coolant NISSAN ALMERA 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1138 of 2898

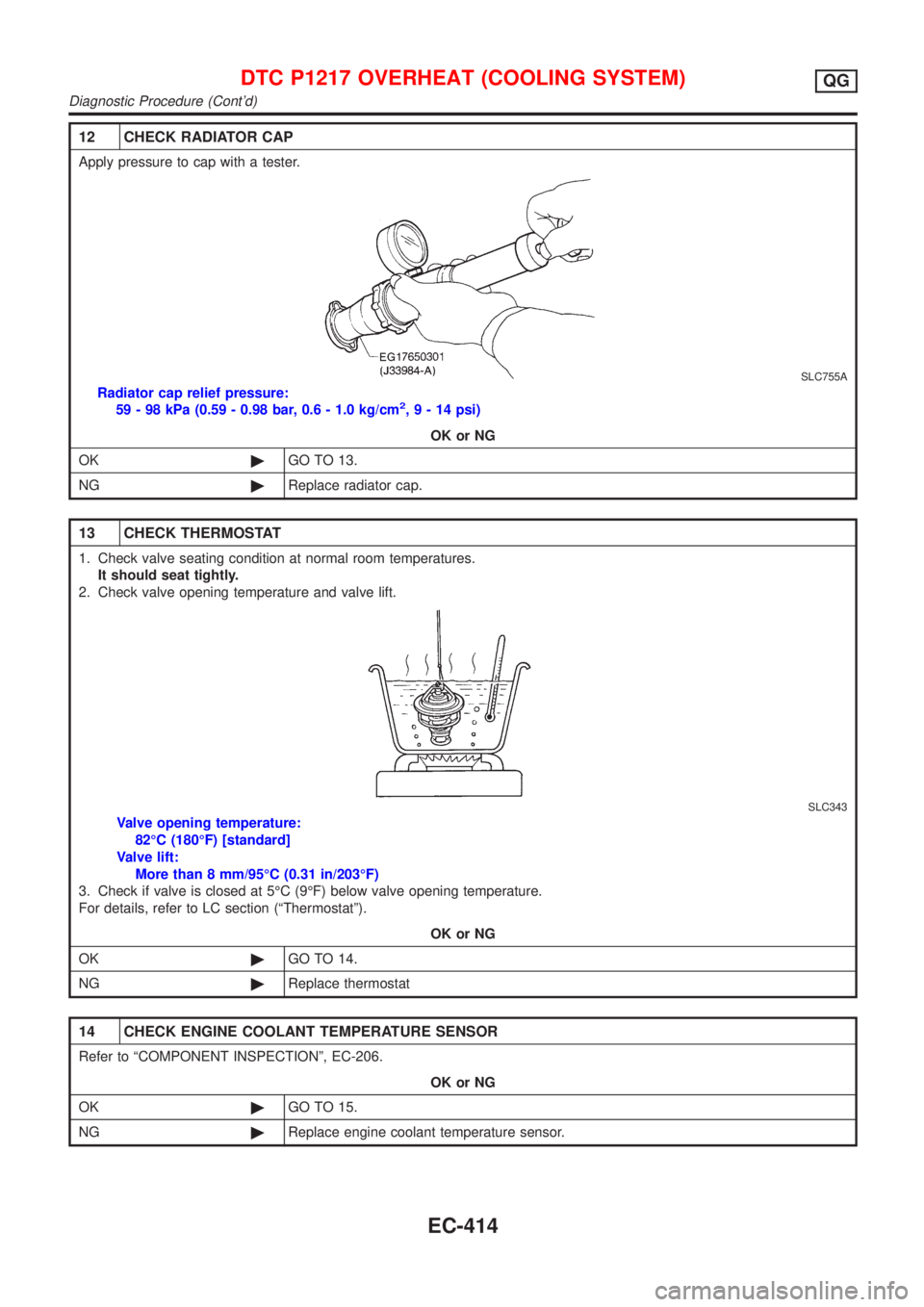

12 CHECK RADIATOR CAP

Apply pressure to cap with a tester.

SLC755A

Radiator cap relief pressure:

59 - 98 kPa (0.59 - 0.98 bar, 0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 13.

NG©Replace radiator cap.

13 CHECK THERMOSTAT

1. Check valve seating condition at normal room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard]

Valve lift:

More than 8 mm/95ÉC (0.31 in/203ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature.

For details, refer to LC section (ªThermostatº).

OK or NG

OK©GO TO 14.

NG©Replace thermostat

14 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to ªCOMPONENT INSPECTIONº, EC-206.

OK or NG

OK©GO TO 15.

NG©Replace engine coolant temperature sensor.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG

Diagnostic Procedure (Cont'd)

EC-414

Page 1140 of 2898

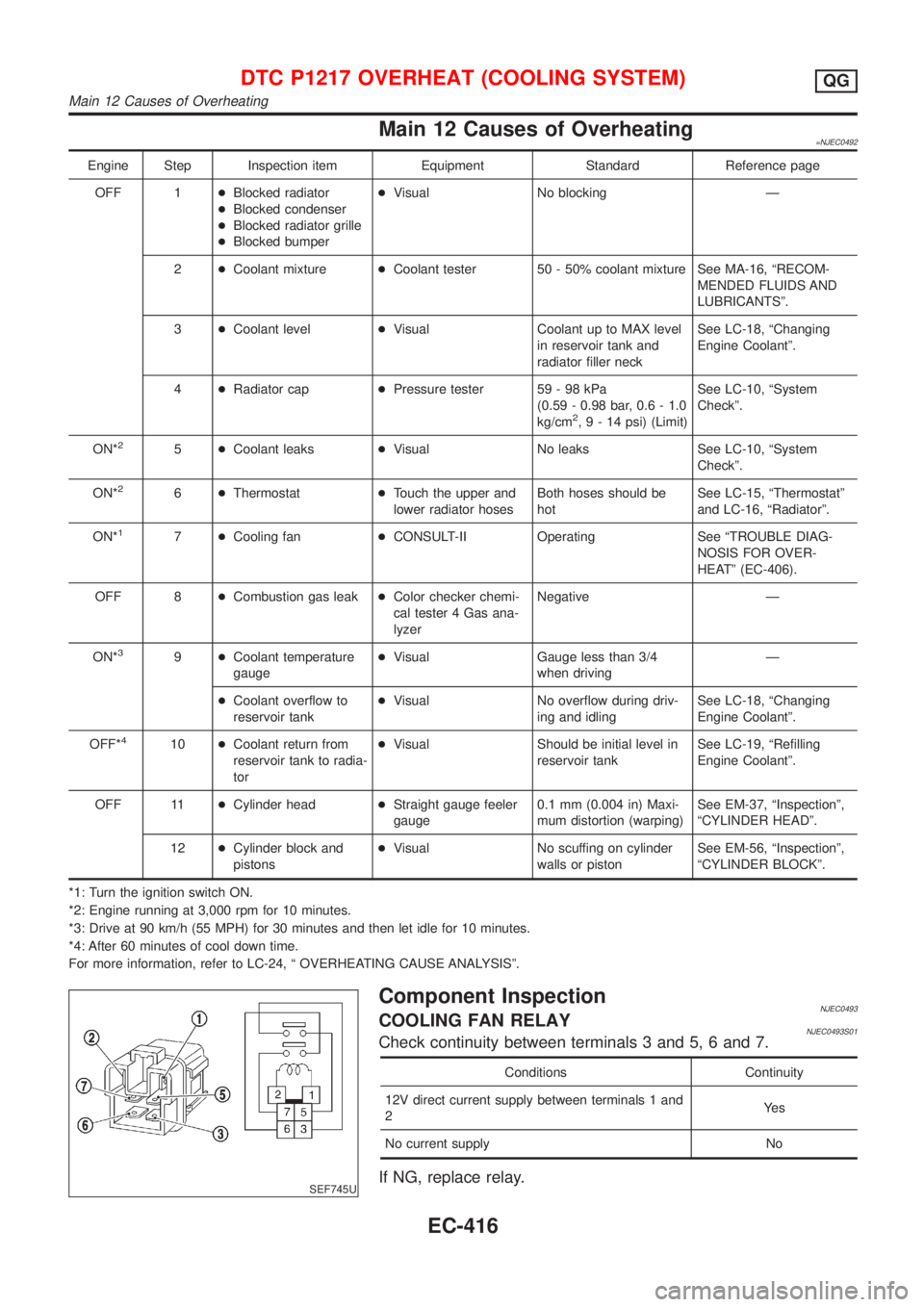

Main 12 Causes of Overheating=NJEC0492

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See MA-16, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee LC-18, ªChanging

Engine Coolantº.

4+Radiator cap+Pressure tester 59 - 98 kPa

(0.59 - 0.98 bar, 0.6 - 1.0

kg/cm

2,9-14psi) (Limit)See LC-10, ªSystem

Checkº.

ON*

25+Coolant leaks+Visual No leaks See LC-10, ªSystem

Checkº.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-15, ªThermostatº

and LC-16, ªRadiatorº.

ON*

17+Cooling fan+CONSULT-II Operating See ªTROUBLE DIAG-

NOSIS FOR OVER-

HEATº (EC-406).

OFF 8+Combustion gas leak+Color checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to

reservoir tank+Visual No overflow during driv-

ing and idlingSee LC-18, ªChanging

Engine Coolantº.

OFF*

410+Coolant return from

reservoir tank to radia-

tor+Visual Should be initial level in

reservoir tankSee LC-19, ªRefilling

Engine Coolantº.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-37, ªInspectionº,

ªCYLINDER HEADº.

12+Cylinder block and

pistons+Visual No scuffing on cylinder

walls or pistonSee EM-56, ªInspectionº,

ªCYLINDER BLOCKº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC-24, ª OVERHEATING CAUSE ANALYSISº.

SEF745U

Component InspectionNJEC0493COOLING FAN RELAYNJEC0493S01Check continuity between terminals 3 and 5, 6 and 7.

Conditions Continuity

12V direct current supply between terminals 1 and

2Ye s

No current supply No

If NG, replace relay.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG

Main 12 Causes of Overheating

EC-416

Page 1143 of 2898

SEF174Y

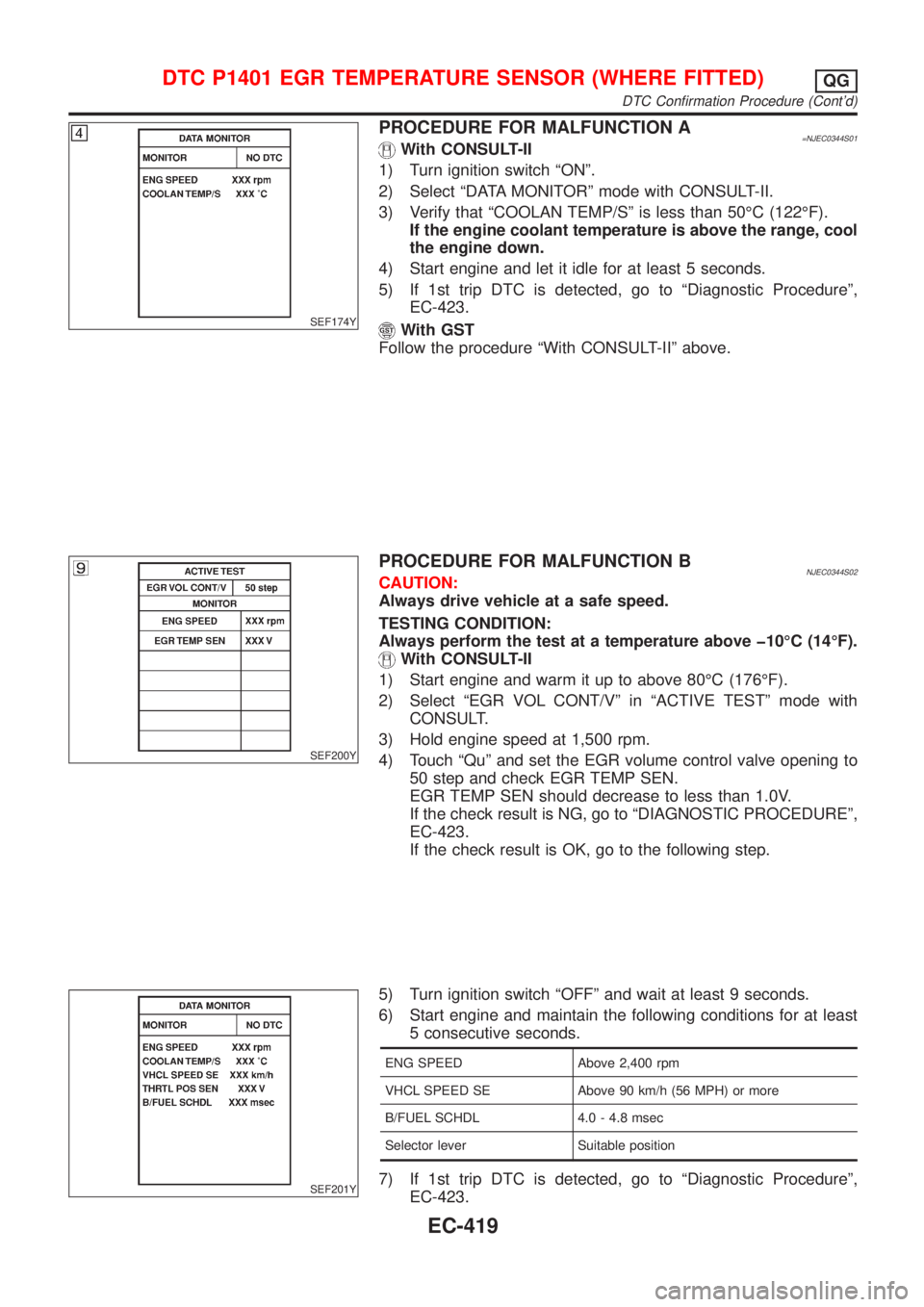

PROCEDURE FOR MALFUNCTION A=NJEC0344S01With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Verify that ªCOOLAN TEMP/Sº is less than 50ÉC (122ÉF).

If the engine coolant temperature is above the range, cool

the engine down.

4) Start engine and let it idle for at least 5 seconds.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-423.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF200Y

PROCEDURE FOR MALFUNCTION BNJEC0344S02CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

Always perform the test at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Start engine and warm it up to above 80ÉC (176ÉF).

2) Select ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT.

3) Hold engine speed at 1,500 rpm.

4) Touch ªQuº and set the EGR volume control valve opening to

50 step and check EGR TEMP SEN.

EGR TEMP SEN should decrease to less than 1.0V.

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

EC-423.

If the check result is OK, go to the following step.

SEF201Y

5) Turn ignition switch ªOFFº and wait at least 9 seconds.

6) Start engine and maintain the following conditions for at least

5 consecutive seconds.

ENG SPEED Above 2,400 rpm

VHCL SPEED SE Above 90 km/h (56 MPH) or more

B/FUEL SCHDL 4.0 - 4.8 msec

Selector lever Suitable position

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-423.

DTC P1401 EGR TEMPERATURE SENSOR (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-419

Page 1149 of 2898

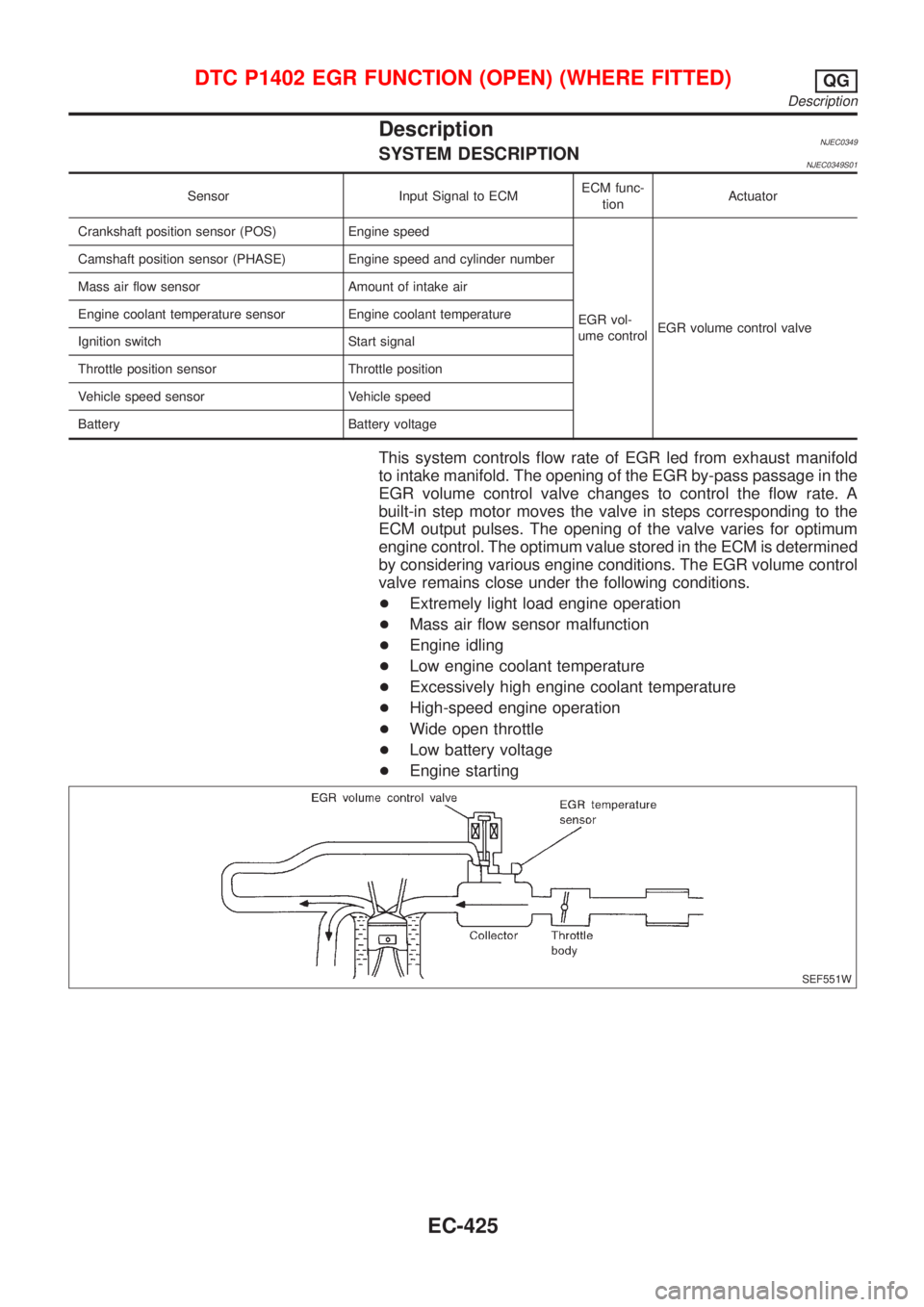

DescriptionNJEC0349SYSTEM DESCRIPTIONNJEC0349S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Extremely light load engine operation

+Mass air flow sensor malfunction

+Engine idling

+Low engine coolant temperature

+Excessively high engine coolant temperature

+High-speed engine operation

+Wide open throttle

+Low battery voltage

+Engine starting

SEF551W

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

Description

EC-425

Page 1150 of 2898

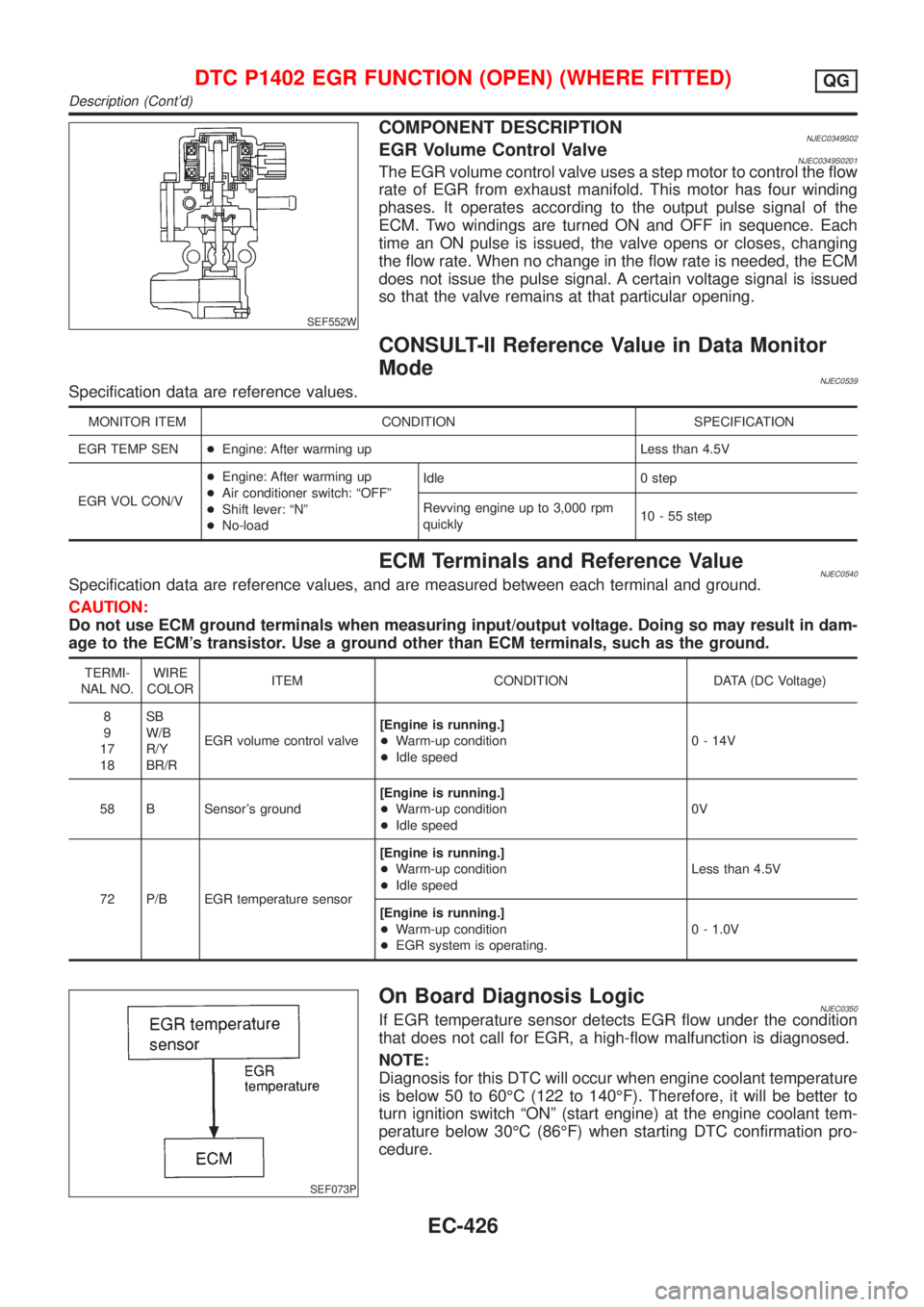

SEF552W

COMPONENT DESCRIPTIONNJEC0349S02EGR Volume Control ValveNJEC0349S0201The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0539Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EGR TEMP SEN+Engine: After warming up Less than 4.5V

EGR VOL CON/V+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: ªNº

+No-loadIdle 0 step

Revving engine up to 3,000 rpm

quickly10 - 55 step

ECM Terminals and Reference ValueNJEC0540Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

8

9

17

18SB

W/B

R/Y

BR/REGR volume control valve[Engine is running.]

+Warm-up condition

+Idle speed0 - 14V

58 B Sensor's ground[Engine is running.]

+Warm-up condition

+Idle speed0V

72 P/B EGR temperature sensor[Engine is running.]

+Warm-up condition

+Idle speedLess than 4.5V

[Engine is running.]

+Warm-up condition

+EGR system is operating.0 - 1.0V

SEF073P

On Board Diagnosis LogicNJEC0350If EGR temperature sensor detects EGR flow under the condition

that does not call for EGR, a high-flow malfunction is diagnosed.

NOTE:

Diagnosis for this DTC will occur when engine coolant temperature

is below 50 to 60ÉC (122 to 140ÉF). Therefore, it will be better to

turn ignition switch ªONº (start engine) at the engine coolant tem-

perature below 30ÉC (86ÉF) when starting DTC confirmation pro-

cedure.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

Description (Cont'd)

EC-426

Page 1151 of 2898

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1402

1402+EGR flow is detected under conditions that do not call for

EGR.+Harness or connectors

(The valve circuit is open or shorted.)

+EGR volume control valve leaking or stuck open

+EGR temperature sensor

SEF202Y

SEF851Y

SEF852Y

SEF236Y

DTC Confirmation ProcedureNJEC0351NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

+Always perform at a temperature above þ10ÉC (14ÉF).

+Engine coolant temperature and EGR temperature must

be verified in ªDATA MONITORº mode with CONSULT-II

before starting DTC WORK SUPPORT test. If it is out of

range below, the test cannot be conducted.

COOLAN TEMP/S: þ10 to 40ÉC (14 to 104ÉF)*

EGR TEMP SEN: Less than 4.8V

If the values are out of the ranges indicated above, park

the vehicle in a cool place and allow the engine tempera-

ture to stabilize. Do not attempt to reduce the engine cool-

ant or EGR temperature with a fan or means other than

ambient air. Doing so may produce an inaccurate diagnos-

tic result.

*: Although CONSULT-II screen displays ªþ10 to 40ÉC (14 to

104ÉF)º as a range of engine coolant temperature, ignore it.

With CONSULT-II

1) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ignition switch ªONº.

2) Select ªEGR SYSTEM P1402º of ªEGR SYSTEMº in ªDTC

WORK SUPPORTº mode with CONSULT-II.

3) Touch ªSTARTº. Follow instruction of CONSULT-II.

4) Start engine and let it idle until ªTESTINGº on CONSULT-II

screen is turned to ªCOMPLETEDº. (It will take 45 seconds or

more.)

If ªTESTINGº is not displayed after 5 minutes, turn ignition

ªOFFº and cool the engine coolant temperature to the

range of þ10 to 40ÉC (14 to 104ÉF). Retry from step 1.

5) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-431.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

On Board Diagnosis Logic (Cont'd)

EC-427

Page 1152 of 2898

SEF947X

With GST

1) Turn ignition switch ªONº and select ªMODE 1º with GST.

2) Check that engine coolant temperature is within the range of

þ10 to 40ÉC (14 to 104ÉF).

3) Check that voltage between ECM terminal 72 (EGR tempera-

ture sensor signal) and ground is less than 4.8V.

4) Start engine and let it idle for at least 45 seconds.

5) Stop engine.

6) Perform from step 1 to 4.

7) Select ªMODE 3º with GST.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-431.

+When using GST, ªDTC Confirmation Procedureº should

be performed twice as much as when using CONSULT-II

because GST cannot display MODE 7 (1st trip DTC) con-

cerning this diagnosis. Therefore, using CONSULT-II is

recommended.

DTC P1402 EGR FUNCTION (OPEN) (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-428

Page 1199 of 2898

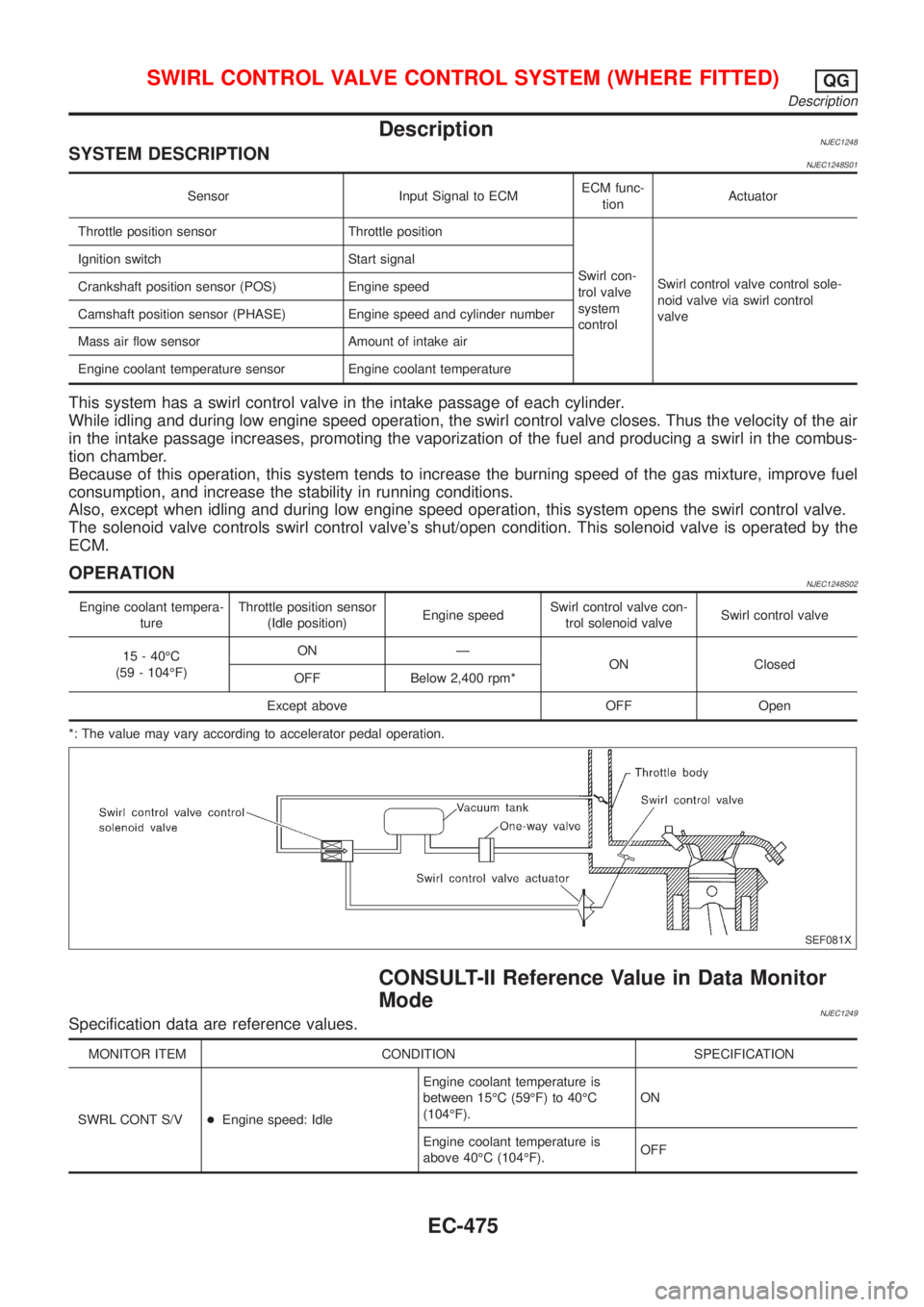

DescriptionNJEC1248SYSTEM DESCRIPTIONNJEC1248S01

Sensor Input Signal to ECMECM func-

tionActuator

Throttle position sensor Throttle position

Swirl con-

trol valve

system

controlSwirl control valve control sole-

noid valve via swirl control

valve Ignition switch Start signal

Crankshaft position sensor (POS) Engine speed

Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

This system has a swirl control valve in the intake passage of each cylinder.

While idling and during low engine speed operation, the swirl control valve closes. Thus the velocity of the air

in the intake passage increases, promoting the vaporization of the fuel and producing a swirl in the combus-

tion chamber.

Because of this operation, this system tends to increase the burning speed of the gas mixture, improve fuel

consumption, and increase the stability in running conditions.

Also, except when idling and during low engine speed operation, this system opens the swirl control valve.

The solenoid valve controls swirl control valve's shut/open condition. This solenoid valve is operated by the

ECM.

OPERATIONNJEC1248S02

Engine coolant tempera-

tureThrottle position sensor

(Idle position)Engine speedSwirl control valve con-

trol solenoid valveSwirl control valve

15 - 40ÉC

(59 - 104ÉF)ON Ð

ON Closed

OFF Below 2,400 rpm*

Except above OFF Open

*: The value may vary according to accelerator pedal operation.

SEF081X

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1249Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

SWRL CONT S/V+Engine speed: IdleEngine coolant temperature is

between 15ÉC (59ÉF) to 40ÉC

(104ÉF).ON

Engine coolant temperature is

above 40ÉC (104ÉF).OFF

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Description

EC-475

Page 1200 of 2898

ECM Terminals and Reference Value=NJEC1250Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

104 SBSwirl control valve control

solenoid valve[Engine is running]

+Engine coolant temperature is between 15ÉC

(59ÉF) to 40ÉC (104ÉF).

+Idle speed0-1V

[Engine is running]

+Engine coolant temperature is above 40ÉC

(104ÉF).

+Idle speedBATTERY VOLTAGE

(11 - 14V)

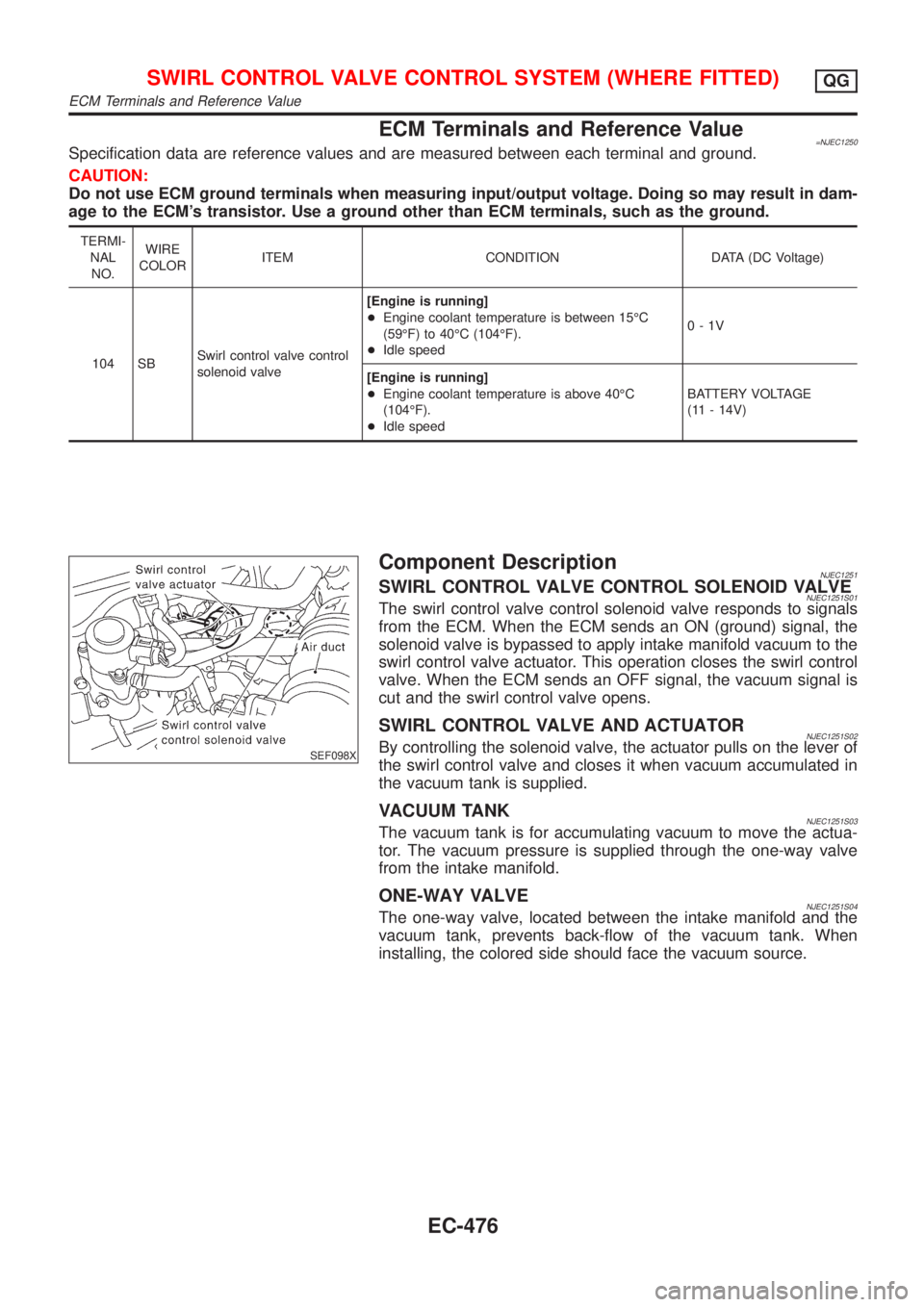

SEF098X

Component DescriptionNJEC1251SWIRL CONTROL VALVE CONTROL SOLENOID VALVENJEC1251S01The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

SWIRL CONTROL VALVE AND ACTUATORNJEC1251S02By controlling the solenoid valve, the actuator pulls on the lever of

the swirl control valve and closes it when vacuum accumulated in

the vacuum tank is supplied.

VACUUM TANKNJEC1251S03The vacuum tank is for accumulating vacuum to move the actua-

tor. The vacuum pressure is supplied through the one-way valve

from the intake manifold.

ONE-WAY VALVENJEC1251S04The one-way valve, located between the intake manifold and the

vacuum tank, prevents back-flow of the vacuum tank. When

installing, the colored side should face the vacuum source.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

ECM Terminals and Reference Value

EC-476

Page 1203 of 2898

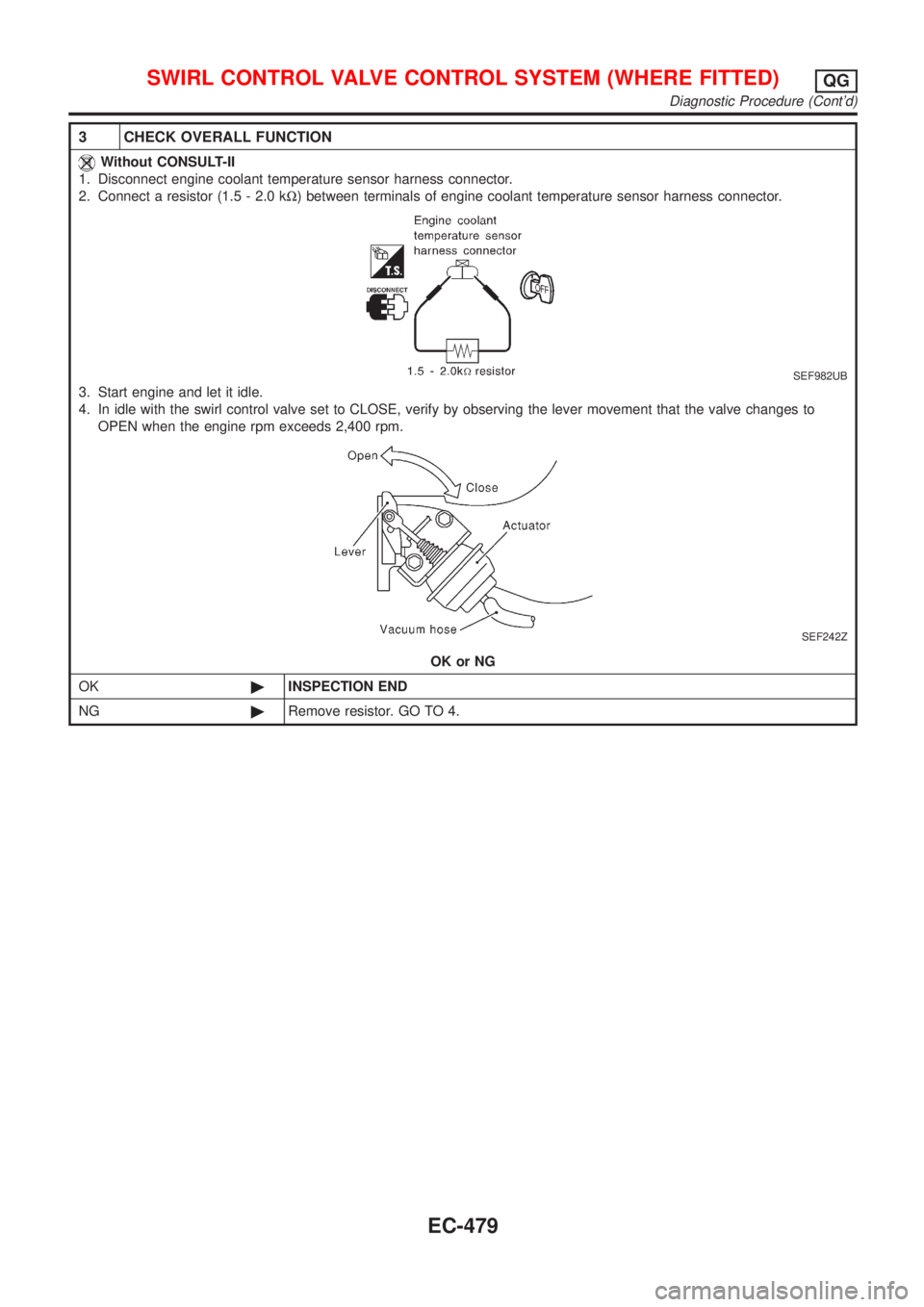

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Disconnect engine coolant temperature sensor harness connector.

2. Connect a resistor (1.5 - 2.0 kW) between terminals of engine coolant temperature sensor harness connector.

SEF982UB

3. Start engine and let it idle.

4. In idle with the swirl control valve set to CLOSE, verify by observing the lever movement that the valve changes to

OPEN when the engine rpm exceeds 2,400 rpm.

SEF242Z

OK or NG

OK©INSPECTION END

NG©Remove resistor. GO TO 4.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-479