battery NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1100 of 2898

DescriptionNJEC0279SYSTEM DESCRIPTIONNJEC0279S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Idle air

controlIACV-AAC valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

PNP switch Park/Neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Cooling fan Cooling fan operation

Electrical load Electrical load signal

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by taking into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering, cool-

ing fan operation and electrical load).

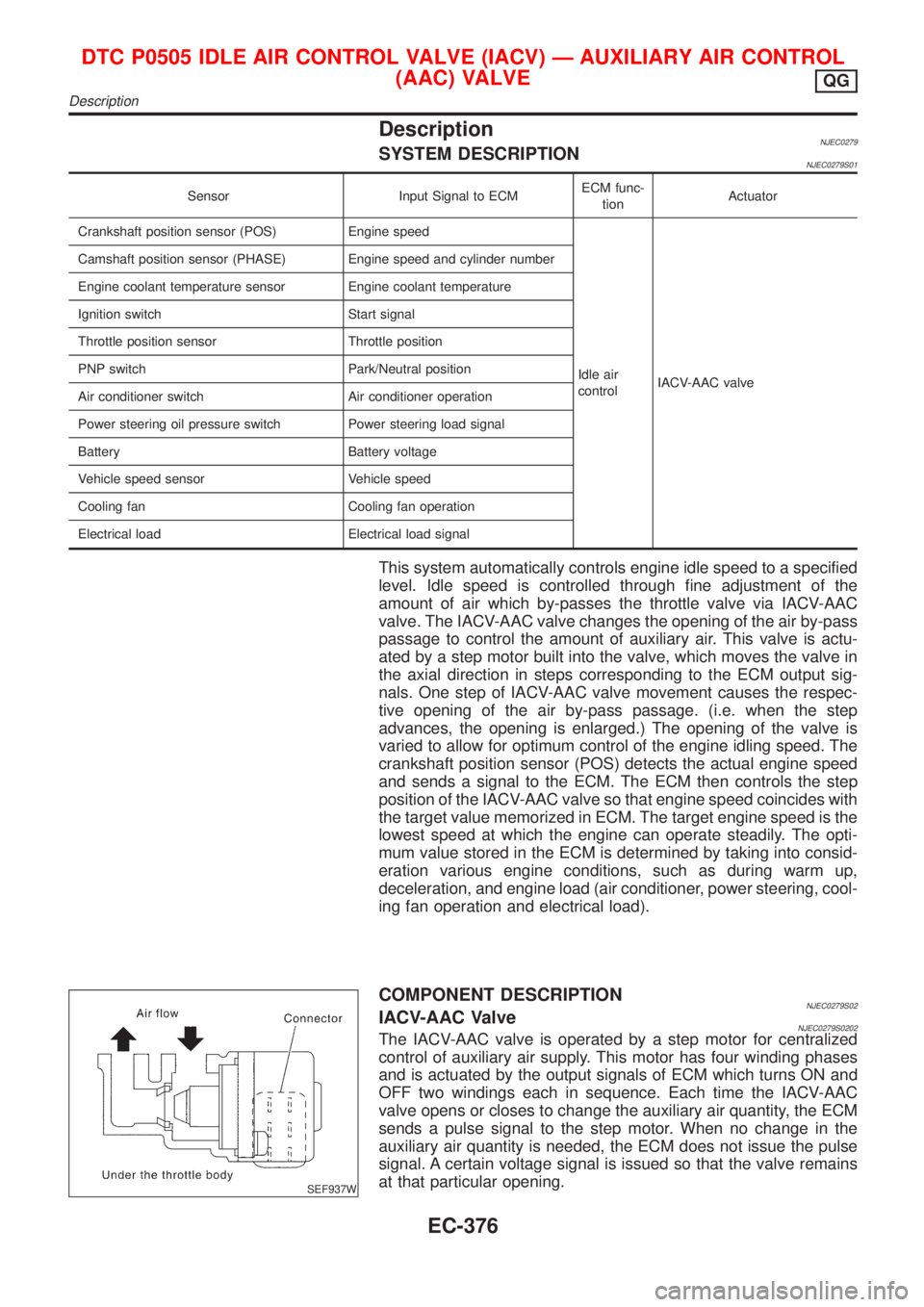

SEF937W

COMPONENT DESCRIPTIONNJEC0279S02IACV-AAC ValveNJEC0279S0202The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in sequence. Each time the IACV-AAC

valve opens or closes to change the auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

QG

Description

EC-376

Page 1109 of 2898

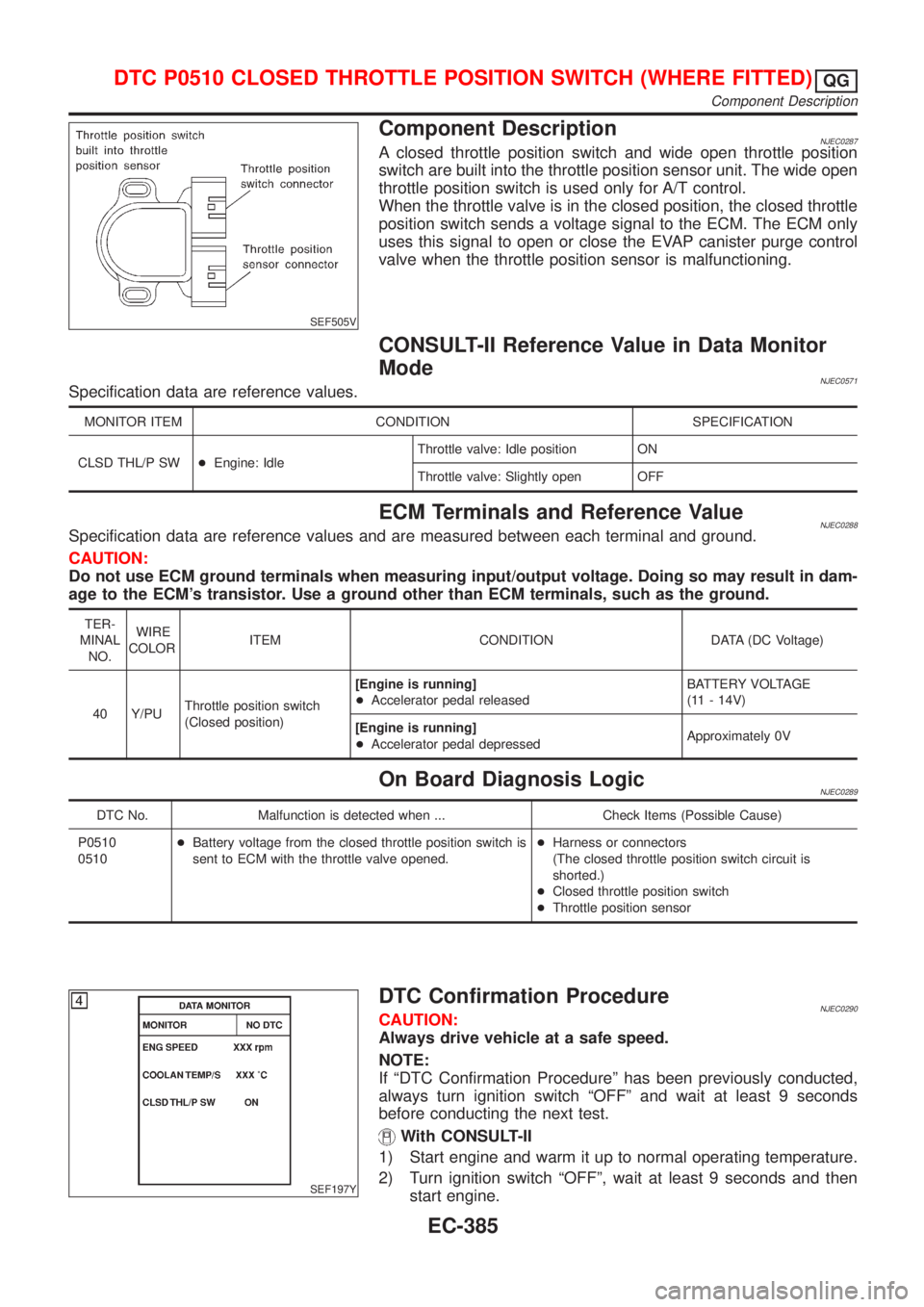

SEF505V

Component DescriptionNJEC0287A closed throttle position switch and wide open throttle position

switch are built into the throttle position sensor unit. The wide open

throttle position switch is used only for A/T control.

When the throttle valve is in the closed position, the closed throttle

position switch sends a voltage signal to the ECM. The ECM only

uses this signal to open or close the EVAP canister purge control

valve when the throttle position sensor is malfunctioning.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0571Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CLSD THL/P SW+Engine: IdleThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

ECM Terminals and Reference ValueNJEC0288Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

40 Y/PUThrottle position switch

(Closed position)[Engine is running]

+Accelerator pedal releasedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Accelerator pedal depressedApproximately 0V

On Board Diagnosis LogicNJEC0289

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0510

0510+Battery voltage from the closed throttle position switch is

sent to ECM with the throttle valve opened.+Harness or connectors

(The closed throttle position switch circuit is

shorted.)

+Closed throttle position switch

+Throttle position sensor

SEF197Y

DTC Confirmation ProcedureNJEC0290CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº, wait at least 9 seconds and then

start engine.

DTC P0510 CLOSED THROTTLE POSITION SWITCH (WHERE FITTED)QG

Component Description

EC-385

Page 1110 of 2898

3) Select ªCLSD THL/P SWº in ªDATA MONITORº mode. If

ªCLSD THL/P SWº is not available, go to step 5.

4) Check the signal under the following conditions.

Condition Signal indication

Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

If the result is NG, go to ªDiagnostic Procedureº, EC-388.

If OK, go to following step.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Drive the vehicle for at least 5 consecutive seconds under the

following condition.

THRTL POS SEN More than 2.3V

VHCL SPEED SE More than 4 km/h (2 MPH)

Selector lever Suitable position

Driving pattern Driving vehicle uphill (Increased engine load)

will help maintain the driving conditions

required for this test.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-388.

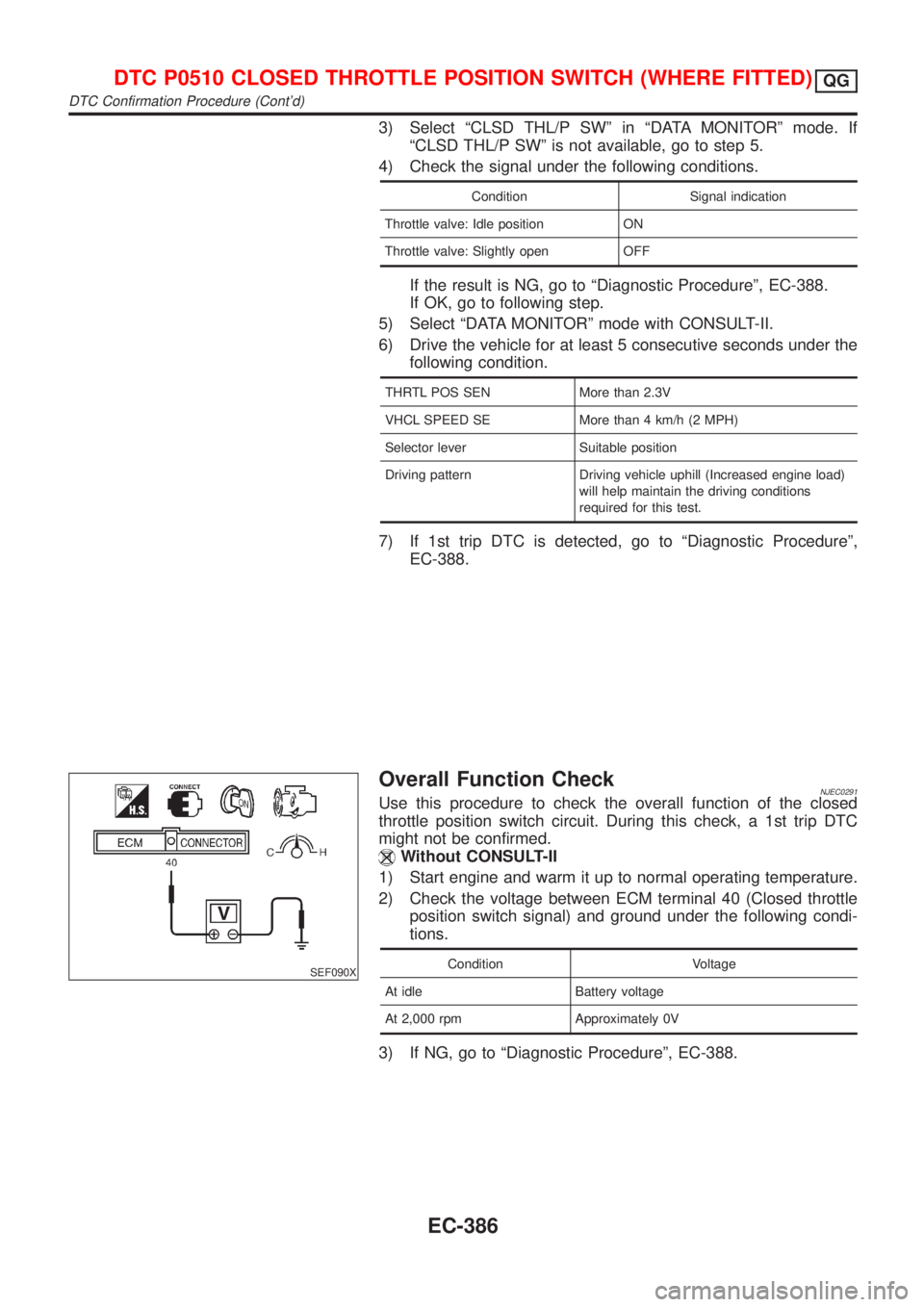

SEF090X

Overall Function CheckNJEC0291Use this procedure to check the overall function of the closed

throttle position switch circuit. During this check, a 1st trip DTC

might not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Check the voltage between ECM terminal 40 (Closed throttle

position switch signal) and ground under the following condi-

tions.

Condition Voltage

At idle Battery voltage

At 2,000 rpm Approximately 0V

3) If NG, go to ªDiagnostic Procedureº, EC-388.

DTC P0510 CLOSED THROTTLE POSITION SWITCH (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-386

Page 1112 of 2898

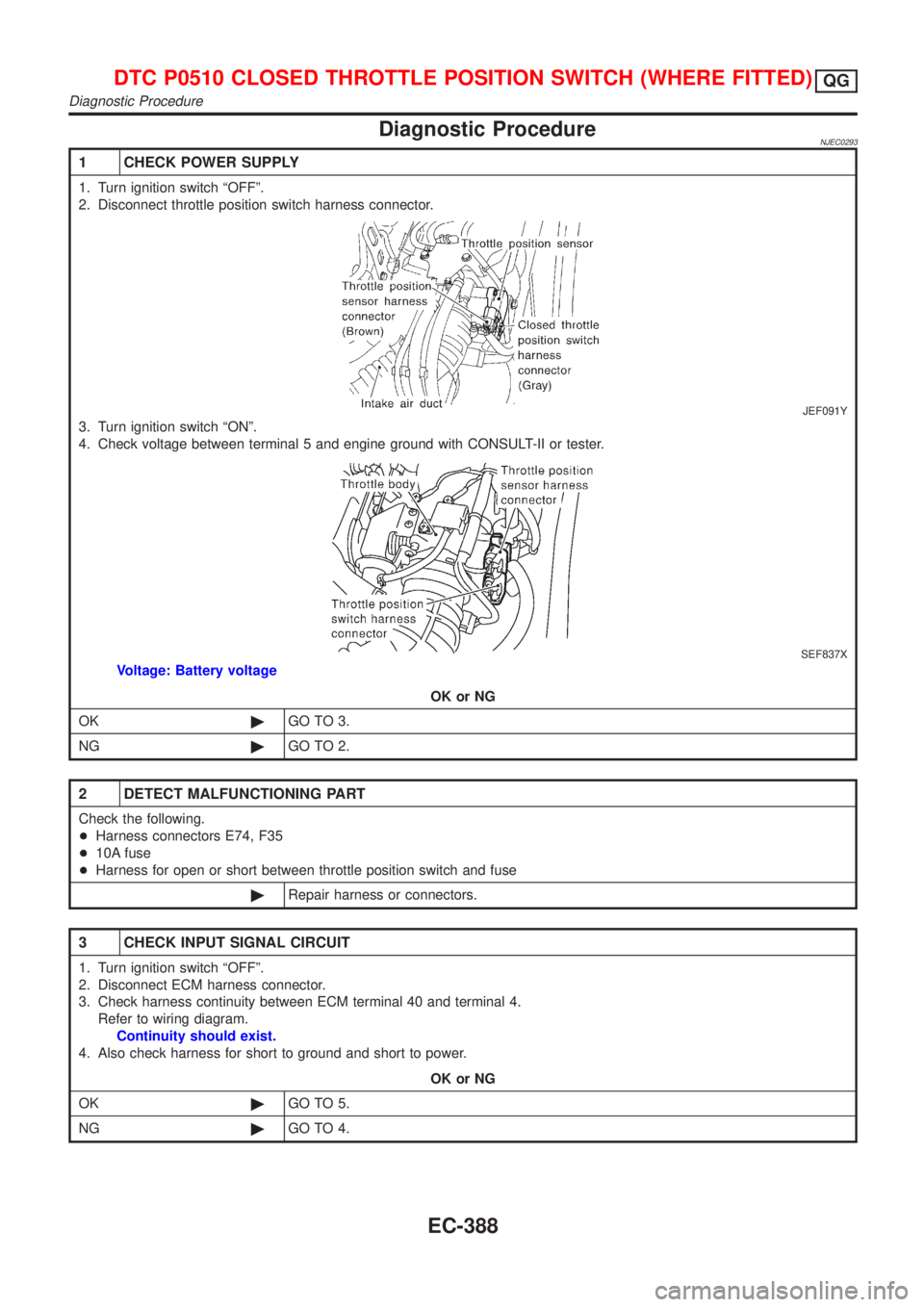

Diagnostic ProcedureNJEC0293

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect throttle position switch harness connector.

JEF091Y

3. Turn ignition switch ªONº.

4. Check voltage between terminal 5 and engine ground with CONSULT-II or tester.

SEF837X

Voltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E74, F35

+10A fuse

+Harness for open or short between throttle position switch and fuse

©Repair harness or connectors.

3 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 40 and terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P0510 CLOSED THROTTLE POSITION SWITCH (WHERE FITTED)QG

Diagnostic Procedure

EC-388

Page 1117 of 2898

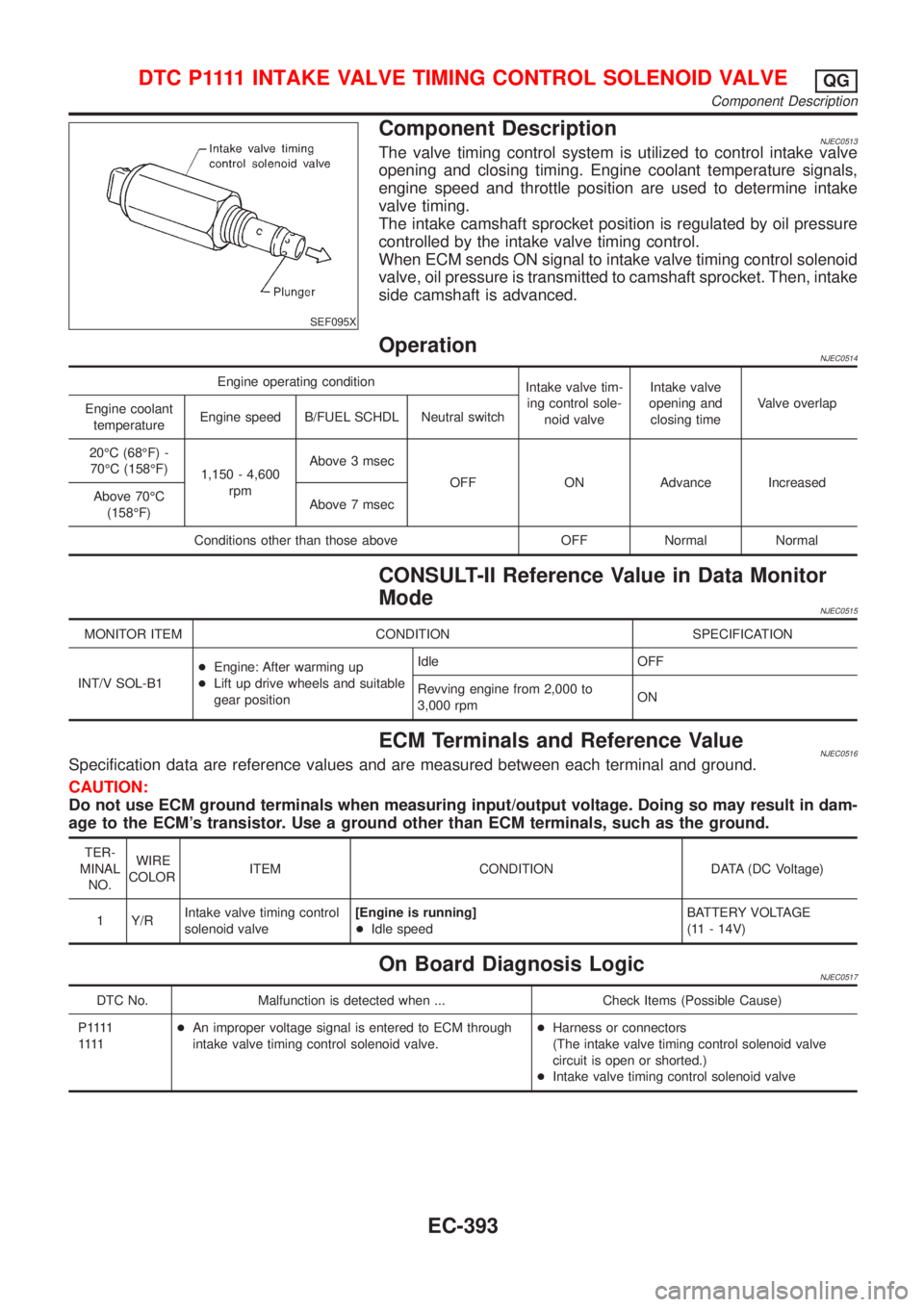

SEF095X

Component DescriptionNJEC0513The valve timing control system is utilized to control intake valve

opening and closing timing. Engine coolant temperature signals,

engine speed and throttle position are used to determine intake

valve timing.

The intake camshaft sprocket position is regulated by oil pressure

controlled by the intake valve timing control.

When ECM sends ON signal to intake valve timing control solenoid

valve, oil pressure is transmitted to camshaft sprocket. Then, intake

side camshaft is advanced.

OperationNJEC0514

Engine operating condition

Intake valve tim-

ing control sole-

noid valveIntake valve

opening and

closing timeValve overlap

Engine coolant

temperatureEngine speed B/FUEL SCHDL Neutral switch

20ÉC (68ÉF) -

70ÉC (158ÉF)

1,150 - 4,600

rpmAbove 3 msec

OFF ON Advance Increased

Above 70ÉC

(158ÉF)Above 7 msec

Conditions other than those above OFF Normal Normal

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0515

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL-B1+Engine: After warming up

+Lift up drive wheels and suitable

gear positionIdle OFF

Revving engine from 2,000 to

3,000 rpmON

ECM Terminals and Reference ValueNJEC0516Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 Y/RIntake valve timing control

solenoid valve[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNJEC0517

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P 1111

1111+An improper voltage signal is entered to ECM through

intake valve timing control solenoid valve.+Harness or connectors

(The intake valve timing control solenoid valve

circuit is open or shorted.)

+Intake valve timing control solenoid valve

D T C P 1111INTAKE VALVE TIMING CONTROL SOLENOID VALVEQG

Component Description

EC-393

Page 1122 of 2898

4 CHECK VALVE TIMING CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº, EC-398.

OK or NG

OK©GO TO 5.

NG©Replace valve timing control solenoid valve.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

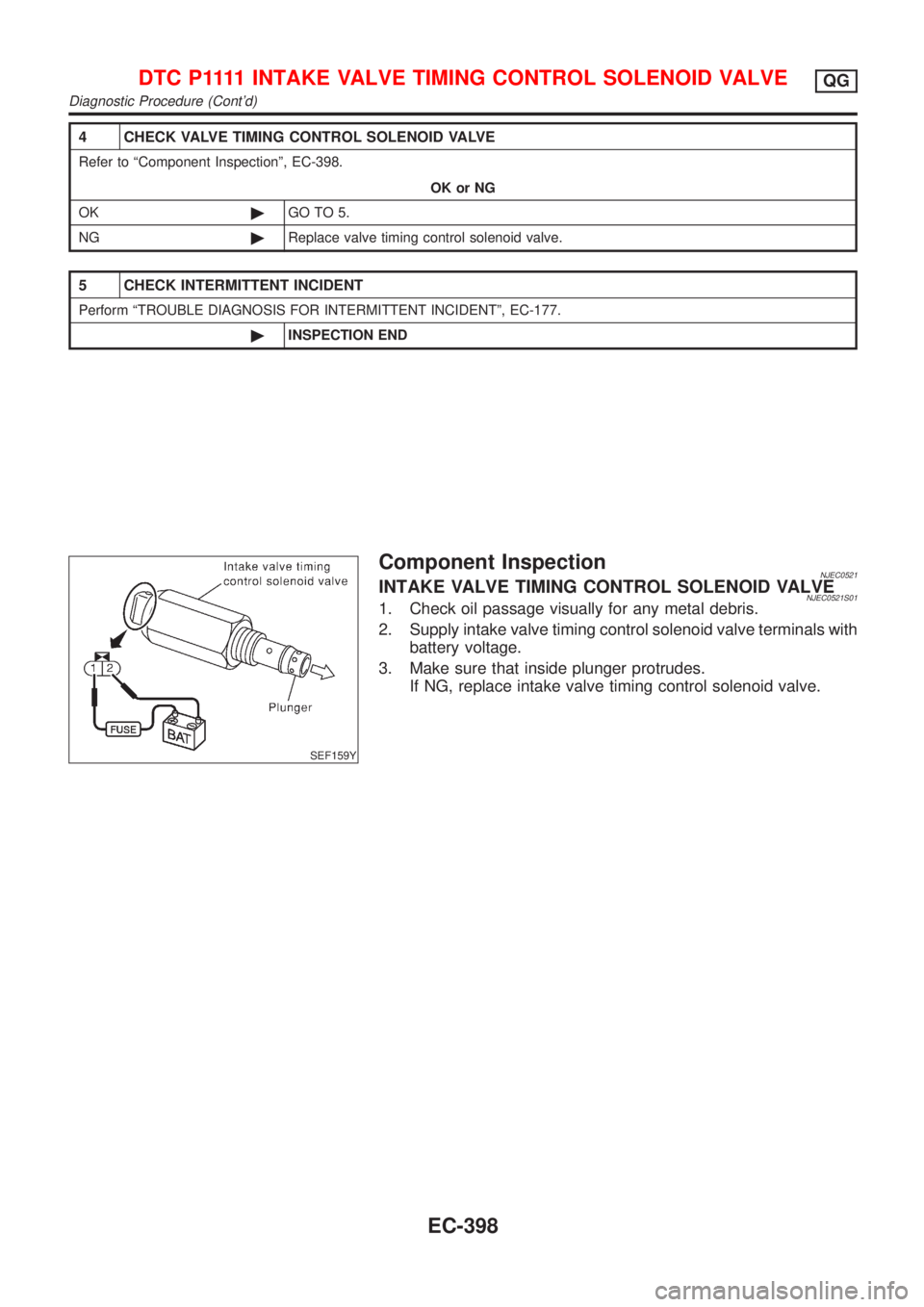

SEF159Y

Component InspectionNJEC0521INTAKE VALVE TIMING CONTROL SOLENOID VALVENJEC0521S011. Check oil passage visually for any metal debris.

2. Supply intake valve timing control solenoid valve terminals with

battery voltage.

3. Make sure that inside plunger protrudes.

If NG, replace intake valve timing control solenoid valve.

D T C P 1111INTAKE VALVE TIMING CONTROL SOLENOID VALVEQG

Diagnostic Procedure (Cont'd)

EC-398

Page 1124 of 2898

ECM Terminals and Reference Value=NJEC0524Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104 SBSwirl control valve control

solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF).

+Idle speed0-1V

[Engine is running]

+Engine coolant temperature is above 40ÉC

(104ÉF).

+Idle speedBATTERY VOLTAGE

(11 - 14V)

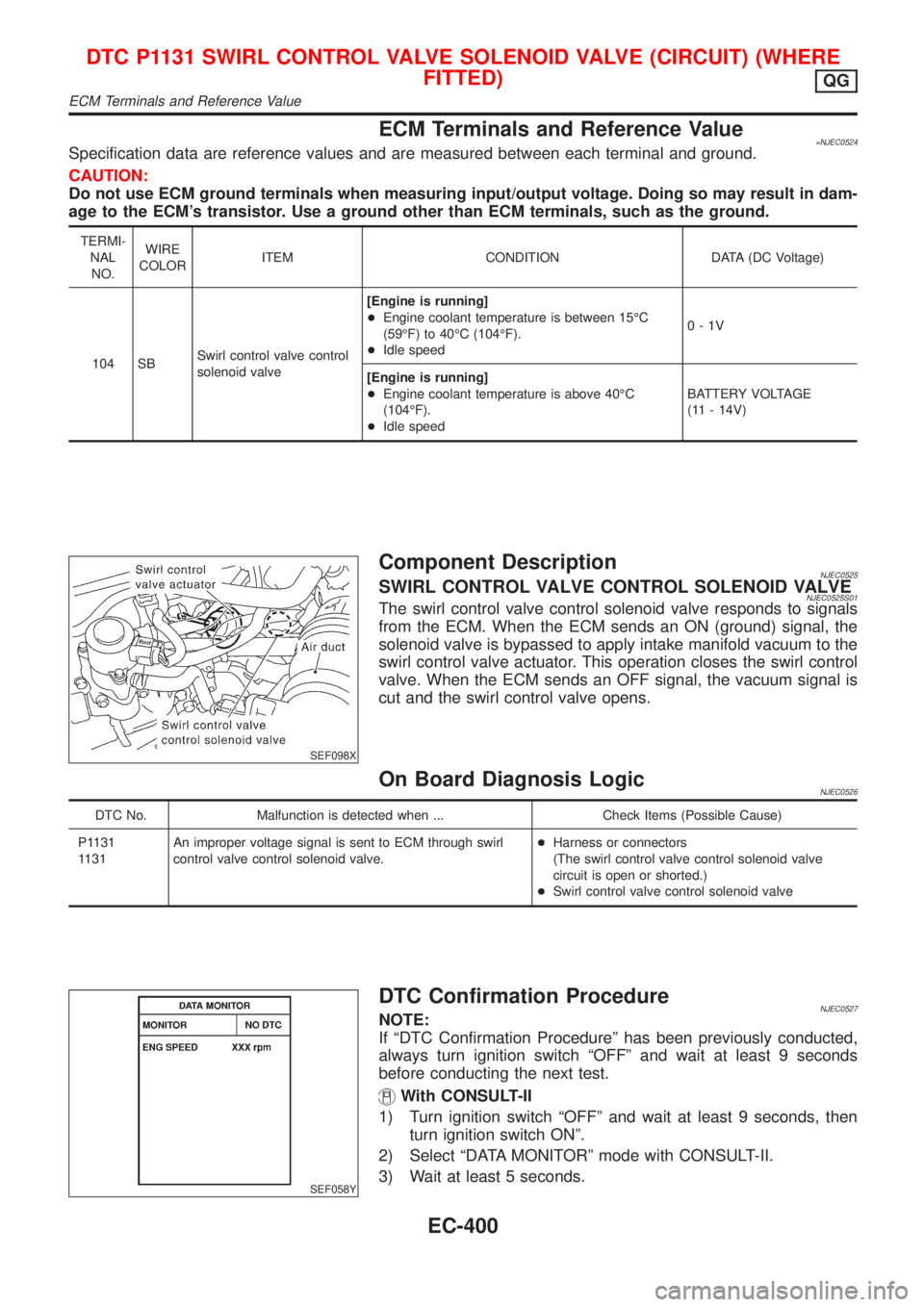

SEF098X

Component DescriptionNJEC0525SWIRL CONTROL VALVE CONTROL SOLENOID VALVENJEC0525S01The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

On Board Diagnosis LogicNJEC0526

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1131

1131An improper voltage signal is sent to ECM through swirl

control valve control solenoid valve.+Harness or connectors

(The swirl control valve control solenoid valve

circuit is open or shorted.)

+Swirl control valve control solenoid valve

SEF058Y

DTC Confirmation ProcedureNJEC0527NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ignition switch ONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

DTC P1131 SWIRL CONTROL VALVE SOLENOID VALVE (CIRCUIT) (WHERE

FITTED)

QG

ECM Terminals and Reference Value

EC-400

Page 1131 of 2898

ECM Terminals and Reference Value=NJEC0487Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

13 LG/R Cooling fan relay[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan is operating0 - 0.6V

23 L/W Air conditioner switch[Engine is running]

+Both air conditioner switch and blower switch are

ªONº (Compressor operates)Approximately 0V

[Engine is running]

+Air conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNJEC0572If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1217

1217+The engine coolant temperature is extraordinary high,

even when the load is not heavy.+Harness or connectors

(The cooling fan circuit is open or shorted)

+Cooling fan

+Thermostat

+Improper ignition timing

+Engine coolant temperature sensor

+Blocked radiator

+Blocked front end (Improper fitting of nose mask)

+Crushed vehicle frontal area (Vehicle frontal is

collided but not repaired)

+Blocked air passage by improper installation of

front fog lamp or fog lamps.

+Improper mixture ratio of coolant

+Damaged bumper

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-416.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC-18,

ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use

coolant with the proper mixture ratio. Refer to MA-18, ªAnti-freeze Coolant Mixture Ratioº, ªRECOM-

MENDED FLUIDS AND LUBRICANTSº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG

ECM Terminals and Reference Value

EC-407

Page 1141 of 2898

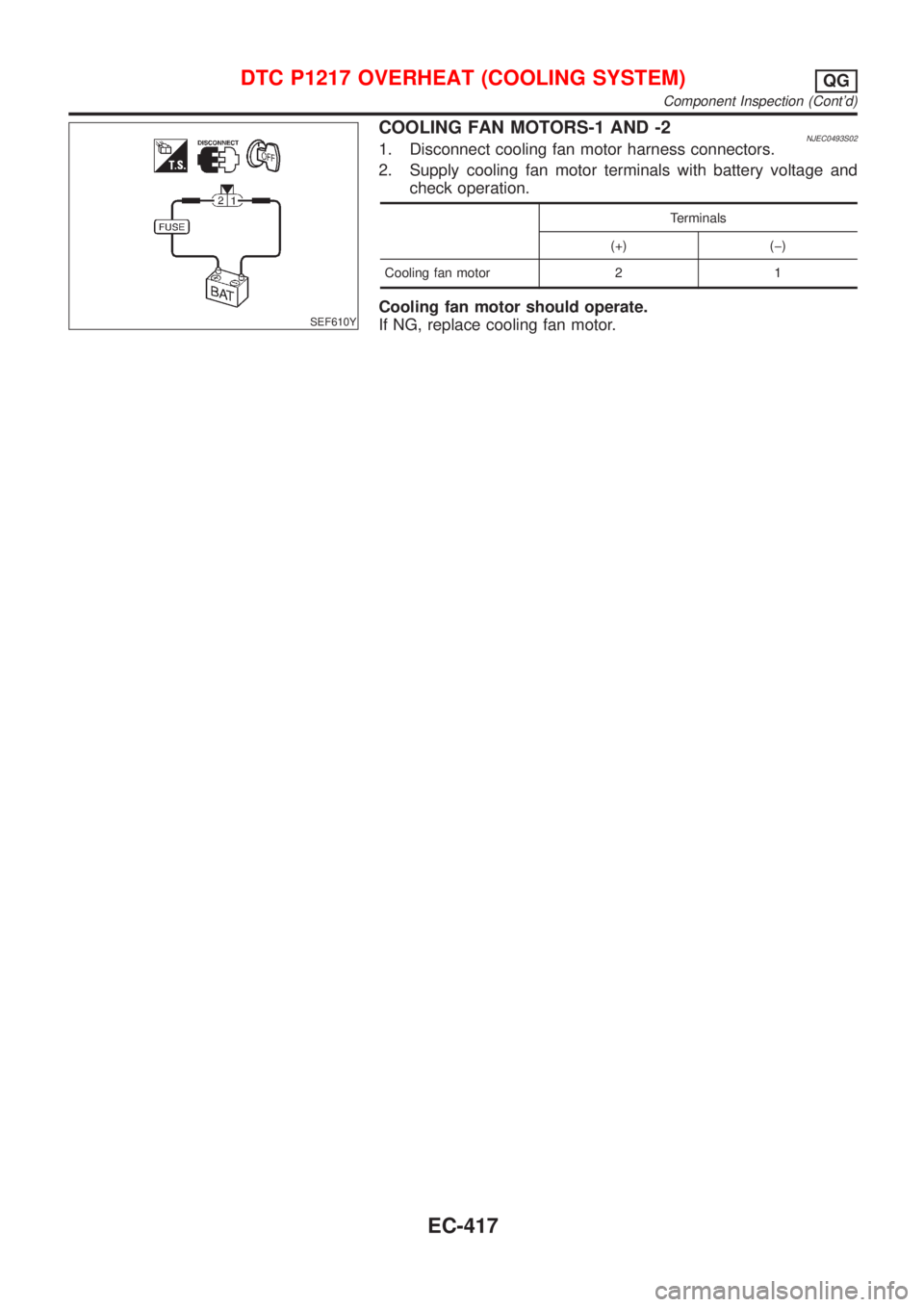

SEF610Y

COOLING FAN MOTORS-1 AND -2NJEC0493S021. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Terminals

(+) (þ)

Cooling fan motor 2 1

Cooling fan motor should operate.

If NG, replace cooling fan motor.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG

Component Inspection (Cont'd)

EC-417

Page 1149 of 2898

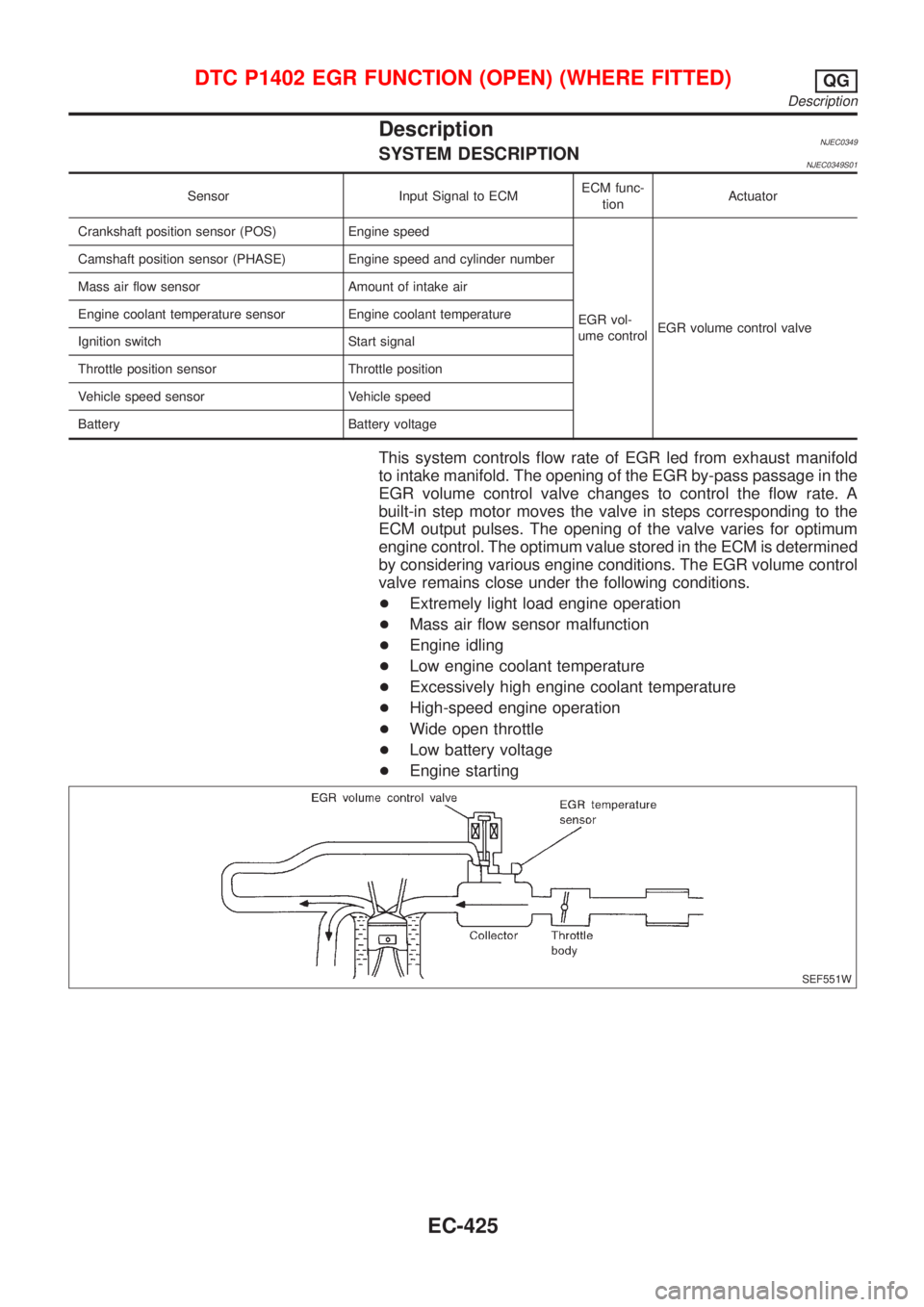

DescriptionNJEC0349SYSTEM DESCRIPTIONNJEC0349S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Extremely light load engine operation

+Mass air flow sensor malfunction

+Engine idling

+Low engine coolant temperature

+Excessively high engine coolant temperature

+High-speed engine operation

+Wide open throttle

+Low battery voltage

+Engine starting

SEF551W

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

Description

EC-425