battery NISSAN ALMERA 2001 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 894 of 2898

![NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

75R

RCamshaft position sen-

sor (PHASE)[Engine is running]

+Warm-up condition

+Idle speed2.0 - 3.0V

SEF977W

[Engine is running]

+Engine spee NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

75R

RCamshaft position sen-

sor (PHASE)[Engine is running]

+Warm-up condition

+Idle speed2.0 - 3.0V

SEF977W

[Engine is running]

+Engine spee](/img/5/57348/w960_57348-893.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

75R

RCamshaft position sen-

sor (PHASE)[Engine is running]

+Warm-up condition

+Idle speed2.0 - 3.0V

SEF977W

[Engine is running]

+Engine speed is 2,000 rpm2.0 - 3.0V

SEF978W

67 W/LPower supply for ECM

(Back-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

70 BR/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature

71 GYThrottle position sensor

signal output[Engine is running]

+Warm-up condition

+Accelerator pedal fully releasedApproximately 0.4V

[Ignition switch ªONº]

+Accelerator pedal fully depressedApproximately 4V

72* P/B EGR temperature sensor[Engine is running]

+Warm-up condition

+Idle speedLess than 4.5V

[Engine is running]

+Warm-up condition

+EGR system is operating0 - 1.0V

73 BMass air flow sensor

ground[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

74 R/LRefrigerant pressure

sensor[Engine is running]

+Air conditioner switch is ªONº

(Compressor operates)1.0 - 4.0V

[Engine is running]

+Warm-up condition

+Idle speed

+Air conditioner switch is turned from ªONº to

ªOFFºVoltage is gradually decreasing.

81 W Knock sensor[Engine is running]

+Idle speed1.0 - 4.0V

82* L/WFuel tank temperature

sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with fuel

temperature

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-170

Page 895 of 2898

![NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 RCrankshaft position sen-

sor (POS)[Engine is running]

+Warm-up condition

+Idle speed3.0 - 4.0V

SEF979W

[Engine is running]

+Engine speed is NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 RCrankshaft position sen-

sor (POS)[Engine is running]

+Warm-up condition

+Idle speed3.0 - 4.0V

SEF979W

[Engine is running]

+Engine speed is](/img/5/57348/w960_57348-894.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 RCrankshaft position sen-

sor (POS)[Engine is running]

+Warm-up condition

+Idle speed3.0 - 4.0V

SEF979W

[Engine is running]

+Engine speed is 2,000 rpm3.0 - 4.0V

SEF980W

86 PU/R Vehicle speed sensor[Engine is running]

+Lift up the vehicle

+Vehicle speed is 40 km/h (25 MPH)2.5-3V

SEF976W

91 PU A/T check signal[Engine is running]

+Idle speed0 - Approximately 5V

92 Y Throttle position sensor[Engine is running]

+Accelerator pedal released0.15 - 0.85V

[Ignition switch ªONº]

+Accelerator pedal fully depressed3.5 - 4.7V

93 G/R Data link connector[Engine is running]

+Idle speed (CONSULT-II or GST is discon-

nected)Approximately 0V

101

103

105

107R/B

YB

GB

L/BInjector No. 1

Injector No. 2

Injector No. 3

Injector No. 4[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-171

Page 896 of 2898

![NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+ NISSAN ALMERA 2001 Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+](/img/5/57348/w960_57348-895.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104* SBSwirl control valve con-

trol solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF)

+Idle speed0-1V

[Engine is running]

+Engine coolant temperature is above 40ÉC

(104ÉF)

+Idle speedBATTERY VOLTAGE

(11 - 14V)

106

108B/Y ECM ground[Engine is running]

+Idle speedEngine ground

11 0

11 2W

WPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

111 R Sensors' power supply[Ignition switch ªONº]Approximately 5V

114 GY/R Adjust switch[Engine is running]

+Idle speed0V

115 LG Data link connector[Engine is running]

+Idle speed (CONSULT-II or GST is discon-

nected)0 - 10V

* If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

ECM Terminals and Reference Value (Cont'd)

EC-172

Page 905 of 2898

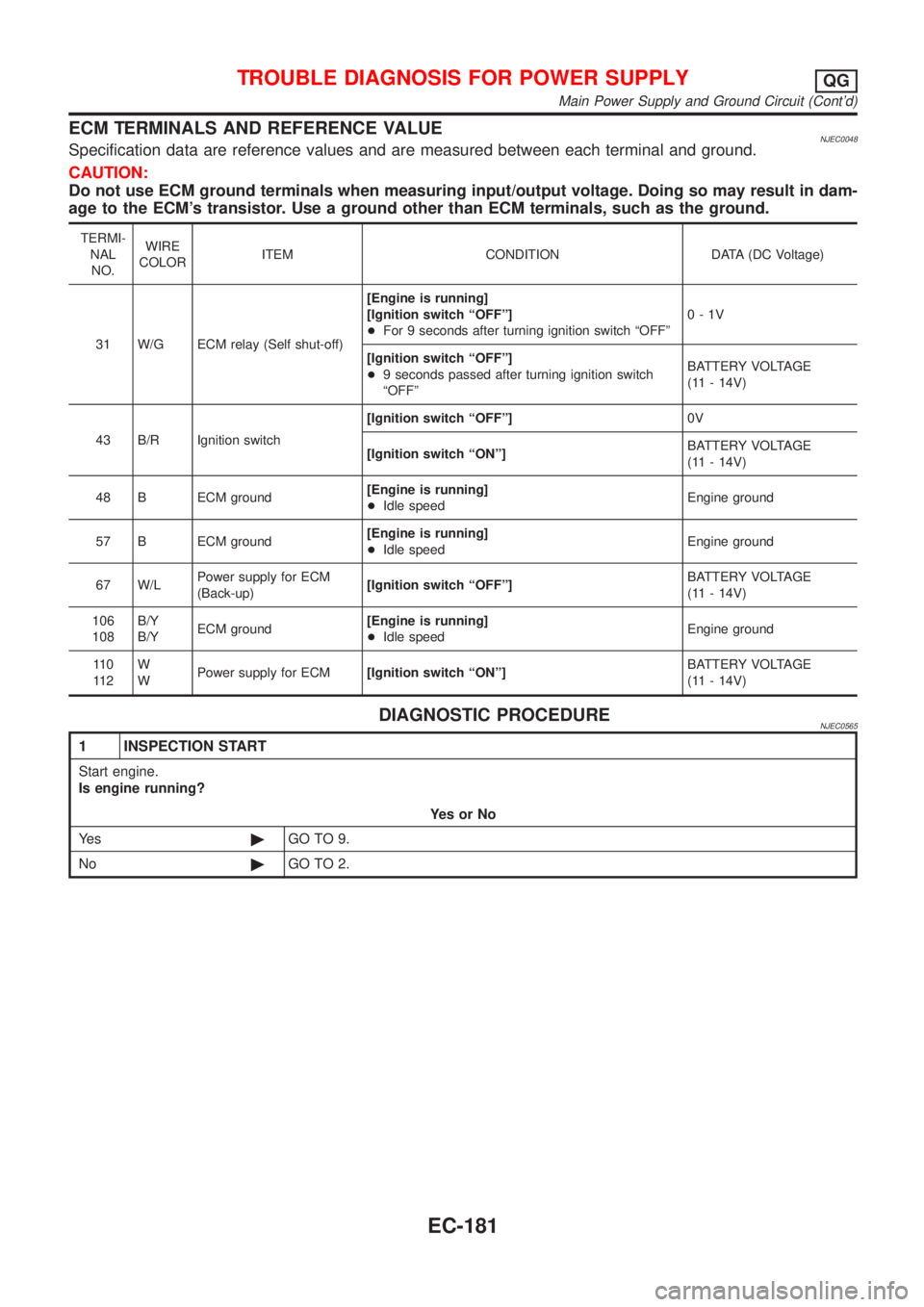

ECM TERMINALS AND REFERENCE VALUENJEC0048Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

31 W/G ECM relay (Self shut-off)[Engine is running]

[Ignition switch ªOFFº]

+For 9 seconds after turning ignition switch ªOFFº0-1V

[Ignition switch ªOFFº]

+9 seconds passed after turning ignition switch

ªOFFºBATTERY VOLTAGE

(11 - 14V)

43 B/R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

48 B ECM ground[Engine is running]

+Idle speedEngine ground

57 B ECM ground[Engine is running]

+Idle speedEngine ground

67 W/LPower supply for ECM

(Back-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

106

108B/Y

B/YECM ground[Engine is running]

+Idle speedEngine ground

11 0

11 2W

WPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

DIAGNOSTIC PROCEDURENJEC0565

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 9.

No©GO TO 2.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-181

Page 907 of 2898

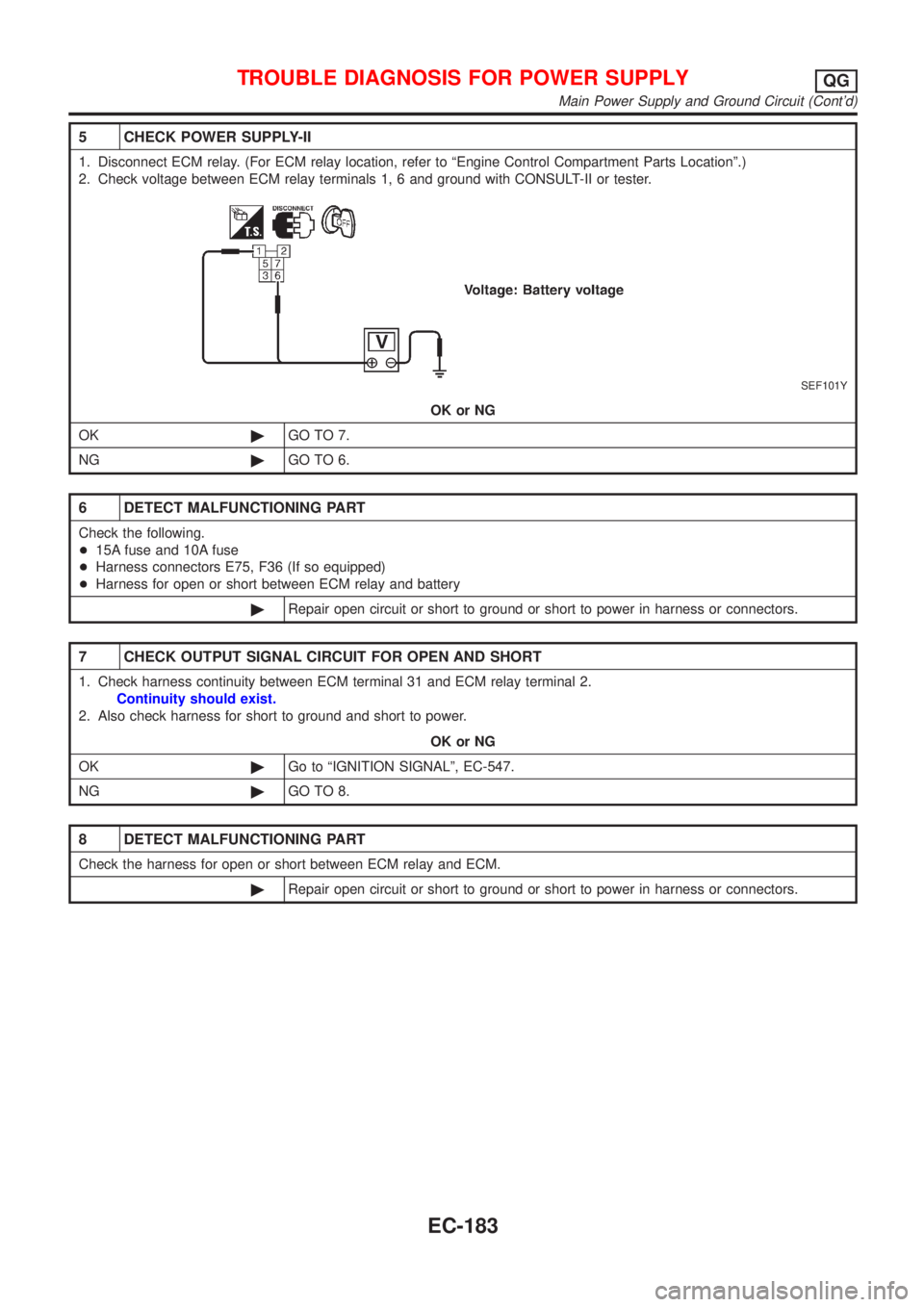

5 CHECK POWER SUPPLY-II

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

2. Check voltage between ECM relay terminals 1, 6 and ground with CONSULT-II or tester.

SEF101Y

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse and 10A fuse

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 31 and ECM relay terminal 2.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©Go to ªIGNITION SIGNALº, EC-547.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM relay and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-183

Page 908 of 2898

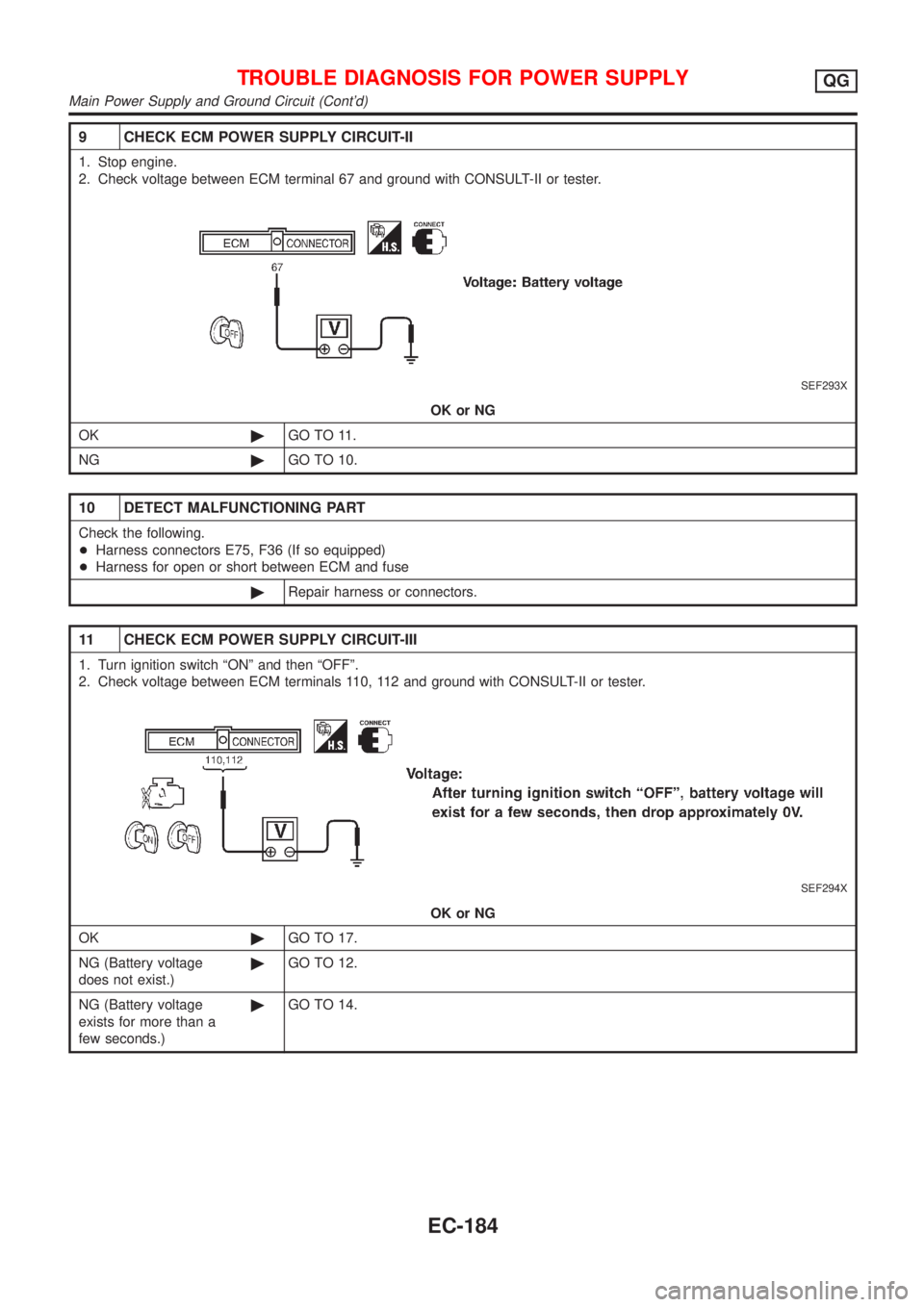

9 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Stop engine.

2. Check voltage between ECM terminal 67 and ground with CONSULT-II or tester.

SEF293X

OK or NG

OK©GO TO 11.

NG©GO TO 10.

10 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between ECM and fuse

©Repair harness or connectors.

11 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch ªONº and then ªOFFº.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF294X

OK or NG

OK©GO TO 17.

NG (Battery voltage

does not exist.)©GO TO 12.

NG (Battery voltage

exists for more than a

few seconds.)©GO TO 14.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-184

Page 932 of 2898

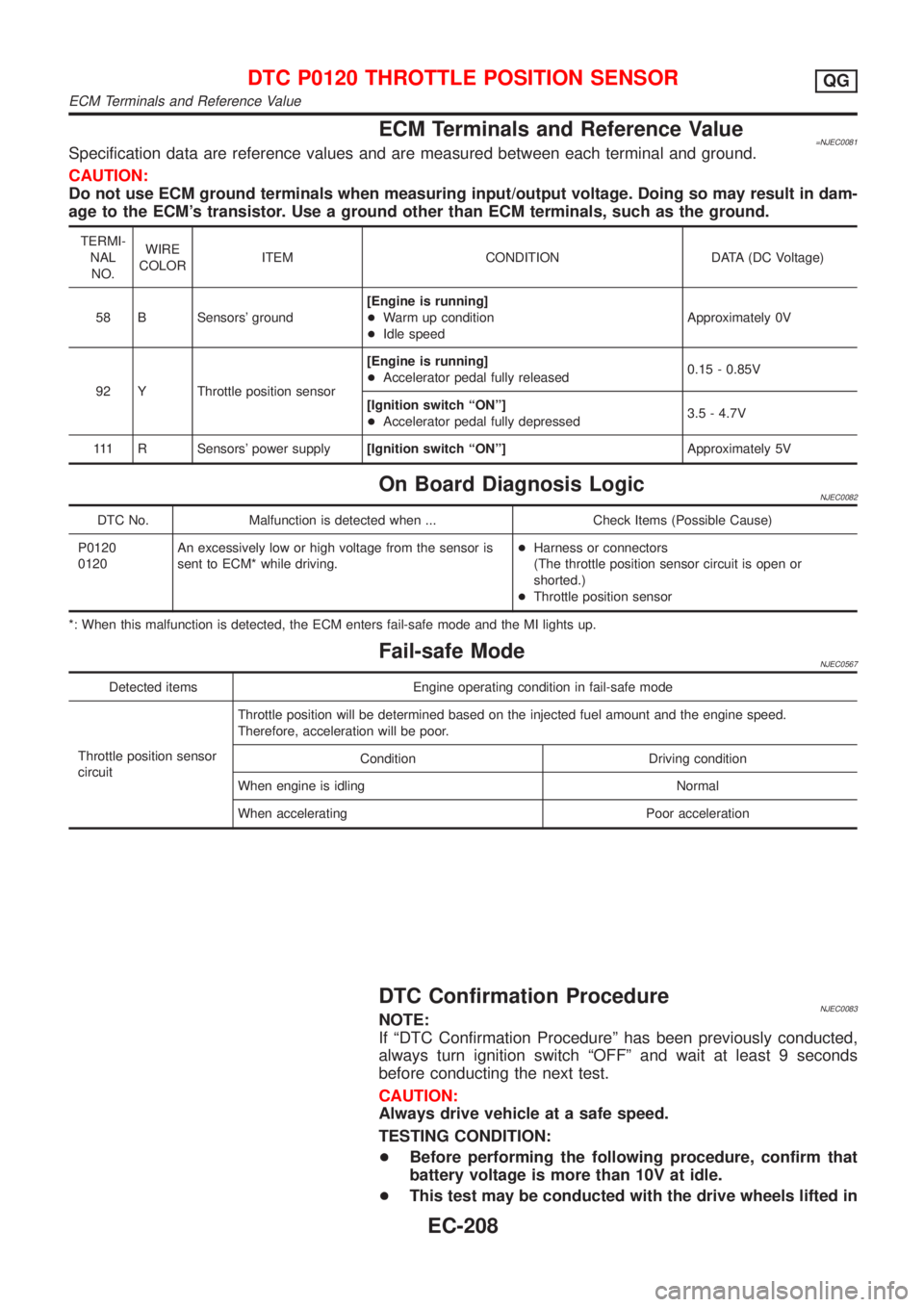

ECM Terminals and Reference Value=NJEC0081Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B Sensors' ground[Engine is running]

+Warm up condition

+Idle speedApproximately 0V

92 Y Throttle position sensor[Engine is running]

+Accelerator pedal fully released0.15 - 0.85V

[Ignition switch ªONº]

+Accelerator pedal fully depressed3.5 - 4.7V

111 R Sensors' power supply[Ignition switch ªONº]Approximately 5V

On Board Diagnosis LogicNJEC0082

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0120

0120An excessively low or high voltage from the sensor is

sent to ECM* while driving.+Harness or connectors

(The throttle position sensor circuit is open or

shorted.)

+Throttle position sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Fail-safe ModeNJEC0567

Detected items Engine operating condition in fail-safe mode

Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and the engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

DTC Confirmation ProcedureNJEC0083NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

+Before performing the following procedure, confirm that

battery voltage is more than 10V at idle.

+This test may be conducted with the drive wheels lifted in

DTC P0120 THROTTLE POSITION SENSORQG

ECM Terminals and Reference Value

EC-208

Page 941 of 2898

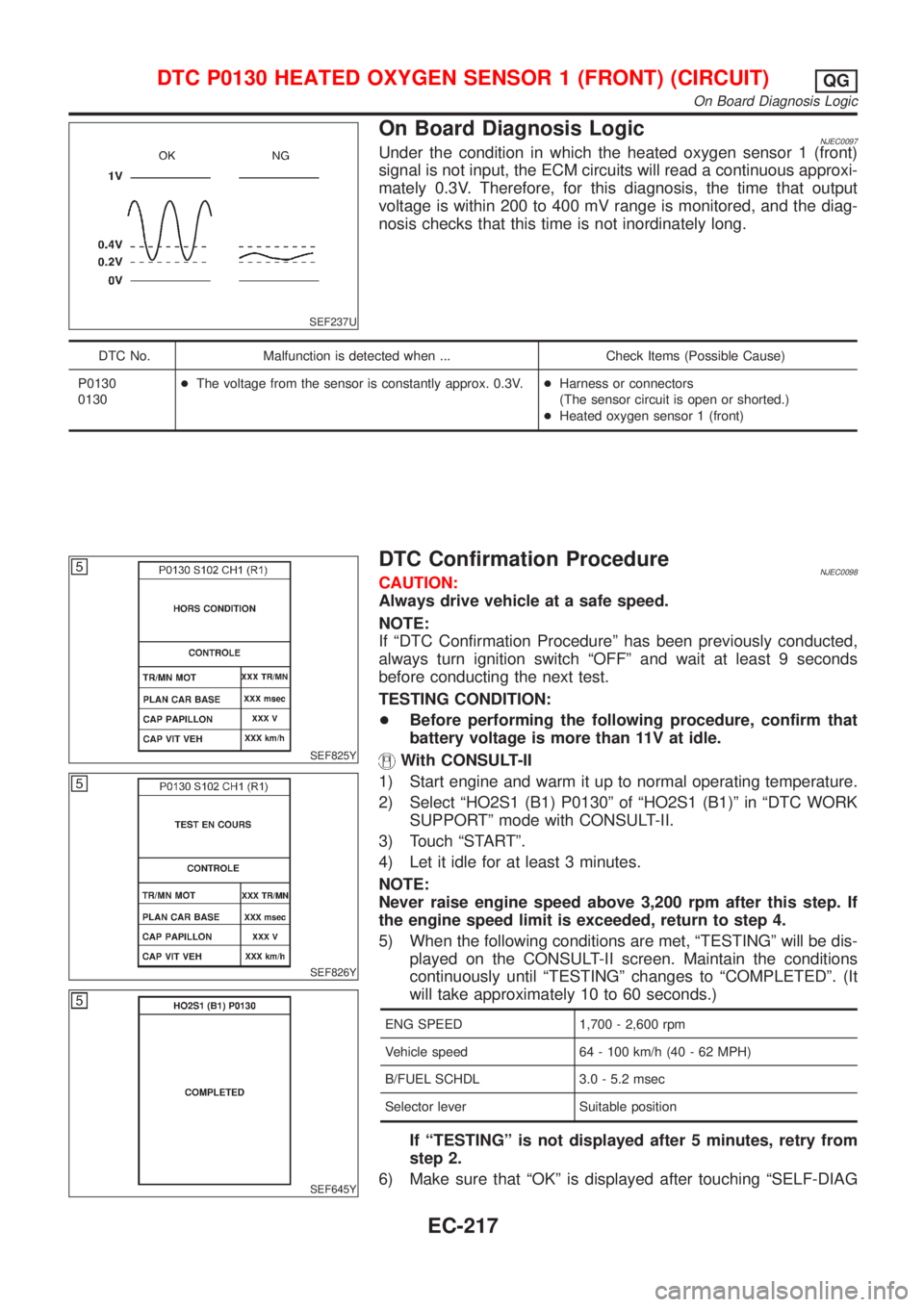

SEF237U

On Board Diagnosis LogicNJEC0097Under the condition in which the heated oxygen sensor 1 (front)

signal is not input, the ECM circuits will read a continuous approxi-

mately 0.3V. Therefore, for this diagnosis, the time that output

voltage is within 200 to 400 mV range is monitored, and the diag-

nosis checks that this time is not inordinately long.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0130

0130+The voltage from the sensor is constantly approx. 0.3V.+Harness or connectors

(The sensor circuit is open or shorted.)

+Heated oxygen sensor 1 (front)

SEF825Y

SEF826Y

SEF645Y

DTC Confirmation ProcedureNJEC0098CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

+Before performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªHO2S1 (B1) P0130º of ªHO2S1 (B1)º in ªDTC WORK

SUPPORTº mode with CONSULT-II.

3) Touch ªSTARTº.

4) Let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 4.

5) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 10 to 60 seconds.)

ENG SPEED 1,700 - 2,600 rpm

Vehicle speed 64 - 100 km/h (40 - 62 MPH)

B/FUEL SCHDL 3.0 - 5.2 msec

Selector lever Suitable position

If ªTESTINGº is not displayed after 5 minutes, retry from

step 2.

6) Make sure that ªOKº is displayed after touching ªSELF-DIAG

DTC P0130 HEATED OXYGEN SENSOR 1 (FRONT) (CIRCUIT)QG

On Board Diagnosis Logic

EC-217

Page 949 of 2898

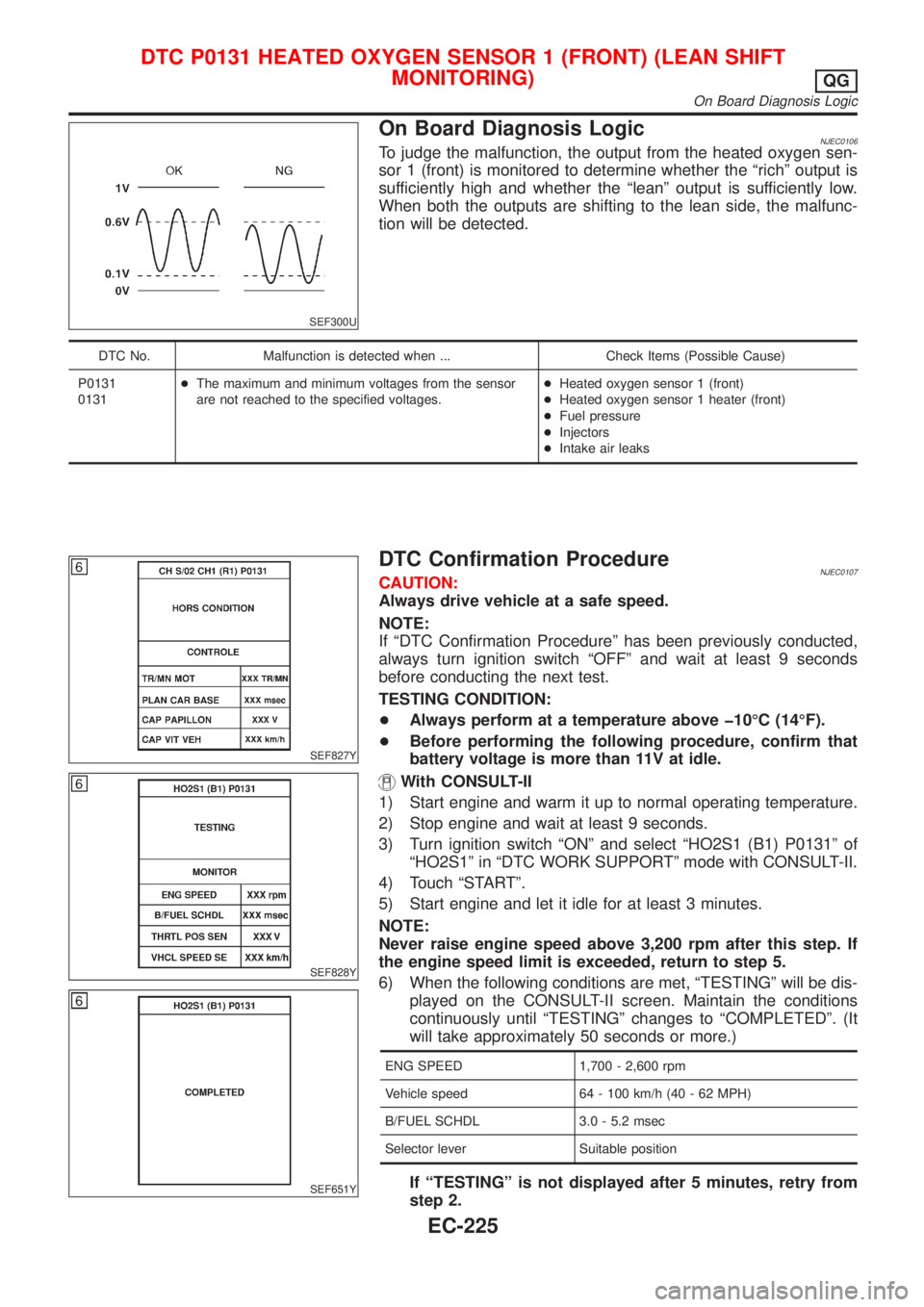

SEF300U

On Board Diagnosis LogicNJEC0106To judge the malfunction, the output from the heated oxygen sen-

sor 1 (front) is monitored to determine whether the ªrichº output is

sufficiently high and whether the ªleanº output is sufficiently low.

When both the outputs are shifting to the lean side, the malfunc-

tion will be detected.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0131

0131+The maximum and minimum voltages from the sensor

are not reached to the specified voltages.+Heated oxygen sensor 1 (front)

+Heated oxygen sensor 1 heater (front)

+Fuel pressure

+Injectors

+Intake air leaks

SEF827Y

SEF828Y

SEF651Y

DTC Confirmation ProcedureNJEC0107CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

+Always perform at a temperature above þ10ÉC (14ÉF).

+Before performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªHO2S1 (B1) P0131º of

ªHO2S1º in ªDTC WORK SUPPORTº mode with CONSULT-II.

4) Touch ªSTARTº.

5) Start engine and let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 5.

6) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 50 seconds or more.)

ENG SPEED 1,700 - 2,600 rpm

Vehicle speed 64 - 100 km/h (40 - 62 MPH)

B/FUEL SCHDL 3.0 - 5.2 msec

Selector lever Suitable position

If ªTESTINGº is not displayed after 5 minutes, retry from

step 2.

DTC P0131 HEATED OXYGEN SENSOR 1 (FRONT) (LEAN SHIFT

MONITORING)

QG

On Board Diagnosis Logic

EC-225

Page 955 of 2898

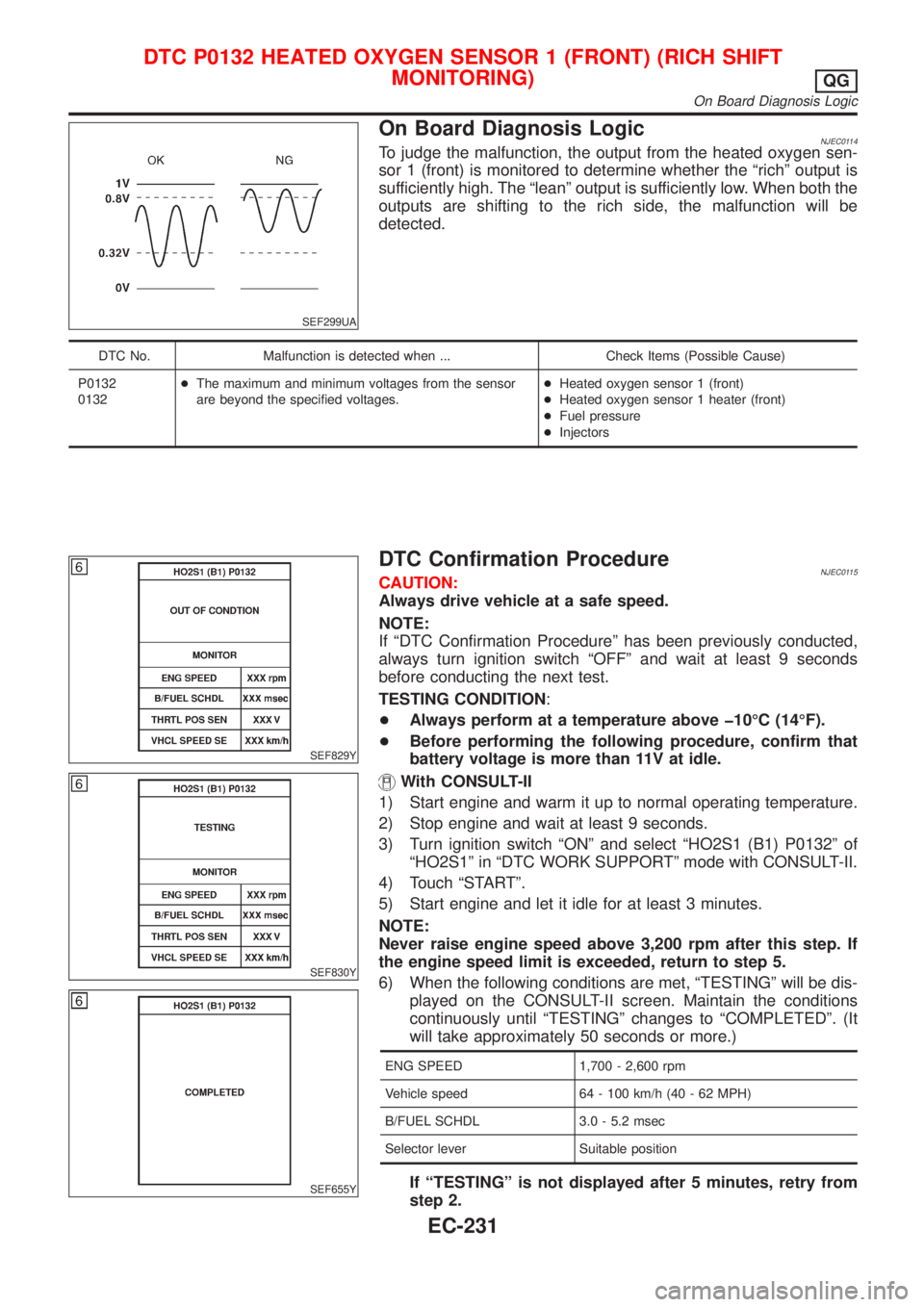

SEF299UA

On Board Diagnosis LogicNJEC0114To judge the malfunction, the output from the heated oxygen sen-

sor 1 (front) is monitored to determine whether the ªrichº output is

sufficiently high. The ªleanº output is sufficiently low. When both the

outputs are shifting to the rich side, the malfunction will be

detected.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0132

0132+The maximum and minimum voltages from the sensor

are beyond the specified voltages.+Heated oxygen sensor 1 (front)

+Heated oxygen sensor 1 heater (front)

+Fuel pressure

+Injectors

SEF829Y

SEF830Y

SEF655Y

DTC Confirmation ProcedureNJEC0115CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

+Always perform at a temperature above þ10ÉC (14ÉF).

+Before performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªHO2S1 (B1) P0132º of

ªHO2S1º in ªDTC WORK SUPPORTº mode with CONSULT-II.

4) Touch ªSTARTº.

5) Start engine and let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 5.

6) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 50 seconds or more.)

ENG SPEED 1,700 - 2,600 rpm

Vehicle speed 64 - 100 km/h (40 - 62 MPH)

B/FUEL SCHDL 3.0 - 5.2 msec

Selector lever Suitable position

If ªTESTINGº is not displayed after 5 minutes, retry from

step 2.

DTC P0132 HEATED OXYGEN SENSOR 1 (FRONT) (RICH SHIFT

MONITORING)

QG

On Board Diagnosis Logic

EC-231