engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 495 of 2898

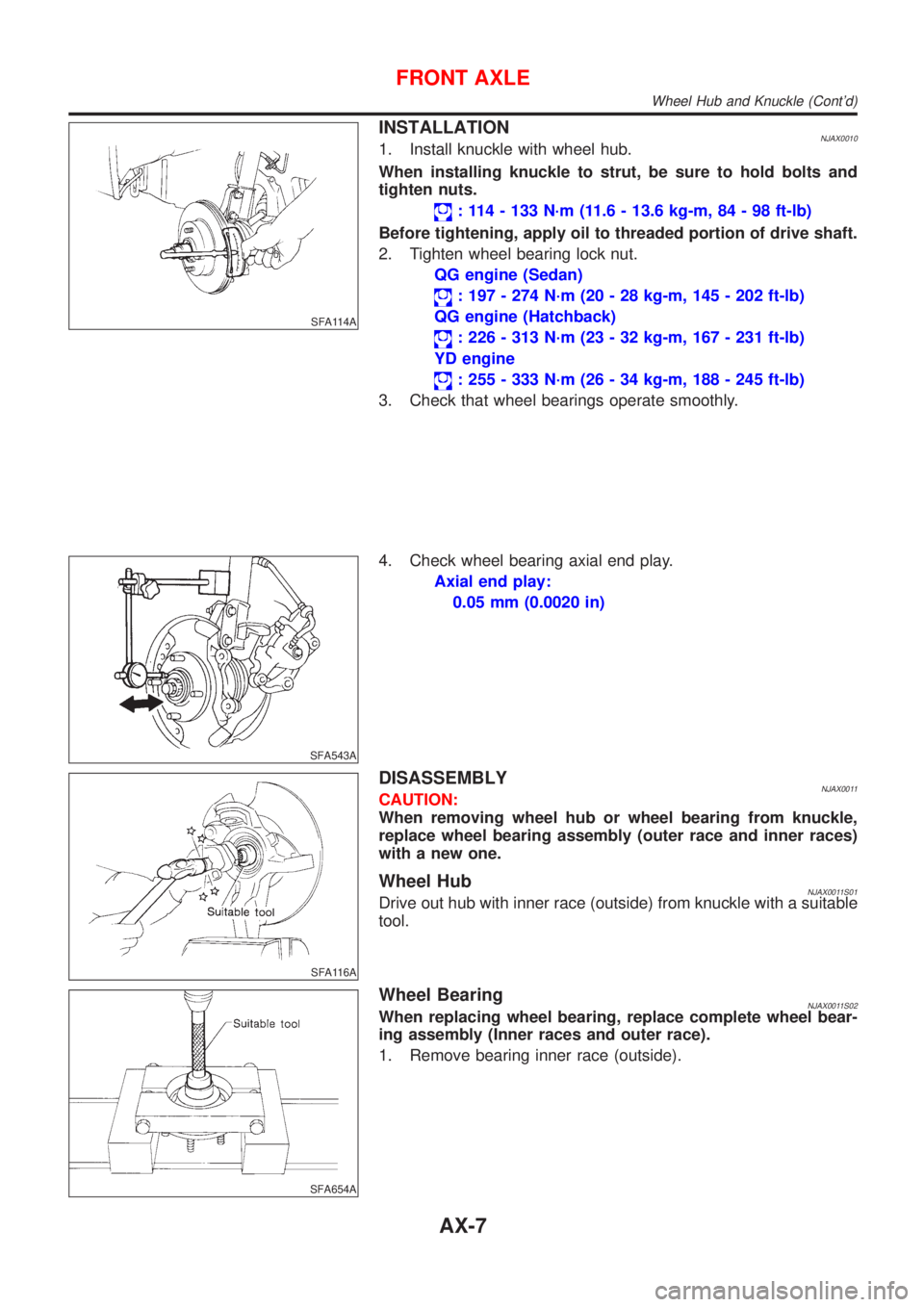

SFA114A

INSTALLATIONNJAX00101. Install knuckle with wheel hub.

When installing knuckle to strut, be sure to hold bolts and

tighten nuts.

: 114 - 133 N´m (11.6 - 13.6 kg-m, 84 - 98 ft-lb)

Before tightening, apply oil to threaded portion of drive shaft.

2. Tighten wheel bearing lock nut.

QG engine (Sedan)

: 197 - 274 N´m (20 - 28 kg-m, 145 - 202 ft-lb)

QG engine (Hatchback)

: 226 - 313 N´m (23 - 32 kg-m, 167 - 231 ft-lb)

YD engine

: 255 - 333 N´m (26 - 34 kg-m, 188 - 245 ft-lb)

3. Check that wheel bearings operate smoothly.

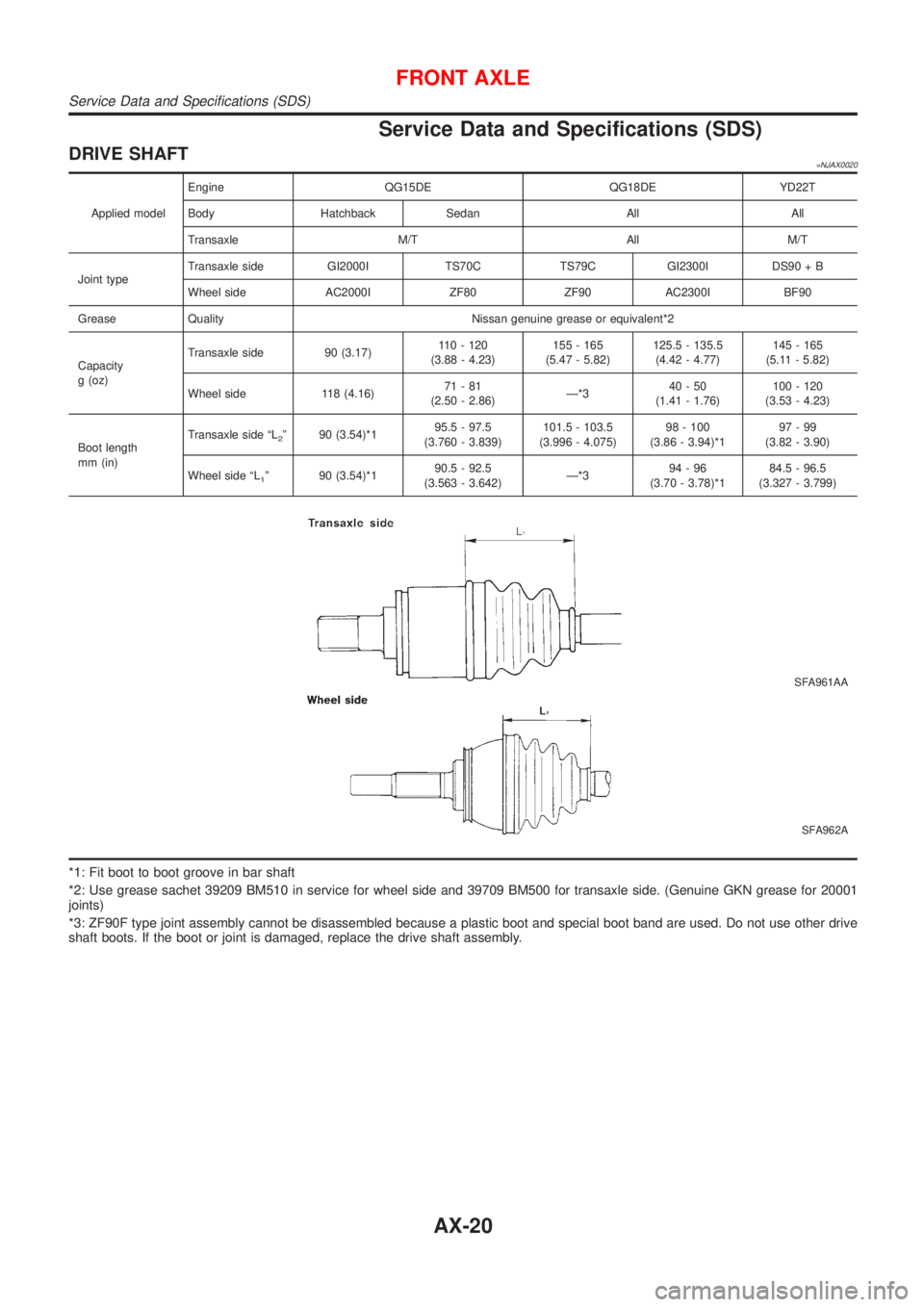

SFA543A

4. Check wheel bearing axial end play.

Axial end play:

0.05 mm (0.0020 in)

SFA116A

DISASSEMBLYNJAX0011CAUTION:

When removing wheel hub or wheel bearing from knuckle,

replace wheel bearing assembly (outer race and inner races)

with a new one.

Wheel HubNJAX0011S01Drive out hub with inner race (outside) from knuckle with a suitable

tool.

SFA654A

Wheel BearingNJAX0011S02When replacing wheel bearing, replace complete wheel bear-

ing assembly (Inner races and outer race).

1. Remove bearing inner race (outside).

FRONT AXLE

Wheel Hub and Knuckle (Cont'd)

AX-7

Page 508 of 2898

Service Data and Specifications (SDS)

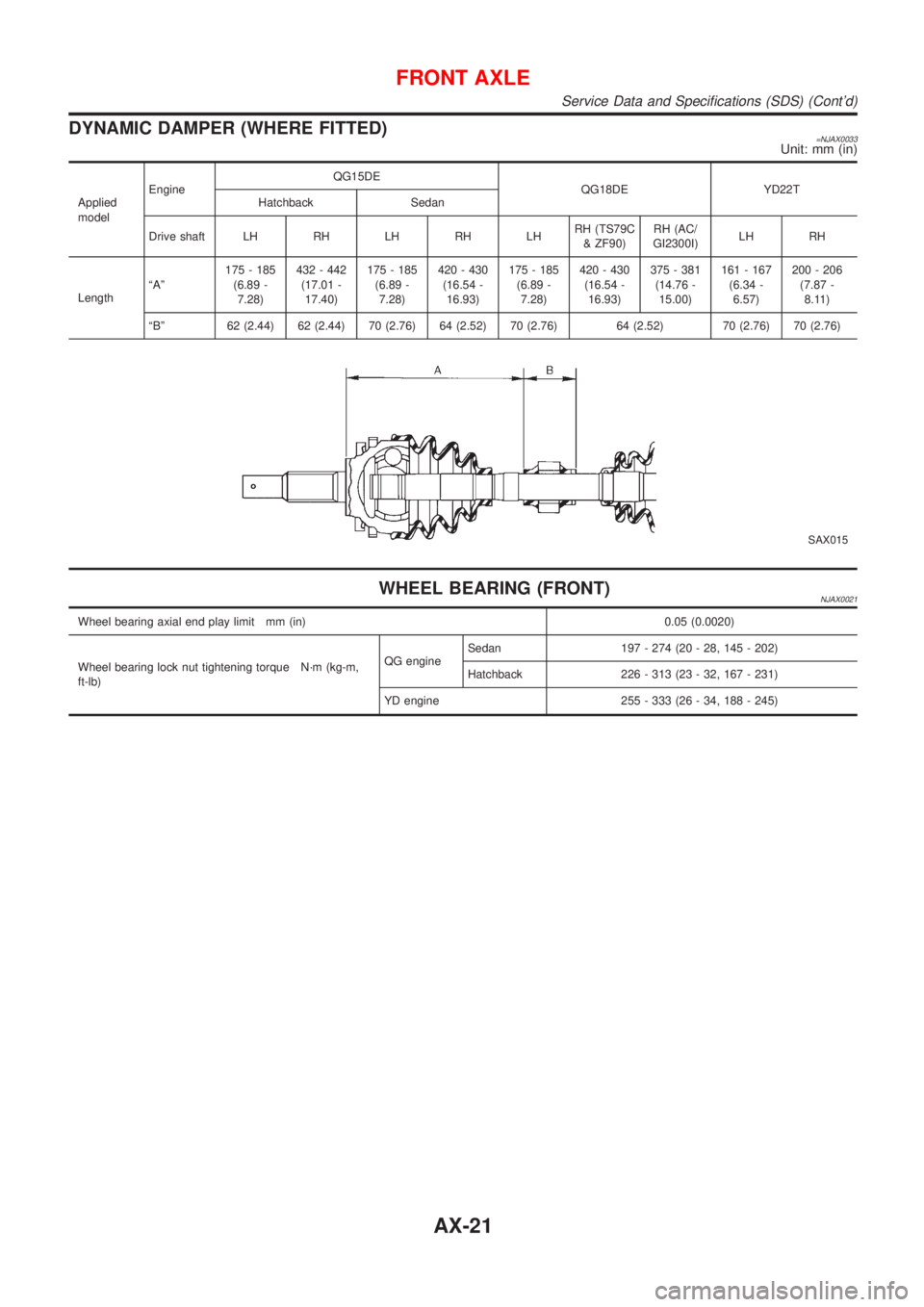

DRIVE SHAFT=NJAX0020

Applied modelEngine QG15DE QG18DE YD22T

Body Hatchback Sedan All All

Transaxle M/T All M/T

Joint typeTransaxle side GI2000I TS70C TS79C GI2300I DS90 + B

Wheel side AC2000I ZF80 ZF90 AC2300I BF90

Grease Quality Nissan genuine grease or equivalent*2

Capacity

g (oz)Transaxle side 90 (3.17)110 - 120

(3.88 - 4.23)155 - 165

(5.47 - 5.82)125.5 - 135.5

(4.42 - 4.77)145 - 165

(5.11 - 5.82)

Wheel side 118 (4.16)71-81

(2.50 - 2.86)Ð*340-50

(1.41 - 1.76)100 - 120

(3.53 - 4.23)

Boot length

mm (in)Transaxle side ªL

2º 90 (3.54)*195.5 - 97.5

(3.760 - 3.839)101.5 - 103.5

(3.996 - 4.075)98 - 100

(3.86 - 3.94)*197-99

(3.82 - 3.90)

Wheel side ªL

1º 90 (3.54)*190.5 - 92.5

(3.563 - 3.642)Ð*394-96

(3.70 - 3.78)*184.5 - 96.5

(3.327 - 3.799)

SFA961AA

SFA962A

*1: Fit boot to boot groove in bar shaft

*2: Use grease sachet 39209 BM510 in service for wheel side and 39709 BM500 for transaxle side. (Genuine GKN grease for 20001

joints)

*3: ZF90F type joint assembly cannot be disassembled because a plastic boot and special boot band are used. Do not use other drive

shaft boots. If the boot or joint is damaged, replace the drive shaft assembly.

FRONT AXLE

Service Data and Specifications (SDS)

AX-20

Page 509 of 2898

DYNAMIC DAMPER (WHERE FITTED)=NJAX0033Unit: mm (in)

Applied

modelEngineQG15DE

QG18DE YD22T

Hatchback Sedan

Drive shaft LH RH LH RH LHRH (TS79C

& ZF90)RH (AC/

GI2300I)LH RH

LengthªAº175 - 185

(6.89 -

7.28)432 - 442

(17.01 -

17.40)175 - 185

(6.89 -

7.28)420 - 430

(16.54 -

16.93)175 - 185

(6.89 -

7.28)420 - 430

(16.54 -

16.93)375 - 381

(14.76 -

15.00)161 - 167

(6.34 -

6.57)200 - 206

(7.87 -

8.11)

ªBº 62 (2.44) 62 (2.44) 70 (2.76) 64 (2.52) 70 (2.76) 64 (2.52) 70 (2.76) 70 (2.76)

SAX015

WHEEL BEARING (FRONT)NJAX0021

Wheel bearing axial end play limit mm (in) 0.05 (0.0020)

Wheel bearing lock nut tightening torque N´m (kg-m,

ft-lb)QG engineSedan 197 - 274 (20 - 28, 145 - 202)

Hatchback 226 - 313 (23 - 32, 167 - 231)

YD engine 255 - 333 (26 - 34, 188 - 245)

FRONT AXLE

Service Data and Specifications (SDS) (Cont'd)

AX-21

Page 510 of 2898

SBR686C

Precautions

PRECAUTIONSNJAX0022+When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use flare nut wrench when removing or installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment.

+Do not jack up at the trailing arm and lateral link.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0032

Tool number

Tool nameDescription

KV40104710

Drift

NT474

Install ABS sensor rotor

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST3072000

Drift

NT115

Install ABS sensor rotor

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

COMMERCIAL SERVICE TOOLSNJAX0024

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

REAR AXLE

Precautions

AX-22

Page 524 of 2898

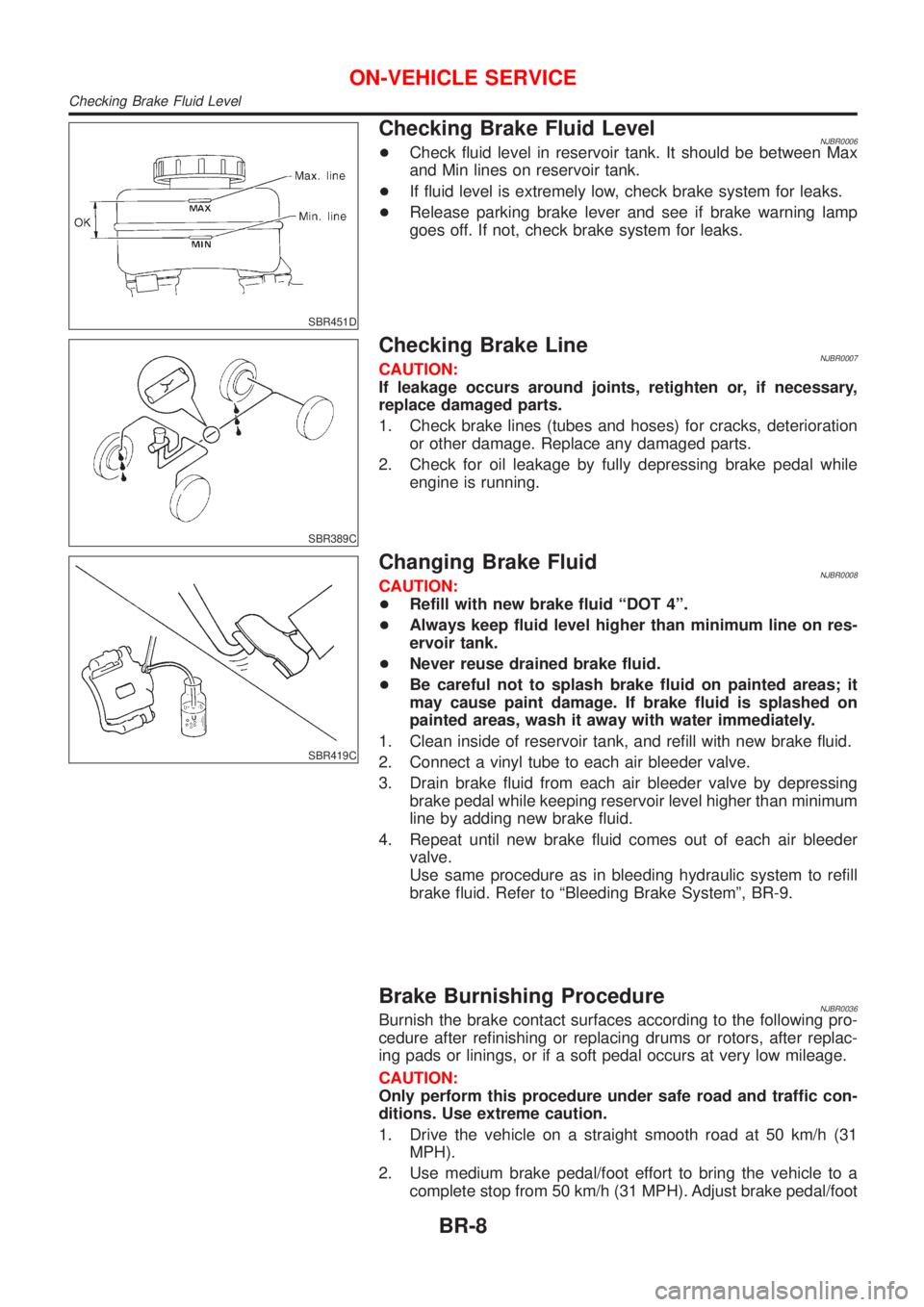

SBR451D

Checking Brake Fluid LevelNJBR0006+Check fluid level in reservoir tank. It should be between Max

and Min lines on reservoir tank.

+If fluid level is extremely low, check brake system for leaks.

+Release parking brake lever and see if brake warning lamp

goes off. If not, check brake system for leaks.

SBR389C

Checking Brake LineNJBR0007CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

1. Check brake lines (tubes and hoses) for cracks, deterioration

or other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running.

SBR419C

Changing Brake FluidNJBR0008CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Always keep fluid level higher than minimum line on res-

ervoir tank.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

1. Clean inside of reservoir tank, and refill with new brake fluid.

2. Connect a vinyl tube to each air bleeder valve.

3. Drain brake fluid from each air bleeder valve by depressing

brake pedal while keeping reservoir level higher than minimum

line by adding new brake fluid.

4. Repeat until new brake fluid comes out of each air bleeder

valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid. Refer to ªBleeding Brake Systemº, BR-9.

Brake Burnishing ProcedureNJBR0036Burnish the brake contact surfaces according to the following pro-

cedure after refinishing or replacing drums or rotors, after replac-

ing pads or linings, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic con-

ditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31

MPH).

2. Use medium brake pedal/foot effort to bring the vehicle to a

complete stop from 50 km/h (31 MPH). Adjust brake pedal/foot

ON-VEHICLE SERVICE

Checking Brake Fluid Level

BR-8

Page 528 of 2898

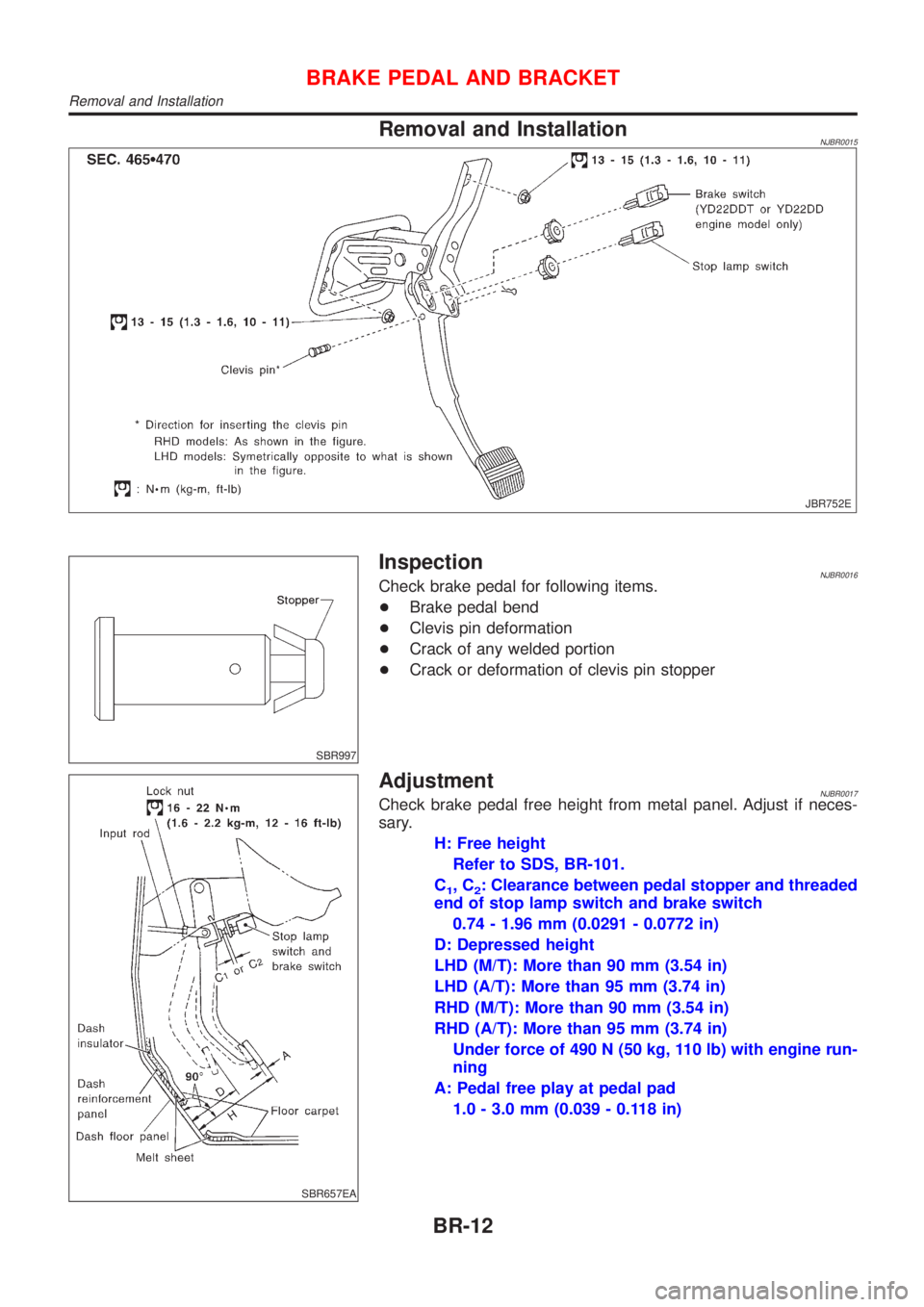

Removal and InstallationNJBR0015

JBR752E

SBR997

InspectionNJBR0016Check brake pedal for following items.

+Brake pedal bend

+Clevis pin deformation

+Crack of any welded portion

+Crack or deformation of clevis pin stopper

SBR657EA

AdjustmentNJBR0017Check brake pedal free height from metal panel. Adjust if neces-

sary.

H: Free height

Refer to SDS, BR-101.

C

1,C2: Clearance between pedal stopper and threaded

end of stop lamp switch and brake switch

0.74 - 1.96 mm (0.0291 - 0.0772 in)

D: Depressed height

LHD (M/T): More than 90 mm (3.54 in)

LHD (A/T): More than 95 mm (3.74 in)

RHD (M/T): More than 90 mm (3.54 in)

RHD (A/T): More than 95 mm (3.74 in)

Under force of 490 N (50 kg, 110 lb) with engine run-

ning

A: Pedal free play at pedal pad

1.0 - 3.0 mm (0.039 - 0.118 in)

BRAKE PEDAL AND BRACKET

Removal and Installation

BR-12

Page 529 of 2898

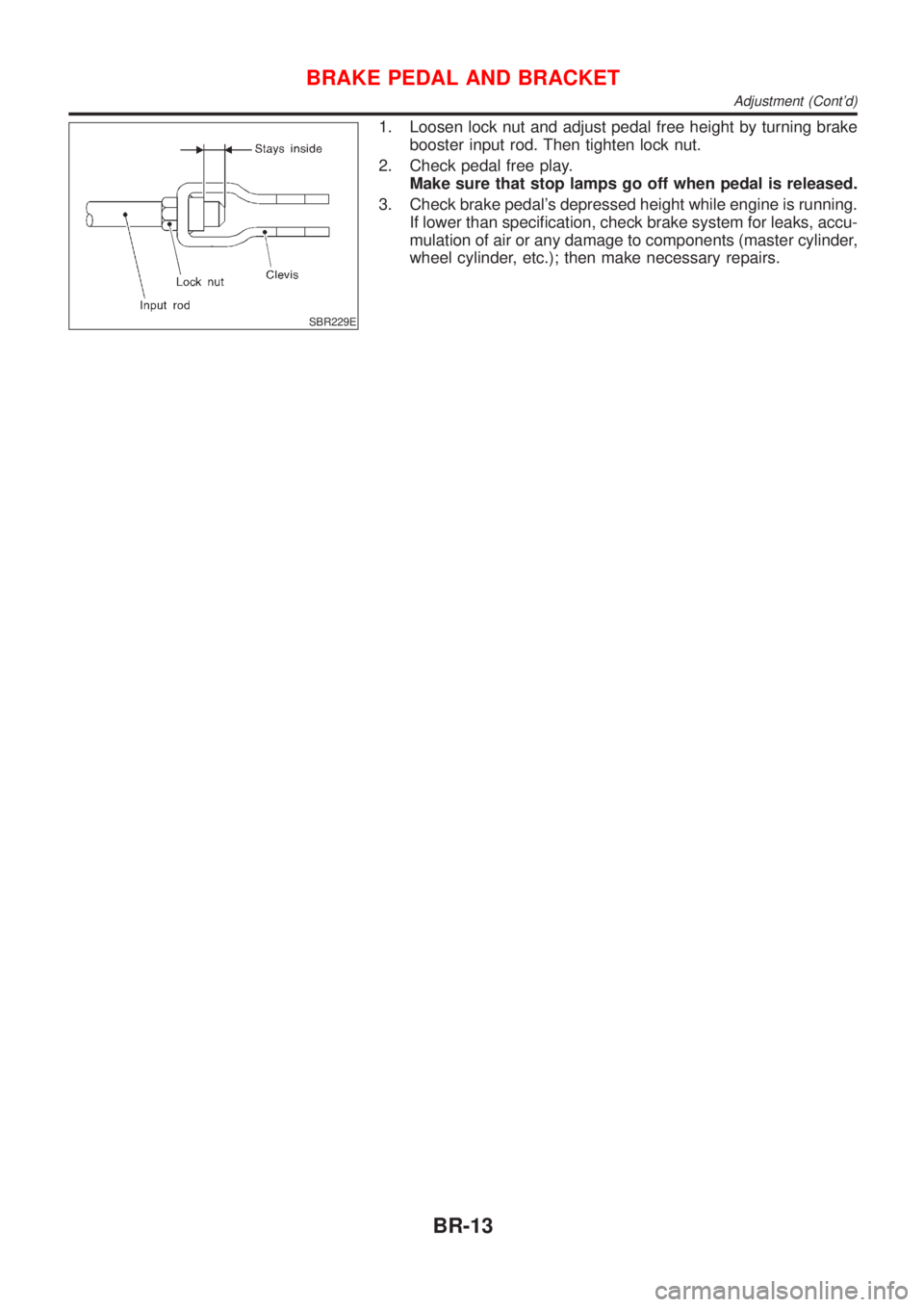

SBR229E

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

2. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

3. Check brake pedal's depressed height while engine is running.

If lower than specification, check brake system for leaks, accu-

mulation of air or any damage to components (master cylinder,

wheel cylinder, etc.); then make necessary repairs.

BRAKE PEDAL AND BRACKET

Adjustment (Cont'd)

BR-13

Page 536 of 2898

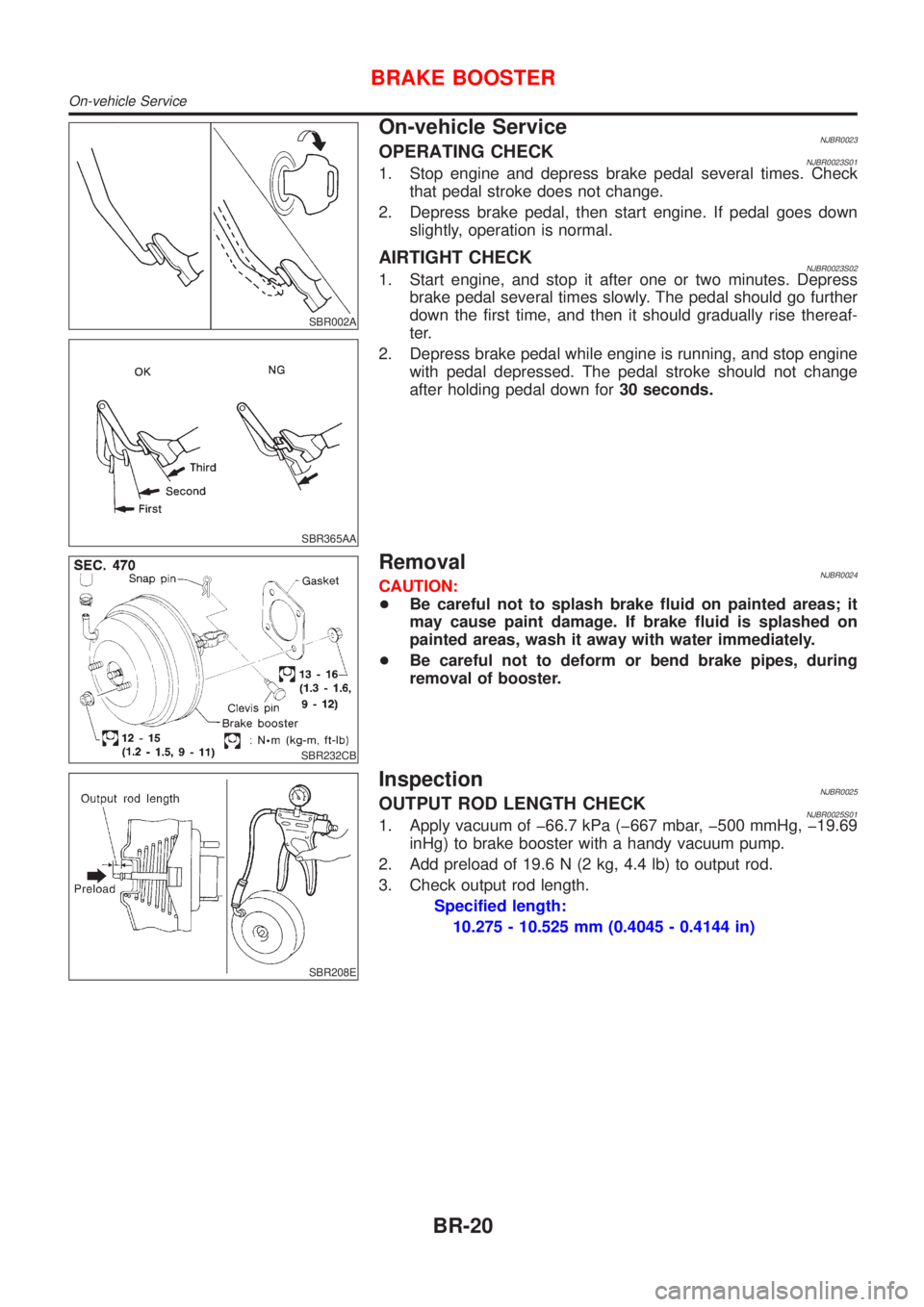

SBR002A

SBR365AA

On-vehicle ServiceNJBR0023OPERATING CHECKNJBR0023S011. Stop engine and depress brake pedal several times. Check

that pedal stroke does not change.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECKNJBR0023S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. The pedal should go further

down the first time, and then it should gradually rise thereaf-

ter.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR232CB

RemovalNJBR0024CAUTION:

+Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

+Be careful not to deform or bend brake pipes, during

removal of booster.

SBR208E

InspectionNJBR0025OUTPUT ROD LENGTH CHECKNJBR0025S011. Apply vacuum of þ66.7 kPa (þ667 mbar, þ500 mmHg, þ19.69

inHg) to brake booster with a handy vacuum pump.

2. Add preload of 19.6 N (2 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

BRAKE BOOSTER

On-vehicle Service

BR-20

Page 538 of 2898

SBR225B

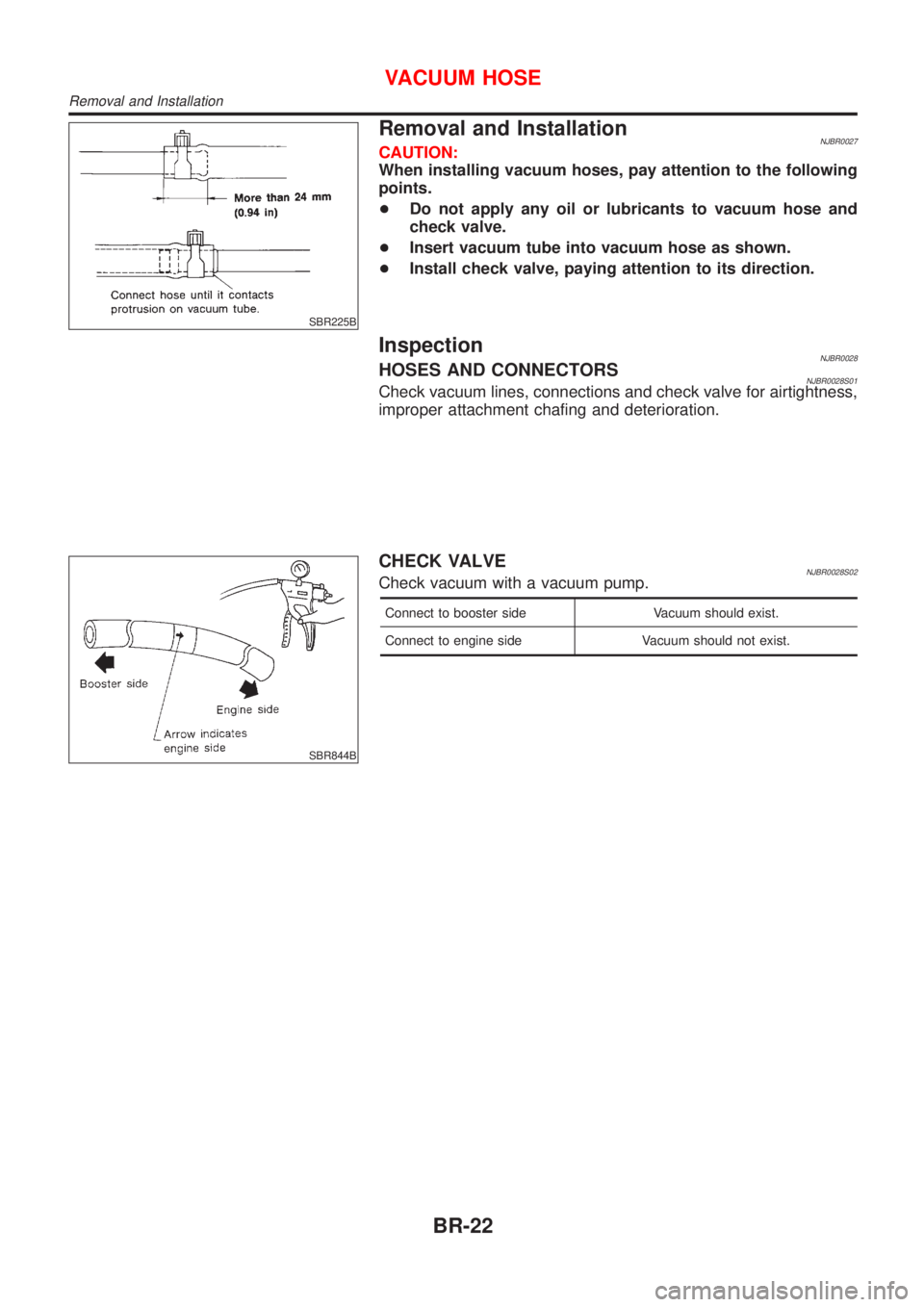

Removal and InstallationNJBR0027CAUTION:

When installing vacuum hoses, pay attention to the following

points.

+Do not apply any oil or lubricants to vacuum hose and

check valve.

+Insert vacuum tube into vacuum hose as shown.

+Install check valve, paying attention to its direction.

InspectionNJBR0028HOSES AND CONNECTORSNJBR0028S01Check vacuum lines, connections and check valve for airtightness,

improper attachment chafing and deterioration.

SBR844B

CHECK VALVENJBR0028S02Check vacuum with a vacuum pump.

Connect to booster side Vacuum should exist.

Connect to engine side Vacuum should not exist.

VACUUM HOSE

Removal and Installation

BR-22

Page 539 of 2898

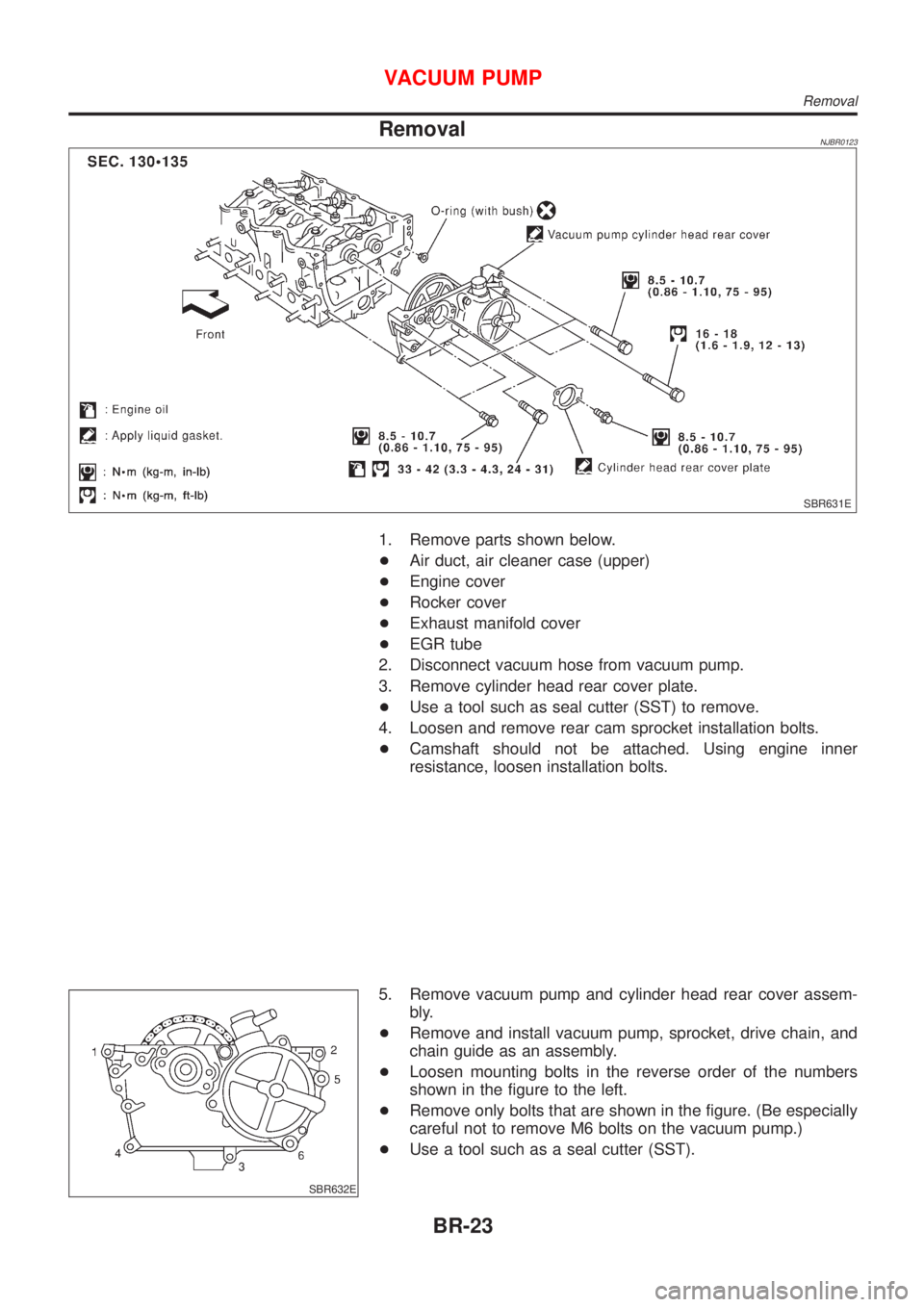

RemovalNJBR0123

SBR631E

1. Remove parts shown below.

+Air duct, air cleaner case (upper)

+Engine cover

+Rocker cover

+Exhaust manifold cover

+EGR tube

2. Disconnect vacuum hose from vacuum pump.

3. Remove cylinder head rear cover plate.

+Use a tool such as seal cutter (SST) to remove.

4. Loosen and remove rear cam sprocket installation bolts.

+Camshaft should not be attached. Using engine inner

resistance, loosen installation bolts.

SBR632E

5. Remove vacuum pump and cylinder head rear cover assem-

bly.

+Remove and install vacuum pump, sprocket, drive chain, and

chain guide as an assembly.

+Loosen mounting bolts in the reverse order of the numbers

shown in the figure to the left.

+Remove only bolts that are shown in the figure. (Be especially

careful not to remove M6 bolts on the vacuum pump.)

+Use a tool such as a seal cutter (SST).

VACUUM PUMP

Removal

BR-23