charging NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2478 of 2898

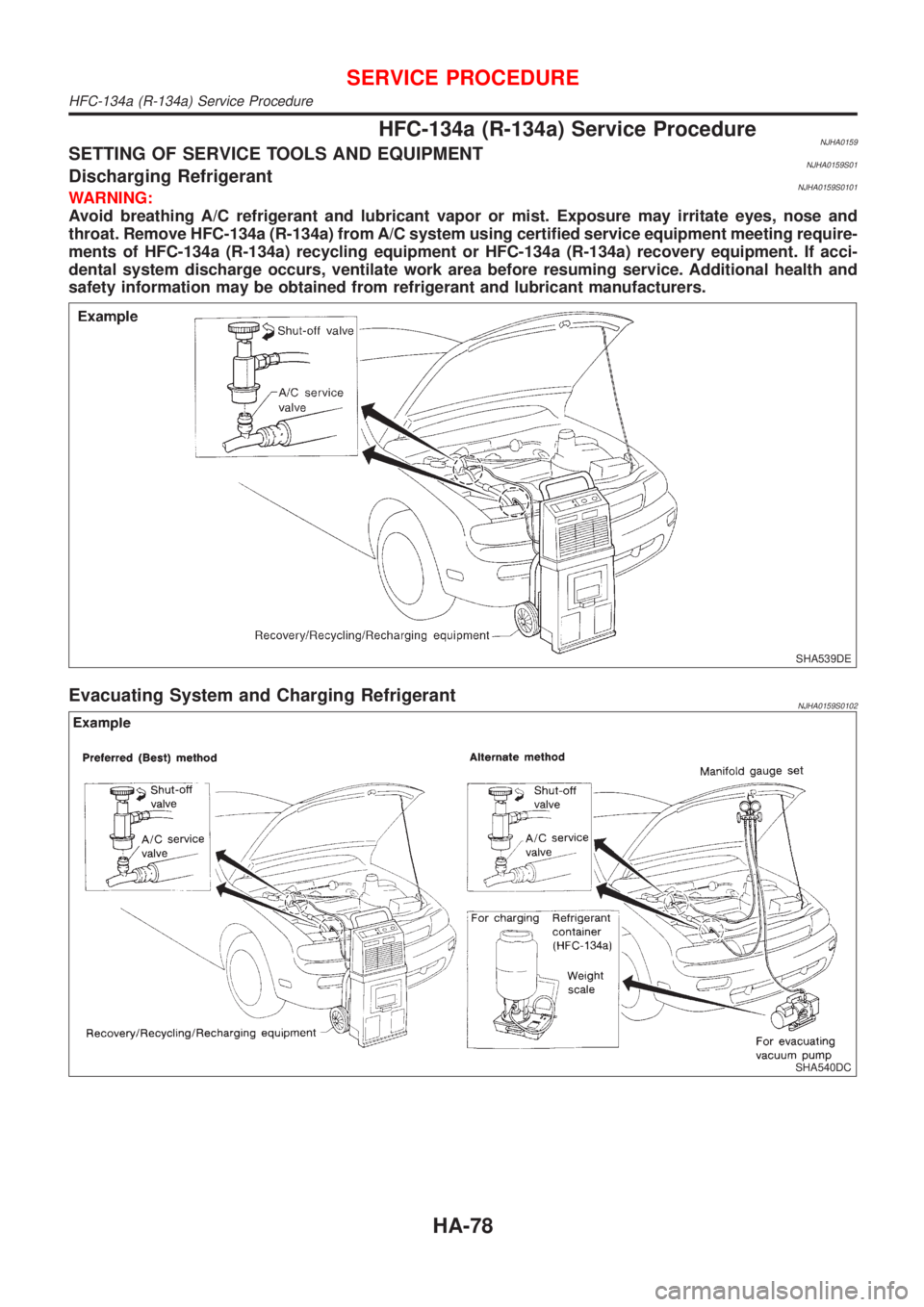

HFC-134a (R-134a) Service ProcedureNJHA0159SETTING OF SERVICE TOOLS AND EQUIPMENTNJHA0159S01Discharging RefrigerantNJHA0159S0101WARNING:

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) from A/C system using certified service equipment meeting require-

ments of HFC-134a (R-134a) recycling equipment or HFC-134a (R-134a) recovery equipment. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and lubricant manufacturers.

SHA539DE

Evacuating System and Charging RefrigerantNJHA0159S0102

SHA540DC

SERVICE PROCEDURE

HFC-134a (R-134a) Service Procedure

HA-78

Page 2482 of 2898

Lubricant Adjusting Procedure for Components

Replacement Except Compressor

=NJHA0160S0201After replacing any of the following major components, add the

correct amount of lubricant to the system.

Amount of lubricant to be added

Part replacedLubricant to be added to

system

Remarks

Amount of lubricant

m!(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is not

replaced. *1

In case of refrigerant

leak30 (1.1) Large leak

Ð Small leak *2

*1: If compressor is replaced, addition of lubricant is included in the table.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor

Replacement

NJHA0160S02021. Discharge refrigerant into the refrigerant recovery/recycling

equipment. Measure lubricant discharged into the recovery/

recycling equipment.

2. Drain the lubricant from the ªoldº (removed) compressor into a

graduated container and recover the amount of lubricant

drained.

3. Drain the lubricant from the ªnewº compressor into a separate,

clean container.

4. Measure an amount of new lubricant installed equal to amount

drained from ªoldº compressor. Add this lubricant to ªnewº com-

pressor through the suction port opening.

5. Measure an amount of new lubricant equal to the amount

recovered during discharging. Add this lubricant to ªnewº com-

pressor through the suction port opening.

6. If the liquid tank also needs to be replaced, add an additional

5m!(0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m!(0.2 Imp fl oz) of lubricant if only

replacing the compressor.

SERVICE PROCEDURE

Maintenance of Lubricant Quantity in Compressor (Cont'd)

HA-82

Page 2497 of 2898

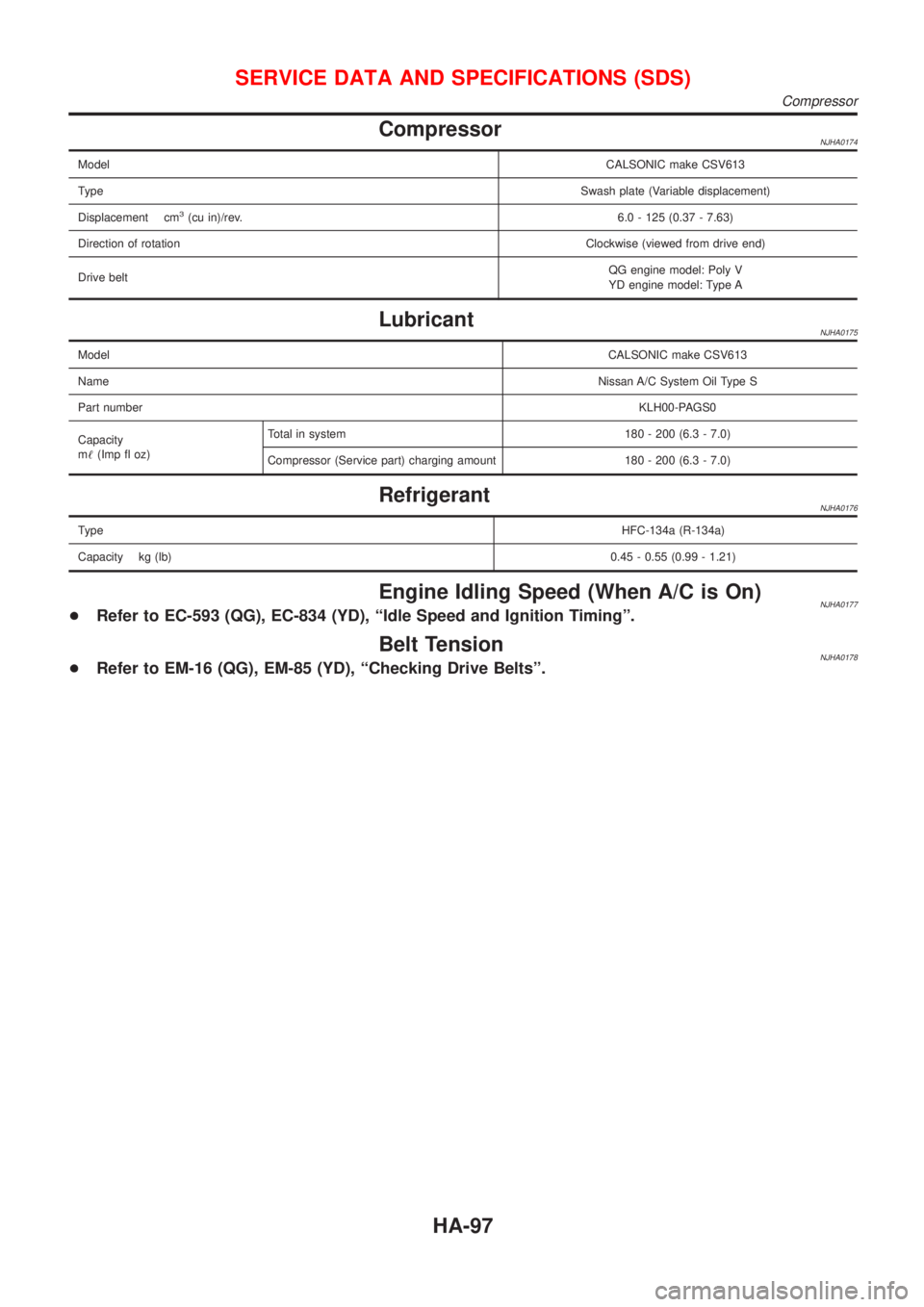

CompressorNJHA0174

ModelCALSONIC make CSV613

TypeSwash plate (Variable displacement)

Displacement cm

3(cu in)/rev.6.0 - 125 (0.37 - 7.63)

Direction of rotationClockwise (viewed from drive end)

Drive beltQG engine model: Poly V

YD engine model: Type A

LubricantNJHA0175

ModelCALSONIC make CSV613

NameNissan A/C System Oil Type S

Part numberKLH00-PAGS0

Capacity

m!(Imp fl oz)Total in system 180 - 200 (6.3 - 7.0)

Compressor (Service part) charging amount 180 - 200 (6.3 - 7.0)

RefrigerantNJHA0176

TypeHFC-134a (R-134a)

Capacity kg (lb)0.45 - 0.55 (0.99 - 1.21)

Engine Idling Speed (When A/C is On)NJHA0177+Refer to EC-593 (QG), EC-834 (YD), ªIdle Speed and Ignition Timingº.

Belt TensionNJHA0178+Refer to EM-16 (QG), EM-85 (YD), ªChecking Drive Beltsº.

SERVICE DATA AND SPECIFICATIONS (SDS)

Compressor

HA-97

Page 2501 of 2898

C

CHARGE - Wiring diagram ....................... SC-27

CHIME - Wiring diagram ................. EL-199, 207

CIGAR - Wiring diagram ................. EL-236, 237

CKPS - Wiring diagram .......... EC-330, 485, 695

CMPS - Wiring diagram .......................... EC-337

CONSULT for ABS .................................... BR-65

CONSULT for engine ........................ EC-83, 632

COOL/F - Wiring diagram ............... EC-409, 730

Camshaft inspection ......................... EM-37, 123

Camshaft position sensor (CMPS) ......... EC-335

Camshaft position sensor (PHASE) ........ EC-335

Canister - See EVAP canister ................... EC-36

Charging system ....................................... SC-26

Cigarette lighter ....................................... EL-236

Circuit breaker ........................................... EL-38

Closed throttle position switch ....... EC-385, 520

Clutch cover .............................................. CL-22

Clutch disc ................................................. CL-22

Clutch master cylinder ............................... CL-11

Clutch operating cylinder ........................... CL-14

Clutch pedal .............................................. CL-10

Clutch release bearing ........................ CL-17, 20

Clutch release mechanism .................. CL-17, 20

Clutch withdrawal lever ....................... CL-17, 20

Coil spring (front) ........................................ SU-9

Coil spring (rear) ....................................... SU-21

Collision diagnosis .................................... RS-85

Combination lamp, rear, removal and

installation .............................................. BT-47

Combination meter removal and instal-

lation - See Instrument panel ................ BT-25

Combination meter .................................. EL-144

Combination switch ................................... EL-56

Compression pressure ............................. EM-83

Compressor clutch removal and

installation .............................................. HA-83

Compressor precaution ............................... HA-5

Compressor special service tool ................. HA-9

Connecting rod bearing clearance ... EM-60, 151

Connecting rod bushing clearance ... EM-61, 153

Connecting rod ................................. EM-57, 146

Console box - See Instrument panel ......... BT-25

Control lever (M/T) .................................... MT-29

Control valve (A/T) ................................... AT-388

Converter housing installation ................. AT-355

Coolant mixture ratio ................................ MA-18

Cooling circuit (engine) ....................... LC-12, 37

Cooling fan control system .................. LC-17, 43

Cooling fan control .......................... EC-406, 730

Cooling fan motor ................................... EC-417

Cooling fan relay ..................................... EC-416

Coupling sleeve (M/T) .................. MT-31, 55, 93

Crankcase emission control system -

See Positive crankcase ventilation ...... EC-39,

613

Crankcase ventilation system - See

Positive crankcase ventilation ....... EC-39, 613

Crankshaft position sensor (OBD) .. EC-328, 484Crankshaft position sensor (POS) .. EC-328, 484

Crankshaft position sensor (TDC) .......... EC-695

Crankshaft ........................................ EM-59, 148

Cylinder block ................................... EM-54, 140

Cylinder head .................................... EM-34, 119

D

DEF - Wiring diagram ...................... EL-242, 250

DTC work support ..................................... EC-92

Data link connector for Consult ........ EC-40, 632

Daytime light system ................................. EL-67

Detonation sensor - See Knock

sensor .................................................. EC-324

Diagnosis sensor unit ............................... RS-26

Diagnostic trouble code (DTC) for

OBD system .................... EC-10, 72, 596, 627

Diagnostic trouble code (DTC) inspec-

tion priority chart .................................. EC-153

Differential gear (FF A/T) ......................... AT-442

Differential gear (FF M/T) ...... MT-31, 44, 55, 93,

107

Dimensions ................................................. GI-43

Dome light - See Interior lamp ................ EL-115

Door glass ................................................. BT-17

Door lock ................................................... BT-21

Door mirror ................................................ BT-75

Door trim .................................................... BT-39

Door, front .................................................. BT-16

Door, rear ................................................... BT-16

Drive plate runout ..................................... EM-62

Drive shaft (front) ...................................... AX-10

Dropping resistor (A/T) .................... AT-182, 245

Dual pressure switch ................................ HA-13

E

ECCS-D control module ........ EC-659, 714, 792,

794, 799, 801

ECM input/output signal ................. EC-164, 659

ECTS - Wiring diagram ................... EC-203, 680

EGR control valve ................................... EC-432

EGR temperature sensor ........................ EC-418

EGR volume control valve ...................... EC-815

EGR/TS - Wiring diagram ....................... EC-421

EGRC1 - Wiring diagram ....... EC-347, 429, 494,

817

EVAP canister purge volume control

solenoid valve ........................................ EC-37

EVAP canister purge volume control

valve ............................................ EC-364, 503

EVAP canister ........................................... EC-37

Electric sunroof ........................................ EL-292

Electrical diagnoses ................................... GI-21

Electrical ignition system .......................... EC-34

Electrical load signal circuit ..................... EC-578

Electrical unit ........................................... EL-581

Electrical units location ............................ EL-517

ALPHABETICAL INDEX

IDX-3

Page 2770 of 2898

![NISSAN ALMERA 2001 User Guide CONSULT-II Diagnostic Code Chart (ªSELF-DIAG

[CURRENT]º)/4-door Sedan

NJRS0048S0101

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replace-

ment.º

NO DTC IS

DETECTED.When malfunction NISSAN ALMERA 2001 User Guide CONSULT-II Diagnostic Code Chart (ªSELF-DIAG

[CURRENT]º)/4-door Sedan

NJRS0048S0101

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replace-

ment.º

NO DTC IS

DETECTED.When malfunction](/img/5/57348/w960_57348-2769.png)

CONSULT-II Diagnostic Code Chart (ªSELF-DIAG

[CURRENT]º)/4-door Sedan

NJRS0048S0101

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replace-

ment.º

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User mode+Low battery voltage (Less than 9V)+Go to DIAGNOSTIC PROCEDURE

3 (RS-66) after charging battery.

+Self-diagnostic result ªSELF-DIAG

[PAST]º (previously stored in the

memory) might not be erased after

repair.

+Intermittent malfunction has been

detected in the past.+Go to DIAGNOSTIC PROCEDURE

4 (RS-68).

+No malfunction is detected.+Go to DIAGNOSTIC PROCEDURE

3 (RS-66).

AIRBAG MODULE

[OPEN]+Driver air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the diagnosis sensor unit.

6. Replace the related harness.

AIRBAG MODULE

[VB-SHORT]+Driver air bag module circuit is shorted to a power supply

circuit. (including the spiral cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace the spiral cable.

4. Replace driver air bag module.

(Before disposal, it must be

deployed.)

5. Replace the diagnosis sensor unit.

6. Replace the related harness. AIRBAG MODULE

[GND-SHORT]+Driver air bag module circuit is shorted to ground. (including

the spiral cable)

AIRBAG MODULE

[SHORT]+Driver air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[VB-SHORT]+Front passenger air bag module circuit is shorted to a power

supply circuit.1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front passenger air bag

module. (Before disposal, it must

be deployed.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. ASSIST A/B MODULE

[OPEN]+Front passenger air bag module circuit is open.

ASSIST A/B MODULE

[GND-SHORT]+Front passenger air bag module circuit is shorted to ground.

ASSIST A/B MODULE

[SHORT]+Front passenger air bag module circuits are shorted to each

other.

SIDE MODULE LH

[OPEN]+Front LH side air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front LH side air bag mod-

ule.

(Before disposal, it must be

deployed.)

4. Replace the diagnosis sensor unit.

5. Replace the related harness. SIDE MODULE LH

[VB-SHORT]+Front LH side air bag module circuit is shorted to a power

supply circuit.

SIDE MODULE LH

[GND-SHORT]+Front LH side air bag module circuit is shorted to ground.

SIDE MODULE LH

[SHORT]+Front LH side air bag module circuits are shorted to each

other.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-62

Page 2774 of 2898

Diagnostic item ExplanationRepair order

Recheck SRS at each

replacement.

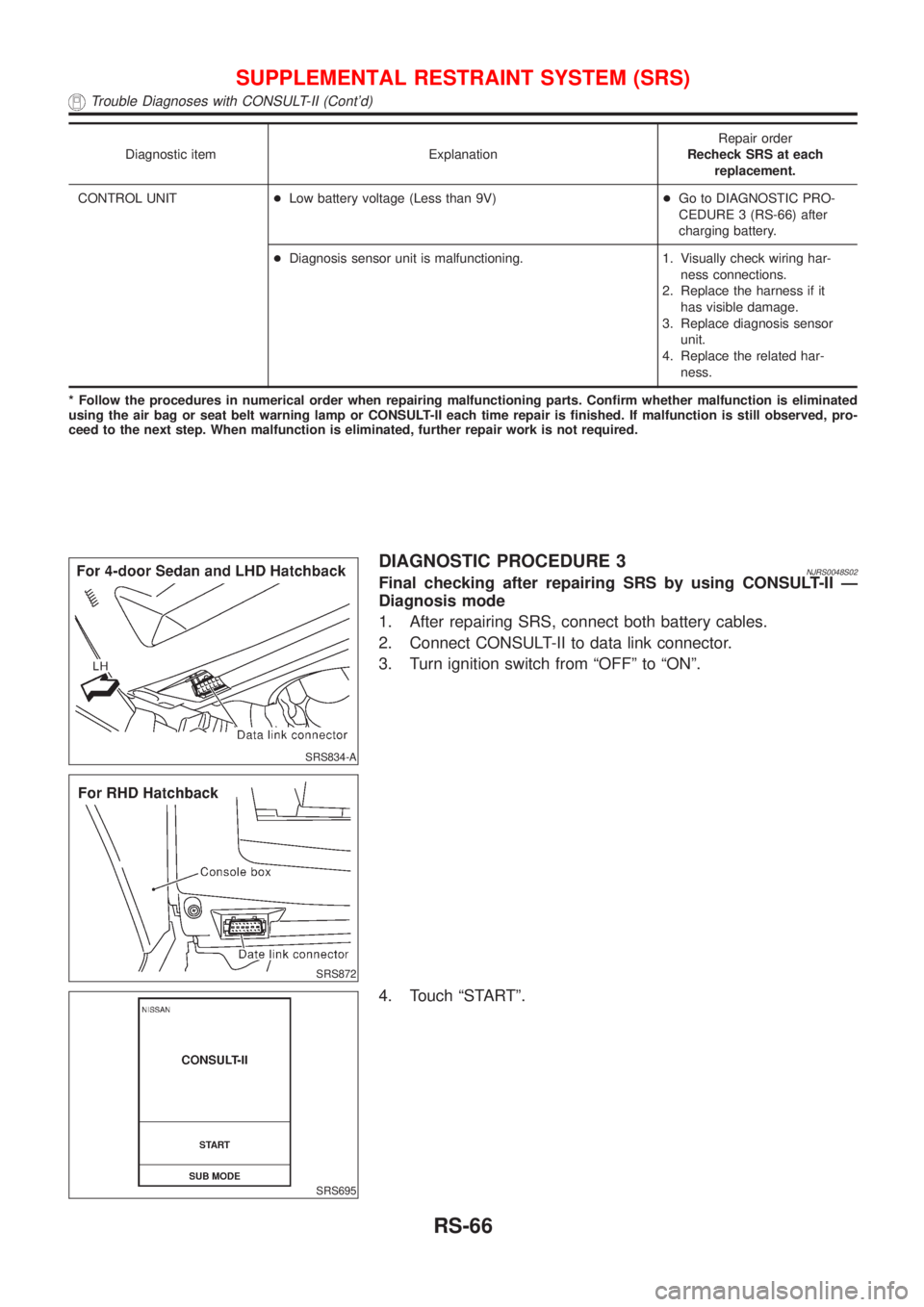

CONTROL UNIT+Low battery voltage (Less than 9V)+Go to DIAGNOSTIC PRO-

CEDURE 3 (RS-66) after

charging battery.

+Diagnosis sensor unit is malfunctioning. 1. Visually check wiring har-

ness connections.

2. Replace the harness if it

has visible damage.

3. Replace diagnosis sensor

unit.

4. Replace the related har-

ness.

* Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is eliminated

using the air bag or seat belt warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, pro-

ceed to the next step. When malfunction is eliminated, further repair work is not required.

SRS834-A

SRS872

DIAGNOSTIC PROCEDURE 3NJRS0048S02Final checking after repairing SRS by using CONSULT-II Ð

Diagnosis mode

1. After repairing SRS, connect both battery cables.

2. Connect CONSULT-II to data link connector.

3. Turn ignition switch from ªOFFº to ªONº.

SRS695

4. Touch ªSTARTº.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-66

Page 2778 of 2898

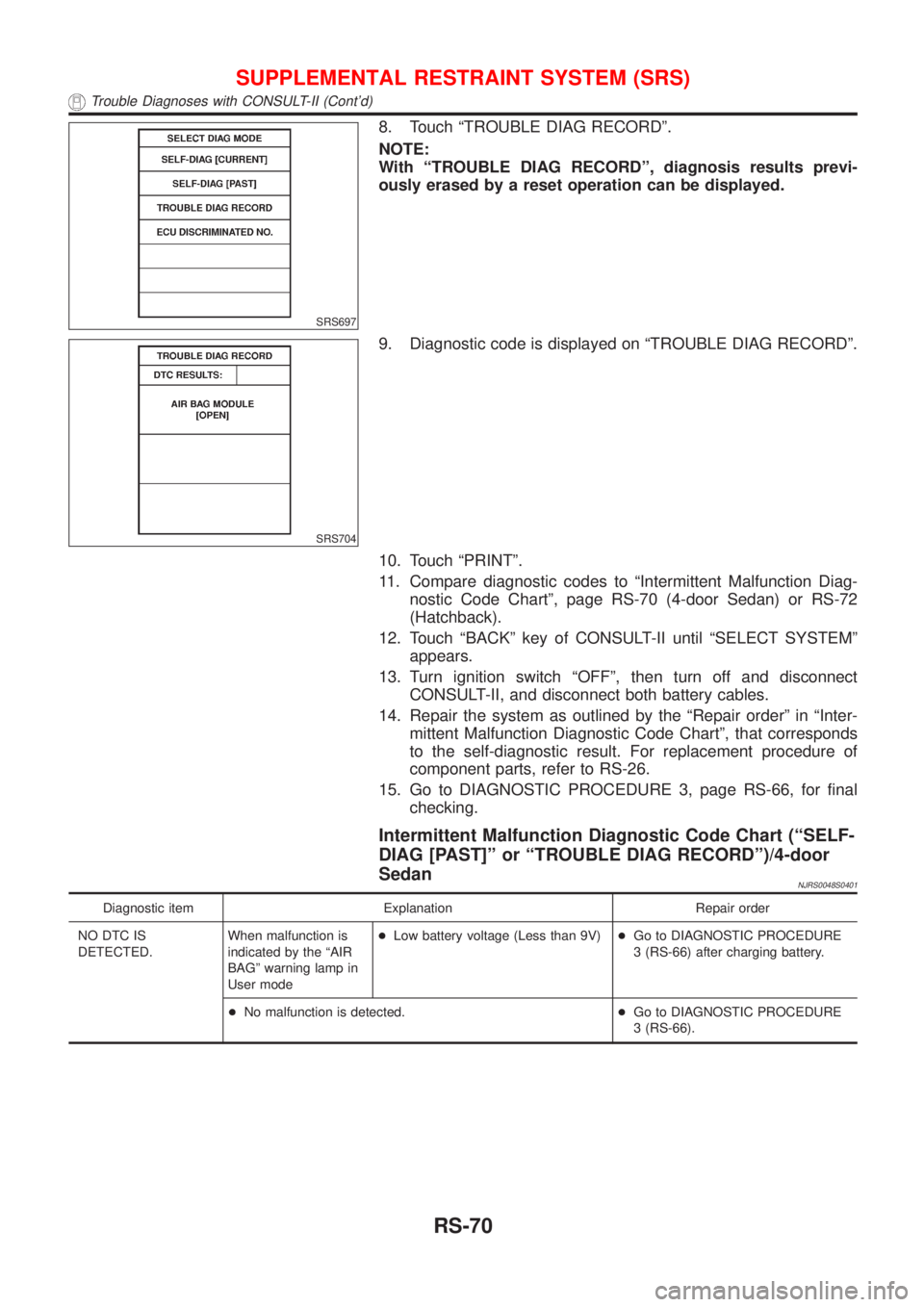

SRS697

8. Touch ªTROUBLE DIAG RECORDº.

NOTE:

With ªTROUBLE DIAG RECORDº, diagnosis results previ-

ously erased by a reset operation can be displayed.

SRS704

9. Diagnostic code is displayed on ªTROUBLE DIAG RECORDº.

10. Touch ªPRINTº.

11. Compare diagnostic codes to ªIntermittent Malfunction Diag-

nostic Code Chartº, page RS-70 (4-door Sedan) or RS-72

(Hatchback).

12. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears.

13. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

14. Repair the system as outlined by the ªRepair orderº in ªInter-

mittent Malfunction Diagnostic Code Chartº, that corresponds

to the self-diagnostic result. For replacement procedure of

component parts, refer to RS-26.

15. Go to DIAGNOSTIC PROCEDURE 3, page RS-66, for final

checking.

Intermittent Malfunction Diagnostic Code Chart (ªSELF-

DIAG [PAST]º or ªTROUBLE DIAG RECORDº)/4-door

Sedan

NJRS0048S0401

Diagnostic item Explanation Repair order

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User mode+Low battery voltage (Less than 9V)+Go to DIAGNOSTIC PROCEDURE

3 (RS-66) after charging battery.

+No malfunction is detected.+Go to DIAGNOSTIC PROCEDURE

3 (RS-66).

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-70

Page 2797 of 2898

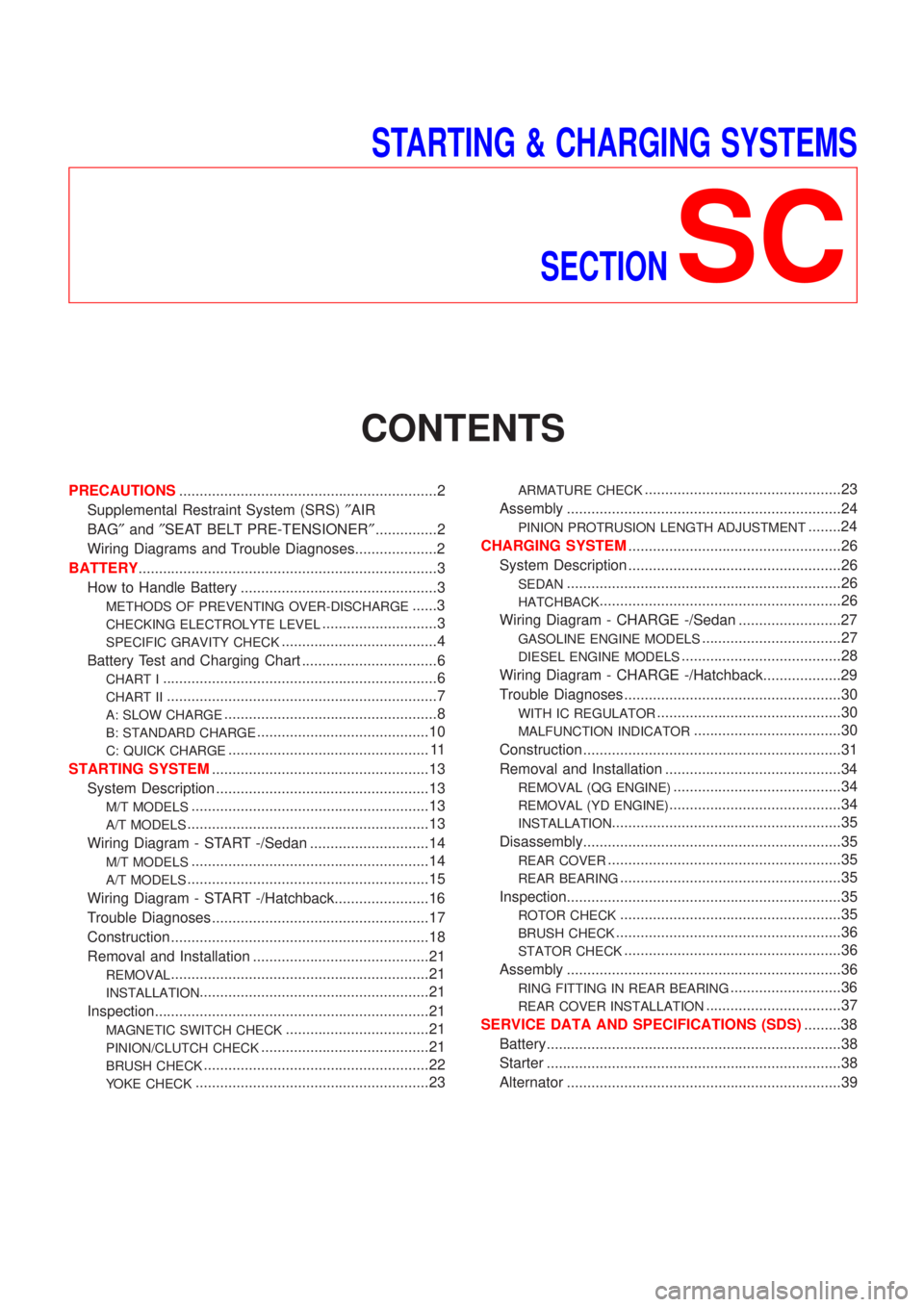

STARTING & CHARGING SYSTEMS

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnoses....................2

BATTERY.........................................................................3

How to Handle Battery ................................................3

METHODS OF PREVENTING OVER-DISCHARGE......3

CHECKING ELECTROLYTE LEVEL............................3

SPECIFIC GRAVITY CHECK......................................4

Battery Test and Charging Chart .................................6

CHART I...................................................................6

CHART II..................................................................7

A: SLOW CHARGE....................................................8

B: STANDARD CHARGE..........................................10

C: QUICK CHARGE................................................. 11

STARTING SYSTEM.....................................................13

System Description ....................................................13

M/T MODELS..........................................................13

A/T MODELS...........................................................13

Wiring Diagram - START -/Sedan .............................14

M/T MODELS..........................................................14

A/T MODELS...........................................................15

Wiring Diagram - START -/Hatchback.......................16

Trouble Diagnoses.....................................................17

Construction ...............................................................18

Removal and Installation ...........................................21

REMOVAL...............................................................21

INSTALLATION........................................................21

Inspection...................................................................21

MAGNETIC SWITCH CHECK...................................21

PINION/CLUTCH CHECK.........................................21

BRUSH CHECK.......................................................22

YOKE CHECK.........................................................23

ARMATURE CHECK................................................23

Assembly ...................................................................24

PINION PROTRUSION LENGTH ADJUSTMENT........24

CHARGING SYSTEM....................................................26

System Description ....................................................26

SEDAN...................................................................26

HATCHBACK...........................................................26

Wiring Diagram - CHARGE -/Sedan .........................27

GASOLINE ENGINE MODELS..................................27

DIESEL ENGINE MODELS.......................................28

Wiring Diagram - CHARGE -/Hatchback...................29

Trouble Diagnoses.....................................................30

WITH IC REGULATOR.............................................30

MALFUNCTION INDICATOR....................................30

Construction ...............................................................31

Removal and Installation ...........................................34

REMOVAL (QG ENGINE).........................................34

REMOVAL (YD ENGINE)..........................................34

INSTALLATION........................................................35

Disassembly...............................................................35

REAR COVER.........................................................35

REAR BEARING......................................................35

Inspection...................................................................35

ROTOR CHECK......................................................35

BRUSH CHECK.......................................................36

STATOR CHECK.....................................................36

Assembly ...................................................................36

RING FITTING IN REAR BEARING...........................36

REAR COVER INSTALLATION.................................37

SERVICE DATA AND SPECIFICATIONS (SDS).........38

Battery........................................................................38

Starter ........................................................................38

Alternator ...................................................................39

Page 2800 of 2898

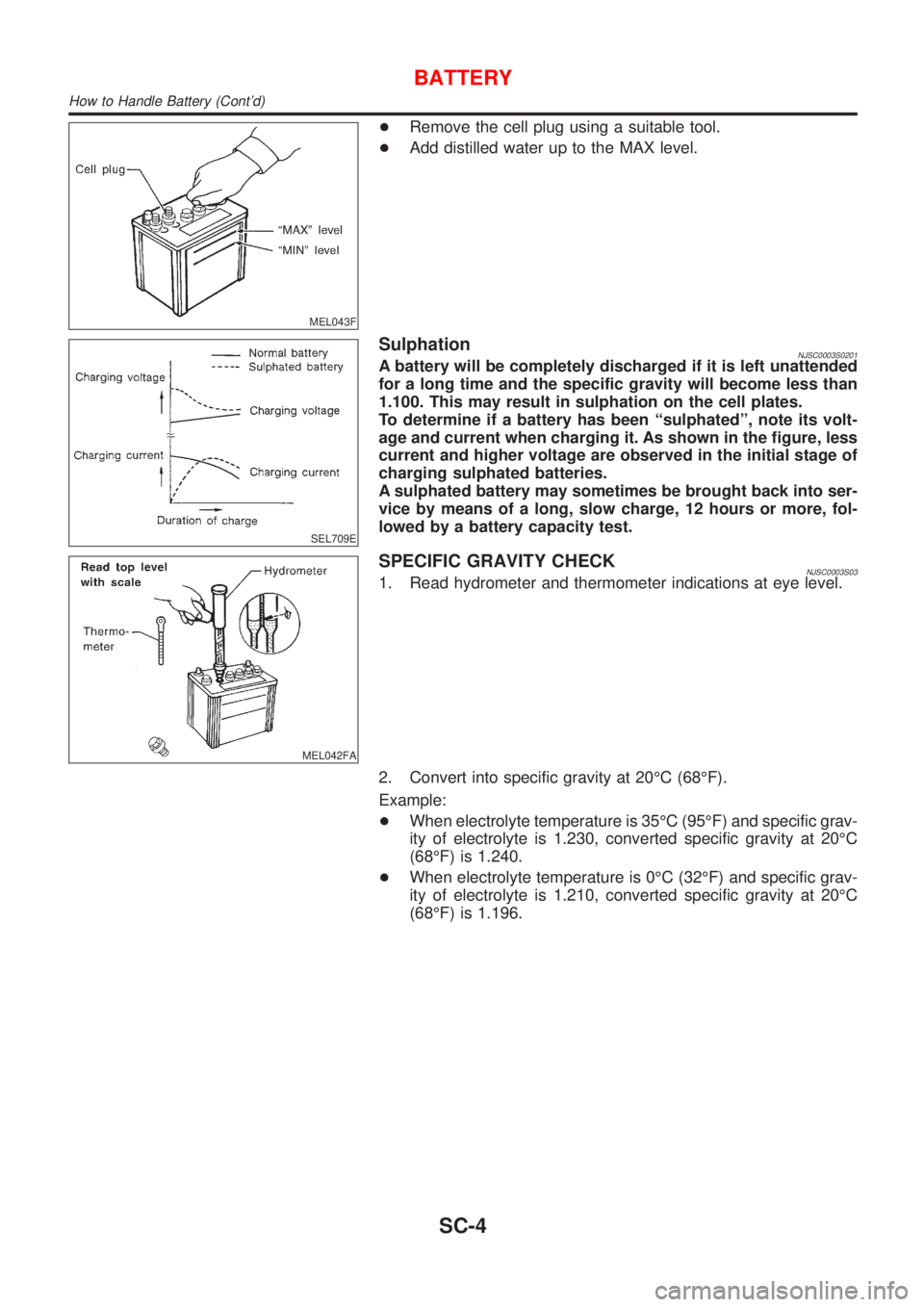

MEL043F

+Remove the cell plug using a suitable tool.

+Add distilled water up to the MAX level.

SEL709E

SulphationNJSC0003S0201A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been ªsulphatedº, note its volt-

age and current when charging it. As shown in the figure, less

current and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

MEL042FA

SPECIFIC GRAVITY CHECKNJSC0003S031. Read hydrometer and thermometer indications at eye level.

2. Convert into specific gravity at 20ÉC (68ÉF).

Example:

+When electrolyte temperature is 35ÉC (95ÉF) and specific grav-

ity of electrolyte is 1.230, converted specific gravity at 20ÉC

(68ÉF) is 1.240.

+When electrolyte temperature is 0ÉC (32ÉF) and specific grav-

ity of electrolyte is 1.210, converted specific gravity at 20ÉC

(68ÉF) is 1.196.

BATTERY

How to Handle Battery (Cont'd)

SC-4

Page 2802 of 2898

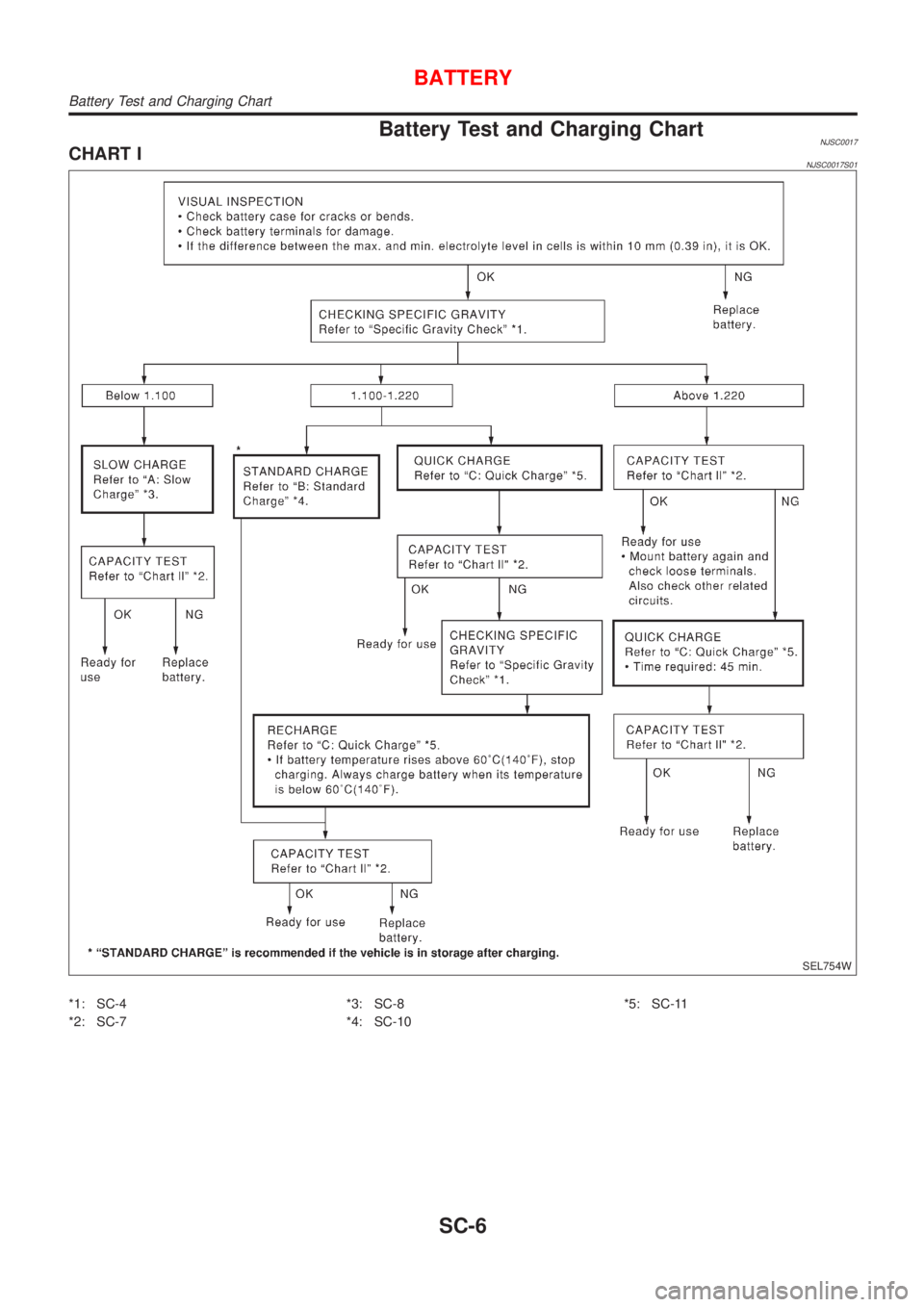

Battery Test and Charging ChartNJSC0017CHART INJSC0017S01

SEL754W

*1: SC-4

*2: SC-7*3: SC-8

*4: SC-10*5: SC-11

BATTERY

Battery Test and Charging Chart

SC-6