fuse NISSAN ALMERA 2001 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1247 of 2898

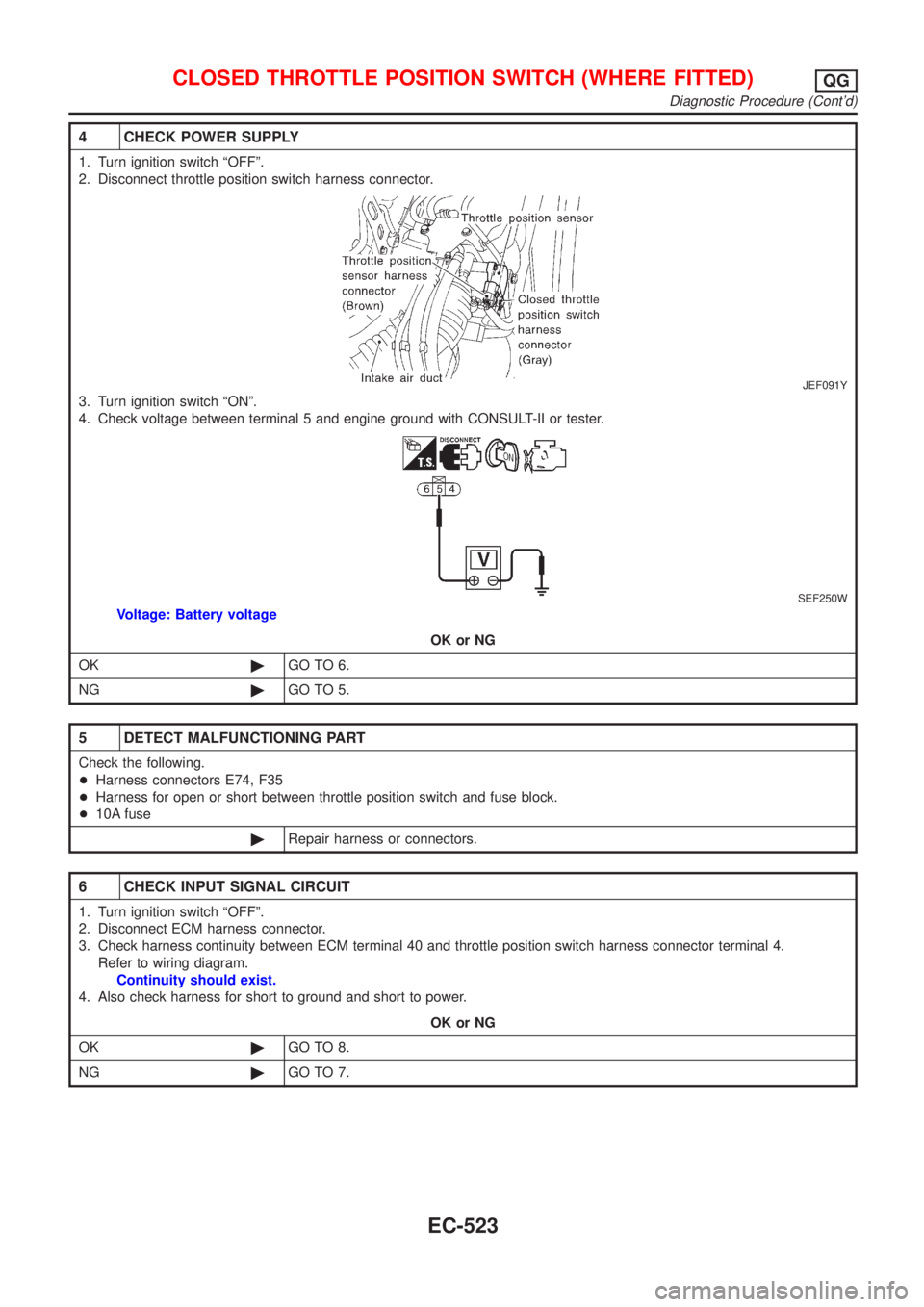

4 CHECK POWER SUPPLY

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect throttle position switch harness connector.

JEF091Y

3. Turn ignition switch ÂȘONÂș.

4. Check voltage between terminal 5 and engine ground with CONSULT-II or tester.

SEF250W

Voltage: Battery voltage

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E74, F35

+Harness for open or short between throttle position switch and fuse block.

+10A fuse

©Repair harness or connectors.

6 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 40 and throttle position switch harness connector terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

CLOSED THROTTLE POSITION SWITCH (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-523

Page 1254 of 2898

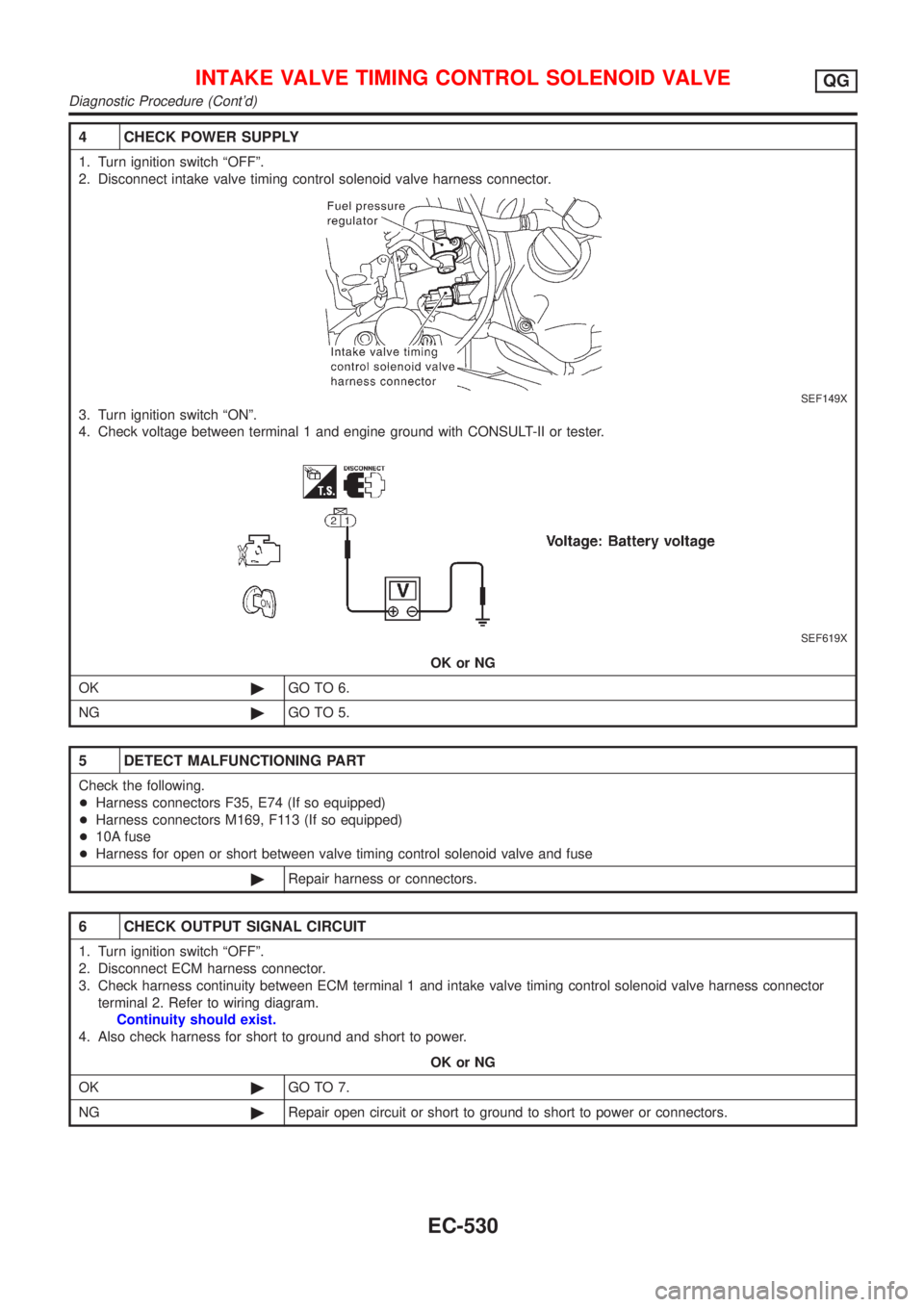

4 CHECK POWER SUPPLY

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect intake valve timing control solenoid valve harness connector.

SEF149X

3. Turn ignition switch ÂȘONÂș.

4. Check voltage between terminal 1 and engine ground with CONSULT-II or tester.

SEF619X

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F35, E74 (If so equipped)

+Harness connectors M169, F113 (If so equipped)

+10A fuse

+Harness for open or short between valve timing control solenoid valve and fuse

©Repair harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 1 and intake valve timing control solenoid valve harness connector

terminal 2. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground to short to power or connectors.

INTAKE VALVE TIMING CONTROL SOLENOID VALVEQG

Diagnostic Procedure (Cont'd)

EC-530

Page 1269 of 2898

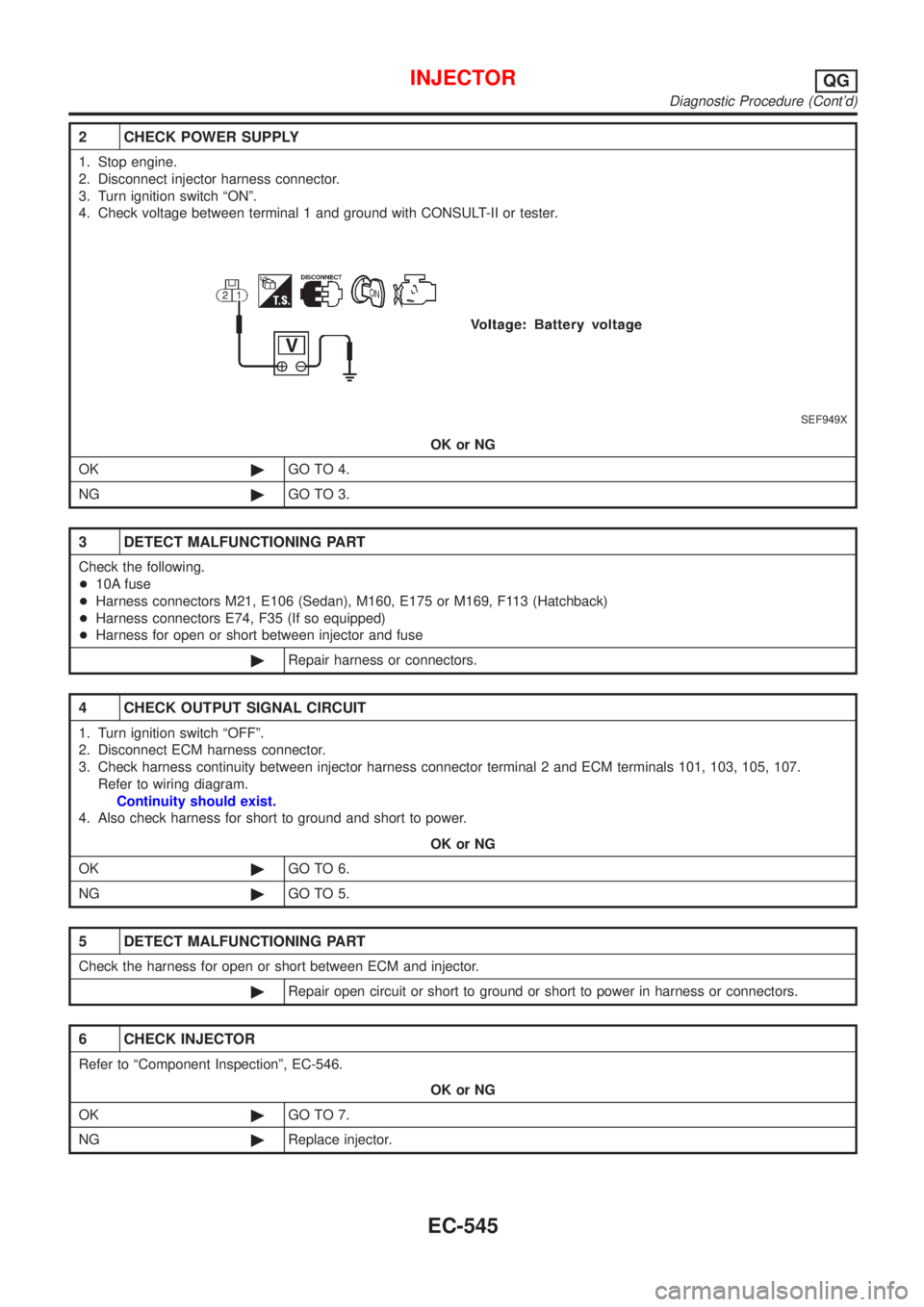

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ÂȘONÂș.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF949X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+Harness connectors M21, E106 (Sedan), M160, E175 or M169, F113 (Hatchback)

+Harness connectors E74, F35 (If so equipped)

+Harness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector harness connector terminal 2 and ECM terminals 101, 103, 105, 107.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INJECTOR

Refer to ÂȘComponent InspectionÂș, EC-546.

OK or NG

OK©GO TO 7.

NG©Replace injector.

INJECTORQG

Diagnostic Procedure (Cont'd)

EC-545

Page 1277 of 2898

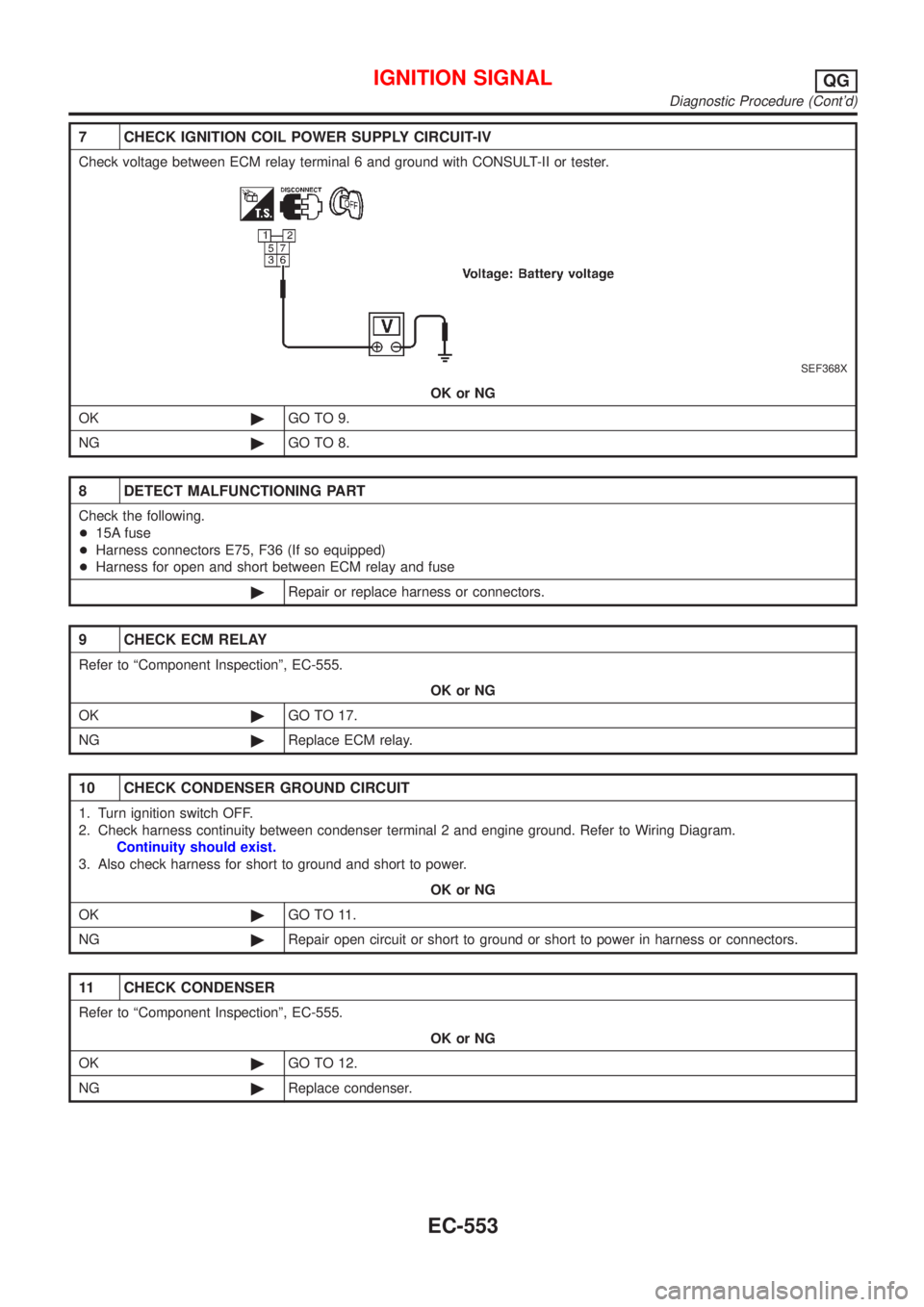

7 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF368X

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse

+Harness connectors E75, F36 (If so equipped)

+Harness for open and short between ECM relay and fuse

©Repair or replace harness or connectors.

9 CHECK ECM RELAY

Refer to ÂȘComponent InspectionÂș, EC-555.

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

10 CHECK CONDENSER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

11 CHECK CONDENSER

Refer to ÂȘComponent InspectionÂș, EC-555.

OK or NG

OK©GO TO 12.

NG©Replace condenser.

IGNITION SIGNALQG

Diagnostic Procedure (Cont'd)

EC-553

Page 1284 of 2898

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+10A fuse

+Harness for open or short between ECM and ignition switch

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Perform ÂȘTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTÂș, EC-177.

©INSPECTION END

START SIGNALQG

Diagnostic Procedure (Cont'd)

EC-560

Page 1289 of 2898

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+15A fuse

+Harness for open or short between fuse and fuel pump relay

©Repair harness or connectors.

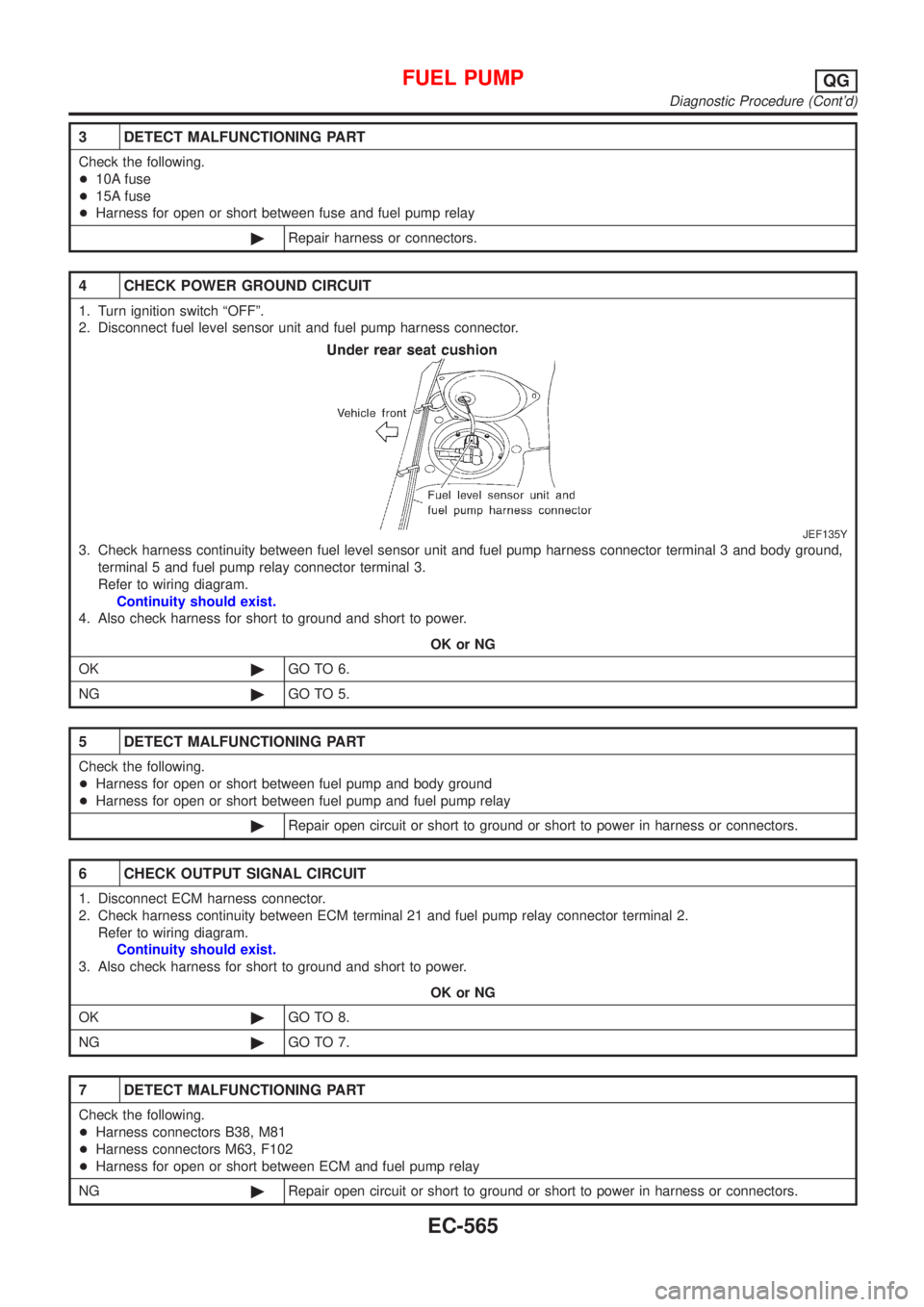

4 CHECK POWER GROUND CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect fuel level sensor unit and fuel pump harness connector.

JEF135Y

3. Check harness continuity between fuel level sensor unit and fuel pump harness connector terminal 3 and body ground,

terminal 5 and fuel pump relay connector terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness for open or short between fuel pump and body ground

+Harness for open or short between fuel pump and fuel pump relay

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 21 and fuel pump relay connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors B38, M81

+Harness connectors M63, F102

+Harness for open or short between ECM and fuel pump relay

NG©Repair open circuit or short to ground or short to power in harness or connectors.

FUEL PUMPQG

Diagnostic Procedure (Cont'd)

EC-565

Page 1309 of 2898

7 CHECK POWER SUPPLY

1. Stop engine.

2. Turn ÂȘOFFÂș the rear window defogger switch.

3. Disconnect rear window defogger relay.

4. Check voltage between terminal 3 (LHD models), 5 (RHD models) and ground with CONSULT-II or tester.

SEF626Z

OK or NG

OK©GO TO 8.

NG©Check the following and repair.

+20A fuse

+Harness for open and short between fuse block and rear window defogger relay

8 CHECK REAR WINDOW DEFOGGER RELAY

Refer to ÂȘComponent InspectionÂș, EC-590.

OK or NG

OK©GO TO 9.

NG©Replace rear window defogger relay.

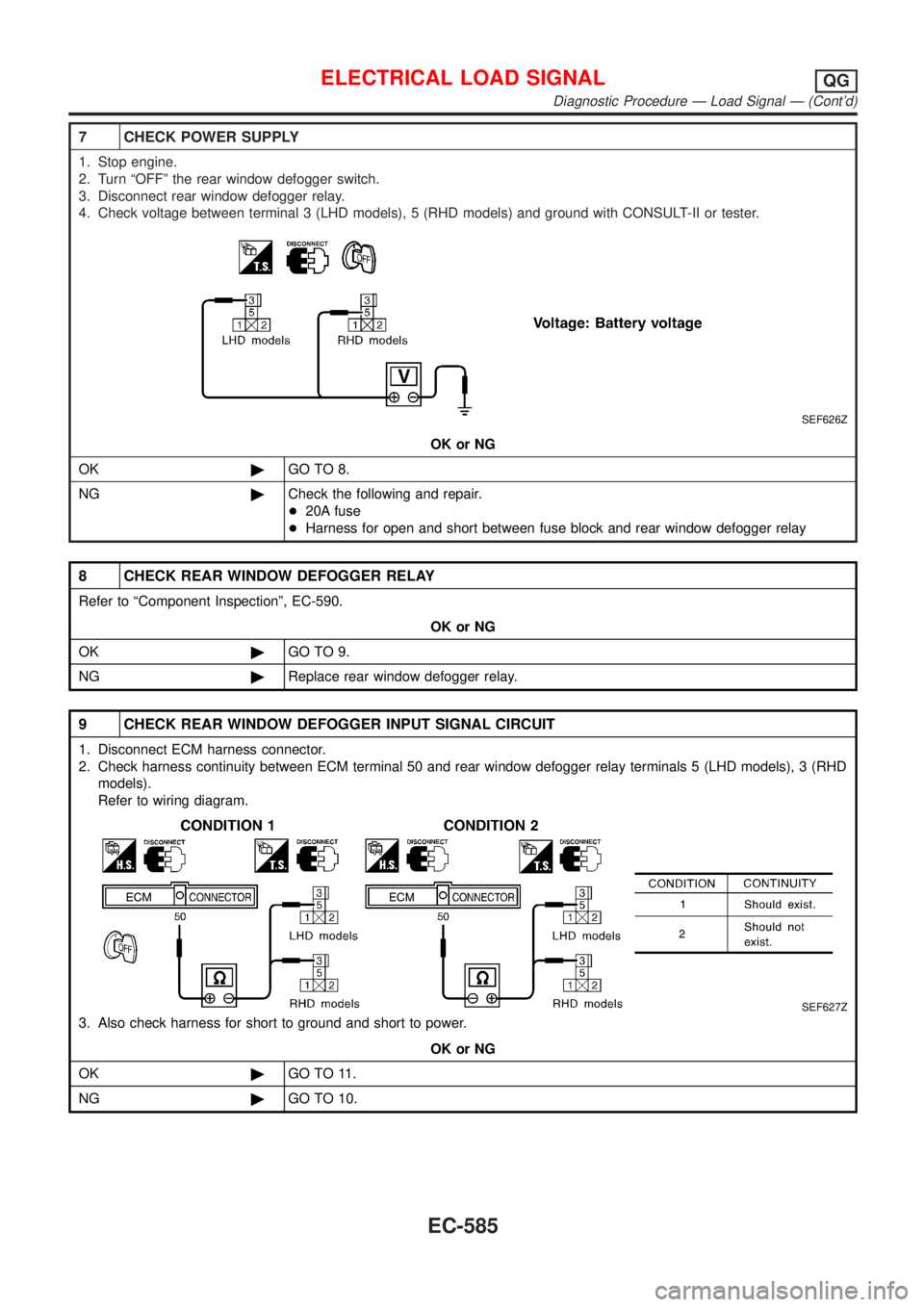

9 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 50 and rear window defogger relay terminals 5 (LHD models), 3 (RHD

models).

Refer to wiring diagram.

SEF627Z

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©GO TO 10.

ELECTRICAL LOAD SIGNALQG

Diagnostic Procedure Ă Load Signal Ă (Cont'd)

EC-585

Page 1393 of 2898

DIAGNOSTIC PROCEDURENJEC0641

1 INSPECTION START

Start engine.

Is engine running?

YesorNo

Ye s©GO TO 13.

No©GO TO 2.

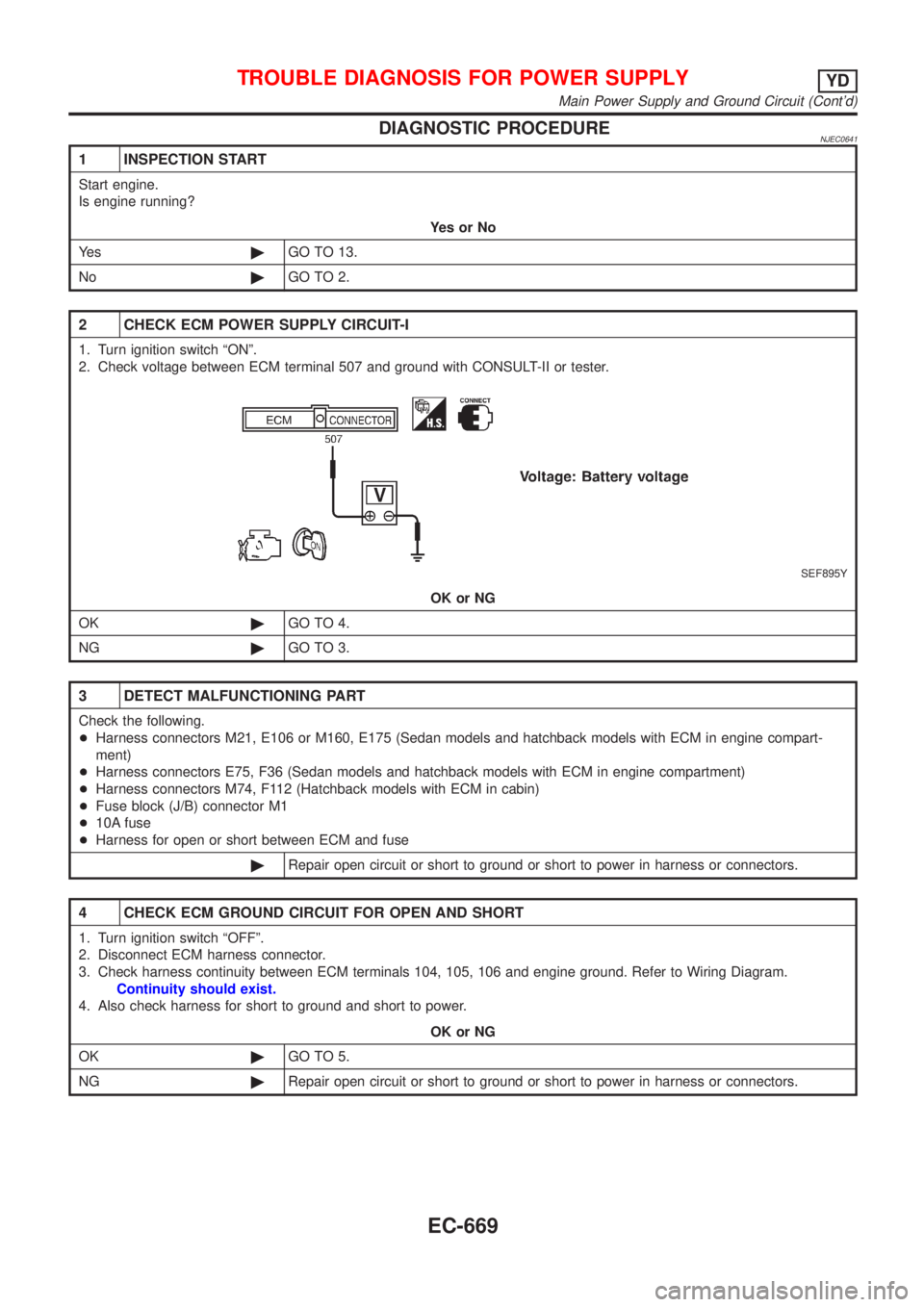

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ÂȘONÂș.

2. Check voltage between ECM terminal 507 and ground with CONSULT-II or tester.

SEF895Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E106 or M160, E175 (Sedan models and hatchback models with ECM in engine compart-

ment)

+Harness connectors E75, F36 (Sedan models and hatchback models with ECM in engine compartment)

+Harness connectors M74, F112 (Hatchback models with ECM in cabin)

+Fuse block (J/B) connector M1

+10A fuse

+Harness for open or short between ECM and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ÂȘOFFÂș.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 104, 105, 106 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-669

Page 1394 of 2898

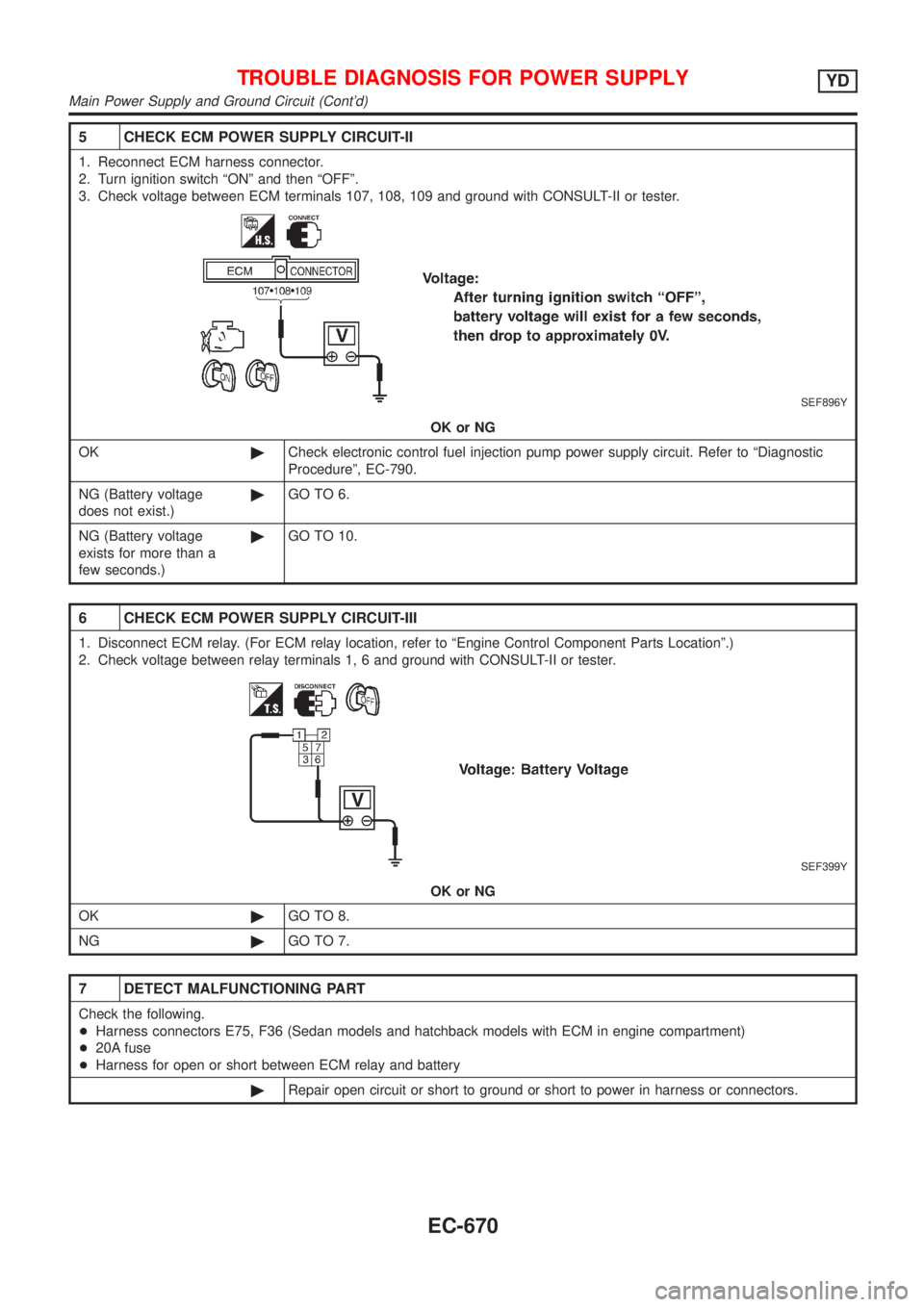

5 CHECK ECM POWER SUPPLY CIRCUIT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ÂȘONÂș and then ÂȘOFFÂș.

3. Check voltage between ECM terminals 107, 108, 109 and ground with CONSULT-II or tester.

SEF896Y

OK or NG

OK©Check electronic control fuel injection pump power supply circuit. Refer to ÂȘDiagnostic

ProcedureÂș, EC-790.

NG (Battery voltage

does not exist.)©GO TO 6.

NG (Battery voltage

exists for more than a

few seconds.)©GO TO 10.

6 CHECK ECM POWER SUPPLY CIRCUIT-III

1. Disconnect ECM relay. (For ECM relay location, refer to ÂȘEngine Control Component Parts LocationÂș.)

2. Check voltage between relay terminals 1, 6 and ground with CONSULT-II or tester.

SEF399Y

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36 (Sedan models and hatchback models with ECM in engine compartment)

+20A fuse

+Harness for open or short between ECM relay and battery

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYYD

Main Power Supply and Ground Circuit (Cont'd)

EC-670

Page 1434 of 2898

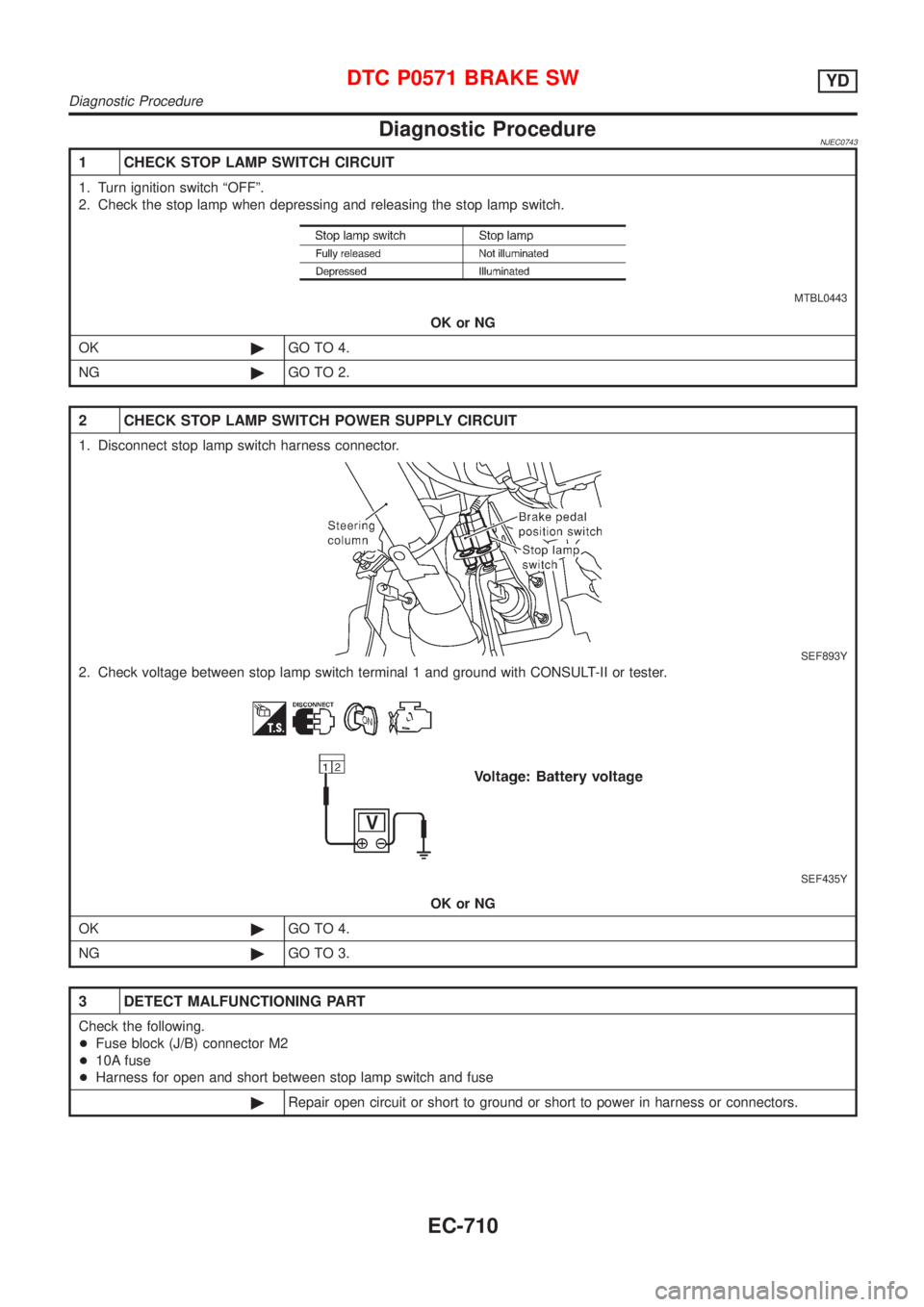

Diagnostic ProcedureNJEC0743

1 CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch ÂȘOFFÂș.

2. Check the stop lamp when depressing and releasing the stop lamp switch.

MTBL0443

OK or NG

OK©GO TO 4.

NG©GO TO 2.

2 CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch harness connector.

SEF893Y

2. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-II or tester.

SEF435Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open and short between stop lamp switch and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0571 BRAKE SWYD

Diagnostic Procedure

EC-710