NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2131 of 2898

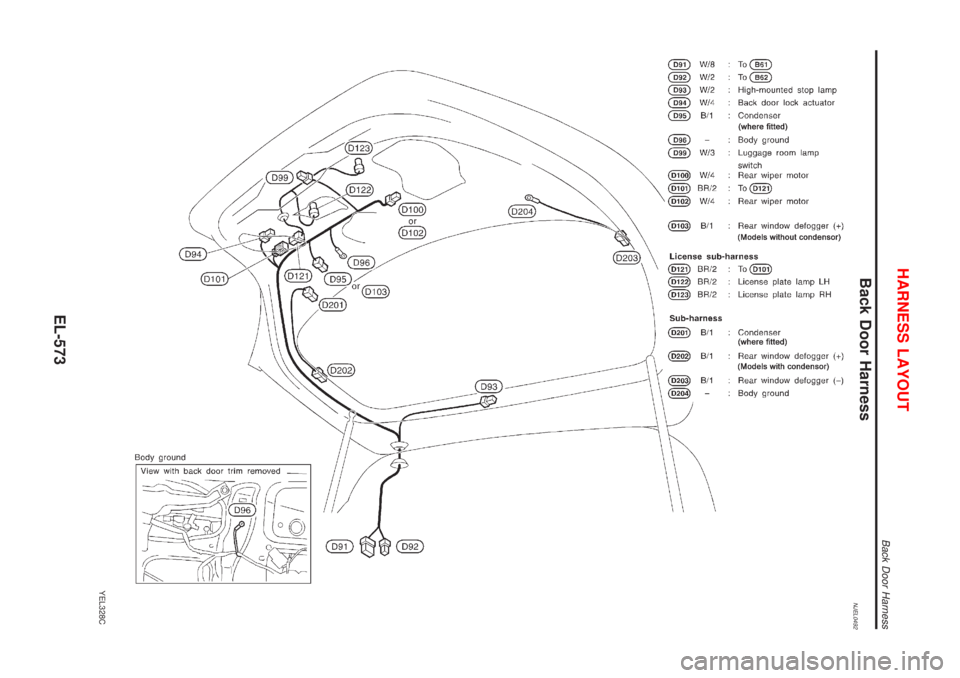

Back Door HarnessNJEL0492

YEL328C

HARNESS LAYOUT

Back Door Harness

EL-573

Page 2132 of 2898

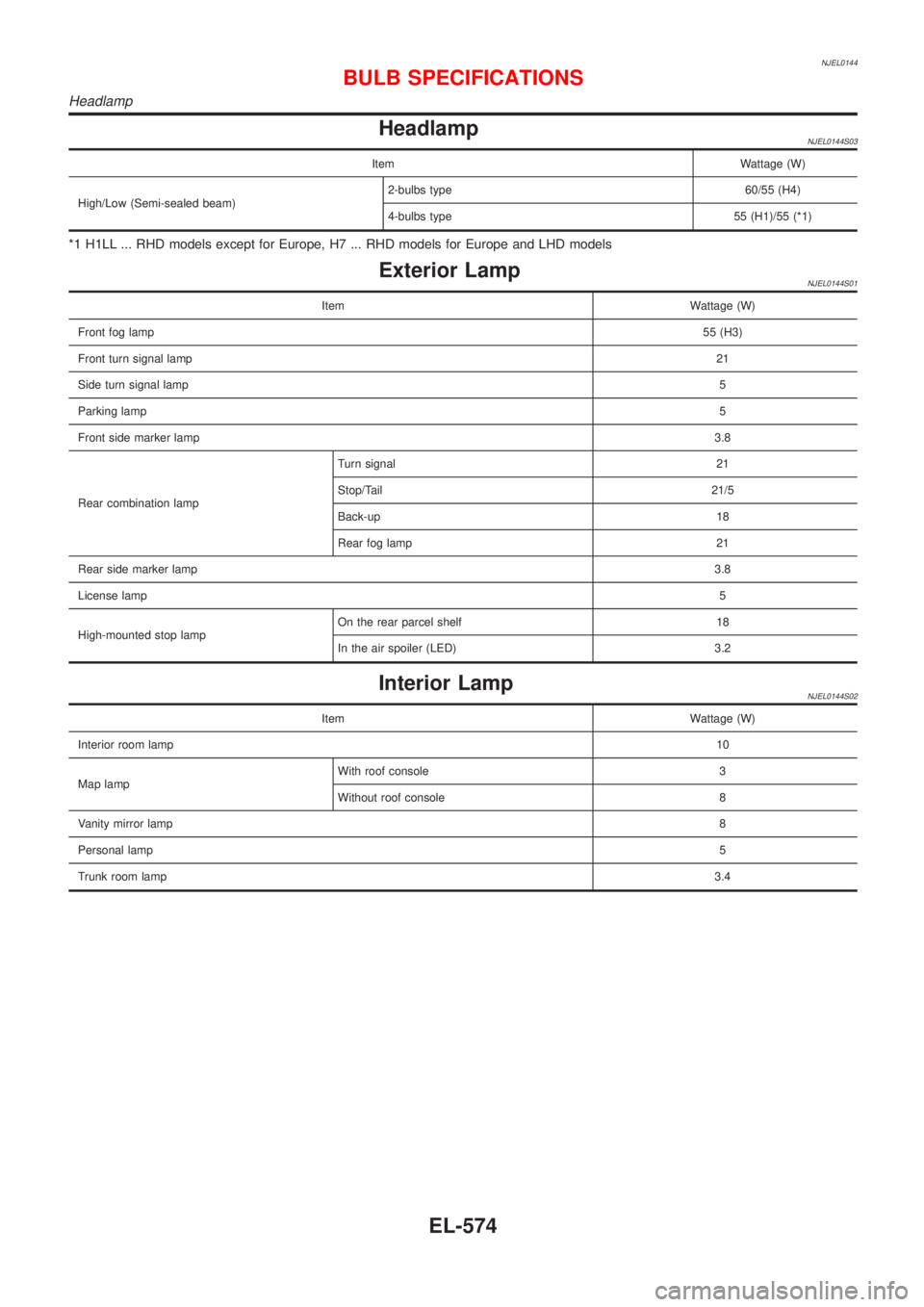

NJEL0144

HeadlampNJEL0144S03

Item Wattage (W)

High/Low (Semi-sealed beam)2-bulbs type 60/55 (H4)

4-bulbs type 55 (H1)/55 (*1)

*1 H1LL ... RHD models except for Europe, H7 ... RHD models for Europe and LHD models

Exterior LampNJEL0144S01

Item Wattage (W)

Front fog lamp55 (H3)

Front turn signal lamp21

Side turn signal lamp5

Parking lamp5

Front side marker lamp3.8

Rear combination lampTurn signal 21

Stop/Tail 21/5

Back-up 18

Rear fog lamp 21

Rear side marker lamp3.8

License lamp5

High-mounted stop lampOn the rear parcel shelf 18

In the air spoiler (LED) 3.2

Interior LampNJEL0144S02

Item Wattage (W)

Interior room lamp10

Map lampWith roof console 3

Without roof console 8

Vanity mirror lamp8

Personal lamp5

Trunk room lamp3.4

BULB SPECIFICATIONS

Headlamp

EL-574

Page 2133 of 2898

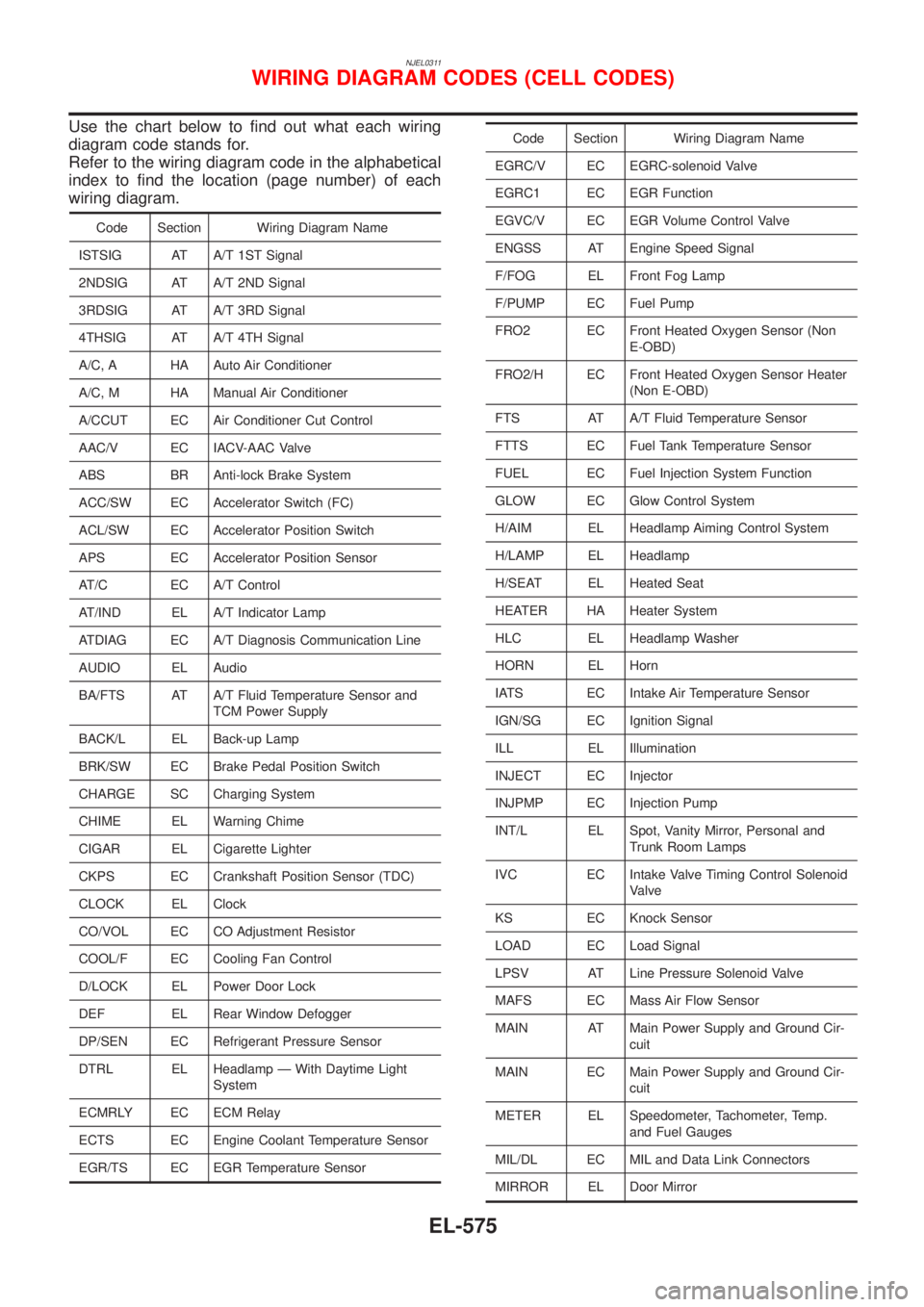

NJEL0311

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

ISTSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Cut Control

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (FC)

ACL/SW EC Accelerator Position Switch

APS EC Accelerator Position Sensor

AT/C EC A/T Control

AT/IND EL A/T Indicator Lamp

ATDIAG EC A/T Diagnosis Communication Line

AUDIO EL Audio

BA/FTS AT A/T Fluid Temperature Sensor and

TCM Power Supply

BACK/L EL Back-up Lamp

BRK/SW EC Brake Pedal Position Switch

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor (TDC)

CLOCK EL Clock

CO/VOL EC CO Adjustment Resistor

COOL/F EC Cooling Fan Control

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DP/SEN EC Refrigerant Pressure Sensor

DTRL EL Headlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGR/TS EC EGR Temperature Sensor

Code Section Wiring Diagram Name

EGRC/V EC EGRC-solenoid Valve

EGRC1 EC EGR Function

EGVC/V EC EGR Volume Control Valve

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FRO2 EC Front Heated Oxygen Sensor (Non

E-OBD)

FRO2/H EC Front Heated Oxygen Sensor Heater

(Non E-OBD)

FTS AT A/T Fluid Temperature Sensor

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Injection System Function

GLOW EC Glow Control System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

H/SEAT EL Heated Seat

HEATER HA Heater System

HLC EL Headlamp Washer

HORN EL Horn

IATS EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP EC Injection Pump

INT/L EL Spot, Vanity Mirror, Personal and

Trunk Room Lamps

IVC EC Intake Valve Timing Control Solenoid

Valve

KS EC Knock Sensor

LOAD EC Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Cir-

cuit

MAIN EC Main Power Supply and Ground Cir-

cuit

METER EL Speedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

WIRING DIAGRAM CODES (CELL CODES)

EL-575

Page 2134 of 2898

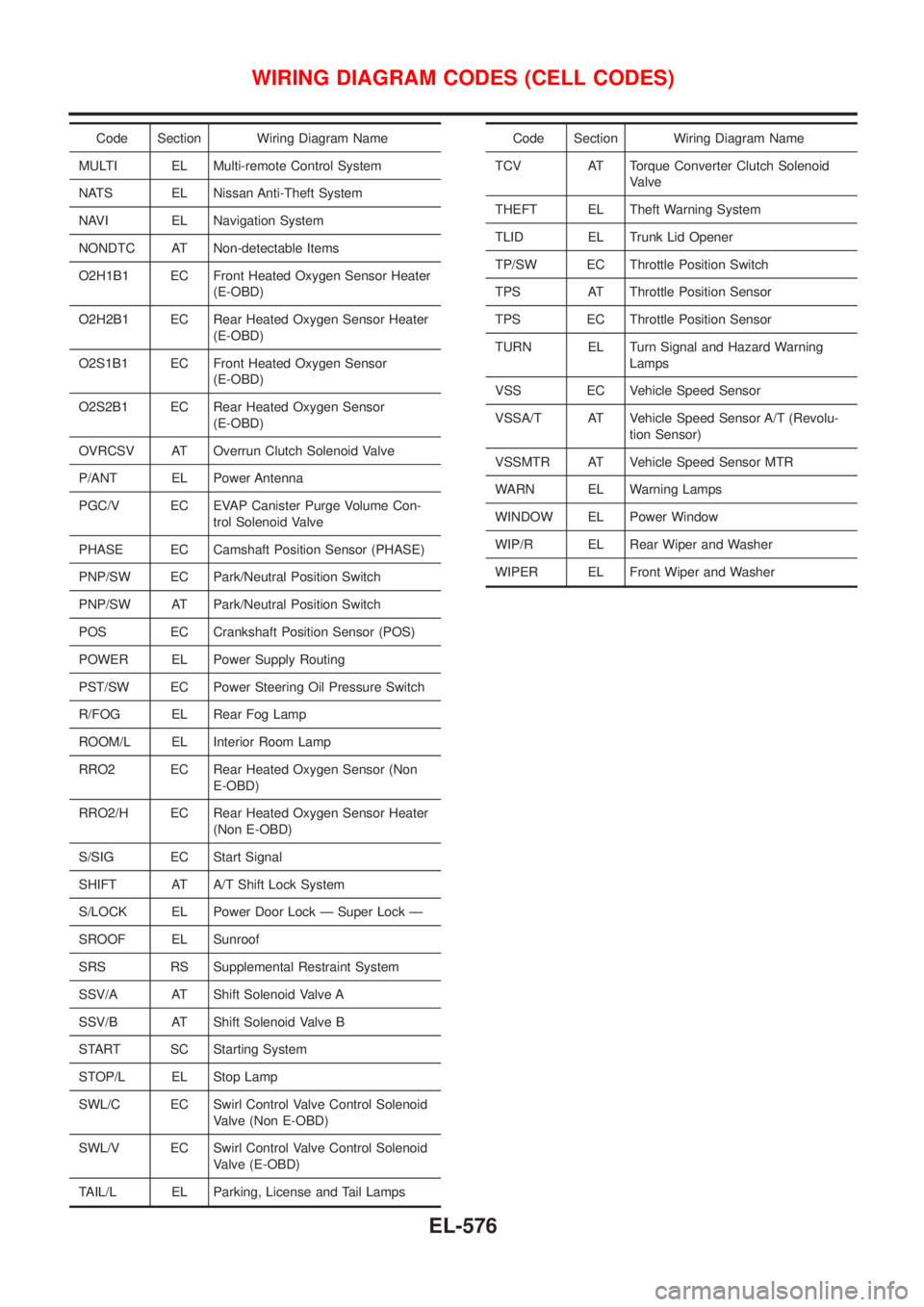

Code Section Wiring Diagram Name

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Front Heated Oxygen Sensor Heater

(E-OBD)

O2H2B1 EC Rear Heated Oxygen Sensor Heater

(E-OBD)

O2S1B1 EC Front Heated Oxygen Sensor

(E-OBD)

O2S2B1 EC Rear Heated Oxygen Sensor

(E-OBD)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume Con-

trol Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

ROOM/L EL Interior Room Lamp

RRO2 EC Rear Heated Oxygen Sensor (Non

E-OBD)

RRO2/H EC Rear Heated Oxygen Sensor Heater

(Non E-OBD)

S/SIG EC Start Signal

SHIFT AT A/T Shift Lock System

S/LOCK EL Power Door Lock Ð Super Lock Ð

SROOF EL Sunroof

SRS RS Supplemental Restraint System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop Lamp

SWL/C EC Swirl Control Valve Control Solenoid

Valve (Non E-OBD)

SWL/V EC Swirl Control Valve Control Solenoid

Valve (E-OBD)

TAIL/L EL Parking, License and Tail LampsCode Section Wiring Diagram Name

TCV AT Torque Converter Clutch Solenoid

Valve

THEFT EL Theft Warning System

TLID EL Trunk Lid Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revolu-

tion Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-576

Page 2135 of 2898

ENGINE MECHANICAL

SECTION

EM

CONTENTS

QG

PRECAUTIONS...............................................................4

Parts Requiring Angular Tightening .............................4

Liquid Gasket Application Procedure ..........................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................7

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................9

NVH Troubleshooting - Engine Noise .........................9

OUTER COMPONENT PARTS..................................... 11

Removal and Installation ........................................... 11

MEASUREMENT OF COMPRESSION PRESSURE....15

DRIVE BELTS................................................................16

Checking ....................................................................16

AIR CLEANER...............................................................18

Cleaning and Changing .............................................18

VISCOUS PAPER TYPE...........................................18

DRY PAPER TYPE..................................................18

SPARK PLUG................................................................19

Checking and Changing ............................................19

OIL PAN.........................................................................20

Components...............................................................20

Removal .....................................................................20

Installation ..................................................................21

TIMING CHAIN..............................................................23

Components...............................................................23

Removal .....................................................................24

Inspection...................................................................27

Installation ..................................................................28

OIL SEAL.......................................................................32

Replacement ..............................................................32

VALVE OIL SEAL.....................................................32

FRONT OIL SEAL....................................................32

REAR OIL SEAL......................................................33

CYLINDER HEAD..........................................................34

Components...............................................................34

Removal .....................................................................35

Disassembly...............................................................37Inspection...................................................................37

CYLINDER HEAD DISTORTION...............................37

CAMSHAFT VISUAL CHECK....................................37

CAMSHAFT RUNOUT..............................................38

CAMSHAFT CAM HEIGHT.......................................38

CAMSHAFT JOURNAL CLEARANCE........................38

CAMSHAFT END PLAY............................................39

CAMSHAFT SPROCKET RUNOUT...........................39

VALVE GUIDE CLEARANCE....................................39

VALVE GUIDE REPLACEMENT................................40

VALVE SEATS.........................................................41

REPLACING VALVE SEAT FOR SERVICE PARTS....41

VALVE DIMENSIONS...............................................42

VALVE SPRING.......................................................42

VALVE LIFTER AND VALVE SHIM............................43

Valve Clearance.........................................................44

CHECKING.............................................................44

ADJUSTING............................................................45

Assembly ...................................................................46

Installation ..................................................................47

ENGINE ASSEMBLY.....................................................51

Removal and Installation ...........................................51

REMOVAL...............................................................52

INSTALLATION........................................................53

CYLINDER BLOCK.......................................................54

Components...............................................................54

Removal and Installation ...........................................55

Disassembly...............................................................55

PISTON AND CRANKSHAFT....................................55

Inspection...................................................................56

PISTON AND PISTON PIN CLEARANCE..................56

PISTON RING SIDE CLEARANCE............................56

PISTON RING END GAP..........................................56

CONNECTING ROD BEND AND TORSION...............57

CYLINDER BLOCK DISTORTION AND WEAR...........57

PISTON-TO-BORE CLEARANCE..............................58

CRANKSHAFT.........................................................59

BEARING CLEARANCE...........................................59

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

..........................................................61

Page 2136 of 2898

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

..........................................62

FLYWHEEL/DRIVE PLATE RUNOUT........................62

Assembly ...................................................................62

PISTON..................................................................62

CRANKSHAFT.........................................................63

SERVICE DATA AND SPECIFICATIONS (SDS).........66

General Specifications ...............................................66

Compression Pressure ..............................................66

Belt Deflection............................................................67

Spark Plug .................................................................67

Cylinder Head ............................................................67

Valve ..........................................................................68

VALVE....................................................................68

VALVE SPRING.......................................................68

VALVE LIFTER........................................................68

VALVE CLEARANCE................................................69

VALVE GUIDE.........................................................69

AVAILABLE SHIMS..................................................69

VALVE SEAT...........................................................71

VALVE SEAT RESURFACE LIMIT.............................72

Camshaft and Camshaft Bearing ..............................72

Cylinder Block ............................................................73

Piston, Piston Ring and Piston Pin ...........................74

PISTON..................................................................74

PISTON RING.........................................................74

PISTON PIN............................................................74

Connecting Rod .........................................................75

Crankshaft..................................................................75

Main Bearing..............................................................75

STANDARD.............................................................75

UNDERSIZE............................................................75

Connecting Rod Bearing ...........................................76

STANDARD SIZE....................................................76

UNDERSIZE............................................................76

Bearing Clearance .....................................................76

Miscellaneous Components.......................................76

YD

PRECAUTIONS.............................................................77

Parts Requiring Angular Tightening ...........................77

Liquid Gasket Application Procedure ........................77

PREPARATION.............................................................78

Special Service Tools ................................................78

Commercial Service Tools .........................................80

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................82

NVH Troubleshooting - Engine Noise .......................82

MEASUREMENT OF COMPRESSION PRESSURE....83

DRIVE BELTS................................................................85

Inspection...................................................................85

Adjustment .................................................................85

AIR CONDITIONER COMPRESSOR BELT................86

ALTERNATOR & WATER PUMP BELT.....................86

Removal .....................................................................86

Installation ..................................................................87

AIR CLEANER...............................................................88

Changing Air Cleaner Filter .......................................88

VISCOUS PAPER TYPE...........................................88

OIL PAN.........................................................................89

Components...............................................................89

Removal .....................................................................89

Installation ..................................................................91

TIMING CHAIN..............................................................94

Secondary Timing Chain ...........................................94

REMOVAL...............................................................94

INSPECTION...........................................................96

INSTALLATION........................................................96

Primary Timing Chain ................................................99

REMOVAL.............................................................100

INSPECTION.........................................................102

INSTALLATION......................................................102

INTAKE MANIFOLD....................................................107

Removal and Installation .........................................107

PREPARATIVE WORK...........................................107

FUEL PIPING........................................................108

INTAKE MANIFOLD...............................................108

EGR VOLUME CONTROL VALVE...........................108

WATER HOSE.......................................................108

Inspection.................................................................109

INTAKE MANIFOLD...............................................109

CATALYST.................................................................. 110

Removal and Installation ......................................... 110

PREPARATIVE WORK........................................... 110

CATALYST............................................................ 110

GUSSET............................................................... 111

EXHAUST MANIFOLD, TURBOCHARGER............... 112

Removal and Installation ......................................... 112

PREPARATIVE WORK........................................... 112

EXHAUST MANIFOLD AND TURBOCHARGER....... 112

EXHAUST MANIFOLD GASKET............................. 113

Disassembly and Assembly ..................................... 113

TURBOCHARGER................................................. 113

Inspection................................................................. 114

EXHAUST MANIFOLD........................................... 114

TURBOCHARGER................................................. 114

ROCKER COVER........................................................ 117

Removal and Installation ......................................... 117

PREPARATIVE WORK........................................... 117

ROCKER COVER.................................................. 117

CYLINDER HEAD........................................................ 119

Components............................................................. 119

Removal ...................................................................120

PREPARATIVE WORK...........................................120

CAMSHAFT...........................................................120

CYLINDER HEAD..................................................121

Disassembly.............................................................121

Inspection.................................................................122

CONTENTS(Cont'd)

EM-2

Page 2137 of 2898

CYLINDER HEAD DISTORTION.............................122

CAMSHAFT VISUAL CHECK..................................123

CAMSHAFT RUNOUT............................................123

CAMSHAFT CAM HEIGHT.....................................123

CAMSHAFT JOURNAL CLEARANCE......................123

CAMSHAFT END PLAY..........................................124

CAMSHAFT SPROCKET RUNOUT.........................124

VALVE GUIDE CLEARANCE..................................124

VALVE GUIDE REPLACEMENT..............................125

VALVE SEATS.......................................................126

REPLACING VALVE SEAT FOR SERVICE PARTS..126

VALVE DIMENSIONS.............................................128

VALVE SPRING.....................................................128

VALVE LIFTER......................................................128

Assembly .................................................................129

Installation ................................................................129

CYLINDER HEAD GASKET SELECTION.................130

CYLINDER HEAD BOLT DEFORMATION CHECK...131

CYLINDER HEAD-TO-BLOCK DIFFERENCE

CHECK

.................................................................131

LIQUID GASKET APPLICATION ON REAR CHAIN

CASE

....................................................................131

CYLINDER HEAD INSTALLATION..........................132

GLOW PLUG INSTALLATION.................................132

CAMSHAFT INSTALLATION...................................132

Valve Clearance.......................................................133

CHECKING...........................................................133

ADJUSTING..........................................................134

ENGINE ASSEMBLY...................................................137

Removal and Installation .........................................137

REMOVAL.............................................................138

INSTALLATION......................................................139

CYLINDER BLOCK.....................................................140

Components.............................................................140

Removal and Installation .........................................141

Disassembly.............................................................141

PISTON AND CRANKSHAFT..................................141

Inspection.................................................................144

CRANKSHAFT END PLAY.....................................144

CONNECTING ROD SIDE CLEARANCE.................144

PISTON AND PISTON PIN CLEARANCE................145

PISTON RING SIDE CLEARANCE..........................145

PISTON RING END GAP........................................145

CONNECTING ROD BEND AND TORSION.............146

CYLINDER BLOCK DISTORTION AND WEAR.........146

PISTON-TO-BORE CLEARANCE............................147

CRANKSHAFT.......................................................148

MAIN BEARING HOUSING INNER DIAMETER........149

BEARING CLEARANCE.........................................149

MAIN BEARING CRUSH HEIGHT...........................153

MAIN BEARING CAP BOLT DEFORMATION...........153

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

........................................................153

CONNECTING ROD BOLT DEFORMATION............154

FLYWHEEL RUNOUT............................................154

OIL JET................................................................154

OIL JET RELIEF VALVE.........................................154

Assembly .................................................................155

PISTON................................................................155

CRANKSHAFT.......................................................155

REPLACEMENT OF PILOT BUSHING.....................158

SERVICE DATA AND SPECIFICATIONS (SDS).......160

General Specifications .............................................160

Compression Pressure ............................................160

Belt Deflection..........................................................160

Cylinder Head ..........................................................160

Valve ........................................................................161

VALVE..................................................................161

VALVE CLEARANCE..............................................161

AVAILABLE SHIMS................................................161

VALVE SPRING.....................................................162

VALVE LIFTER......................................................162

VALVE GUIDE.......................................................163

Valve Seat................................................................164

Camshaft and Camshaft Bearing ............................166

Cylinder Block ..........................................................167

Piston, Piston Ring and Piston Pin .........................167

AVAILABLE PISTON..............................................167

PISTON RING.......................................................168

PISTON PIN..........................................................168

Connecting Rod .......................................................168

Crankshaft................................................................168

Available Main Bearing ............................................169

UNDERSIZE..........................................................169

Available Connecting Rod Bearing..........................169

CONNECTING ROD BEARING...............................169

UNDERSIZE..........................................................170

Miscellaneous Components.....................................170

BEARING CLEARANCE.........................................170

CONTENTS(Cont'd)

EM-3

Page 2138 of 2898

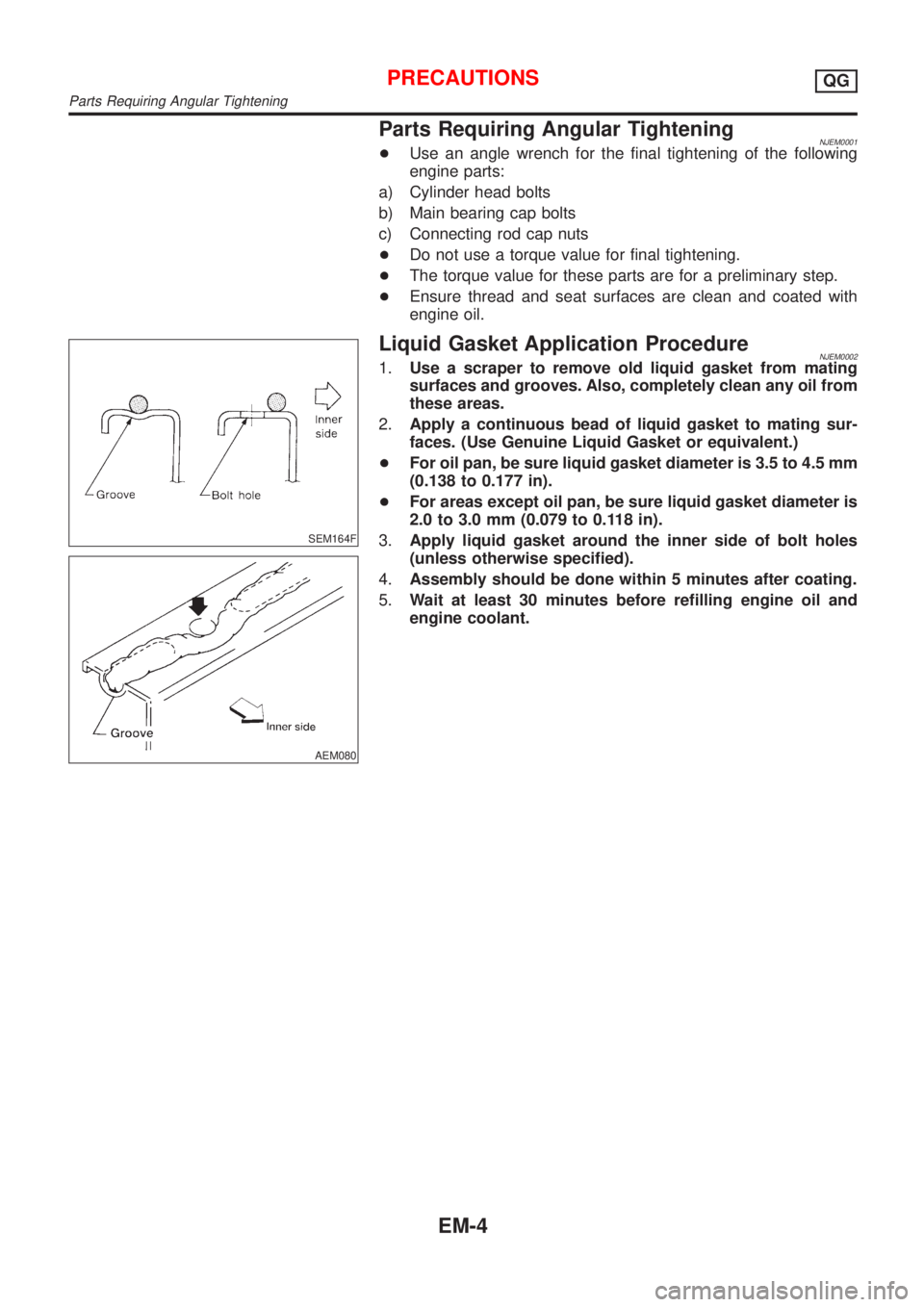

Parts Requiring Angular TighteningNJEM0001+Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

+Do not use a torque value for final tightening.

+The torque value for these parts are for a preliminary step.

+Ensure thread and seat surfaces are clean and coated with

engine oil.

SEM164F

AEM080

Liquid Gasket Application ProcedureNJEM00021.Use a scraper to remove old liquid gasket from mating

surfaces and grooves. Also, completely clean any oil from

these areas.

2.Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

+For areas except oil pan, be sure liquid gasket diameter is

2.0 to 3.0 mm (0.079 to 0.118 in).

3.Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4.Assembly should be done within 5 minutes after coating.

5.Wait at least 30 minutes before refilling engine oil and

engine coolant.

PRECAUTIONSQG

Parts Requiring Angular Tightening

EM-4

Page 2139 of 2898

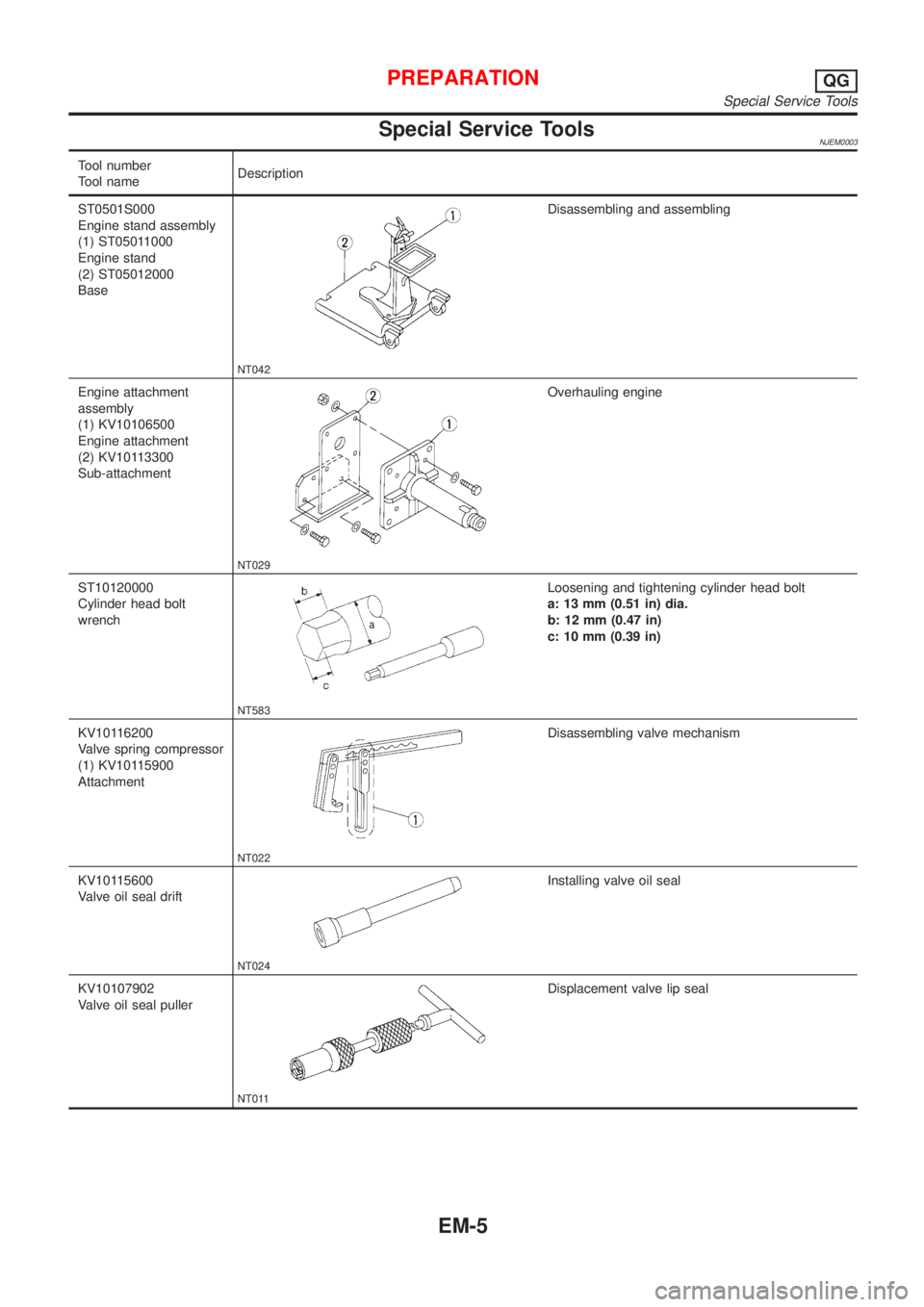

Special Service ToolsNJEM0003

Tool number

Tool nameDescription

ST0501S000

Engine stand assembly

(1) ST05011000

Engine stand

(2) ST05012000

Base

NT042

Disassembling and assembling

Engine attachment

assembly

(1) KV10106500

Engine attachment

(2) KV10113300

Sub-attachment

NT029

Overhauling engine

ST10120000

Cylinder head bolt

wrench

NT583

Loosening and tightening cylinder head bolt

a: 13 mm (0.51 in) dia.

b: 12 mm (0.47 in)

c: 10 mm (0.39 in)

KV10116200

Valve spring compressor

(1) KV10115900

Attachment

NT022

Disassembling valve mechanism

KV10115600

Valve oil seal drift

NT024

Installing valve oil seal

KV10107902

Valve oil seal puller

NT011

Displacement valve lip seal

PREPARATIONQG

Special Service Tools

EM-5

Page 2140 of 2898

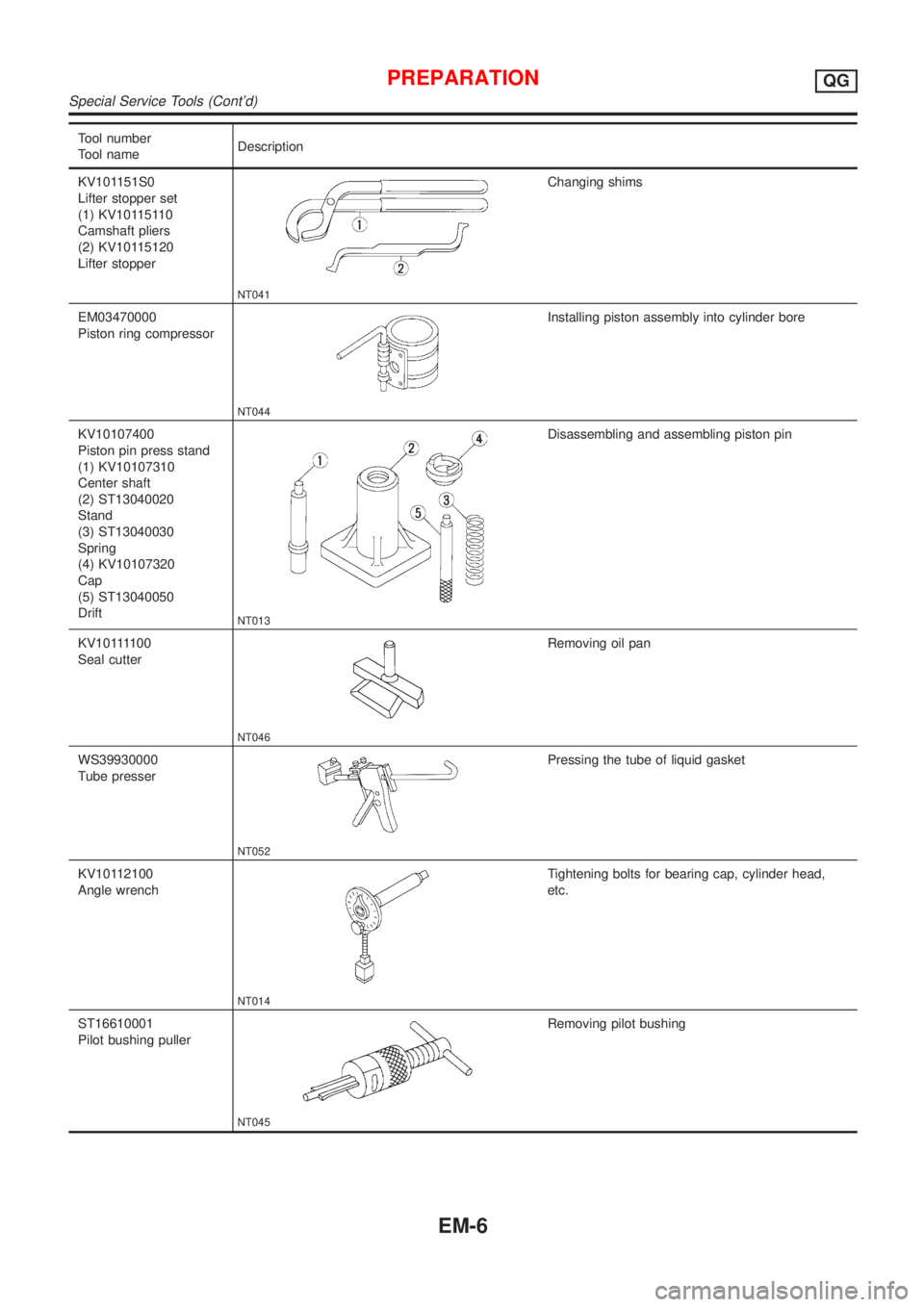

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

(1) KV10115110

Camshaft pliers

(2) KV10115120

Lifter stopper

NT041

Changing shims

EM03470000

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

KV10107400

Piston pin press stand

(1) KV10107310

Center shaft

(2) ST13040020

Stand

(3) ST13040030

Spring

(4) KV10107320

Cap

(5) ST13040050

Drift

NT013

Disassembling and assembling piston pin

KV101111 0 0

Seal cutter

NT046

Removing oil pan

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

ST16610001

Pilot bushing puller

NT045

Removing pilot bushing

PREPARATIONQG

Special Service Tools (Cont'd)

EM-6