wheel MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 5 of 2103

GENERAL How to Use This

HOW TO USE THIS MANUAL

MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designati on

(engine type, transaxle type, etc.). A description

of these designations is covered in this manual

under “VEHICLE IDENTIFICATION”.

ON-VEHICLE SERVICE

“On-vehicle Service” are procedures for performing

inspections and adjustments of particularly impor-

tant locations with regard to the construction and

for maintenance and servicing, but other inspec-

tions (for looseness, play, cracking, damage, etc.

must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attention must to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TERMS DEFINITION

STANDARD VALUE

Indicates the value used as the standard for judgin g

the quality of a part or assembly on inspection

or the value to which the part or assembly is cor-

rected and adjusted. It is given by tolerance.

LIMIT

Indicates a maximum or minimum value, the part

or assembly should be kept within, in order to be functional. This value is established outside the

standard value range.

REFERENCE VALUE

Indicates the adjustment value prior to starting th e

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTION

Indicates the presentation of information particula rly

vital to the worker during the performance of maint e-

nance and servicing procedures in order to avoid

the possibility of injury to the worker, or damage

to component parts, or a reduction of component

or vehicle function or performance, etc..

TIGHTENING TORQUE INDICATION

The tightening torque shown in this manual is a

basic value with a tolerance of

10% except the

following cases when the upper. and

of tightening torque are given. (1) The tolerance of the ‘basic value

10%.

(2) Special bolts or, the ‘like are

(3) Special tightening methods are used.

SPECIAL TOOL NOTE

When the MMC special tool is described, please

refer to the special tool

is located at the beginning of each group, for a

cross reference from the tool, number

to the special tool number that available in your

market..

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T

Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T

Indicates the automatic transaxle, or models equip ped with the automatic transaxle.

MFI: Indicates the

fuel injection, or engines equipped with the fuel injection.

Turbo: Indicates the engine with turbocharger, or m odels equipped

such an

Non-turbo: Indicates the engine without turbocharger, or models equipped with, such anengine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or mode ls equipped with the

braking

Page 22 of 2103

GENERAL before Service

PRECAUTIONS BEFORE SERVICE.

SUPPLEMENTAL RESTRAINT SYSTEM

1. to follow when servicing SRS

(1) Be sure to read GROUP Supplemental Restraint System

For safe operations, please follow the directions a nd heed all

(2) Always use the designated special tools and tes t equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before” further work;

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the bat tery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components (SRS-ECU air bag module and

clock spring). If faulty, replace it.

(5) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

Sun visor

l Glove box

. S R S - E C U

l Steering wheel

l Air bag module

l Clock spring

l Steering gear and linkage clamp

(6) Store components removed from the SRS

a clean and dry place.

The air bag module should be stored on a flat surfa ce and placed so that the pad surface is’

facing upward.

Do not place anything on top of it.

(7) Be sure to deploy the air bag before disposing of the air bag’module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP

Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the

check the SRS warning light operation to make sure

that the system functions properly.

2.Observe the following when carrying out operations on places where SRS components are installed,’

.,

including operations not directly related to the SR S air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over so remove the SRS compo-

nents before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lig ht operation to make sure that the system

functions properly.

SERVICING THE ELECTRICAL SYSTEM

1. Note the following before proceeding with work o n the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that co uld result

in a fire in the vehicle.

2.When servicing the electrical system, disconnect th e nega-

tive cable terminal from the battery.

Page 24 of 2103

GENERAL Towing and Hoisting

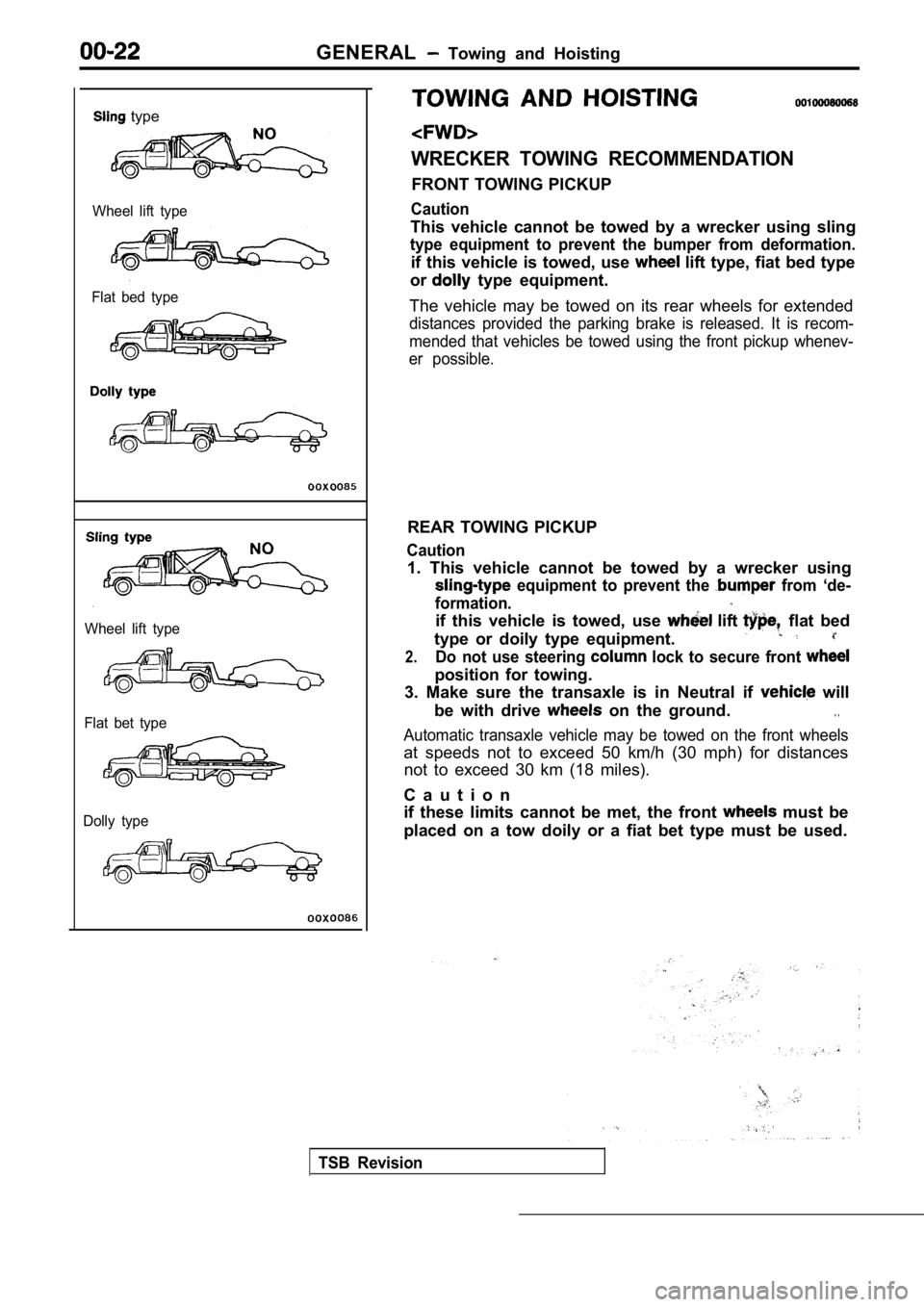

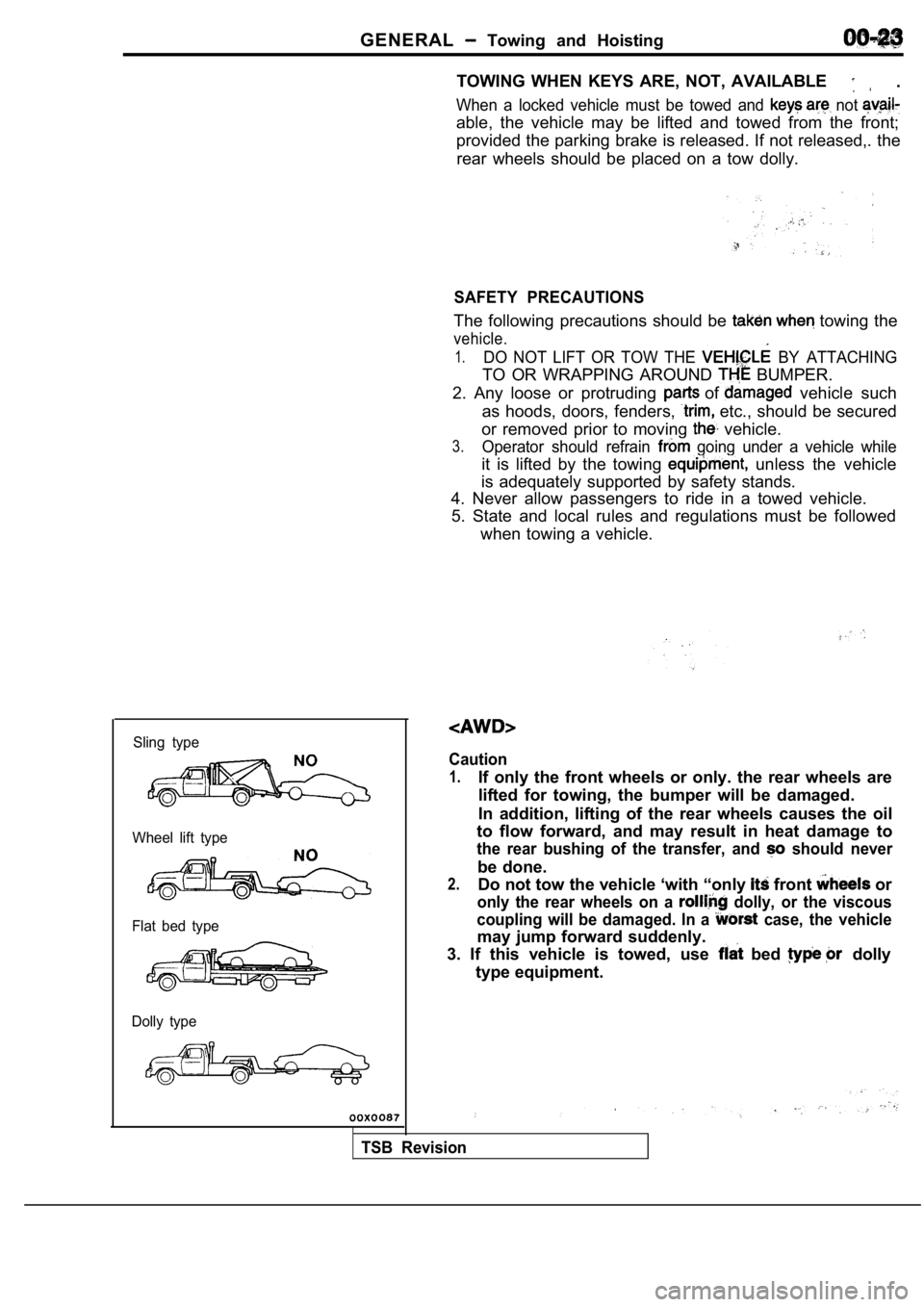

type

Wheel lift type

Flat bed type

Wheel lift type

Flat bet type

Dolly type

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sli ng

type equipment to prevent the bumper from deformati on.

if this vehicle is towed, use lift type, fiat bed type

or

type equipment.

The vehicle may be towed on its rear wheels for ext ended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front picku p whenev-

er possible.

REAR TOWING PICKUP

Caution

1. This vehicle cannot be towed by a wrecker using

equipment to prevent the from ‘de-

formation.

if this vehicle is towed, use lift flat bed

type or doily type equipment.

2.Do not use steering lock to secure front

position for towing.

3. Make sure the transaxle is in Neutral if

will

be with drive

on the ground.. .

Automatic transaxle vehicle may be towed on the fro nt wheels

at speeds not to exceed 50 km/h (30 mph) for distan ces

not to exceed 30 km (18 miles).

C a u t i o n

if these limits cannot be met, the front

must be

placed on a tow doily or a fiat bet type must be us ed.

TSB Revision

Page 25 of 2103

GENERAL Towing and Hoisting

Sling type

Wheel lift type

Flat bed type

Dolly type

TOWING WHEN KEYS ARE, NOT, AVAILABLE .

When a locked vehicle must be towed and not

able, the vehicle may be lifted and towed from the front;

provided the parking brake is released. If not rele ased,. the

rear wheels should be placed on a tow dolly.

SAFETY PRECAUTIONS

The following precautions should be towing the

vehicle.

1.DO NOT LIFT OR TOW THE BY ATTACHING

TO OR WRAPPING AROUND BUMPER.

2. Any loose or protruding

of vehicle such

as hoods, doors, fenders,

etc., should be secured

or removed prior to moving

vehicle.

3.Operator should refrain going under a vehicle while

it is lifted by the towing unless the vehicle

is adequately supported by safety stands.

4. Never allow passengers to ride in a towed vehicl e.

5. State and local rules and regulations must be fo llowed

when towing a vehicle.

Caution

1.If only the front wheels or only. the rear wheels a re

lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes the oil

to flow forward, and may result in heat damage to

the rear bushing of the transfer, and should never

be done.

2.Do not tow the vehicle ‘with “only front or

only the rear wheels on a dolly, or the viscous

coupling will be damaged. In a

case, the vehicle

may jump forward suddenly.

3. If this vehicle is towed, use

bed dolly

type equipment.

TSB Revision

Page 28 of 2103

G E N E R A L Special Handling AWD M o d e l s

0 0 0 0 3 6 8 5

0 0 1 0 0 7 4 0 0 1 0

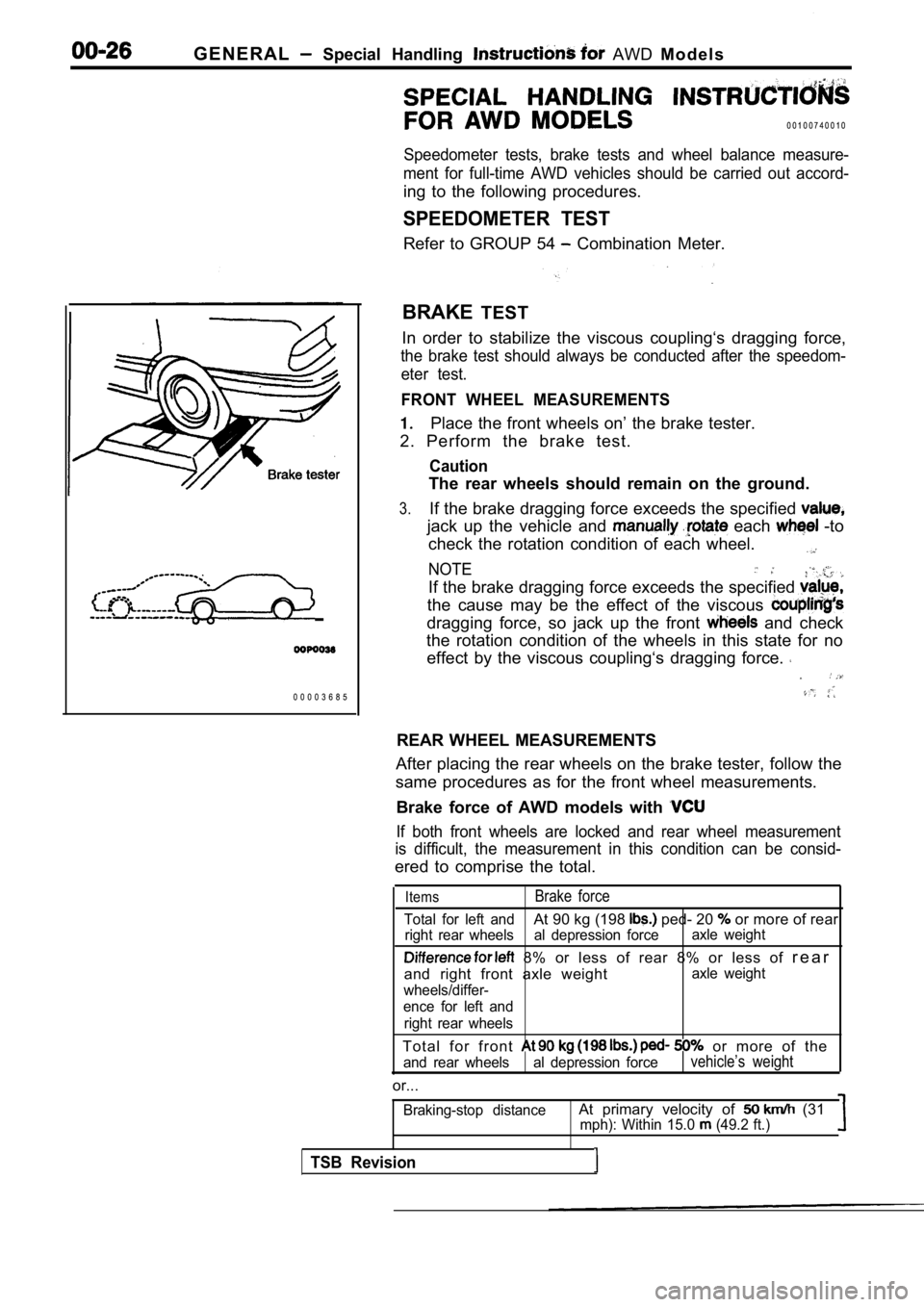

Speedometer tests, brake tests and wheel balance me asure-

ment for full-time AWD vehicles should be carried o ut accord-

ing to the following procedures.

SPEEDOMETER TEST

Refer to GROUP 54 Combination Meter.

BRAKE TEST

In order to stabilize the viscous coupling‘s draggi ng force,

the brake test should always be conducted after the speedom-

eter test.

FRONT WHEEL MEASUREMENTS

Place the front wheels on’ the brake tester.

2. Perform the brake test.

Caution

The rear wheels should remain on the ground.

3.If the brake dragging force exceeds the specified

jack up the vehicle and each -to

check the rotation condition of each wheel.

NOTE

If the brake dragging force exceeds the specified

the cause may be the effect of the viscous

dragging force, so jack up the front and check

the rotation condition of the wheels in this state for no

effect by the viscous coupling‘s dragging force.

REAR WHEEL MEASUREMENTS

After placing the rear wheels on the brake tester, follow the

same procedures as for the front wheel measurements .

Brake force of AWD models with

If both front wheels are locked and rear wheel meas urement

is difficult, the measurement in this condition can be consid-

ered to comprise the total.

ItemsBrake force

Total for left andAt 90 kg (198 ped- 20 or more of rear

right rear wheels al depression forceaxle weight

8% or less of rear 8% or less of

r e a r

and right front axle weight

axle weight

wheels/differ-

ence for left and

right rear wheels

T o t a l f o r f r o n t or more of the

and rear wheels al depression forcevehicle’s weight

or...

Braking-stop distanceAt primary velocity of (31mph): Within 15.0 (49.2 ft.)

TSB Revision

Page 29 of 2103

GENERAL Special Handling Instructions for Models

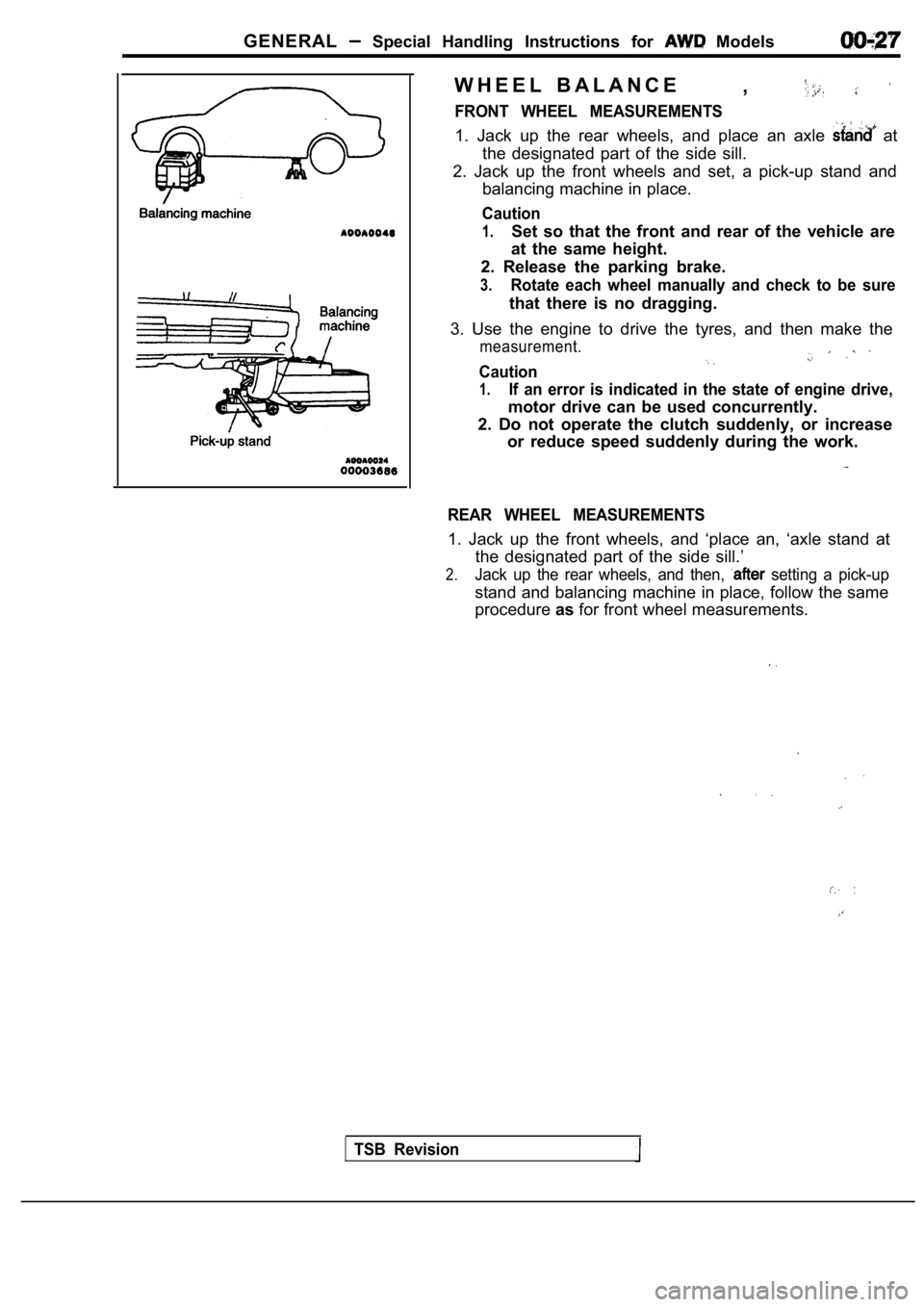

W H E E L B A L A N C E,

FRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle at

the designated part of the side sill.

2. Jack up the front wheels and set, a pick-up stan d and

balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are

at the same height.

2. Release the parking brake.

3.Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tyres, and then make the

measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2. Do not operate the clutch suddenly, or increase or reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and ‘place an, ‘axle s tand at

the designated part of the side sill.’

2.Jack up the rear wheels, and then, setting a pick-up

stand and balancing machine in place, follow the sa me

procedure asfor front wheel measurements.

TSB Revision

Page 32 of 2103

GENERAL General and

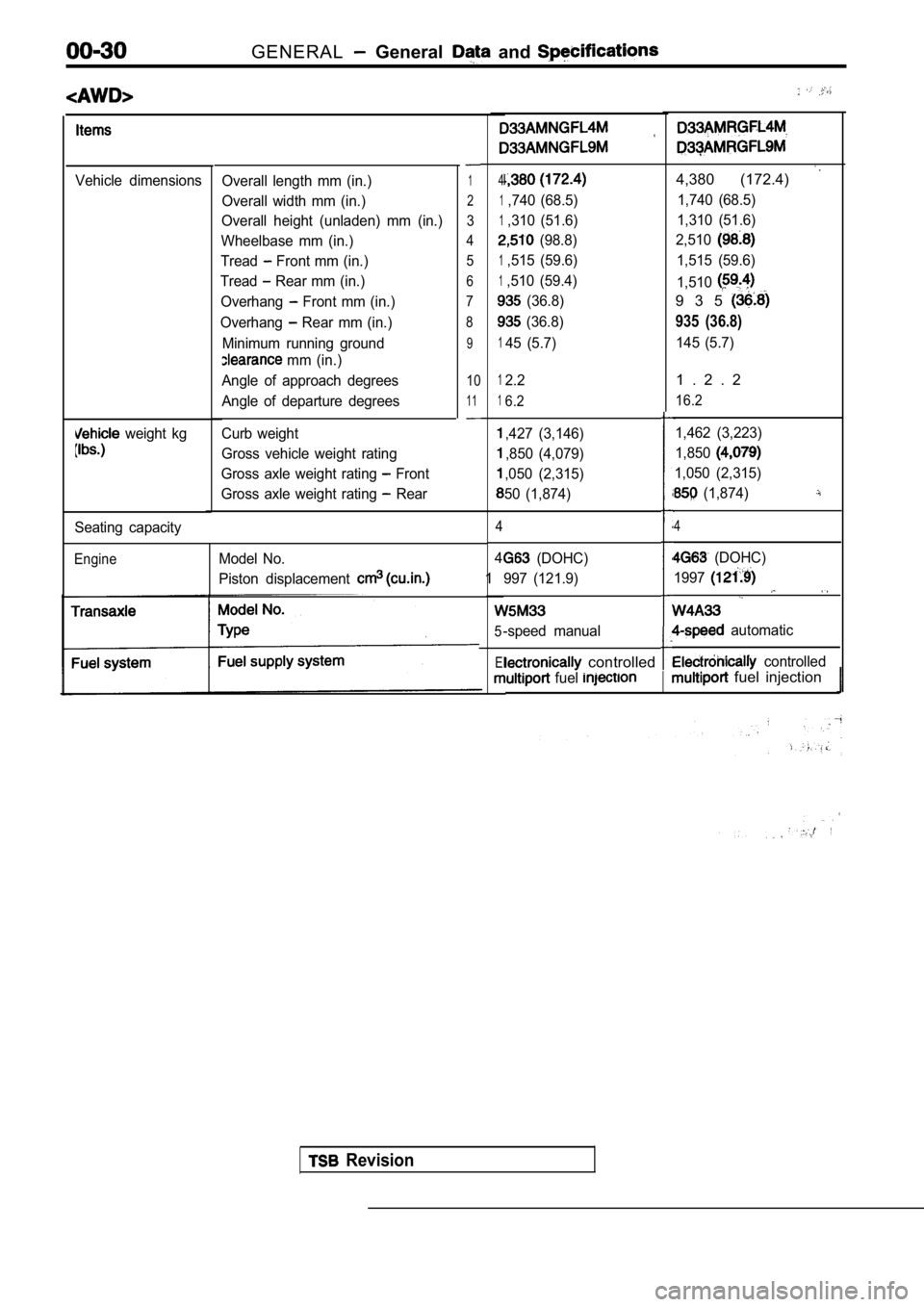

Vehicle dimensions

weight kg

Overall length mm (in.)

Overall width mm (in.)

Overall height (unladen) mm (in.)

Wheelbase mm (in.)

Tread

Front mm (in.)

Tread

Rear mm (in.)

Overhang

Front mm (in.)

Overhang

Rear mm (in.)

Minimum running ground

mm (in.)

Angle of approach degrees

Angle of departure degrees

Curb weight

Gross vehicle weight rating

Gross axle weight rating

Front

Gross axle weight rating

Rear

1

2

3

4 5

6

7

8

9

10

11

Seating capacity

EngineModel No.

Piston displacement

4

1,740 (68.5)

1,310 (51.6)

(98.8)

1,515 (59.6)

1,510 (59.4)

(36.8)

(36.8)

145 (5.7)

4,380 (172.4)

1,740 (68.5)

1,310 (51.6)

2,510

1,515 (59.6)

1,510

9 3 5

935 (36.8)

145 (5.7)

12.2

16.2

,427 (3,146)

,850 (4,079)

,050 (2,315)

50 (1,874)

4

4

1

5

El

1 . 2 . 2

16.2

1,462 (3,223)

1,850

1,050 (2,315)

(1,874)

4

(DOHC)

997 (121.9)

-speed manual

(DOHC)

1997

automatic

controlled controlled

fuel fuel injection

Revision

Page 51 of 2103

GENERAL Maintenance

a

Engine (Non-turbo)>

in plug

Engine>

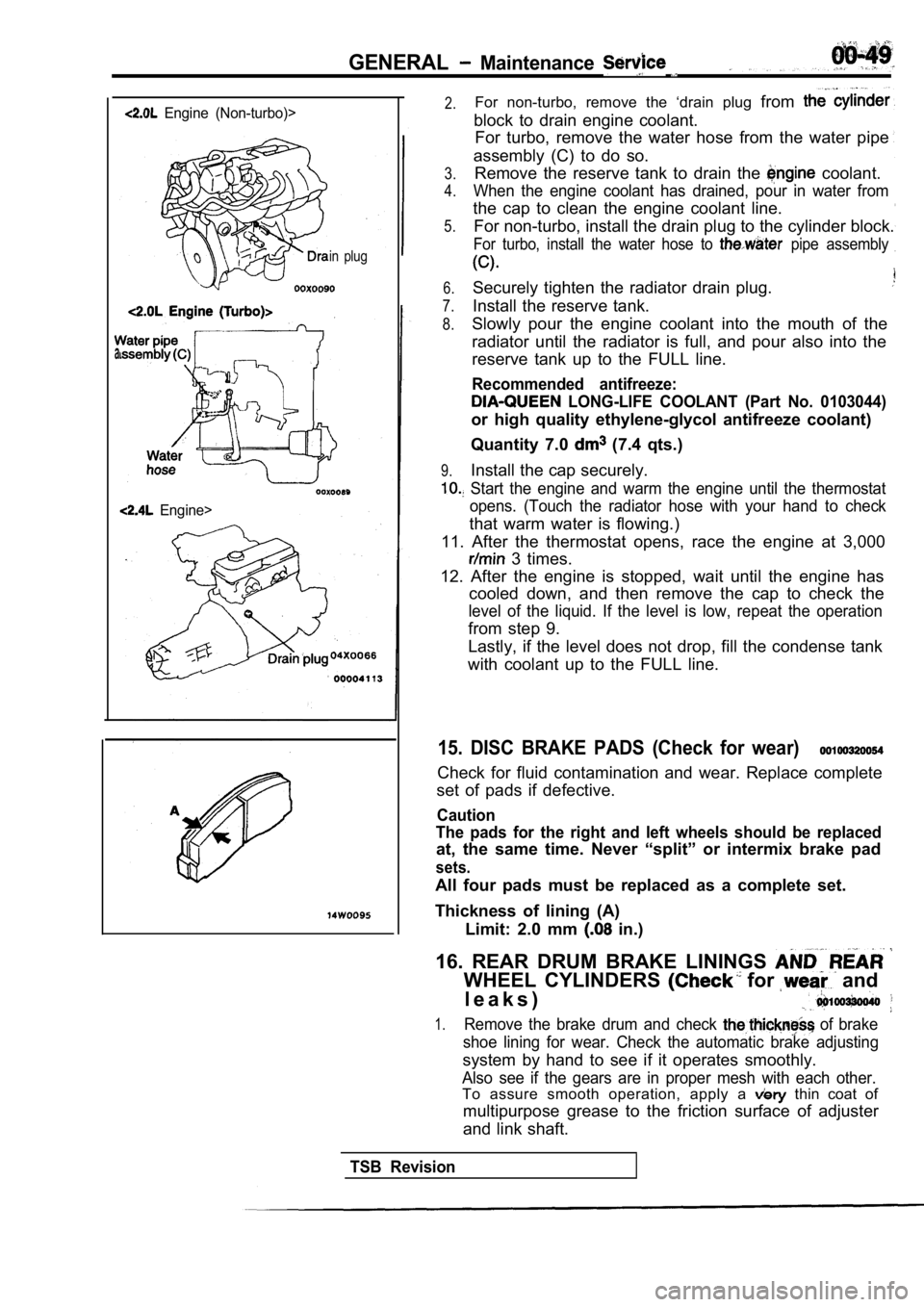

2.For non-turbo, remove the ‘drain plug from

block to drain engine coolant.

For turbo, remove the water hose from the water pip e

assembly (C) to do so.

3.

4.

5.Remove the reserve tank to drain the coolant.

When the engine coolant has drained, pour in water from

the cap to clean the engine coolant line.

For non-turbo, install the drain plug to the cylind er block.

For turbo, install the water hose to pipe assembly

6.

7.

8.

Securely tighten the radiator drain plug.

Install the reserve tank.

9.

Slowly pour the engine coolant into the mouth of th e

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended antifreeze:

LONG-LIFE COOLANT (Part No. 0103044)

or high quality ethylene-glycol antifreeze coolant)

Quantity 7.0

(7.4 qts.)

Install the cap securely.

Start the engine and warm the engine until the the rmostat

opens. (Touch the radiator hose with your hand to c heck

that warm water is flowing.)

11. After the thermostat opens, race the engine at 3,000

3 times.

12. After the engine is stopped, wait until the eng ine has

cooled down, and then remove the cap to check the

level of the liquid. If the level is low, repeat th e operation

from step 9.

Lastly, if the level does not drop, fill the conden se tank

with coolant up to the FULL line.

15. DISC BRAKE PADS (Check for wear)

Check for fluid contamination and wear. Replace com plete

set of pads if defective.

Caution

The pads for the right and left wheels should be re placed

at, the same time. Never “split” or intermix brake pad

sets.

All four pads must be replaced as a complete set.

Thickness of lining (A) Limit: 2.0 mm

in.)

16. REAR DRUM BRAKE LININGS

WHEEL CYLINDERS for and

l e a k s )

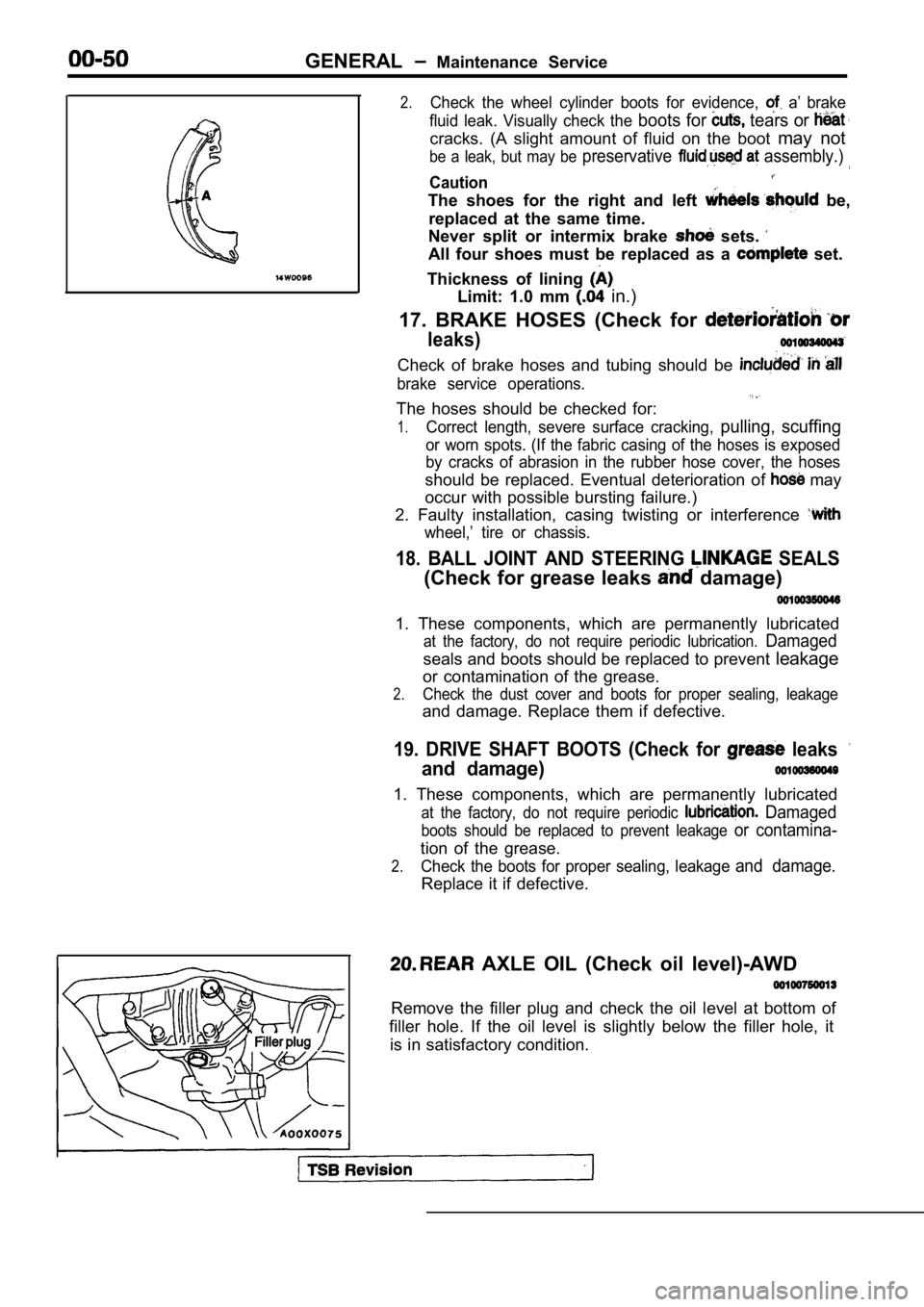

1.Remove the brake drum and check of brake

shoe lining for wear. Check the automatic brake adj usting

system by hand to see if it operates smoothly.

Also see if the gears are in proper mesh with each other.

To assure smooth operation, apply a thin coat of

multipurpose grease to the friction surface of adju ster

and link shaft.

TSB Revision

Page 52 of 2103

GENERAL Maintenance Service

2.Check the wheel cylinder boots for evidence, a’ brake

fluid leak. Visually check the

boots for tears or

cracks. (A slight amount of fluid on the boot may not

be a leak, but may be preservative assembly.)

Caution

The shoes for the right and left be,

replaced at the same time.

Never split or intermix brake

sets.

All four shoes must be replaced as a set.

Thickness of lining

Limit: 1.0 mm in.)

17. BRAKE HOSES (Check for

leaks)

Check of brake hoses and tubing should be

brake service operations.

The hoses should be checked for:

1.Correct length, severe surface cracking, pulling, scuffing

or worn spots. (If the fabric casing of the hoses i s exposed

by cracks of abrasion in the rubber hose cover, the hoses

should be replaced. Eventual deterioration of may

occur with possible bursting failure.)

2. Faulty installation, casing twisting or interfer ence

wheel,’ tire or chassis.

18. BALL JOINT AND STEERING SEALS

(Check for grease leaks damage)

1. These components, which are permanently lubricat ed

at the factory, do not require periodic lubrication. Damaged

seals and boots should be replaced to prevent leakage

or contamination of the grease.

2.Check the dust cover and boots for proper sealing, leakage

and damage. Replace them if defective.

19. DRIVE SHAFT BOOTS (Check for leaks

and damage)

1. These components, which are permanently lubricat ed

at the factory, do not require periodic Damaged

boots should be replaced to prevent leakage or contamina-

tion of the grease.

2.Check the boots for proper sealing, leakage and damage.

Replace it if defective.

AXLE OIL (Check oil level)-AWD

Remove the filler plug and check the oil level at bottom of

filler hole. If the oil level is slightly below the filler hole, it

is in satisfactory condition.