NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 171 of 2898

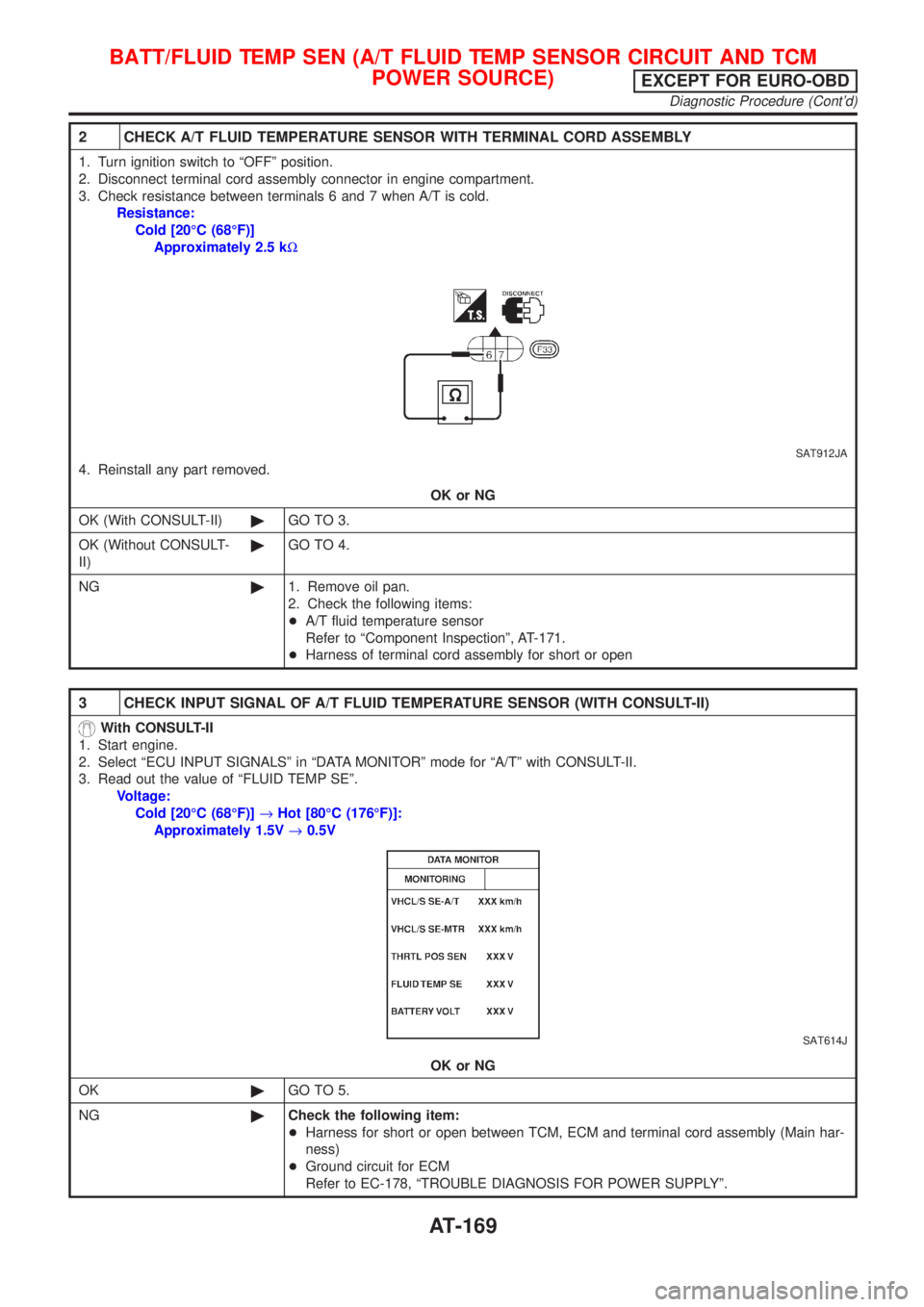

2 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT912JA

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©1. Remove oil pan.

2. Check the following items:

+A/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-171.

+Harness of terminal cord assembly for short or open

3 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT614J

OK or NG

OK©GO TO 5.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC-178, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-169

Page 172 of 2898

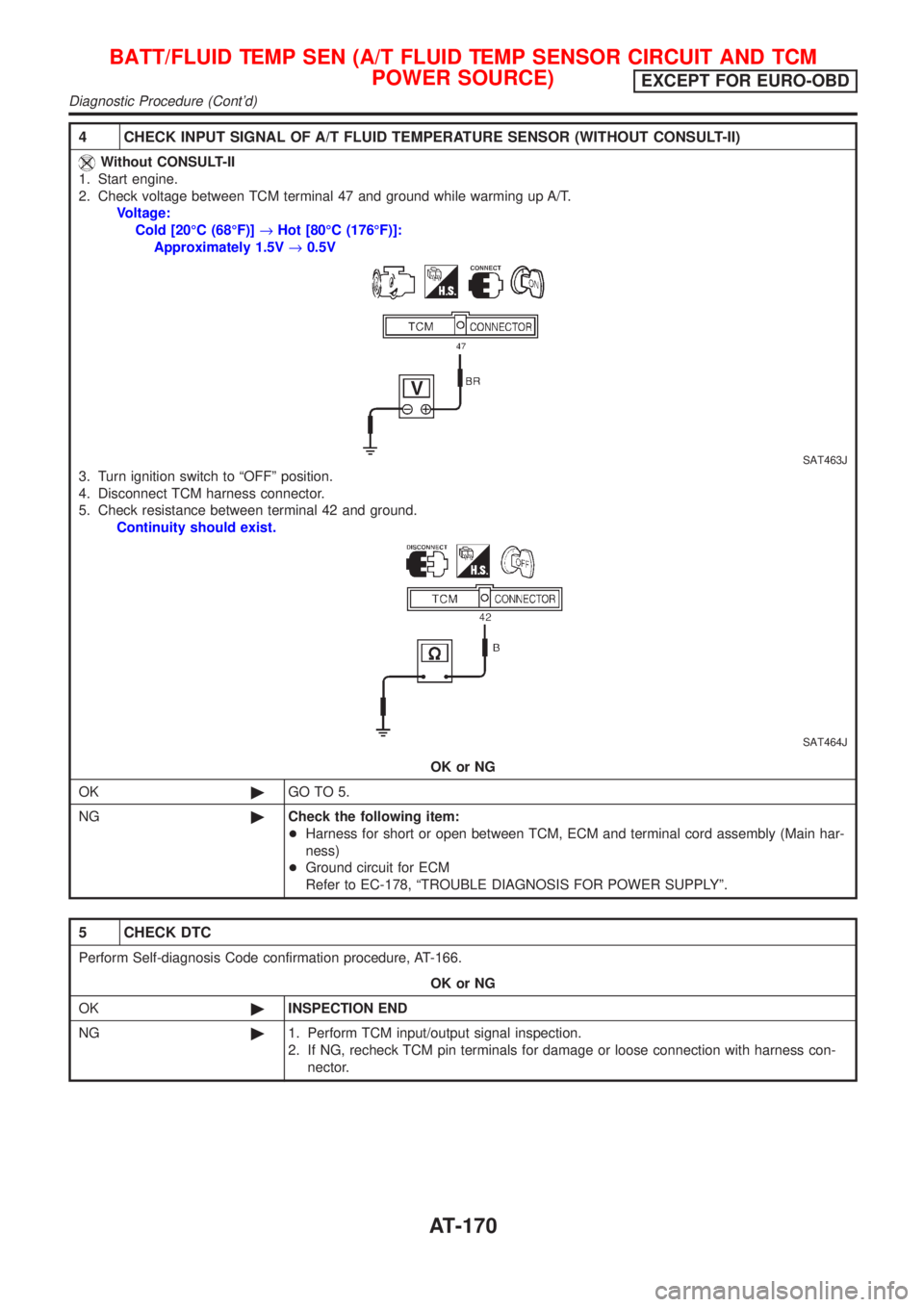

4 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT463J

3. Turn ignition switch to ªOFFº position.

4. Disconnect TCM harness connector.

5. Check resistance between terminal 42 and ground.

Continuity should exist.

SAT464J

OK or NG

OK©GO TO 5.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC-178, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

5 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-166.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-170

Page 173 of 2898

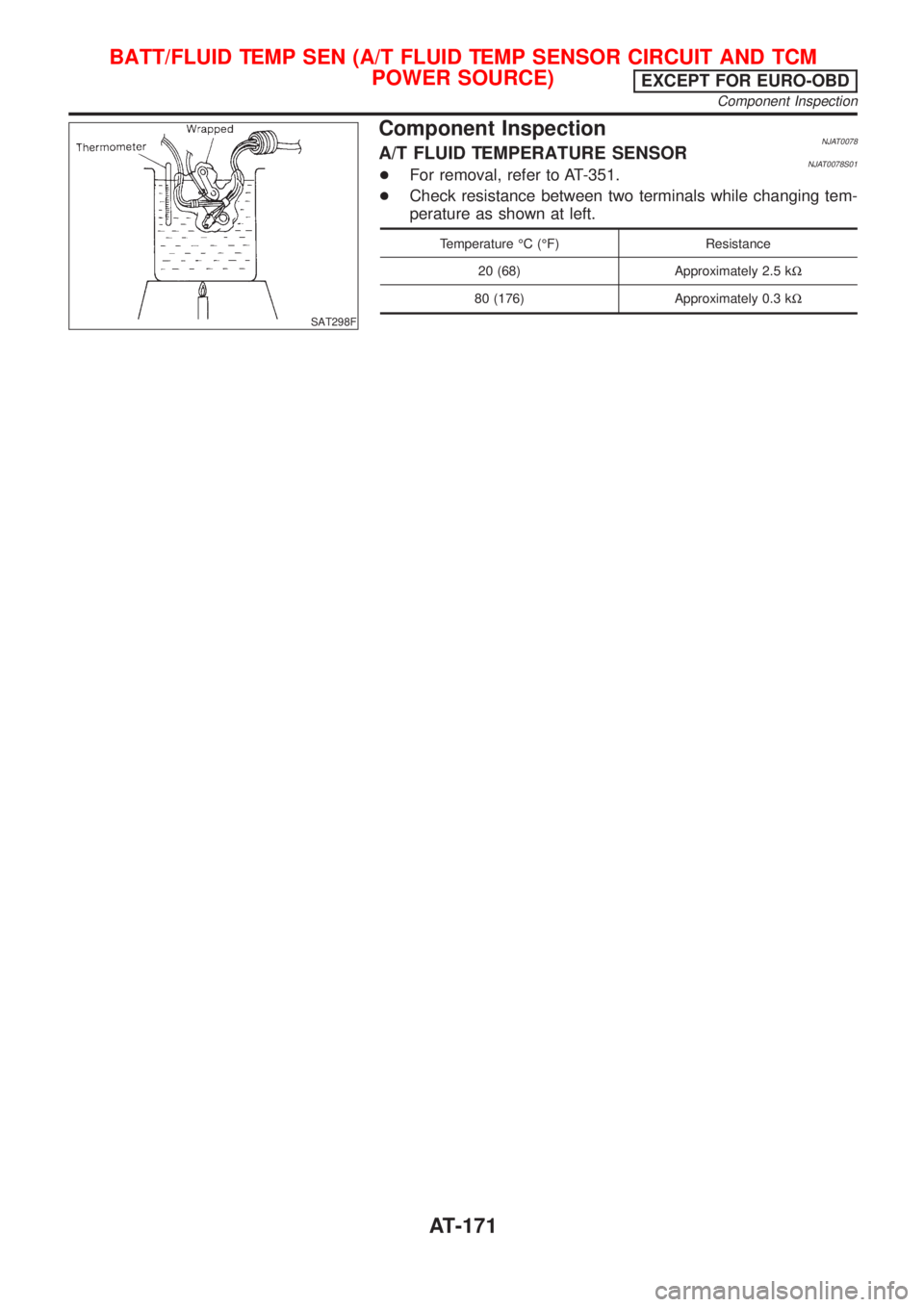

SAT298F

Component InspectionNJAT0078A/T FLUID TEMPERATURE SENSORNJAT0078S01+For removal, refer to AT-351.

+Check resistance between two terminals while changing tem-

perature as shown at left.

Temperature ÉC (ÉF) Resistance

20 (68) Approximately 2.5 kW

80 (176) Approximately 0.3 kW

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Component Inspection

AT-171

Page 174 of 2898

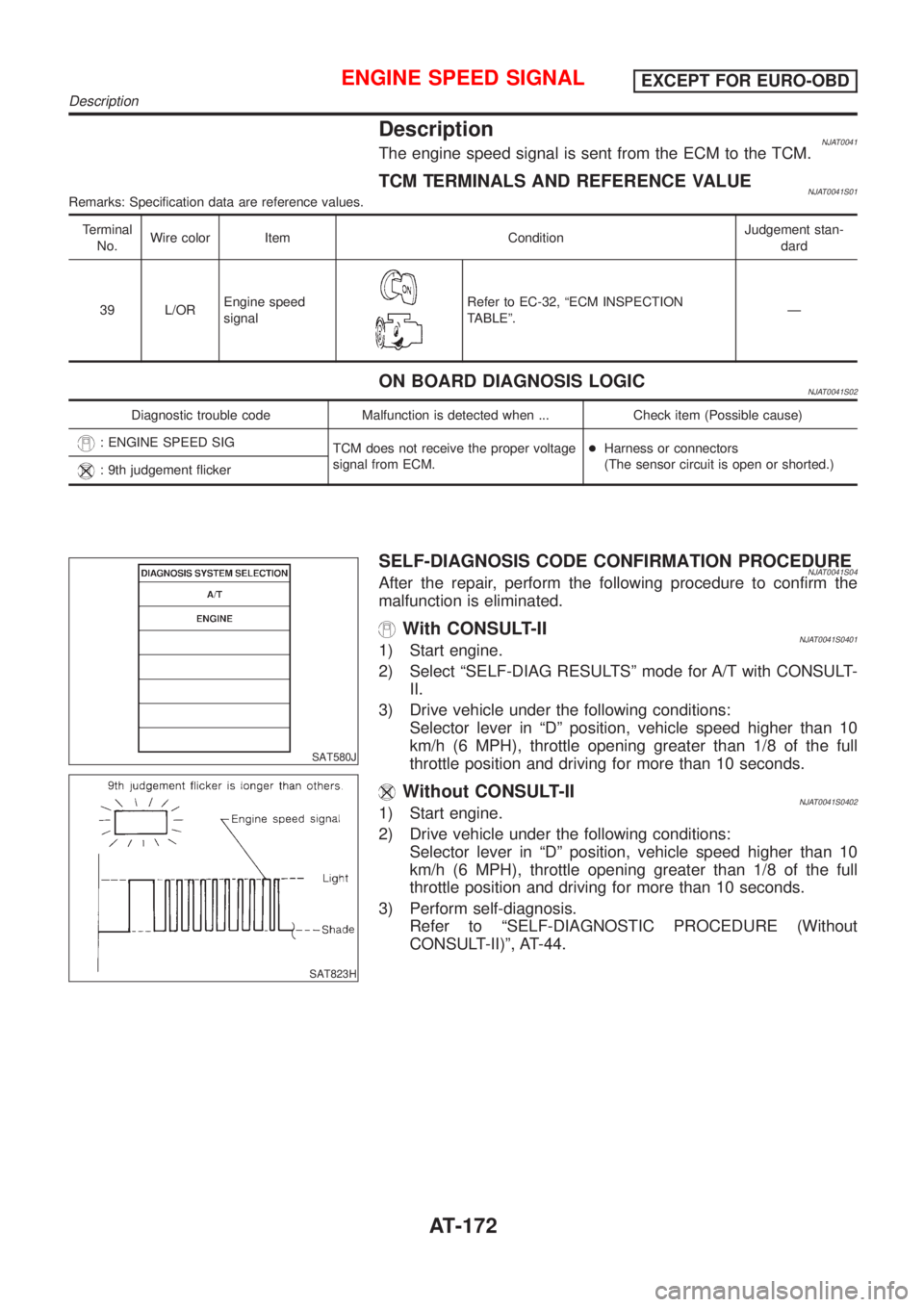

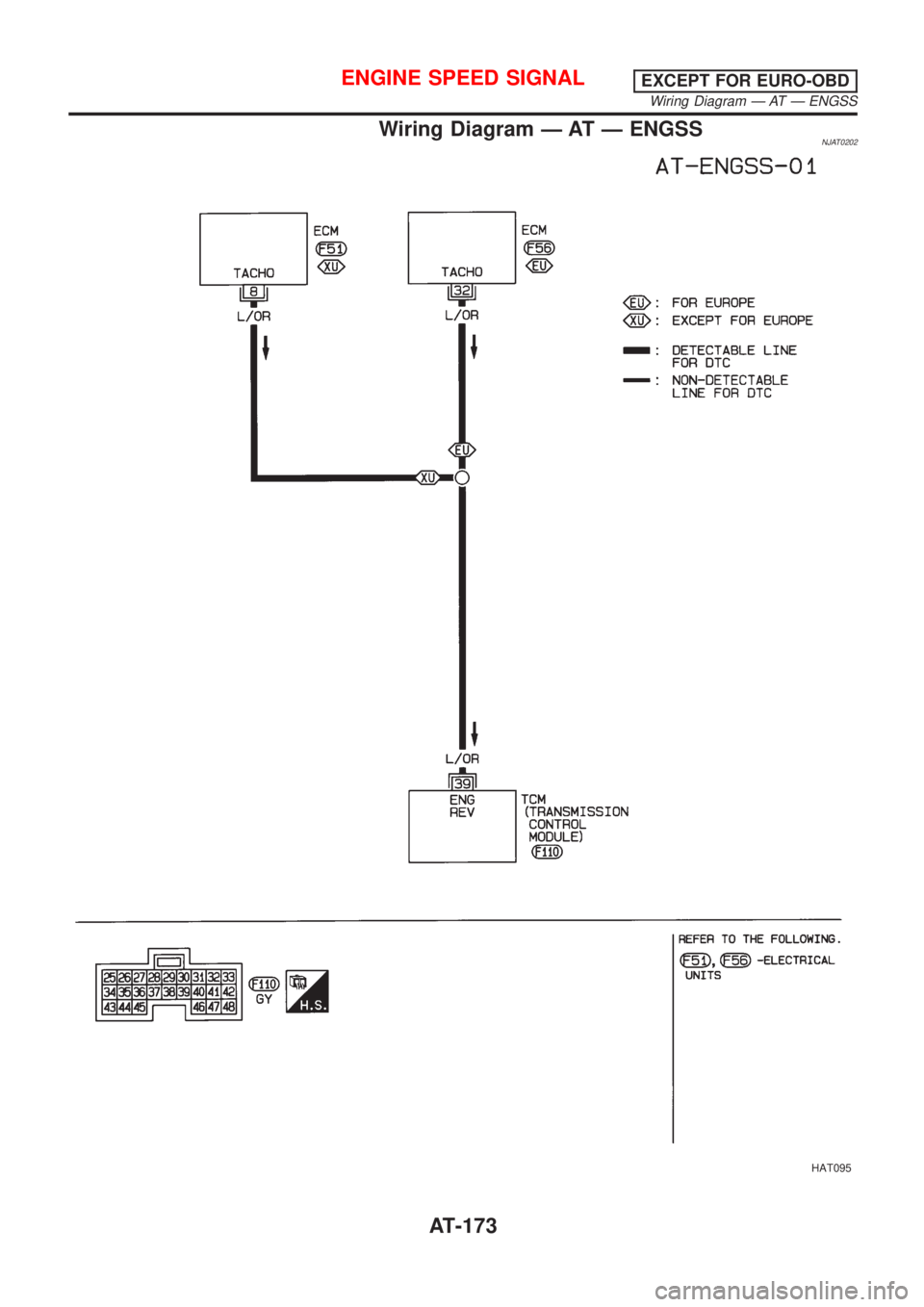

DescriptionNJAT0041The engine speed signal is sent from the ECM to the TCM.

TCM TERMINALS AND REFERENCE VALUENJAT0041S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

39 L/OREngine speed

signal

Refer to EC-32, ªECM INSPECTION

TABLEº.Ð

ON BOARD DIAGNOSIS LOGICNJAT0041S02

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: ENGINE SPEED SIG

TCM does not receive the proper voltage

signal from ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

: 9th judgement flicker

SAT580J

SAT823H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0041S04After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0041S04011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher than 10

km/h (6 MPH), throttle opening greater than 1/8 of the full

throttle position and driving for more than 10 seconds.

Without CONSULT-IINJAT0041S04021) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher than 10

km/h (6 MPH), throttle opening greater than 1/8 of the full

throttle position and driving for more than 10 seconds.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-44.

ENGINE SPEED SIGNALEXCEPT FOR EURO-OBD

Description

AT-172

Page 175 of 2898

Wiring Diagram Ð AT Ð ENGSSNJAT0202

HAT095

ENGINE SPEED SIGNALEXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð ENGSS

AT-173

Page 176 of 2898

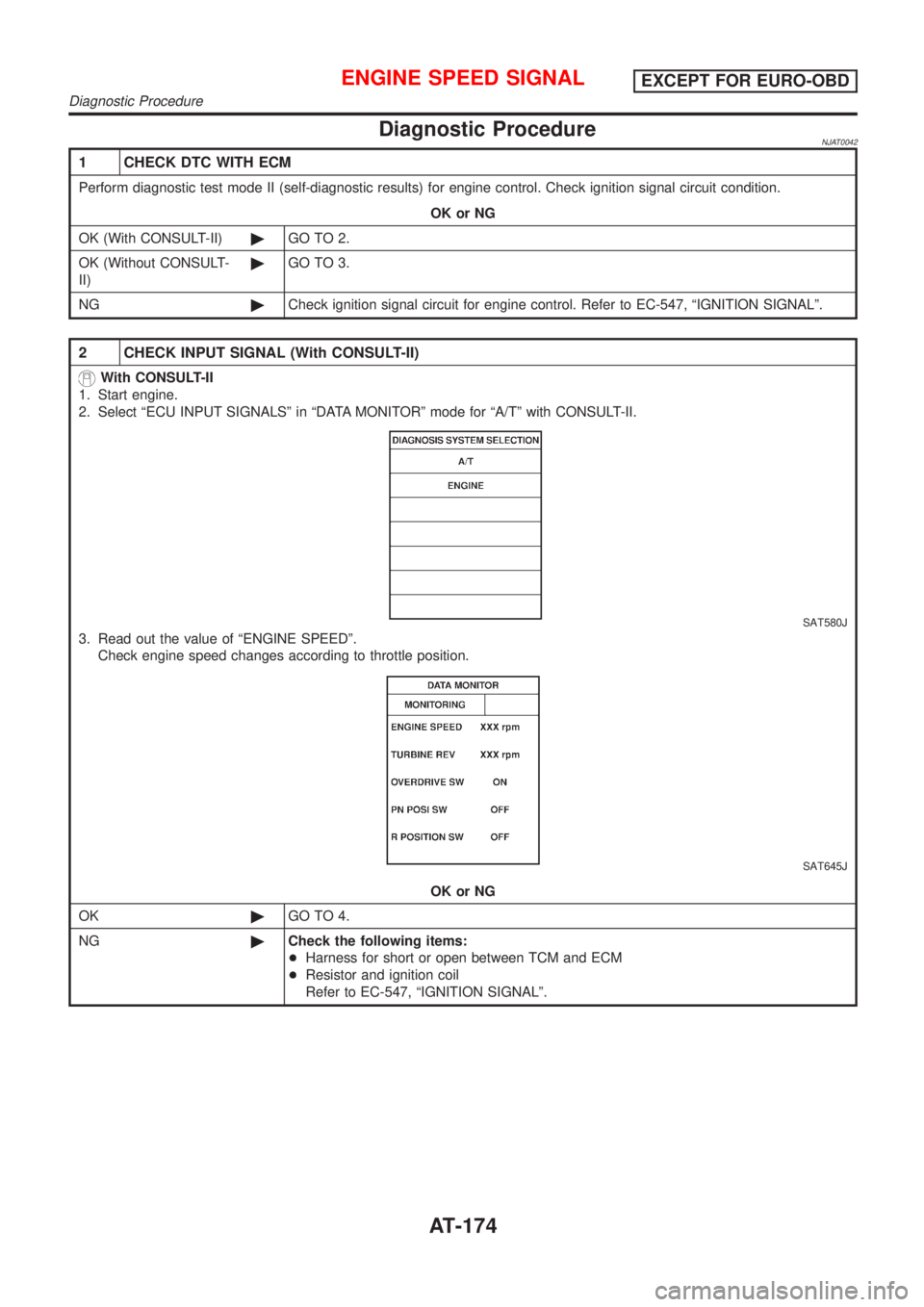

Diagnostic ProcedureNJAT0042

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control. Check ignition signal circuit condition.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check ignition signal circuit for engine control. Refer to EC-547, ªIGNITION SIGNALº.

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT580J

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

SAT645J

OK or NG

OK©GO TO 4.

NG©Check the following items:

+Harness for short or open between TCM and ECM

+Resistor and ignition coil

Refer to EC-547, ªIGNITION SIGNALº.

ENGINE SPEED SIGNALEXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-174

Page 177 of 2898

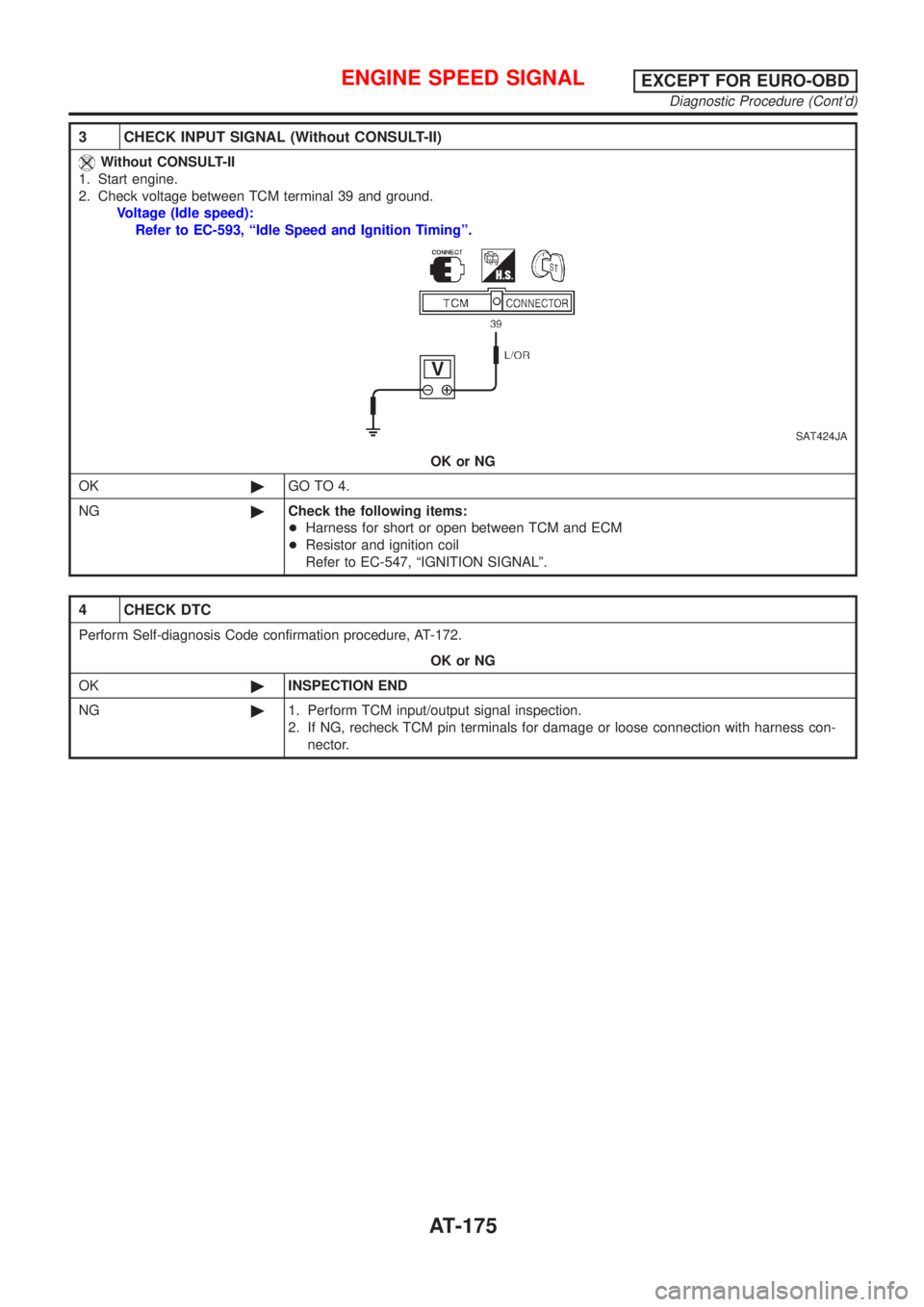

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 39 and ground.

Voltage (Idle speed):

Refer to EC-593, ªIdle Speed and Ignition Timingº.

SAT424JA

OK or NG

OK©GO TO 4.

NG©Check the following items:

+Harness for short or open between TCM and ECM

+Resistor and ignition coil

Refer to EC-547, ªIGNITION SIGNALº.

4 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-172.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

ENGINE SPEED SIGNALEXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-175

Page 178 of 2898

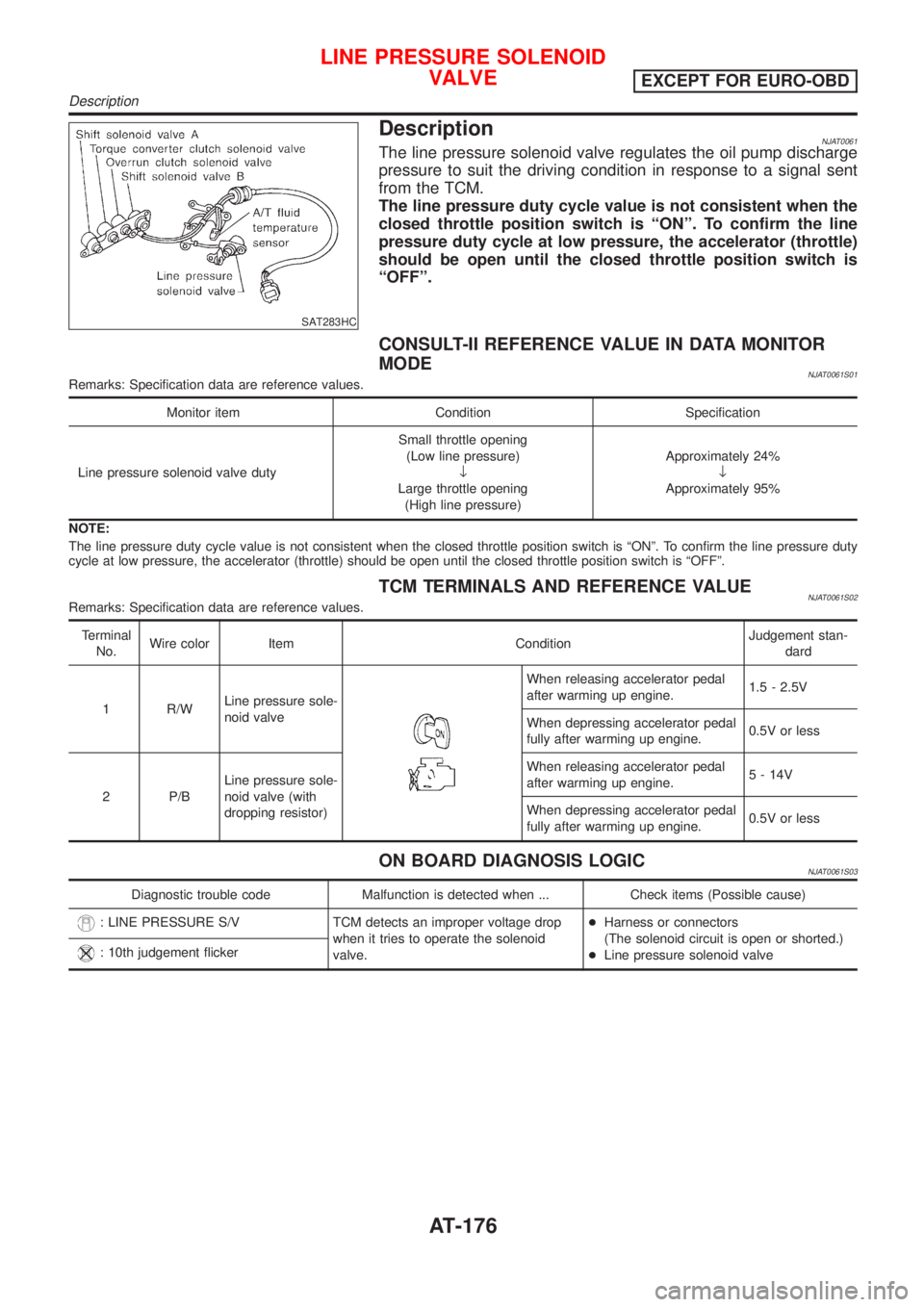

SAT283HC

DescriptionNJAT0061The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NJAT0061S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

¯

Large throttle opening

(High line pressure)Approximately 24%

¯

Approximately 95%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENJAT0061S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

1 R/WLine pressure sole-

noid valve

When releasing accelerator pedal

after warming up engine.1.5 - 2.5V

When depressing accelerator pedal

fully after warming up engine.0.5V or less

2 P/BLine pressure sole-

noid valve (with

dropping resistor)When releasing accelerator pedal

after warming up engine.5 - 14V

When depressing accelerator pedal

fully after warming up engine.0.5V or less

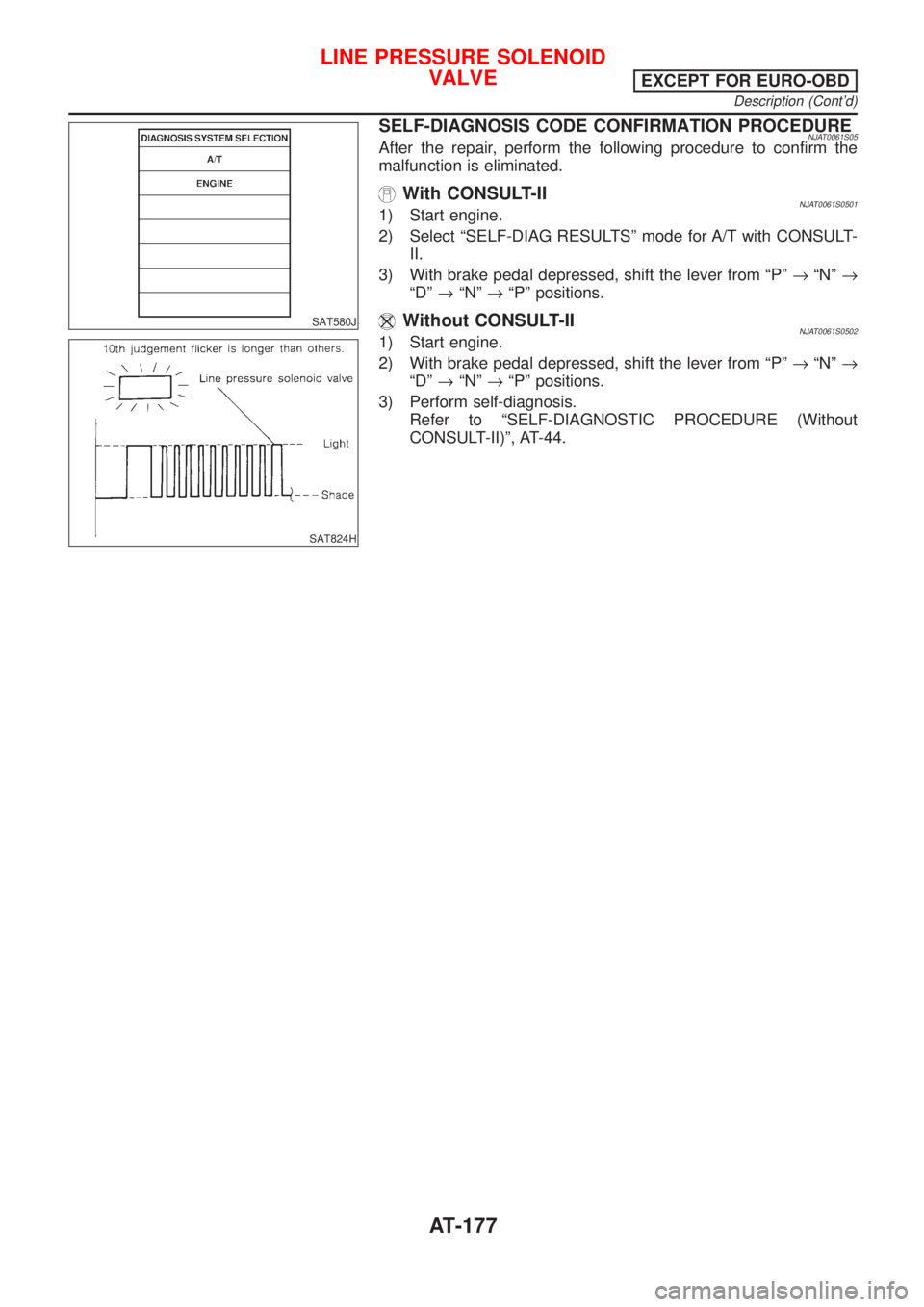

ON BOARD DIAGNOSIS LOGICNJAT0061S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: LINE PRESSURE S/V TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Line pressure solenoid valve

: 10th judgement flicker

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Description

AT-176

Page 179 of 2898

SAT580J

SAT824H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0061S05After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0061S05011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

Without CONSULT-IINJAT0061S05021) Start engine.

2) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-44.

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Description (Cont'd)

AT-177

Page 180 of 2898

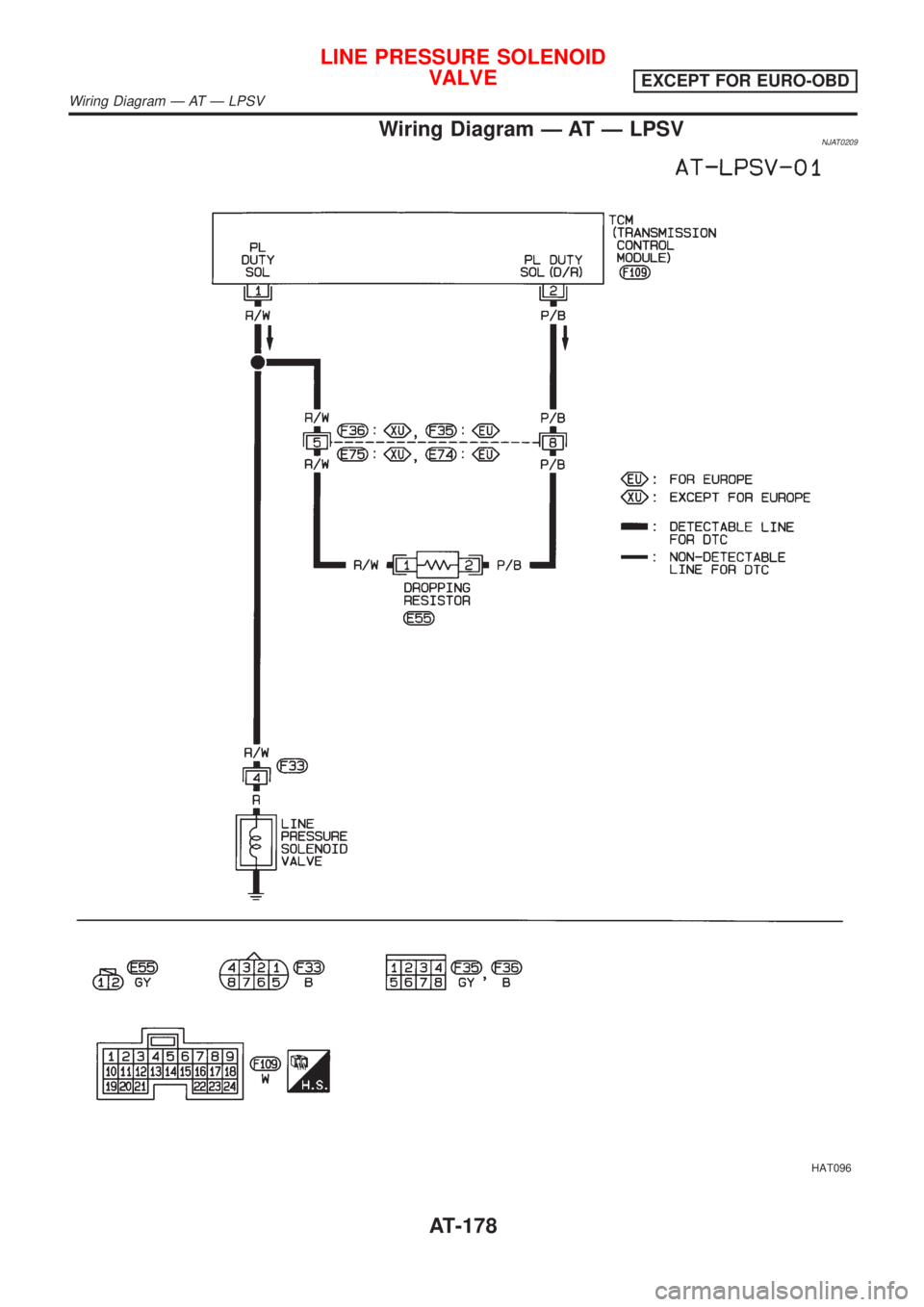

Wiring Diagram Ð AT Ð LPSVNJAT0209

HAT096

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð LPSV

AT-178