engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 540 of 2898

SBR633E

InstallationNJBR01241. Assemble vacuum pump and cylinder head rear cover

assembly, referring to ªComponentº in the next page.

2. Install vacuum pump and cylinder head rear cover assembly to

cylinder head.

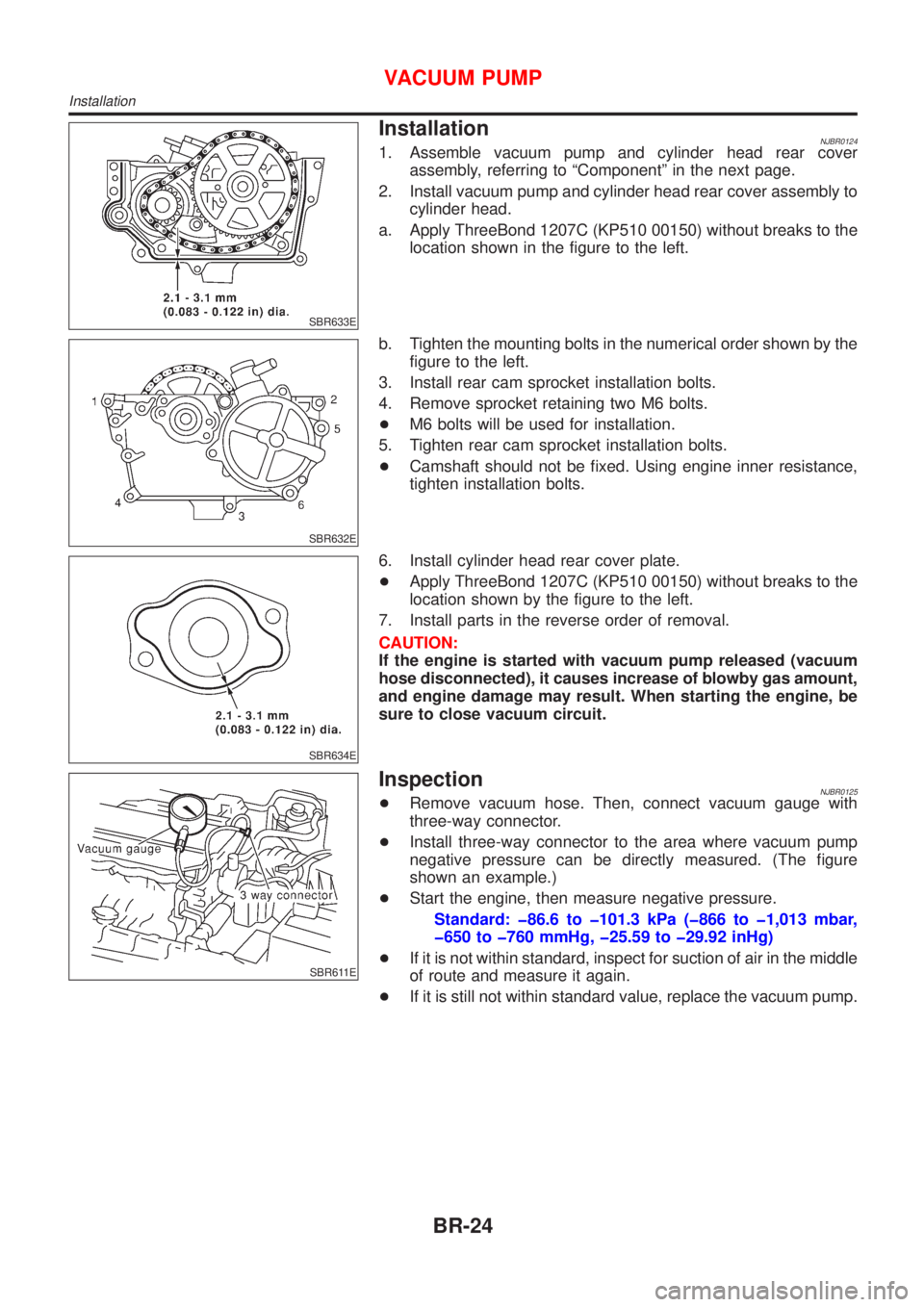

a. Apply ThreeBond 1207C (KP510 00150) without breaks to the

location shown in the figure to the left.

SBR632E

b. Tighten the mounting bolts in the numerical order shown by the

figure to the left.

3. Install rear cam sprocket installation bolts.

4. Remove sprocket retaining two M6 bolts.

+M6 bolts will be used for installation.

5. Tighten rear cam sprocket installation bolts.

+Camshaft should not be fixed. Using engine inner resistance,

tighten installation bolts.

SBR634E

6. Install cylinder head rear cover plate.

+Apply ThreeBond 1207C (KP510 00150) without breaks to the

location shown by the figure to the left.

7. Install parts in the reverse order of removal.

CAUTION:

If the engine is started with vacuum pump released (vacuum

hose disconnected), it causes increase of blowby gas amount,

and engine damage may result. When starting the engine, be

sure to close vacuum circuit.

SBR611E

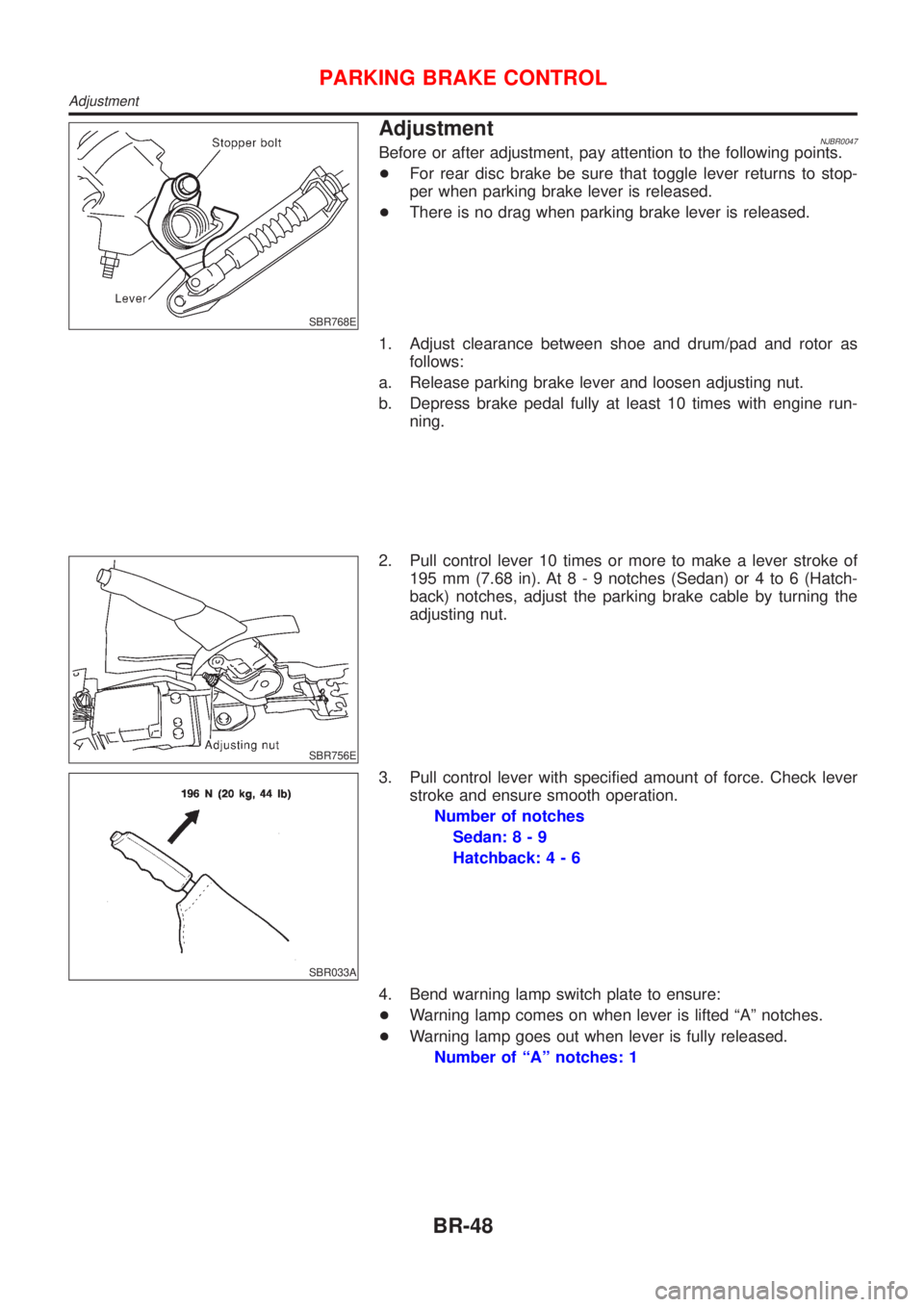

InspectionNJBR0125+Remove vacuum hose. Then, connect vacuum gauge with

three-way connector.

+Install three-way connector to the area where vacuum pump

negative pressure can be directly measured. (The figure

shown an example.)

+Start the engine, then measure negative pressure.

Standard: þ86.6 to þ101.3 kPa (þ866 to þ1,013 mbar,

þ650 to þ760 mmHg, þ25.59 to þ29.92 inHg)

+If it is not within standard, inspect for suction of air in the middle

of route and measure it again.

+If it is still not within standard value, replace the vacuum pump.

VACUUM PUMP

Installation

BR-24

Page 564 of 2898

SBR768E

AdjustmentNJBR0047Before or after adjustment, pay attention to the following points.

+For rear disc brake be sure that toggle lever returns to stop-

per when parking brake lever is released.

+There is no drag when parking brake lever is released.

1. Adjust clearance between shoe and drum/pad and rotor as

follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

SBR756E

2. Pull control lever 10 times or more to make a lever stroke of

195 mm (7.68 in). At8-9notches (Sedan) or 4 to 6 (Hatch-

back) notches, adjust the parking brake cable by turning the

adjusting nut.

SBR033A

3. Pull control lever with specified amount of force. Check lever

stroke and ensure smooth operation.

Number of notches

Sedan:8-9

Hatchback:4-6

4. Bend warning lamp switch plate to ensure:

+Warning lamp comes on when lever is lifted ªAº notches.

+Warning lamp goes out when lever is fully released.

Number of ªAº notches: 1

PARKING BRAKE CONTROL

Adjustment

BR-48

Page 579 of 2898

Self-diagnosis (Only Models with Data Link

Connector Terminal No. 9)

NJBR0091FUNCTIONNJBR0091S01+When a problem occurs in the ABS, the ABS warning lamp on

the instrument panel comes on. To start the self-diagnostic

results mode, ground the self-diagnostic (check) terminal

located on ªData link connectorº. The location of the malfunc-

tion is indicated by the ABS warning lamp flashing.

SELF-DIAGNOSIS PROCEDURENJBR0091S021. Drive vehicle over 30 km/h (19 MPH) for at least one minute.

2. Turn ignition switch ªOFFº.

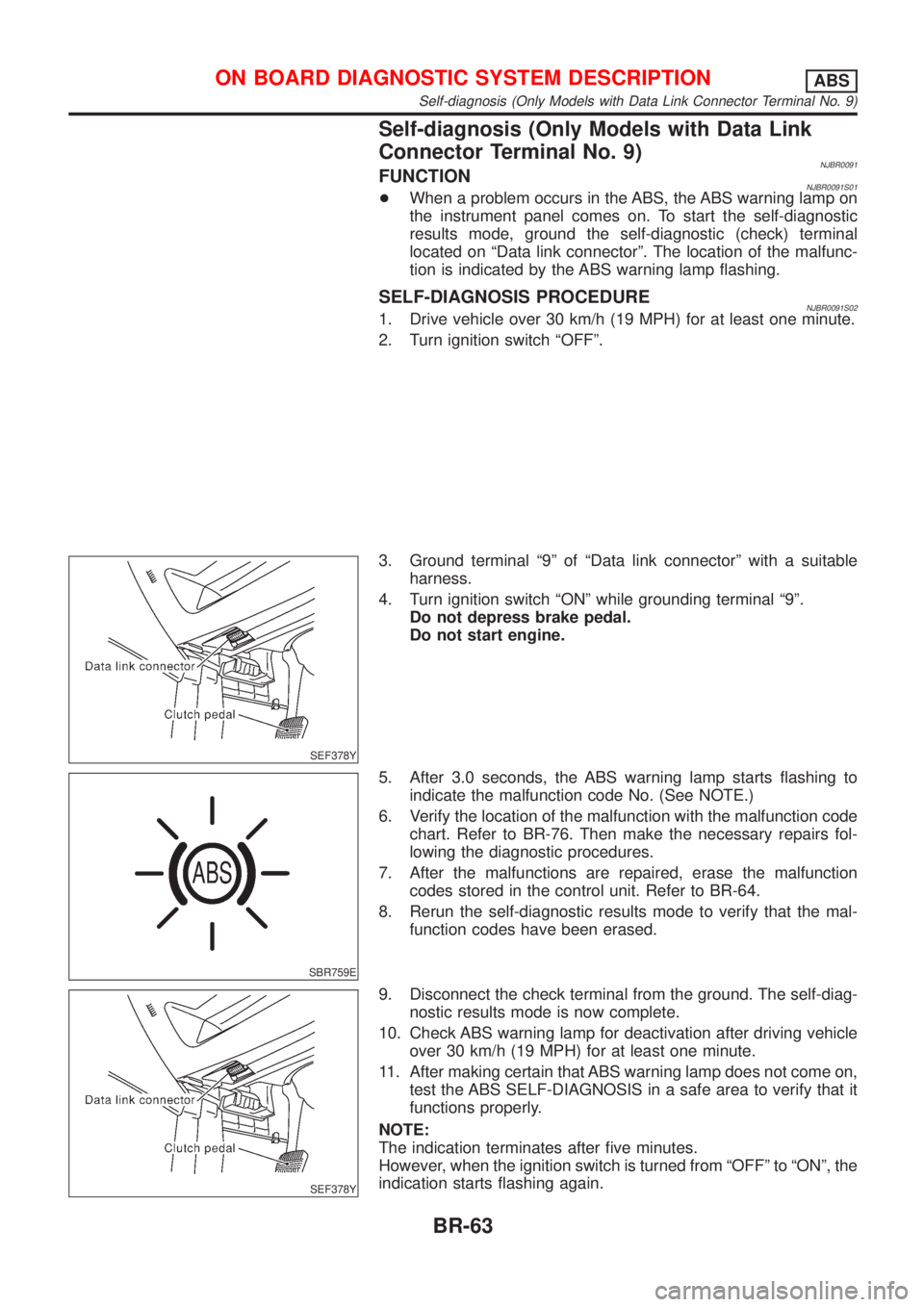

SEF378Y

3. Ground terminal ª9º of ªData link connectorº with a suitable

harness.

4. Turn ignition switch ªONº while grounding terminal ª9º.

Do not depress brake pedal.

Do not start engine.

SBR759E

5. After 3.0 seconds, the ABS warning lamp starts flashing to

indicate the malfunction code No. (See NOTE.)

6. Verify the location of the malfunction with the malfunction code

chart. Refer to BR-76. Then make the necessary repairs fol-

lowing the diagnostic procedures.

7. After the malfunctions are repaired, erase the malfunction

codes stored in the control unit. Refer to BR-64.

8. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

SEF378Y

9. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

10. Check ABS warning lamp for deactivation after driving vehicle

over 30 km/h (19 MPH) for at least one minute.

11. After making certain that ABS warning lamp does not come on,

test the ABS SELF-DIAGNOSIS in a safe area to verify that it

functions properly.

NOTE:

The indication terminates after five minutes.

However, when the ignition switch is turned from ªOFFº to ªONº, the

indication starts flashing again.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

Self-diagnosis (Only Models with Data Link Connector Terminal No. 9)

BR-63

Page 581 of 2898

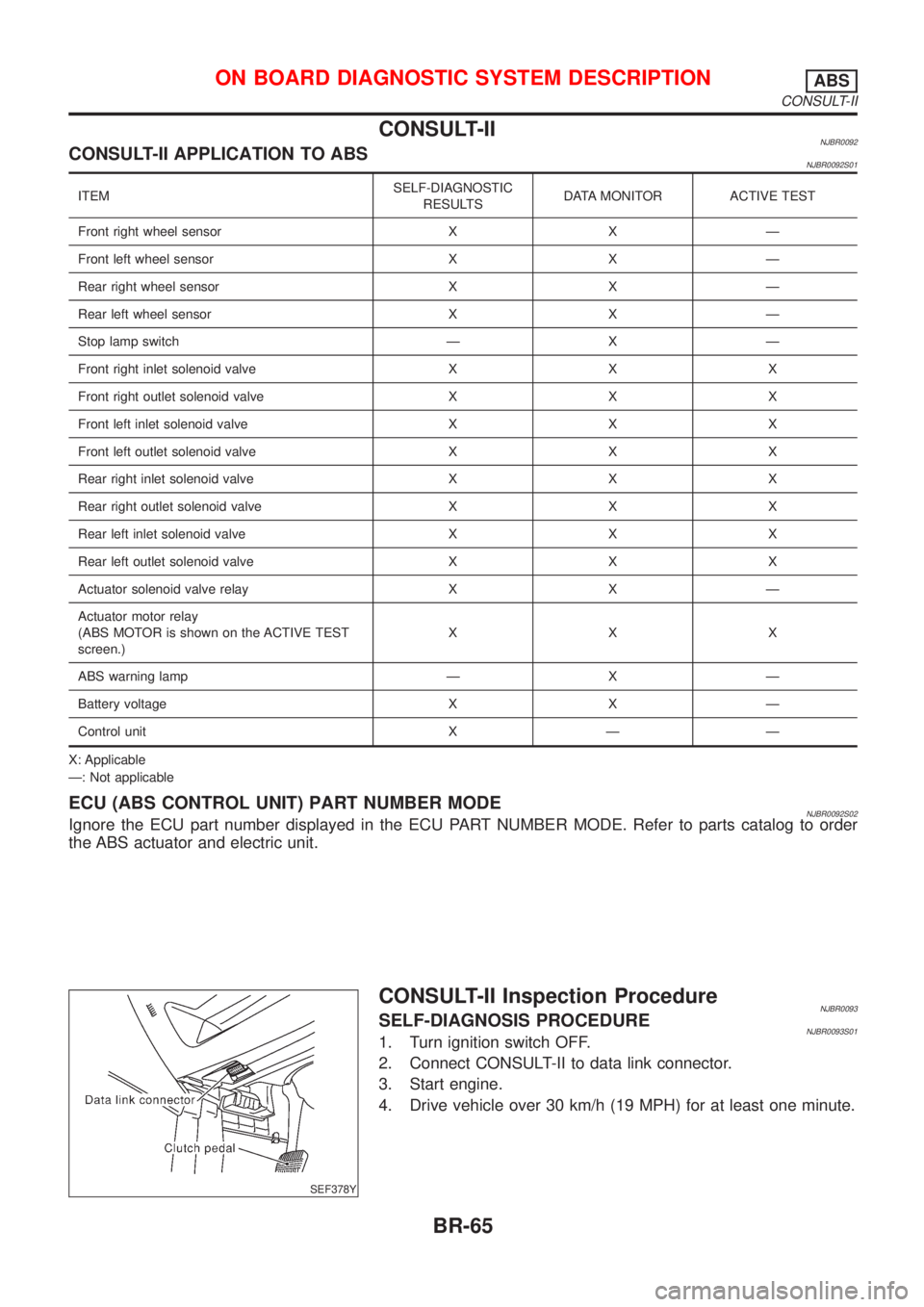

CONSULT-IINJBR0092CONSULT-II APPLICATION TO ABSNJBR0092S01

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X Ð

Front left wheel sensor X X Ð

Rear right wheel sensor X X Ð

Rear left wheel sensor X X Ð

Stop lamp switch Ð X Ð

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear right inlet solenoid valve X X X

Rear right outlet solenoid valve X X X

Rear left inlet solenoid valve X X X

Rear left outlet solenoid valve X X X

Actuator solenoid valve relay X X Ð

Actuator motor relay

(ABS MOTOR is shown on the ACTIVE TEST

screen.)XXX

ABS warning lamp Ð X Ð

Battery voltage X X Ð

Control unit X Ð Ð

X: Applicable

Ð: Not applicable

ECU (ABS CONTROL UNIT) PART NUMBER MODENJBR0092S02Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ABS actuator and electric unit.

SEF378Y

CONSULT-II Inspection ProcedureNJBR0093SELF-DIAGNOSIS PROCEDURENJBR0093S011. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector.

3. Start engine.

4. Drive vehicle over 30 km/h (19 MPH) for at least one minute.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II

BR-65

Page 582 of 2898

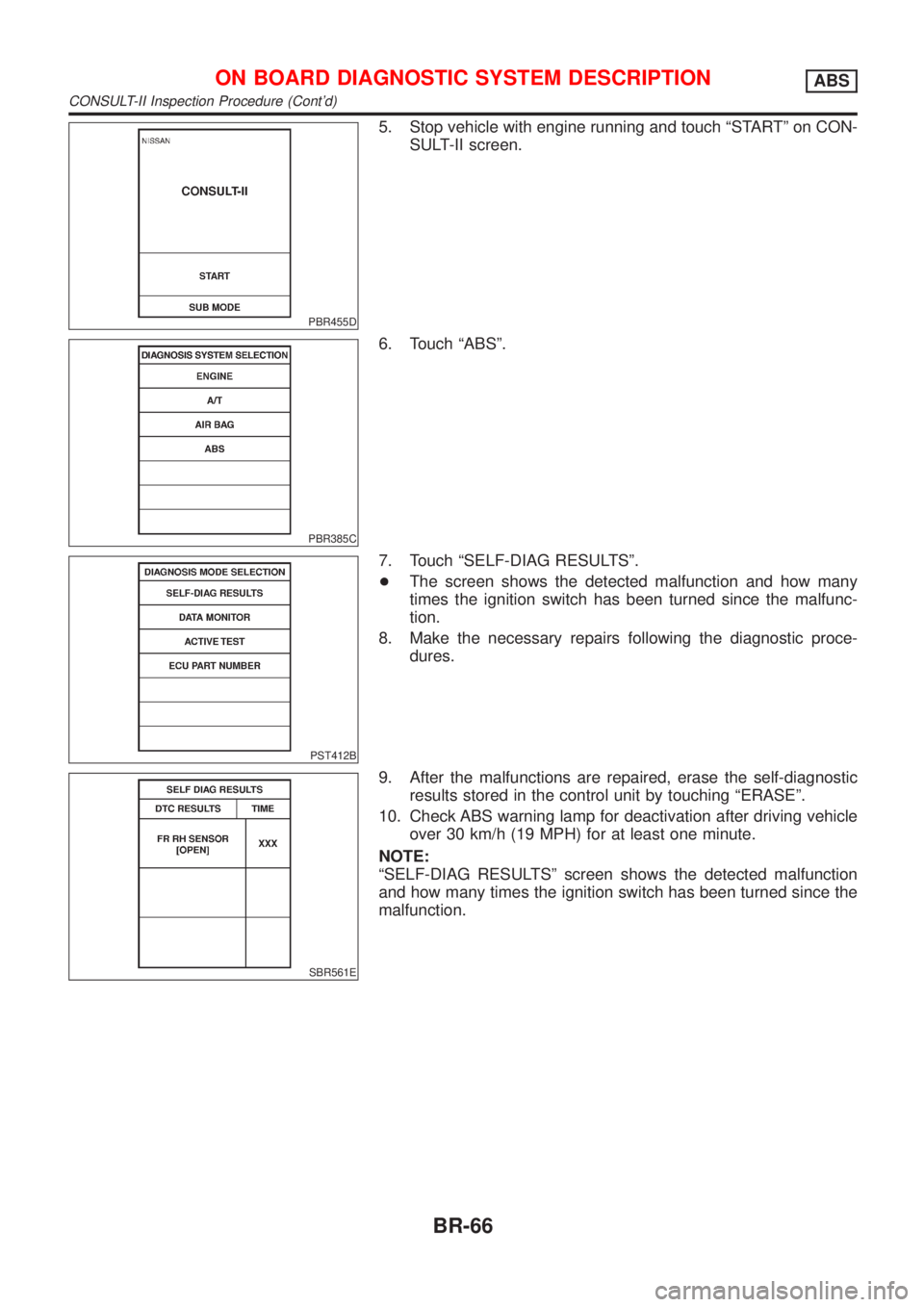

PBR455D

5. Stop vehicle with engine running and touch ªSTARTº on CON-

SULT-II screen.

PBR385C

6. Touch ªABSº.

PST412B

7. Touch ªSELF-DIAG RESULTSº.

+The screen shows the detected malfunction and how many

times the ignition switch has been turned since the malfunc-

tion.

8. Make the necessary repairs following the diagnostic proce-

dures.

SBR561E

9. After the malfunctions are repaired, erase the self-diagnostic

results stored in the control unit by touching ªERASEº.

10. Check ABS warning lamp for deactivation after driving vehicle

over 30 km/h (19 MPH) for at least one minute.

NOTE:

ªSELF-DIAG RESULTSº screen shows the detected malfunction

and how many times the ignition switch has been turned since the

malfunction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont'd)

BR-66

Page 585 of 2898

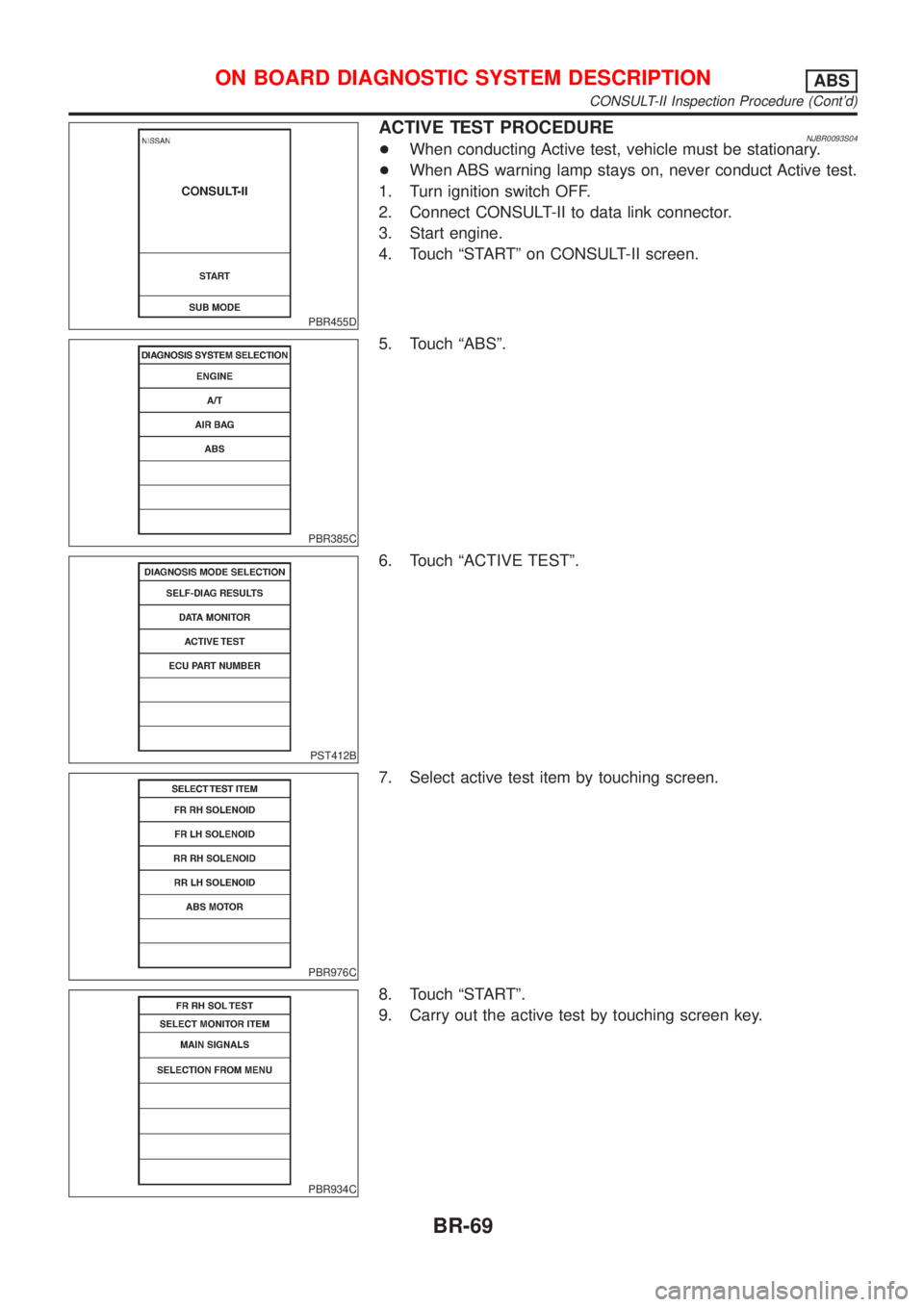

PBR455D

ACTIVE TEST PROCEDURENJBR0093S04+When conducting Active test, vehicle must be stationary.

+When ABS warning lamp stays on, never conduct Active test.

1. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector.

3. Start engine.

4. Touch ªSTARTº on CONSULT-II screen.

PBR385C

5. Touch ªABSº.

PST412B

6. Touch ªACTIVE TESTº.

PBR976C

7. Select active test item by touching screen.

PBR934C

8. Touch ªSTARTº.

9. Carry out the active test by touching screen key.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont'd)

BR-69

Page 586 of 2898

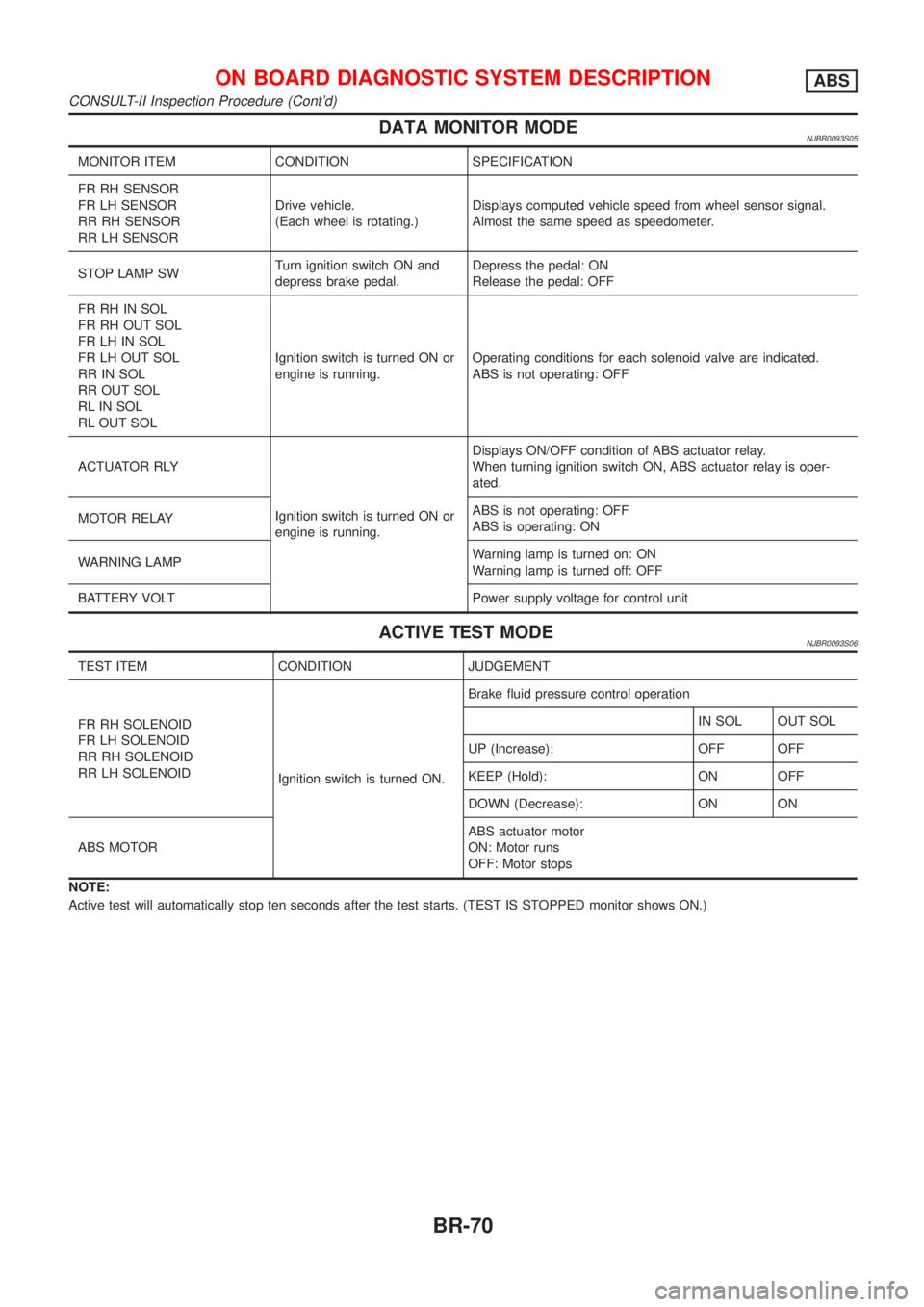

DATA MONITOR MODENJBR0093S05

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSORDrive vehicle.

(Each wheel is rotating.)Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

STOP LAMP SWTurn ignition switch ON and

depress brake pedal.Depress the pedal: ON

Release the pedal: OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL

RL IN SOL

RL OUT SOLIgnition switch is turned ON or

engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

ACTUATOR RLY

Ignition switch is turned ON or

engine is running.Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON, ABS actuator relay is oper-

ated.

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

WARNING LAMPWarning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

ACTIVE TEST MODENJBR0093S06

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

RR RH SOLENOID

RR LH SOLENOID

Ignition switch is turned ON.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase): OFF OFF

KEEP (Hold): ON OFF

DOWN (Decrease): ON ON

ABS MOTORABS actuator motor

ON: Motor runs

OFF: Motor stops

NOTE:

Active test will automatically stop ten seconds after the test starts. (TEST IS STOPPED monitor shows ON.)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont'd)

BR-70

Page 590 of 2898

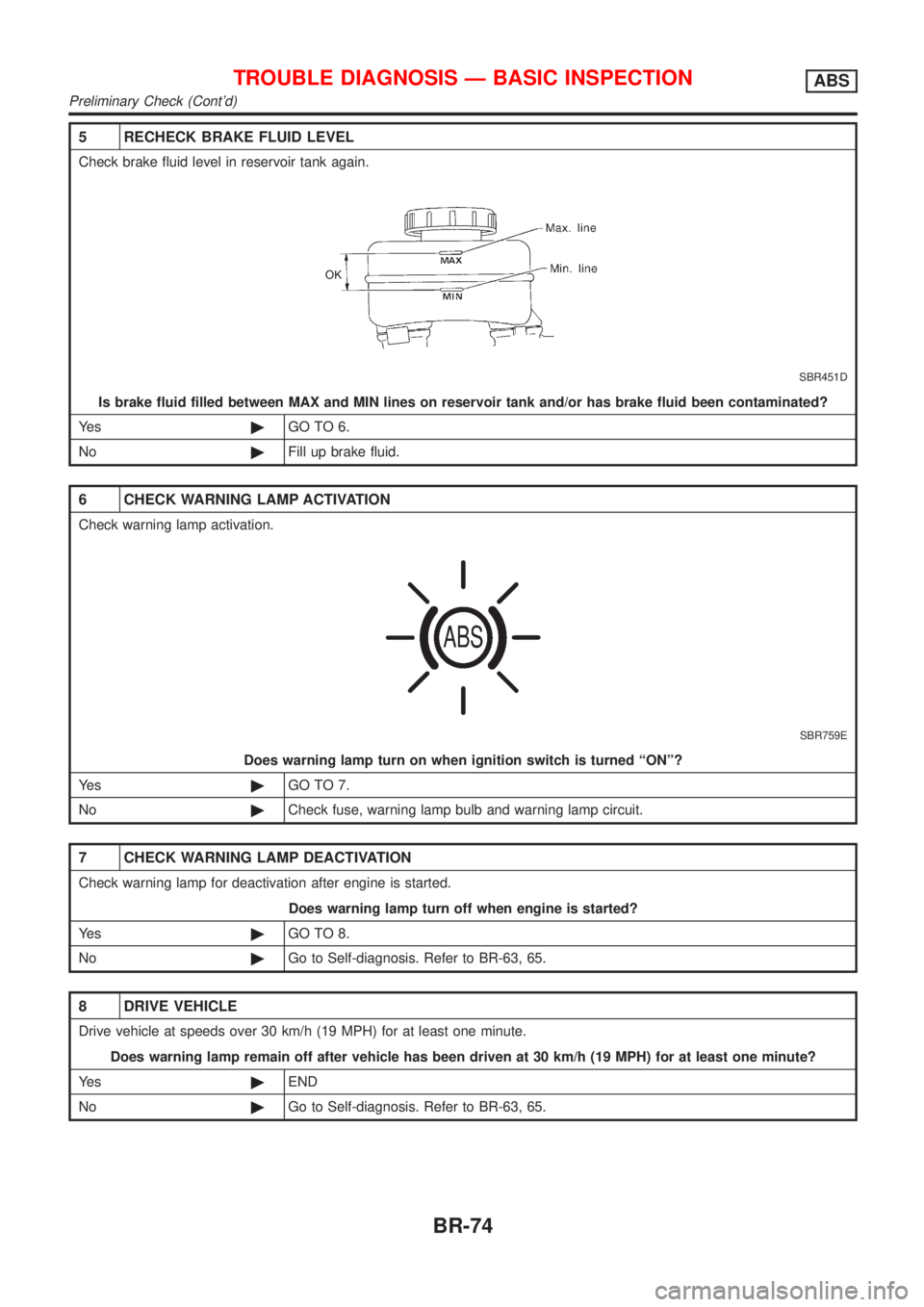

5 RECHECK BRAKE FLUID LEVEL

Check brake fluid level in reservoir tank again.

SBR451D

Is brake fluid filled between MAX and MIN lines on reservoir tank and/or has brake fluid been contaminated?

Ye s©GO TO 6.

No©Fill up brake fluid.

6 CHECK WARNING LAMP ACTIVATION

Check warning lamp activation.

SBR759E

Does warning lamp turn on when ignition switch is turned ªONº?

Ye s©GO TO 7.

No©Check fuse, warning lamp bulb and warning lamp circuit.

7 CHECK WARNING LAMP DEACTIVATION

Check warning lamp for deactivation after engine is started.

Does warning lamp turn off when engine is started?

Ye s©GO TO 8.

No©Go to Self-diagnosis. Refer to BR-63, 65.

8 DRIVE VEHICLE

Drive vehicle at speeds over 30 km/h (19 MPH) for at least one minute.

Does warning lamp remain off after vehicle has been driven at 30 km/h (19 MPH) for at least one minute?

Ye s©END

No©Go to Self-diagnosis. Refer to BR-63, 65.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Preliminary Check (Cont'd)

BR-74

Page 603 of 2898

2 CHECK CONNECTOR

1. Disconnect ABS actuator and electric unit connector. Check terminals for damage or loose connections. Then recon-

nect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 3.

No©INSPECTION END

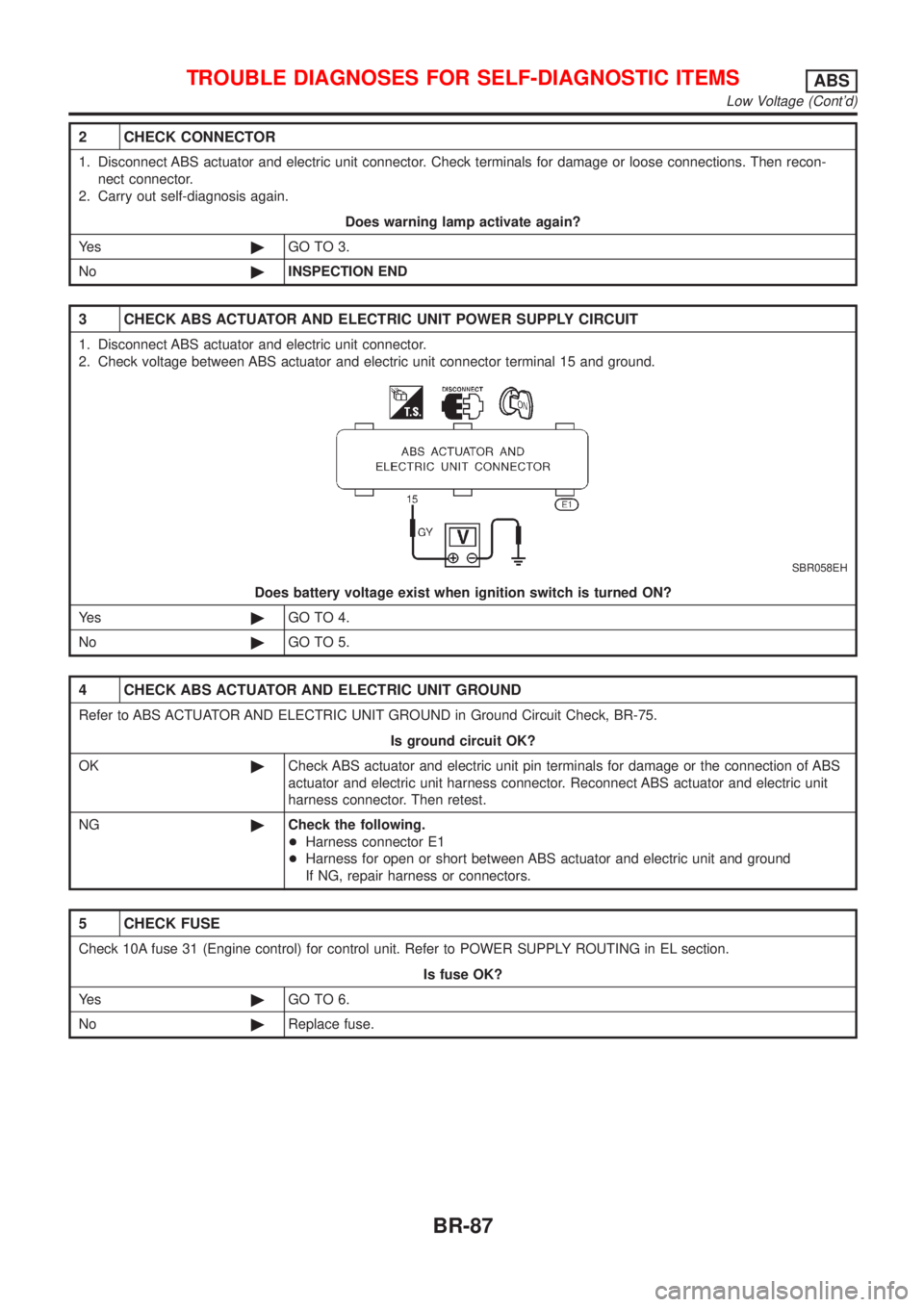

3 CHECK ABS ACTUATOR AND ELECTRIC UNIT POWER SUPPLY CIRCUIT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 15 and ground.

SBR058EH

Does battery voltage exist when ignition switch is turned ON?

Ye s©GO TO 4.

No©GO TO 5.

4 CHECK ABS ACTUATOR AND ELECTRIC UNIT GROUND

Refer to ABS ACTUATOR AND ELECTRIC UNIT GROUND in Ground Circuit Check, BR-75.

Is ground circuit OK?

OK©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

NG©Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and ground

If NG, repair harness or connectors.

5 CHECK FUSE

Check 10A fuse 31 (Engine control) for control unit. Refer to POWER SUPPLY ROUTING in EL section.

Is fuse OK?

Ye s©GO TO 6.

No©Replace fuse.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Low Voltage (Cont'd)

BR-87

Page 608 of 2898

5. Pedal Vibration and Noise=NJBR0108

1 INSPECTION START

Pedal vibration and noise inspection

SAT797A

©GO TO 2.

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-63, BR-65.

No©GO TO 3.

3 RECHECK SYMPTOM

Does the symptom appear when electrical equipment switches (such as headlamp) are operated?

Ye s©GO TO 4.

No©Go to ª3. CHECK WARNING LAMP INDICATIONº in ª2. Unexpected Pedal Actionº,

BR-89.

4 CHECK WHEEL SENSOR

Check wheel sensor shield ground. For location of shield ground, refer to wiring diagram and ªHARNESS LAYOUTº in EL

section.

Is wheel sensor shield grounded properly?

Ye s©Check ABS actuator and electric unit pin terminals for damage or the connection of ABS

actuator and electric unit harness connector. Reconnect ABS actuator and electric unit

harness connector. Then retest.

No©Repair.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

+Applying brake gradually when shifting or operating clutch.

+Low friction (slippery) road.

+High speed cornering.

+Driving over bumps and pot holes.

+Engine speed is over 5,000 rpm with vehicle stopped.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise

BR-92