transmission oil NISSAN ALMERA 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2602 of 2898

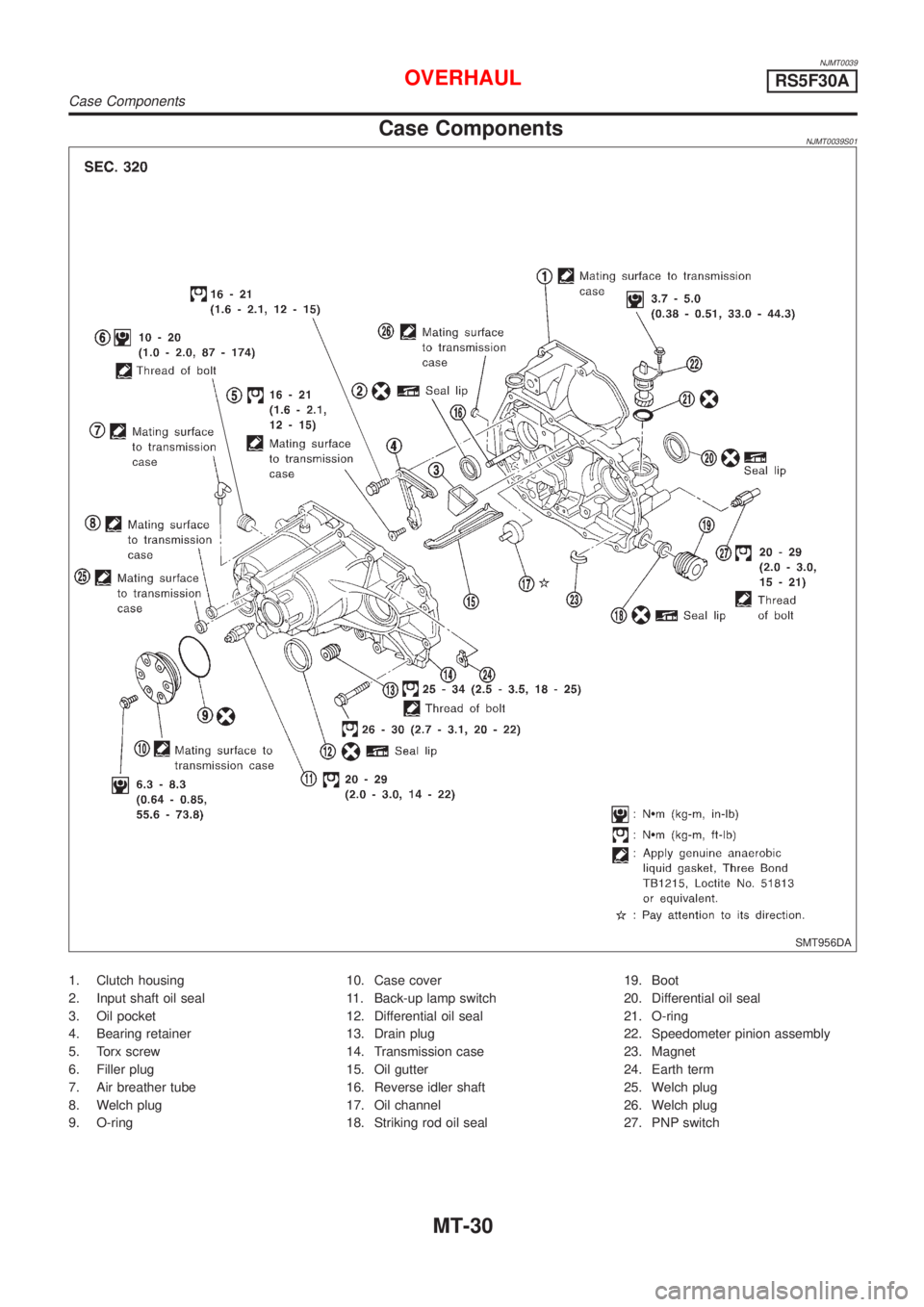

NJMT0039

Case ComponentsNJMT0039S01

SMT956DA

1. Clutch housing

2. Input shaft oil seal

3. Oil pocket

4. Bearing retainer

5. Torx screw

6. Filler plug

7. Air breather tube

8. Welch plug

9. O-ring10. Case cover

11. Back-up lamp switch

12. Differential oil seal

13. Drain plug

14. Transmission case

15. Oil gutter

16. Reverse idler shaft

17. Oil channel

18. Striking rod oil seal19. Boot

20. Differential oil seal

21. O-ring

22. Speedometer pinion assembly

23. Magnet

24. Earth term

25. Welch plug

26. Welch plug

27. PNP switch

OVERHAULRS5F30A

Case Components

MT-30

Page 2605 of 2898

NJMT0040

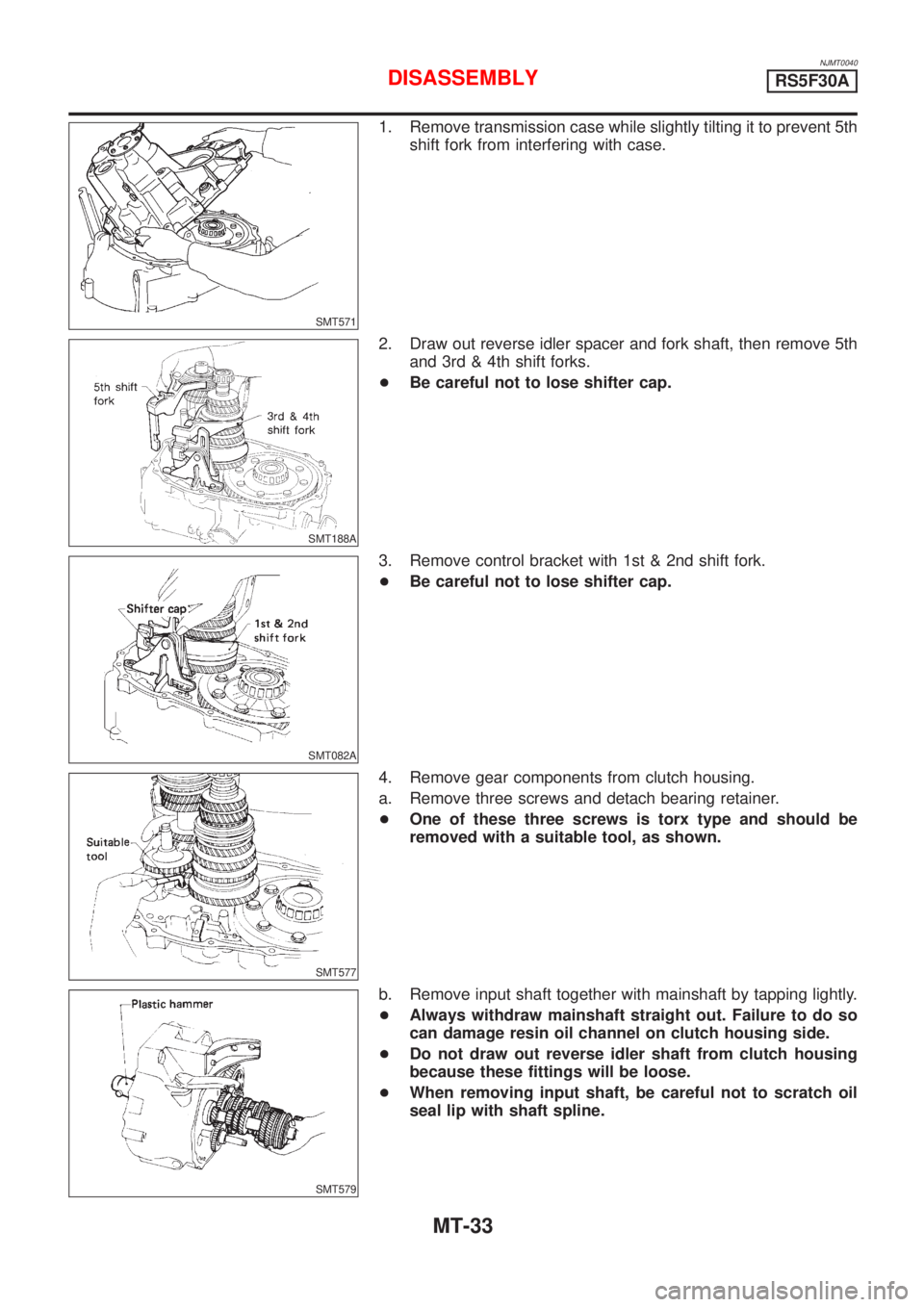

SMT571

1. Remove transmission case while slightly tilting it to prevent 5th

shift fork from interfering with case.

SMT188A

2. Draw out reverse idler spacer and fork shaft, then remove 5th

and 3rd & 4th shift forks.

+Be careful not to lose shifter cap.

SMT082A

3. Remove control bracket with 1st & 2nd shift fork.

+Be careful not to lose shifter cap.

SMT577

4. Remove gear components from clutch housing.

a. Remove three screws and detach bearing retainer.

+One of these three screws is torx type and should be

removed with a suitable tool, as shown.

SMT579

b. Remove input shaft together with mainshaft by tapping lightly.

+Always withdraw mainshaft straight out. Failure to do so

can damage resin oil channel on clutch housing side.

+Do not draw out reverse idler shaft from clutch housing

because these fittings will be loose.

+When removing input shaft, be careful not to scratch oil

seal lip with shaft spline.

DISASSEMBLYRS5F30A

MT-33

Page 2619 of 2898

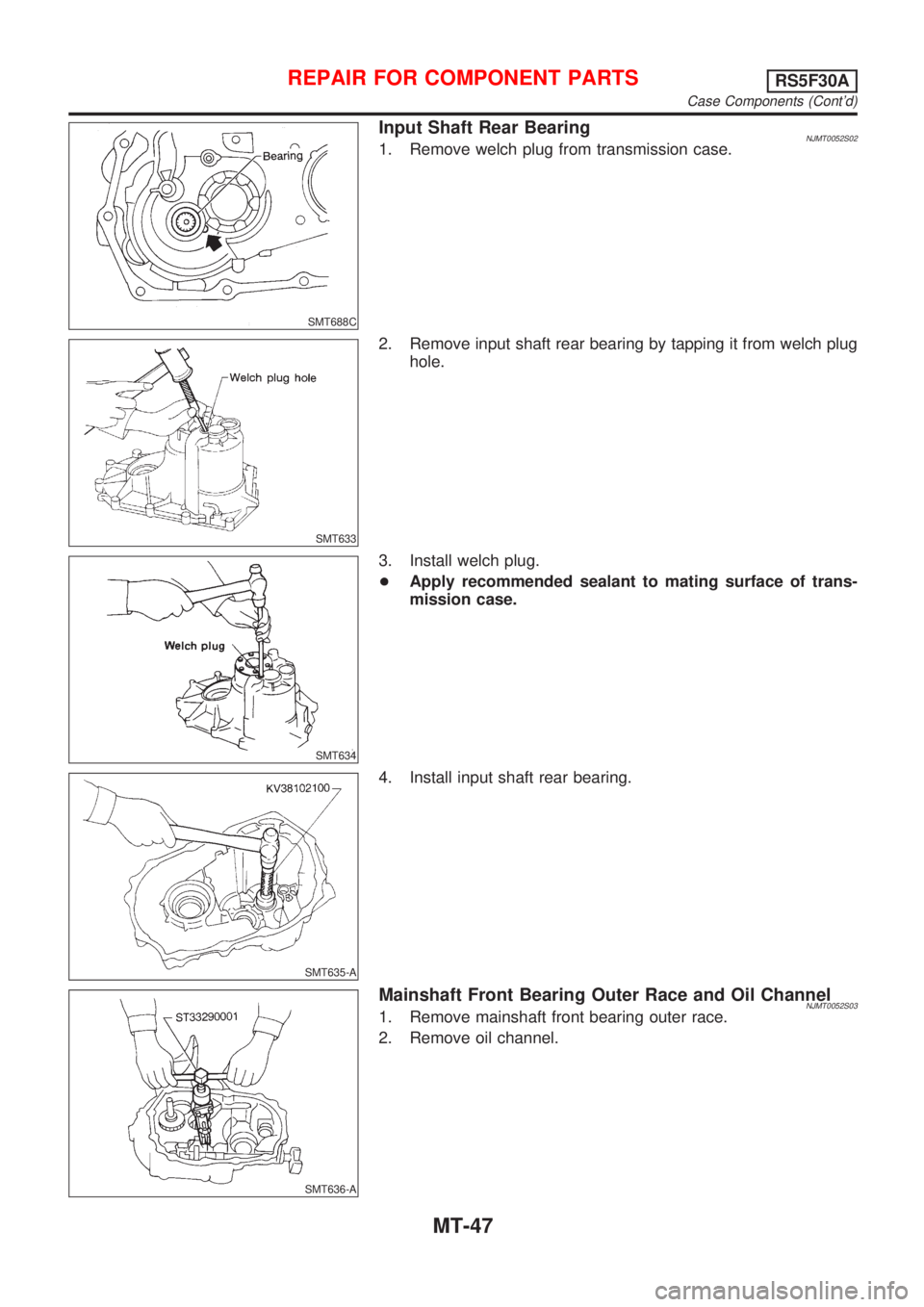

SMT688C

Input Shaft Rear BearingNJMT0052S021. Remove welch plug from transmission case.

SMT633

2. Remove input shaft rear bearing by tapping it from welch plug

hole.

SMT634

3. Install welch plug.

+Apply recommended sealant to mating surface of trans-

mission case.

SMT635-A

4. Install input shaft rear bearing.

SMT636-A

Mainshaft Front Bearing Outer Race and Oil ChannelNJMT0052S031. Remove mainshaft front bearing outer race.

2. Remove oil channel.

REPAIR FOR COMPONENT PARTSRS5F30A

Case Components (Cont'd)

MT-47

Page 2626 of 2898

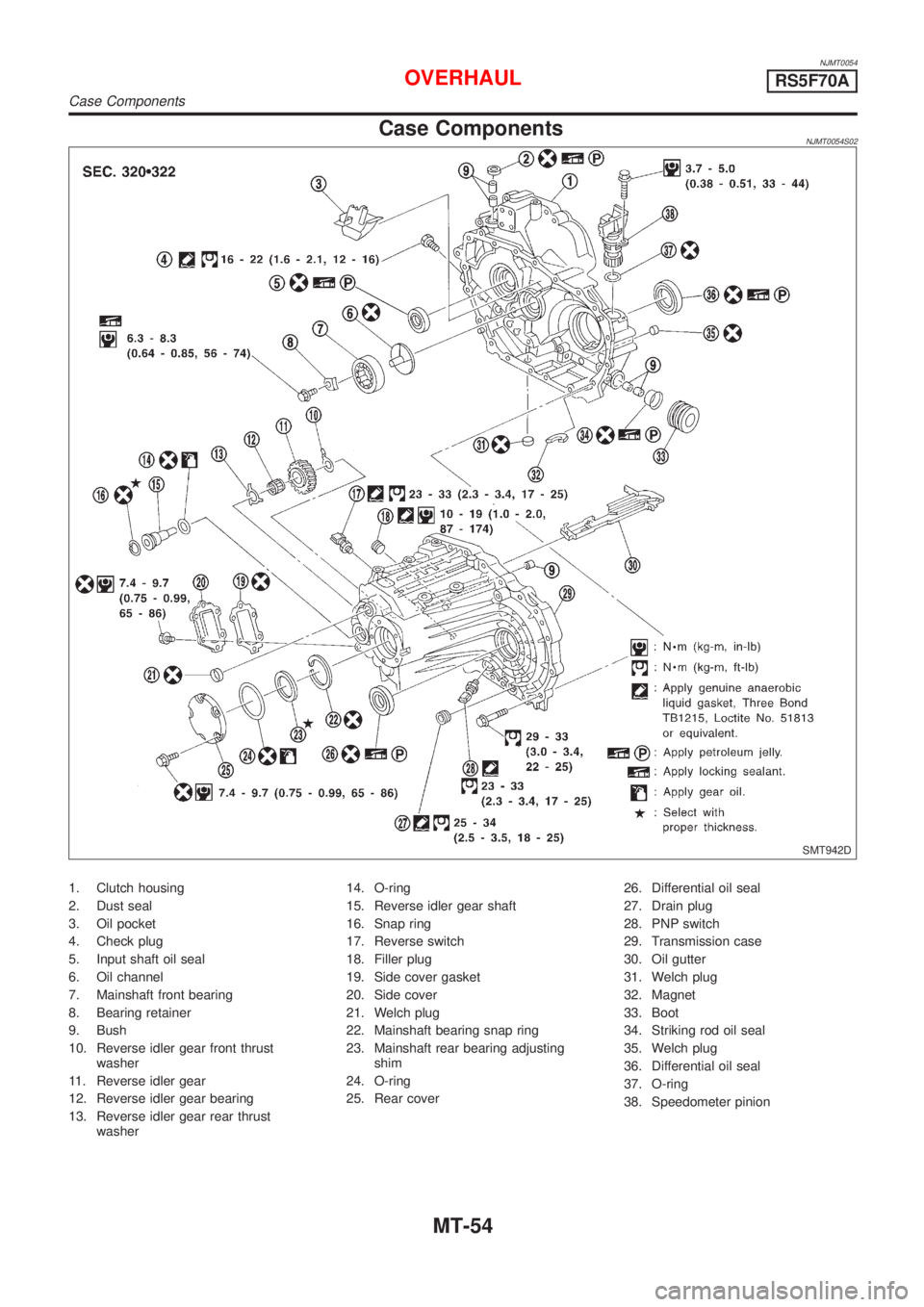

NJMT0054

Case ComponentsNJMT0054S02

SMT942D

1. Clutch housing

2. Dust seal

3. Oil pocket

4. Check plug

5. Input shaft oil seal

6. Oil channel

7. Mainshaft front bearing

8. Bearing retainer

9. Bush

10. Reverse idler gear front thrust

washer

11. Reverse idler gear

12. Reverse idler gear bearing

13. Reverse idler gear rear thrust

washer14. O-ring

15. Reverse idler gear shaft

16. Snap ring

17. Reverse switch

18. Filler plug

19. Side cover gasket

20. Side cover

21. Welch plug

22. Mainshaft bearing snap ring

23. Mainshaft rear bearing adjusting

shim

24. O-ring

25. Rear cover26. Differential oil seal

27. Drain plug

28. PNP switch

29. Transmission case

30. Oil gutter

31. Welch plug

32. Magnet

33. Boot

34. Striking rod oil seal

35. Welch plug

36. Differential oil seal

37. O-ring

38. Speedometer pinion

OVERHAULRS5F70A

Case Components

MT-54

Page 2664 of 2898

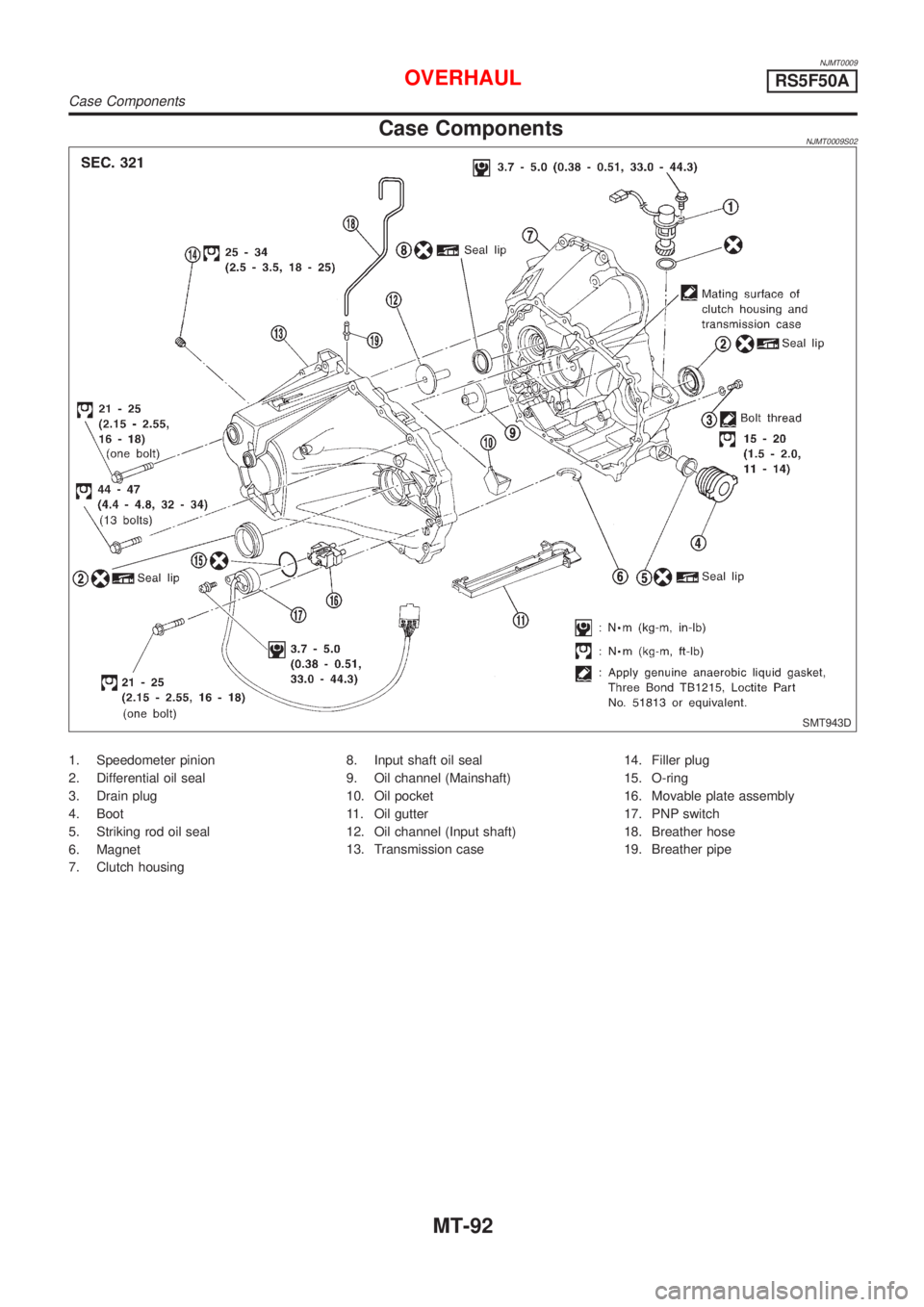

NJMT0009

Case ComponentsNJMT0009S02

SMT943D

1. Speedometer pinion

2. Differential oil seal

3. Drain plug

4. Boot

5. Striking rod oil seal

6. Magnet

7. Clutch housing8. Input shaft oil seal

9. Oil channel (Mainshaft)

10. Oil pocket

11. Oil gutter

12. Oil channel (Input shaft)

13. Transmission case14. Filler plug

15. O-ring

16. Movable plate assembly

17. PNP switch

18. Breather hose

19. Breather pipe

OVERHAULRS5F50A

Case Components

MT-92

Page 2893 of 2898

SRA695A

SSU038

REMOVALNJSU0031S01CAUTION:

+Before removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Failure to

do so may result in damage to the sensor wires and the

sensor becoming inoperative.

+Remove suspension assembly.

1. Disconnect brake hydraulic lines and parking brake cable at

toggle lever. (Models with drum brakes.)

+Drain brake fluid before disconnecting brake lines.

2. Disconnect parking brake cable from caliper and remove brake

caliper and rotor. (Models with disc brakes.)

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop

out.

Make sure brake hose is not twisted.

3. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link (Body side).

4. Lower transmission jack, and remove suspension.

5. Remove strut securing nuts (upper side). Then pull out strut

assembly.

SRA697A

INSTALLATIONNJSU0031S02+Install suspension assembly.

CAUTION:

Refill with new brake fluid ªDOT 4º.

Never reuse drained brake fluid.

1. Attach torsion beam, at trailing arm and lateral link, to vehicle.

Do not tighten bolts at this time.

SRA698A

2. Using a transmission jack, place lateral link and control rod

horizontally against torsion beam. Tighten lateral link on

vehicle.

3. Attach shock absorber assembly to vehicle. Then tighten the

lower side of shock absorber assembly.

4. Lower torsion beam to fully extended position. Remove trans-

mission jack and tighten torsion beam, at trailing arm, to speci-

fied torque. Refer to SU-20.

5. Install brake hydraulic lines and tighten flare nuts.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

6. Install ABS wheel sensor.

Coil Spring and Shock Absorber

REMOVAL AND INSTALLATIONNJSU0032Remove shock absorber upper and lower fixing nuts.

Do not remove piston rod lock nut on vehicle.

REAR SUSPENSION

Removal and Installation (Cont'd)

SU-21