alternator NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2201 of 2898

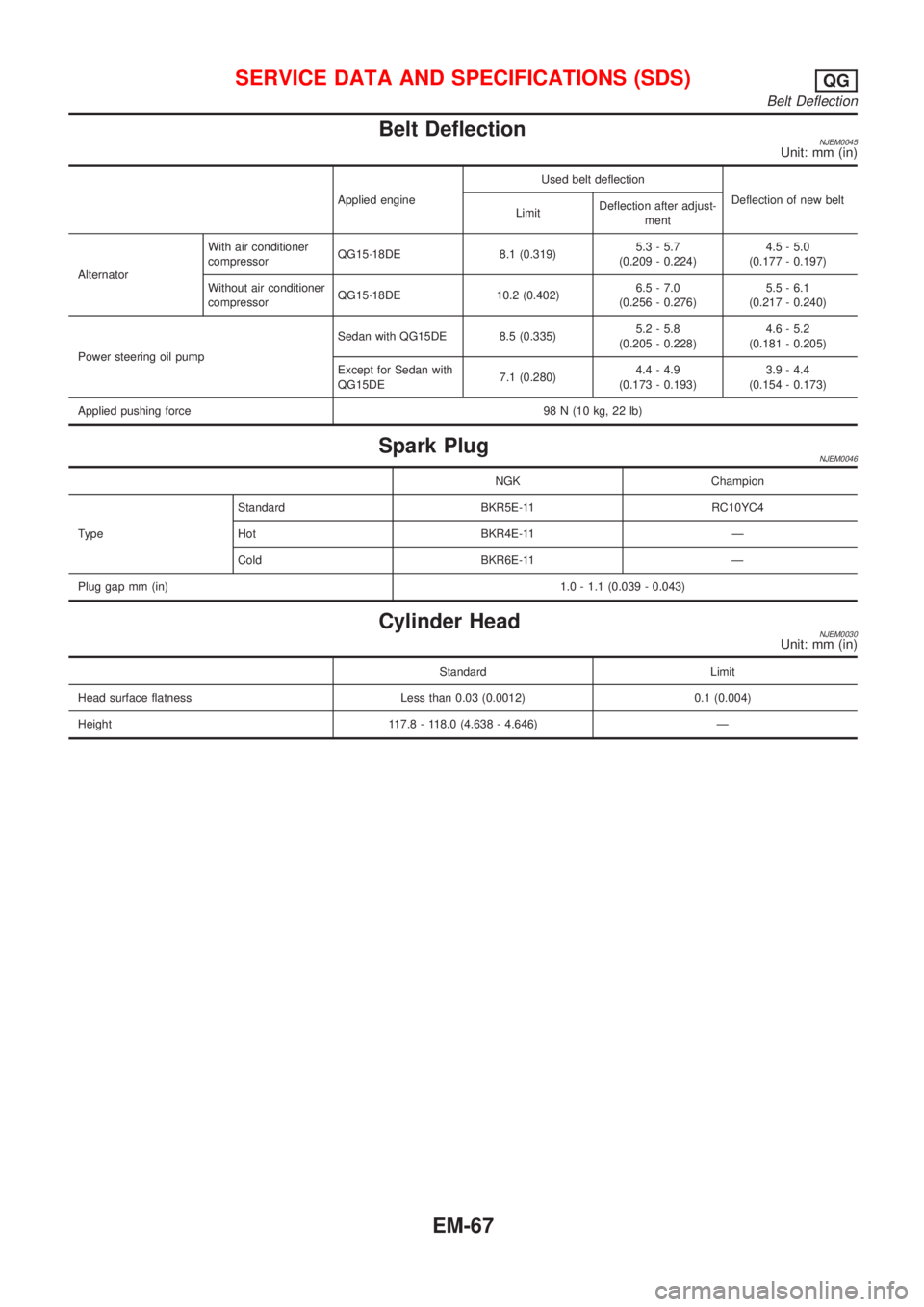

Belt DeflectionNJEM0045Unit: mm (in)

Applied engineUsed belt deflection

Deflection of new belt

LimitDeflection after adjust-

ment

AlternatorWith air conditioner

compressorQG15´18DE 8.1 (0.319)5.3 - 5.7

(0.209 - 0.224)4.5 - 5.0

(0.177 - 0.197)

Without air conditioner

compressorQG15´18DE 10.2 (0.402)6.5 - 7.0

(0.256 - 0.276)5.5 - 6.1

(0.217 - 0.240)

Power steering oil pumpSedan with QG15DE 8.5 (0.335)5.2 - 5.8

(0.205 - 0.228)4.6 - 5.2

(0.181 - 0.205)

Except for Sedan with

QG15DE7.1 (0.280)4.4 - 4.9

(0.173 - 0.193)3.9 - 4.4

(0.154 - 0.173)

Applied pushing force 98 N (10 kg, 22 lb)

Spark PlugNJEM0046

NGK Champion

TypeStandard BKR5E-11 RC10YC4

Hot BKR4E-11 Ð

Cold BKR6E-11 Ð

Plug gap mm (in)1.0 - 1.1 (0.039 - 0.043)

Cylinder HeadNJEM0030Unit: mm (in)

Standard Limit

Head surface flatness Less than 0.03 (0.0012) 0.1 (0.004)

Height 117.8 - 118.0 (4.638 - 4.646) Ð

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Belt Deflection

EM-67

Page 2219 of 2898

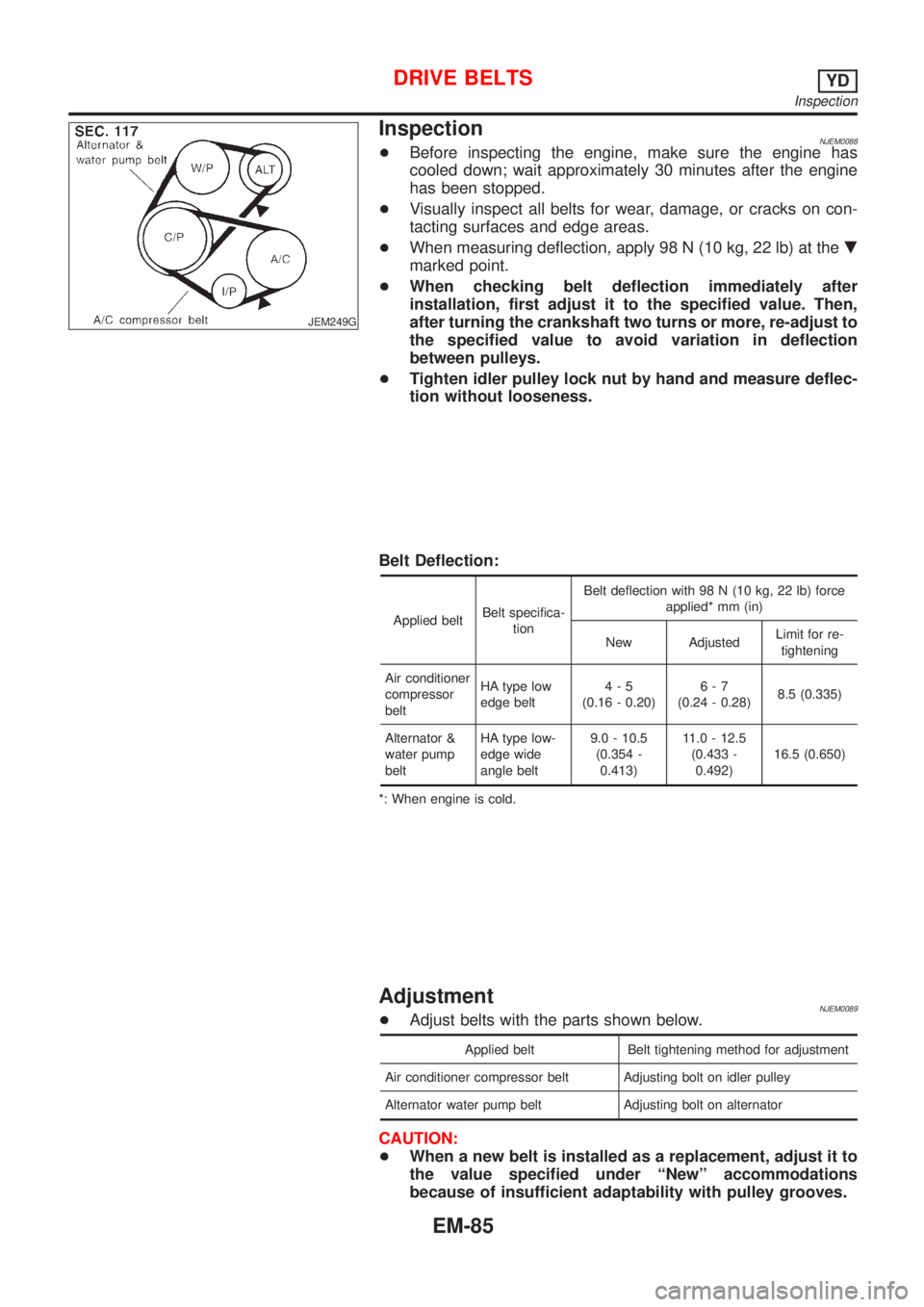

JEM249G

InspectionNJEM0088+Before inspecting the engine, make sure the engine has

cooled down; wait approximately 30 minutes after the engine

has been stopped.

+Visually inspect all belts for wear, damage, or cracks on con-

tacting surfaces and edge areas.

+When measuring deflection, apply 98 N (10 kg, 22 lb) at the.

marked point.

+When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

after turning the crankshaft two turns or more, re-adjust to

the specified value to avoid variation in deflection

between pulleys.

+Tighten idler pulley lock nut by hand and measure deflec-

tion without looseness.

Belt Deflection:

Applied beltBelt specifica-

tionBelt deflection with 98 N (10 kg, 22 lb) force

applied* mm (in)

New AdjustedLimit for re-

tightening

Air conditioner

compressor

beltHA type low

edge belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator &

water pump

beltHA type low-

edge wide

angle belt9.0 - 10.5

(0.354 -

0.413)11.0 - 12.5

(0.433 -

0.492)16.5 (0.650)

*: When engine is cold.

AdjustmentNJEM0089+Adjust belts with the parts shown below.

Applied belt Belt tightening method for adjustment

Air conditioner compressor belt Adjusting bolt on idler pulley

Alternator water pump belt Adjusting bolt on alternator

CAUTION:

+When a new belt is installed as a replacement, adjust it to

the value specified under ªNewº accommodations

because of insufficient adaptability with pulley grooves.

DRIVE BELTSYD

Inspection

EM-85

Page 2220 of 2898

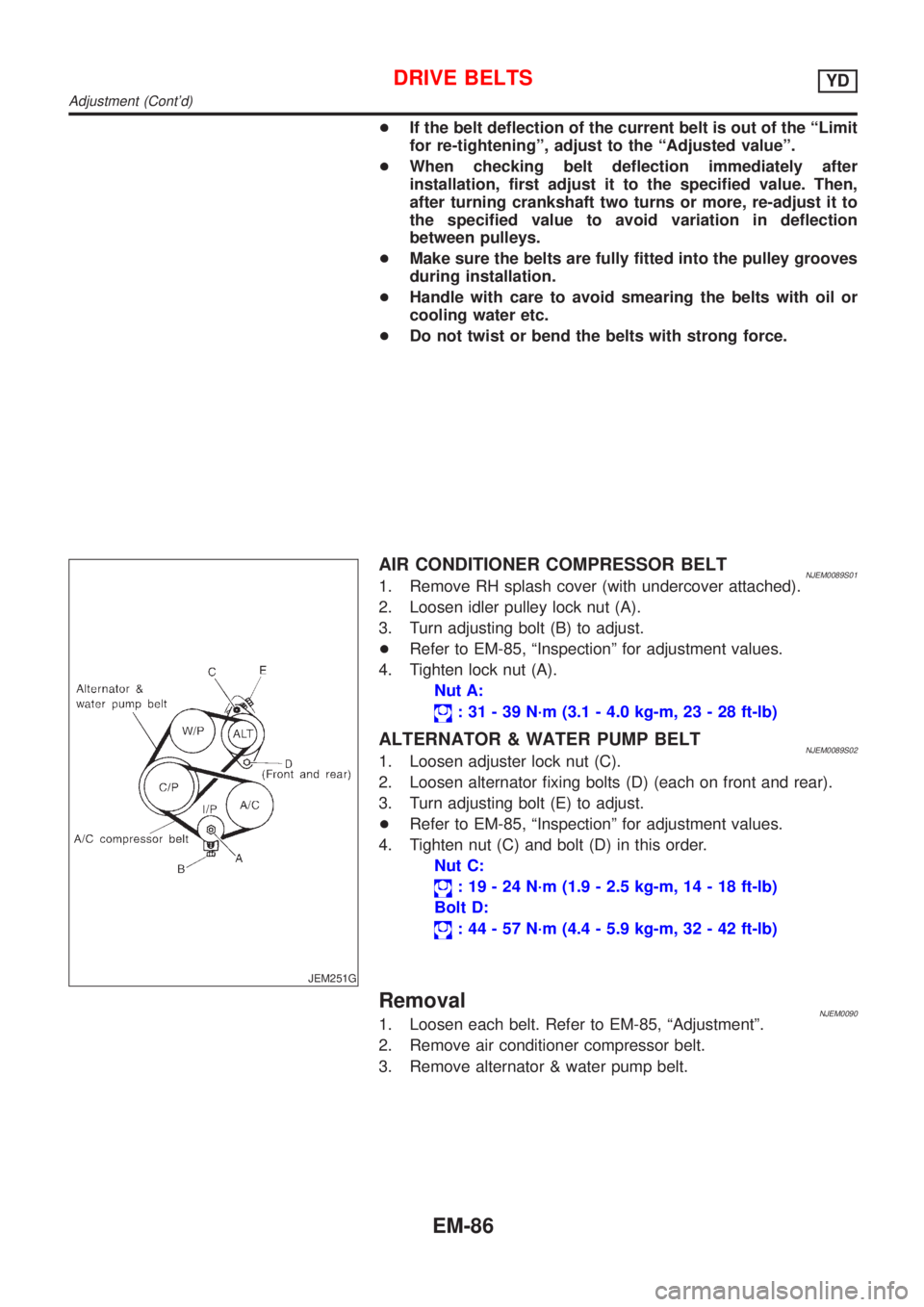

+If the belt deflection of the current belt is out of the ªLimit

for re-tighteningº, adjust to the ªAdjusted valueº.

+When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

after turning crankshaft two turns or more, re-adjust it to

the specified value to avoid variation in deflection

between pulleys.

+Make sure the belts are fully fitted into the pulley grooves

during installation.

+Handle with care to avoid smearing the belts with oil or

cooling water etc.

+Do not twist or bend the belts with strong force.

JEM251G

AIR CONDITIONER COMPRESSOR BELTNJEM0089S011. Remove RH splash cover (with undercover attached).

2. Loosen idler pulley lock nut (A).

3. Turn adjusting bolt (B) to adjust.

+Refer to EM-85, ªInspectionº for adjustment values.

4. Tighten lock nut (A).

Nut A:

: 31 - 39 N´m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

ALTERNATOR & WATER PUMP BELTNJEM0089S021. Loosen adjuster lock nut (C).

2. Loosen alternator fixing bolts (D) (each on front and rear).

3. Turn adjusting bolt (E) to adjust.

+Refer to EM-85, ªInspectionº for adjustment values.

4. Tighten nut (C) and bolt (D) in this order.

Nut C:

: 19 - 24 N´m (1.9 - 2.5 kg-m, 14 - 18 ft-lb)

Bolt D:

: 44 - 57 N´m (4.4 - 5.9 kg-m, 32 - 42 ft-lb)

RemovalNJEM00901. Loosen each belt. Refer to EM-85, ªAdjustmentº.

2. Remove air conditioner compressor belt.

3. Remove alternator & water pump belt.

DRIVE BELTSYD

Adjustment (Cont'd)

EM-86

Page 2272 of 2898

crankshaft position sensor (TDC sensor) from the assem-

bly.

+Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-44, ªChanging Engine Coolantº.

3. Remove the following parts:

+Battery

+RH and LH front wheels

+RH and LH splash covers (combined with undercover)

+Auxiliary belts

+Alternator

+Alternator brackets

+Radiator and cooling fan

+Engine cover

+Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

+Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

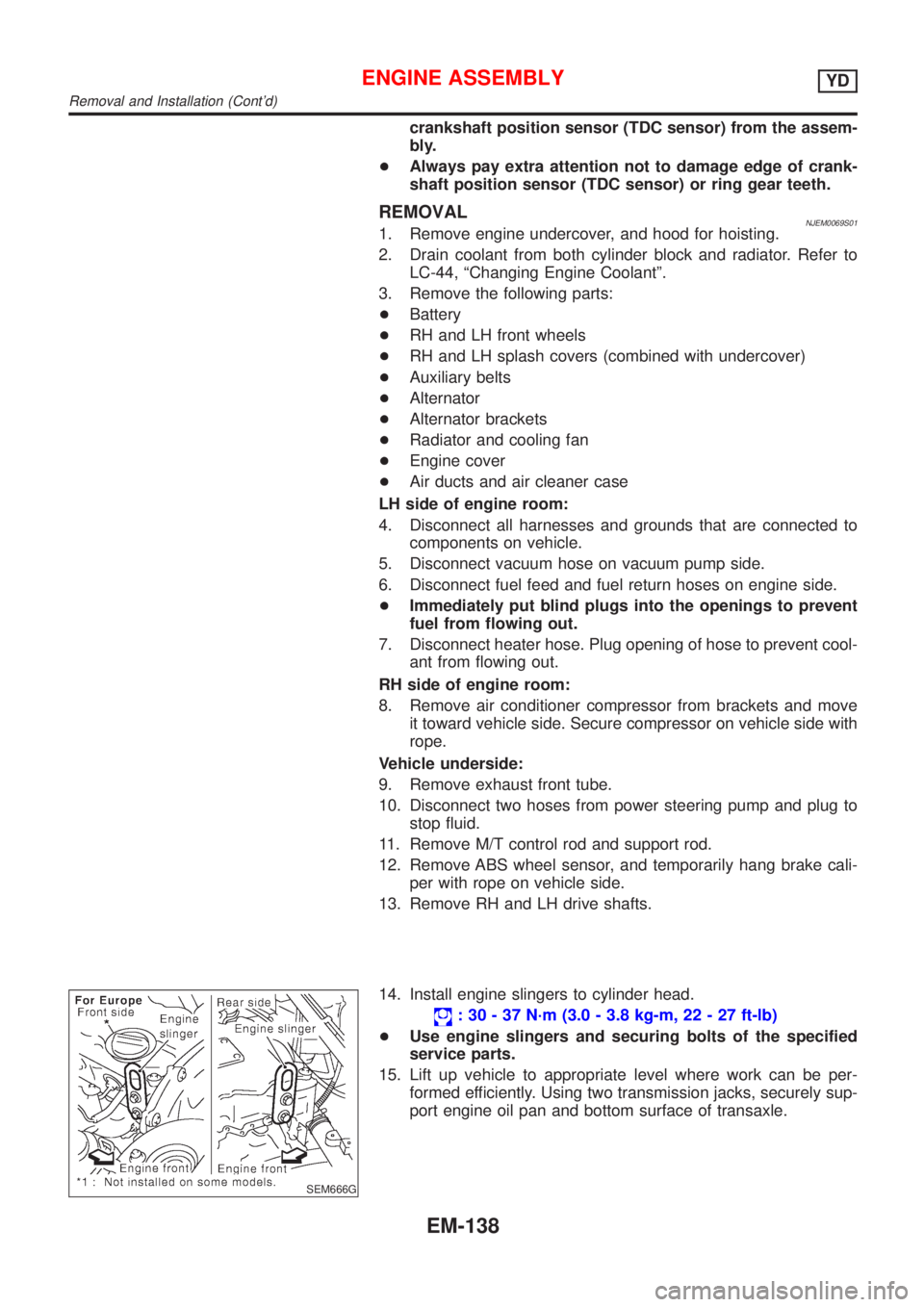

SEM666G

14. Install engine slingers to cylinder head.

: 30 - 37 N´m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

+Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont'd)

EM-138

Page 2292 of 2898

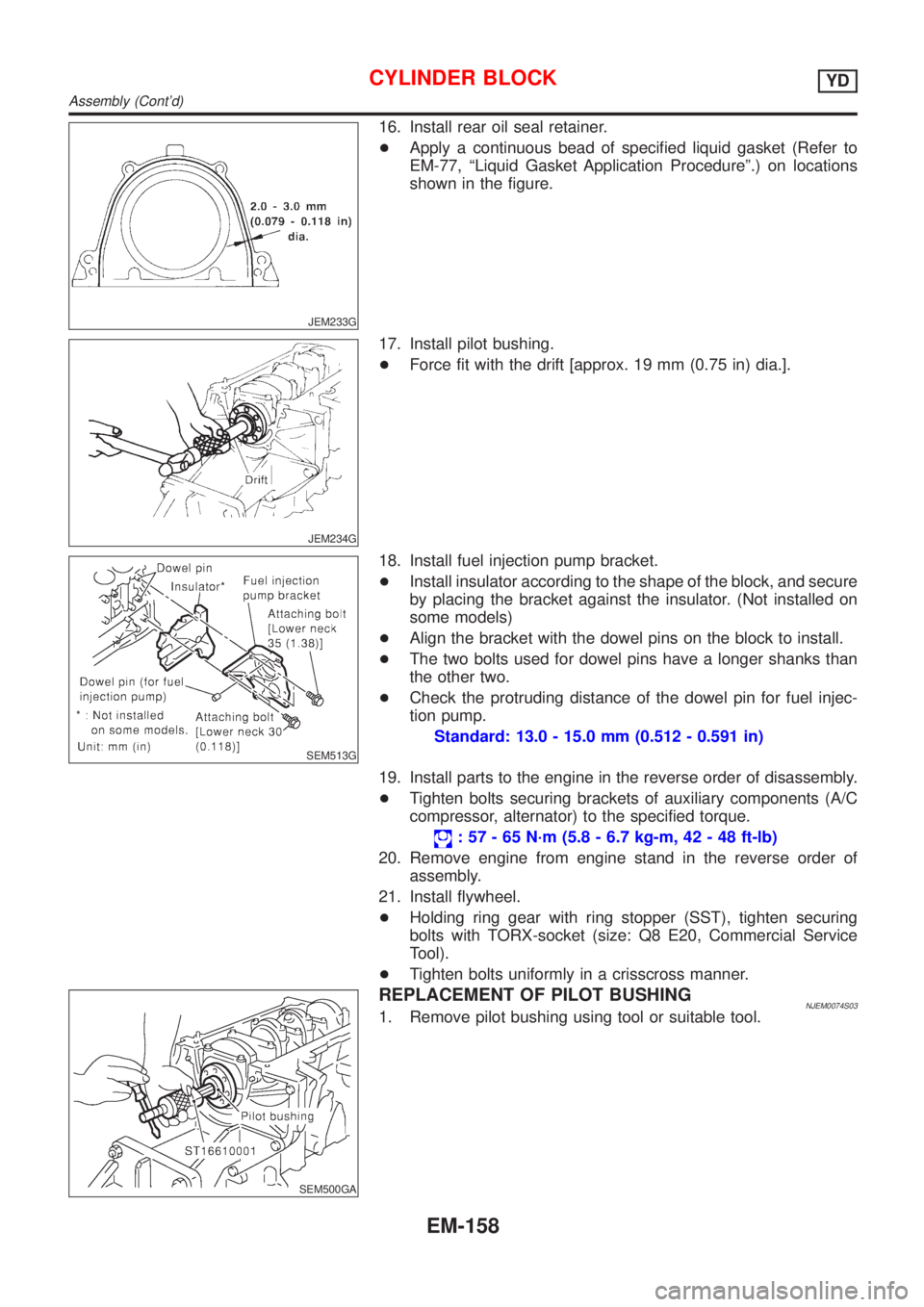

JEM233G

16. Install rear oil seal retainer.

+Apply a continuous bead of specified liquid gasket (Refer to

EM-77, ªLiquid Gasket Application Procedureº.) on locations

shown in the figure.

JEM234G

17. Install pilot bushing.

+Force fit with the drift [approx. 19 mm (0.75 in) dia.].

SEM513G

18. Install fuel injection pump bracket.

+Install insulator according to the shape of the block, and secure

by placing the bracket against the insulator. (Not installed on

some models)

+Align the bracket with the dowel pins on the block to install.

+The two bolts used for dowel pins have a longer shanks than

the other two.

+Check the protruding distance of the dowel pin for fuel injec-

tion pump.

Standard: 13.0 - 15.0 mm (0.512 - 0.591 in)

19. Install parts to the engine in the reverse order of disassembly.

+Tighten bolts securing brackets of auxiliary components (A/C

compressor, alternator) to the specified torque.

: 57 - 65 N´m (5.8 - 6.7 kg-m, 42 - 48 ft-lb)

20. Remove engine from engine stand in the reverse order of

assembly.

21. Install flywheel.

+Holding ring gear with ring stopper (SST), tighten securing

bolts with TORX-socket (size: Q8 E20, Commercial Service

Tool).

+Tighten bolts uniformly in a crisscross manner.

SEM500GA

REPLACEMENT OF PILOT BUSHINGNJEM0074S031. Remove pilot bushing using tool or suitable tool.

CYLINDER BLOCKYD

Assembly (Cont'd)

EM-158

Page 2294 of 2898

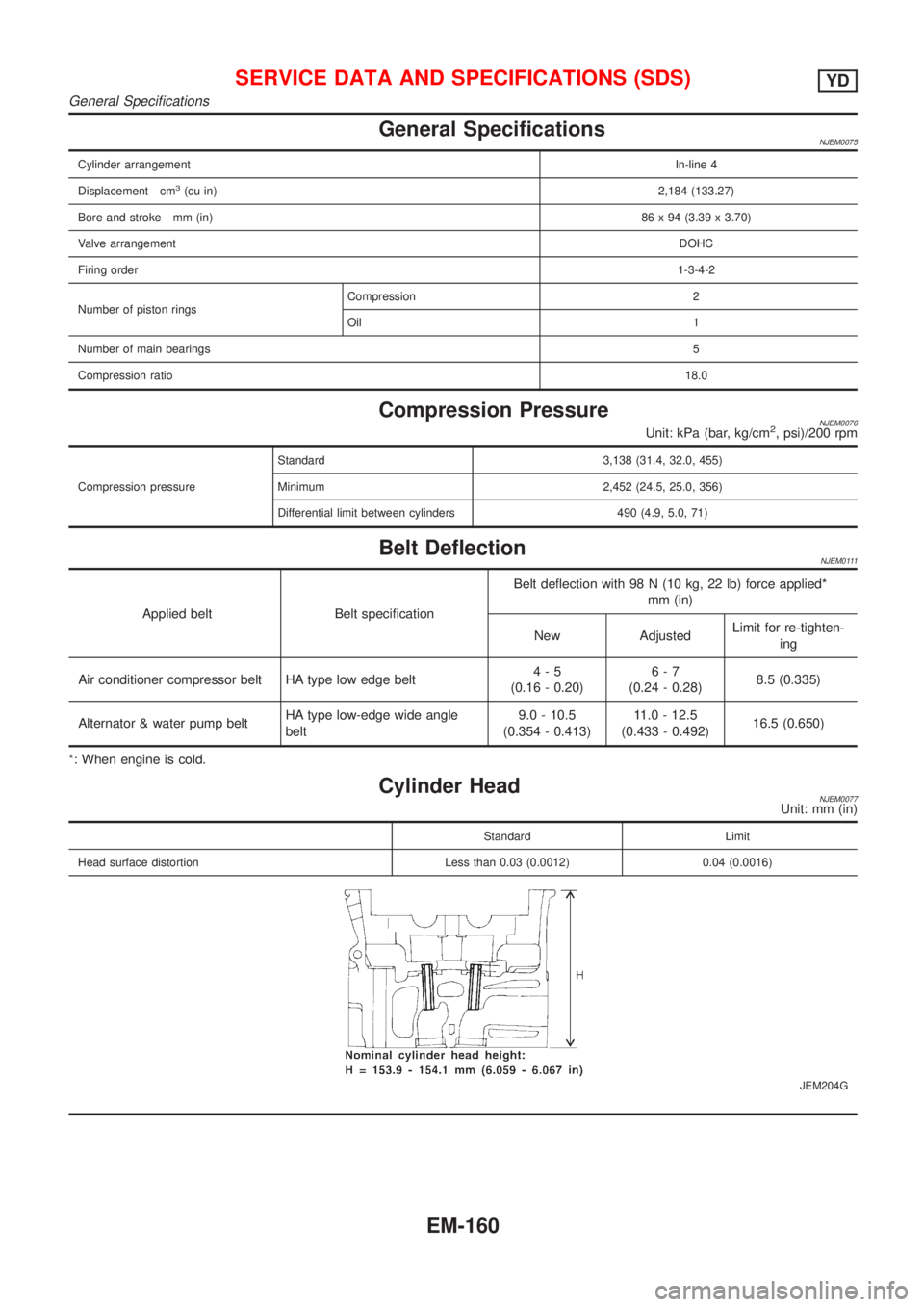

General SpecificationsNJEM0075

Cylinder arrangementIn-line 4

Displacement cm

3(cu in)2,184 (133.27)

Bore and stroke mm (in)86 x 94 (3.39 x 3.70)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio18.0

Compression PressureNJEM0076Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 3,138 (31.4, 32.0, 455)

Minimum 2,452 (24.5, 25.0, 356)

Differential limit between cylinders 490 (4.9, 5.0, 71)

Belt DeflectionNJEM0111

Applied belt Belt specificationBelt deflection with 98 N (10 kg, 22 lb) force applied*

mm (in)

New AdjustedLimit for re-tighten-

ing

Air conditioner compressor belt HA type low edge belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator & water pump beltHA type low-edge wide angle

belt9.0 - 10.5

(0.354 - 0.413)11.0 - 12.5

(0.433 - 0.492)16.5 (0.650)

*: When engine is cold.

Cylinder HeadNJEM0077Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.04 (0.0016)

JEM204G

SERVICE DATA AND SPECIFICATIONS (SDS)YD

General Specifications

EM-160

Page 2500 of 2898

A

A/C HFC134a (R134a) system precaution . HA-2

A/C HFC134a (R134a) system service

procedure .............................................. HA-78

A/C HFC134a (R134a) system service

tools ....................................................... HA-11

A/C HFC134a system service equip-

ment precaution ....................................... HA-6

A/C air flow ............................................... HA-20

A/C component layout .............................. HA-18

A/C compressor clutch removal and

installation .............................................. HA-83

A/C compressor precaution ........................ HA-5

A/C compressor special service tool .......... HA-9

A/C control linkage adjustment

(manual A/C) ......................................... HA-41

A/C control operation (manual A/C) .......... HA-19

A/C diagnostic work flow

(manual A/C) ........................................ HA-33

A/C harness layout (manual A/C) ............. HA-22

A/C lubricant (R134a) ............................... HA-80

A/C operational check ............................... HA-34

A/C performance chart .............................. HA-71

A/C performance test diagnoses .............. HA-69

A/C relay ................................................... HA-66

A/C service data specification .................. HA-97

A/C switch ................................................. HA-67

A/C, M - Wiring diagram ........................... HA-27

A/CCUT - Wiring diagram ....................... EC-830

A/T - Wiring diagram - AT - 1ST .............. AT-207

A/T - Wiring diagram - AT - 2ND ............. AT-214

A/T - Wiring diagram - AT - 3RD ............. AT-220

A/T - Wiring diagram - AT - 4TH .............. AT-227

A/T - Wiring diagram - AT - BA/FTS ....... AT-167,

276

A/T - Wiring diagram - AT - ENG SS ...... AT-173,

201

A/T - Wiring diagram - AT - FTS .............. AT-191

A/T - Wiring diagram - AT - LPSV ... AT-178, 241

A/T - Wiring diagram - AT - MAIN ........... AT-123

A/T - Wiring diagram - AT -

NONDTC .............................................. AT-292

A/T - Wiring diagram - AT -

OVRCSV ...................................... AT-155, 270

A/T - Wiring diagram - AT - PNP/SW ...... AT-185

A/T - Wiring diagram - AT - SSV/A .. AT-144, 248

A/T - Wiring diagram - AT - SSV/B .. AT-150, 254

A/T - Wiring diagram - AT - TCV ..... AT-161, 235

A/T - Wiring diagram - AT - TPS ..... AT-136, 261

A/T - Wiring diagram - AT - VSS/AT ....... AT-128,

197

A/T - Wiring diagram - AT -

VSSMTR ...................................... AT-132, 283

A/T IND - Wiring diagram ........................ EL-195

A/T control ............................................... EC-532

A/T diagnosis communication line .......... EC-434

A/T fluid temperature sensor ................... AT-194A/T shift lock system - Wiring

diagram ................................................ AT-344

A/T shift lock system ................................ AT-343

A/T trouble diagnoses .......................... AT-69, 74

AAC/V - Wiring diagram ................. EC-378, 513

ABS (anti-lock brake system) ................... BR-49

ABS - Wiring diagram ............................... BR-54

ABS sensor rotor ....................................... AX-24

APS - Wiring diagram ............................. EC-685

ATDIAG - Wiring diagram ............... EC-435, 533

Accelerator control system .................... FE-3, 19

Accelerator position sensor .................... EC-685

Air bag disposal ........................................ RS-40

Air bag precautions ...................................... GI-3

Air bag ....................................................... RS-20

Air bleeding (hydraulic clutch) ................... CL-10

Air bleeding for brake system ..................... BR-9

Air conditioner cut control ................. EC-35, 612

Air flow meter - See Mass air flow

sensor .......................................... EC-187, 673

Air mix door control linkage

adjustment ............................................. HA-43

Air spoiler, rear .......................................... BT-47

Alternator ................................................... SC-31

Angular tightening application .............. EM-4, 77

Antenna - See Power antenna ................ EL-282

Anti-lock brake system - Wiring

diagram .................................................. BR-54

Audio and A/C control removal and

installation - See Instrument panel ........ BT-25

Audio ........................................................ EL-258

Automatic transaxle number ...................... GI-41

Auxiliary air control (AAC) valve ..... EC-376, 511

B

Back-up lamp switch (M/T) ....................... MT-21

Back-up lamp ............................................. EL-87

Ball joint (front) .......................................... SU-13

Basic inspection ...................... EC-100, 128, 641

Battery ......................................................... SC-3

Baulk ring (M/T) ............................ MT-31, 55, 93

Blower motor ............................................. HA-54

Blower resistor .......................................... HA-54

Board-on lift ................................................ GI-44

Body alignment .......................................... BT-77

Brake booster ............................................ BR-20

Brake fluid change ...................................... BR-8

Brake fluid level and line check .................. BR-8

Brake hydraulic line .................................. BR-10

Brake master cylinder ............................... BR-14

Brake pedal ............................................... BR-12

Bulb specifications ................................... EL-574

Bumper, front .............................................. BT-7

Bumper, rear .............................................. BT-10

ALPHABETICAL INDEX

IDX-2

Page 2502 of 2898

Electronic fuel injection pump ........ EC-618, 716,

723, 757, 764, 771, 778, 785, 803

Engine compartment ................................. BT-78

Engine control circuit diagram .......... EC-25, 606

Engine control component parts

location .......................................... EC-21, 603

Engine control module (ECM) ....... EC-391, 659,

714, 792, 794, 799, 801

Engine control system diagram and

chart .............................................. EC-29, 608

Engine coolant temperature sensor

(ECTS) ........................................ EC-201, 680

Engine fail-safe system ........................... EC-154

Engine oil precautions .................................. GI-7

Engine outer component parts ................. EM-11

Engine removal ................................ EM-51, 137

Engine room - See Engine

compartment .......................................... BT-78

Engine serial number ................................. GI-41

Evaporative emission (EVAP)

system ................................................... EC-36

Exhaust gas recirculation (EGR)

valve .................................... EC-343, 425, 491

Exhaust system ................................... FE-15, 32

Exterior ...................................................... BT-47

F

F/PUMP - Wiring diagram ....................... EC-563

FR02 - Wiring diagram ... EC-219, 239, 247, 451

FR02/H - Wiring diagram ................ EC-254, 458

FUEL - Wiring diagram ................... EC-299, 307

Fan switch ................................................. HA-54

Final drive (FF A/T) .................................. AT-442

Final drive (FF M/T) .............. MT-44, 77, 93, 107

Finisher, interior - See Trim ....................... BT-31

Finisher, trunk lid ....................................... BT-45

Floor trim ................................................... BT-31

Fluid temperature sensor (A/T) ................ AT-194

Fluids ........................................................ MA-16

Flywheel (clutch) ....................................... CL-22

Flywheel runout ................................ EM-62, 154

Fog lamp, front, removal and

installation ................................................ BT-7

Fog lamp, front .......................................... EL-89

Fork rod (M/T) .............................. MT-32, 56, 94

Forward clutch ......................................... AT-412

Freeze frame data .............................. EC-61, 72

Front axle .................................................... AX-2

Front bumper ............................................... BT-7

Front combination lamp removal and

installation ................................................ BT-7

Front disc brake ........................................ BR-27

Front door .................................................. BT-16

Front fog lamp removal and

installation ................................................ BT-7

Front fog lamp ........................................... EL-89

Front heated oxygen sensor (HO2S)

heater .......................................... EC-252, 457Front heated oxygen sensor (HO2S) ..... EC-216,

224, 230, 236, 245, 450

Front seat belt ............................................. RS-5

Front seat .................................................. BT-56

Front suspension ........................................ SU-2

Front washer ............................................ EL-215

Front wiper ............................................... EL-215

Fuel cut control (at no load & high

engine speed) ............................... EC-36, 612

Fuel gauge ............................................... EL-144

Fuel injection system .............. EC-297, 305, 610

Fuel injector ............................................ EC-541

Fuel precautions ........................................... GI-8

Fuel pressure check ................................. EC-40

Fuel pressure regulator ............................. EC-41

Fuel pressure release ............................... EC-40

Fuel pump relay ...................................... EC-561

Fuel pump ............................................... EC-561

Fuel system ........................................... FE-5, 20

Fuel tank vacuum relief valve ................... EC-37

Fuse block ............................................... EL-577

Fuse ........................................................... EL-38

Fusible link ................................................. EL-38

G

GLOW - Wiring diagram ......................... EC-806

Garage jack and safety stand .................... GI-45

Gauges .................................................... EL-144

Gear components (M/T) ............... MT-31, 55, 93

Generator - See Alternator ....................... SC-31

Generic scan tool (GST) ........................... EC-94

Glass .......................................................... BT-17

Glow plug ................................................ EC-806

Glow relay ............................................... EC-806

Grease ...................................................... MA-16

Ground distribution .................................... EL-39

H

H/LAMP - Wiring diagram ................... EL-60, 61

HEATER - Wiring diagram ........................ HA-24

HFC134a (R134a) system

precaution ................................................ HA-2

HFC134a (R134a) system service

procedure .............................................. HA-78

HFC134a (R134a) system service

tools ....................................................... HA-11

HFC134a system service equipment

precaution ................................................ HA-6

HORN - Wiring diagram .................. EL-234, 235

HSEAT - Wiring diagram ................. EL-288, 290

Harness connector ...................................... EL-6

Harness layout ......................................... EL-522

Hazard warning lamp ................................ EL-96

Headlamp removal and installation ............. BT-7

Headlamp washer .................................... EL-231

Headlamp .................................................. EL-60

ALPHABETICAL INDEX

IDX-4

Page 2797 of 2898

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -/Sedan .............................14

M/T MODELS..........................................................14

A/T MODELS...........................................................15

Wiring Diagram - START -/Hatchback.......................16

Trouble Diagnoses.....................................................17

Construction ...............................................................18

Removal and Installation ...........................................21

REMOVAL...............................................................21

INSTALLATION........................................................21

Inspection...................................................................21

MAGNETIC SWITCH CHECK...................................21

PINION/CLUTCH CHECK.........................................21

BRUSH CHECK.......................................................22

YOKE CHECK.........................................................23

ARMATURE CHECK................................................23

Assembly ...................................................................24

PINION PROTRUSION LENGTH ADJUSTMENT........24

CHARGING SYSTEM....................................................26

System Description ....................................................26

SEDAN...................................................................26

HATCHBACK...........................................................26

Wiring Diagram - CHARGE -/Sedan .........................27

GASOLINE ENGINE MODELS..................................27

DIESEL ENGINE MODELS.......................................28

Wiring Diagram - CHARGE -/Hatchback...................29

Trouble Diagnoses.....................................................30

WITH IC REGULATOR.............................................30

MALFUNCTION INDICATOR....................................30

Construction ...............................................................31

Removal and Installation ...........................................34

REMOVAL (QG ENGINE).........................................34

REMOVAL (YD ENGINE)..........................................34

INSTALLATION........................................................35

Disassembly...............................................................35

REAR COVER.........................................................35

REAR BEARING......................................................35

Inspection...................................................................35

ROTOR CHECK......................................................35

BRUSH CHECK.......................................................36

STATOR CHECK.....................................................36

Assembly ...................................................................36

RING FITTING IN REAR BEARING...........................36

REAR COVER INSTALLATION.................................37

SERVICE DATA AND SPECIFICATIONS (SDS).........38

Battery........................................................................38

Starter ........................................................................38

Alternator ...................................................................39

Page 2822 of 2898

System DescriptionNJSC0009SEDANNJSC0009S01The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (A/T models with QG13DE engine and M/T models with gasoline engine) or 100A (A/T models

except QG13DE engine and diesel engine models) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 17 (Models with tachometer) or 22 (Models without tachometer) for the

charge warning lamp.

Ground is supplied to terminal 62 (Models with tachometer) or 61 (Models without tachometer) of the combi-

nation meter through terminal 3 (L) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

HATCHBACKNJSC0009S02The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (Gasoline engine models without daytime light system) or 100A (A/T models, diesel engine mod-

els and gasoline engine models with daytime light system) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 40 or 1

Ground is supplied to terminal 1 or 28 of the combination meter through terminal 3 (L) of the alternator. With

power and ground supplied, the charge warning lamp will illuminate. When the alternator is providing suffi-

cient voltage with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

CHARGING SYSTEM

System Description

SC-26