differential NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 447 of 2898

SAT970H

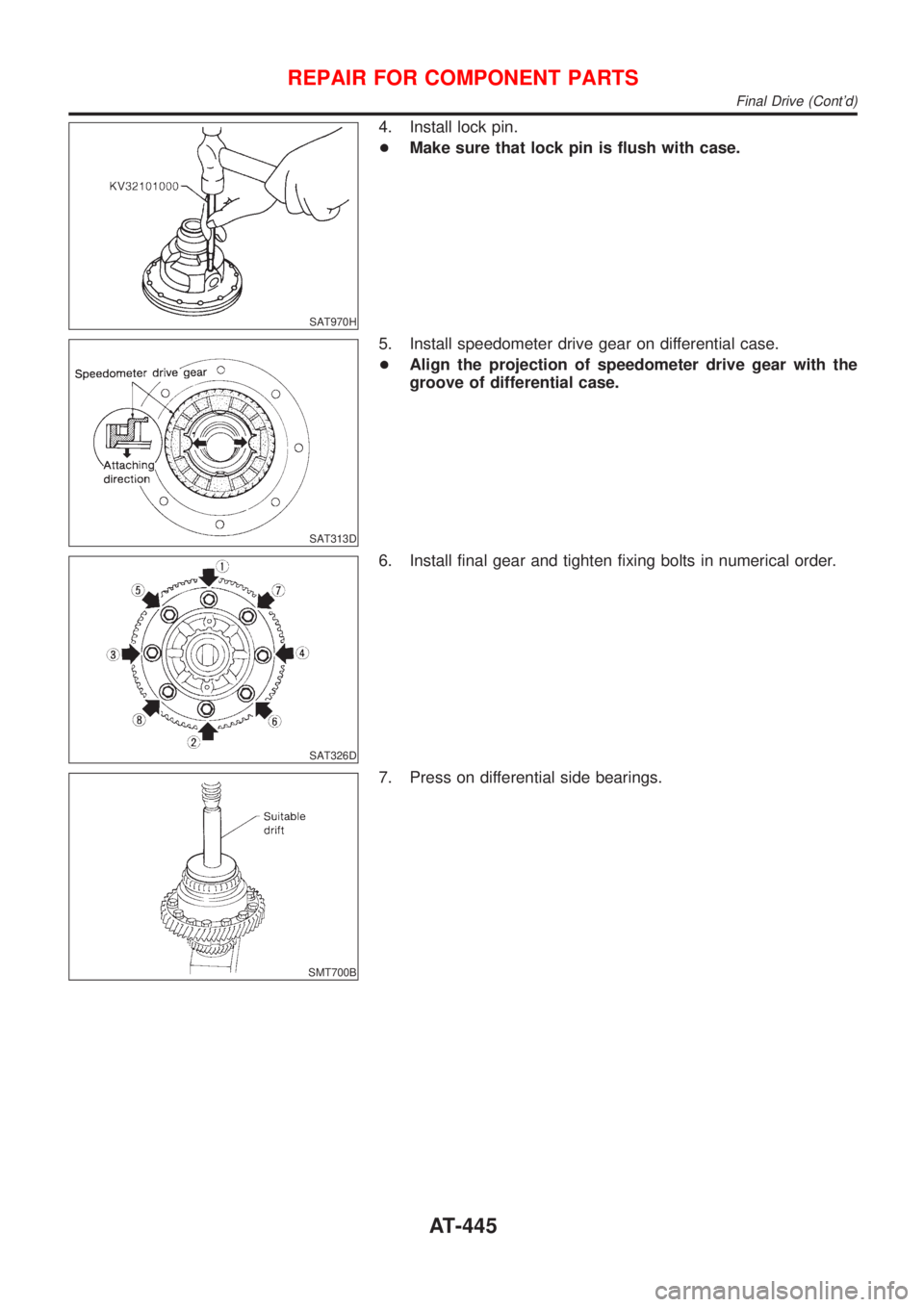

4. Install lock pin.

+Make sure that lock pin is flush with case.

SAT313D

5. Install speedometer drive gear on differential case.

+Align the projection of speedometer drive gear with the

groove of differential case.

SAT326D

6. Install final gear and tighten fixing bolts in numerical order.

SMT700B

7. Press on differential side bearings.

REPAIR FOR COMPONENT PARTS

Final Drive (Cont'd)

AT-445

Page 448 of 2898

SAT311G

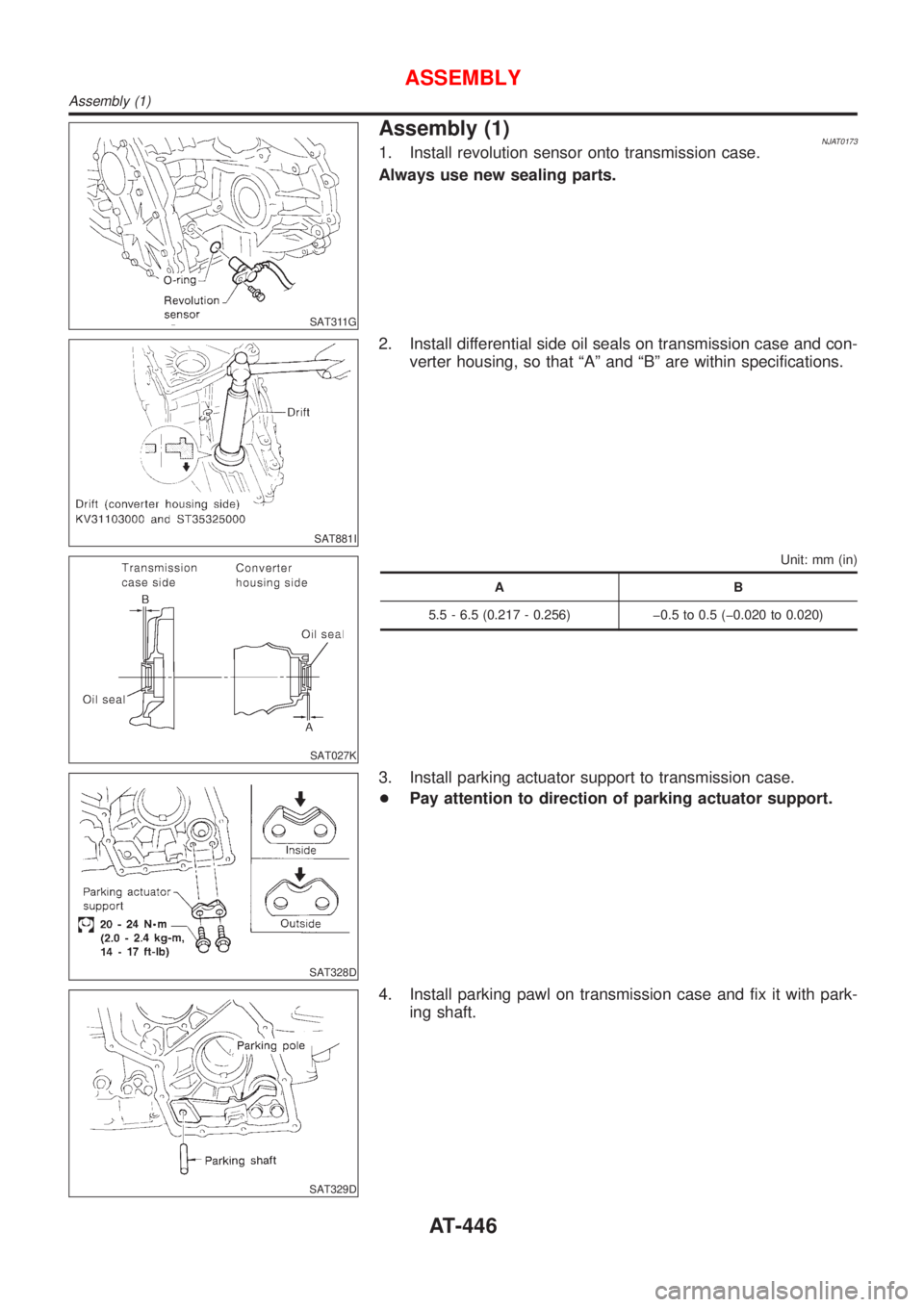

Assembly (1)NJAT01731. Install revolution sensor onto transmission case.

Always use new sealing parts.

SAT881I

2. Install differential side oil seals on transmission case and con-

verter housing, so that ªAº and ªBº are within specifications.

SAT027K

Unit: mm (in)

AB

5.5 - 6.5 (0.217 - 0.256) þ0.5 to 0.5 (þ0.020 to 0.020)

SAT328D

3. Install parking actuator support to transmission case.

+Pay attention to direction of parking actuator support.

SAT329D

4. Install parking pawl on transmission case and fix it with park-

ing shaft.

ASSEMBLY

Assembly (1)

AT-446

Page 449 of 2898

SAT330D

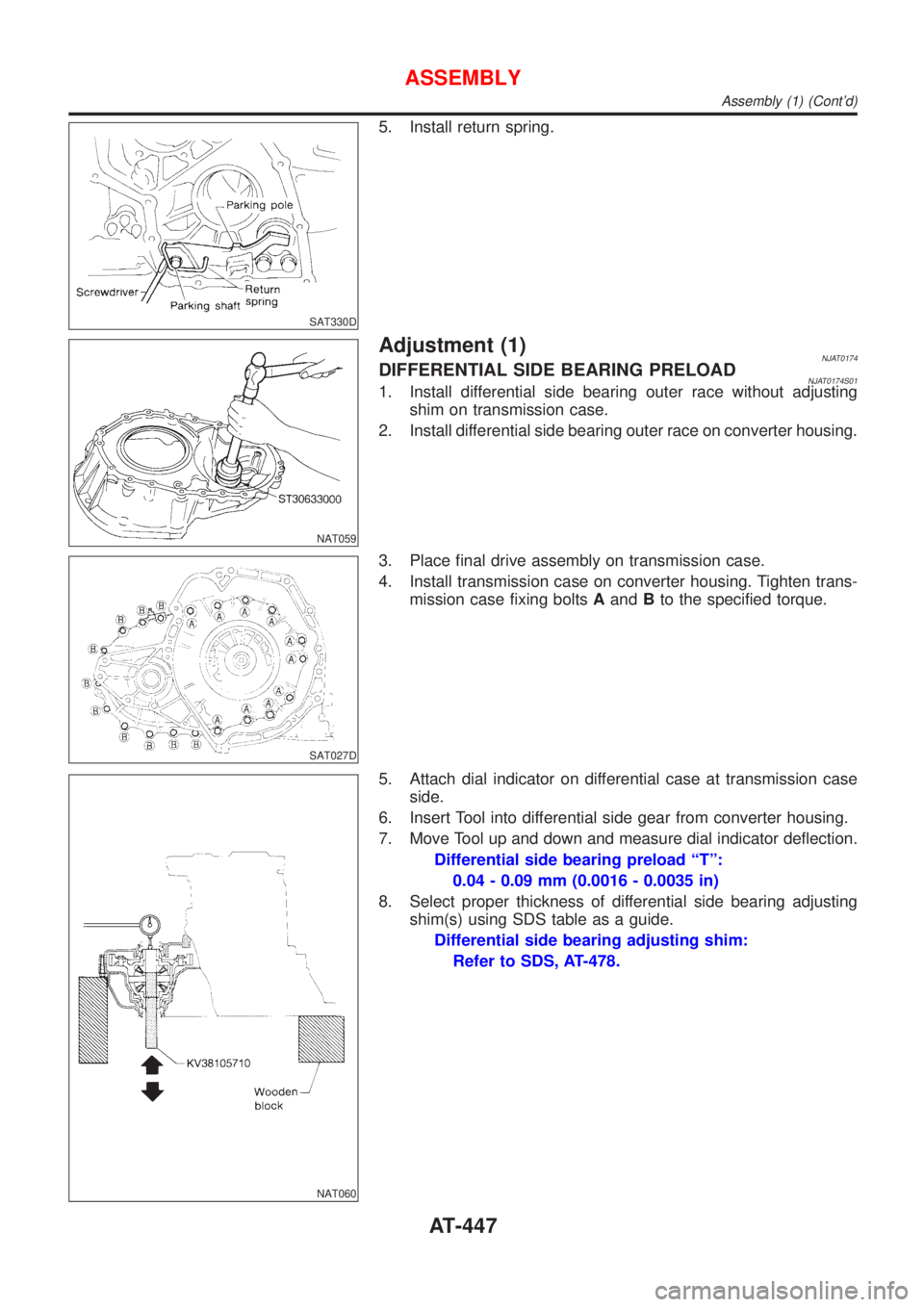

5. Install return spring.

NAT059

Adjustment (1)NJAT0174DIFFERENTIAL SIDE BEARING PRELOADNJAT0174S011. Install differential side bearing outer race without adjusting

shim on transmission case.

2. Install differential side bearing outer race on converter housing.

SAT027D

3. Place final drive assembly on transmission case.

4. Install transmission case on converter housing. Tighten trans-

mission case fixing boltsAandBto the specified torque.

NAT060

5. Attach dial indicator on differential case at transmission case

side.

6. Insert Tool into differential side gear from converter housing.

7. Move Tool up and down and measure dial indicator deflection.

Differential side bearing preload ªTº:

0.04 - 0.09 mm (0.0016 - 0.0035 in)

8. Select proper thickness of differential side bearing adjusting

shim(s) using SDS table as a guide.

Differential side bearing adjusting shim:

Refer to SDS, AT-478.

ASSEMBLY

Assembly (1) (Cont'd)

AT-447

Page 450 of 2898

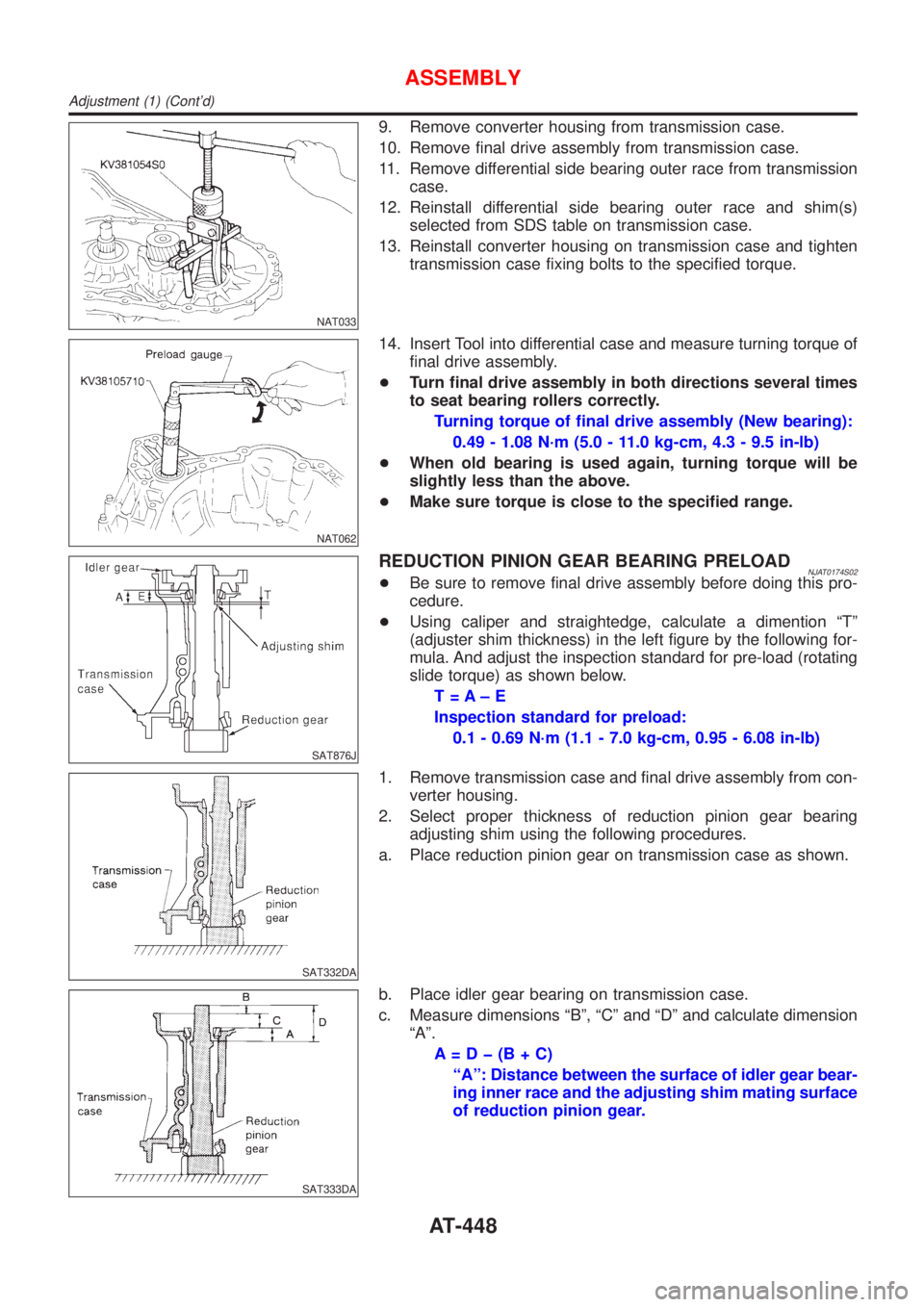

NAT033

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case.

12. Reinstall differential side bearing outer race and shim(s)

selected from SDS table on transmission case.

13. Reinstall converter housing on transmission case and tighten

transmission case fixing bolts to the specified torque.

NAT062

14. Insert Tool into differential case and measure turning torque of

final drive assembly.

+Turn final drive assembly in both directions several times

to seat bearing rollers correctly.

Turning torque of final drive assembly (New bearing):

0.49 - 1.08 N´m (5.0 - 11.0 kg-cm, 4.3 - 9.5 in-lb)

+When old bearing is used again, turning torque will be

slightly less than the above.

+Make sure torque is close to the specified range.

SAT876J

REDUCTION PINION GEAR BEARING PRELOADNJAT0174S02+Be sure to remove final drive assembly before doing this pro-

cedure.

+Using caliper and straightedge, calculate a dimention ªTº

(adjuster shim thickness) in the left figure by the following for-

mula. And adjust the inspection standard for pre-load (rotating

slide torque) as shown below.

T=A±E

Inspection standard for preload:

0.1 - 0.69 N´m (1.1 - 7.0 kg-cm, 0.95 - 6.08 in-lb)

SAT332DA

1. Remove transmission case and final drive assembly from con-

verter housing.

2. Select proper thickness of reduction pinion gear bearing

adjusting shim using the following procedures.

a. Place reduction pinion gear on transmission case as shown.

SAT333DA

b. Place idler gear bearing on transmission case.

c. Measure dimensions ªBº, ªCº and ªDº and calculate dimension

ªAº.

A=Dþ(B+C)

ªAº: Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating surface

of reduction pinion gear.

ASSEMBLY

Adjustment (1) (Cont'd)

AT-448

Page 467 of 2898

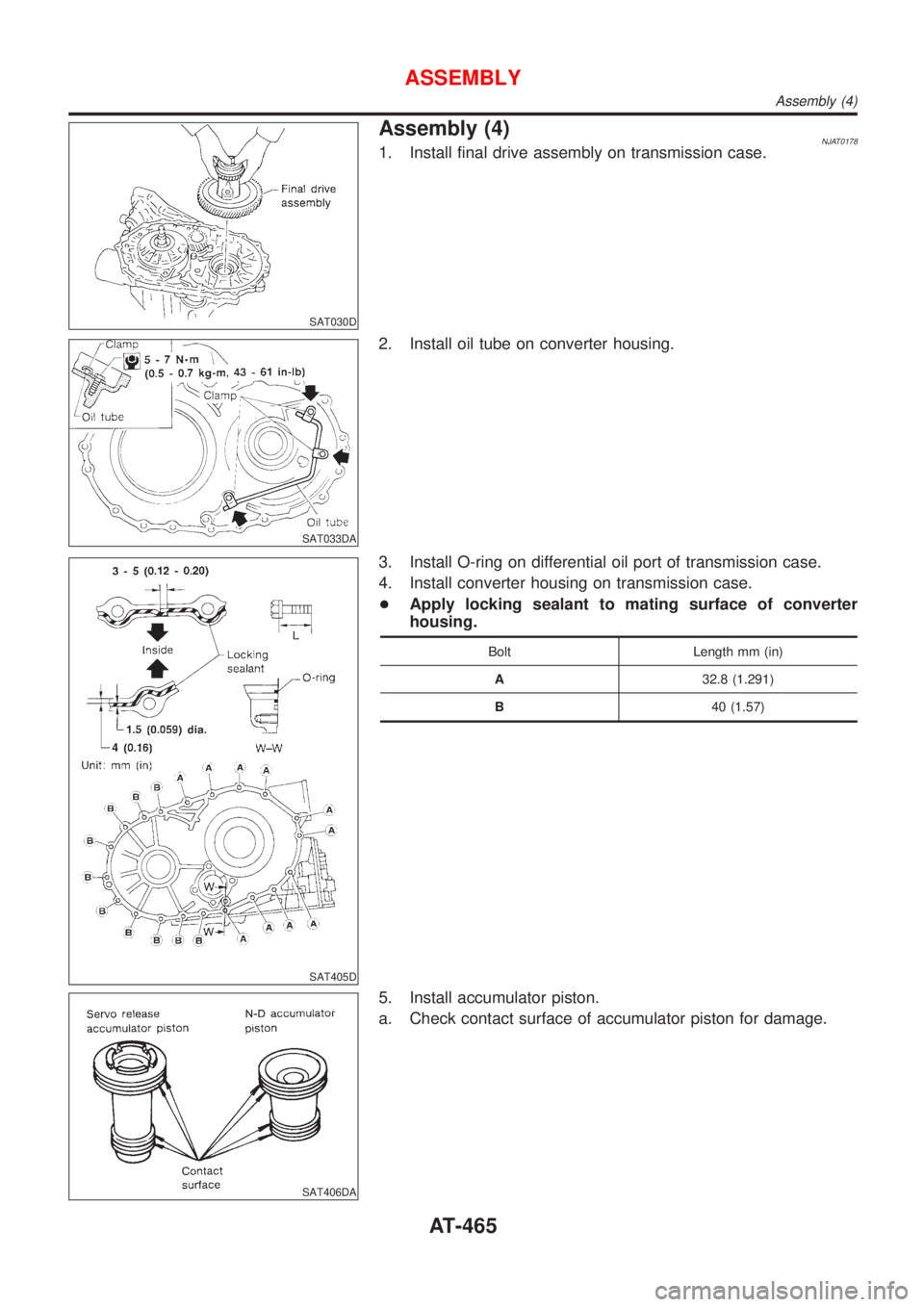

SAT030D

Assembly (4)NJAT01781. Install final drive assembly on transmission case.

SAT033DA

2. Install oil tube on converter housing.

SAT405D

3. Install O-ring on differential oil port of transmission case.

4. Install converter housing on transmission case.

+Apply locking sealant to mating surface of converter

housing.

Bolt Length mm (in)

A32.8 (1.291)

B40 (1.57)

SAT406DA

5. Install accumulator piston.

a. Check contact surface of accumulator piston for damage.

ASSEMBLY

Assembly (4)

AT-465

Page 480 of 2898

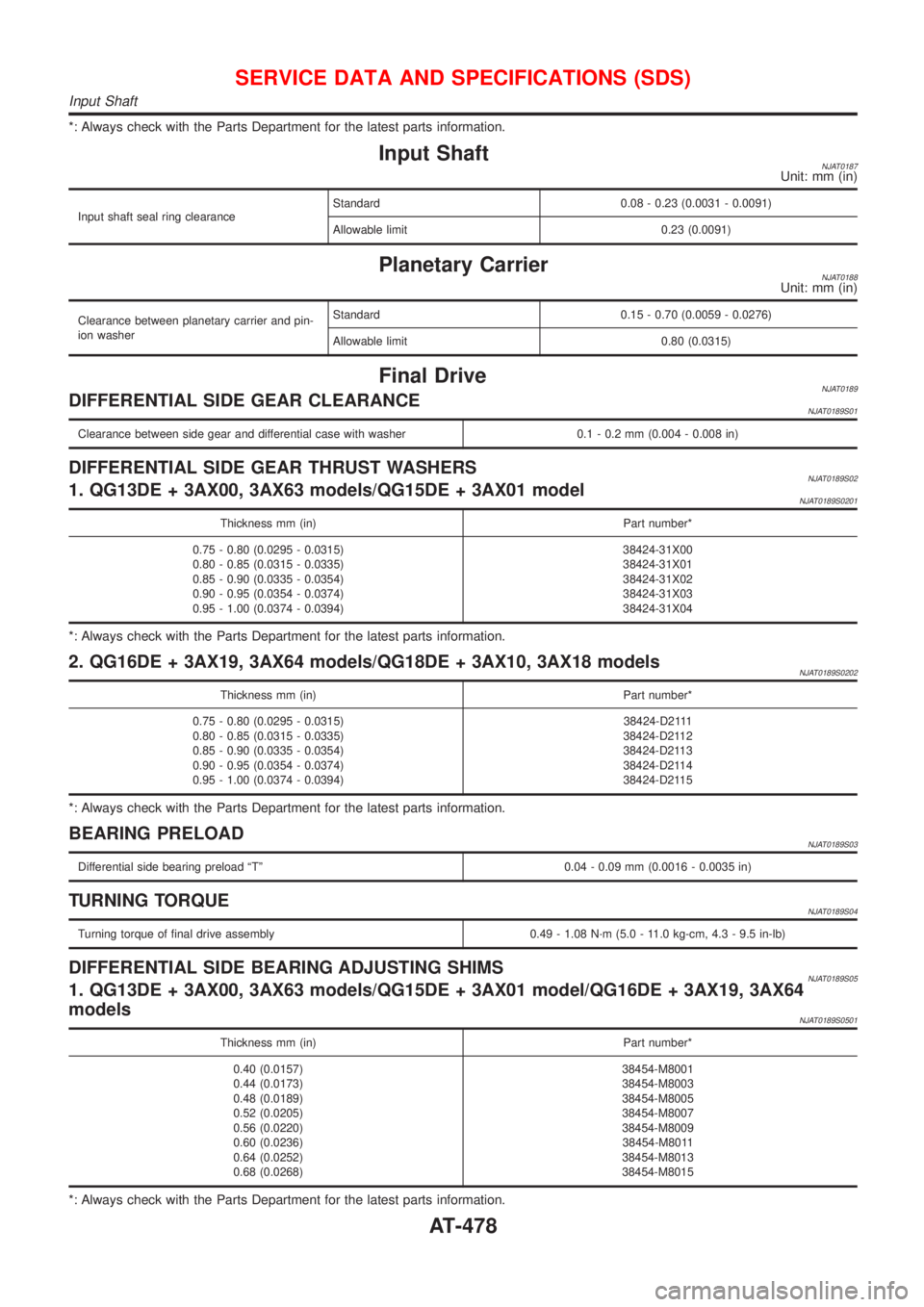

*: Always check with the Parts Department for the latest parts information.

Input ShaftNJAT0187Unit: mm (in)

Input shaft seal ring clearanceStandard 0.08 - 0.23 (0.0031 - 0.0091)

Allowable limit 0.23 (0.0091)

Planetary CarrierNJAT0188Unit: mm (in)

Clearance between planetary carrier and pin-

ion washerStandard 0.15 - 0.70 (0.0059 - 0.0276)

Allowable limit 0.80 (0.0315)

Final DriveNJAT0189DIFFERENTIAL SIDE GEAR CLEARANCENJAT0189S01

Clearance between side gear and differential case with washer 0.1 - 0.2 mm (0.004 - 0.008 in)

DIFFERENTIAL SIDE GEAR THRUST WASHERSNJAT0189S021. QG13DE + 3AX00, 3AX63 models/QG15DE + 3AX01 modelNJAT0189S0201

Thickness mm (in) Part number*

0.75 - 0.80 (0.0295 - 0.0315)

0.80 - 0.85 (0.0315 - 0.0335)

0.85 - 0.90 (0.0335 - 0.0354)

0.90 - 0.95 (0.0354 - 0.0374)

0.95 - 1.00 (0.0374 - 0.0394)38424-31X00

38424-31X01

38424-31X02

38424-31X03

38424-31X04

*: Always check with the Parts Department for the latest parts information.

2. QG16DE + 3AX19, 3AX64 models/QG18DE + 3AX10, 3AX18 modelsNJAT0189S0202

Thickness mm (in) Part number*

0.75 - 0.80 (0.0295 - 0.0315)

0.80 - 0.85 (0.0315 - 0.0335)

0.85 - 0.90 (0.0335 - 0.0354)

0.90 - 0.95 (0.0354 - 0.0374)

0.95 - 1.00 (0.0374 - 0.0394)38424-D2111

38424-D2112

38424-D2113

38424-D2114

38424-D2115

*: Always check with the Parts Department for the latest parts information.

BEARING PRELOADNJAT0189S03

Differential side bearing preload ªTº 0.04 - 0.09 mm (0.0016 - 0.0035 in)

TURNING TORQUENJAT0189S04

Turning torque of final drive assembly 0.49 - 1.08 N´m (5.0 - 11.0 kg-cm, 4.3 - 9.5 in-lb)

DIFFERENTIAL SIDE BEARING ADJUSTING SHIMSNJAT0189S051. QG13DE + 3AX00, 3AX63 models/QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64

models

NJAT0189S0501

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)38454-M8001

38454-M8003

38454-M8005

38454-M8007

38454-M8009

38454-M8011

38454-M8013

38454-M8015

*: Always check with the Parts Department for the latest parts information.

SERVICE DATA AND SPECIFICATIONS (SDS)

Input Shaft

AT-478

Page 481 of 2898

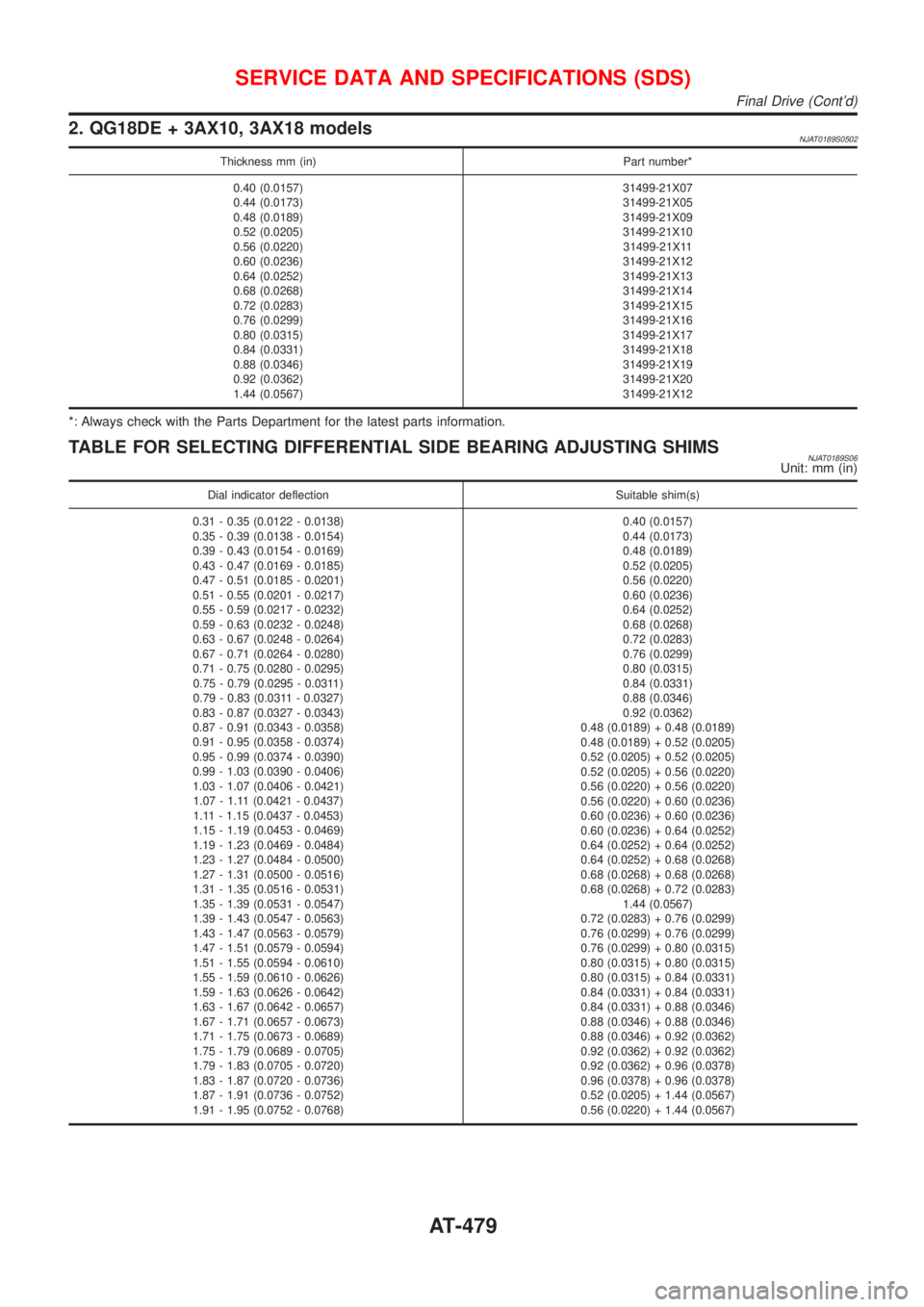

2. QG18DE + 3AX10, 3AX18 modelsNJAT0189S0502

Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

0.92 (0.0362)

1.44 (0.0567)31499-21X07

31499-21X05

31499-21X09

31499-21X10

31499-21X11

31499-21X12

31499-21X13

31499-21X14

31499-21X15

31499-21X16

31499-21X17

31499-21X18

31499-21X19

31499-21X20

31499-21X12

*: Always check with the Parts Department for the latest parts information.

TABLE FOR SELECTING DIFFERENTIAL SIDE BEARING ADJUSTING SHIMSNJAT0189S06Unit: mm (in)

Dial indicator deflection Suitable shim(s)

0.31 - 0.35 (0.0122 - 0.0138)

0.35 - 0.39 (0.0138 - 0.0154)

0.39 - 0.43 (0.0154 - 0.0169)

0.43 - 0.47 (0.0169 - 0.0185)

0.47 - 0.51 (0.0185 - 0.0201)

0.51 - 0.55 (0.0201 - 0.0217)

0.55 - 0.59 (0.0217 - 0.0232)

0.59 - 0.63 (0.0232 - 0.0248)

0.63 - 0.67 (0.0248 - 0.0264)

0.67 - 0.71 (0.0264 - 0.0280)

0.71 - 0.75 (0.0280 - 0.0295)

0.75 - 0.79 (0.0295 - 0.0311)

0.79 - 0.83 (0.0311 - 0.0327)

0.83 - 0.87 (0.0327 - 0.0343)

0.87 - 0.91 (0.0343 - 0.0358)

0.91 - 0.95 (0.0358 - 0.0374)

0.95 - 0.99 (0.0374 - 0.0390)

0.99 - 1.03 (0.0390 - 0.0406)

1.03 - 1.07 (0.0406 - 0.0421)

1.07 - 1.11 (0.0421 - 0.0437)

1.11 - 1.15 (0.0437 - 0.0453)

1.15 - 1.19 (0.0453 - 0.0469)

1.19 - 1.23 (0.0469 - 0.0484)

1.23 - 1.27 (0.0484 - 0.0500)

1.27 - 1.31 (0.0500 - 0.0516)

1.31 - 1.35 (0.0516 - 0.0531)

1.35 - 1.39 (0.0531 - 0.0547)

1.39 - 1.43 (0.0547 - 0.0563)

1.43 - 1.47 (0.0563 - 0.0579)

1.47 - 1.51 (0.0579 - 0.0594)

1.51 - 1.55 (0.0594 - 0.0610)

1.55 - 1.59 (0.0610 - 0.0626)

1.59 - 1.63 (0.0626 - 0.0642)

1.63 - 1.67 (0.0642 - 0.0657)

1.67 - 1.71 (0.0657 - 0.0673)

1.71 - 1.75 (0.0673 - 0.0689)

1.75 - 1.79 (0.0689 - 0.0705)

1.79 - 1.83 (0.0705 - 0.0720)

1.83 - 1.87 (0.0720 - 0.0736)

1.87 - 1.91 (0.0736 - 0.0752)

1.91 - 1.95 (0.0752 - 0.0768)0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

0.92 (0.0362)

0.48 (0.0189) + 0.48 (0.0189)

0.48 (0.0189) + 0.52 (0.0205)

0.52 (0.0205) + 0.52 (0.0205)

0.52 (0.0205) + 0.56 (0.0220)

0.56 (0.0220) + 0.56 (0.0220)

0.56 (0.0220) + 0.60 (0.0236)

0.60 (0.0236) + 0.60 (0.0236)

0.60 (0.0236) + 0.64 (0.0252)

0.64 (0.0252) + 0.64 (0.0252)

0.64 (0.0252) + 0.68 (0.0268)

0.68 (0.0268) + 0.68 (0.0268)

0.68 (0.0268) + 0.72 (0.0283)

1.44 (0.0567)

0.72 (0.0283) + 0.76 (0.0299)

0.76 (0.0299) + 0.76 (0.0299)

0.76 (0.0299) + 0.80 (0.0315)

0.80 (0.0315) + 0.80 (0.0315)

0.80 (0.0315) + 0.84 (0.0331)

0.84 (0.0331) + 0.84 (0.0331)

0.84 (0.0331) + 0.88 (0.0346)

0.88 (0.0346) + 0.88 (0.0346)

0.88 (0.0346) + 0.92 (0.0362)

0.92 (0.0362) + 0.92 (0.0362)

0.92 (0.0362) + 0.96 (0.0378)

0.96 (0.0378) + 0.96 (0.0378)

0.52 (0.0205) + 1.44 (0.0567)

0.56 (0.0220) + 1.44 (0.0567)

SERVICE DATA AND SPECIFICATIONS (SDS)

Final Drive (Cont'd)

AT-479

Page 490 of 2898

SBR686C

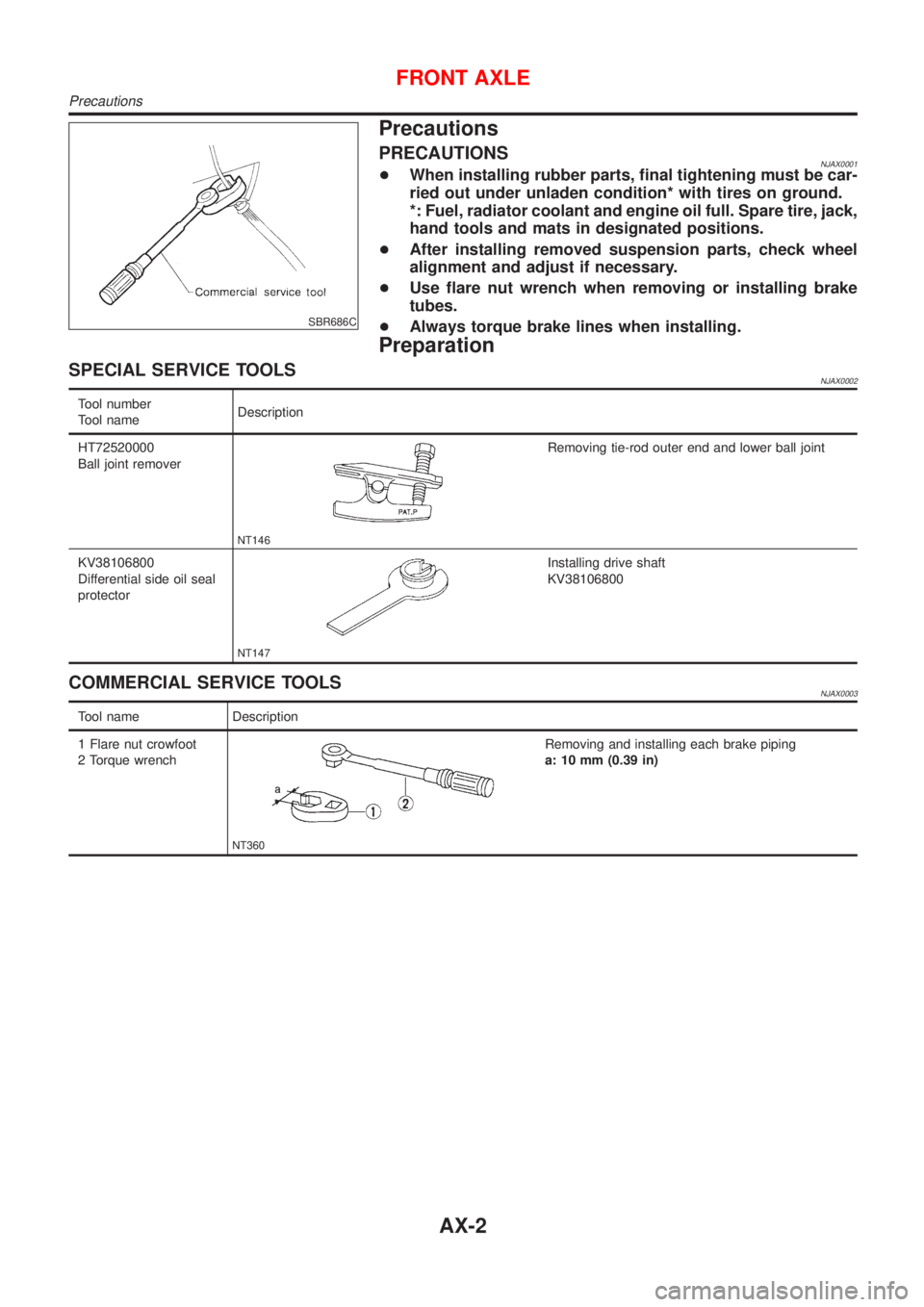

Precautions

PRECAUTIONSNJAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNJAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2

Page 500 of 2898

SFA730

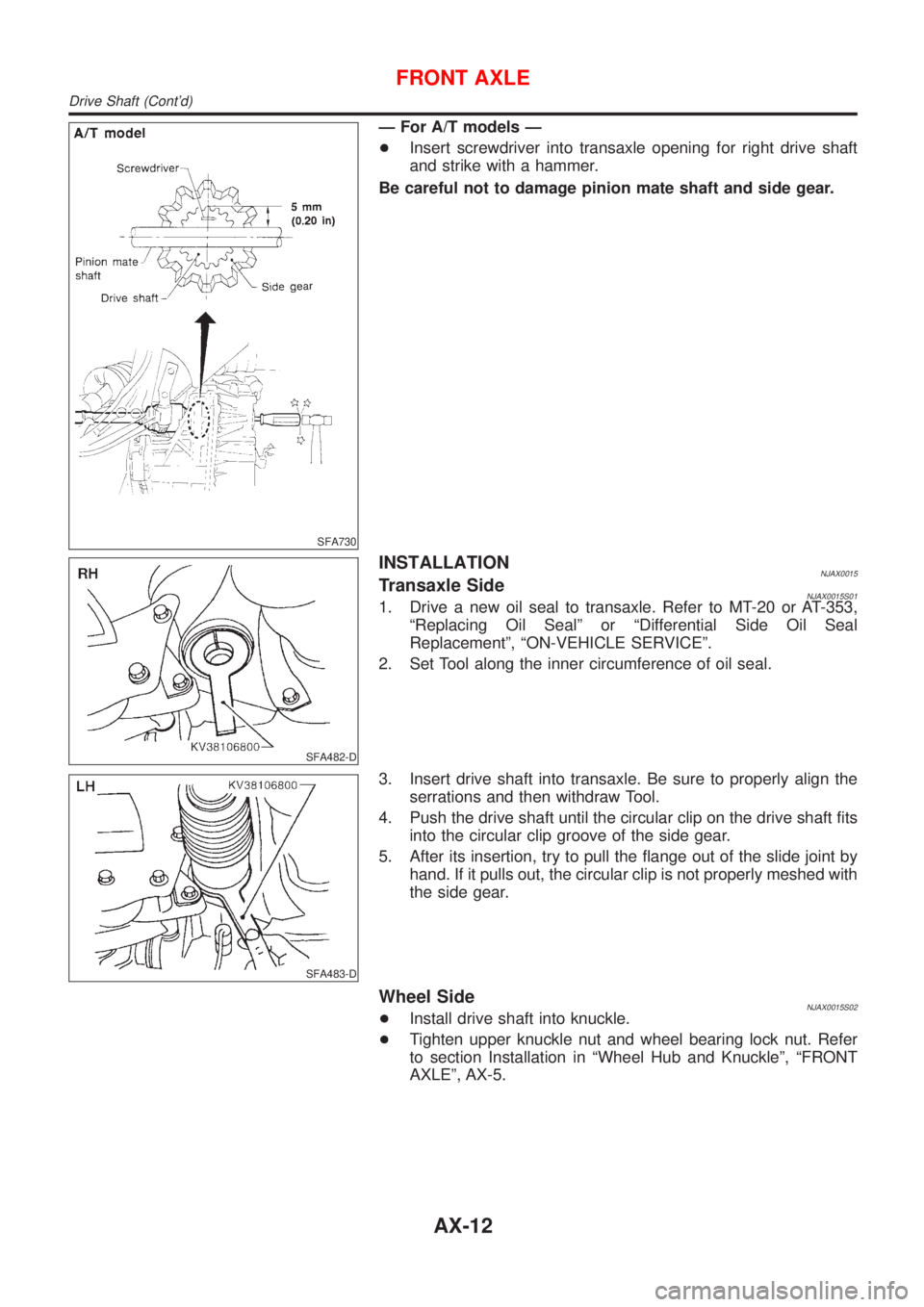

Ð For A/T models Ð

+Insert screwdriver into transaxle opening for right drive shaft

and strike with a hammer.

Be careful not to damage pinion mate shaft and side gear.

SFA482-D

INSTALLATIONNJAX0015Transaxle SideNJAX0015S011. Drive a new oil seal to transaxle. Refer to MT-20 or AT-353,

ªReplacing Oil Sealº or ªDifferential Side Oil Seal

Replacementº, ªON-VEHICLE SERVICEº.

2. Set Tool along the inner circumference of oil seal.

SFA483-D

3. Insert drive shaft into transaxle. Be sure to properly align the

serrations and then withdraw Tool.

4. Push the drive shaft until the circular clip on the drive shaft fits

into the circular clip groove of the side gear.

5. After its insertion, try to pull the flange out of the slide joint by

hand. If it pulls out, the circular clip is not properly meshed with

the side gear.

Wheel SideNJAX0015S02+Install drive shaft into knuckle.

+Tighten upper knuckle nut and wheel bearing lock nut. Refer

to section Installation in ªWheel Hub and Knuckleº, ªFRONT

AXLEº, AX-5.

FRONT AXLE

Drive Shaft (Cont'd)

AX-12

Page 2294 of 2898

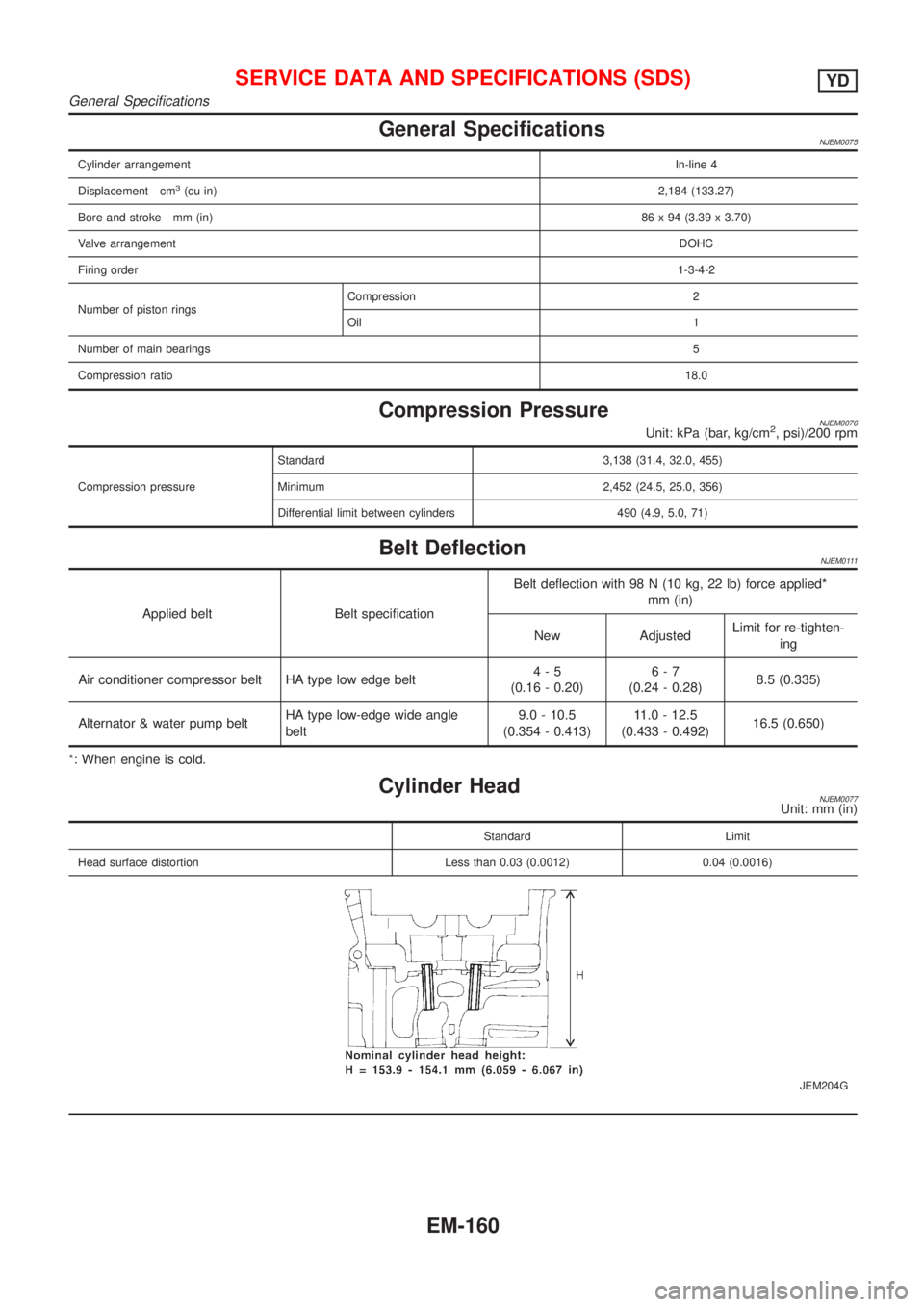

General SpecificationsNJEM0075

Cylinder arrangementIn-line 4

Displacement cm

3(cu in)2,184 (133.27)

Bore and stroke mm (in)86 x 94 (3.39 x 3.70)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio18.0

Compression PressureNJEM0076Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 3,138 (31.4, 32.0, 455)

Minimum 2,452 (24.5, 25.0, 356)

Differential limit between cylinders 490 (4.9, 5.0, 71)

Belt DeflectionNJEM0111

Applied belt Belt specificationBelt deflection with 98 N (10 kg, 22 lb) force applied*

mm (in)

New AdjustedLimit for re-tighten-

ing

Air conditioner compressor belt HA type low edge belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator & water pump beltHA type low-edge wide angle

belt9.0 - 10.5

(0.354 - 0.413)11.0 - 12.5

(0.433 - 0.492)16.5 (0.650)

*: When engine is cold.

Cylinder HeadNJEM0077Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.04 (0.0016)

JEM204G

SERVICE DATA AND SPECIFICATIONS (SDS)YD

General Specifications

EM-160