manual transmission NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 353 of 2898

SAT992C

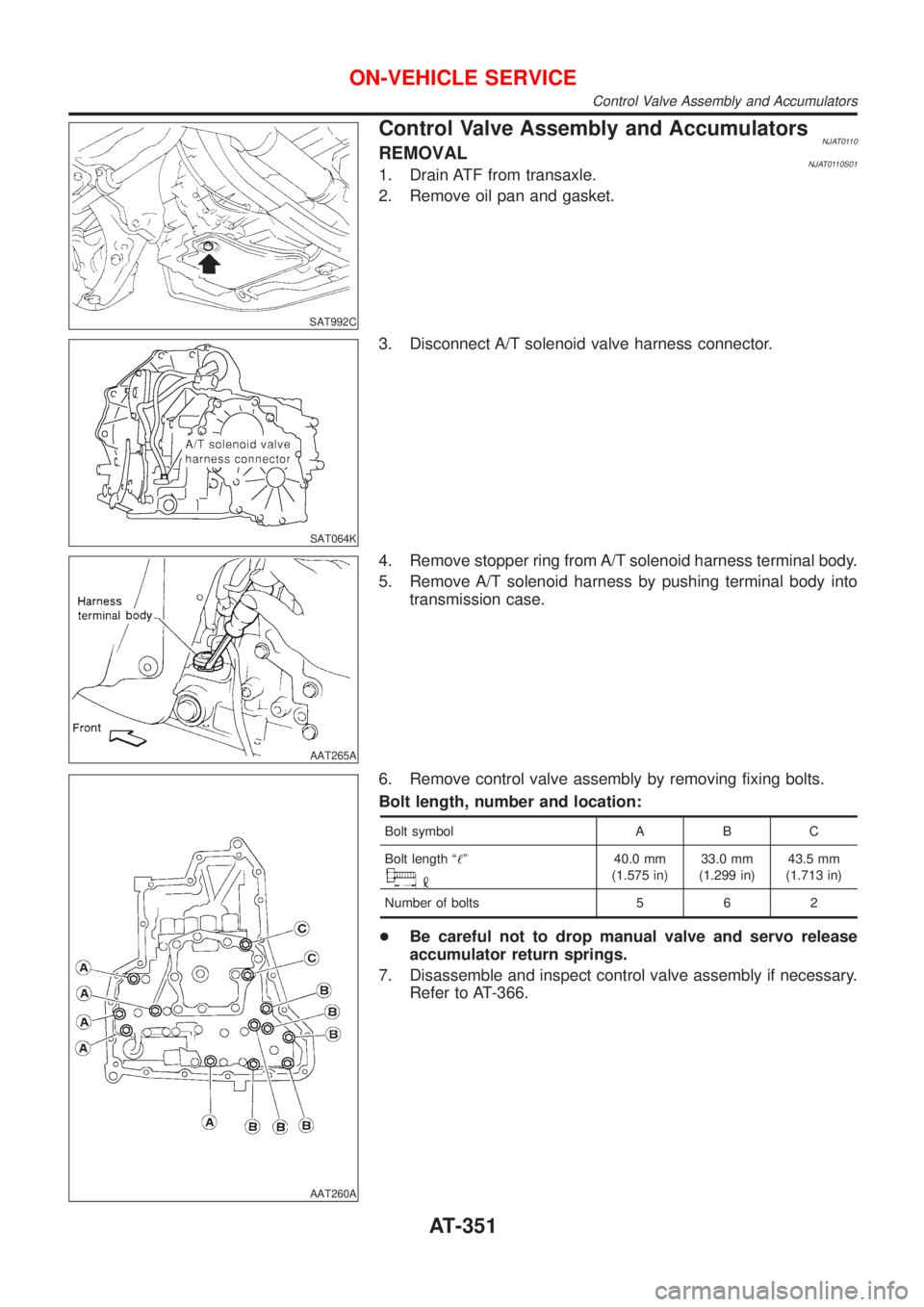

Control Valve Assembly and AccumulatorsNJAT0110REMOVALNJAT0110S011. Drain ATF from transaxle.

2. Remove oil pan and gasket.

SAT064K

3. Disconnect A/T solenoid valve harness connector.

AAT265A

4. Remove stopper ring from A/T solenoid harness terminal body.

5. Remove A/T solenoid harness by pushing terminal body into

transmission case.

AAT260A

6. Remove control valve assembly by removing fixing bolts.

Bolt length, number and location:

Bolt symbol A B C

Bolt length ª!º

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

+Be careful not to drop manual valve and servo release

accumulator return springs.

7. Disassemble and inspect control valve assembly if necessary.

Refer to AT-366.

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators

AT-351

Page 354 of 2898

SAT935J

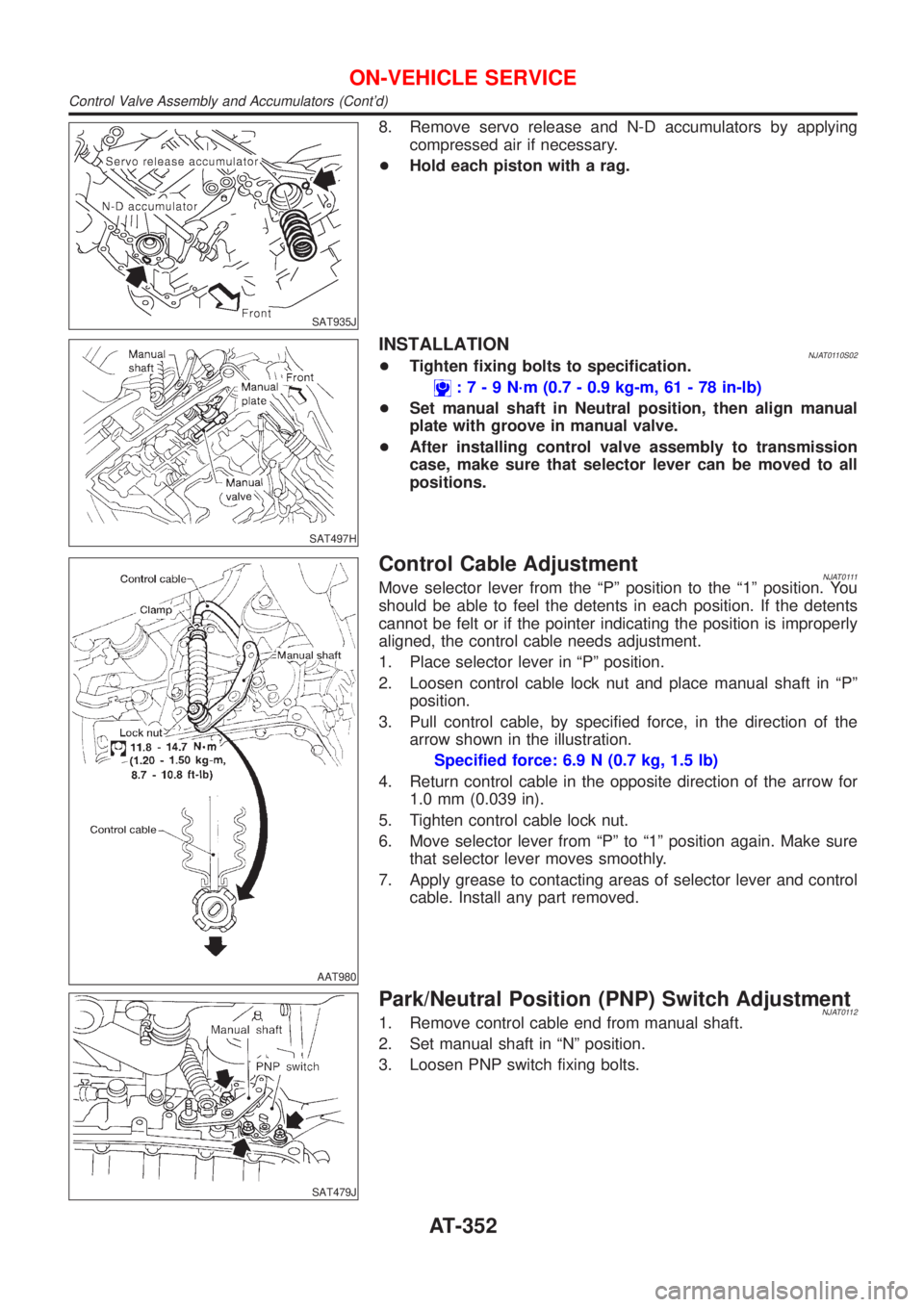

8. Remove servo release and N-D accumulators by applying

compressed air if necessary.

+Hold each piston with a rag.

SAT497H

INSTALLATIONNJAT0110S02+Tighten fixing bolts to specification.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

+Set manual shaft in Neutral position, then align manual

plate with groove in manual valve.

+After installing control valve assembly to transmission

case, make sure that selector lever can be moved to all

positions.

AAT980

Control Cable AdjustmentNJAT0111Move selector lever from the ªPº position to the ª1º position. You

should be able to feel the detents in each position. If the detents

cannot be felt or if the pointer indicating the position is improperly

aligned, the control cable needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen control cable lock nut and place manual shaft in ªPº

position.

3. Pull control cable, by specified force, in the direction of the

arrow shown in the illustration.

Specified force: 6.9 N (0.7 kg, 1.5 lb)

4. Return control cable in the opposite direction of the arrow for

1.0 mm (0.039 in).

5. Tighten control cable lock nut.

6. Move selector lever from ªPº to ª1º position again. Make sure

that selector lever moves smoothly.

7. Apply grease to contacting areas of selector lever and control

cable. Install any part removed.

SAT479J

Park/Neutral Position (PNP) Switch AdjustmentNJAT01121. Remove control cable end from manual shaft.

2. Set manual shaft in ªNº position.

3. Loosen PNP switch fixing bolts.

ON-VEHICLE SERVICE

Control Valve Assembly and Accumulators (Cont'd)

AT-352

Page 370 of 2898

AAT262A

b. Remove stopper ring from terminal body.

c. Push terminal body into transmission case and draw out sole-

noid harness.

SAT017D

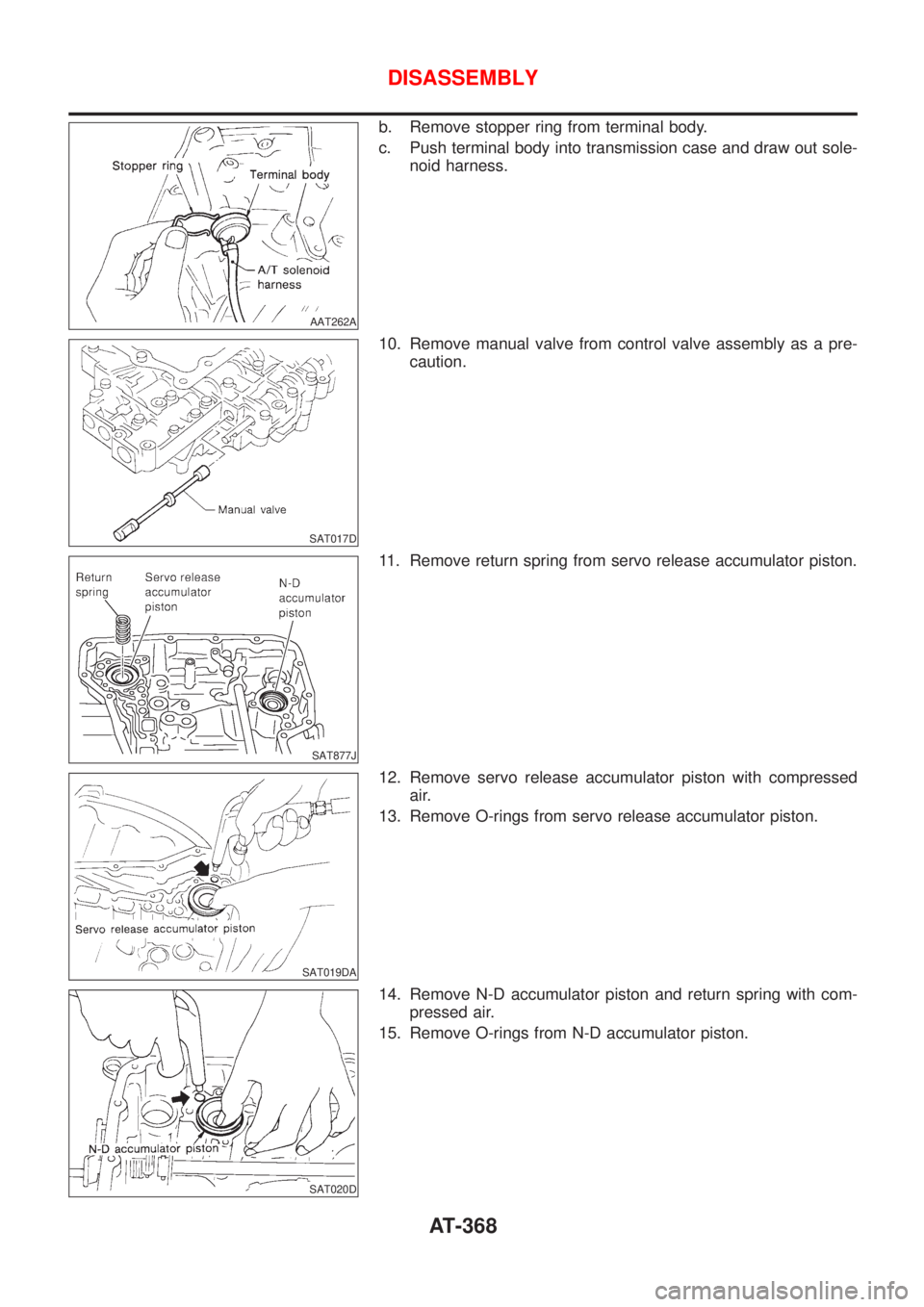

10. Remove manual valve from control valve assembly as a pre-

caution.

SAT877J

11. Remove return spring from servo release accumulator piston.

SAT019DA

12. Remove servo release accumulator piston with compressed

air.

13. Remove O-rings from servo release accumulator piston.

SAT020D

14. Remove N-D accumulator piston and return spring with com-

pressed air.

15. Remove O-rings from N-D accumulator piston.

DISASSEMBLY

AT-368

Page 378 of 2898

SAT272E

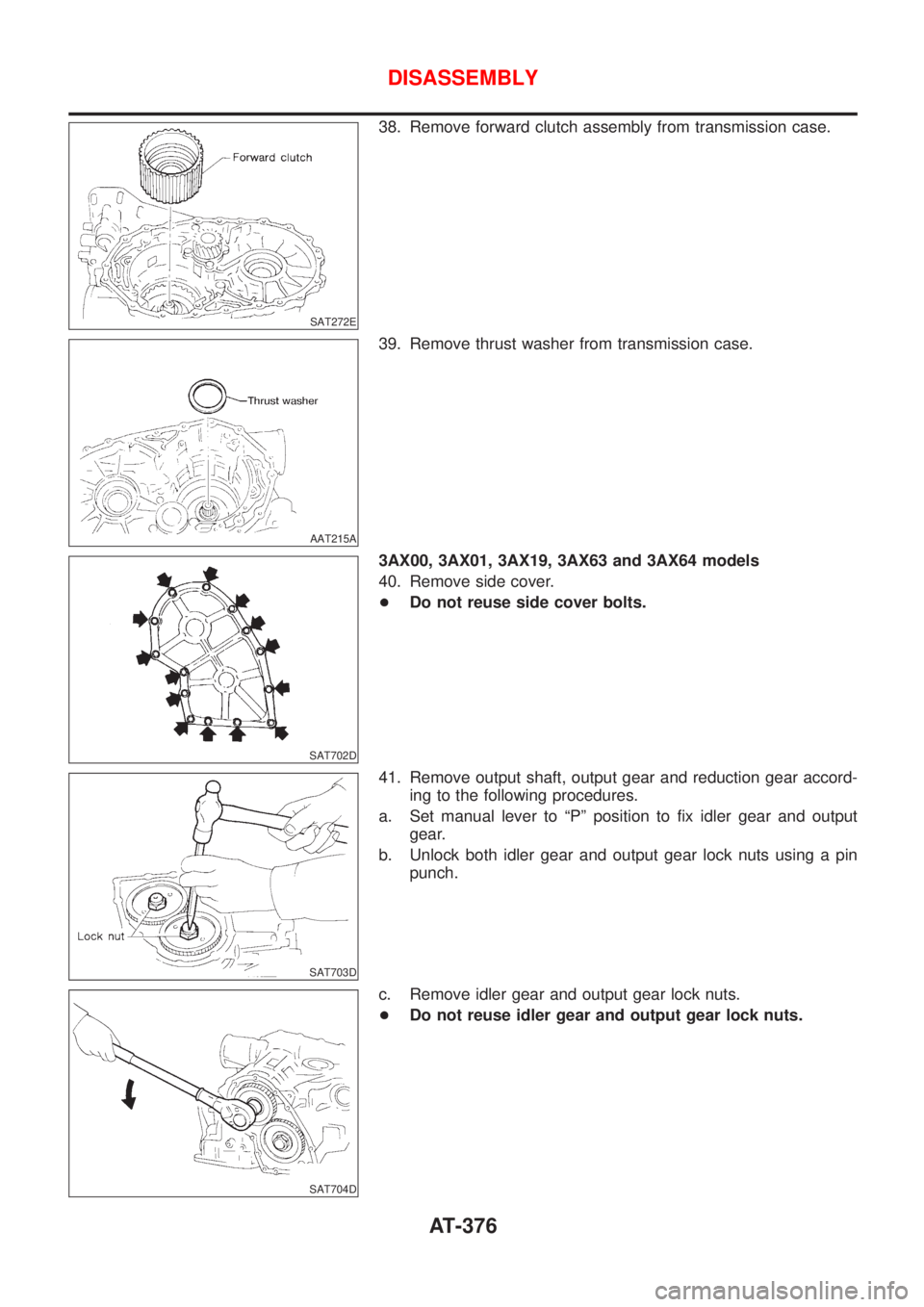

38. Remove forward clutch assembly from transmission case.

AAT215A

39. Remove thrust washer from transmission case.

SAT702D

3AX00, 3AX01, 3AX19, 3AX63 and 3AX64 models

40. Remove side cover.

+Do not reuse side cover bolts.

SAT703D

41. Remove output shaft, output gear and reduction gear accord-

ing to the following procedures.

a. Set manual lever to ªPº position to fix idler gear and output

gear.

b. Unlock both idler gear and output gear lock nuts using a pin

punch.

SAT704D

c. Remove idler gear and output gear lock nuts.

+Do not reuse idler gear and output gear lock nuts.

DISASSEMBLY

AT-376

Page 383 of 2898

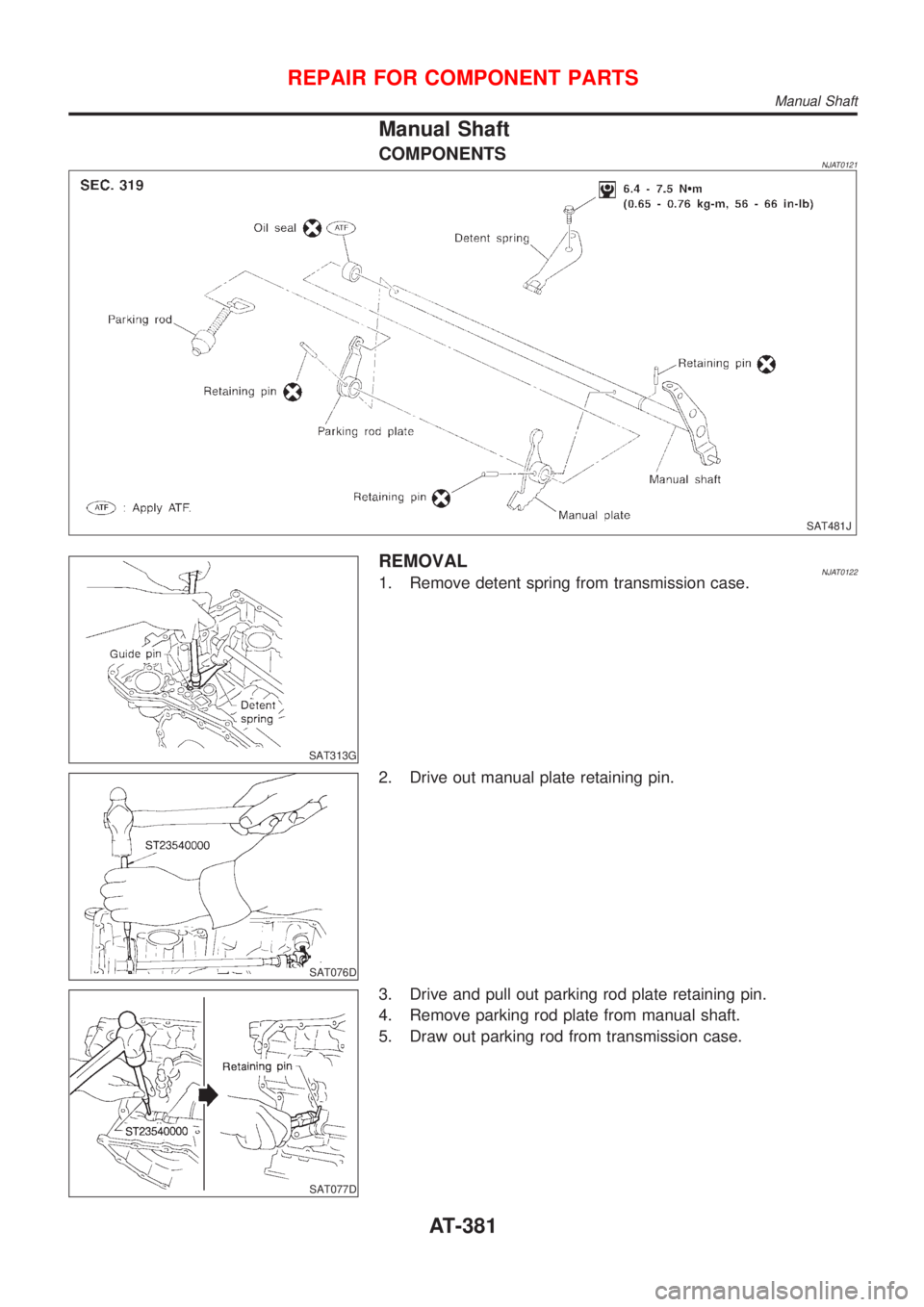

Manual Shaft

COMPONENTSNJAT0121

SAT481J

SAT313G

REMOVALNJAT01221. Remove detent spring from transmission case.

SAT076D

2. Drive out manual plate retaining pin.

SAT077D

3. Drive and pull out parking rod plate retaining pin.

4. Remove parking rod plate from manual shaft.

5. Draw out parking rod from transmission case.

REPAIR FOR COMPONENT PARTS

Manual Shaft

AT-381

Page 384 of 2898

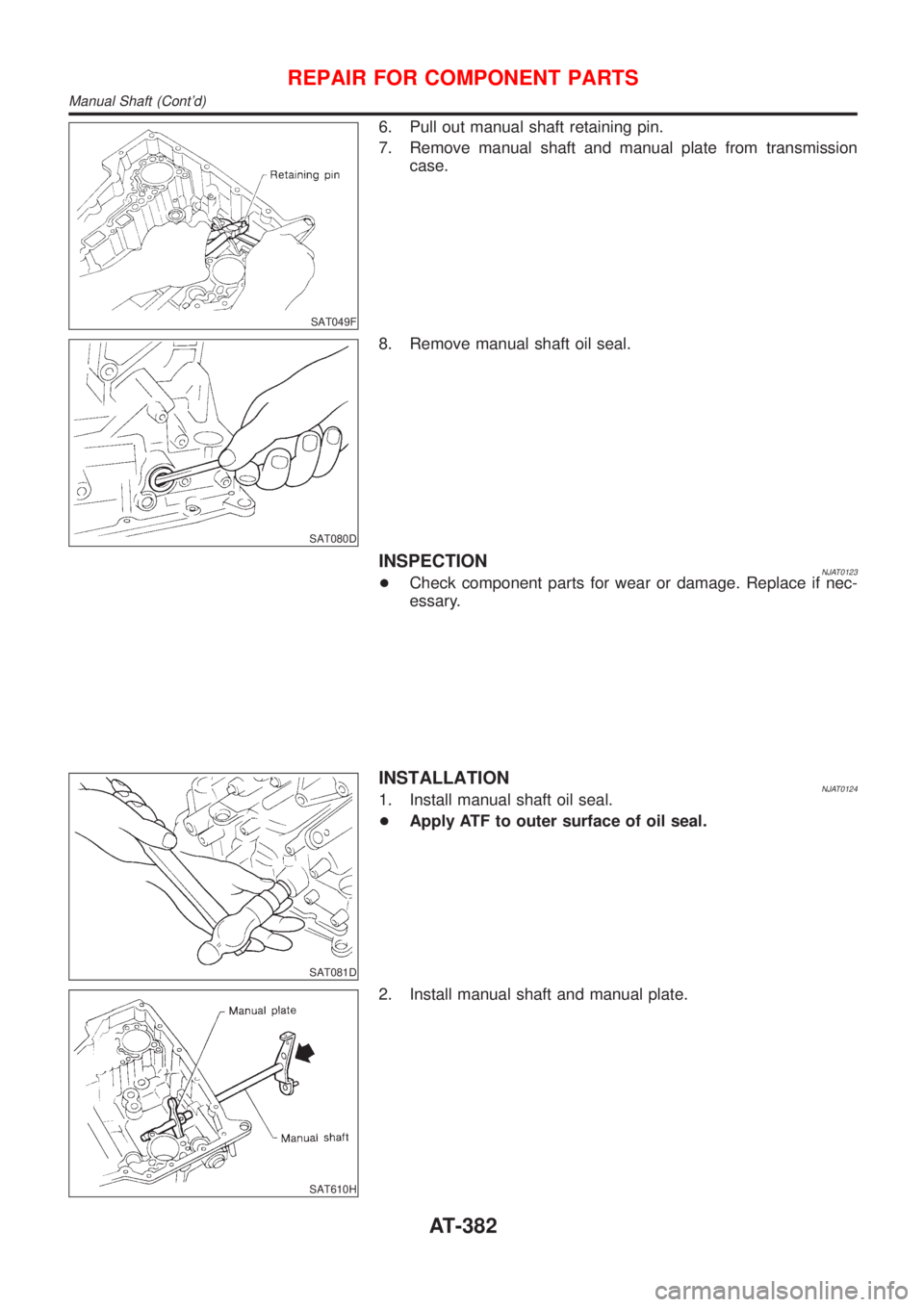

SAT049F

6. Pull out manual shaft retaining pin.

7. Remove manual shaft and manual plate from transmission

case.

SAT080D

8. Remove manual shaft oil seal.

INSPECTIONNJAT0123+Check component parts for wear or damage. Replace if nec-

essary.

SAT081D

INSTALLATIONNJAT01241. Install manual shaft oil seal.

+Apply ATF to outer surface of oil seal.

SAT610H

2. Install manual shaft and manual plate.

REPAIR FOR COMPONENT PARTS

Manual Shaft (Cont'd)

AT-382

Page 385 of 2898

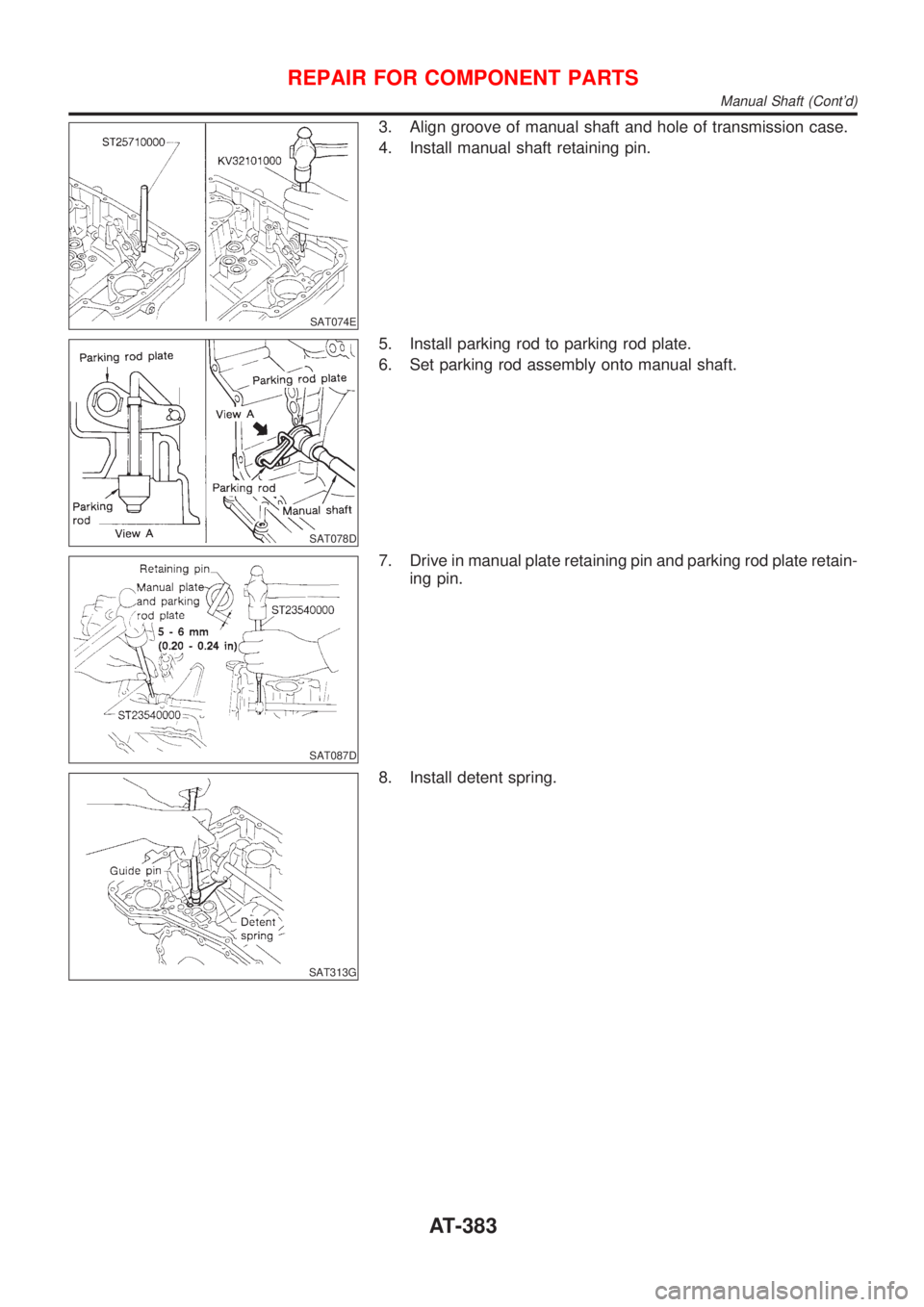

SAT074E

3. Align groove of manual shaft and hole of transmission case.

4. Install manual shaft retaining pin.

SAT078D

5. Install parking rod to parking rod plate.

6. Set parking rod assembly onto manual shaft.

SAT087D

7. Drive in manual plate retaining pin and parking rod plate retain-

ing pin.

SAT313G

8. Install detent spring.

REPAIR FOR COMPONENT PARTS

Manual Shaft (Cont'd)

AT-383

Page 468 of 2898

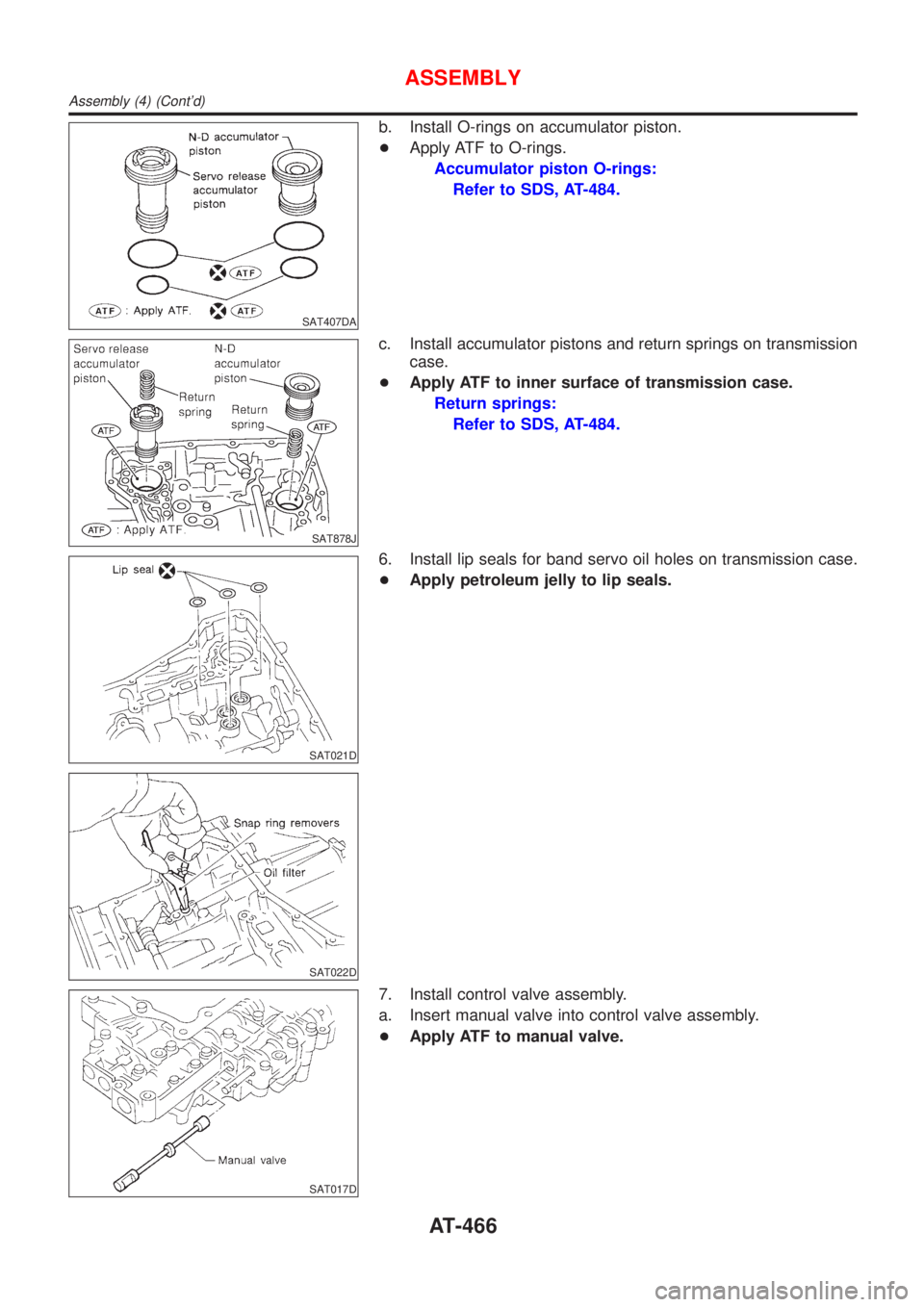

SAT407DA

b. Install O-rings on accumulator piston.

+Apply ATF to O-rings.

Accumulator piston O-rings:

Refer to SDS, AT-484.

SAT878J

c. Install accumulator pistons and return springs on transmission

case.

+Apply ATF to inner surface of transmission case.

Return springs:

Refer to SDS, AT-484.

SAT021D

SAT022D

6. Install lip seals for band servo oil holes on transmission case.

+Apply petroleum jelly to lip seals.

SAT017D

7. Install control valve assembly.

a. Insert manual valve into control valve assembly.

+Apply ATF to manual valve.

ASSEMBLY

Assembly (4) (Cont'd)

AT-466

Page 470 of 2898

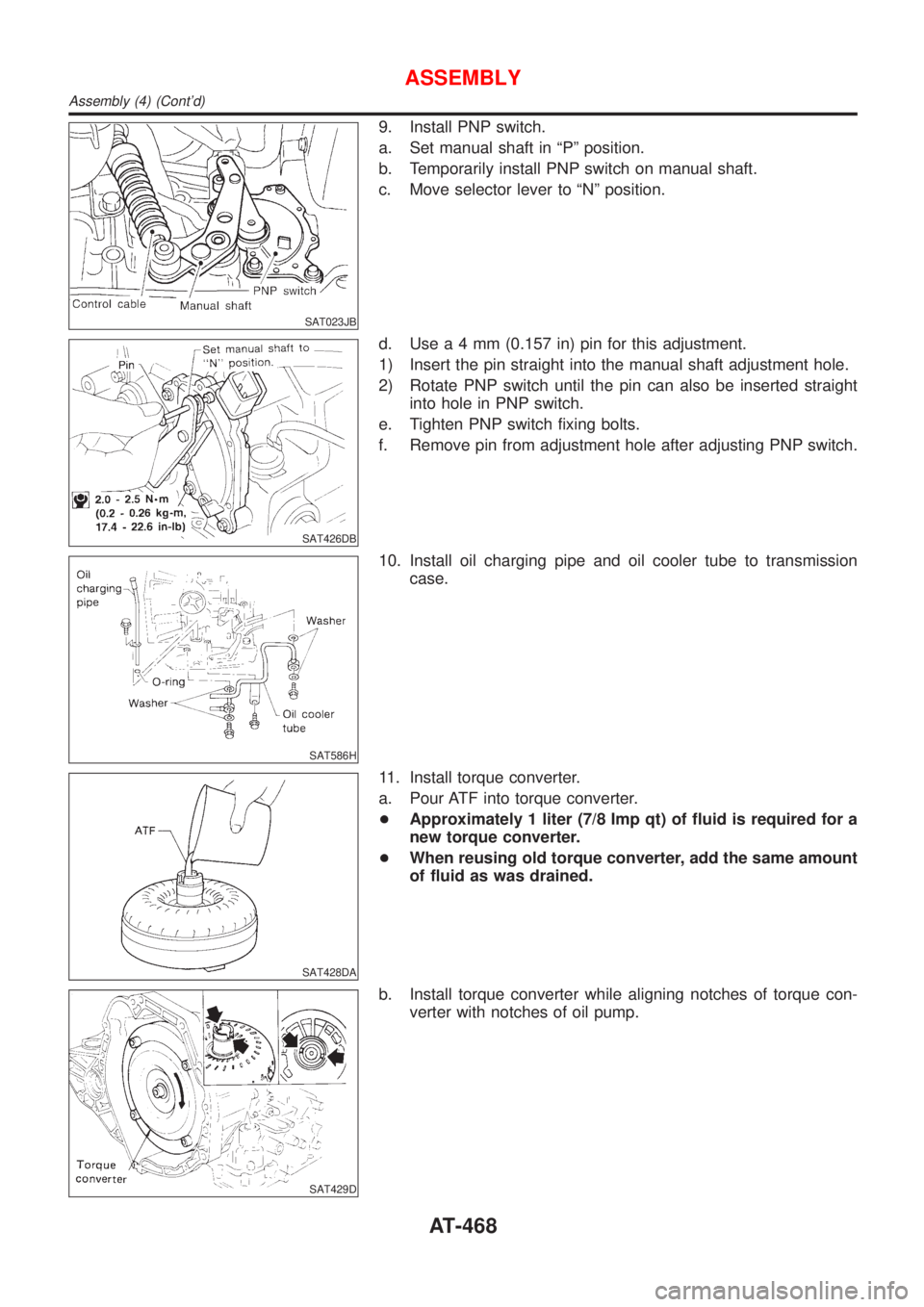

SAT023JB

9. Install PNP switch.

a. Set manual shaft in ªPº position.

b. Temporarily install PNP switch on manual shaft.

c. Move selector lever to ªNº position.

SAT426DB

d. Usea4mm(0.157 in) pin for this adjustment.

1) Insert the pin straight into the manual shaft adjustment hole.

2) Rotate PNP switch until the pin can also be inserted straight

into hole in PNP switch.

e. Tighten PNP switch fixing bolts.

f. Remove pin from adjustment hole after adjusting PNP switch.

SAT586H

10. Install oil charging pipe and oil cooler tube to transmission

case.

SAT428DA

11. Install torque converter.

a. Pour ATF into torque converter.

+Approximately 1 liter (7/8 Imp qt) of fluid is required for a

new torque converter.

+When reusing old torque converter, add the same amount

of fluid as was drained.

SAT429D

b. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

ASSEMBLY

Assembly (4) (Cont'd)

AT-468

Page 740 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnoses sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnoses sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harness can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T

NJEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission Control Module) before returning the vehicle to the customer.

PRECAUTIONSQG

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-16