wheel NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2391 of 2898

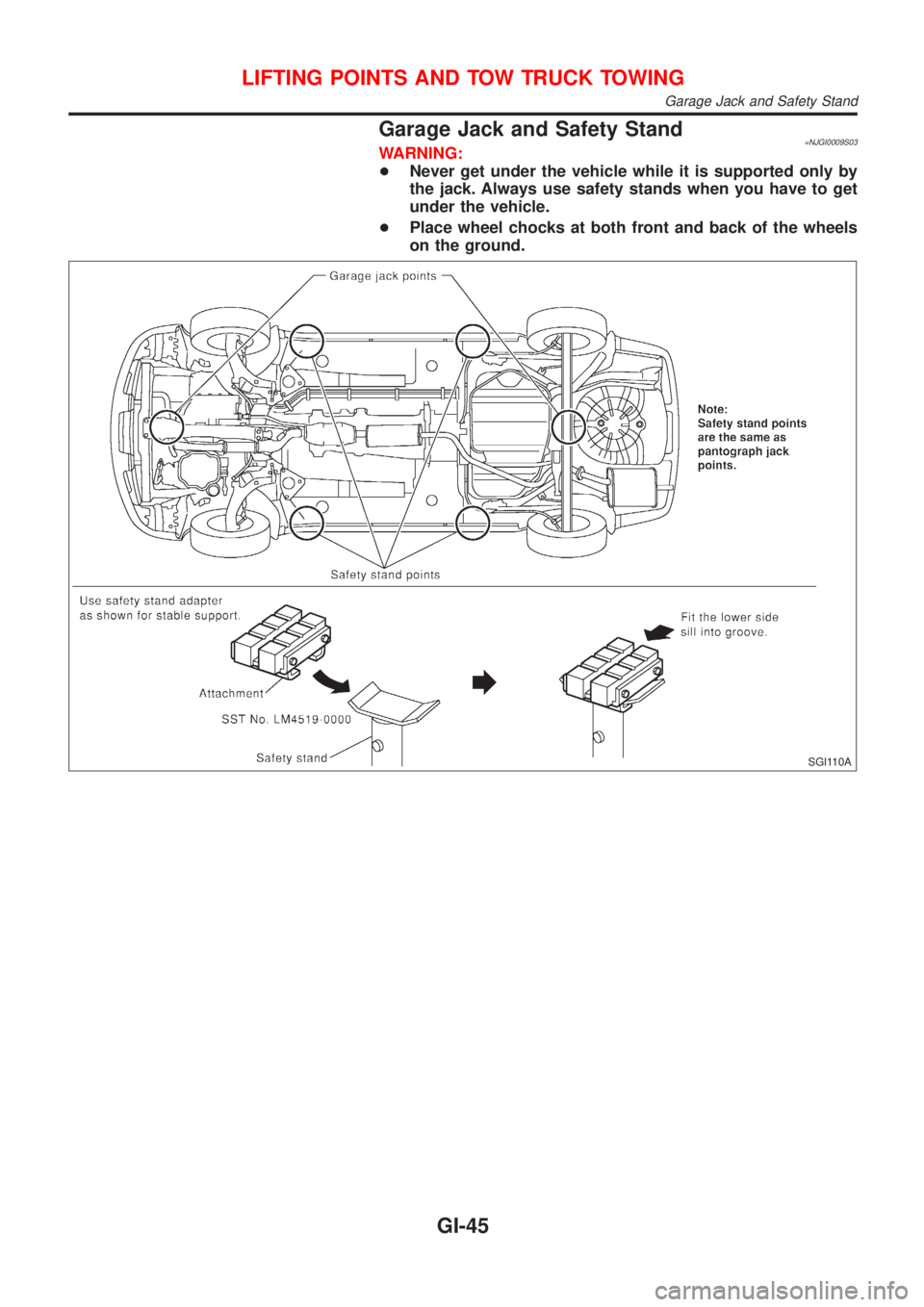

Garage Jack and Safety Stand=NJGI0009S03WARNING:

+Never get under the vehicle while it is supported only by

the jack. Always use safety stands when you have to get

under the vehicle.

+Place wheel chocks at both front and back of the wheels

on the ground.

SGI110A

LIFTING POINTS AND TOW TRUCK TOWING

Garage Jack and Safety Stand

GI-45

Page 2393 of 2898

SGI805

SGI987

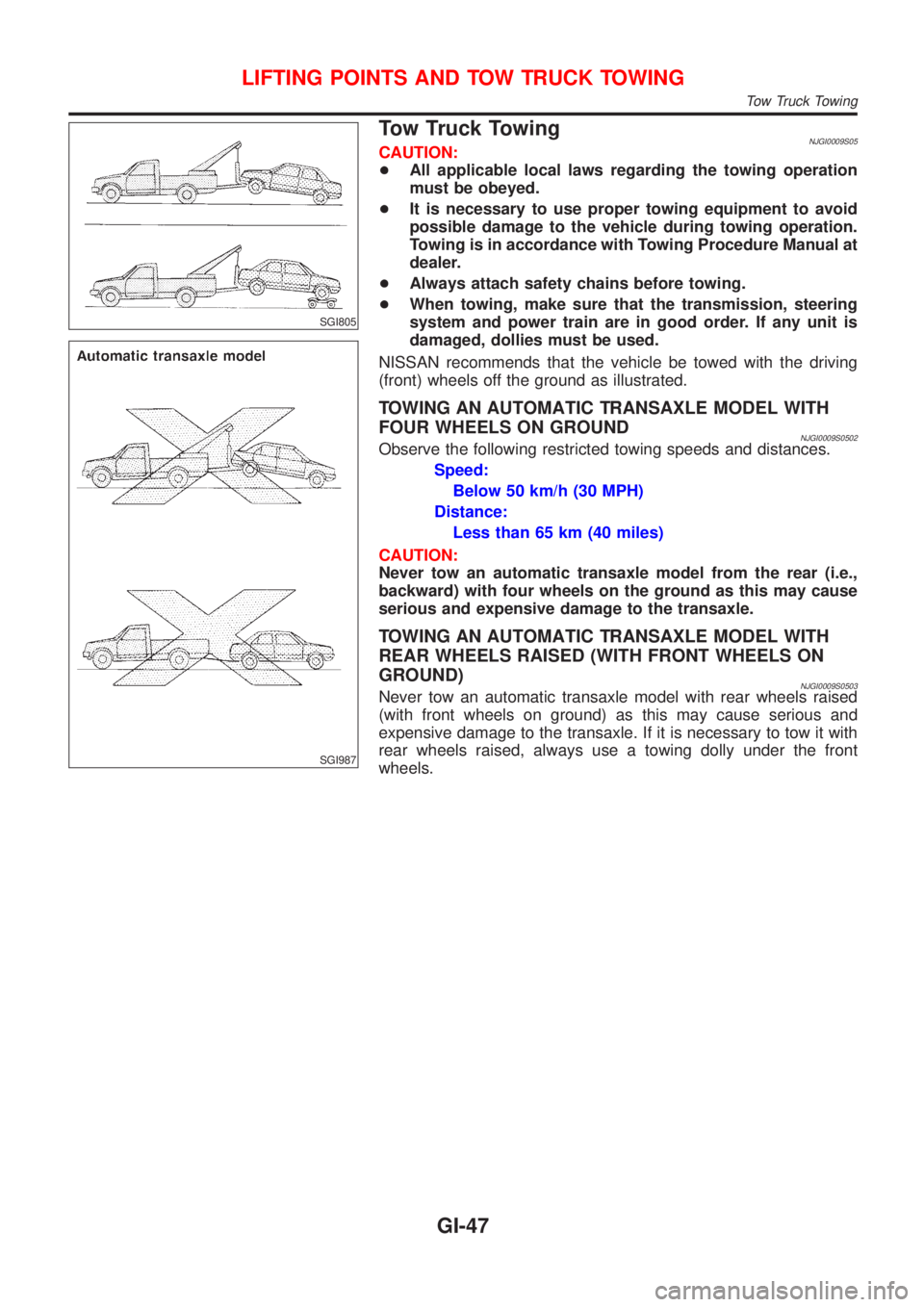

Tow Truck TowingNJGI0009S05CAUTION:

+All applicable local laws regarding the towing operation

must be obeyed.

+It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during towing operation.

Towing is in accordance with Towing Procedure Manual at

dealer.

+Always attach safety chains before towing.

+When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

FOUR WHEELS ON GROUND

NJGI0009S0502Observe the following restricted towing speeds and distances.

Speed:

Below 50 km/h (30 MPH)

Distance:

Less than 65 km (40 miles)

CAUTION:

Never tow an automatic transaxle model from the rear (i.e.,

backward) with four wheels on the ground as this may cause

serious and expensive damage to the transaxle.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

REAR WHEELS RAISED (WITH FRONT WHEELS ON

GROUND)

NJGI0009S0503Never tow an automatic transaxle model with rear wheels raised

(with front wheels on ground) as this may cause serious and

expensive damage to the transaxle. If it is necessary to tow it with

rear wheels raised, always use a towing dolly under the front

wheels.

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing

GI-47

Page 2402 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJHA0190The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

NJHA0113WARNING:

+CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed, compressor fail-

ure is likely to occur.

+Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

+The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

a) When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

b) When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as pos-

sible to minimize the entry of moisture into system.

c) Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

d) Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Remove R-134a from the A/C system, using certified service equipment meeting

requirements of R-134a recycling equipment, or R-134a recovery equipment. If accidental system

discharge occurs, ventilate work area before resuming service. Additional health and safety

information may be obtained from refrigerant and lubricant manufacturers.

e) Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsNJHA0114WARNING:

+Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

+Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

HA-2

Page 2502 of 2898

Electronic fuel injection pump ........ EC-618, 716,

723, 757, 764, 771, 778, 785, 803

Engine compartment ................................. BT-78

Engine control circuit diagram .......... EC-25, 606

Engine control component parts

location .......................................... EC-21, 603

Engine control module (ECM) ....... EC-391, 659,

714, 792, 794, 799, 801

Engine control system diagram and

chart .............................................. EC-29, 608

Engine coolant temperature sensor

(ECTS) ........................................ EC-201, 680

Engine fail-safe system ........................... EC-154

Engine oil precautions .................................. GI-7

Engine outer component parts ................. EM-11

Engine removal ................................ EM-51, 137

Engine room - See Engine

compartment .......................................... BT-78

Engine serial number ................................. GI-41

Evaporative emission (EVAP)

system ................................................... EC-36

Exhaust gas recirculation (EGR)

valve .................................... EC-343, 425, 491

Exhaust system ................................... FE-15, 32

Exterior ...................................................... BT-47

F

F/PUMP - Wiring diagram ....................... EC-563

FR02 - Wiring diagram ... EC-219, 239, 247, 451

FR02/H - Wiring diagram ................ EC-254, 458

FUEL - Wiring diagram ................... EC-299, 307

Fan switch ................................................. HA-54

Final drive (FF A/T) .................................. AT-442

Final drive (FF M/T) .............. MT-44, 77, 93, 107

Finisher, interior - See Trim ....................... BT-31

Finisher, trunk lid ....................................... BT-45

Floor trim ................................................... BT-31

Fluid temperature sensor (A/T) ................ AT-194

Fluids ........................................................ MA-16

Flywheel (clutch) ....................................... CL-22

Flywheel runout ................................ EM-62, 154

Fog lamp, front, removal and

installation ................................................ BT-7

Fog lamp, front .......................................... EL-89

Fork rod (M/T) .............................. MT-32, 56, 94

Forward clutch ......................................... AT-412

Freeze frame data .............................. EC-61, 72

Front axle .................................................... AX-2

Front bumper ............................................... BT-7

Front combination lamp removal and

installation ................................................ BT-7

Front disc brake ........................................ BR-27

Front door .................................................. BT-16

Front fog lamp removal and

installation ................................................ BT-7

Front fog lamp ........................................... EL-89

Front heated oxygen sensor (HO2S)

heater .......................................... EC-252, 457Front heated oxygen sensor (HO2S) ..... EC-216,

224, 230, 236, 245, 450

Front seat belt ............................................. RS-5

Front seat .................................................. BT-56

Front suspension ........................................ SU-2

Front washer ............................................ EL-215

Front wiper ............................................... EL-215

Fuel cut control (at no load & high

engine speed) ............................... EC-36, 612

Fuel gauge ............................................... EL-144

Fuel injection system .............. EC-297, 305, 610

Fuel injector ............................................ EC-541

Fuel precautions ........................................... GI-8

Fuel pressure check ................................. EC-40

Fuel pressure regulator ............................. EC-41

Fuel pressure release ............................... EC-40

Fuel pump relay ...................................... EC-561

Fuel pump ............................................... EC-561

Fuel system ........................................... FE-5, 20

Fuel tank vacuum relief valve ................... EC-37

Fuse block ............................................... EL-577

Fuse ........................................................... EL-38

Fusible link ................................................. EL-38

G

GLOW - Wiring diagram ......................... EC-806

Garage jack and safety stand .................... GI-45

Gauges .................................................... EL-144

Gear components (M/T) ............... MT-31, 55, 93

Generator - See Alternator ....................... SC-31

Generic scan tool (GST) ........................... EC-94

Glass .......................................................... BT-17

Glow plug ................................................ EC-806

Glow relay ............................................... EC-806

Grease ...................................................... MA-16

Ground distribution .................................... EL-39

H

H/LAMP - Wiring diagram ................... EL-60, 61

HEATER - Wiring diagram ........................ HA-24

HFC134a (R134a) system

precaution ................................................ HA-2

HFC134a (R134a) system service

procedure .............................................. HA-78

HFC134a (R134a) system service

tools ....................................................... HA-11

HFC134a system service equipment

precaution ................................................ HA-6

HORN - Wiring diagram .................. EL-234, 235

HSEAT - Wiring diagram ................. EL-288, 290

Harness connector ...................................... EL-6

Harness layout ......................................... EL-522

Hazard warning lamp ................................ EL-96

Headlamp removal and installation ............. BT-7

Headlamp washer .................................... EL-231

Headlamp .................................................. EL-60

ALPHABETICAL INDEX

IDX-4

Page 2504 of 2898

NVH troubleshooting (SU) ........................ SU-16

NVH troubleshooting (CL) ........................... CL-4

NVIS (Nissan vehicle immobiliser sys-

tem) precautions ....................................... GI-3

Neutral position switch .................... EC-437, 536

O

Oil pan (engine) .................................. EM-20, 89

Oil pressure (engine) ............................ LC-5, 28

Oil pump (A/T) ......................................... AT-384

Oil pump (engine) ................................. LC-5, 28

Oil pump regulator valve (engine) ......... LC-8, 30

Oil seal replacement (engine) .................. EM-32

On board diagnostic system ............. EC-59, 627

Operating cylinder (clutch) ........................ CL-14

Overdrive control switch .......................... AT-341

Overrun clutch .......................................... AT-412

P

P/ANT - Wiring diagram .......................... EL-282

PCV (positive crankcase

ventilation) ..................................... EC-39, 613

PGC/V - Wiring diagram ................. EC-366, 505

PNP/SW - Wiring diagram ...... EC-439, 537, 826

POWER - Wiring diagram ................... EL-11, 28

PST/SW - Wiring diagram ....................... EC-568

Park/Neutral position switch ... EC-437, 536, 826

Park/neutral position switch (A/T) ............ AT-183

Park/neutral position switch (M/T) ............ MT-21

Parking brake control ................................ BR-47

Parking lamp .............................................. EL-81

Piston assembly ............................... EM-62, 155

Piston pin inspection ........................ EM-56, 145

Piston ring inspection ....................... EM-56, 145

Piston to bore clearance .................. EM-58, 147

Power antenna ........................................ EL-282

Power door lock ....................................... EL-314

Power door mirror .................................... EL-294

Power steering fluid level ............................ ST-7

Power steering gear .................................. ST-16

Power steering hydraulic pressure .............. ST-9

Power steering oil pressure switch ......... EC-567

Power steering oil pump ............................ ST-25

Power steering system bleeding ................. ST-8

Power supply routing ................................. EL-10

Power window ......................................... EL-298

Precautions (General) .................................. GI-4

Pressure plate - See Clutch cover ............ CL-22

Priming pump .................................. EC-625, 641

Q

Quick-glow system .................................. EC-806

R

RR02 - Wiring diagram .......... EC-261, 270, 278,

286, 463

RR02/H - Wiring diagram ............... EC-293, 470

Radiator ............................................... LC-16, 42

Radio - See Audio ................................... EL-258

Rear air spoiler .......................................... BT-47

Rear axle (disc brake type) ....................... AX-24

Rear axle ................................................... AX-22

Rear bumper .............................................. BT-10

Rear combination lamp removal and

installation .............................................. BT-47

Rear disc brake .................................. BR-35, 43

Rear door ................................................... BT-16

Rear drum brake ....................................... BR-31

Rear heated oxygen sensor (HO2S)

heater .......................................... EC-291, 469

Rear heated oxygen sensor (HO2S) ..... EC-258,

267, 275, 284, 462

Rear seat belt ............................................ RS-11

Rear seat ................................................... BT-60

Rear suspension ....................................... SU-16

Rear window defogger ............................ EL-240

Rear window .............................................. BT-71

Refrigerant connection precaution .............. HA-3

Refrigerant general precaution ................... HA-2

Refrigerant lines ........................................ HA-91

Refrigeration cycle .................................... HA-13

Release bearing (clutch) ..................... CL-17, 20

Removal and installation (A/T) ................ AT-354

Reverse clutch ......................................... AT-403

Reverse idler shaft (M/T) .............. MT-30, 54, 93

Reverse lamp switch (M/T) - See

Back-up lamp switch (M/T) ................... MT-21

Reverse main gear (M/T) ............. MT-31, 55, 93

Road wheel size ......................................... GI-43

Roof trim .................................................... BT-43

Room lamp - See Interior lamp ............... EL-115

S

S/LOCK - Wiring diagram ............... EL-318, 335,

352, 372

S/SIG - Wiring diagram ........................... EC-558

SAE J1930 terminology list ........................ GI-50

SHIFT - Wiring diagram ........................... AT-344

SROOF - Wiring diagram ........................ EL-292

SRS - See Supplemental Restraint

System ................................................... RS-20

START - Wiring diagram ........................... SC-14

STOP/L - Wiring diagram .................... EL-85, 86

SWL/V - Wiring diagram ................. EC-399, 475

Seal - See Exterior .................................... BT-47

Seat belt pre-tensioner disposal ............... RS-40

Seat belt pre-tensioner ............................... RS-3

Seat belt, front ............................................ RS-5

Seat belt, rear ............................................ RS-11

Seat, front .................................................. BT-56

ALPHABETICAL INDEX

IDX-6

Page 2505 of 2898

Seat, rear ................................................... BT-60

Self-diagnostic results ....................... EC-74, 628

Shift control components (M/T) .... MT-32, 56, 94

Shift fork (M/T) .............................. MT-32, 56, 94

Shift lever .................................................. MT-29

Shift lock system ...................................... AT-343

Shift schedule .......................................... AT-470

Shift solenoid valve A (A/T) ..... AT-204, 209, 222

Shift solenoid valve B (A/T) ............. AT-204, 209

Shock absorber (front) .............................. SU-10

Shock absorber (rear) ............................... SU-21

Side air bag ........................................ RS-36, 38

Side trim .................................................... BT-31

Spare tire size ............................................ GI-43

Speedometer ........................................... EL-144

Spiral cable ............................................... RS-29

Spot lamp ................................................ EL-141

Spring (Wheelarch) height .......................... SU-6

Stabilizer bar (front) ................................... SU-11

Stall test (A/T) ............................................ AT-80

Standardized relay ....................................... EL-8

Start signal ...................................... EC-557, 823

Starter ....................................................... SC-18

Starting system ......................................... SC-13

Steering linkage ......................................... ST-16

Steering switch .......................................... EL-59

Steering wheel and column ....................... ST-11

Steering wheel play ..................................... ST-6

Steering wheel turning force ....................... ST-8

Stop lamp .................................................. EL-85

Striking rod (M/T) .......................... MT-32, 56, 94

Strut (front) .................................................. SU-9

Strut (rear) ................................................. SU-20

Sub-gear (M/T) ................................... MT-31, 55

Sunroof, electric ....................................... EL-292

Sunroof ...................................................... BT-63

Super lock ................................................ EL-349

Supplemental Restraint System ............... RS-20

Supplemental restraint system - Wiring

diagram .................................................. RS-53

Swirl control valve control solenoid

valve ............................................ EC-399, 475

Symbols and abbreviations ........................ GI-10

Symptom matrix chart ..................... EC-155, 646

Synchronizer (M/T) ....................... MT-31, 55, 93

System readiness test (SRT) code ........... EC-62

T

TCM circuit diagram ................................... AT-17

TCM inspection table ............................... AT-119

TFTS - Wiring diagram ........................... EC-315

TP/SW - Wiring diagram ................. EC-387, 521

TPS - Wiring diagram ............................. EC-210

TURN - Wiring diagram ........................... EL-103

Tachometer .............................................. EL-144

Tail lamp .................................................... EL-81

Tank fuel temperature sensor ................. EC-313

Thermostat .......................................... LC-15, 41Three way catalyst precautions ................... GI-6

Three way catalyst .................................. EC-359

Throttle position sensor (TPS) ................ EC-207

Throttle position sensor

adjustment ................................... EC-100, 128

Throttle position switch ........... AT-141, 267, 341,

EC-385, 520

Throwout bearing - See Clutch release

bearing ............................................. CL-17, 20

Tie-rod ball joints ....................................... ST-20

Tie-rod ........................................................ ST-16

Tightening torque of standard bolts ........... GI-49

Timing chain ....................................... EM-23, 94

Tire size ...................................................... GI-43

Torque converter installation .................... AT-355

Tow truck towing ........................................ GI-47

Transmission case (M/T) .............. MT-30, 54, 92

Tread-FR&RR (Dimensions) ...................... GI-43

Trim ............................................................ BT-31

Trouble diagnoses ...................................... GI-31

Trunk lid finisher ........................................ BT-45

Trunk lid opener - See Trunk lid ................ BT-10

Trunk lid trim .............................................. BT-45

Trunk lid ..................................................... BT-10

Trunk room lamp ..................................... EL-141

Trunk room trim ......................................... BT-45

Turn signal lamp ........................................ EL-96

Two trip detection logic ............................. EC-59

Two-pole lift ................................................ GI-46

U

Under body ................................................ BT-80

V

VSS - Wiring diagram ..................... EC-372, 701

Vacuum hose (brake system) ................... BR-22

Vacuum hose drawing (Engine control) .... EC-30

Vacuum pump ........................................... BR-23

Valve clearance ................................ EM-44, 133

Valve guide ....................................... EM-39, 124

Valve lifter ................................................. EM-43

Valve seat ......................................... EM-41, 126

Valve spring ...................................... EM-42, 128

Vehicle speed sensor (VSS) ........... EC-370, 701

Viscosity number (SAE) ............................ MA-17

Viscous coupling (FF M/T) ........................ MT-93

W

WARN - Wiring diagram .......................... EL-190

WIP/R - Wiring diagram .................. EL-225, 227

WIPER - Wiring diagram ................. EL-217, 220

Warning chime ......................................... EL-197

Warning lamps ......................................... EL-184

Washer, front ........................................... EL-215

ALPHABETICAL INDEX

IDX-7

Page 2506 of 2898

Water pump ......................................... LC-14, 39

Water temperature gauge ........................ EL-144

Weatherstrip - See Exterior ....................... BT-47

Wheel alignment (rear) ............................. SU-18

Wheel bearing (front) .................................. AX-3

Wheel bearing (rear) ................................. AX-23

Wheel hub (front) ........................................ AX-5

Wheel hub (rear) ....................................... AX-24

Wheel sensors (ABS) ............................... BR-97

Wheelarch height ........................................ SU-6

Wheelbase (Dimensions) ........................... GI-43

Wide open & closed throttle positionswitch ................................................... EC-207

Width (Dimensions) .................................... GI-43

Window, rear .............................................. BT-71

Windshield ................................................. BT-71

Wiper, front .............................................. EL-215

Wiring diagram (cell code) list ................. EL-575

Wiring diagrams .......................................... GI-11

Withdrawal lever (clutch) ..................... CL-17, 20

Wrist pin -

See Piston pin inspection ............. EM-56, 145

ALPHABETICAL INDEX

IDX-8

Page 2520 of 2898

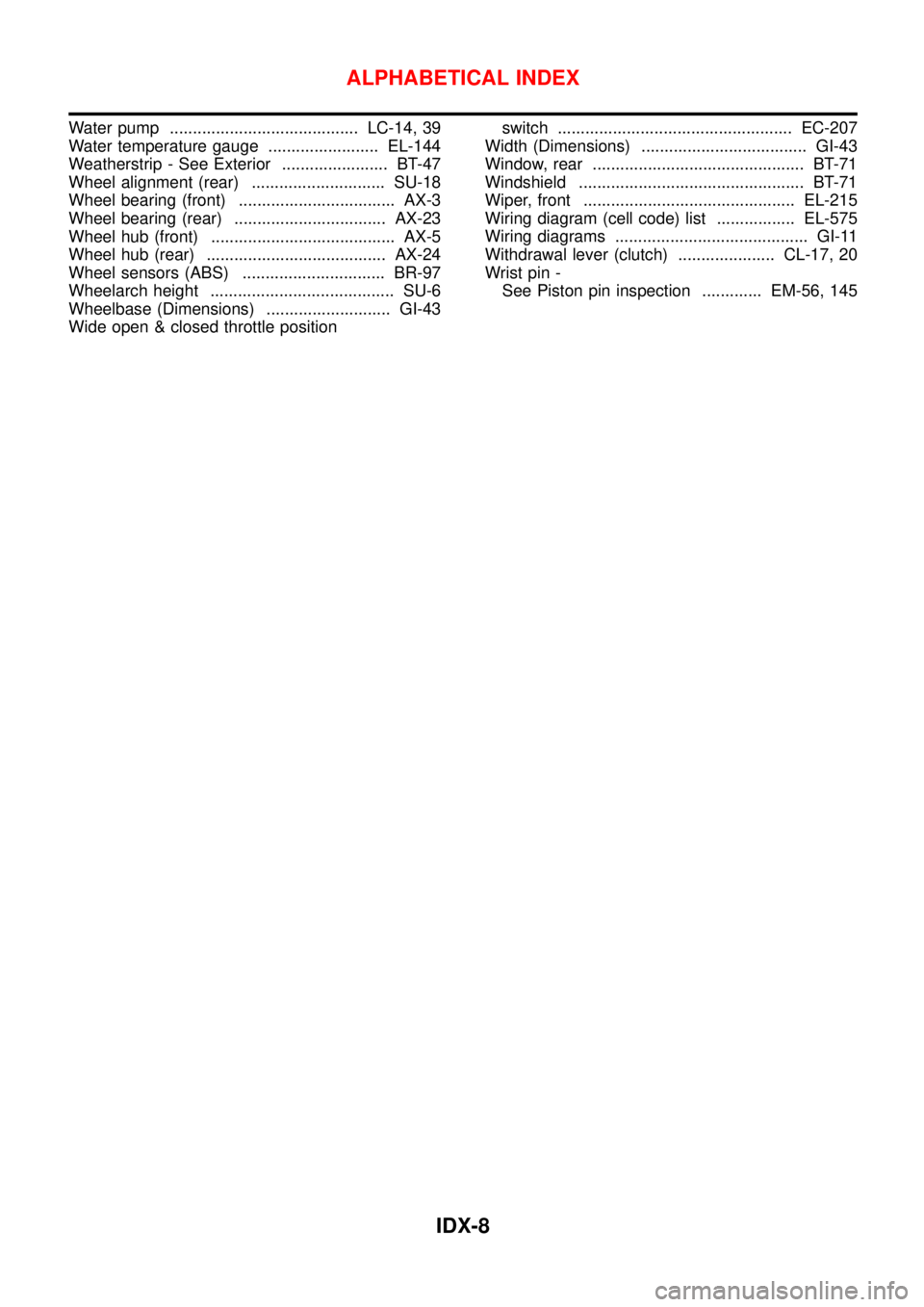

Water Pump

REMOVAL AND INSTALLATIONNJLC0018

SEM858F

SEM859F

CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belt.

+Water pump cannot be disassembled and should be

replaced as a unit.

+After installing water pump, and check for leaks using

radiator cap tester.

1. Drain engine coolant.

Refer to LC-18, ªChanging Engine Coolantº.

2. Remove drive belts and idler pulley.

3. Loosen water pump pulley bolts.

4. Remove water pump pulley.

5. Remove front right wheel.

6. Remove front right undercover and front right fender protector.

7. Remove water pump bolts.

8. Remove water pump.

9. Reinstall parts in reverse order of removal.

SEM860F

INSPECTIONNJLC0019+Check body assembly and vane for rust or corrosion.

+Check for rough operation due to excessive end play.

ENGINE COOLING SYSTEMQG

Water Pump

LC-14

Page 2531 of 2898

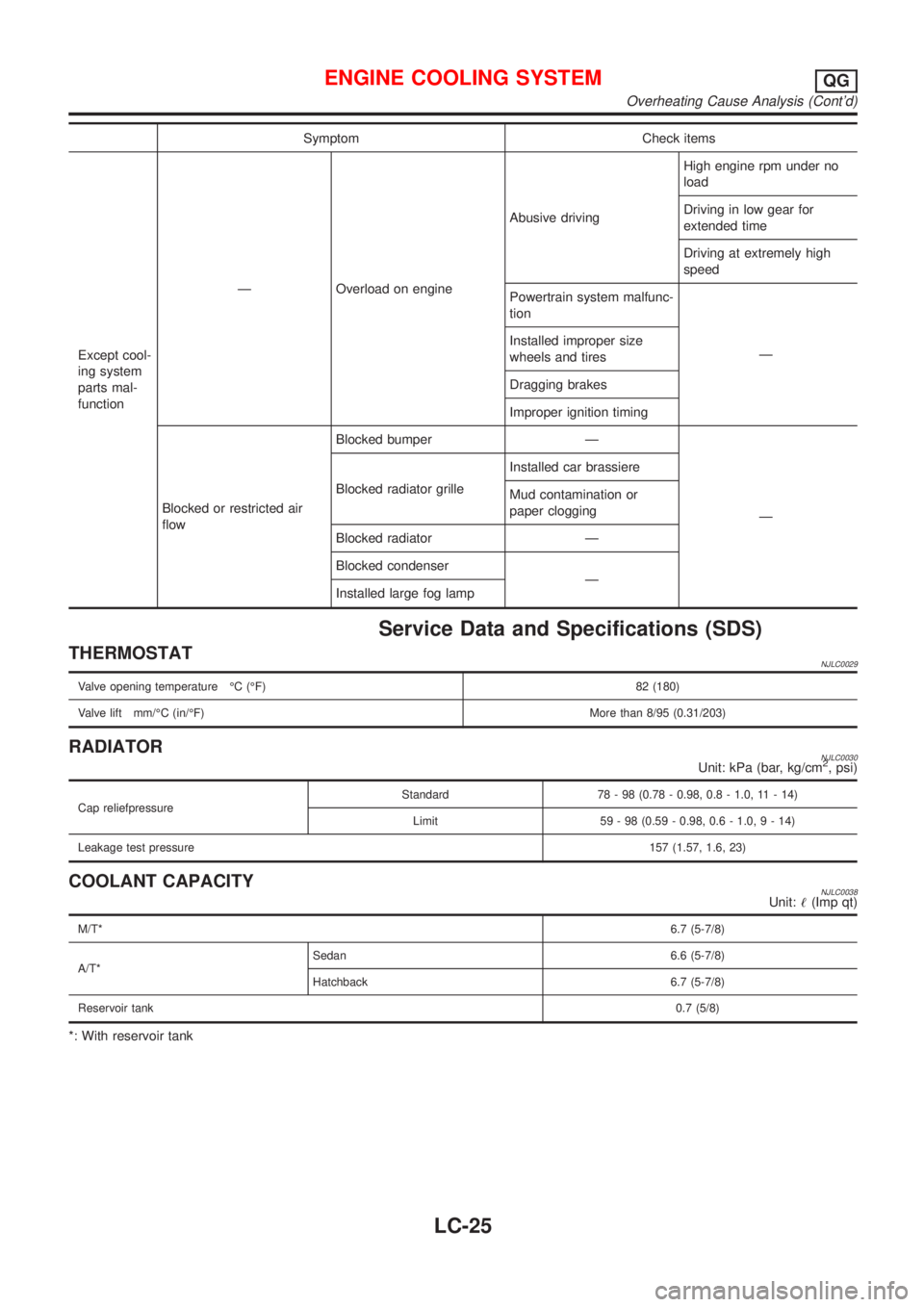

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNJLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNJLC0038Unit:!(Imp qt)

M/T*6.7 (5-7/8)

A/T*Sedan 6.6 (5-7/8)

Hatchback 6.7 (5-7/8)

Reservoir tank0.7 (5/8)

*: With reservoir tank

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-25

Page 2538 of 2898

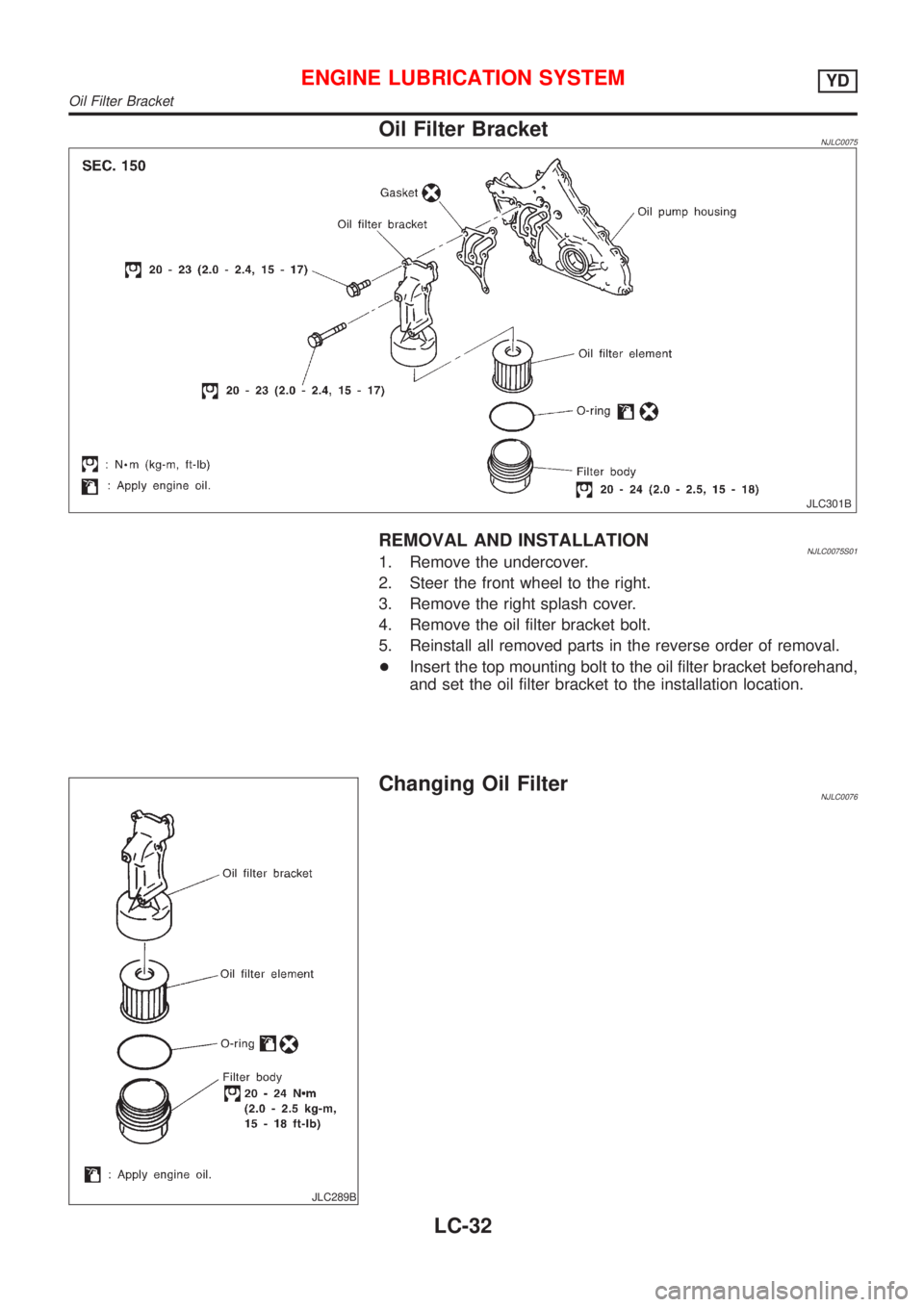

Oil Filter BracketNJLC0075

JLC301B

REMOVAL AND INSTALLATIONNJLC0075S011. Remove the undercover.

2. Steer the front wheel to the right.

3. Remove the right splash cover.

4. Remove the oil filter bracket bolt.

5. Reinstall all removed parts in the reverse order of removal.

+Insert the top mounting bolt to the oil filter bracket beforehand,

and set the oil filter bracket to the installation location.

JLC289B

Changing Oil FilterNJLC0076

ENGINE LUBRICATION SYSTEMYD

Oil Filter Bracket

LC-32