NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1391 of 2898

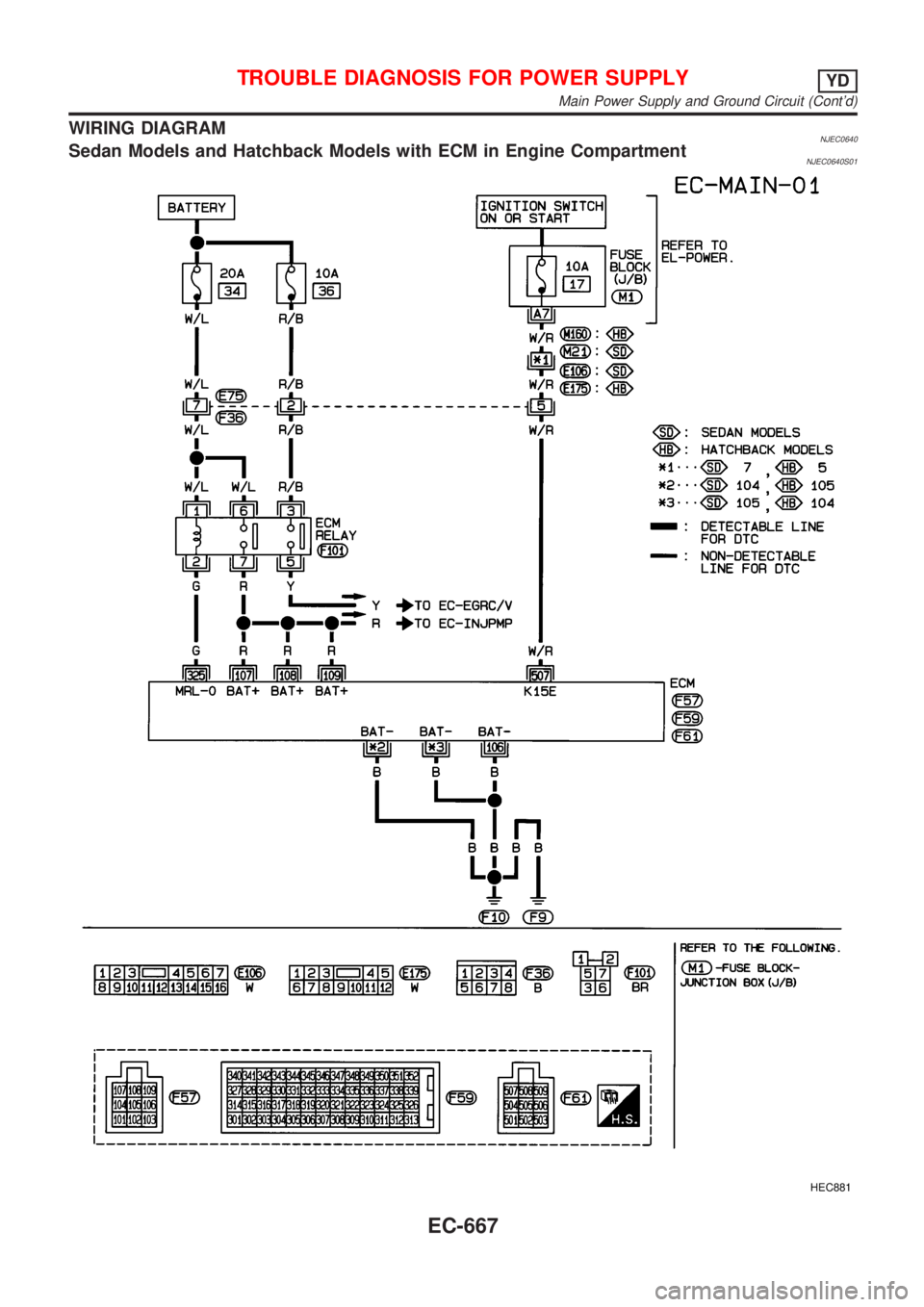

WIRING DIAGRAMNJEC0640Sedan Models and Hatchback Models with ECM in Engine CompartmentNJEC0640S01

HEC881

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-667

Page 1392 of 2898

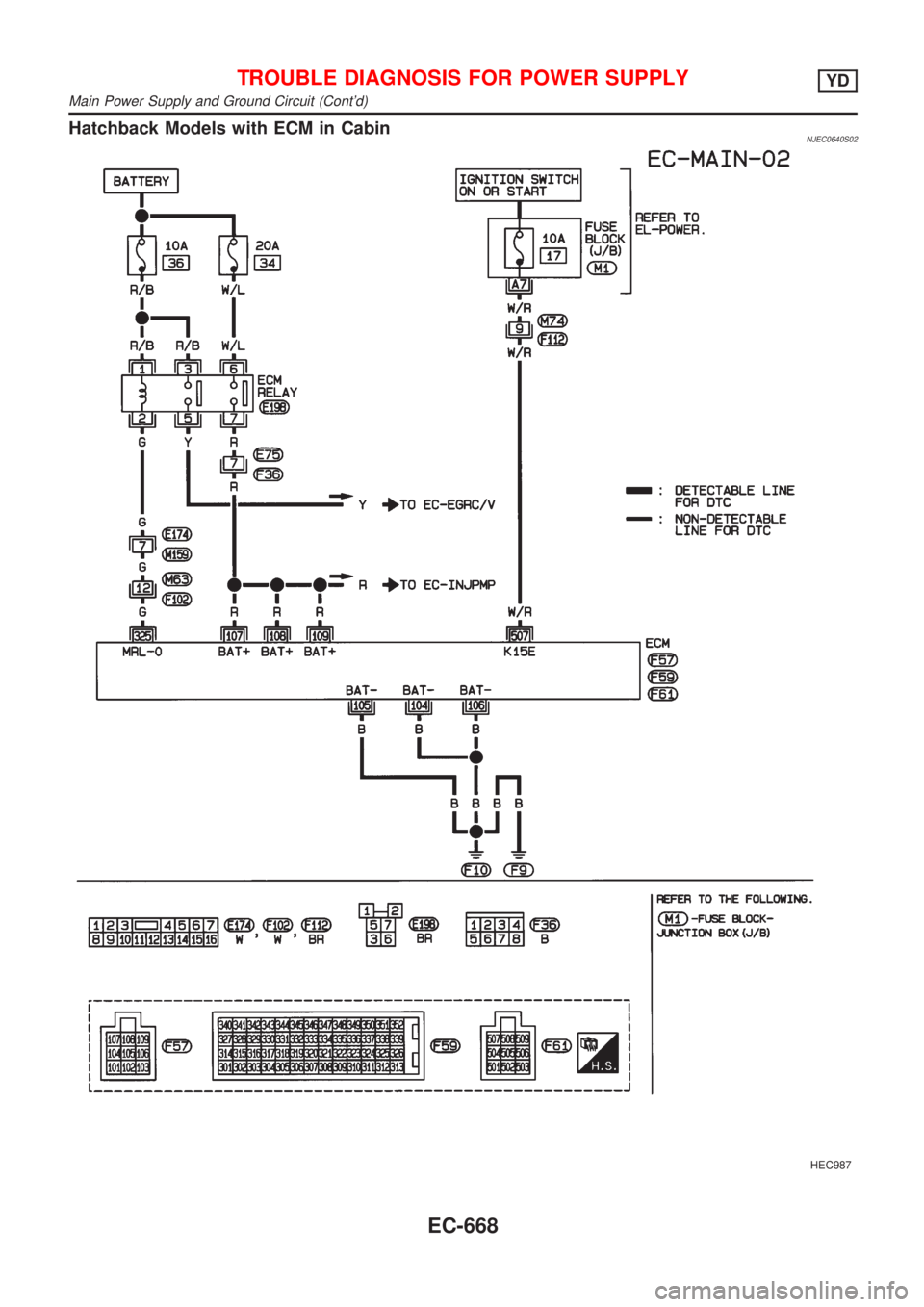

Hatchback Models with ECM in CabinNJEC0640S02

HEC987

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-668

Page 1393 of 2898

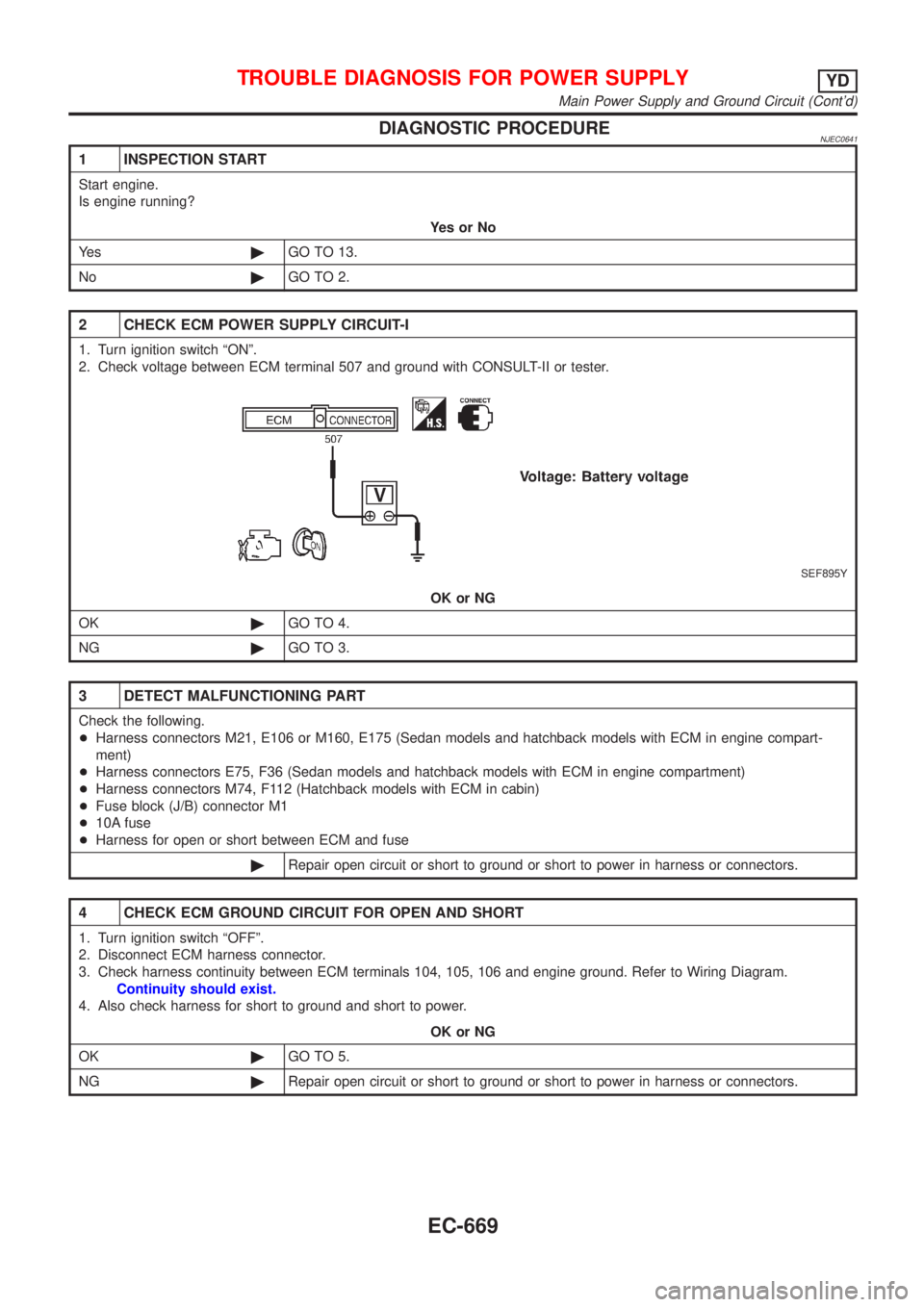

DIAGNOSTIC PROCEDURENJEC0641

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 13.

No©GO TO 2.

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 507 and ground with CONSULT-II or tester.

SEF895Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E106 or M160, E175 (Sedan models and hatchback models with ECM in engine compart-

ment)

+Harness connectors E75, F36 (Sedan models and hatchback models with ECM in engine compartment)

+Harness connectors M74, F112 (Hatchback models with ECM in cabin)

+Fuse block (J/B) connector M1

+10A fuse

+Harness for open or short between ECM and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 104, 105, 106 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-669

Page 1394 of 2898

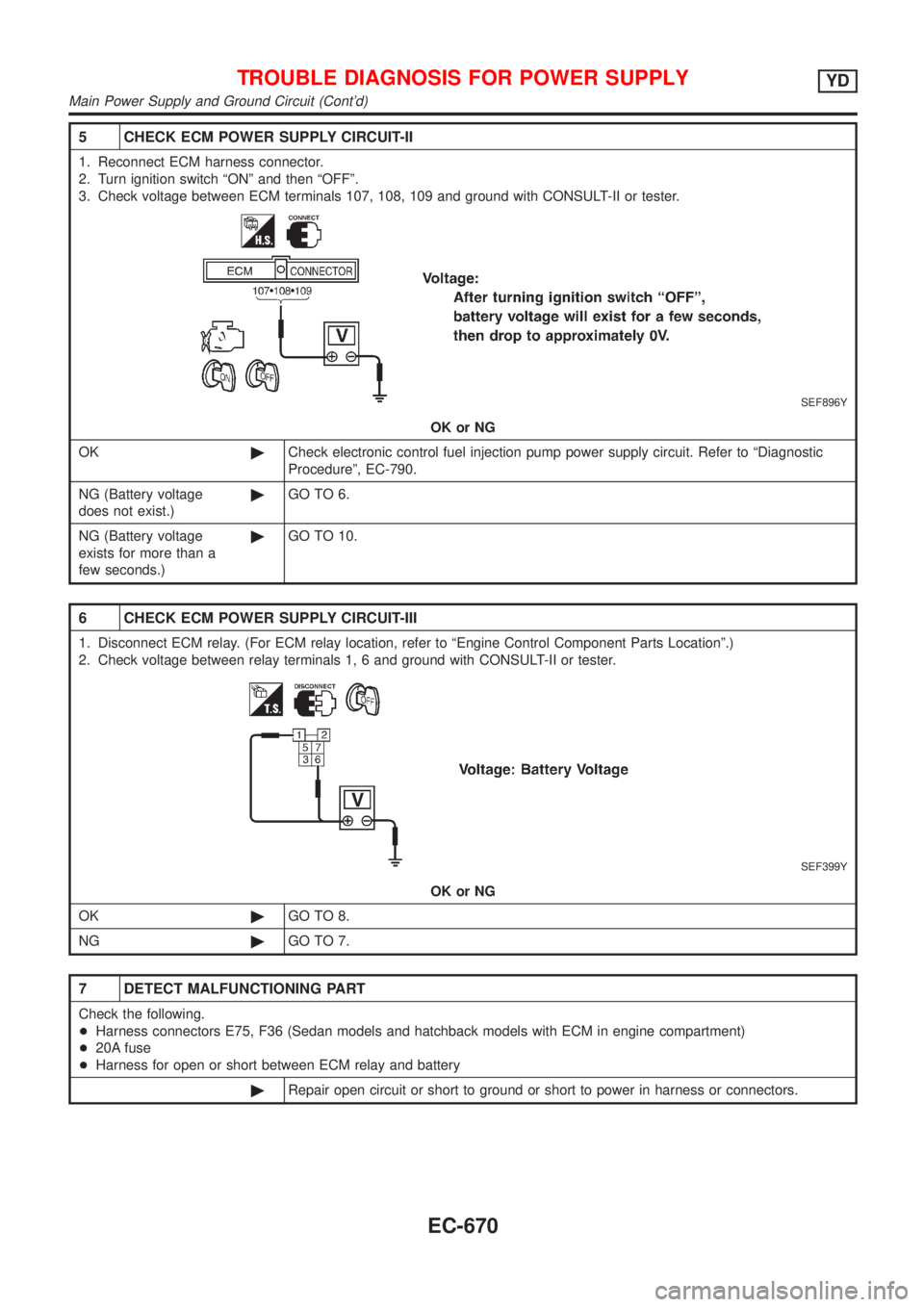

5 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ªONº and then ªOFFº.

3. Check voltage between ECM terminals 107, 108, 109 and ground with CONSULT-II or tester.

SEF896Y

OK or NG

OK©Check electronic control fuel injection pump power supply circuit. Refer to ªDiagnostic

Procedureº, EC-790.

NG (Battery voltage

does not exist.)©GO TO 6.

NG (Battery voltage

exists for more than a

few seconds.)©GO TO 10.

6 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Component Parts Locationº.)

2. Check voltage between relay terminals 1, 6 and ground with CONSULT-II or tester.

SEF399Y

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (Sedan models and hatchback models with ECM in engine compartment)

+20A fuse

+Harness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-670

Page 1395 of 2898

8 CHECK OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 325 and ECM relay terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E174, M159 (Hatchback models with ECM in cabin)

+Harness connectors M63, F102 (Hatchback models with ECM in cabin)

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

10 CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Check harness continuity between ECM terminals 107, 108, 109 and ECM relay terminal 7. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 12.

NG©GO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (Hatchback models with ECM in cabin)

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

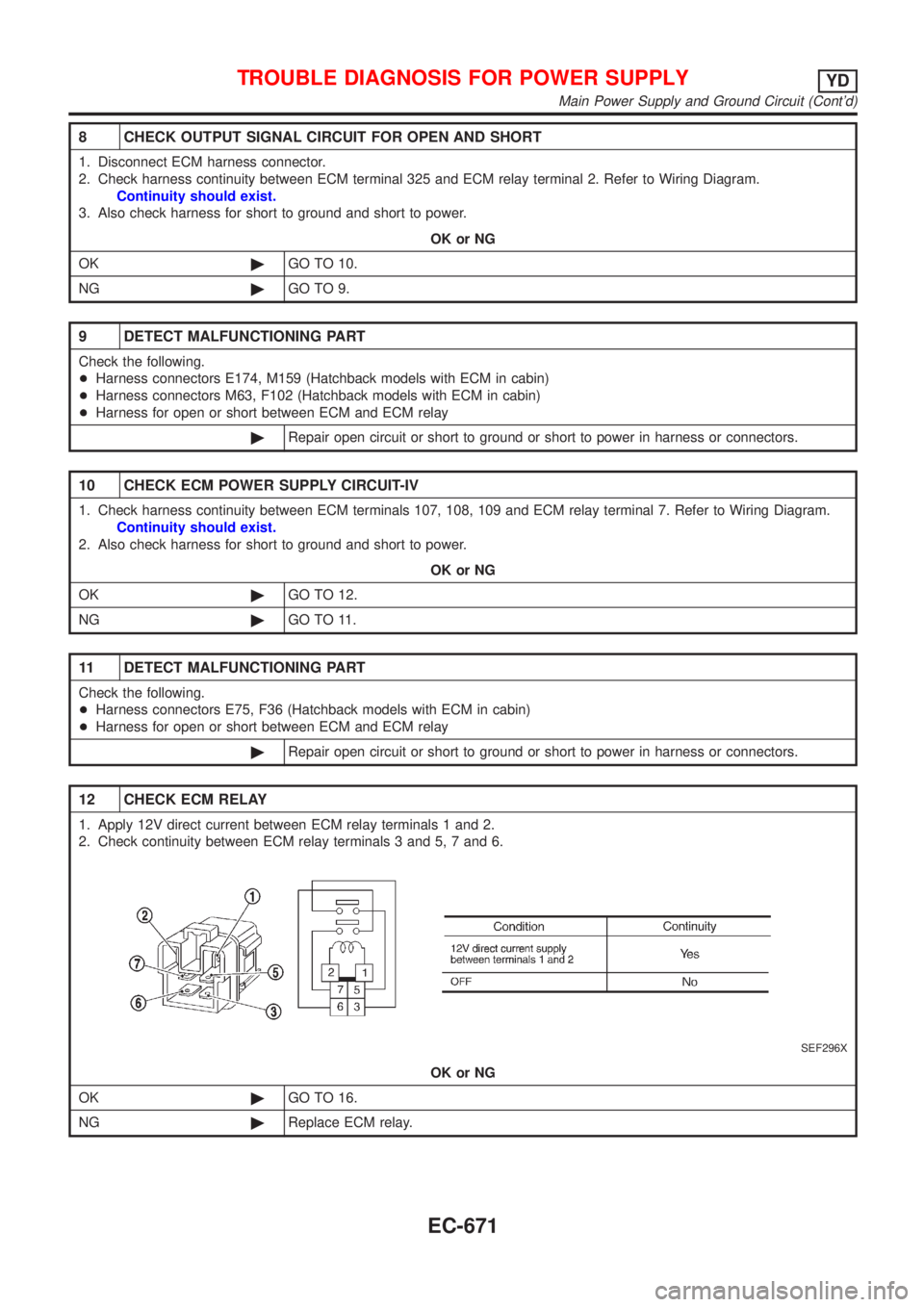

12 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 7 and 6.

SEF296X

OK or NG

OK©GO TO 16.

NG©Replace ECM relay.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-671

Page 1396 of 2898

13 CHECK ECM POWER SUPPLY CIRCUIT-V

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Component Parts Locationº.)

3. Disconnect ECM harness connector.

4. Check harness continuity between ECM terminals 107, 108, 109 and ECM relay terminal 7. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 15.

NG©GO TO 14.

14 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (New H/B)

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

15 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 104, 105, 106 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

16 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-665.

©INSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-672

Page 1397 of 2898

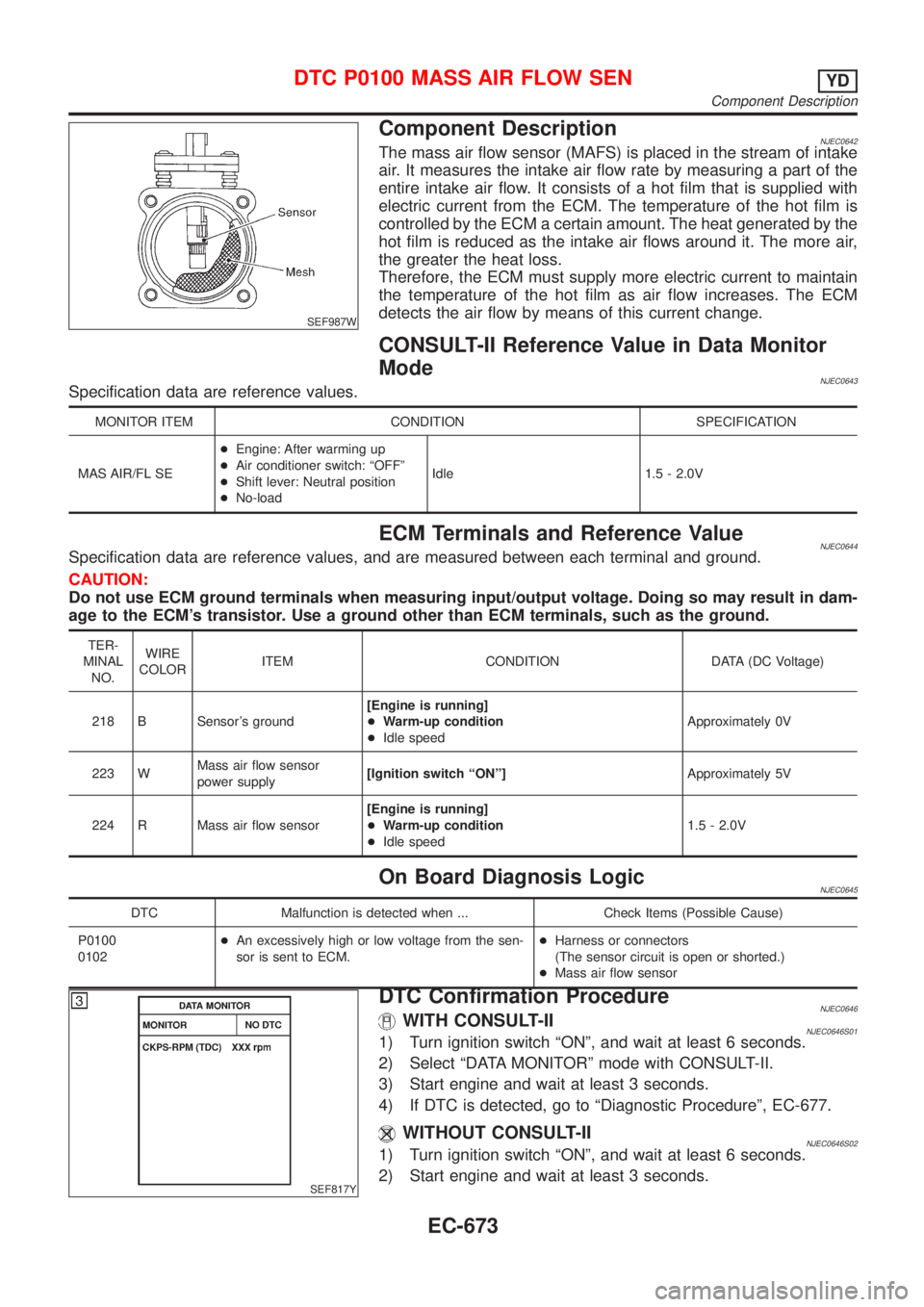

SEF987W

Component DescriptionNJEC0642The mass air flow sensor (MAFS) is placed in the stream of intake

air. It measures the intake air flow rate by measuring a part of the

entire intake air flow. It consists of a hot film that is supplied with

electric current from the ECM. The temperature of the hot film is

controlled by the ECM a certain amount. The heat generated by the

hot film is reduced as the intake air flows around it. The more air,

the greater the heat loss.

Therefore, the ECM must supply more electric current to maintain

the temperature of the hot film as air flow increases. The ECM

detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0643Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: Neutral position

+No-loadIdle 1.5 - 2.0V

ECM Terminals and Reference ValueNJEC0644Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

218 B Sensor's ground[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

223 WMass air flow sensor

power supply[Ignition switch ªONº]Approximately 5V

224 R Mass air flow sensor[Engine is running]

+Warm-up condition

+Idle speed1.5 - 2.0V

On Board Diagnosis LogicNJEC0645

DTC Malfunction is detected when ... Check Items (Possible Cause)

P0100

0102+An excessively high or low voltage from the sen-

sor is sent to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Mass air flow sensor

SEF817Y

DTC Confirmation ProcedureNJEC0646WITH CONSULT-IINJEC0646S011) Turn ignition switch ªONº, and wait at least 6 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 3 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-677.

WITHOUT CONSULT-IINJEC0646S021) Turn ignition switch ªONº, and wait at least 6 seconds.

2) Start engine and wait at least 3 seconds.

DTC P0100 MASS AIR FLOW SENYD

Component Description

EC-673

Page 1398 of 2898

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-677.

DTC P0100 MASS AIR FLOW SENYD

DTC Confirmation Procedure (Cont'd)

EC-674

Page 1399 of 2898

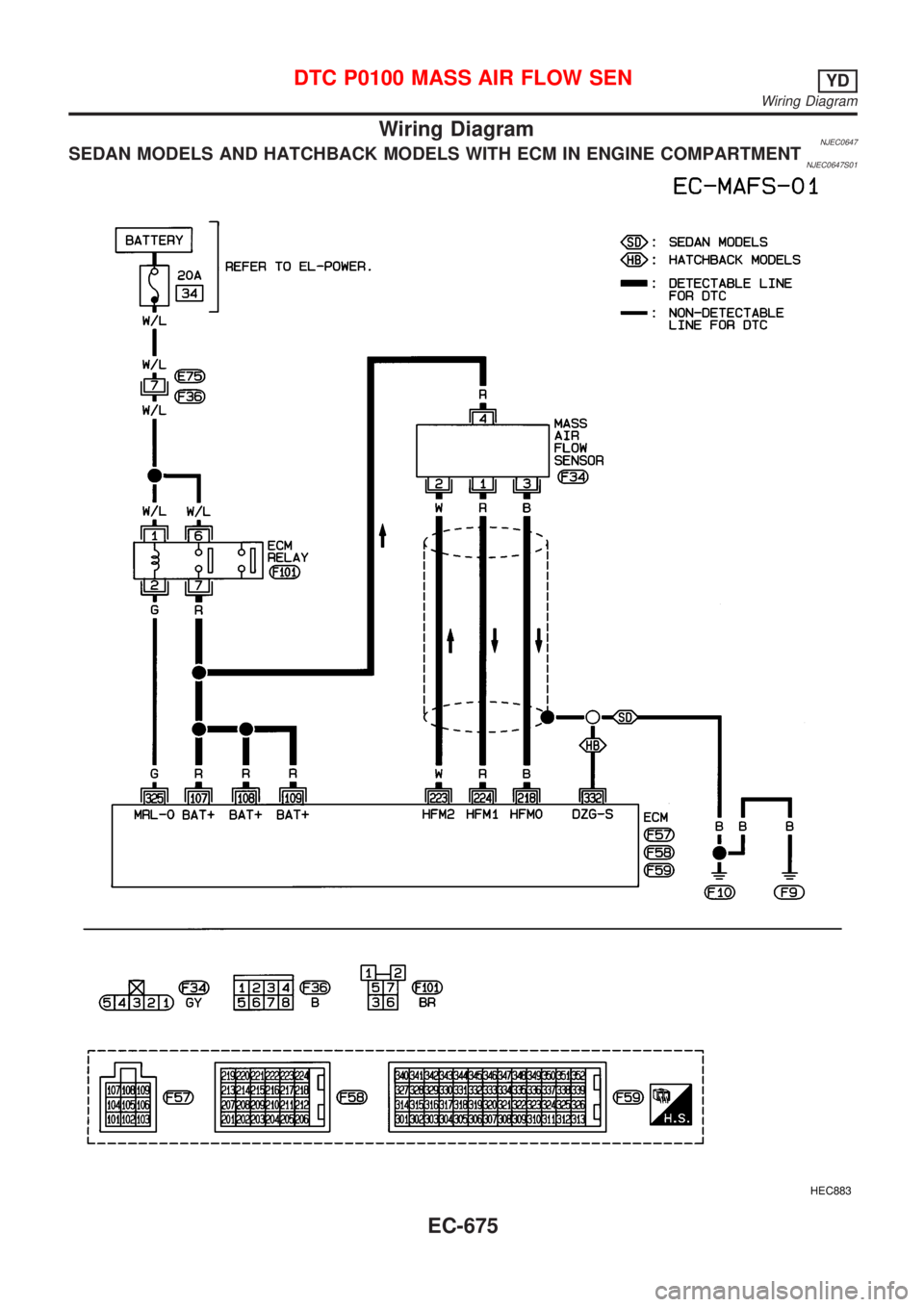

Wiring DiagramNJEC0647SEDAN MODELS AND HATCHBACK MODELS WITH ECM IN ENGINE COMPARTMENTNJEC0647S01

HEC883

DTC P0100 MASS AIR FLOW SENYD

Wiring Diagram

EC-675

Page 1400 of 2898

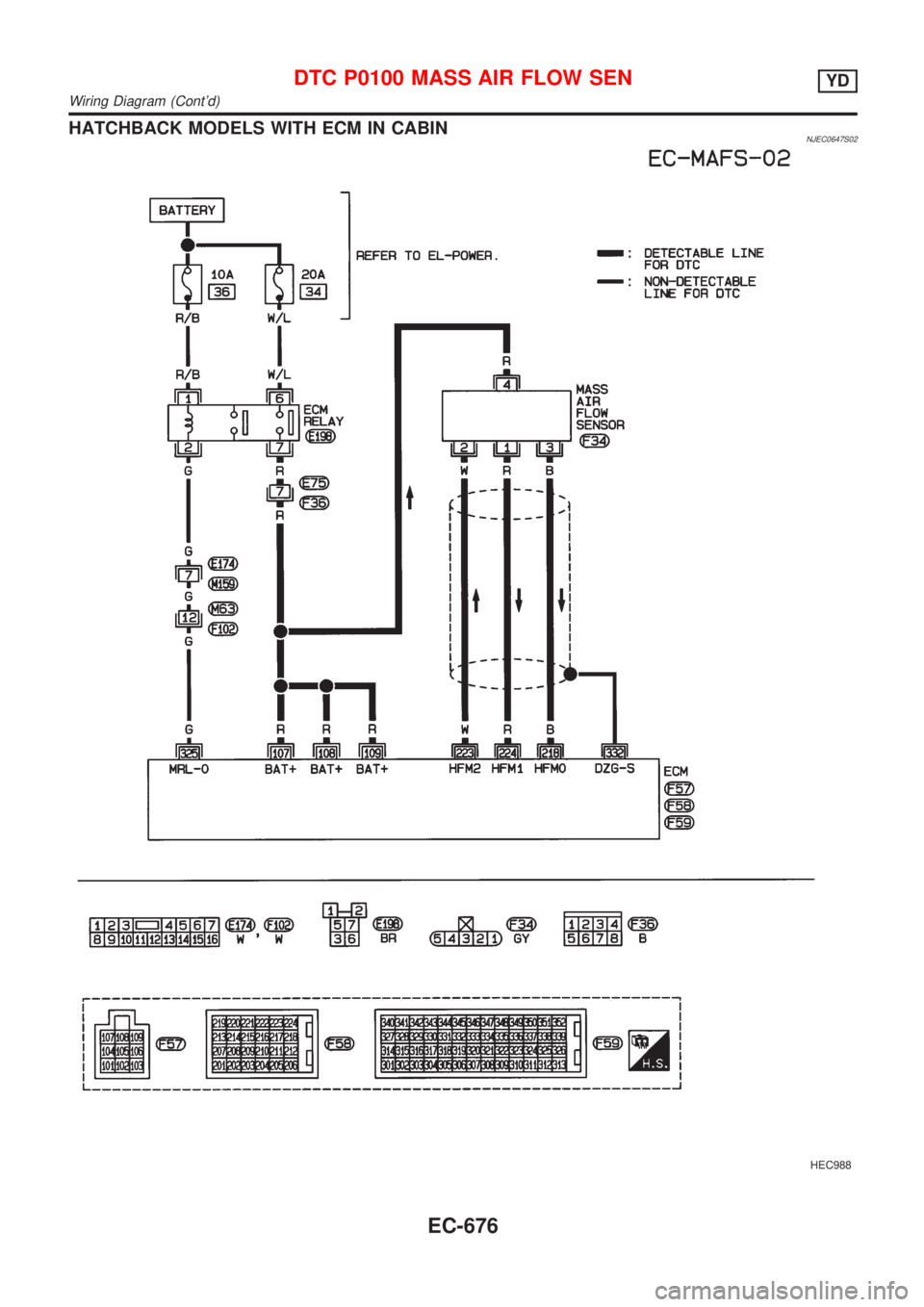

HATCHBACK MODELS WITH ECM IN CABINNJEC0647S02

HEC988

DTC P0100 MASS AIR FLOW SENYD

Wiring Diagram (Cont'd)

EC-676