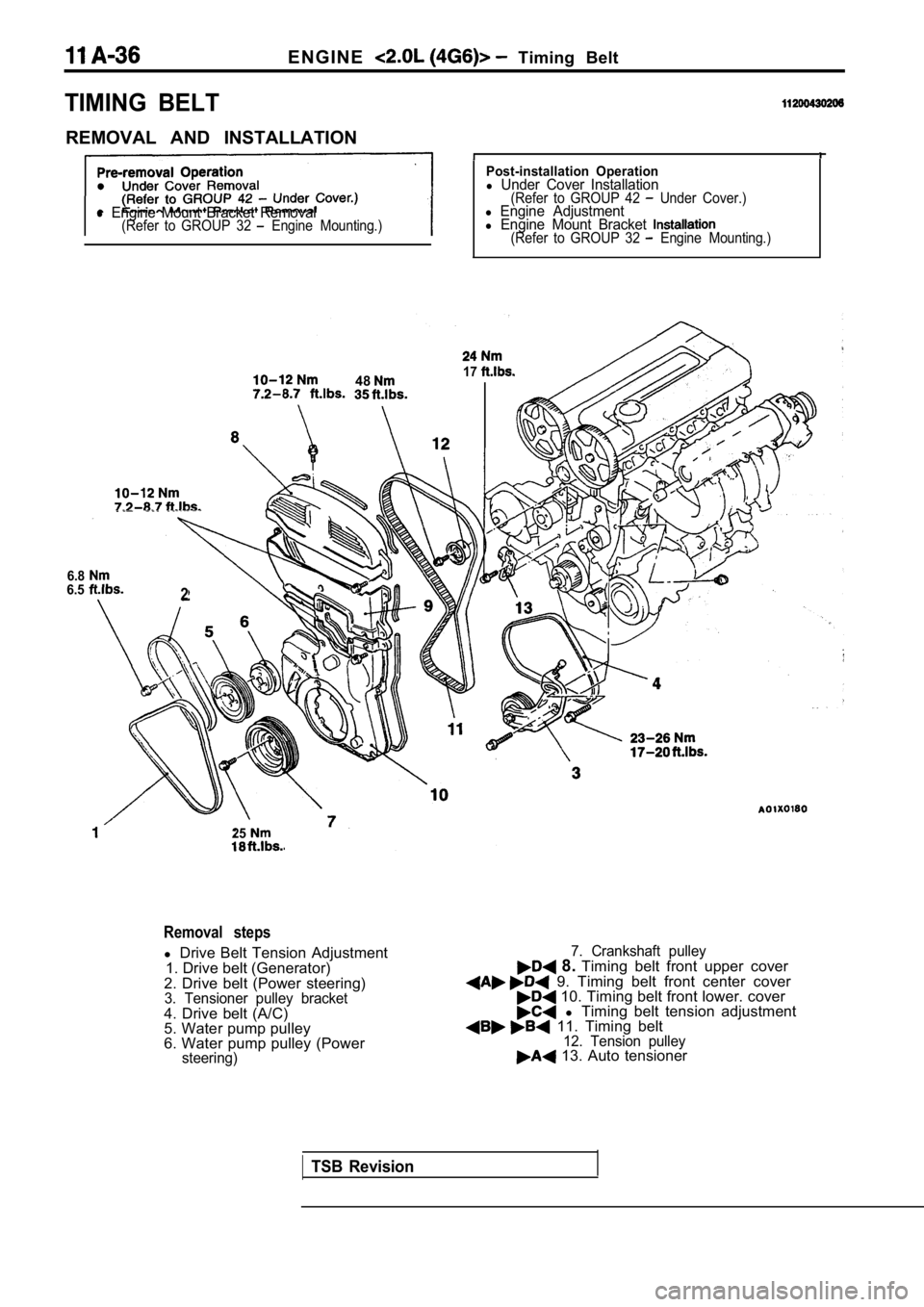

E N G I N E Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

l Engine Mount Bracket Removal(Refer to GROUP 32 Engine Mounting.)

Post-installation Operationl Under Cover Installation(Refer to GROUP 42 Under Cover.)l Engine Adjustmentl Engine Mount Bracket (Refer to GROUP 32 Engine Mounting.)

4817

6.86.52

25

Removal steps

l Drive Belt Tension Adjustment

1. Drive belt (Generator)

2. Drive belt (Power steering)

3. Tensioner pulley bracket4. Drive belt (A/C)

5. Water pump pulley

6. Water pump pulley (Power

steering)

7. Crankshaft pulley 8. Timing belt front upper cover 9. Timing belt front center cover 10. Timing belt front lower. cover l Timing belt tension adjustment 11. Timing belt12. Tension pulley 13. Auto tensioner

TSB Revision

Page 97 of 2103

ENGINE Timing

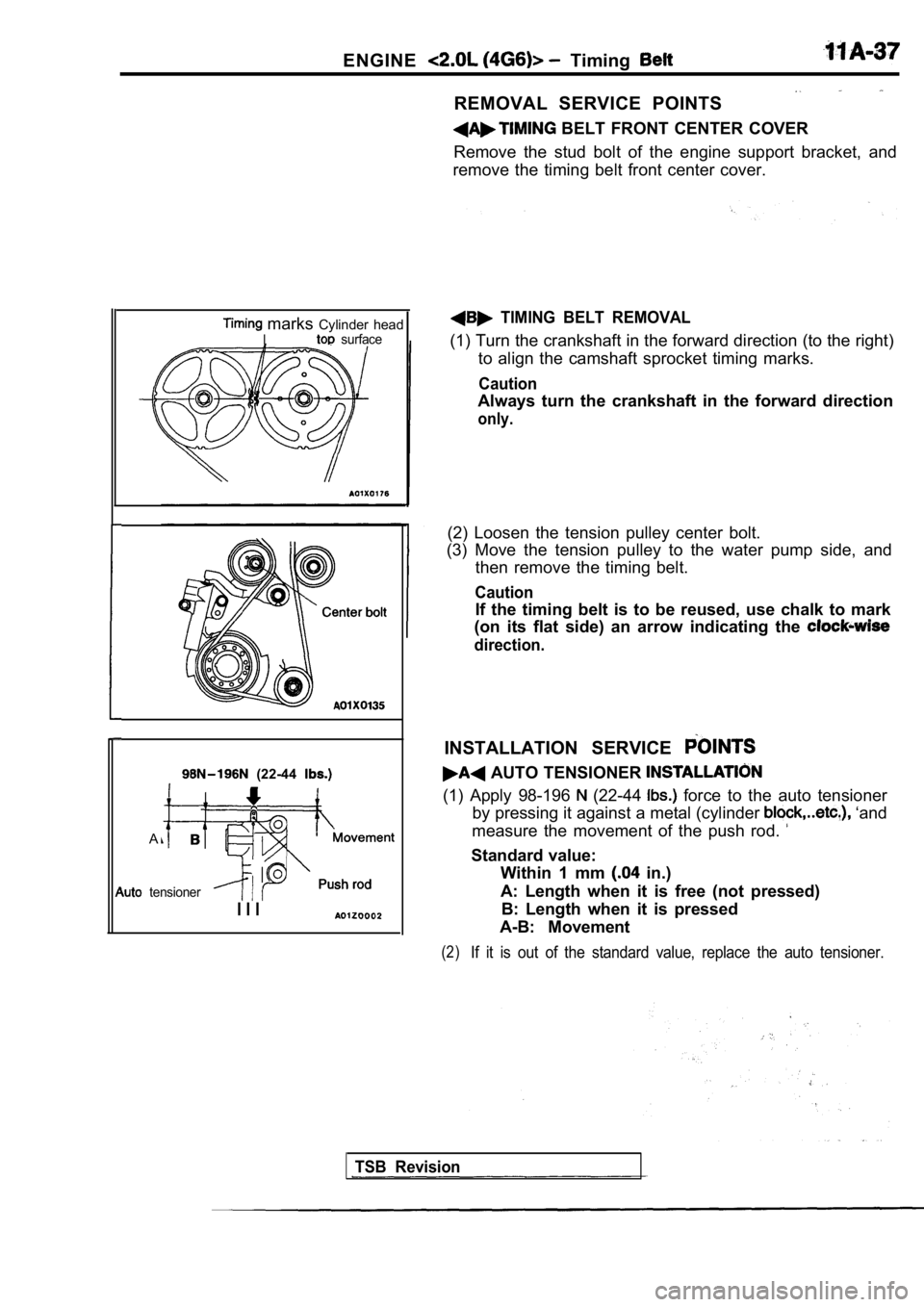

(22-44

A

tensioner

marks Cylinder headI surface

I I I

REMOVAL SERVICE POINTS

BELT FRONT CENTER COVER

Remove the stud bolt of the engine support bracket, and

remove the timing belt front center cover.

TIMING BELT REMOVAL

(1) Turn the crankshaft in the forward direction (t o the right)

to align the camshaft sprocket timing marks.

Caution

Always turn the crankshaft in the forward direction

only.

(2) Loosen the tension pulley center bolt.

(3) Move the tension pulley to the water pump side, and

then remove the timing belt.

Caution

If the timing belt is to be reused, use chalk to ma rk

(on its flat side) an arrow indicating the

direction.

INSTALLATION SERVICE

AUTO TENSIONER

(1) Apply 98-196 (22-44 force to the auto tensioner

by pressing it against a metal (cylinder

‘and

measure the movement of the push rod.

Standard value: Within 1 mm

in.)

A: Length when it is free (not pressed) B: Length when it is pressed

A-B: Movement

(2)If it is out of the standard value, replace the aut o tensioner.

TSB Revision

Page 105 of 2103

CONTENTS

BRACKET65

CRANKSHAFT, FLYWHEEL ANDDRIVE PLATE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

CYLINDER HEAD AND VALVES . . . . . . . . . . . 36

EXHAUST MANIFOLD AND

WATER PUMP. . . . . . . * . . . . . . . . . . . . . . . . . . . .29

FRONT CASE, COUNTERBALANCE

SHAFT AND OIL PAN . . . . . . . . . . . . . . . . . . . . . 42

FUEL AND EMISSION CONTROL

PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

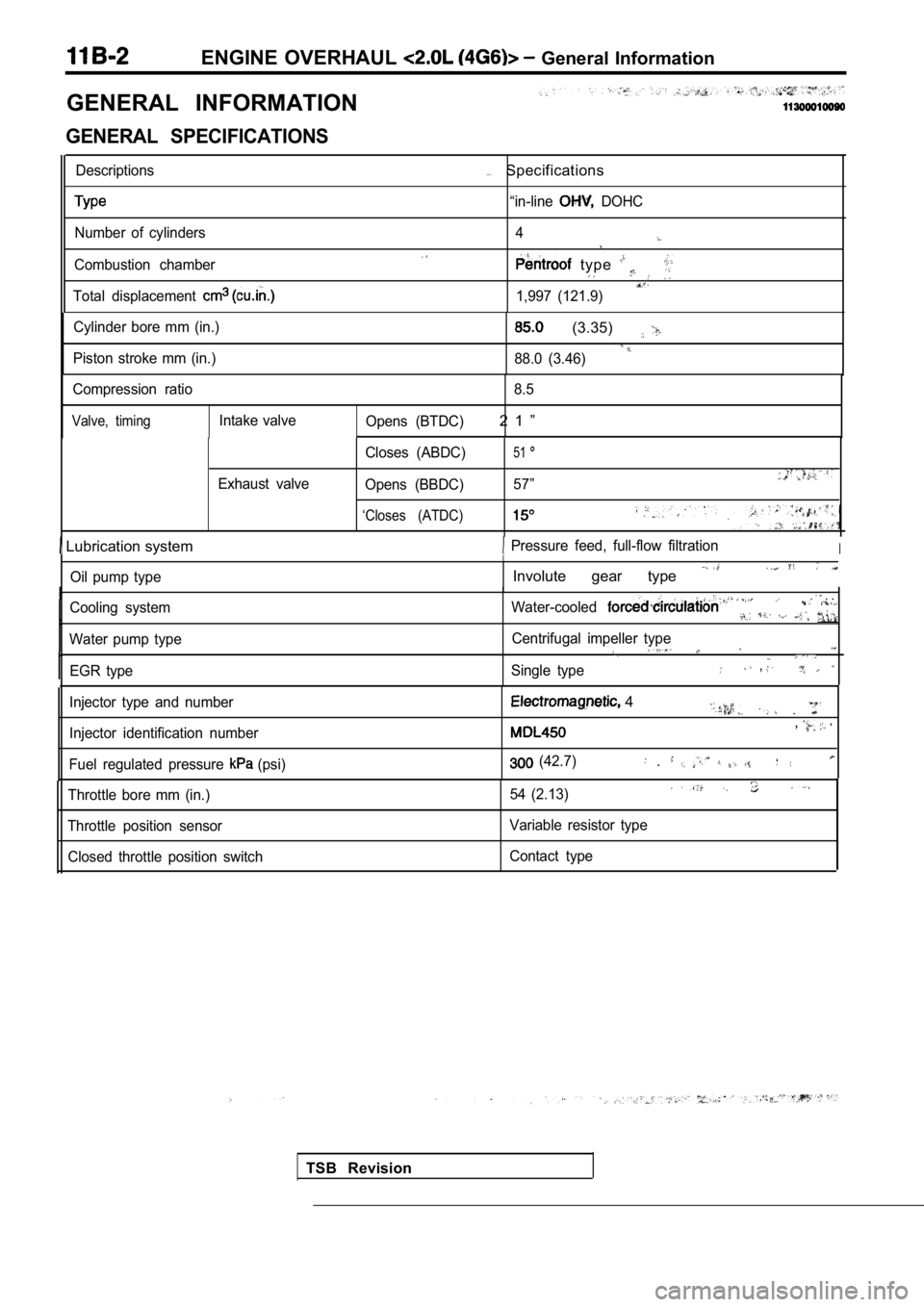

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

General Specifications . . . . . . . . . . . . . . . . . . , . . . . .2

GENERATOR IGNITION SYSTEM. . . . .11

INTAKE MANIFOLD. . . . . . . . . . . . . . . . . . . . . .

PISTON AND CONNECTING ROD..

. . . . . . . .51

ROCKER ARMS AND CAMSHAFT. . . . . . . .

SPECIAL TOOLS

. . . . . . . . . . . . . . . . . . . . . . . . . . .8

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . .3

Rework Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . .4

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ..

Service Specifications. . . . . . . . . . . . . . . . . . . ....3

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TIMING BELT

. . . . . . . . . . . . . . . . . .. . . . . . . . .

,

Page 106 of 2103

ENGINE OVERHAUL General Information

GENERAL INFORMATION

GENERAL SPECIFICATIONS

Descriptions

Number of cylinders

Combustion chamber

Total displacement

. . .Specifications

“in-line DOHC

4

type

1,997 (121.9)

Cylinder bore mm (in.)

Piston stroke mm (in.)

(3.35)

88.0 (3.46)

Compression ratio 8.5

Valve, timingIntake valve

Opens (BTDC)2 1 ”

Exhaust valve Closes (ABDC)

51

Opens (BBDC)

57”

‘Closes (ATDC)

Lubrication system Pressure feed, full-flow filtrationI

Oil pump type

Cooling system

Water pump type EGR type

I

Involute gear type

Water-cooled . .

Centrifugal impeller type

Single type,

TSB Revision

Injector type and number

Injector identification number

Fuel regulated pressure

(psi)

4

,

(42.7) .

Throttle bore mm (in.)

Throttle position sensor Closed throttle position switch 54 (2.13)

Variable resistor type

Contact type

Page 115 of 2103

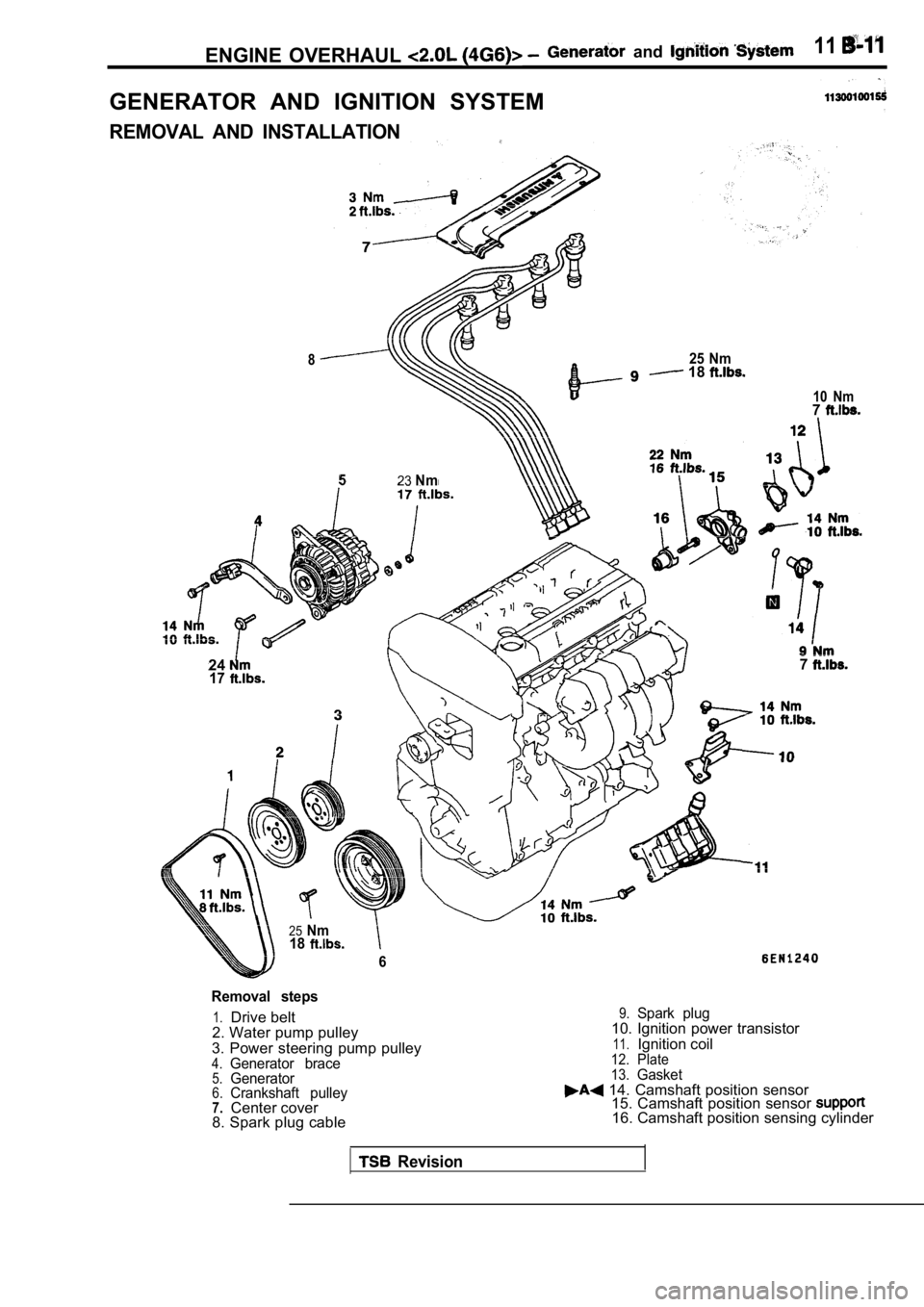

ENGINE OVERHAUL and 11

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

825 Nm 18

523Nm

24177

25Nm18

6

10 Nm7

Removal steps

1.Drive belt

2. Water pump pulley

3. Power steering pump pulley

4.Generator brace5.Generator6.Crankshaft pulley7.Center cover

8. Spark plug cable

9.Spark plug10. Ignition power transistor

11.Ignition coil12. Plate

13.Gasket 14. Camshaft position sensor 15. Camshaft position sensor

16. Camshaft position sensing cylinder

Revision