suspension NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2567 of 2898

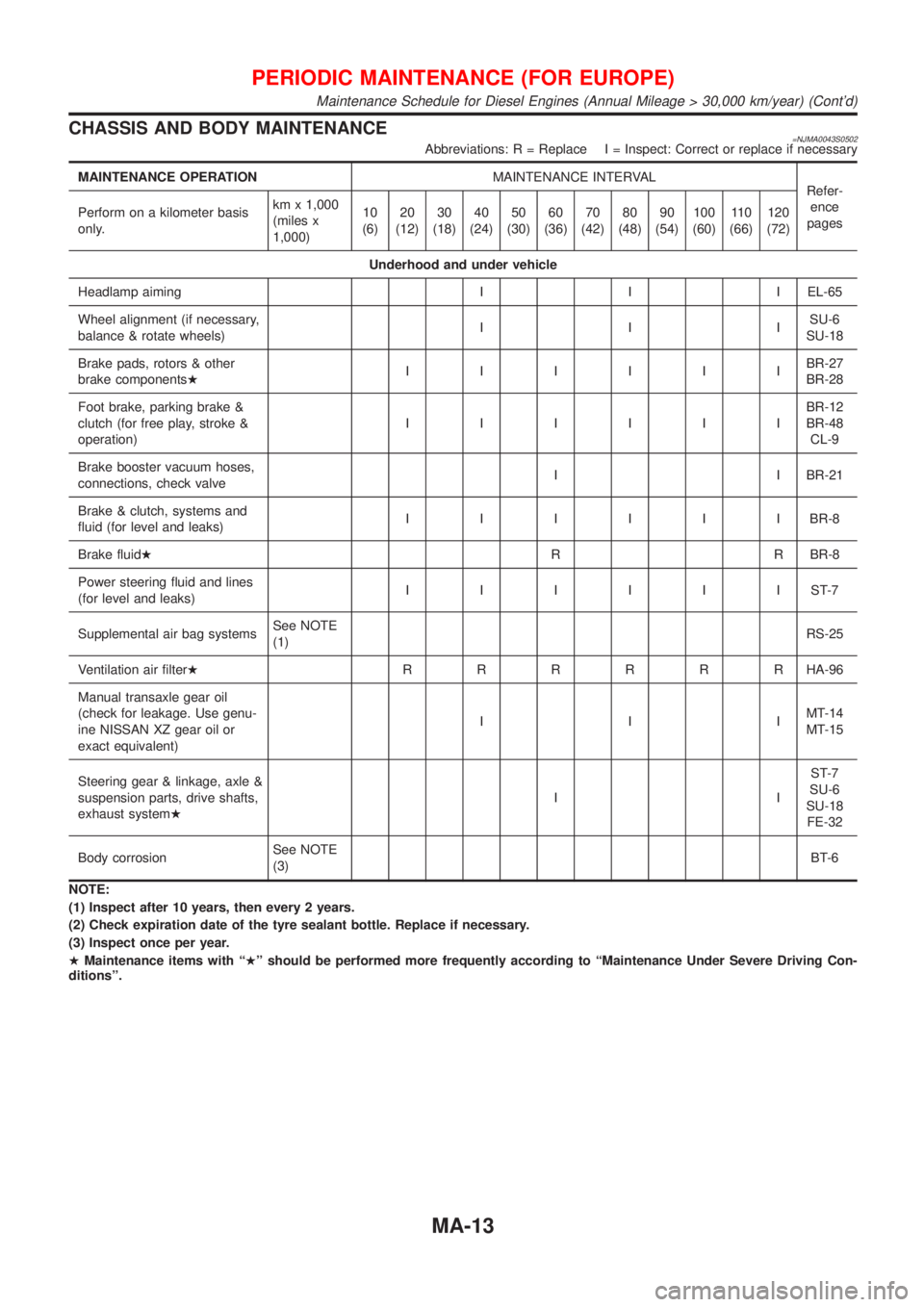

CHASSIS AND BODY MAINTENANCE=NJMA0043S0502Abbreviations: R = Replace I = Inspect: Correct or replace if necessary

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

pages Perform on a kilometer basis

only.km x 1,000

(miles x

1,000)10

(6)20

(12)30

(18)40

(24)50

(30)60

(36)70

(42)80

(48)90

(54)100

(60)11 0

(66)120

(72)

Underhood and under vehicle

Headlamp aiming I I I EL-65

Wheel alignment (if necessary,

balance & rotate wheels)IIISU-6

SU-18

Brake pads, rotors & other

brake componentsHIIIIIIBR-27

BR-28

Foot brake, parking brake &

clutch (for free play, stroke &

operation)IIIIIIBR-12

BR-48

CL-9

Brake booster vacuum hoses,

connections, check valveI I BR-21

Brake & clutch, systems and

fluid (for level and leaks)IIIIIIBR-8

Brake fluidHR R BR-8

Power steering fluid and lines

(for level and leaks)IIIIIIST-7

Supplemental air bag systemsSee NOTE

(1)RS-25

Ventilation air filterHRRRRRRHA-96

Manual transaxle gear oil

(check for leakage. Use genu-

ine NISSAN XZ gear oil or

exact equivalent)IIIMT-14

MT-15

Steering gear & linkage, axle &

suspension parts, drive shafts,

exhaust systemHIIST-7

SU-6

SU-18

FE-32

Body corrosionSee NOTE

(3)BT-6

NOTE:

(1) Inspect after 10 years, then every 2 years.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

(3) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance Under Severe Driving Con-

ditionsº.

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Schedule for Diesel Engines (Annual Mileage > 30,000 km/year) (Cont'd)

MA-13

Page 2569 of 2898

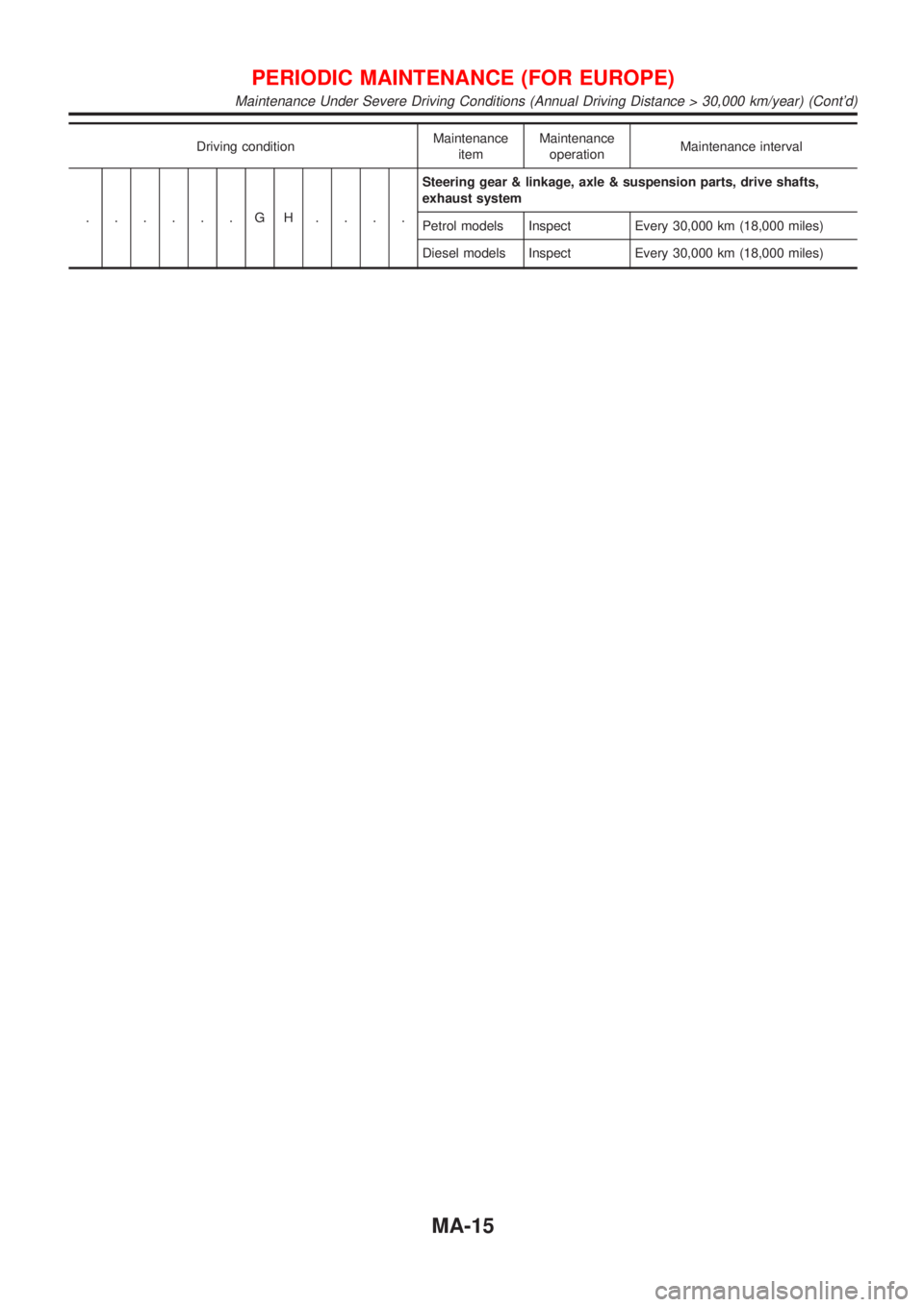

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

......GH....Steering gear & linkage, axle & suspension parts, drive shafts,

exhaust system

Petrol models Inspect Every 30,000 km (18,000 miles)

Diesel models Inspect Every 30,000 km (18,000 miles)

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km/year) (Cont'd)

MA-15

Page 2599 of 2898

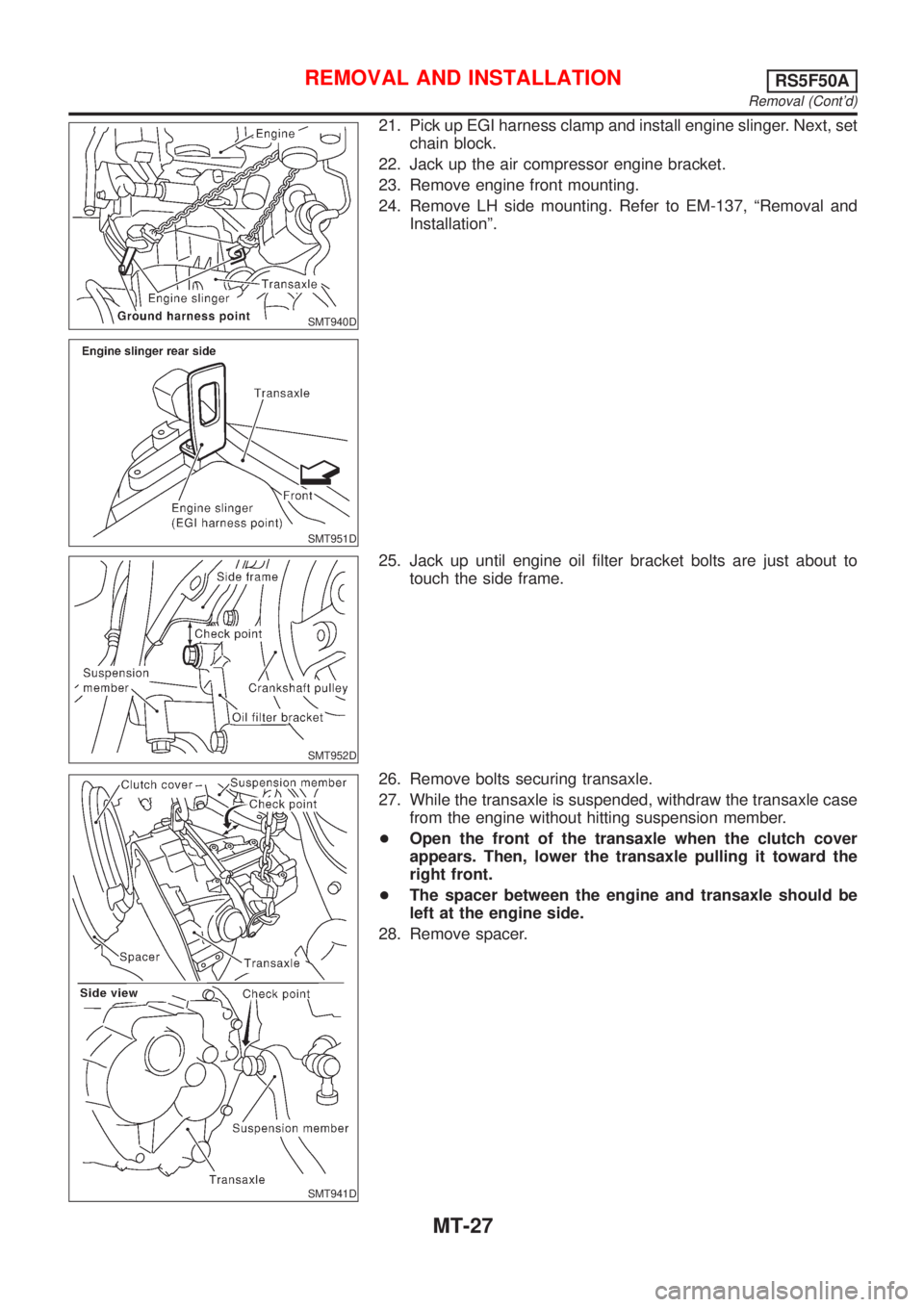

SMT940D

SMT951D

21. Pick up EGI harness clamp and install engine slinger. Next, set

chain block.

22. Jack up the air compressor engine bracket.

23. Remove engine front mounting.

24. Remove LH side mounting. Refer to EM-137, ªRemoval and

Installationº.

SMT952D

25. Jack up until engine oil filter bracket bolts are just about to

touch the side frame.

SMT941D

26. Remove bolts securing transaxle.

27. While the transaxle is suspended, withdraw the transaxle case

from the engine without hitting suspension member.

+Open the front of the transaxle when the clutch cover

appears. Then, lower the transaxle pulling it toward the

right front.

+The spacer between the engine and transaxle should be

left at the engine side.

28. Remove spacer.

REMOVAL AND INSTALLATIONRS5F50A

Removal (Cont'd)

MT-27

Page 2600 of 2898

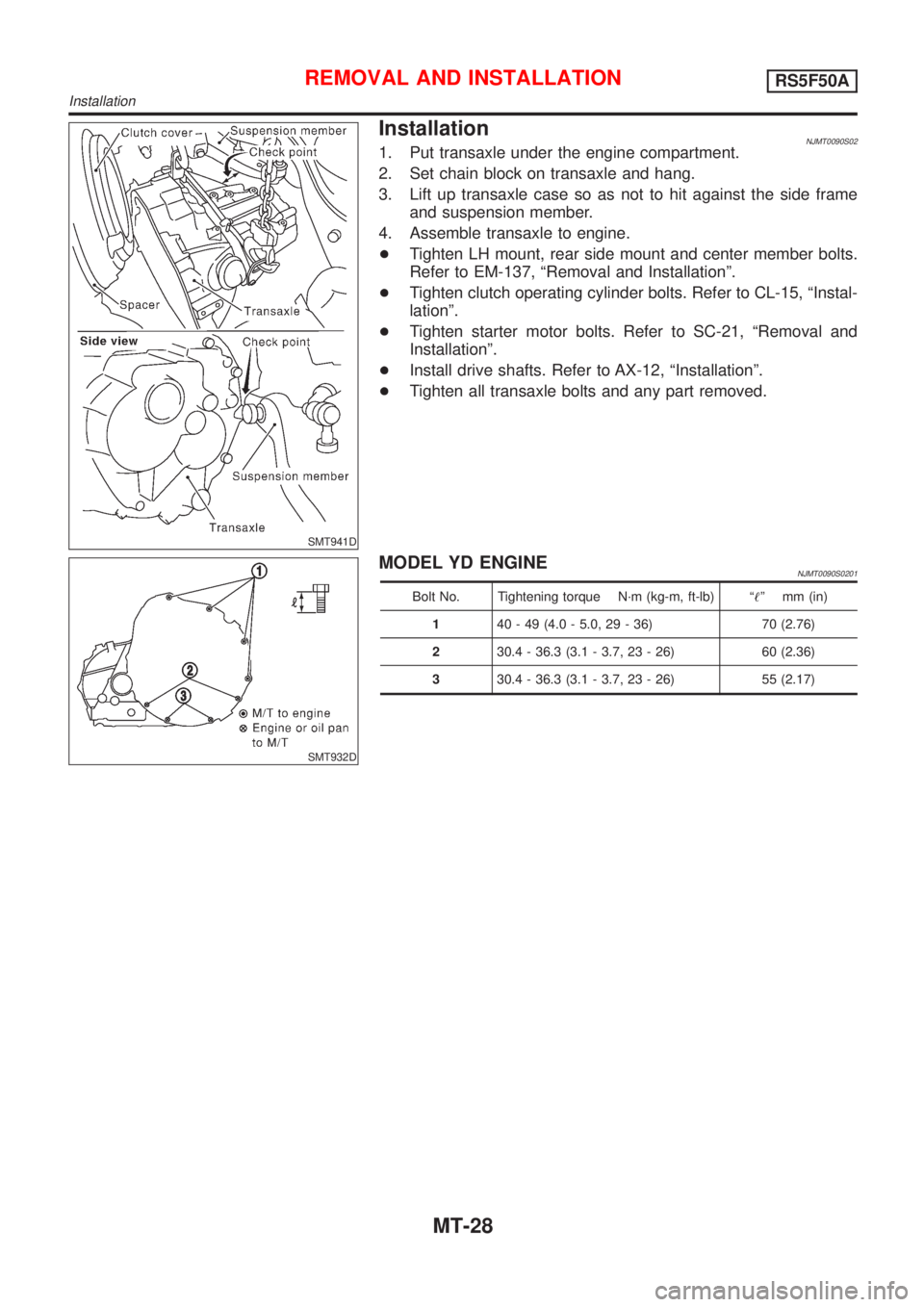

SMT941D

InstallationNJMT0090S021. Put transaxle under the engine compartment.

2. Set chain block on transaxle and hang.

3. Lift up transaxle case so as not to hit against the side frame

and suspension member.

4. Assemble transaxle to engine.

+Tighten LH mount, rear side mount and center member bolts.

Refer to EM-137, ªRemoval and Installationº.

+Tighten clutch operating cylinder bolts. Refer to CL-15, ªInstal-

lationº.

+Tighten starter motor bolts. Refer to SC-21, ªRemoval and

Installationº.

+Install drive shafts. Refer to AX-12, ªInstallationº.

+Tighten all transaxle bolts and any part removed.

SMT932D

MODEL YD ENGINENJMT0090S0201

Bolt No. Tightening torque N´m (kg-m, ft-lb) ª!º mm (in)

140 - 49 (4.0 - 5.0, 29 - 36) 70 (2.76)

230.4 - 36.3 (3.1 - 3.7, 23 - 26) 60 (2.36)

330.4 - 36.3 (3.1 - 3.7, 23 - 26) 55 (2.17)

REMOVAL AND INSTALLATIONRS5F50A

Installation

MT-28

Page 2841 of 2898

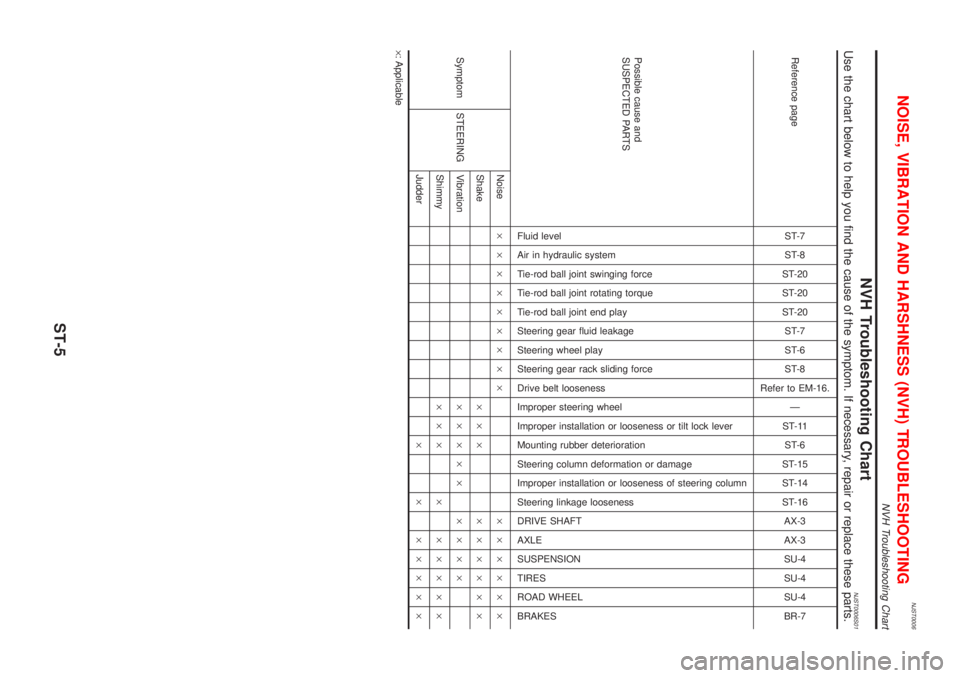

NJST0006

NVH Troubleshooting ChartNJST0006S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-7

ST-8

ST-20

ST-20

ST-20

ST-7

ST-6

ST-8

Refer to EM-16.

Ð

ST-11

ST-6

ST-15

ST-14

ST-16

AX-3

AX-3

SU-4

SU-4

SU-4

BR-7

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symptom STEERINGNoise´´´´´´´´´ ´´´´´´

Shake´´´ ´´´´´´

Vibration´´´´´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-5

Page 2842 of 2898

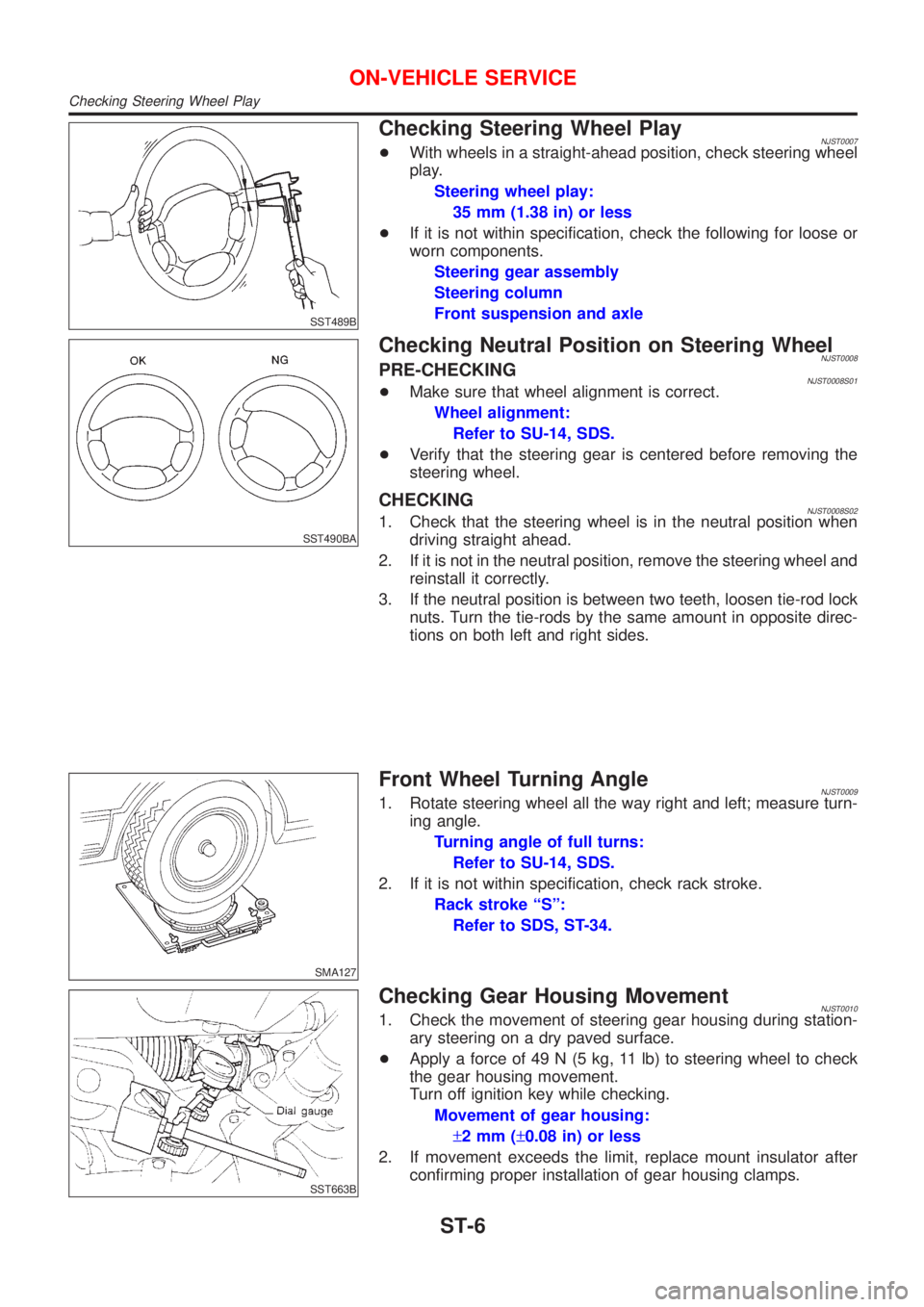

SST489B

Checking Steering Wheel PlayNJST0007+With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

+If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

SST490BA

Checking Neutral Position on Steering WheelNJST0008PRE-CHECKINGNJST0008S01+Make sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-14, SDS.

+Verify that the steering gear is centered before removing the

steering wheel.

CHECKINGNJST0008S021. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite direc-

tions on both left and right sides.

SMA127

Front Wheel Turning AngleNJST00091. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Turning angle of full turns:

Refer to SU-14, SDS.

2. If it is not within specification, check rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-34.

SST663B

Checking Gear Housing MovementNJST00101. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

+Apply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

ON-VEHICLE SERVICE

Checking Steering Wheel Play

ST-6

Page 2873 of 2898

FRONT & REAR SUSPENSION

SECTION

SU

CONTENTS

FRONT SUSPENSION....................................................2

Precautions ..................................................................2

PRECAUTIONS.........................................................2

Preparation ..................................................................2

SPECIAL SERVICE TOOLS........................................2

COMMERCIAL SERVICE TOOLS................................2

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................4

NVH TROUBLESHOOTING CHART............................4

Components.................................................................5

On-vehicle Service.......................................................6

FRONT SUSPENSION PARTS...................................6

BALANCING WHEELS...............................................7

TIRE ROTATION.......................................................7

FRONT WHEEL ALIGNMENT.....................................7

Coil Spring and Shock Absorber .................................9

COMPONENTS.........................................................9

REMOVAL AND INSTALLATION...............................10

DISASSEMBLY........................................................10

INSPECTION...........................................................10

ASSEMBLY............................................................. 11

Stabilizer Bar ............................................................. 11

REMOVAL AND INSTALLATION............................... 11

Transverse Link and Lower Ball Joint .......................12

REMOVAL AND INSTALLATION...............................12

INSPECTION...........................................................13

Service Data and Specifications (SDS).....................14

GENERAL SPECIFICATIONS (FRONT).....................14

FRONT WHEEL ALIGNMENT (UNLADEN*1).............14

LOWER BALL JOINT...............................................14

WHEELARCH HEIGHT (UNLADEN*1).......................15

WHEEL RUNOUT....................................................15

WHEEL BALANCE...................................................15

REAR SUSPENSION.....................................................16

Precautions ................................................................16

PRECAUTIONS.......................................................16

Preparation ................................................................16

COMMERCIAL SERVICE TOOLS..............................16

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................16

Components...............................................................17

On-vehicle Service.....................................................18

REAR SUSPENSION PARTS...................................18

REAR WHEEL ALIGNMENT.....................................18

Removal and Installation ...........................................20

REMOVAL...............................................................21

INSTALLATION........................................................21

Coil Spring and Shock Absorber ...............................21

REMOVAL AND INSTALLATION...............................21

DISASSEMBLY........................................................22

INSPECTION...........................................................22

ASSEMBLY.............................................................22

Torsion Beam, Lateral Link and Control Rod ............23

DISASSEMBLY........................................................23

INSPECTION...........................................................23

ASSEMBLY.............................................................23

Service Data and Specifications (SDS).....................25

GENERAL SPECIFICATIONS (REAR).......................25

REAR WHEEL ALIGNMENT (UNLADEN*).................25

Page 2874 of 2898

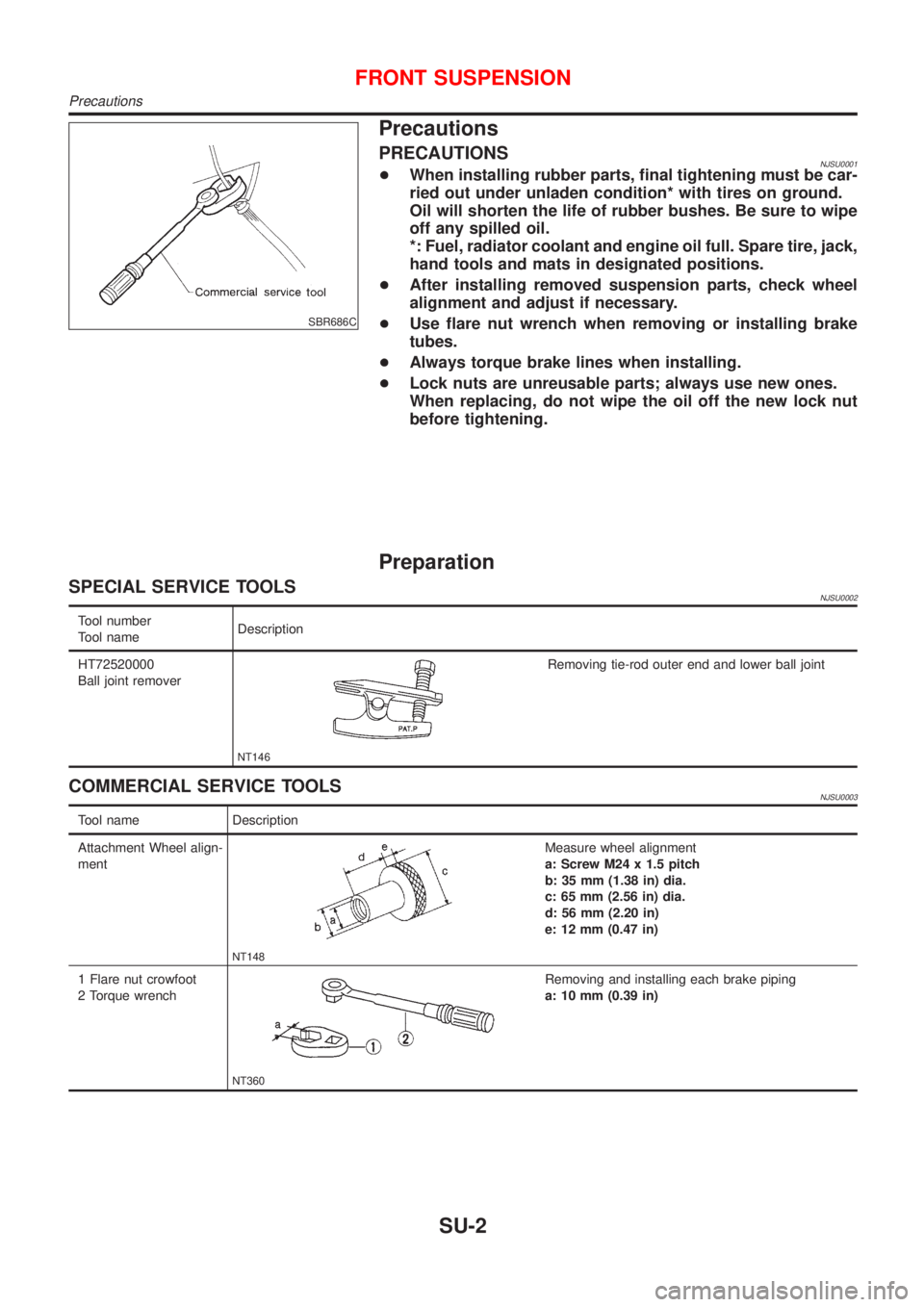

SBR686C

Precautions

PRECAUTIONSNJSU0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

Oil will shorten the life of rubber bushes. Be sure to wipe

off any spilled oil.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

+Lock nuts are unreusable parts; always use new ones.

When replacing, do not wipe the oil off the new lock nut

before tightening.

Preparation

SPECIAL SERVICE TOOLSNJSU0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

COMMERCIAL SERVICE TOOLSNJSU0003

Tool name Description

Attachment Wheel align-

ment

NT148

Measure wheel alignment

a: Screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in)

e: 12 mm (0.47 in)

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT SUSPENSION

Precautions

SU-2

Page 2875 of 2898

Tool name Description

Spring compressor

NT717

Removing and installing coil spring

FRONT SUSPENSION

Preparation (Cont'd)

SU-3

Page 2876 of 2898

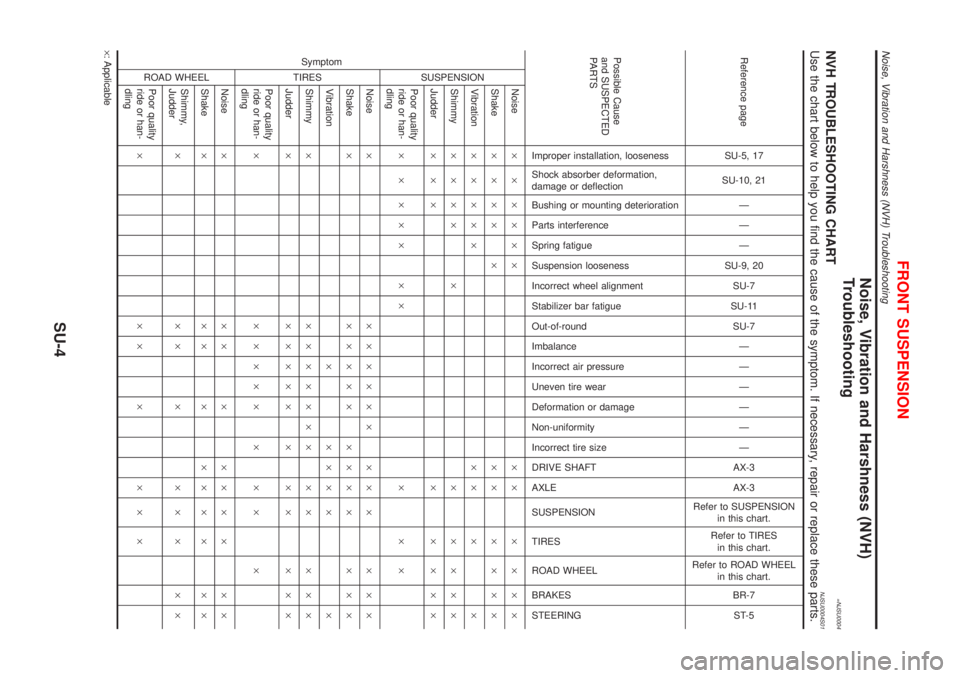

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NJSU0004NVH TROUBLESHOOTING CHARTNJSU0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

SU-5, 17

SU-10, 21

Ð

Ð

Ð

SU-9, 20

SU-7

SU-11

SU-7

Ð

Ð

Ð

Ð

Ð

Ð

AX-3

AX-3

Refer to SUSPENSION

in this chart.

Refer to TIRES

in this chart.

Refer to ROAD WHEEL

in this chart.

BR-7

ST-5

Possible Cause

and SUSPECTED

PA R T S

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

Out-of-round

Imbalance

Incorrect air pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING Symptom

SUSPENSION

Noise´ ´ ´´´´ ´´ ´ ´ ´´

Shake´ ´ ´´ ´ ´´ ´ ´ ´´

Vibration´ ´ ´´´ ´´ ´ ´

Shimmy´´´´ ´ ´ ´ ´´´

Judder´´´ ´ ´ ´´´

Poor quality

ride or han-

dling´ ´ ´´´ ´´ ´ ´ ´

TIRES

Noise´ ´´´´´´ ´´ ´ ´ ´´

Shake´ ´´´´´ ´´´ ´ ´ ´´

Vibration´ ´´´ ´ ´

Shimmy´ ´´´´´´´ ´ ´ ´ ´´

Judder´ ´´´´´ ´ ´ ´ ´ ´´

Poor quality

ride or han-

dling´ ´´´´´ ´ ´ ´ ´

ROAD WHEEL

Noise´ ´´´´´´´´´

Shake´ ´´´´´´´´´

Shimmy,

Judder´´´´´´´´´

Poor quality

ride or han-

dling´´´´´´´

´: Applicable

FRONT SUSPENSION

Noise, Vibration and Harshness (NVH) Troubleshooting

SU-4