transmission oil NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 422 of 2898

SAT242D

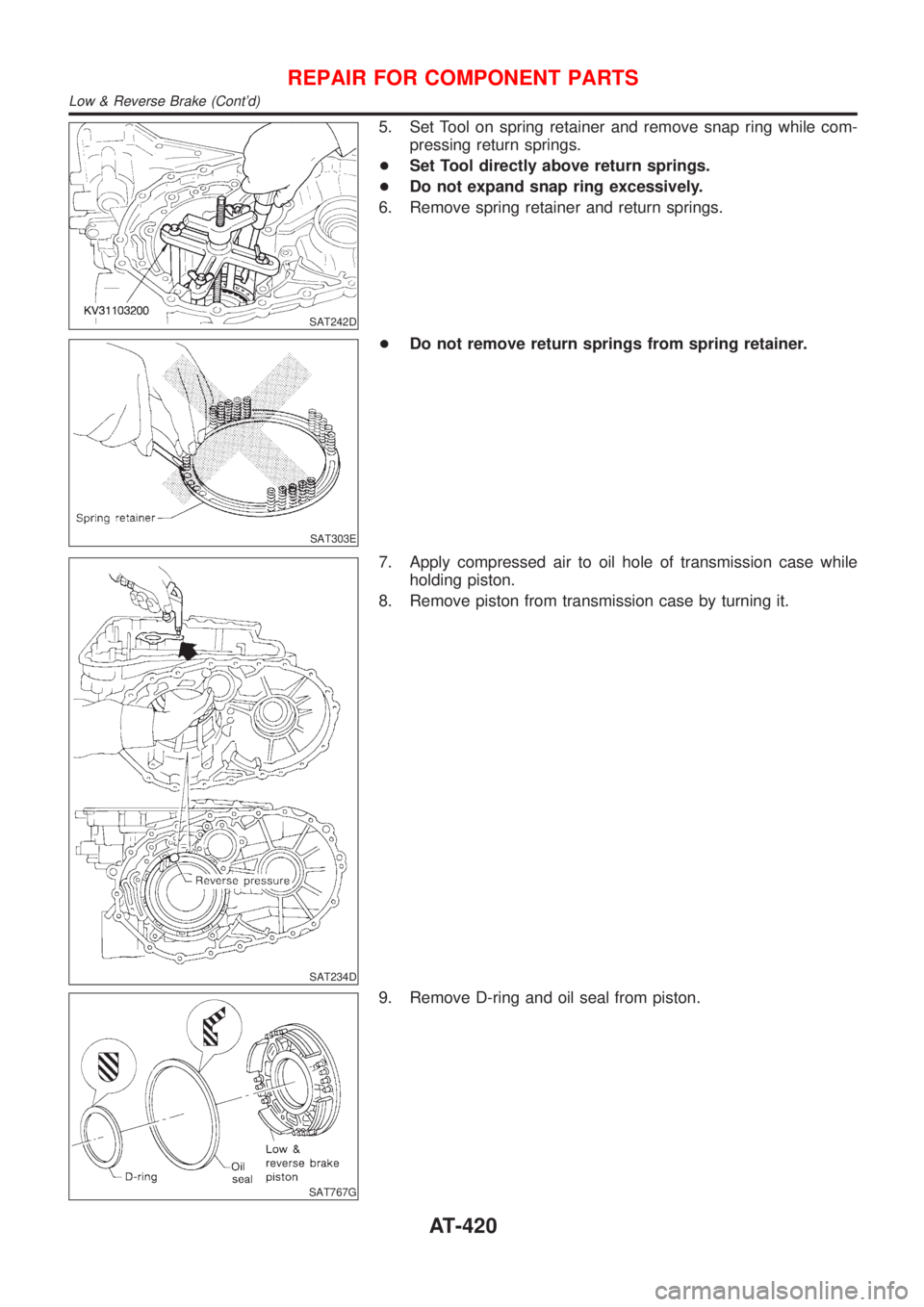

5. Set Tool on spring retainer and remove snap ring while com-

pressing return springs.

+Set Tool directly above return springs.

+Do not expand snap ring excessively.

6. Remove spring retainer and return springs.

SAT303E

+Do not remove return springs from spring retainer.

SAT234D

7. Apply compressed air to oil hole of transmission case while

holding piston.

8. Remove piston from transmission case by turning it.

SAT767G

9. Remove D-ring and oil seal from piston.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-420

Page 423 of 2898

INSPECTIONNJAT0155Low & Reverse Clutch Snap Ring, Spring Retainer and

Return Springs

NJAT0155S01+Check for deformation, fatigue or damage.

+Replace if necessary.

+When replacing spring retainer and return springs,

replace them as a set.

SAT162D

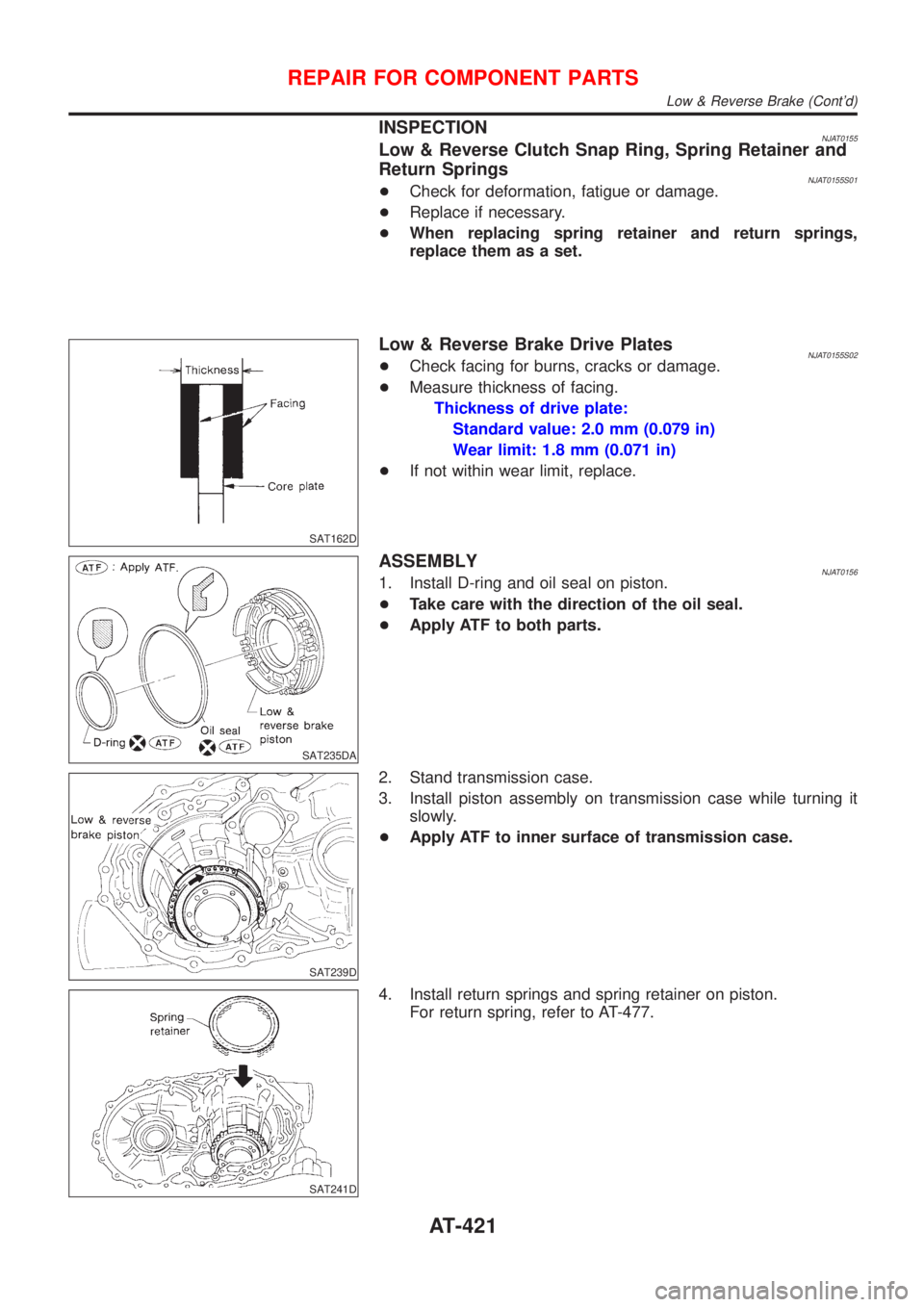

Low & Reverse Brake Drive PlatesNJAT0155S02+Check facing for burns, cracks or damage.

+Measure thickness of facing.

Thickness of drive plate:

Standard value: 2.0 mm (0.079 in)

Wear limit: 1.8 mm (0.071 in)

+If not within wear limit, replace.

SAT235DA

ASSEMBLYNJAT01561. Install D-ring and oil seal on piston.

+Take care with the direction of the oil seal.

+Apply ATF to both parts.

SAT239D

2. Stand transmission case.

3. Install piston assembly on transmission case while turning it

slowly.

+Apply ATF to inner surface of transmission case.

SAT241D

4. Install return springs and spring retainer on piston.

For return spring, refer to AT-477.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-421

Page 439 of 2898

SAT661D

+Roll paper around seal rings to prevent seal rings from

spreading.

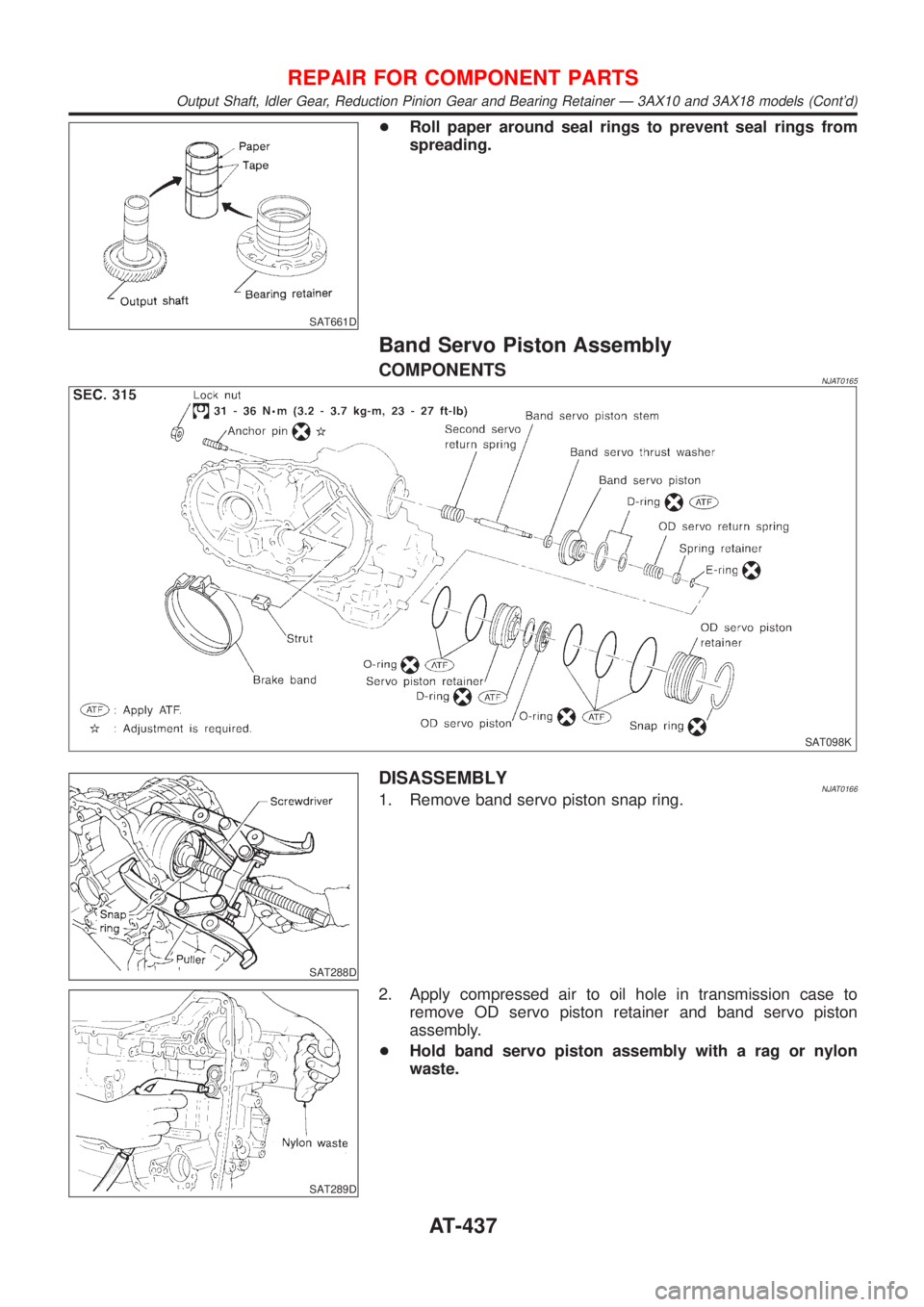

Band Servo Piston Assembly

COMPONENTSNJAT0165

SAT098K

SAT288D

DISASSEMBLYNJAT01661. Remove band servo piston snap ring.

SAT289D

2. Apply compressed air to oil hole in transmission case to

remove OD servo piston retainer and band servo piston

assembly.

+Hold band servo piston assembly with a rag or nylon

waste.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-437

Page 448 of 2898

SAT311G

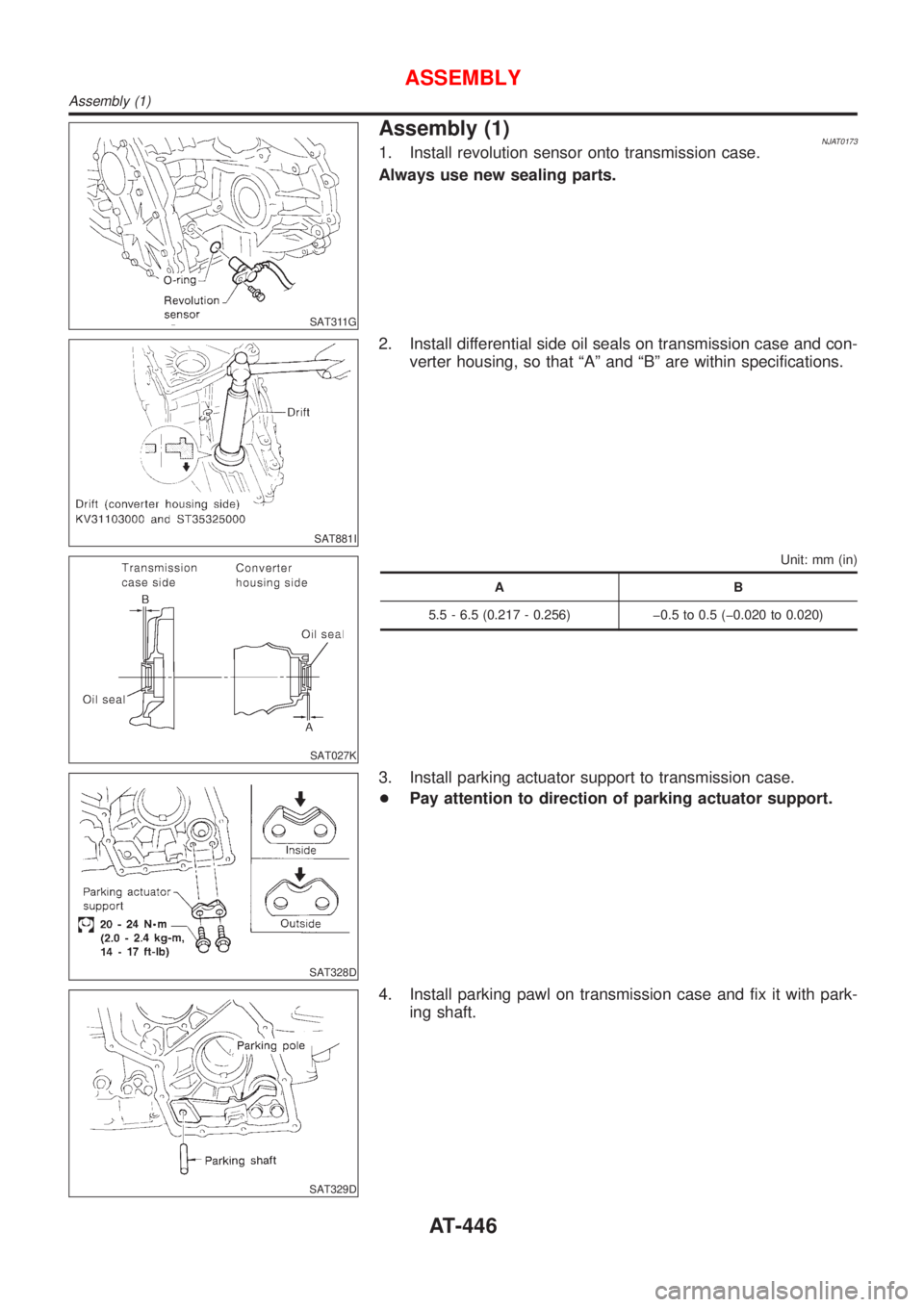

Assembly (1)NJAT01731. Install revolution sensor onto transmission case.

Always use new sealing parts.

SAT881I

2. Install differential side oil seals on transmission case and con-

verter housing, so that ªAº and ªBº are within specifications.

SAT027K

Unit: mm (in)

AB

5.5 - 6.5 (0.217 - 0.256) þ0.5 to 0.5 (þ0.020 to 0.020)

SAT328D

3. Install parking actuator support to transmission case.

+Pay attention to direction of parking actuator support.

SAT329D

4. Install parking pawl on transmission case and fix it with park-

ing shaft.

ASSEMBLY

Assembly (1)

AT-446

Page 461 of 2898

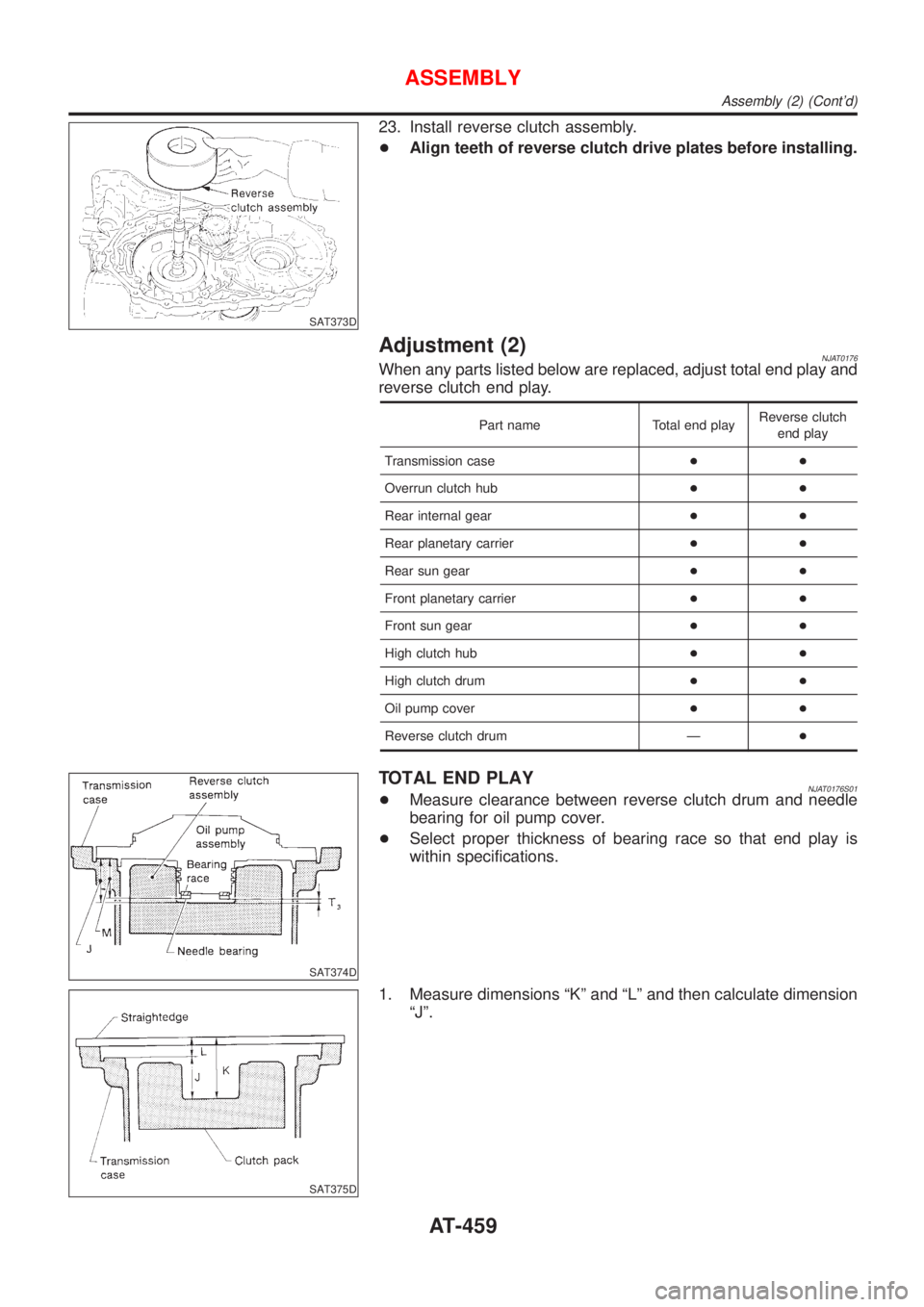

SAT373D

23. Install reverse clutch assembly.

+Align teeth of reverse clutch drive plates before installing.

Adjustment (2)NJAT0176When any parts listed below are replaced, adjust total end play and

reverse clutch end play.

Part name Total end playReverse clutch

end play

Transmission case++

Overrun clutch hub++

Rear internal gear++

Rear planetary carrier++

Rear sun gear++

Front planetary carrier++

Front sun gear++

High clutch hub++

High clutch drum++

Oil pump cover++

Reverse clutch drum Ð+

SAT374D

TOTAL END PLAYNJAT0176S01+Measure clearance between reverse clutch drum and needle

bearing for oil pump cover.

+Select proper thickness of bearing race so that end play is

within specifications.

SAT375D

1. Measure dimensions ªKº and ªLº and then calculate dimension

ªJº.

ASSEMBLY

Assembly (2) (Cont'd)

AT-459

Page 462 of 2898

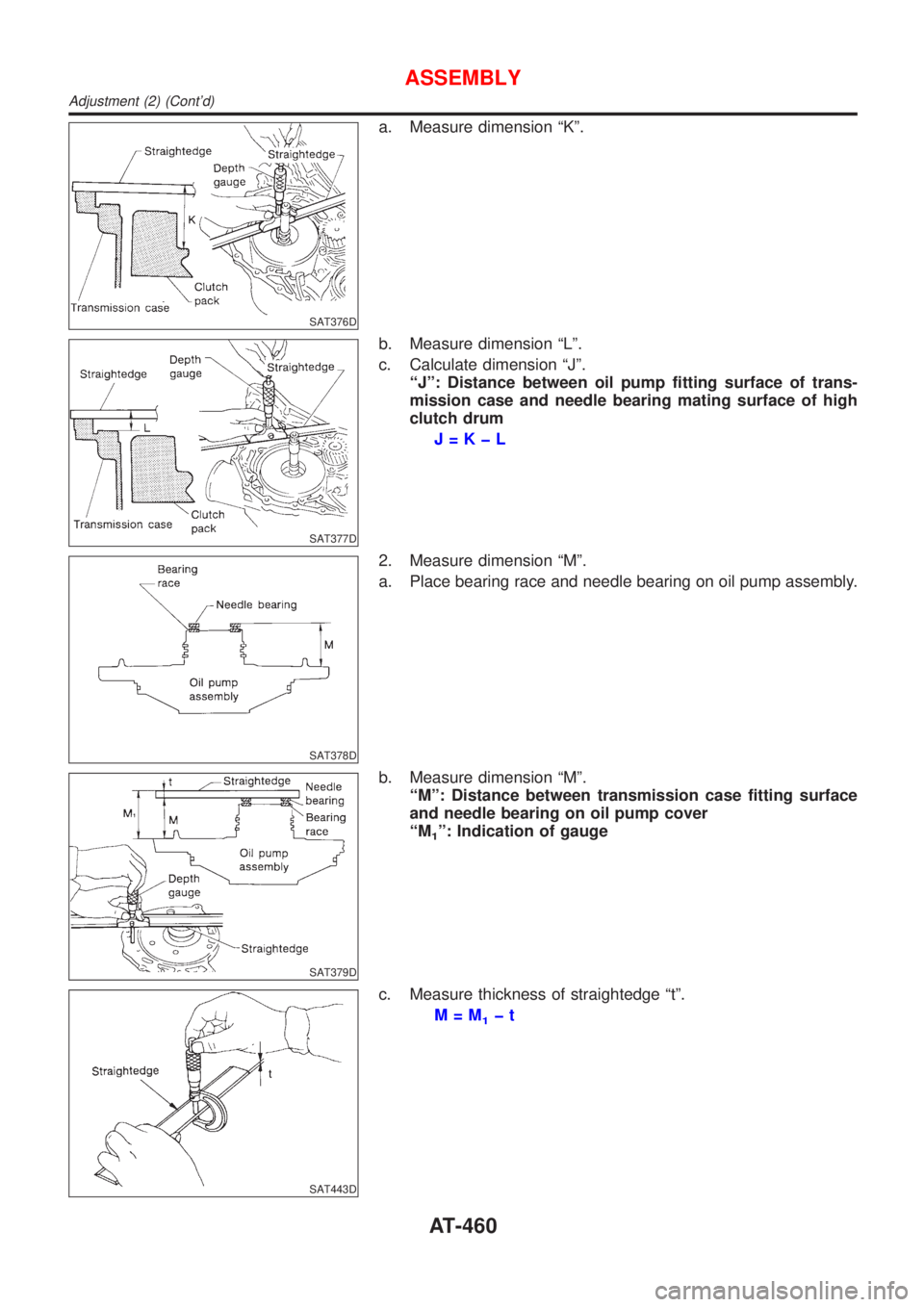

SAT376D

a. Measure dimension ªKº.

SAT377D

b. Measure dimension ªLº.

c. Calculate dimension ªJº.

ªJº: Distance between oil pump fitting surface of trans-

mission case and needle bearing mating surface of high

clutch drum

J=KþL

SAT378D

2. Measure dimension ªMº.

a. Place bearing race and needle bearing on oil pump assembly.

SAT379D

b. Measure dimension ªMº.

ªMº: Distance between transmission case fitting surface

and needle bearing on oil pump cover

ªM

1º: Indication of gauge

SAT443D

c. Measure thickness of straightedge ªtº.

M=M

1þt

ASSEMBLY

Adjustment (2) (Cont'd)

AT-460

Page 465 of 2898

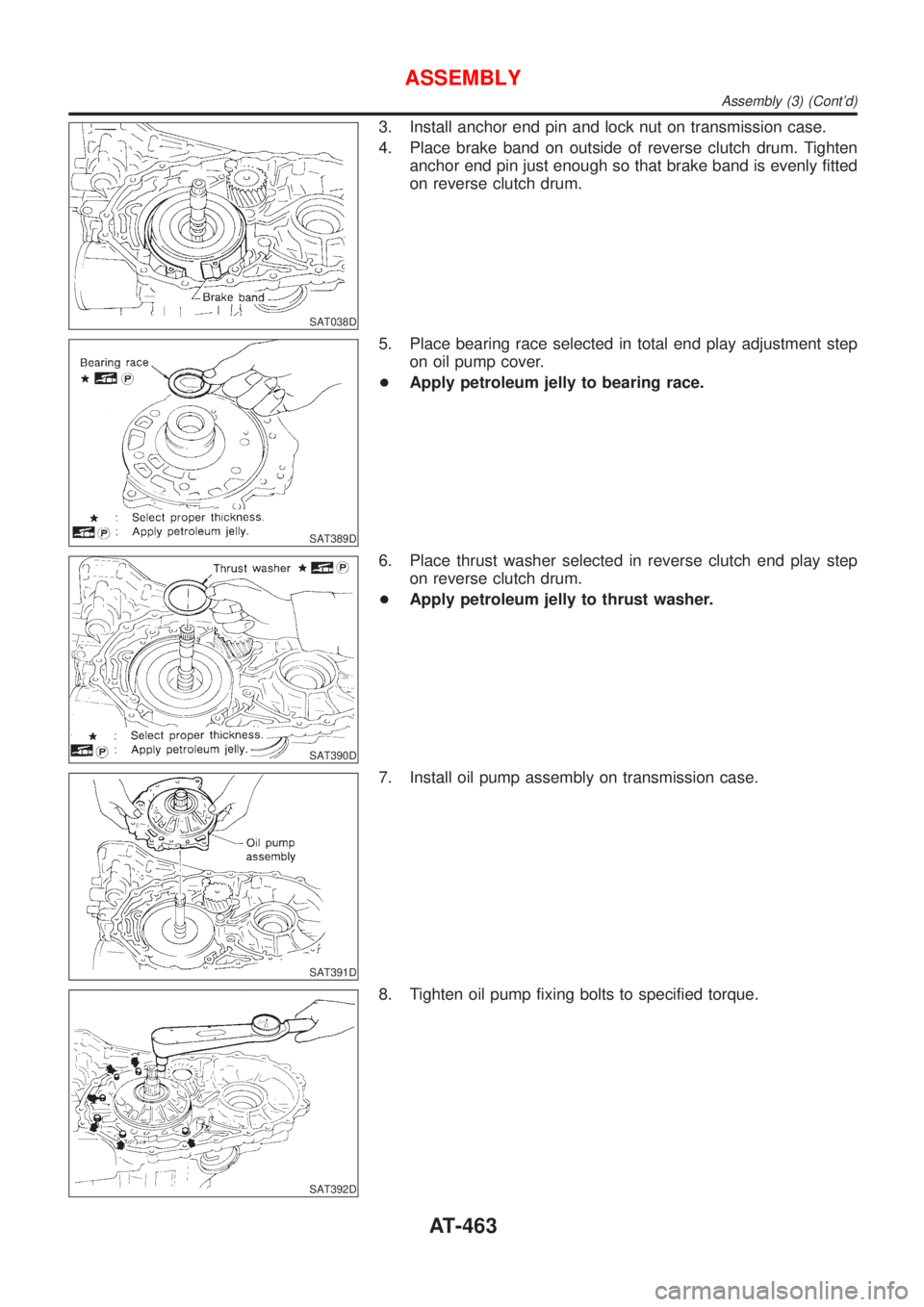

SAT038D

3. Install anchor end pin and lock nut on transmission case.

4. Place brake band on outside of reverse clutch drum. Tighten

anchor end pin just enough so that brake band is evenly fitted

on reverse clutch drum.

SAT389D

5. Place bearing race selected in total end play adjustment step

on oil pump cover.

+Apply petroleum jelly to bearing race.

SAT390D

6. Place thrust washer selected in reverse clutch end play step

on reverse clutch drum.

+Apply petroleum jelly to thrust washer.

SAT391D

7. Install oil pump assembly on transmission case.

SAT392D

8. Tighten oil pump fixing bolts to specified torque.

ASSEMBLY

Assembly (3) (Cont'd)

AT-463

Page 466 of 2898

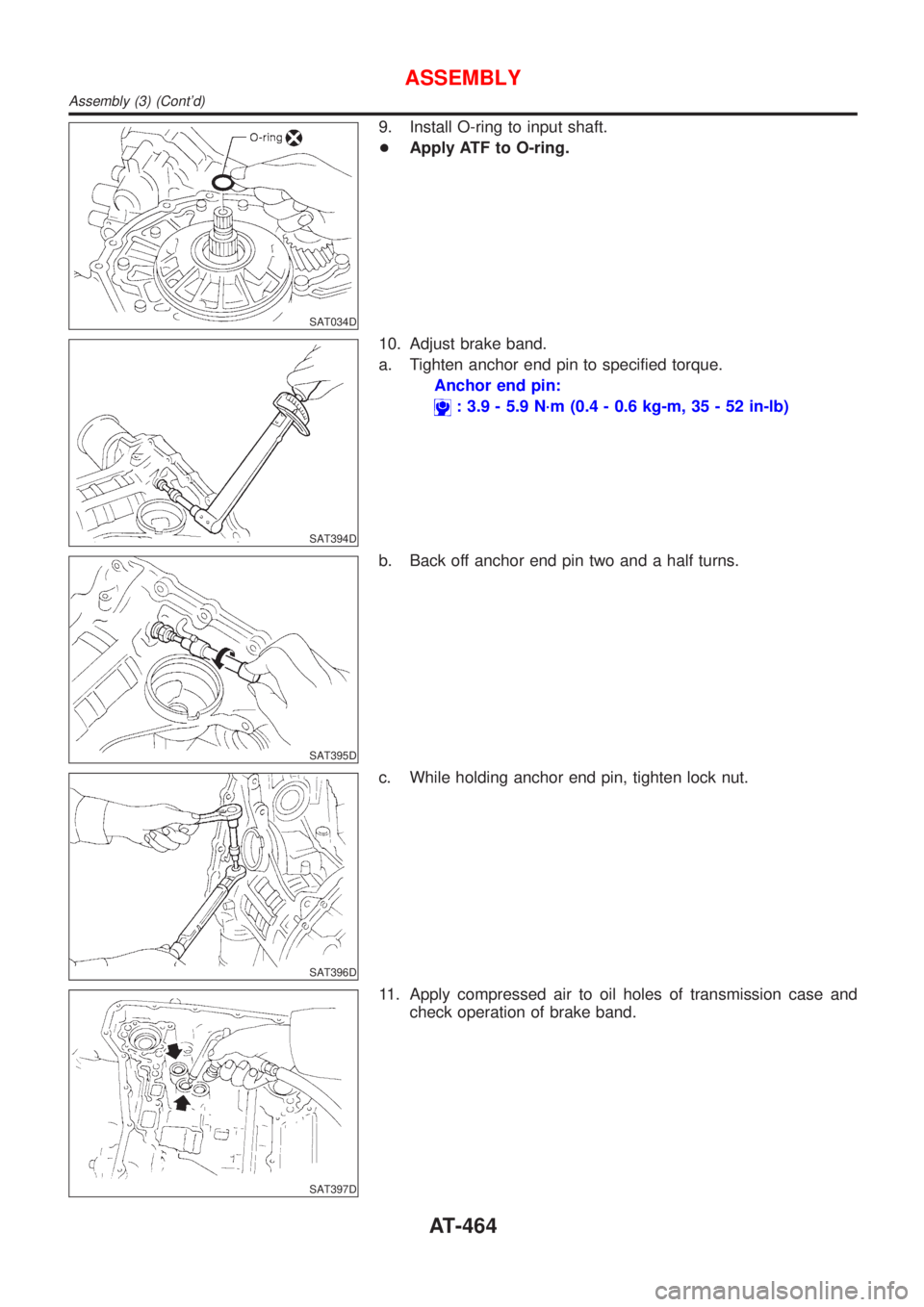

SAT034D

9. Install O-ring to input shaft.

+Apply ATF to O-ring.

SAT394D

10. Adjust brake band.

a. Tighten anchor end pin to specified torque.

Anchor end pin:

: 3.9 - 5.9 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

SAT395D

b. Back off anchor end pin two and a half turns.

SAT396D

c. While holding anchor end pin, tighten lock nut.

SAT397D

11. Apply compressed air to oil holes of transmission case and

check operation of brake band.

ASSEMBLY

Assembly (3) (Cont'd)

AT-464

Page 467 of 2898

SAT030D

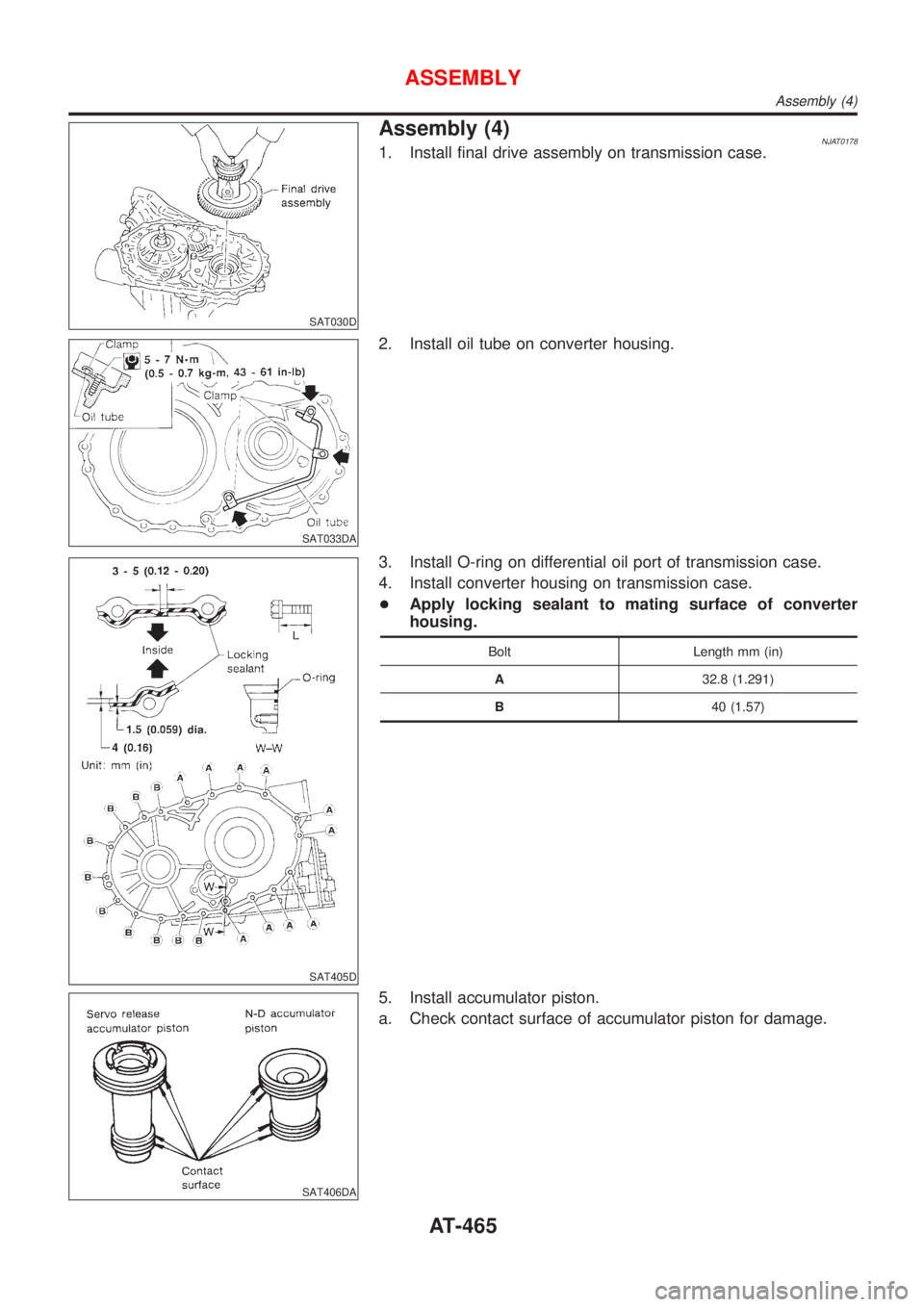

Assembly (4)NJAT01781. Install final drive assembly on transmission case.

SAT033DA

2. Install oil tube on converter housing.

SAT405D

3. Install O-ring on differential oil port of transmission case.

4. Install converter housing on transmission case.

+Apply locking sealant to mating surface of converter

housing.

Bolt Length mm (in)

A32.8 (1.291)

B40 (1.57)

SAT406DA

5. Install accumulator piston.

a. Check contact surface of accumulator piston for damage.

ASSEMBLY

Assembly (4)

AT-465

Page 468 of 2898

SAT407DA

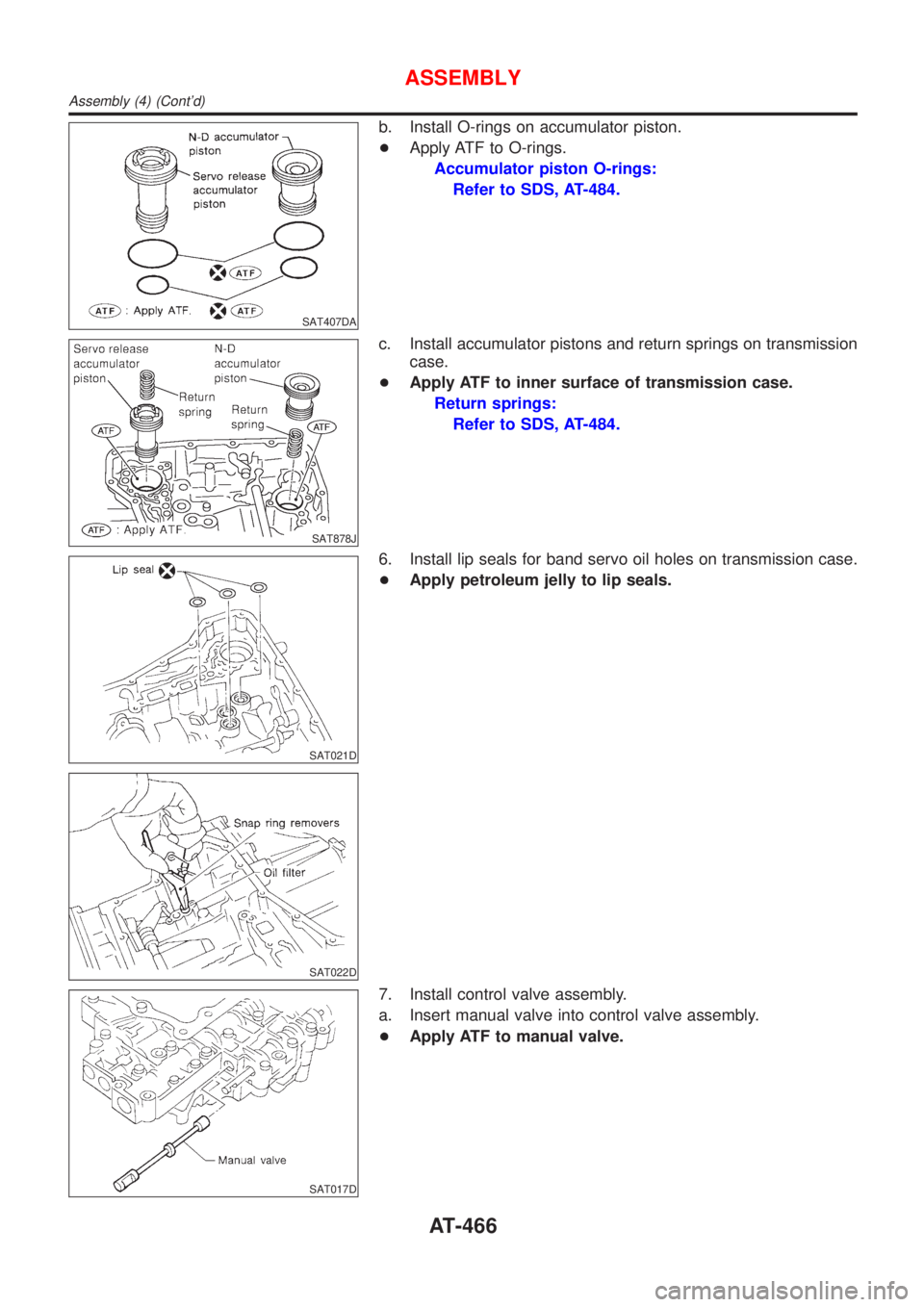

b. Install O-rings on accumulator piston.

+Apply ATF to O-rings.

Accumulator piston O-rings:

Refer to SDS, AT-484.

SAT878J

c. Install accumulator pistons and return springs on transmission

case.

+Apply ATF to inner surface of transmission case.

Return springs:

Refer to SDS, AT-484.

SAT021D

SAT022D

6. Install lip seals for band servo oil holes on transmission case.

+Apply petroleum jelly to lip seals.

SAT017D

7. Install control valve assembly.

a. Insert manual valve into control valve assembly.

+Apply ATF to manual valve.

ASSEMBLY

Assembly (4) (Cont'd)

AT-466