ECO mode MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

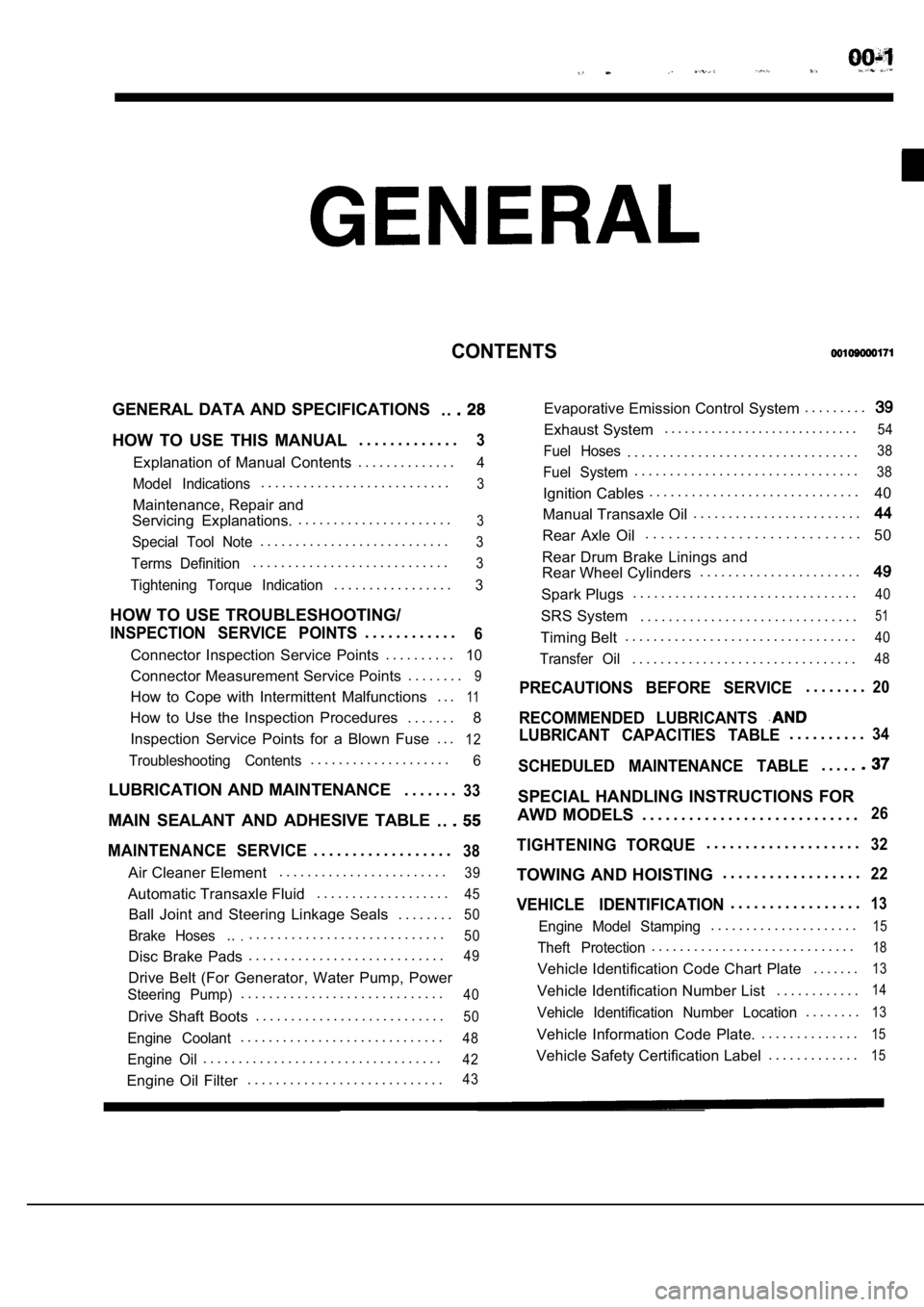

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 389 of 2103

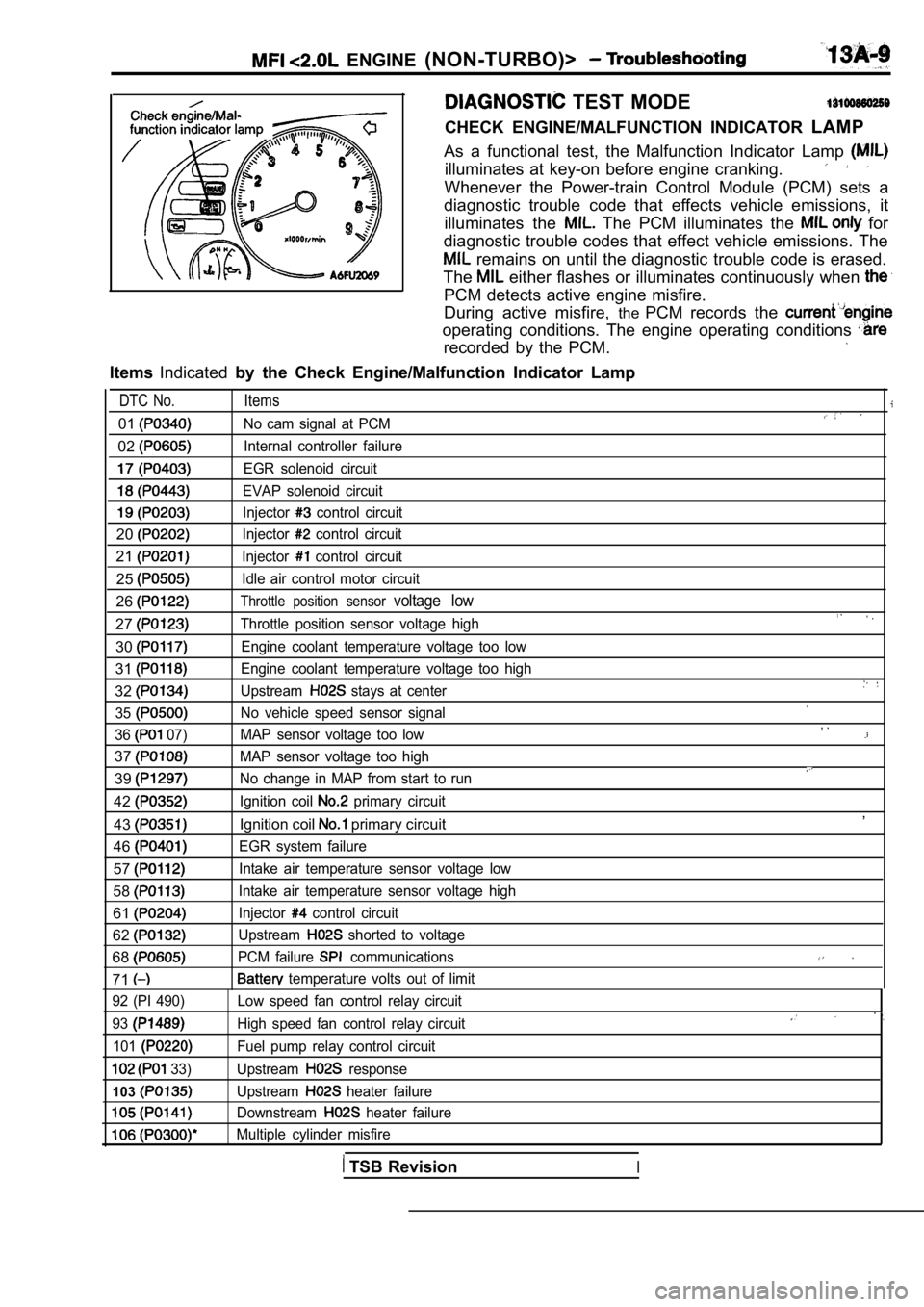

ENGINE (NON-TURBO)>

TEST MODE

CHECK ENGINE/MALFUNCTION INDICATOR LAMP

As a functional test, the Malfunction Indicator Lam p

illuminates at key-on before engine cranking.

Whenever the Power-train Control Module (PCM) sets a

diagnostic trouble code that effects vehicle emissi ons, it

illuminates the

The PCM illuminates the for

diagnostic trouble codes that effect vehicle emissi ons. The

remains on until the diagnostic trouble code is erased.

The

either flashes or illuminates continuously when

PCM detects active engine misfire.

During active misfire, thePCM records the

operating conditions. The engine operating conditio ns

recorded by the PCM.

ItemsIndicated by the Check Engine/Malfunction Indicator Lamp

DTC No. Items

01No cam signal at PCM

02Internal controller failure

EGR solenoid circuit

EVAP solenoid circuit

Injector control circuit

20Injector control circuit

21Injector control circuit

25Idle air control motor circuit

26Throttle position sensor voltage low

27Throttle position sensor voltage high

30Engine coolant temperature voltage too low

31Engine coolant temperature voltage too high

32Upstream stays at center

35

No vehicle speed sensor signal

36

07) MAP sensor voltage too low

37MAP sensor voltage too high

39No change in MAP from start to run

42Ignition coil primary circuit

43Ignition coil primary circuit

46

EGR system failure

57Intake air temperature sensor voltage low

58Intake air temperature sensor voltage high

61Injector control circuit

62Upstream shorted to voltage

68PCM failure communications

71 temperature volts out of limit

, .

,

92 (PI 490)

93

101

33)

103

Low speed fan control relay circuit

High speed fan control relay circuit

Fuel pump relay control circuit

Upstream

response

Upstream

heater failure

Downstream

heater failure

Multiple cylinder misfire

TSB RevisionI

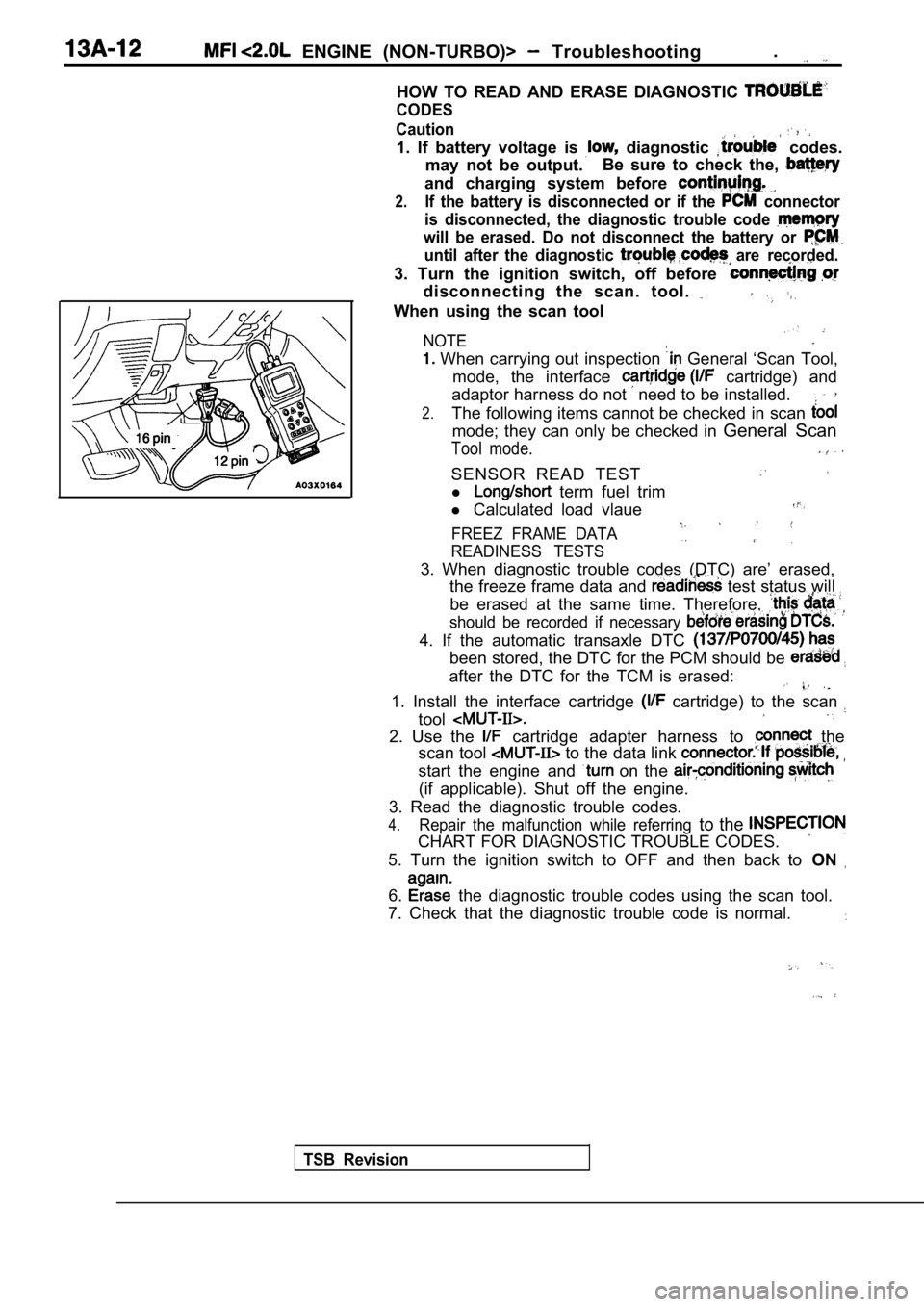

Page 392 of 2103

ENGINE (NON-TURBO)> Troubleshooting.

HOW TO READ AND ERASE DIAGNOSTIC

CODES

TSB Revision Caution

1. If battery voltage is diagnostic codes.

may not be output. Be sure to check the,

and charging system before

2.If the battery is disconnected or if the connector

is disconnected, the diagnostic trouble code

will be erased. Do not disconnect the battery or

until after the diagnostic are recorded.

3. Turn the ignition switch, off before

disconnecting the scan. tool.

When using the scan tool

NOTE

When carrying out inspection General ‘Scan Tool,

mode, the interface

cartridge) and

adaptor harness do not

need to be installed.

2.The following items cannot be checked in scan

mode; they can only be checked in General Scan

Tool mode.

SENSOR READ TEST

l term fuel trim

l Calculated load vlaue

FREEZ FRAME DATA

READINESS TESTS

3. When diagnostic trouble codes (DTC) are’ erased,

the freeze frame data and

test status will

be erased at the same time. Therefore,

should be recorded if necessary

4. If the automatic transaxle DTC

been stored, the DTC for the PCM should be

after the DTC for the TCM is erased:

1. Install the interface cartridge cartridge) to the scan

tool

2. Use the cartridge adapter harness to the

scan tool

to the data link

start the engine and on the

(if applicable). Shut off the engine.

3. Read the diagnostic trouble codes.

4.Repair the malfunction while referring to the

CHART FOR DIAGNOSTIC TROUBLE CODES.

5. Turn the ignition switch to OFF and then back to ON

6. the diagnostic trouble codes using the scan tool.

7. Check that the diagnostic trouble code is normal .

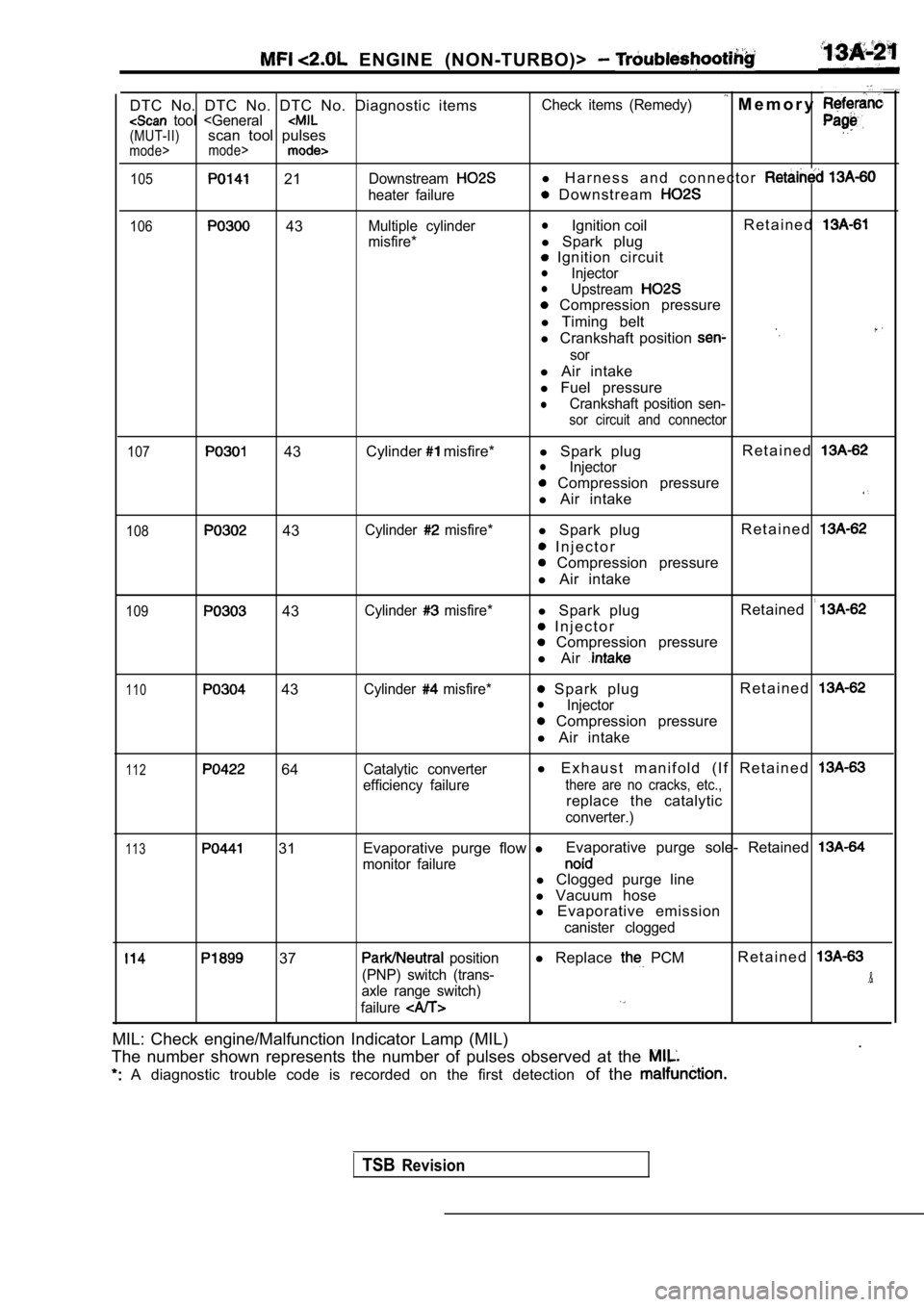

Page 401 of 2103

ENGINE (NON-TURBO)>

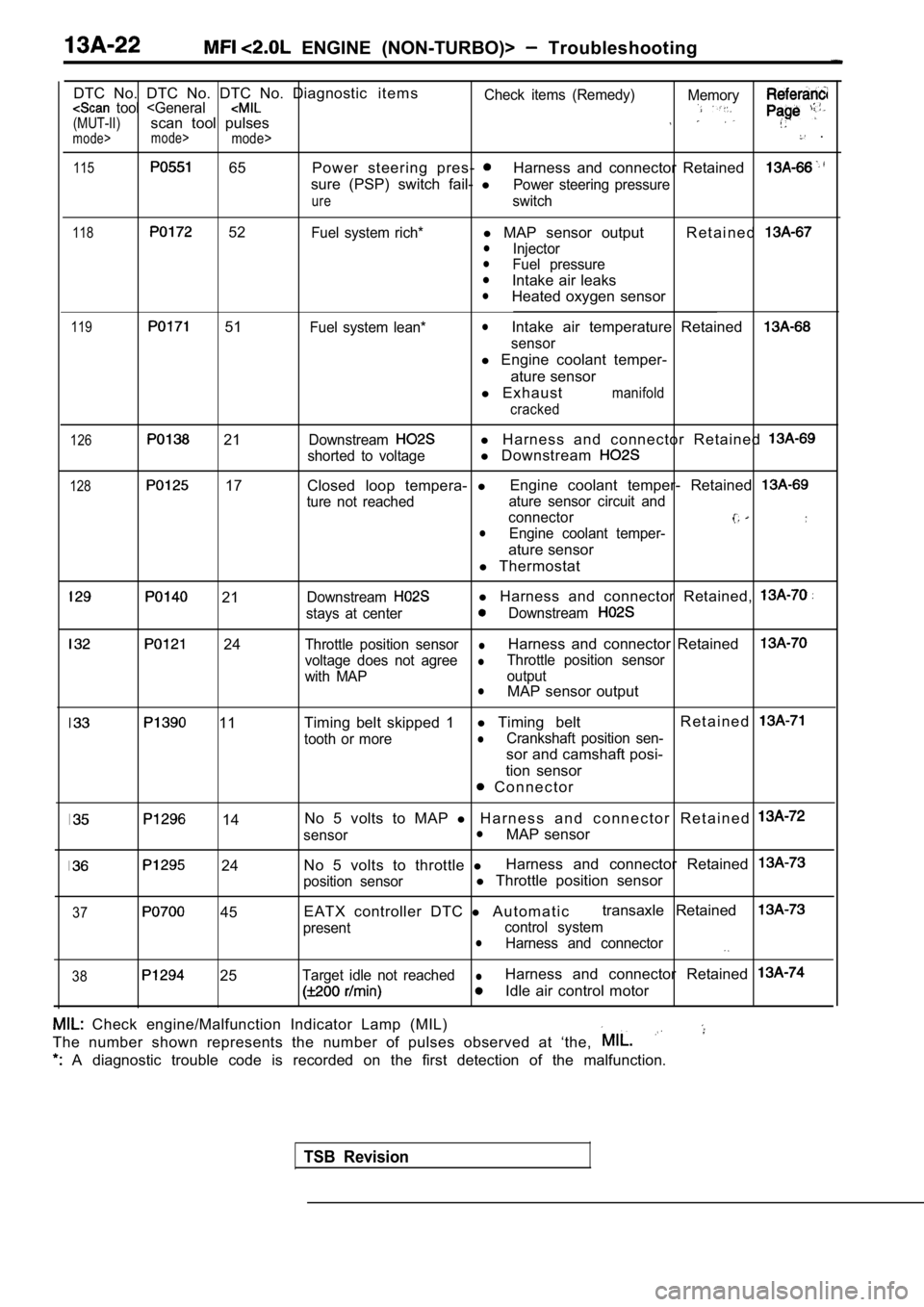

DTC No. DTC No. DTC No. Diagnostic items tool

105 21Downstream

heater failure

106 43Multiple cylinder

misfire* Check items (Remedy)

M e m o r y

l

H a r n e s s a n d c o n n e c t o r

D o w n s t r e a m

lIgnition coil R e t a i n e d

l

Spark plug

Ignition circuitlInjectorlUpstream

Compression pressure

l Timing belt

l Crankshaft position

sor

l Air intake

l Fuel pressure

lCrankshaft position sen-

sor circuit and connector

107

43 Cylinder misfire*

l Spark plug R e t a i n e dlInjector

Compression pressure

l Air intake

108 43Cylinder misfire*l Spark plug R e t a i n e d

I n j e c t o r

Compression pressure

l Air intake

109 43Cylinder misfire*l Spark plug Retained

I n j e c t o r

Compression pressure

l Air

110 43Cylinder misfire* Spark plug R e t a i n e dlInjector

Compression pressure

l Air intake

112 64Catalytic converter

efficiency failurel E x h a u s t m a n i f o l d ( I f R e t a i n e d

there are no cracks, etc.,

replace the catalytic

converter.)

113 31 Evaporative purge flow

lEvaporative purge sole- Retained

monitor failurel

Clogged purge line

l Vacuum hose

l Evaporative emission

canister clogged

37 position

(PNP) switch (trans-

axle range switch)

failurel Replace PCMR e t a i n e d

.&

MIL: Check engine/Malfunction Indicator Lamp (MIL)

.

The number shown represents the number of pulses ob served at the

A diagnostic trouble code is recorded on the first detection of the

TSBRevision

Page 402 of 2103

ENGINE (NON-TURBO)> Troubleshooting

DTC No. DTC No. DTC No. Diagnostic i t e m s

Check items (Remedy) Memory tool

115 65 Power steering pres- Harness and connector Retained

sure (PSP) switch fail-

lPower steering pressure

ureswitch

118 52Fuel system rich*l MAP sensor output R e t a i n e dlInjectorlFuel pressurelIntake air leakslHeated oxygen sensor

119 51Fuel system lean*lIntake air temperature Retained

sensor

l Engine coolant temper-

ature sensor

l E x h a u s t

manifold

cracked

126 21

128 17

Downstreaml H a r n e s s a n d c o n n e c t o r R e t a i n e d

shorted to voltagel Downstream

Closed loop tempera- lEngine coolant temper- Retained

ture not reached ature sensor circuit and

connector

lEngine coolant temper-

ature sensor

l Thermostat

21

24

11

Downstreaml Harness and connector Retained,

stays at centerDownstream

Throttle position sensorlHarness and connector Retained

voltage does not agreelThrottle position sensor

with MAP output

lMAP sensor output

Timing belt skipped 1 l

Timing belt R e t a i n e d

tooth or morelCrankshaft position sen-

sor and camshaft posi-

tion sensor

C o n n e c t o r

37

14

24

45 No 5 volts to MAP

l H a r n e s s a n d c o n n e c t o r R e t a i n e d

sensorlMAP sensor

No 5 volts to throttle lHarness and connector Retained

position sensorl

Throttle position sensor

EATX controller DTC l A u t o m a t i c transaxle Retained

present

control systemlHarness and connector

38 25Target idle not reachedlHarness and connector Retained

Idle air control motor

Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses ob served at ‘the,

A diagnostic trouble code is recorded on the first detection of the malfunction.

TSB Revision

Page 418 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE

Scan tool 31 .

Code General scan tool Engine Coolant Temperature

No.Sensor Voltage Too High

22

[Comment]

Backgroundl Sensor signal circuit open

Data from the engine coolant MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE

Scan tool 31 .

Code General scan tool Engine Coolant Temperature

No.Sensor Voltage Too High

22

[Comment]

Backgroundl Sensor signal circuit open

Data from the engine coolant](/img/19/57345/w960_57345-417.png)

ENGINE

Scan tool 31 .

Code General scan tool Engine Coolant Temperature

No.Sensor Voltage Too High

22

[Comment]

Backgroundl Sensor signal circuit open

Data from the engine coolant temperature sensor is used in most fuel and spark relatedl

Sensor internally openlcontrol functions.l PCM failedl When DTC is set, the PCM uses a default value as th e engine coolant temperature, andthe vehicle enters the limp-in mode.Range of Checkl Ignition switch: ON ,

Set Condition,lEngine coolant temperature sensor output voltage re mains more than for 3 seconds.

(Refer to

NG Replace

OK

Measure at the engine coolant temperature sensor lDisconnect the connector, and measure at the harnes s side.

l Continuity between 1 and ground

OK: Continuity

OK

OK

NG

NG

Check the harness wire between the PCM and the engi ne coolanttemperature sensor connector. Repair, if

Repair..

.

Check the harness wire between the coolanttemperature sensor connector.

[Comment] OK

Replace the PCM.

NG

Repair

Upstream Stays

Backgroundl

Sensor output voltage is checked.lIf voltage stays at center instead of switching, an open circuit is likely.

Range of Check

l 2 minutes after starting engine

l Engine coolant temperature: More than

Set ConditionNeither rich nor lean condition is detected from th e upstream heated oxygen sensor input.(Voltage is 0.5 volts for 1.5 minutes)

Check the heated oxygen sensor (front). [Refer to

l Heated oxygen sensor (front) Sensor signal circuit l PCM failed

OK. .

NGCheck the following connectors: Repair

Check trouble symptom.

Check the harness wire between Repair

sensor (front) connector.

OK

Replace the PCM.

TSB Revision

Page 429 of 2103

ENGINE , Troubleshooting

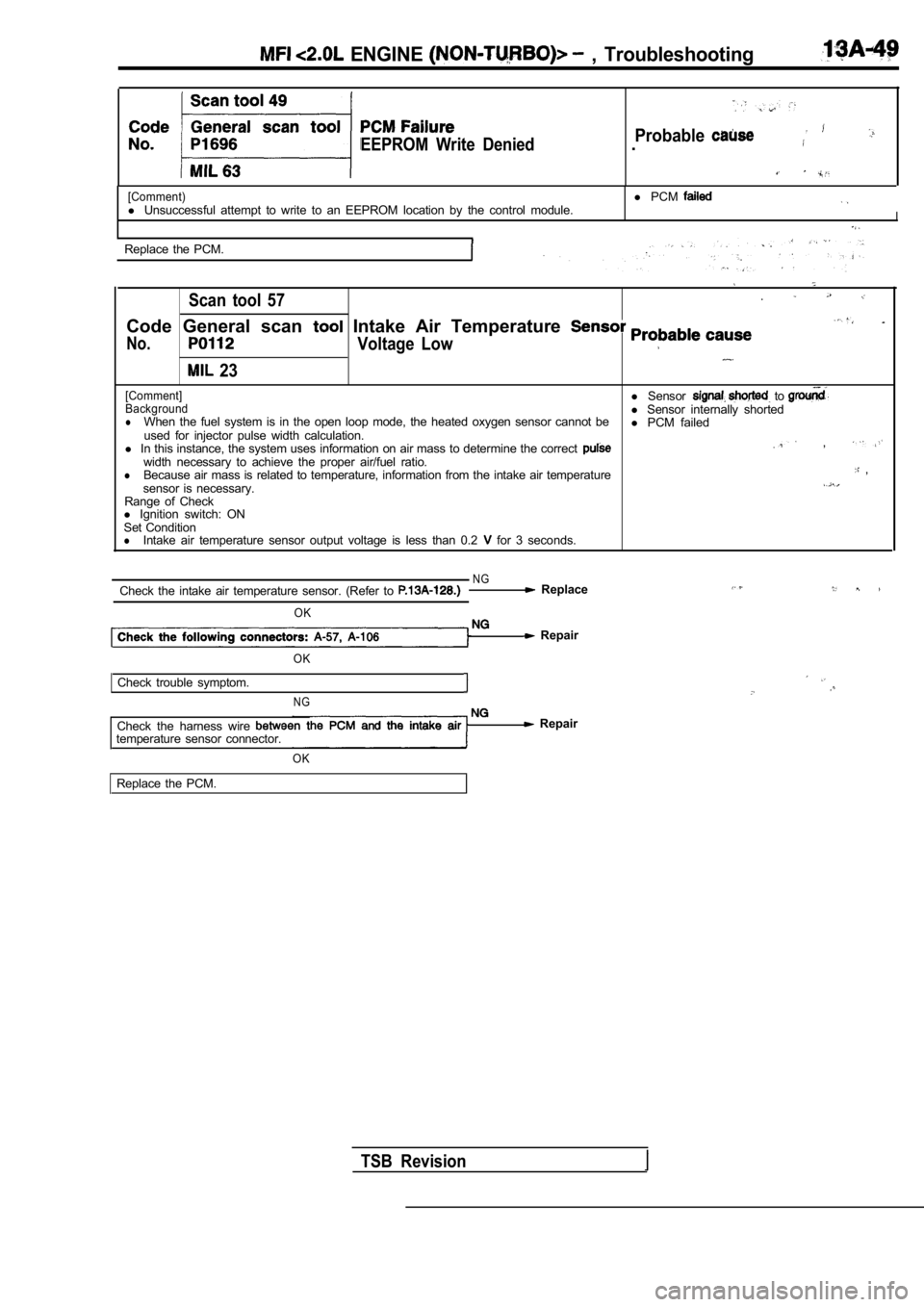

EEPROM Write DeniedProbable.

[Comment)l Unsuccessful attempt to write to an EEPROM location by the control module.l

PCMI

Replace the PCM.

Scan tool 57

Code General scan Intake Air Temperature

No.Voltage Low

23

[Comment]l Sensor to Backgroundl Sensor internally shortedlWhen the fuel system is in the open loop mode, the heated oxygen sensor cannot be

l PCM failed

used for injector pulse width calculation.

l In this instance, the system uses information on ai r mass to determine the correct

,

width necessary to achieve the proper air/fuel rati o.lBecause air mass is related to temperature, informa tion from the intake air temperature ,

sensor is necessary.

Range of Check

l Ignition switch: ON

Set Condition

lIntake air temperature sensor output voltage is les s than 0.2 for 3 seconds.

N GCheck the intake air temperature sensor. (Refer to Replace

OK

Repair

OK

Check trouble symptom.

N G

Check the harness wire temperature sensor connector.

OK

Repair

Replace the PCM.

TSB Revision

Page 537 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

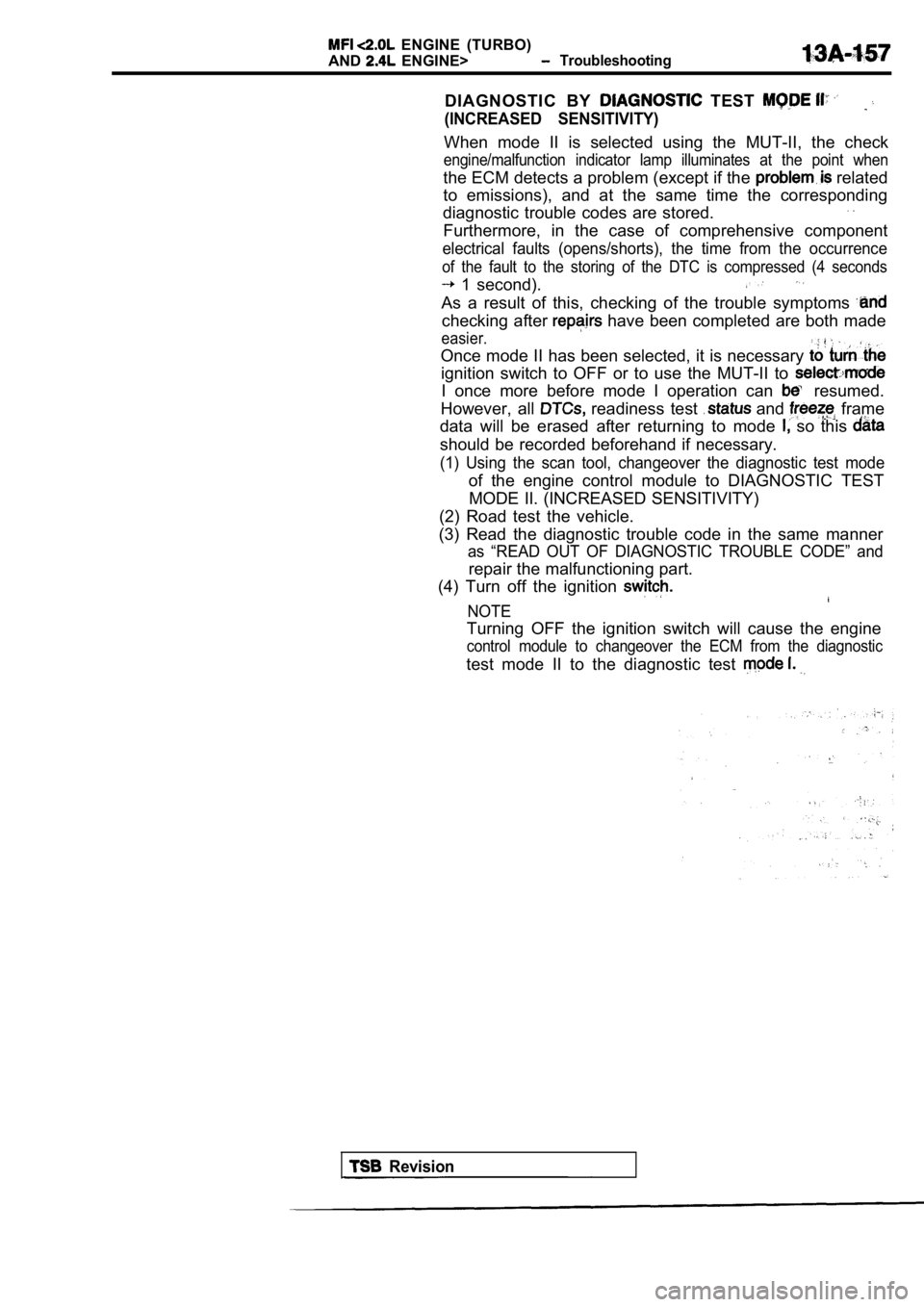

DIAGNOSTIC BY TEST

(INCREASED SENSITIVITY)

When mode II is selected using the MUT-II, the chec k

engine/malfunction indicator lamp illuminates at the point when

the ECM detects a problem (except if the related

to emissions), and at the same time the correspondi ng

diagnostic trouble codes are stored.

Furthermore, in the case of comprehensive component

electrical faults (opens/shorts), the time from the occurrence

of the fault to the storing of the DTC is compresse d (4 seconds

1 second).

As a result of this, checking of the trouble symptoms

checking after have been completed are both made

easier.

Once mode II has been selected, it is necessary

ignition switch to OFF or to use the MUT-II to

I once more before mode I operation can resumed.

However, all

readiness test and frame

data will be erased after returning to mode

so this

should be recorded beforehand if necessary.

(1) Using the scan tool, changeover the diagnostic test mode

of the engine control module to DIAGNOSTIC TEST

MODE II. (INCREASED SENSITIVITY)

(2) Road test the vehicle.

(3) Read the diagnostic trouble code in the same ma nner

as “READ OUT OF DIAGNOSTIC TROUBLE CODE” and

repair the malfunctioning part.

(4) Turn off the ignition

NOTE

Turning OFF the ignition switch will cause the engi ne

control module to changeover the ECM from the diagn ostic

test mode II to the diagnostic test

Revision

Page 538 of 2103

ENGINE

A N D E N G I N E > .

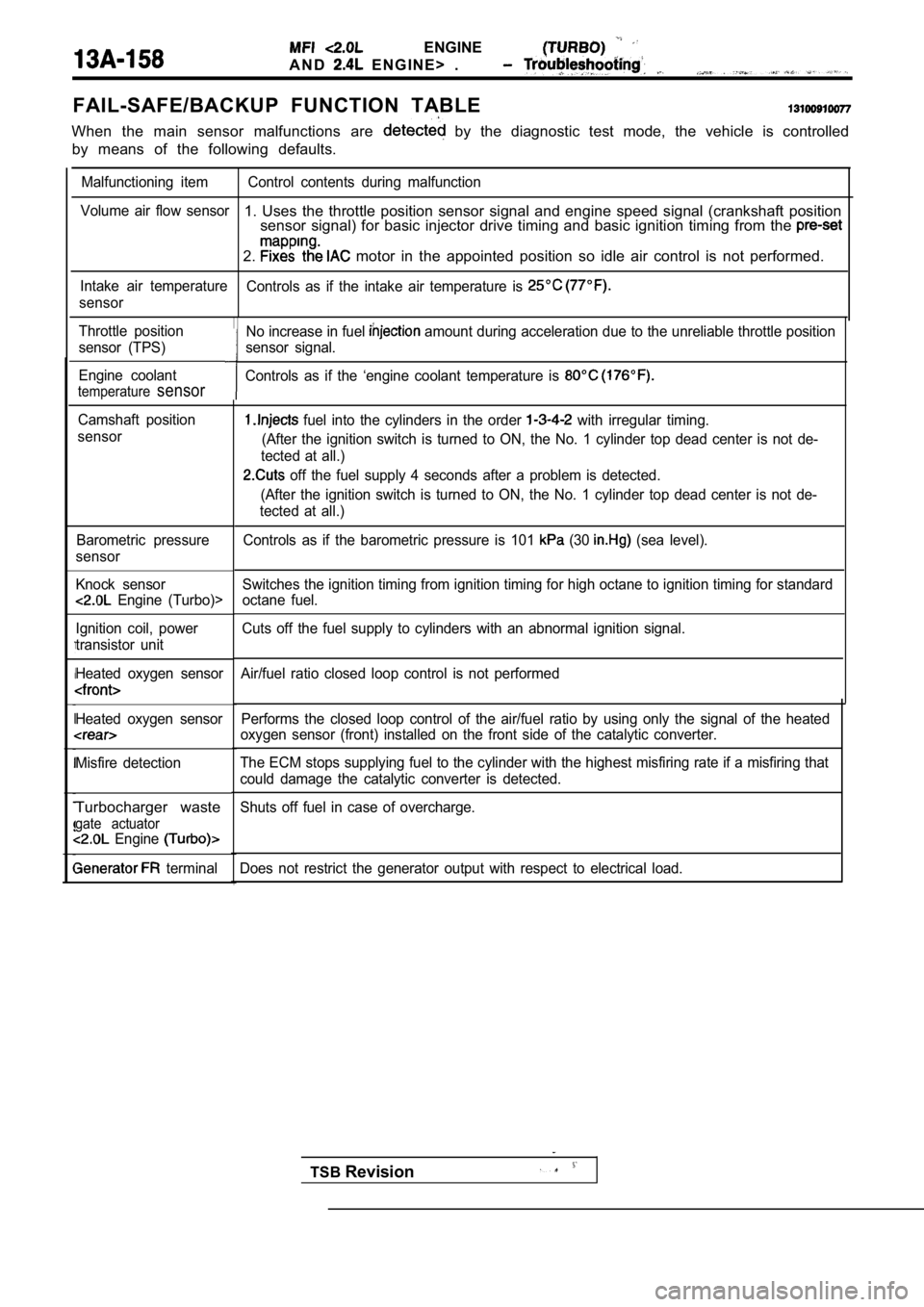

FAIL-SAFE/BACKUP FUNCTION TABLE

When the main sensor malfunctions are by the diagnostic test mode, the vehicle is controlled

by means of the following defaults.

Malfunctioning item Control contents during malfunct ion

Volume air flow sensor

1. Uses the throttle position sensor signal and eng ine speed signal (crankshaft position

sensor signal) for basic injector drive timing and basic ignition timing from the

2. motor in the appointed position so idle air contro l is not performed.

Intake air temperature

Controls as if the intake air temperature is

sensor

Throttle position

sensor (TPS)

Engine coolant

temperaturesensor

Camshaft position

sensor

Barometric pressure

sensor

Knock sensor

Engine (Turbo)>

Ignition coil, power

transistor unit

Heated oxygen sensor

Heated oxygen sensor

Misfire detection

Turbocharger waste

gate actuator Engine

terminal Performs the closed loop control of the air/fuel ra

tio by using only the signal of the heated

oxygen sensor (front) installed on the front side o f the catalytic converter.

The ECM stops supplying fuel to the cylinder with t he highest misfiring rate if a misfiring that

could damage the catalytic converter is detected.

Shuts off fuel in case of overcharge.

Does not restrict the generator output with respect to electrical load.

No increase in fuel amount during acceleration due to the unreliable throttle position

sensor signal.

Controls as if the ‘engine coolant temperature is

fuel into the cylinders in the order with irregular timing.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

off the fuel supply 4 seconds after a problem is d etected.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

Controls as if the barometric pressure is 101

(30 (sea level).

Switches the ignition timing from ignition timing f or high octane to ignition timing for standard

octane fuel.

Cuts off the fuel supply to cylinders with an abnor mal ignition signal.

Air/fuel ratio closed loop control is not performed

TSB Revision

Page 1128 of 2103

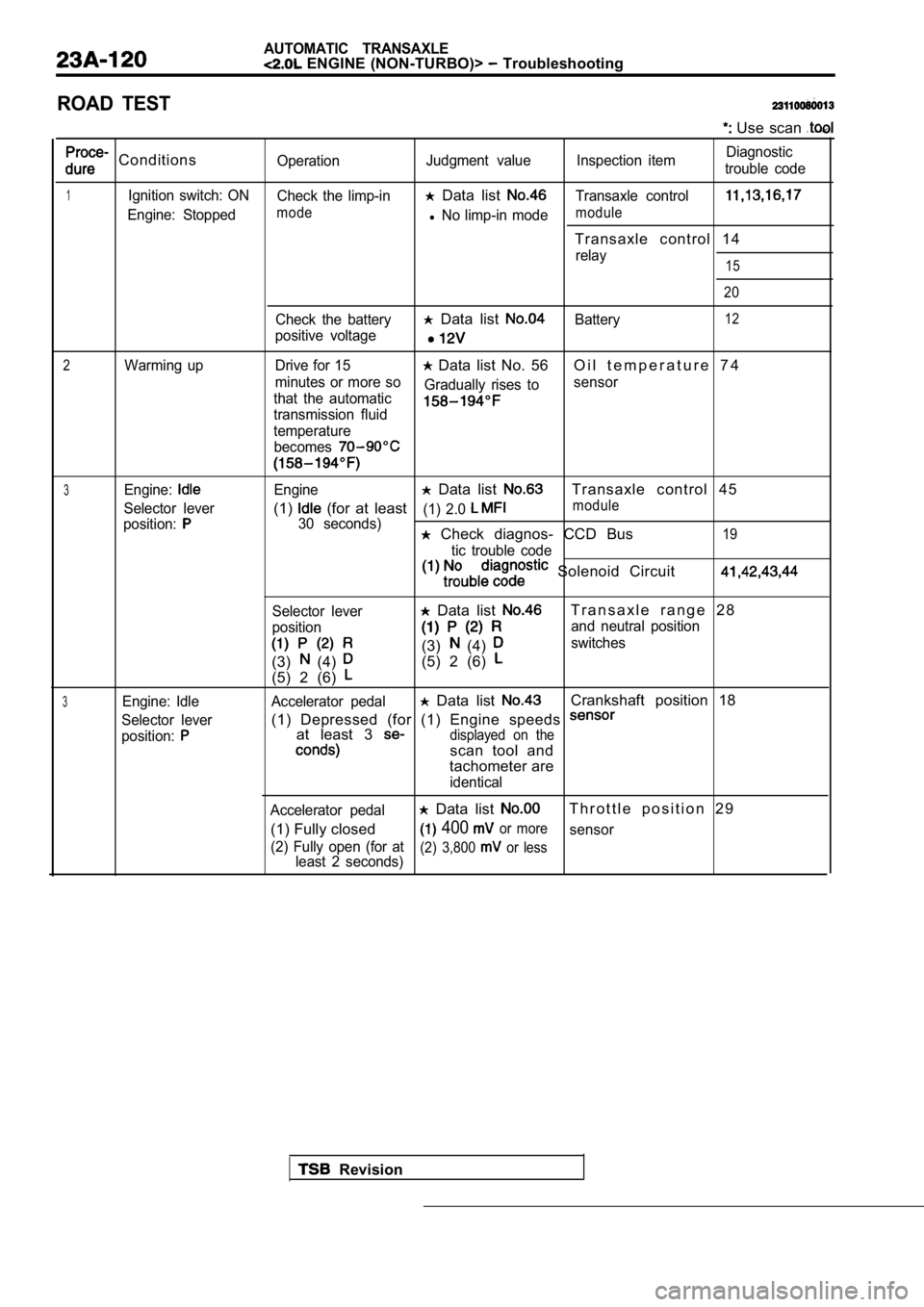

AUTOMATIC TRANSAXLE ENGINE (NON-TURBO)> Troubleshooting

ROAD TEST

Use scan

ConditionsOperationJudgment value Inspection item Diagnostic

trouble code

1Ignition switch: ON Check the limp-in Data list Transaxle control

Engine: Stoppedmodel No limp-in modemodule

Transaxle control 14

relay15

20

Check the battery Data list Battery12

positive voltage

2Warming up Drive for 15 Data list No. 56 O i l t e m p e r a t u r e 7 4

minutes or more so

that the automatic Gradually rises to

sensor

transmission fluid

temperature

becomes

3Engine:Engine Data list Transaxle control 45

Selector lever(1) (for at least(1) 2.0 module

position:30 seconds) Check diagnos- CCD Bus19

tic trouble code

Solenoid Circuit

Selector lever

position

(3) (4)

(5) 2 (6)

Data list T r a n s a x l e r a n g e 2 8

and neutral position

(3) (4) switches

(5) 2 (6)

3Engine: Idle Accelerator pedal Data list Crankshaft position 18

Selector lever(1) Depressed (for (1) Engine speeds

position:at least 3 displayed on the

scan tool and

tachometer are

identical

Accelerator pedal

Data list T h r o t t l e p o s i t i o n 2 9

(1) Fully closed

400 or moresensor

(2) Fully open (for at least 2 seconds)

(2) 3,800 or less

Revision