transmission NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 118 of 2898

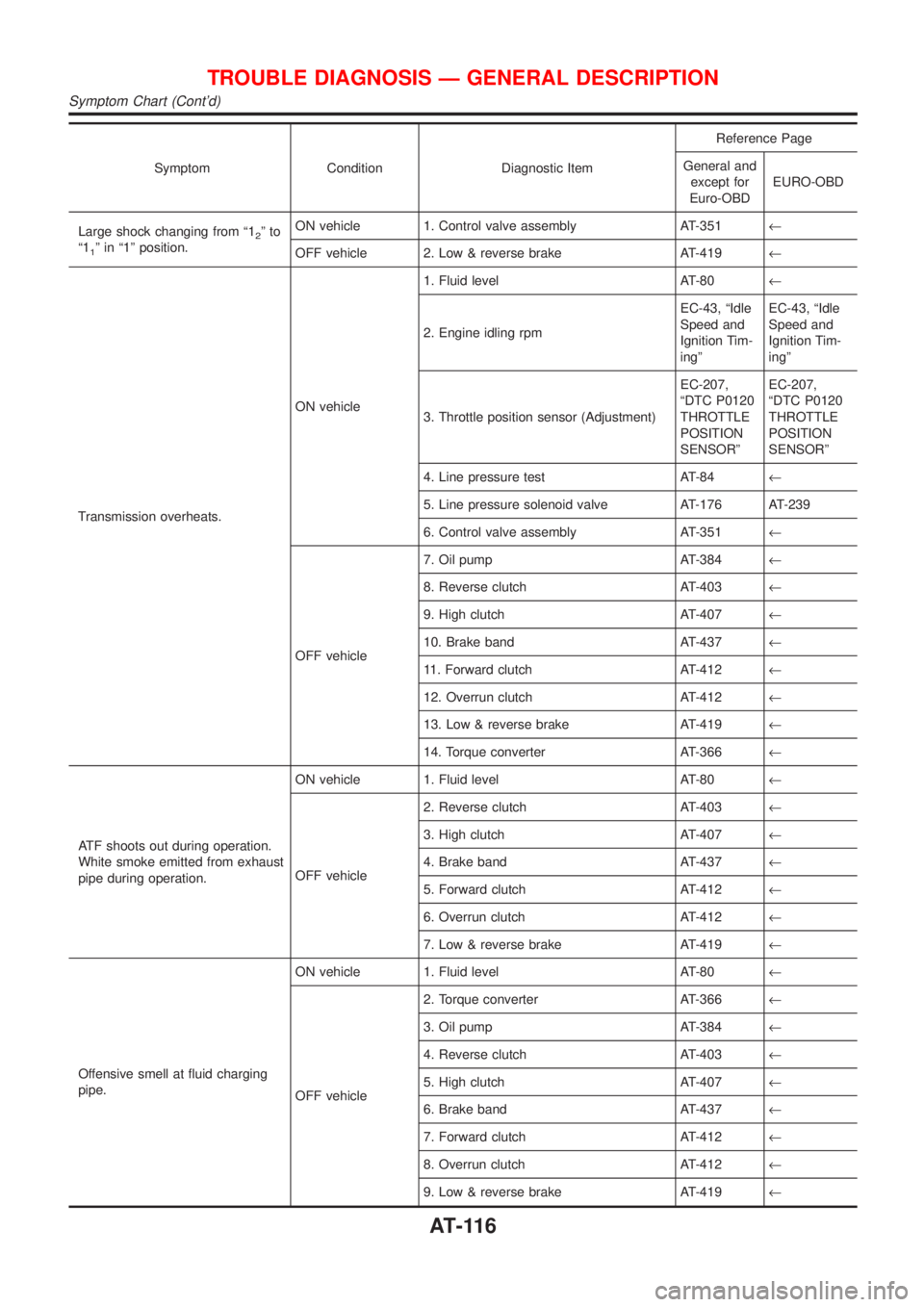

Symptom Condition Diagnostic ItemReference Page

General and

except for

Euro-OBDEURO-OBD

Large shock changing from ª1

2ºto

ª1

1º in ª1º position.ON vehicle 1. Control valve assembly AT-351¬

OFF vehicle 2. Low & reverse brake AT-419¬

Transmission overheats.ON vehicle1. Fluid level AT-80¬

2. Engine idling rpmEC-43, ªIdle

Speed and

Ignition Tim-

ingºEC-43, ªIdle

Speed and

Ignition Tim-

ingº

3. Throttle position sensor (Adjustment)EC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORºEC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORº

4. Line pressure test AT-84¬

5. Line pressure solenoid valve AT-176 AT-239

6. Control valve assembly AT-351¬

OFF vehicle7. Oil pump AT-384¬

8. Reverse clutch AT-403¬

9. High clutch AT-407¬

10. Brake band AT-437¬

11. Forward clutch AT-412¬

12. Overrun clutch AT-412¬

13. Low & reverse brake AT-419¬

14. Torque converter AT-366¬

ATF shoots out during operation.

White smoke emitted from exhaust

pipe during operation.ON vehicle 1. Fluid level AT-80¬

OFF vehicle2. Reverse clutch AT-403¬

3. High clutch AT-407¬

4. Brake band AT-437¬

5. Forward clutch AT-412¬

6. Overrun clutch AT-412¬

7. Low & reverse brake AT-419¬

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid level AT-80¬

OFF vehicle2. Torque converter AT-366¬

3. Oil pump AT-384¬

4. Reverse clutch AT-403¬

5. High clutch AT-407¬

6. Brake band AT-437¬

7. Forward clutch AT-412¬

8. Overrun clutch AT-412¬

9. Low & reverse brake AT-419¬

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-116

Page 185 of 2898

SAT088JA

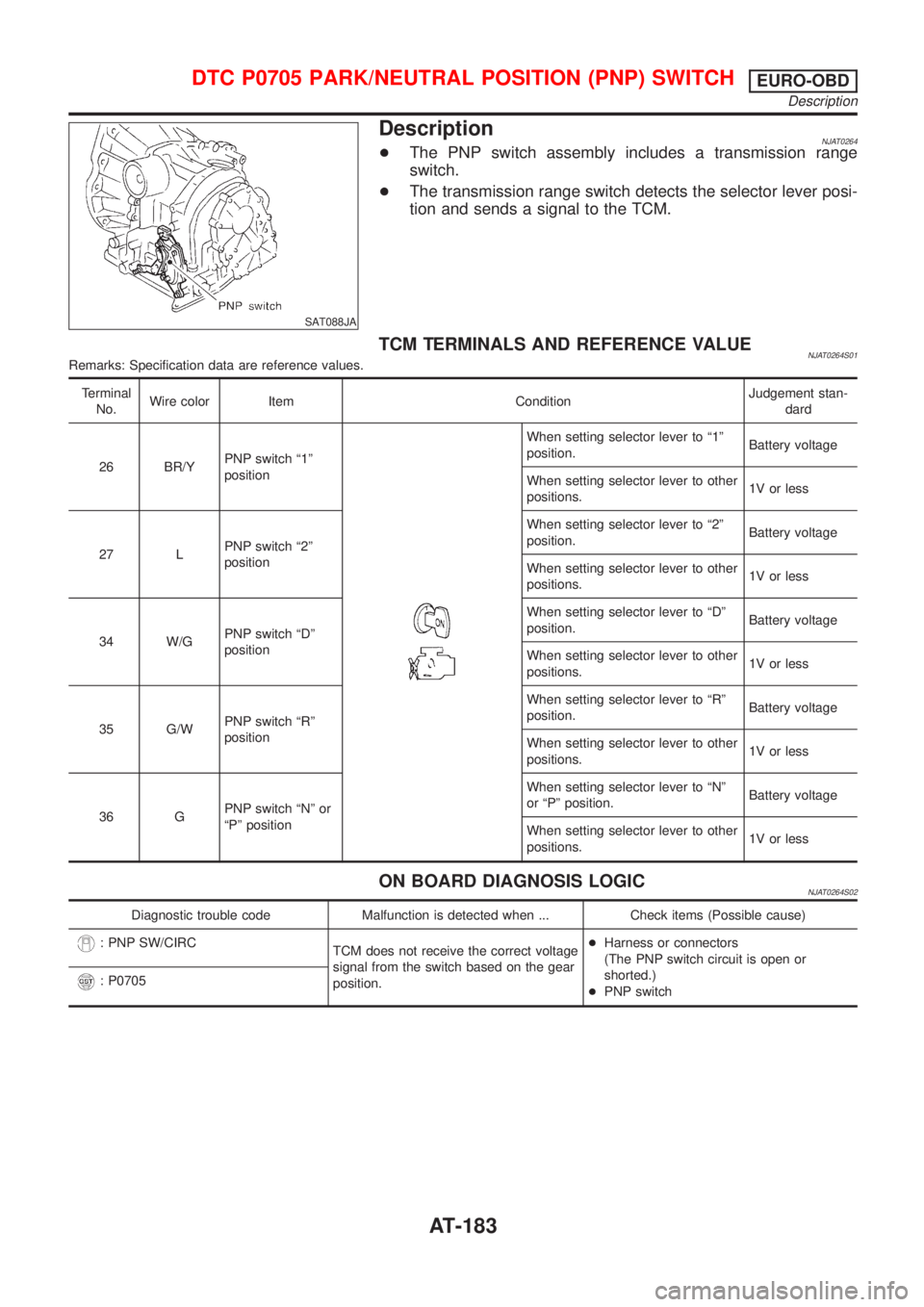

DescriptionNJAT0264+The PNP switch assembly includes a transmission range

switch.

+The transmission range switch detects the selector lever posi-

tion and sends a signal to the TCM.

TCM TERMINALS AND REFERENCE VALUENJAT0264S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

26 BR/YPNP switch ª1º

position

When setting selector lever to ª1º

position.Battery voltage

When setting selector lever to other

positions.1V or less

27 LPNP switch ª2º

positionWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to other

positions.1V or less

34 W/GPNP switch ªDº

positionWhen setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.1V or less

35 G/WPNP switch ªRº

positionWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.1V or less

36 GPNP switch ªNº or

ªPº positionWhen setting selector lever to ªNº

or ªPº position.Battery voltage

When setting selector lever to other

positions.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0264S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: PNP SW/CIRC

TCM does not receive the correct voltage

signal from the switch based on the gear

position.+Harness or connectors

(The PNP switch circuit is open or

shorted.)

+PNP switch

: P0705

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Description

AT-183

Page 208 of 2898

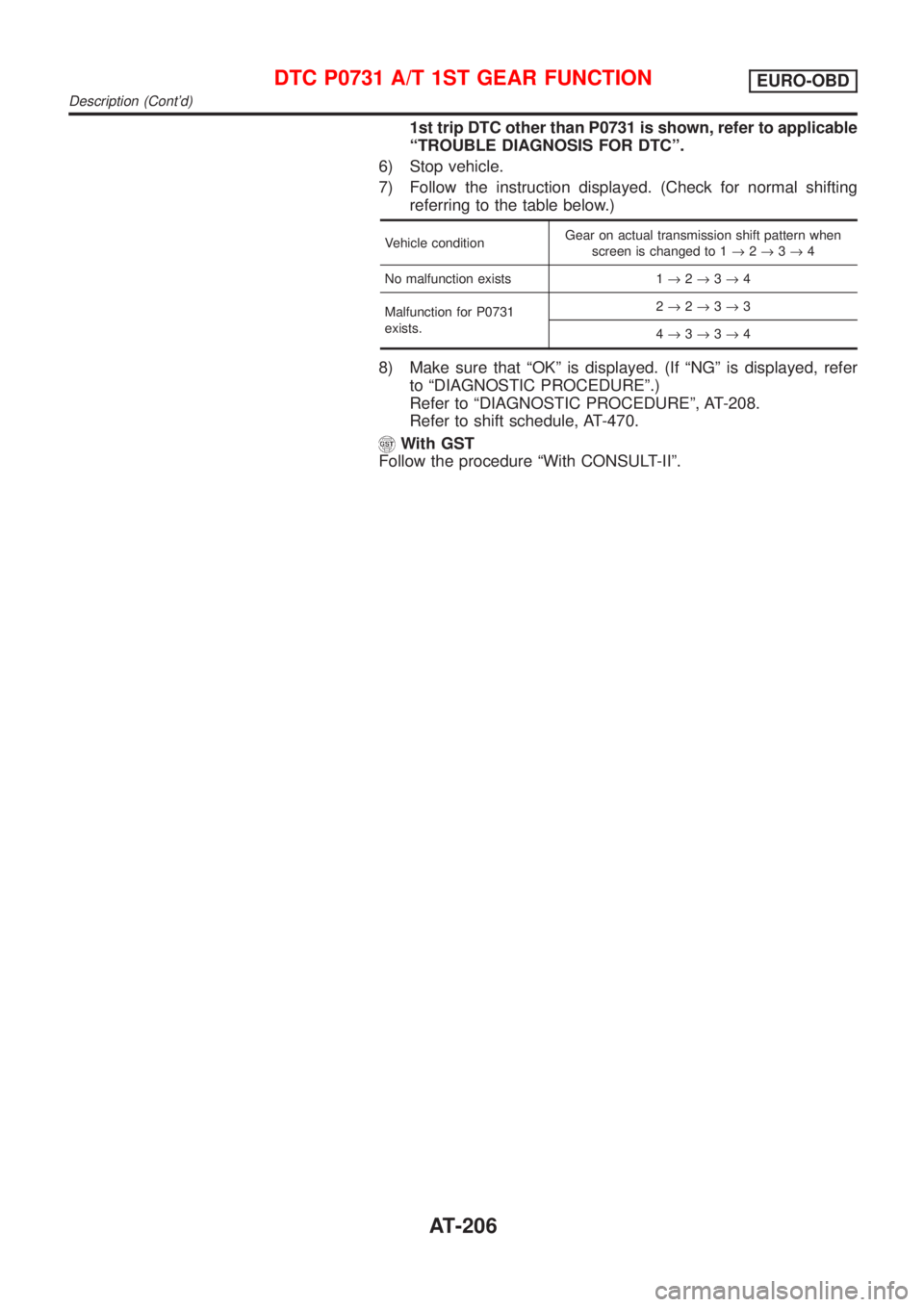

1st trip DTC other than P0731 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists 1®2®3®4

Malfunction for P0731

exists.2®2®3®3

4®3®3®4

8) Make sure that ªOKº is displayed. (If ªNGº is displayed, refer

to ªDIAGNOSTIC PROCEDUREº.)

Refer to ªDIAGNOSTIC PROCEDUREº, AT-208.

Refer to shift schedule, AT-470.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0731 A/T 1ST GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-206

Page 214 of 2898

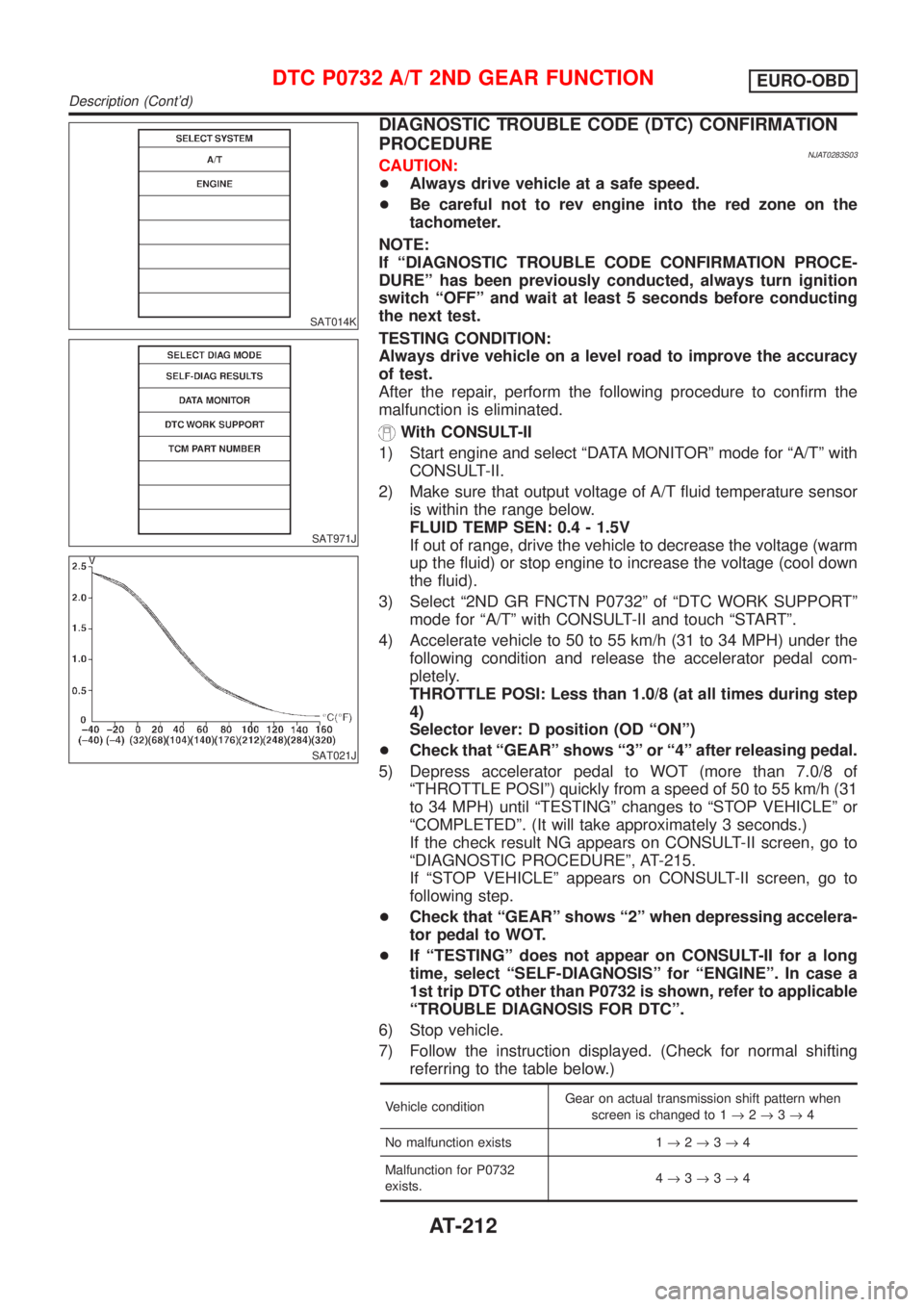

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0283S03CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª2ND GR FNCTN P0732º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 50 to 55 km/h (31 to 34 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª3º or ª4º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 50 to 55 km/h (31

to 34 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-215.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

+Check that ªGEARº shows ª2º when depressing accelera-

tor pedal to WOT.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

1st trip DTC other than P0732 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists 1®2®3®4

Malfunction for P0732

exists.4®3®3®4

DTC P0732 A/T 2ND GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-212

Page 220 of 2898

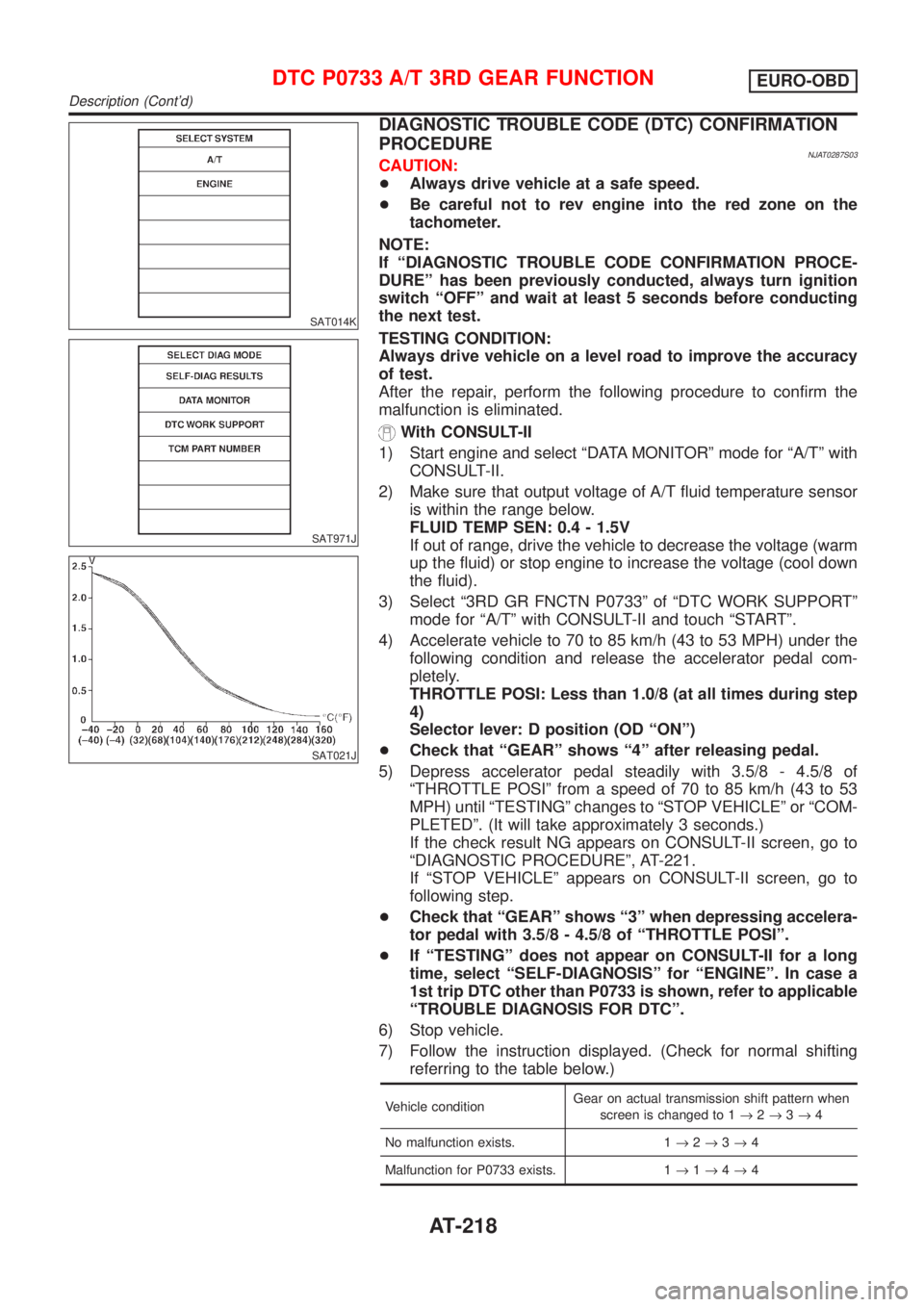

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0287S03CAUTION:

+Always drive vehicle at a safe speed.

+Be careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITION:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª3RD GR FNCTN P0733º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 70 to 85 km/h (43 to 53 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

+Check that ªGEARº shows ª4º after releasing pedal.

5) Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of

ªTHROTTLE POSIº from a speed of 70 to 85 km/h (43 to 53

MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or ªCOM-

PLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-221.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

+Check that ªGEARº shows ª3º when depressing accelera-

tor pedal with 3.5/8 - 4.5/8 of ªTHROTTLE POSIº.

+If ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAGNOSISº for ªENGINEº. In case a

1st trip DTC other than P0733 is shown, refer to applicable

ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists. 1®2®3®4

Malfunction for P0733 exists. 1®1®4®4

DTC P0733 A/T 3RD GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-218

Page 228 of 2898

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1®2®3®4

No malfunction exists 1®2®3®4

Malfunction for P0734 exists. 1®2®2®1

8) Make sure that ªOKº is displayed. (If ªNGº is displayed, refer

to ªDIAGNOSTIC PROCEDUREº.)

Refer to ªDIAGNOSTIC PROCEDUREº, AT-228.

Refer to shift schedule, AT-470.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0734 A/T 4TH GEAR FUNCTIONEURO-OBD

Description (Cont'd)

AT-226

Page 249 of 2898

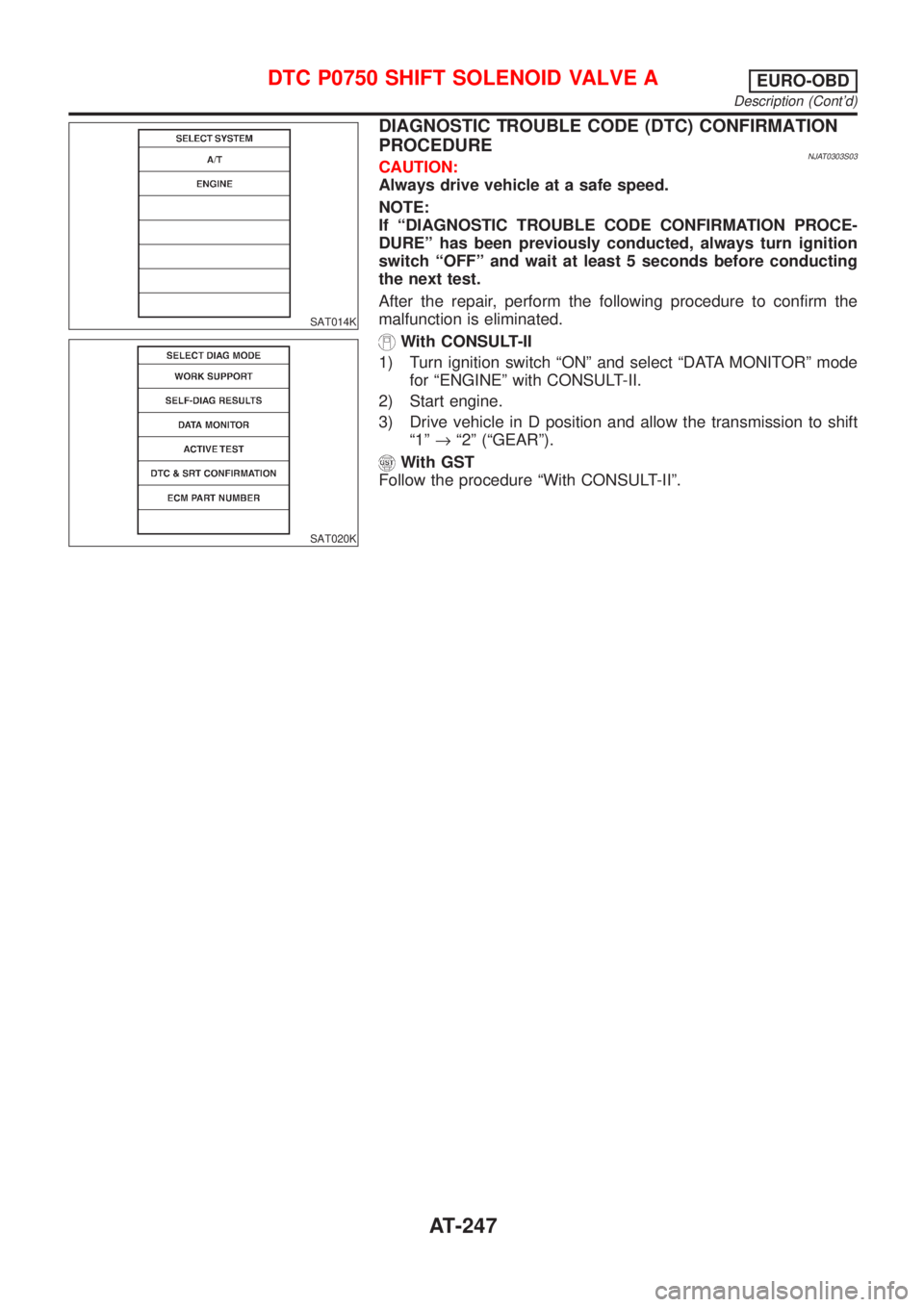

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0303S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Drive vehicle in D position and allow the transmission to shift

ª1º®ª2º (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0750 SHIFT SOLENOID VALVE AEURO-OBD

Description (Cont'd)

AT-247

Page 255 of 2898

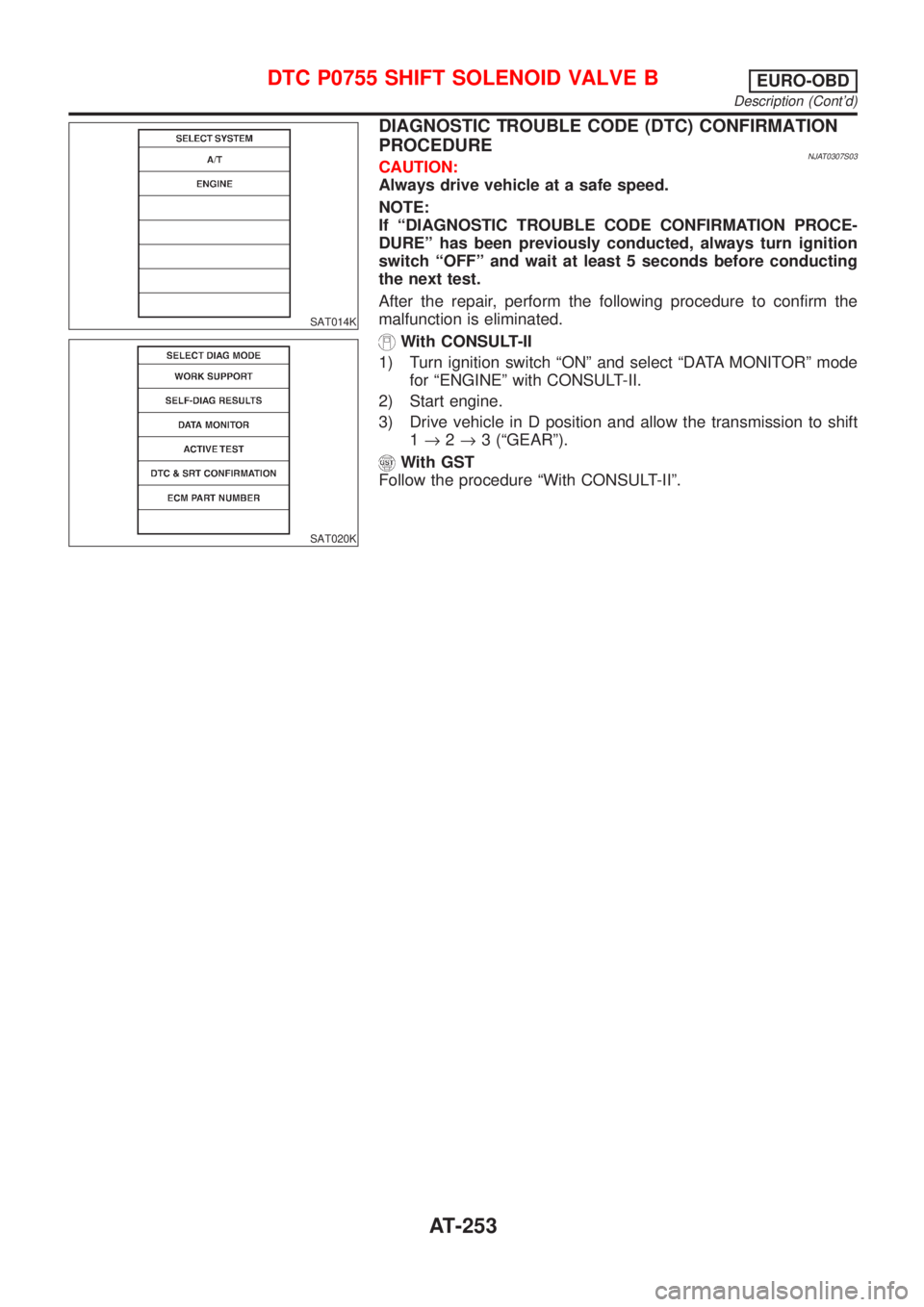

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0307S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Drive vehicle in D position and allow the transmission to shift

1®2®3 (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0755 SHIFT SOLENOID VALVE BEURO-OBD

Description (Cont'd)

AT-253

Page 336 of 2898

20. Vehicle Does Not Decelerate By Engine

Brake

=NJAT0350SYMPTOM:

Vehicle does not decelerate by engine brake when shifting

from 2

2(12)to11.

1 CHECK SYMPTOM

Is 6. Vehicle Does Not Creep Backward In ªRº Position OK?

YesorNo

Ye s©Go to 15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3), AT-328.

No©Go to 6. Vehicle Does Not Creep Backward In ªRº Position, AT-305.

SAT088JA

SAT360H

SAT004K

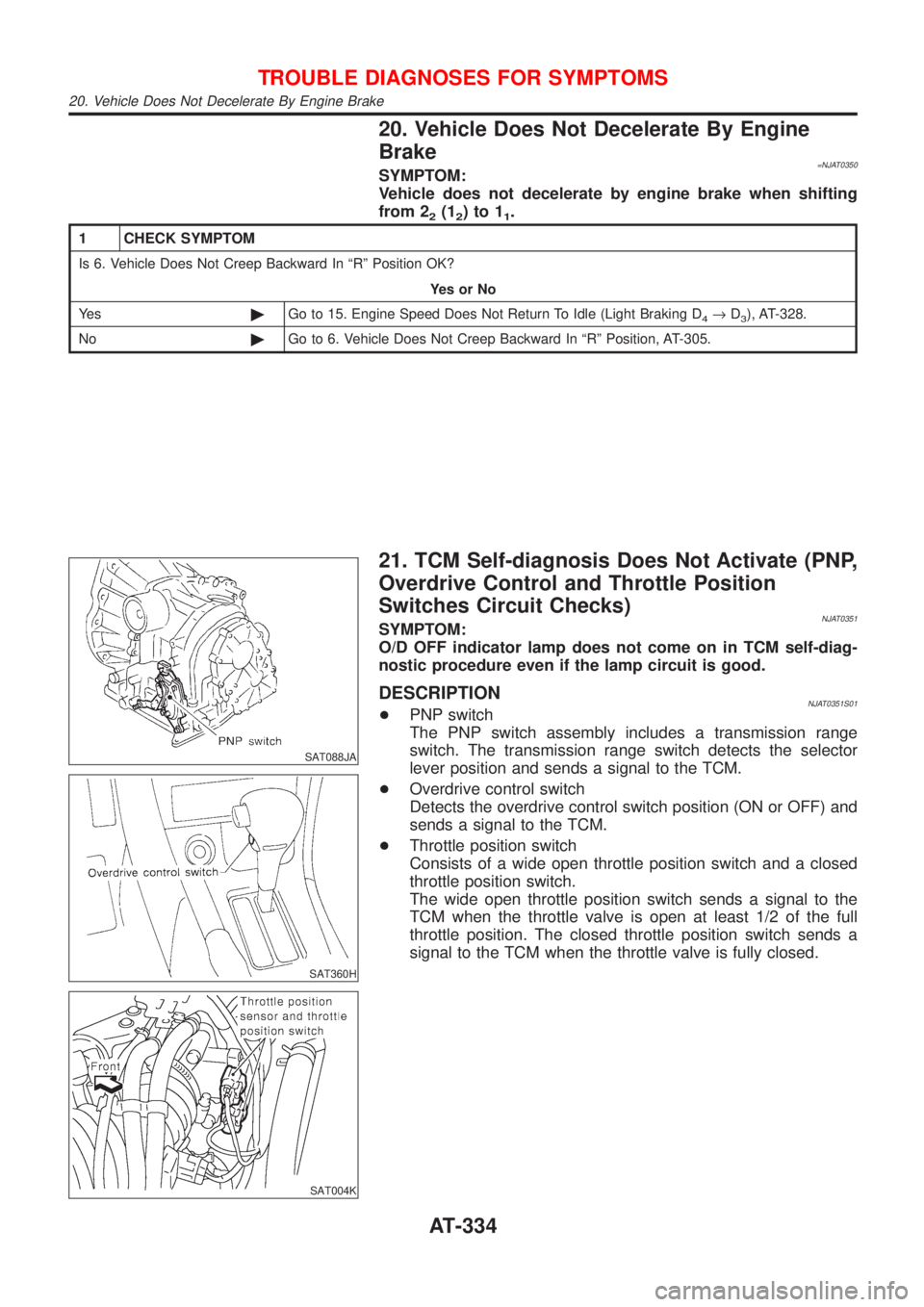

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position

Switches Circuit Checks)

NJAT0351SYMPTOM:

O/D OFF indicator lamp does not come on in TCM self-diag-

nostic procedure even if the lamp circuit is good.

DESCRIPTIONNJAT0351S01+PNP switch

The PNP switch assembly includes a transmission range

switch. The transmission range switch detects the selector

lever position and sends a signal to the TCM.

+Overdrive control switch

Detects the overdrive control switch position (ON or OFF) and

sends a signal to the TCM.

+Throttle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

TROUBLE DIAGNOSES FOR SYMPTOMS

20. Vehicle Does Not Decelerate By Engine Brake

AT-334

Page 353 of 2898

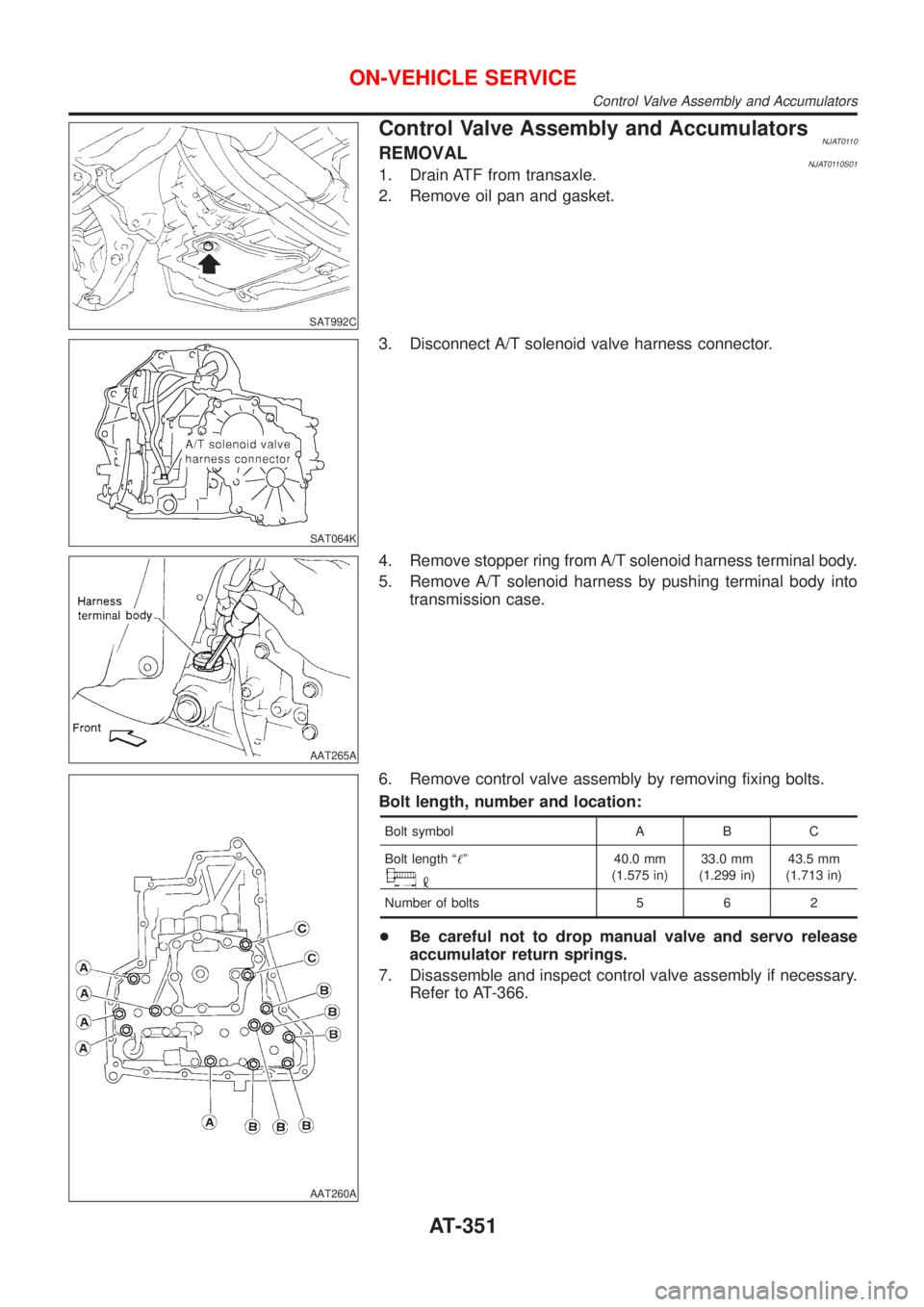

SAT992C

Control Valve Assembly and AccumulatorsNJAT0110REMOVALNJAT0110S011. Drain ATF from transaxle.

2. Remove oil pan and gasket.

SAT064K

3. Disconnect A/T solenoid valve harness connector.

AAT265A

4. Remove stopper ring from A/T solenoid harness terminal body.

5. Remove A/T solenoid harness by pushing terminal body into

transmission case.

AAT260A

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

Bolt symbol A B C

Bolt length ª!º

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

+Be careful not to drop manual valve and servo release

accumulator return springs.

7. Disassemble and inspect control valve assembly if necessary.

Refer to AT-366.

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators

AT-351