battery NISSAN ALMERA 2001 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 156 of 2898

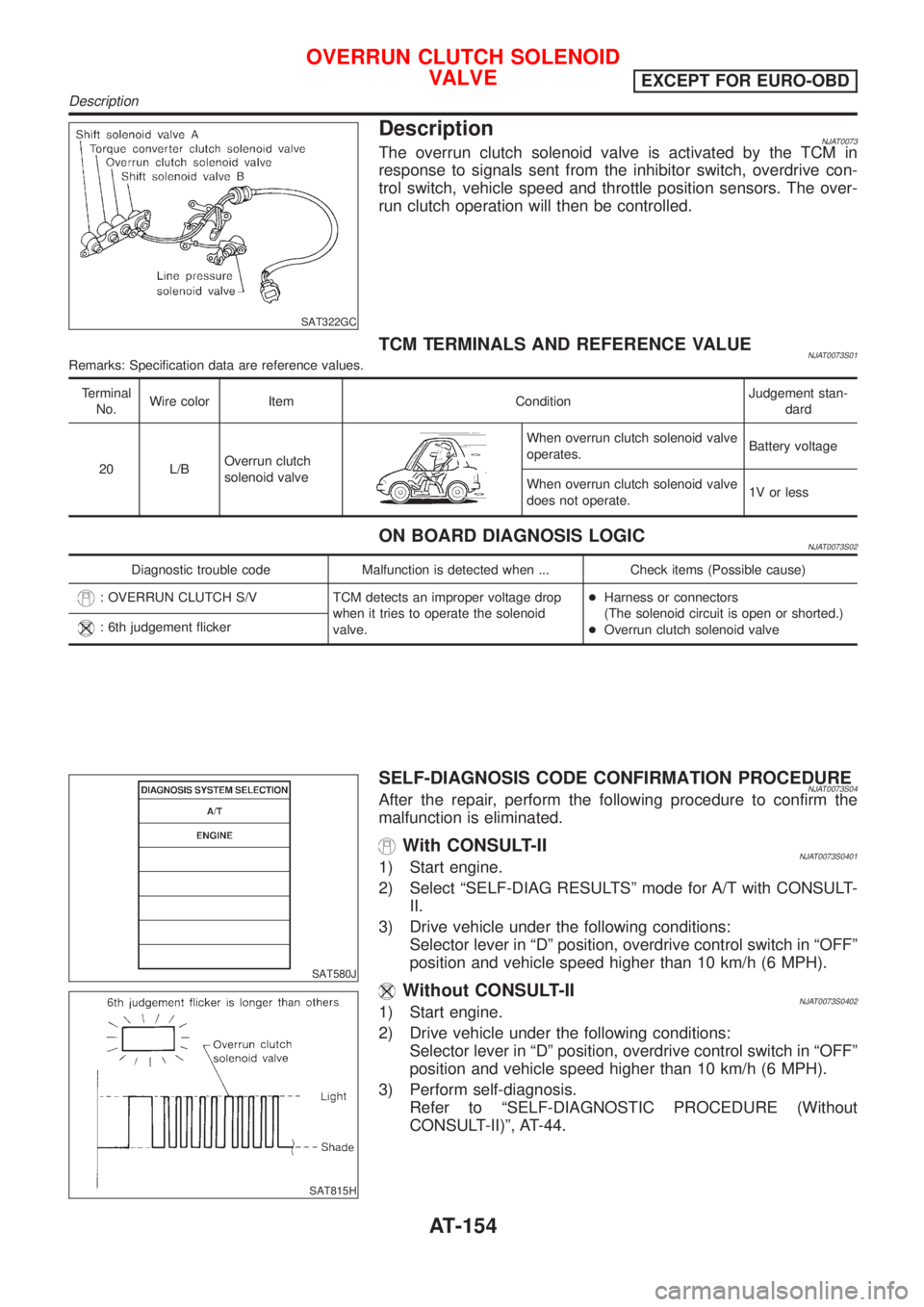

SAT322GC

DescriptionNJAT0073The overrun clutch solenoid valve is activated by the TCM in

response to signals sent from the inhibitor switch, overdrive con-

trol switch, vehicle speed and throttle position sensors. The over-

run clutch operation will then be controlled.

TCM TERMINALS AND REFERENCE VALUENJAT0073S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

20 L/BOverrun clutch

solenoid valve

When overrun clutch solenoid valve

operates.Battery voltage

When overrun clutch solenoid valve

does not operate.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0073S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: OVERRUN CLUTCH S/V TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Overrun clutch solenoid valve

: 6th judgement flicker

SAT580J

SAT815H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0073S04After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0073S04011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, overdrive control switch in ªOFFº

position and vehicle speed higher than 10 km/h (6 MPH).

Without CONSULT-IINJAT0073S04021) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, overdrive control switch in ªOFFº

position and vehicle speed higher than 10 km/h (6 MPH).

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-44.

OVERRUN CLUTCH SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Description

AT-154

Page 160 of 2898

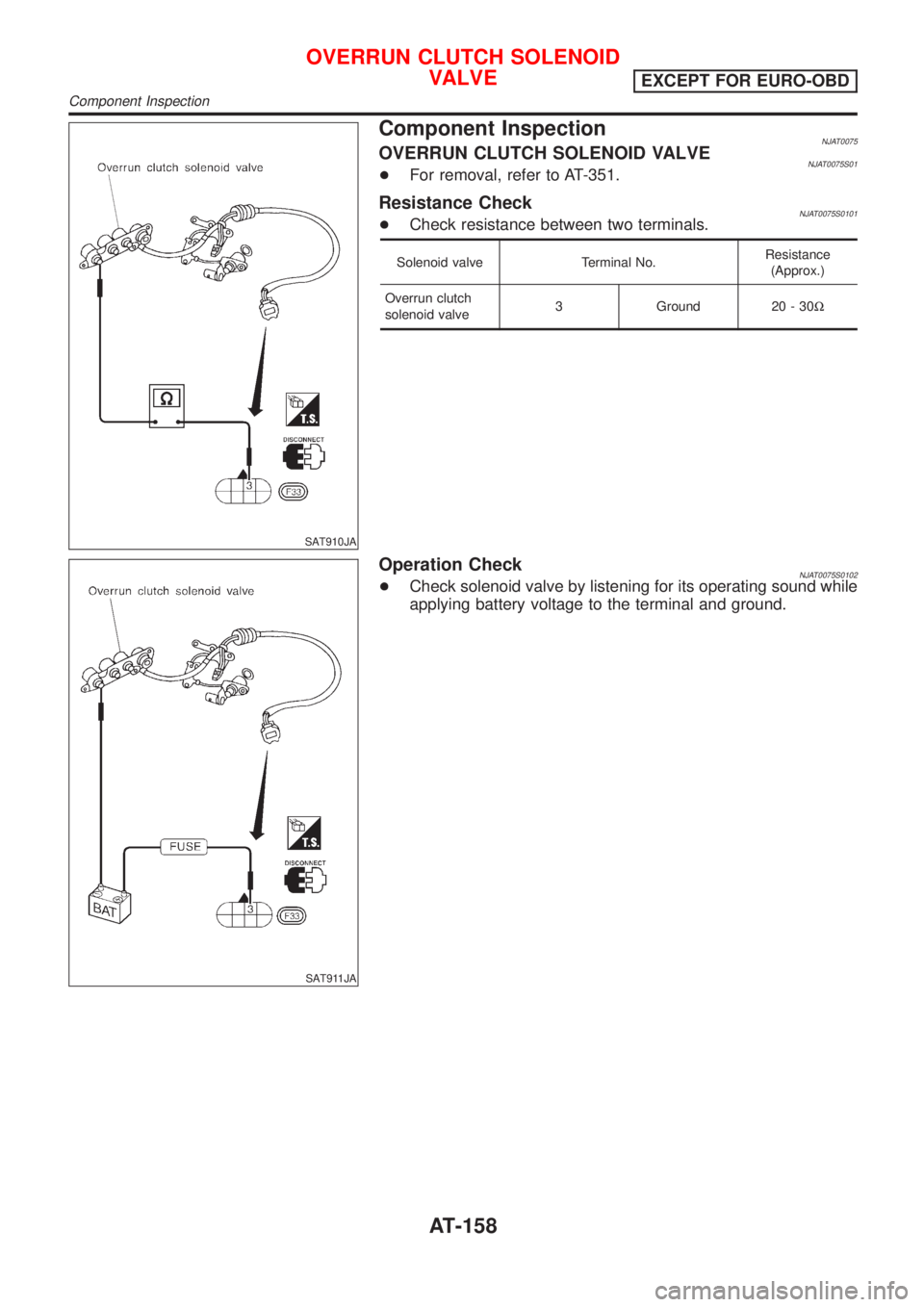

SAT910JA

Component InspectionNJAT0075OVERRUN CLUTCH SOLENOID VALVENJAT0075S01+For removal, refer to AT-351.

Resistance CheckNJAT0075S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Overrun clutch

solenoid valve3 Ground 20 - 30W

SAT911JA

Operation CheckNJAT0075S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

OVERRUN CLUTCH SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Component Inspection

AT-158

Page 166 of 2898

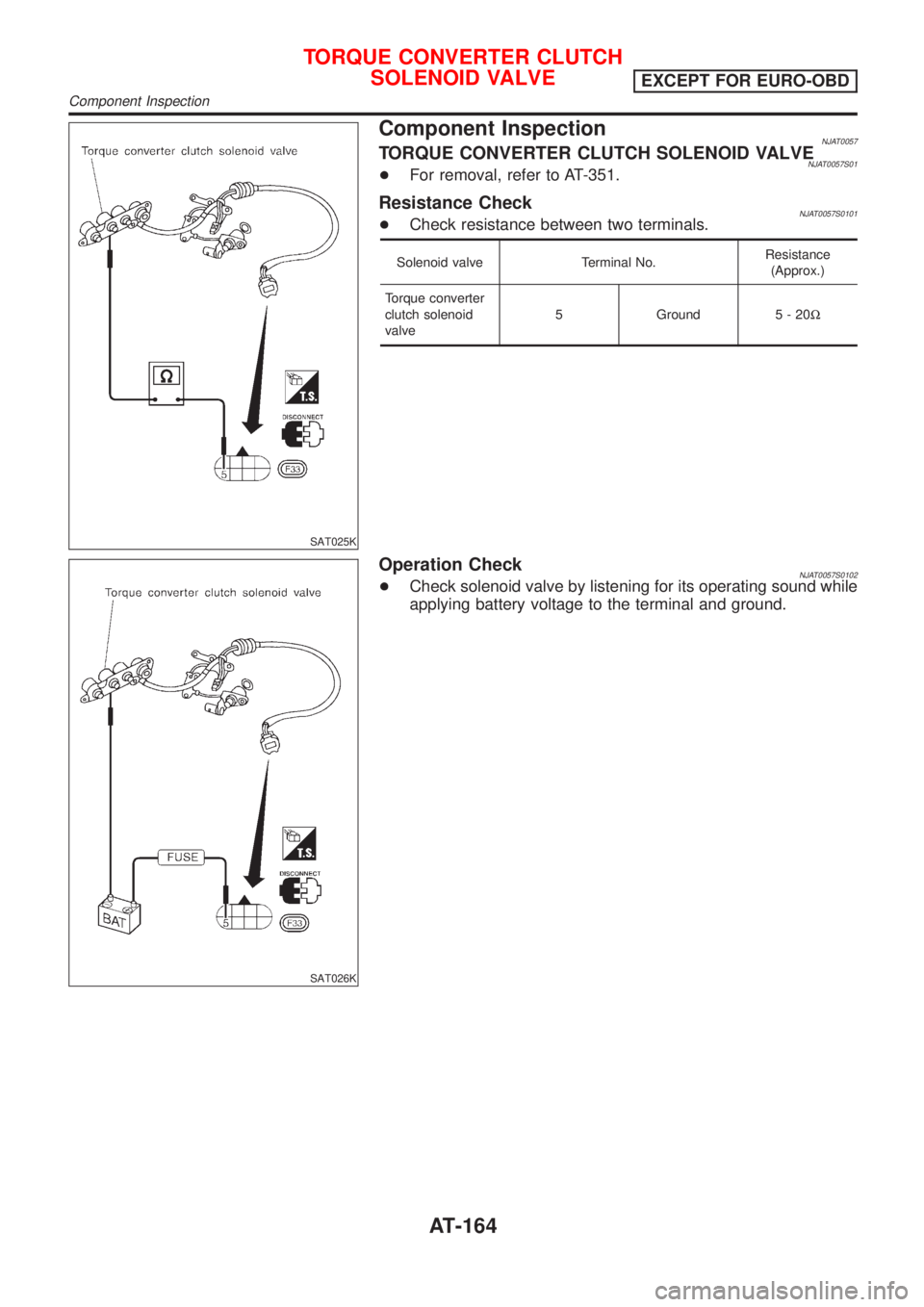

SAT025K

Component InspectionNJAT0057TORQUE CONVERTER CLUTCH SOLENOID VALVENJAT0057S01+For removal, refer to AT-351.

Resistance CheckNJAT0057S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Torque converter

clutch solenoid

valve5 Ground 5 - 20W

SAT026K

Operation CheckNJAT0057S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Component Inspection

AT-164

Page 167 of 2898

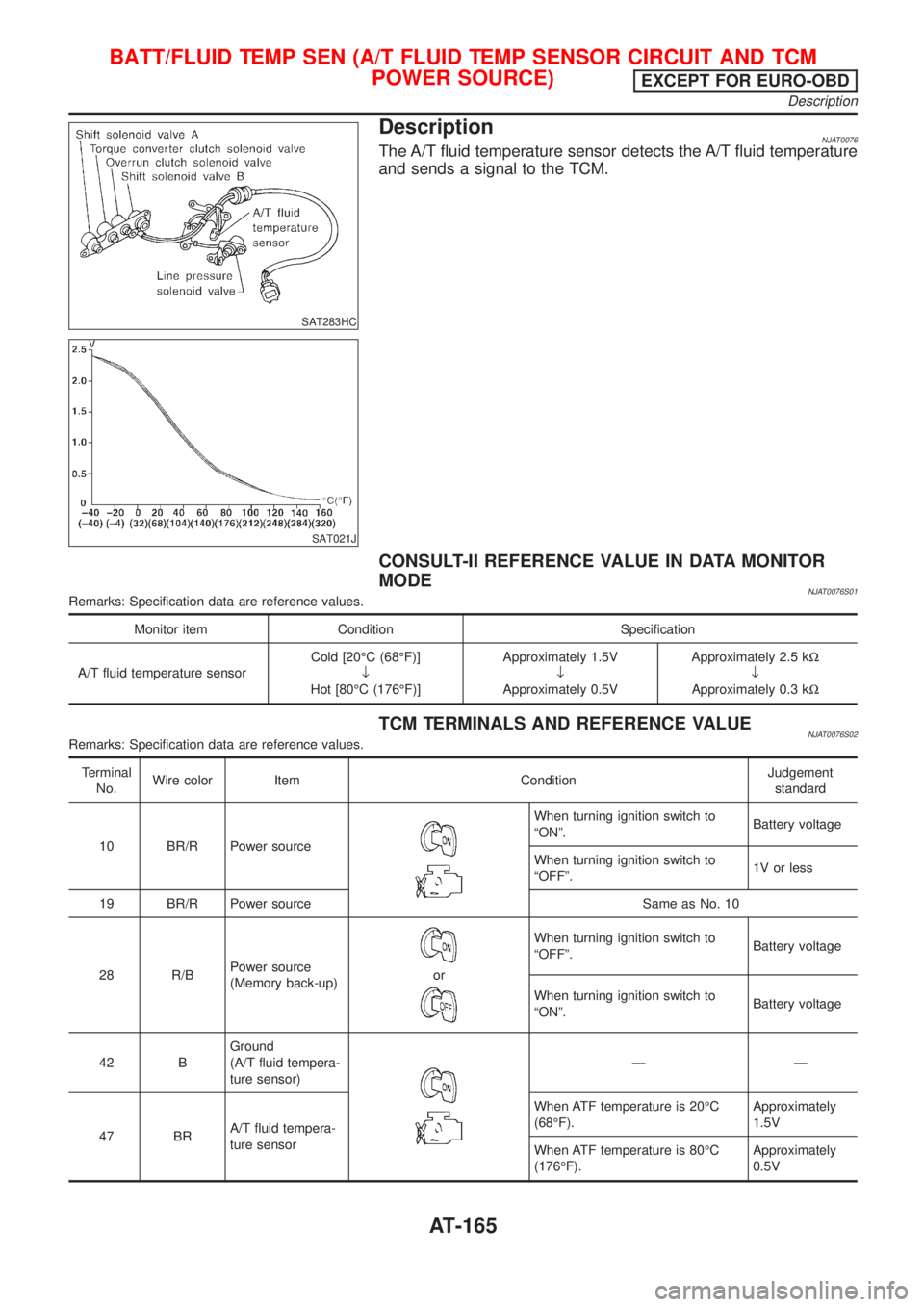

SAT283HC

SAT021J

DescriptionNJAT0076The A/T fluid temperature sensor detects the A/T fluid temperature

and sends a signal to the TCM.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NJAT0076S01Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid temperature sensorCold [20ÉC (68ÉF)]

¯

Hot [80ÉC (176ÉF)]Approximately 1.5V

¯

Approximately 0.5VApproximately 2.5 kW

¯

Approximately 0.3 kW

TCM TERMINALS AND REFERENCE VALUENJAT0076S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

10 BR/R Power source

When turning ignition switch to

ªONº.Battery voltage

When turning ignition switch to

ªOFFº.1V or less

19 BR/R Power source Same as No. 10

28 R/BPower source

(Memory back-up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to

ªONº.Battery voltage

42 BGround

(A/T fluid tempera-

ture sensor)

ÐÐ

47 BRA/T fluid tempera-

ture sensorWhen ATF temperature is 20ÉC

(68ÉF).Approximately

1.5V

When ATF temperature is 80ÉC

(176ÉF).Approximately

0.5V

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Description

AT-165

Page 170 of 2898

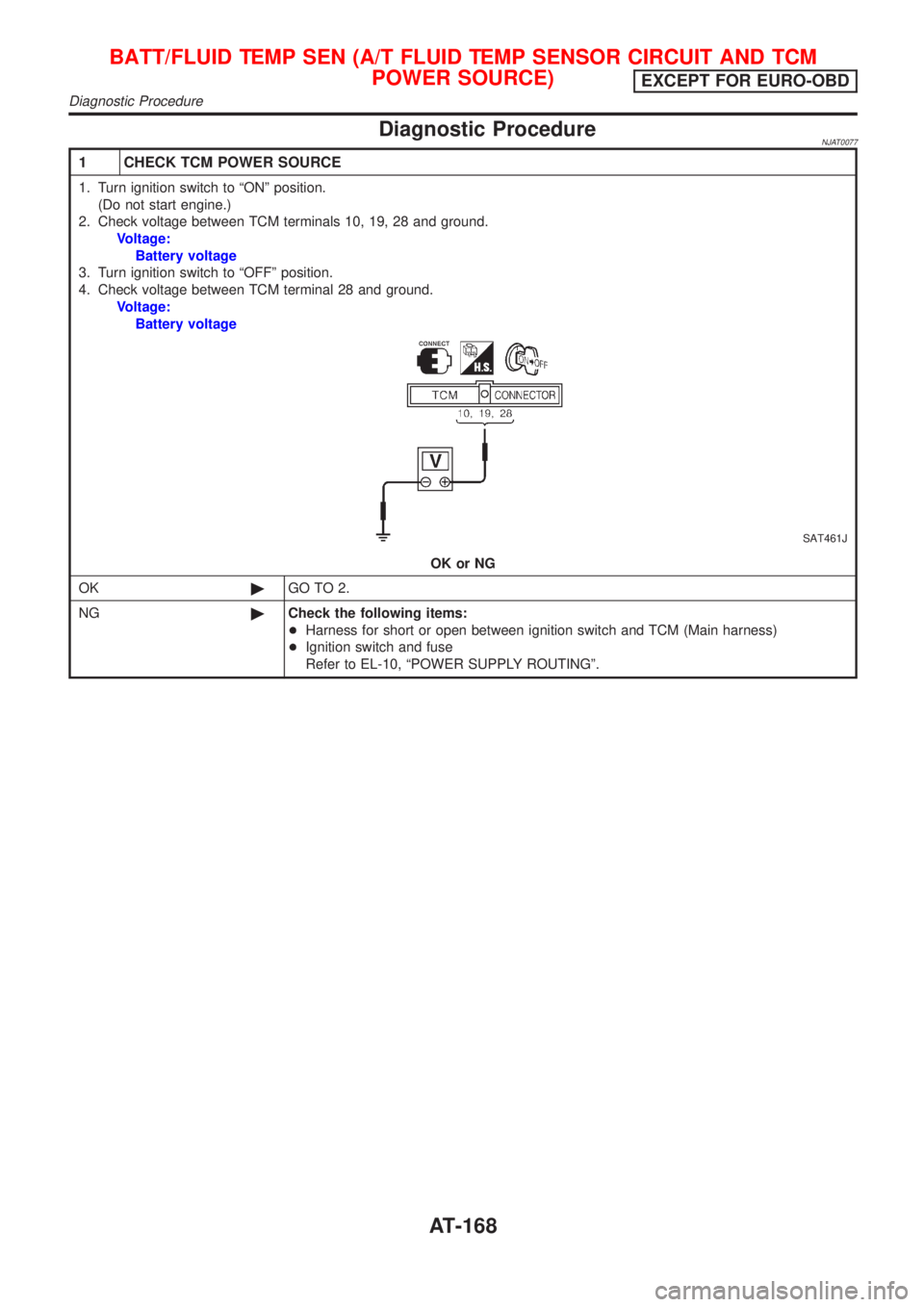

Diagnostic ProcedureNJAT0077

1 CHECK TCM POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 10, 19, 28 and ground.

Voltage:

Battery voltage

3. Turn ignition switch to ªOFFº position.

4. Check voltage between TCM terminal 28 and ground.

Voltage:

Battery voltage

SAT461J

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Harness for short or open between ignition switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL-10, ªPOWER SUPPLY ROUTINGº.

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-168

Page 184 of 2898

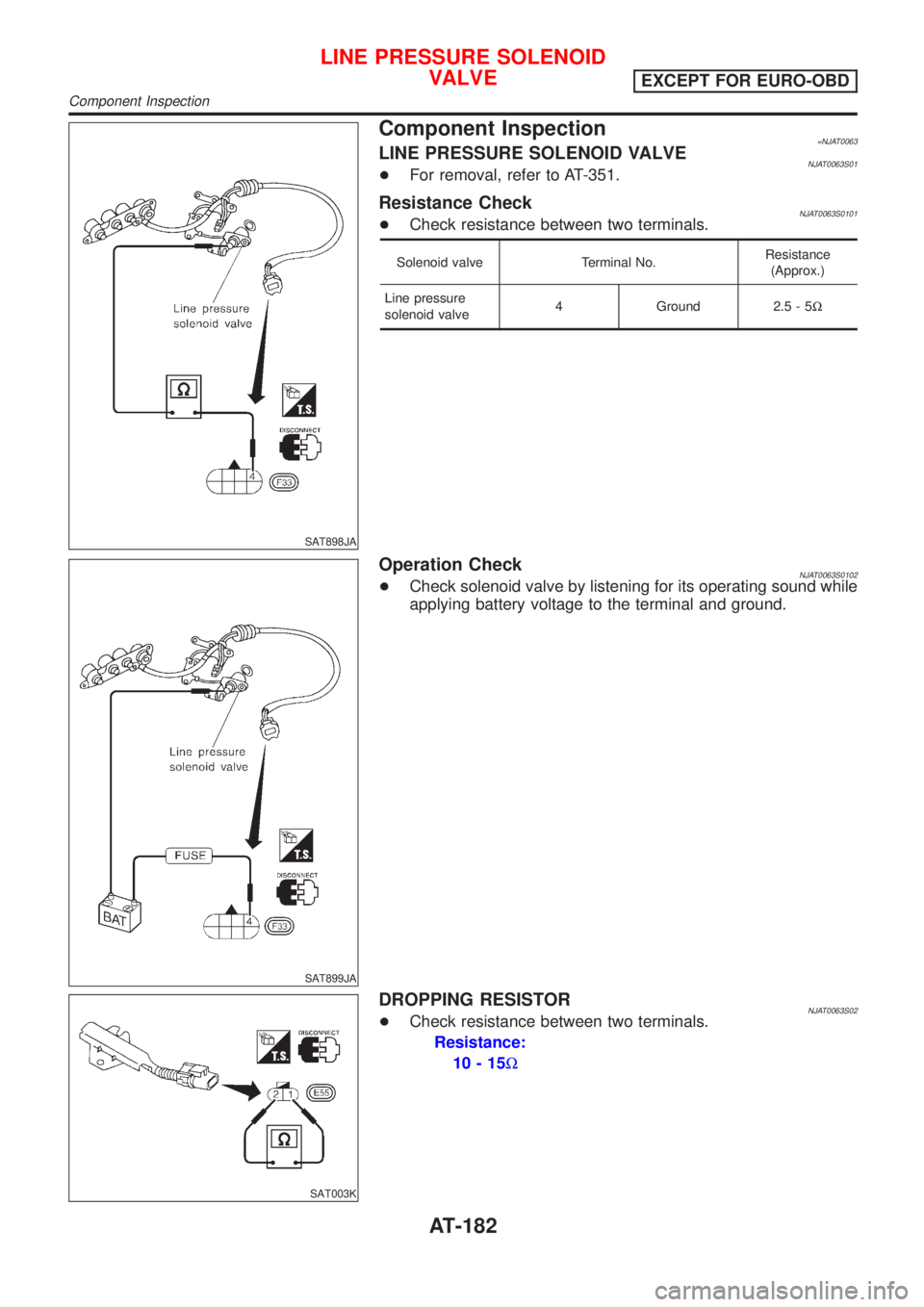

SAT898JA

Component Inspection=NJAT0063LINE PRESSURE SOLENOID VALVENJAT0063S01+For removal, refer to AT-351.

Resistance CheckNJAT0063S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve4 Ground 2.5 - 5W

SAT899JA

Operation CheckNJAT0063S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

SAT003K

DROPPING RESISTORNJAT0063S02+Check resistance between two terminals.

Resistance:

10-15W

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Component Inspection

AT-182

Page 185 of 2898

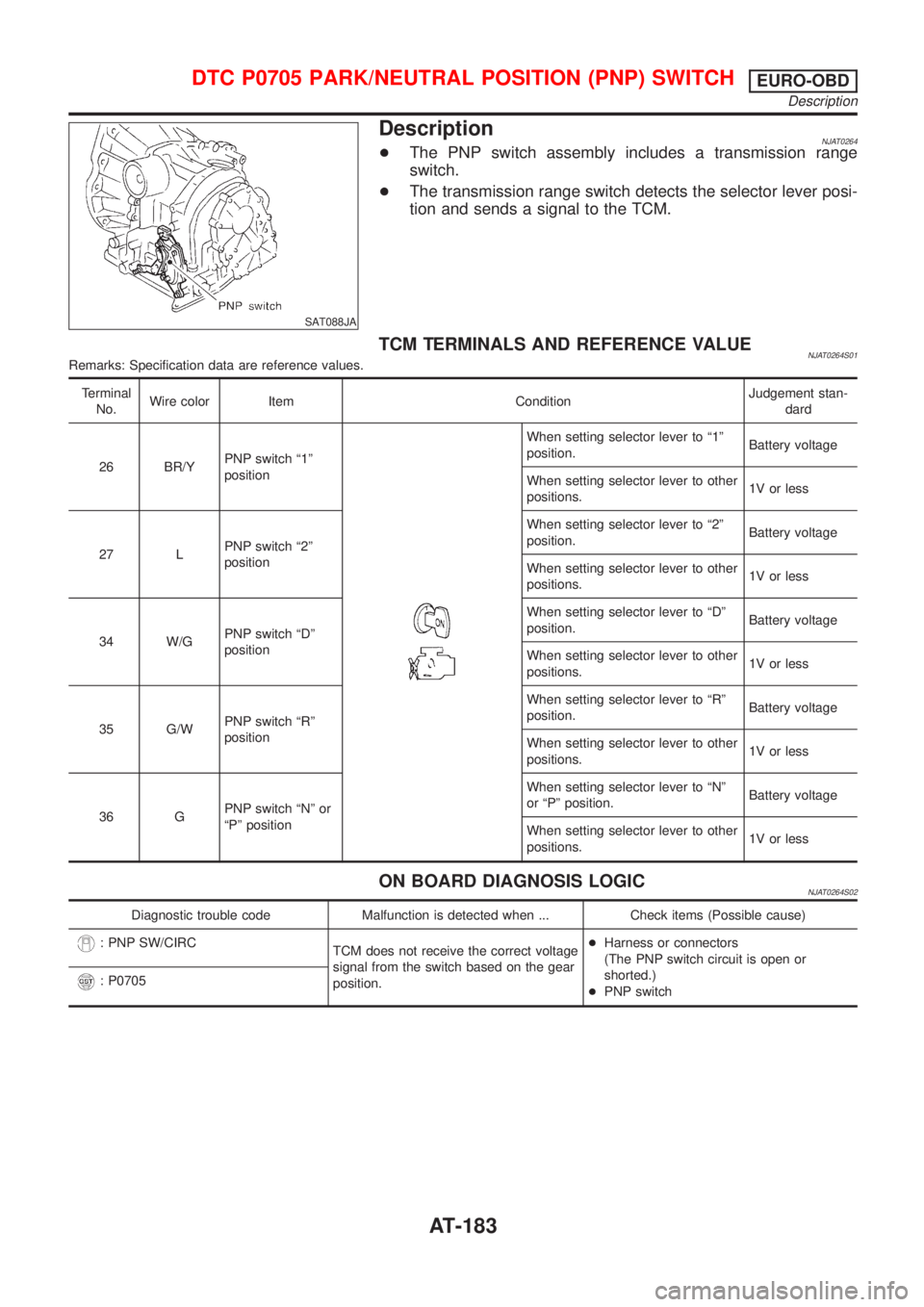

SAT088JA

DescriptionNJAT0264+The PNP switch assembly includes a transmission range

switch.

+The transmission range switch detects the selector lever posi-

tion and sends a signal to the TCM.

TCM TERMINALS AND REFERENCE VALUENJAT0264S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

26 BR/YPNP switch ª1º

position

When setting selector lever to ª1º

position.Battery voltage

When setting selector lever to other

positions.1V or less

27 LPNP switch ª2º

positionWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to other

positions.1V or less

34 W/GPNP switch ªDº

positionWhen setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.1V or less

35 G/WPNP switch ªRº

positionWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.1V or less

36 GPNP switch ªNº or

ªPº positionWhen setting selector lever to ªNº

or ªPº position.Battery voltage

When setting selector lever to other

positions.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0264S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: PNP SW/CIRC

TCM does not receive the correct voltage

signal from the switch based on the gear

position.+Harness or connectors

(The PNP switch circuit is open or

shorted.)

+PNP switch

: P0705

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Description

AT-183

Page 189 of 2898

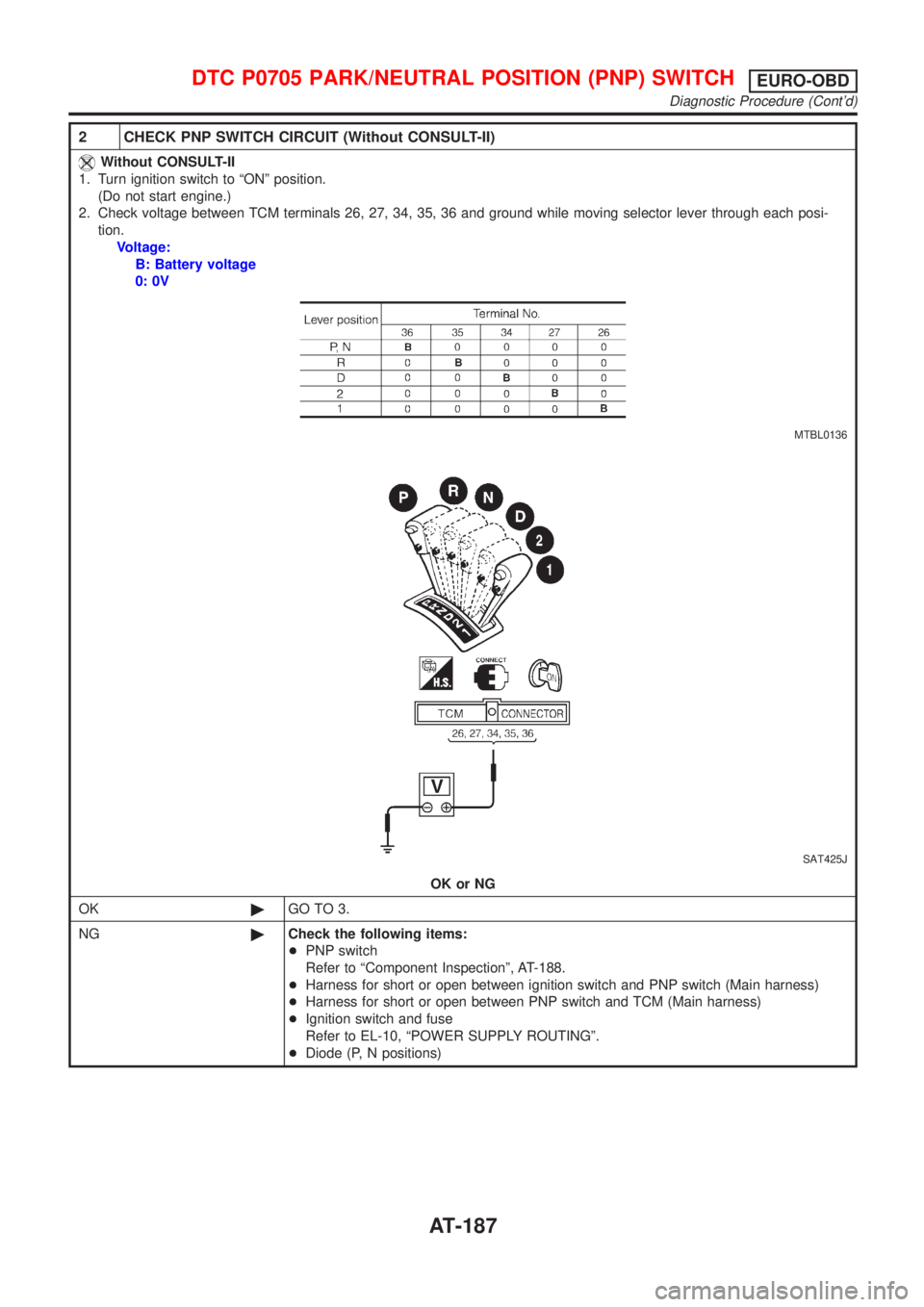

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 26, 27, 34, 35, 36 and ground while moving selector lever through each posi-

tion.

Voltage:

B: Battery voltage

0: 0V

MTBL0136

SAT425J

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-188.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL-10, ªPOWER SUPPLY ROUTINGº.

+Diode (P, N positions)

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Diagnostic Procedure (Cont'd)

AT-187

Page 206 of 2898

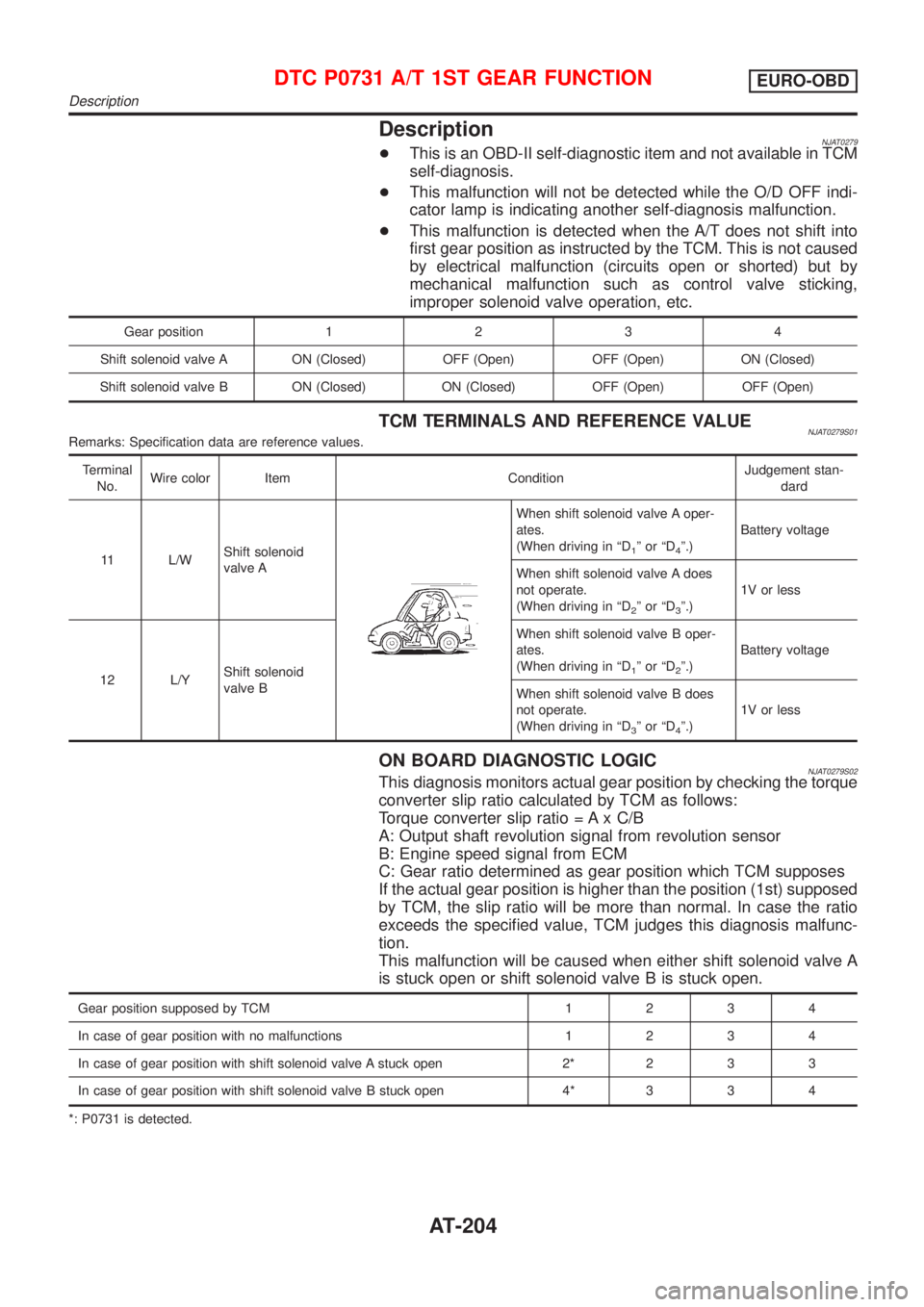

DescriptionNJAT0279+This is an OBD-II self-diagnostic item and not available in TCM

self-diagnosis.

+This malfunction will not be detected while the O/D OFF indi-

cator lamp is indicating another self-diagnosis malfunction.

+This malfunction is detected when the A/T does not shift into

first gear position as instructed by the TCM. This is not caused

by electrical malfunction (circuits open or shorted) but by

mechanical malfunction such as control valve sticking,

improper solenoid valve operation, etc.

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

TCM TERMINALS AND REFERENCE VALUENJAT0279S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

11 L/WShift solenoid

valve A

When shift solenoid valve A oper-

ates.

(When driving in ªD

1ºorªD4º.)Battery voltage

When shift solenoid valve A does

not operate.

(When driving in ªD

2ºorªD3º.)1V or less

12 L/YShift solenoid

valve BWhen shift solenoid valve B oper-

ates.

(When driving in ªD

1ºorªD2º.)Battery voltage

When shift solenoid valve B does

not operate.

(When driving in ªD

3ºorªD4º.)1V or less

ON BOARD DIAGNOSTIC LOGICNJAT0279S02This diagnosis monitors actual gear position by checking the torque

converter slip ratio calculated by TCM as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (1st) supposed

by TCM, the slip ratio will be more than normal. In case the ratio

exceeds the specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when either shift solenoid valve A

is stuck open or shift solenoid valve B is stuck open.

Gear position supposed by TCM1234

In case of gear position with no malfunctions1234

In case of gear position with shift solenoid valve A stuck open 2* 2 3 3

In case of gear position with shift solenoid valve B stuck open 4* 3 3 4

*: P0731 is detected.

DTC P0731 A/T 1ST GEAR FUNCTIONEURO-OBD

Description

AT-204

Page 212 of 2898

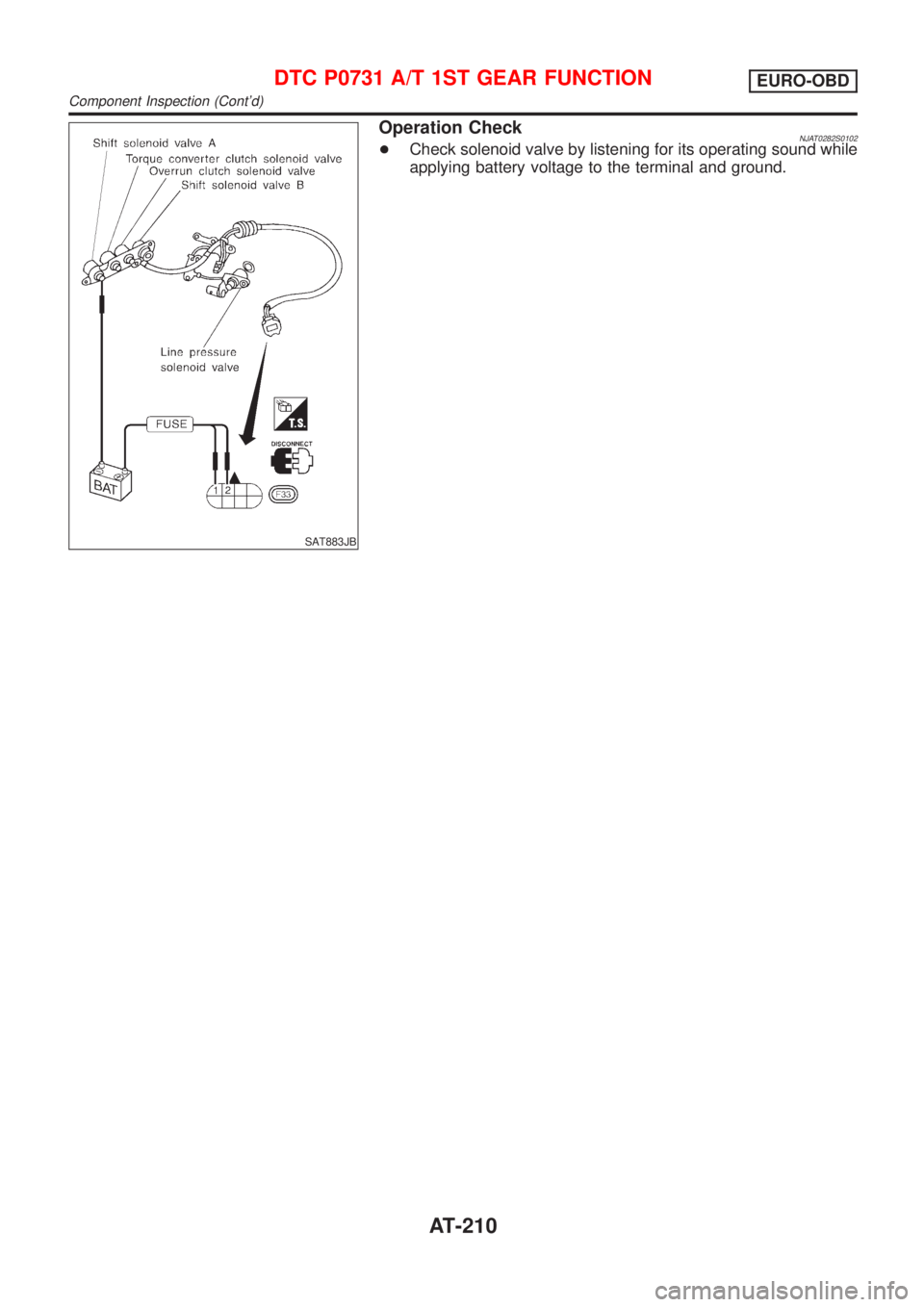

SAT883JB

Operation CheckNJAT0282S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

DTC P0731 A/T 1ST GEAR FUNCTIONEURO-OBD

Component Inspection (Cont'd)

AT-210