fuel cap NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 744 of 2898

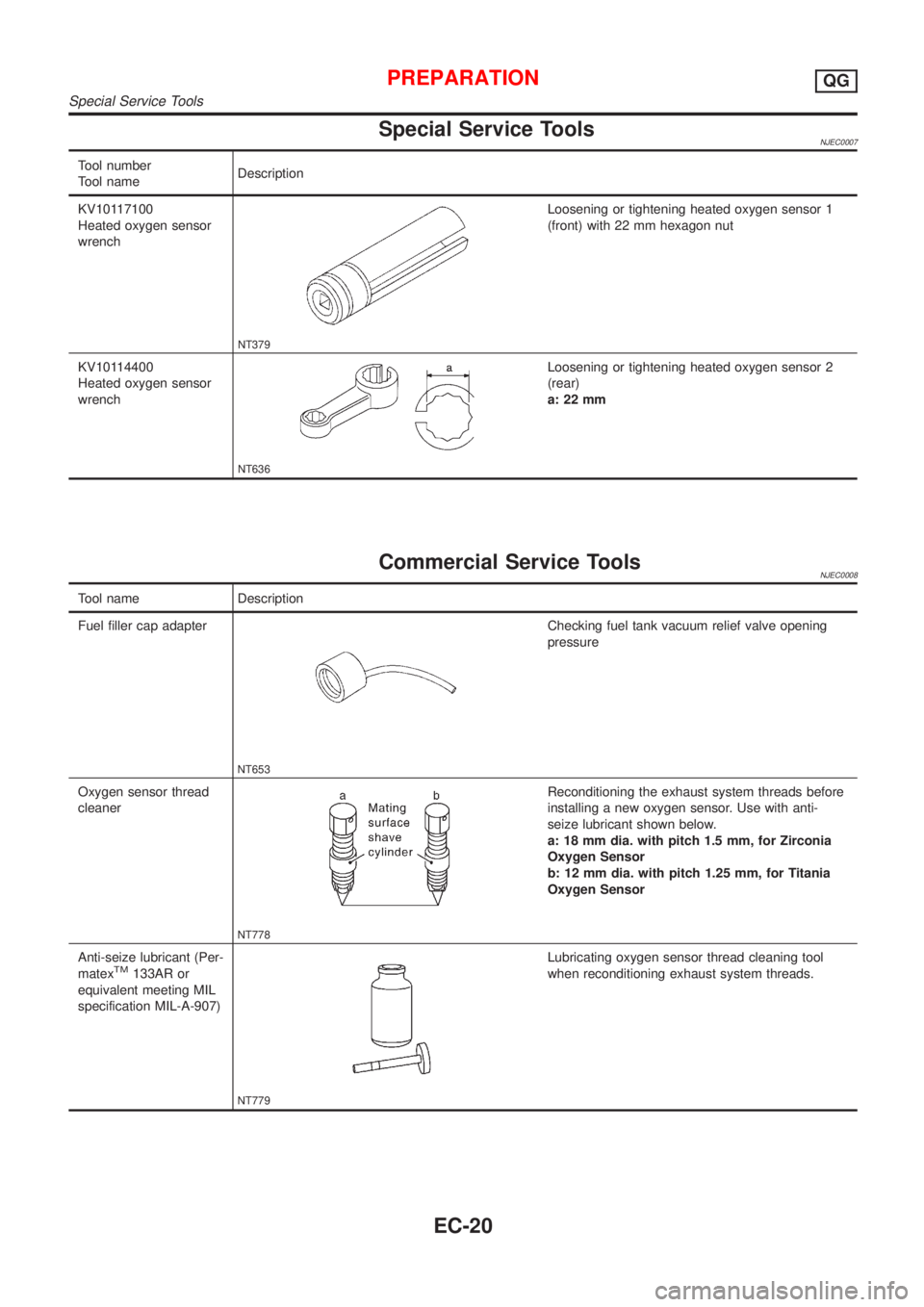

Special Service ToolsNJEC0007

Tool number

Tool nameDescription

KV10117100

Heated oxygen sensor

wrench

NT379

Loosening or tightening heated oxygen sensor 1

(front) with 22 mm hexagon nut

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening heated oxygen sensor 2

(rear)

a: 22 mm

Commercial Service ToolsNJEC0008

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Oxygen sensor thread

cleaner

NT778

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm dia. with pitch 1.5 mm, for Zirconia

Oxygen Sensor

b: 12 mm dia. with pitch 1.25 mm, for Titania

Oxygen Sensor

Anti-seize lubricant (Per-

matex

TM133AR or

equivalent meeting MIL

specification MIL-A-907)

NT779

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

PREPARATIONQG

Special Service Tools

EC-20

Page 761 of 2898

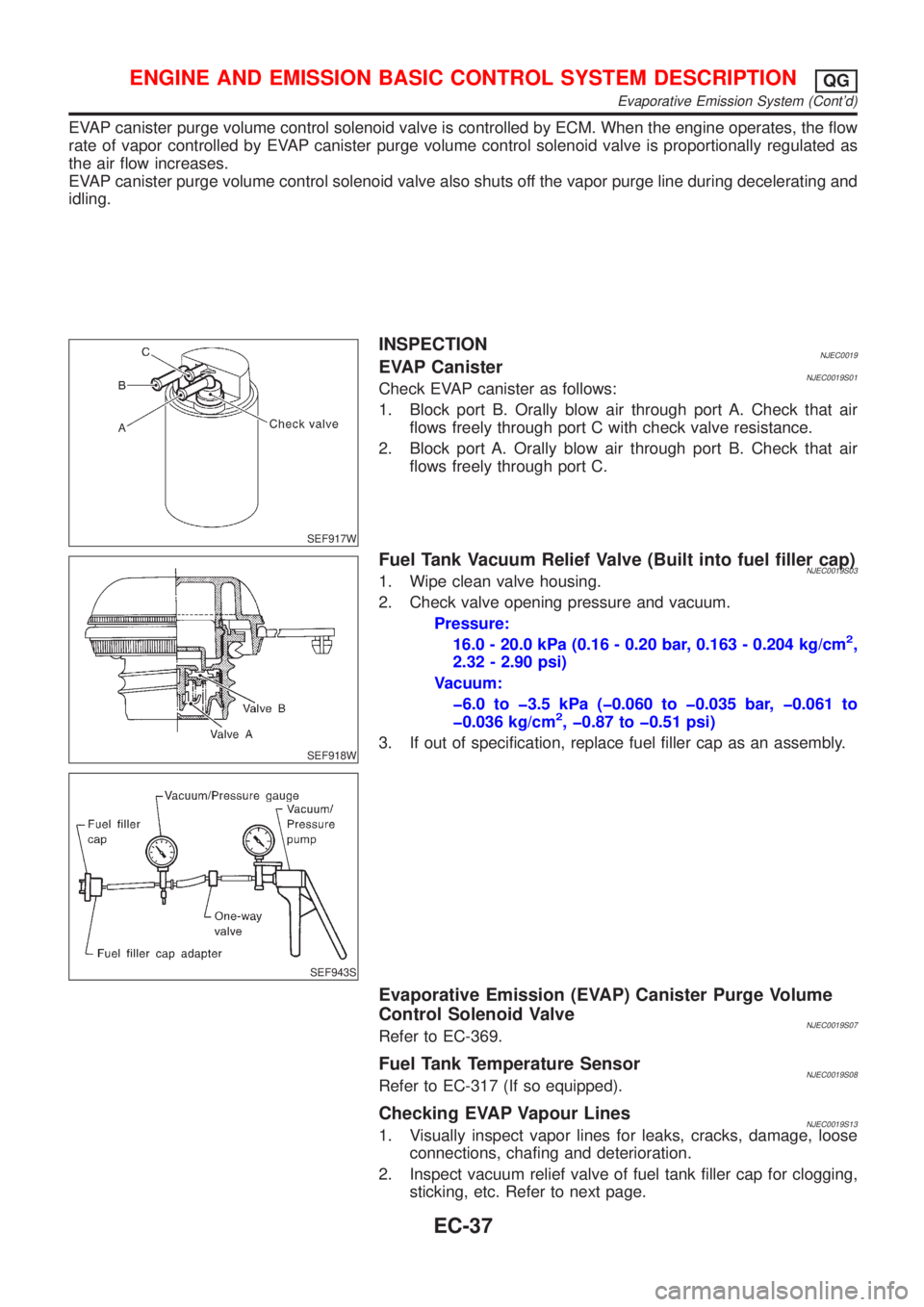

EVAP canister purge volume control solenoid valve is controlled by ECM. When the engine operates, the flow

rate of vapor controlled by EVAP canister purge volume control solenoid valve is proportionally regulated as

the air flow increases.

EVAP canister purge volume control solenoid valve also shuts off the vapor purge line during decelerating and

idling.

SEF917W

INSPECTIONNJEC0019EVAP CanisterNJEC0019S01Check EVAP canister as follows:

1. Block port B. Orally blow air through port A. Check that air

flows freely through port C with check valve resistance.

2. Block port A. Orally blow air through port B. Check that air

flows freely through port C.

SEF918W

SEF943S

Fuel Tank Vacuum Relief Valve (Built into fuel filler cap)NJEC0019S031. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

Pressure:

16.0 - 20.0 kPa (0.16 - 0.20 bar, 0.163 - 0.204 kg/cm

2,

2.32 - 2.90 psi)

Vacuum:

þ6.0 to þ3.5 kPa (þ0.060 to þ0.035 bar, þ0.061 to

þ0.036 kg/cm

2, þ0.87 to þ0.51 psi)

3. If out of specification, replace fuel filler cap as an assembly.

Evaporative Emission (EVAP) Canister Purge Volume

Control Solenoid Valve

NJEC0019S07Refer to EC-369.

Fuel Tank Temperature SensorNJEC0019S08Refer to EC-317 (If so equipped).

Checking EVAP Vapour LinesNJEC0019S131. Visually inspect vapor lines for leaks, cracks, damage, loose

connections, chafing and deterioration.

2. Inspect vacuum relief valve of fuel tank filler cap for clogging,

sticking, etc. Refer to next page.

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONQG

Evaporative Emission System (Cont'd)

EC-37

Page 765 of 2898

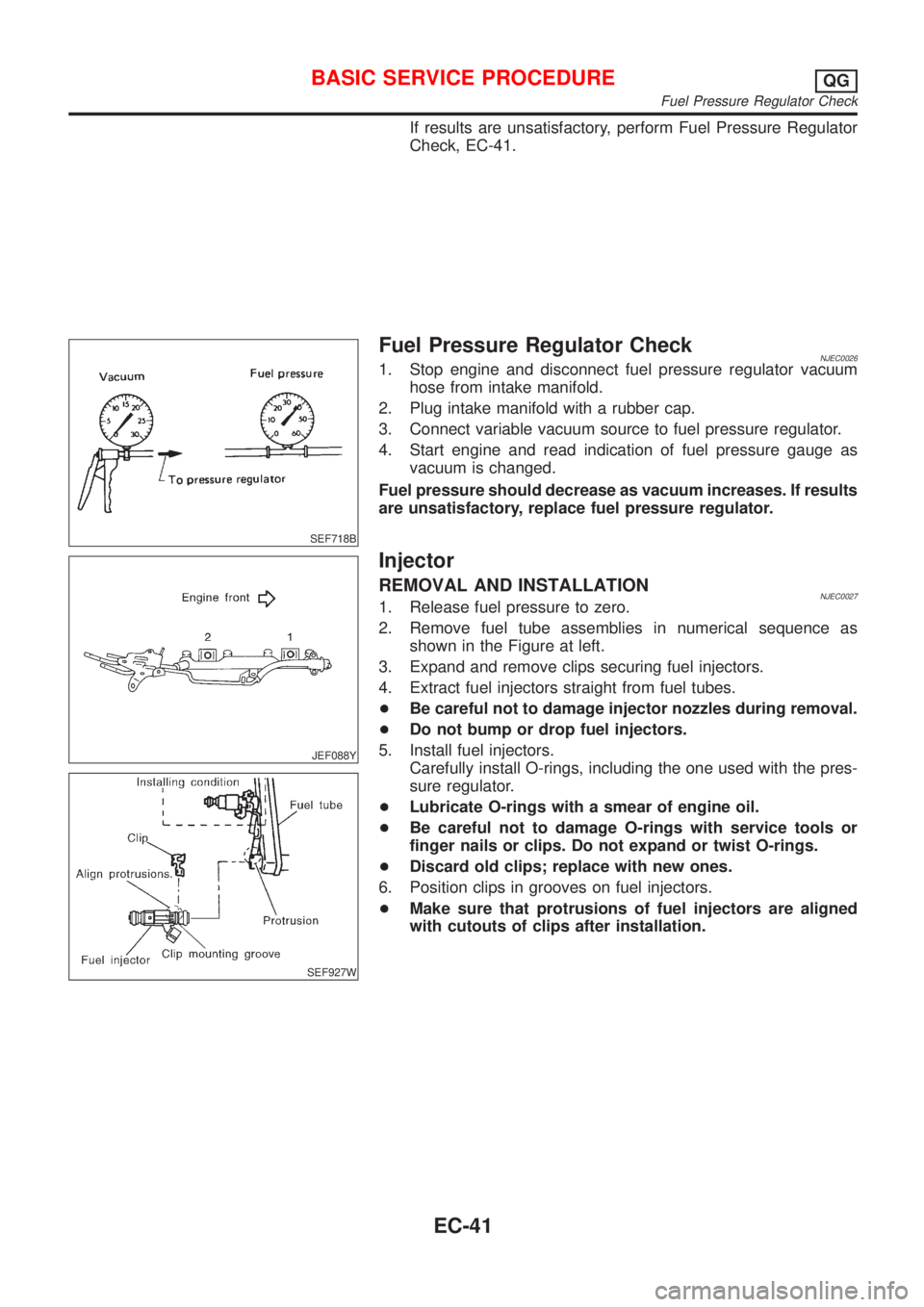

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-41.

SEF718B

Fuel Pressure Regulator CheckNJEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

JEF088Y

SEF927W

Injector

REMOVAL AND INSTALLATIONNJEC00271. Release fuel pressure to zero.

2. Remove fuel tube assemblies in numerical sequence as

shown in the Figure at left.

3. Expand and remove clips securing fuel injectors.

4. Extract fuel injectors straight from fuel tubes.

+Be careful not to damage injector nozzles during removal.

+Do not bump or drop fuel injectors.

5. Install fuel injectors.

Carefully install O-rings, including the one used with the pres-

sure regulator.

+Lubricate O-rings with a smear of engine oil.

+Be careful not to damage O-rings with service tools or

finger nails or clips. Do not expand or twist O-rings.

+Discard old clips; replace with new ones.

6. Position clips in grooves on fuel injectors.

+Make sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

BASIC SERVICE PROCEDUREQG

Fuel Pressure Regulator Check

EC-41

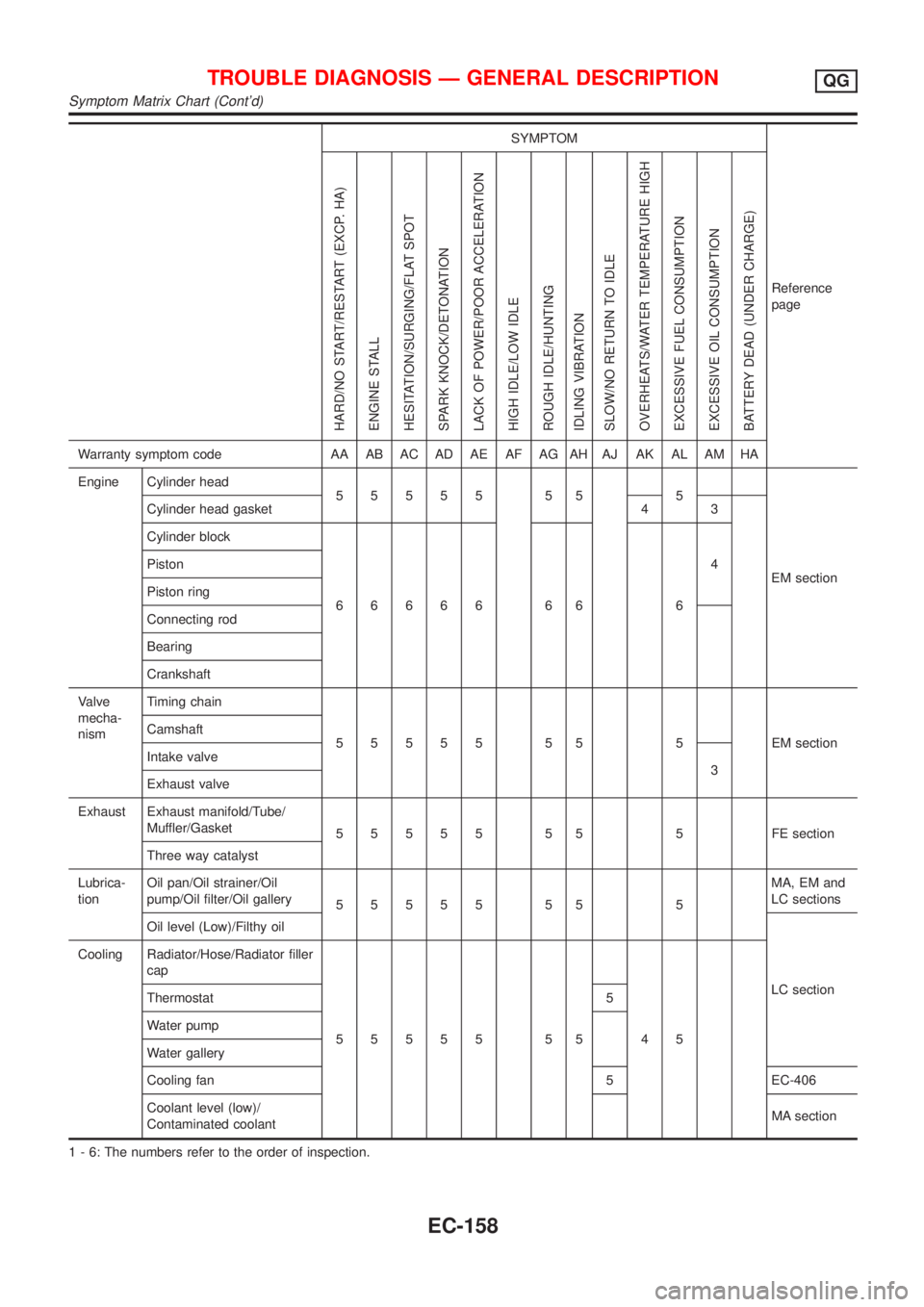

Page 882 of 2898

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

55555 55 5 EMsection Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/

Muffler/Gasket

55555 55 5 FEsection

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil

pump/Oil filter/Oil gallery

55555 55 5MA, EM and

LC sections

Oil level (Low)/Filthy oil

LC section Cooling Radiator/Hose/Radiator filler

cap

55555 55 45 Thermostat 5

Water pump

Water gallery

Cooling fan 5 EC-406

Coolant level (low)/

Contaminated coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

Symptom Matrix Chart (Cont'd)

EC-158

Page 982 of 2898

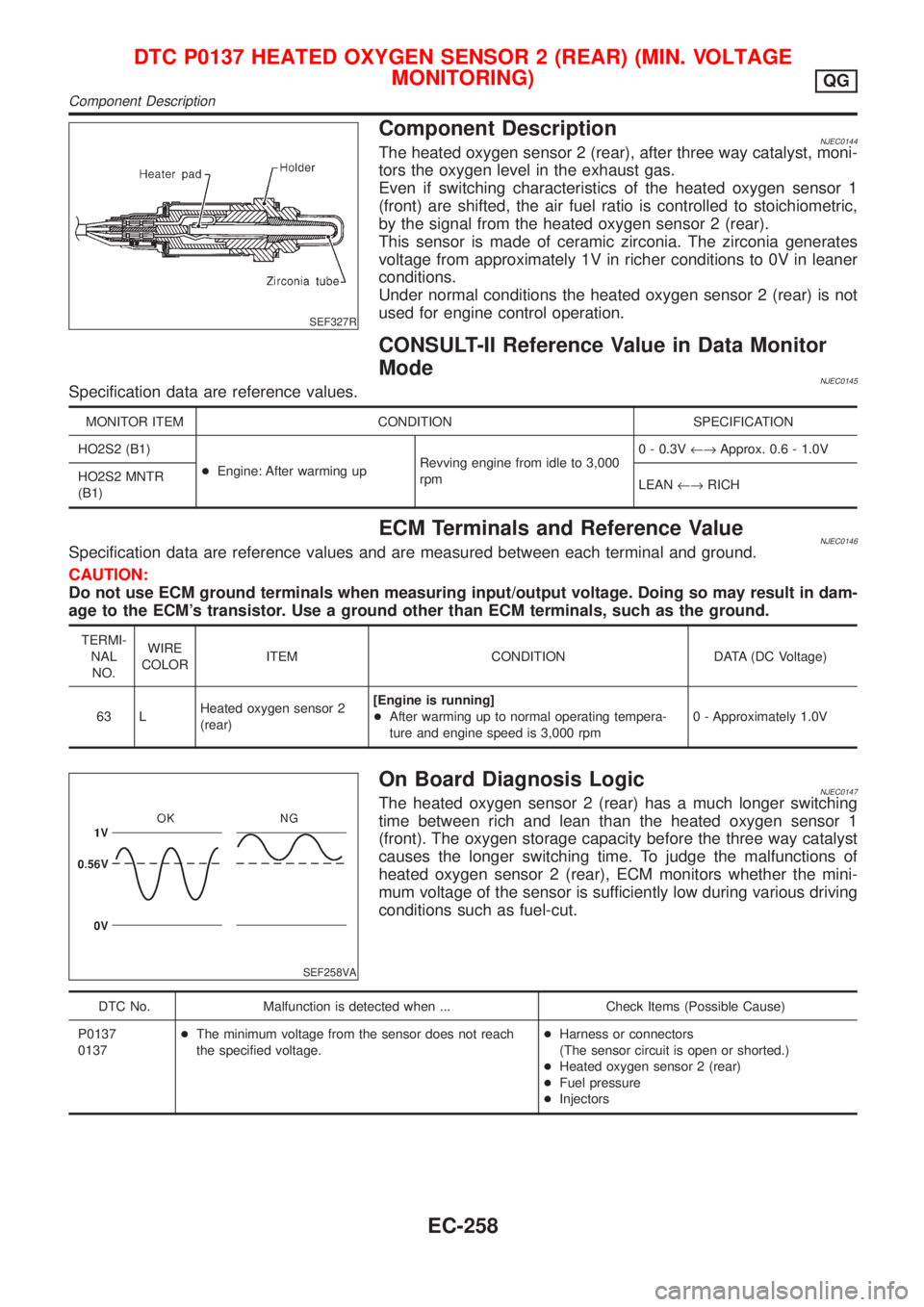

SEF327R

Component DescriptionNJEC0144The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0145Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNJEC0146Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and engine speed is 3,000 rpm0 - Approximately 1.0V

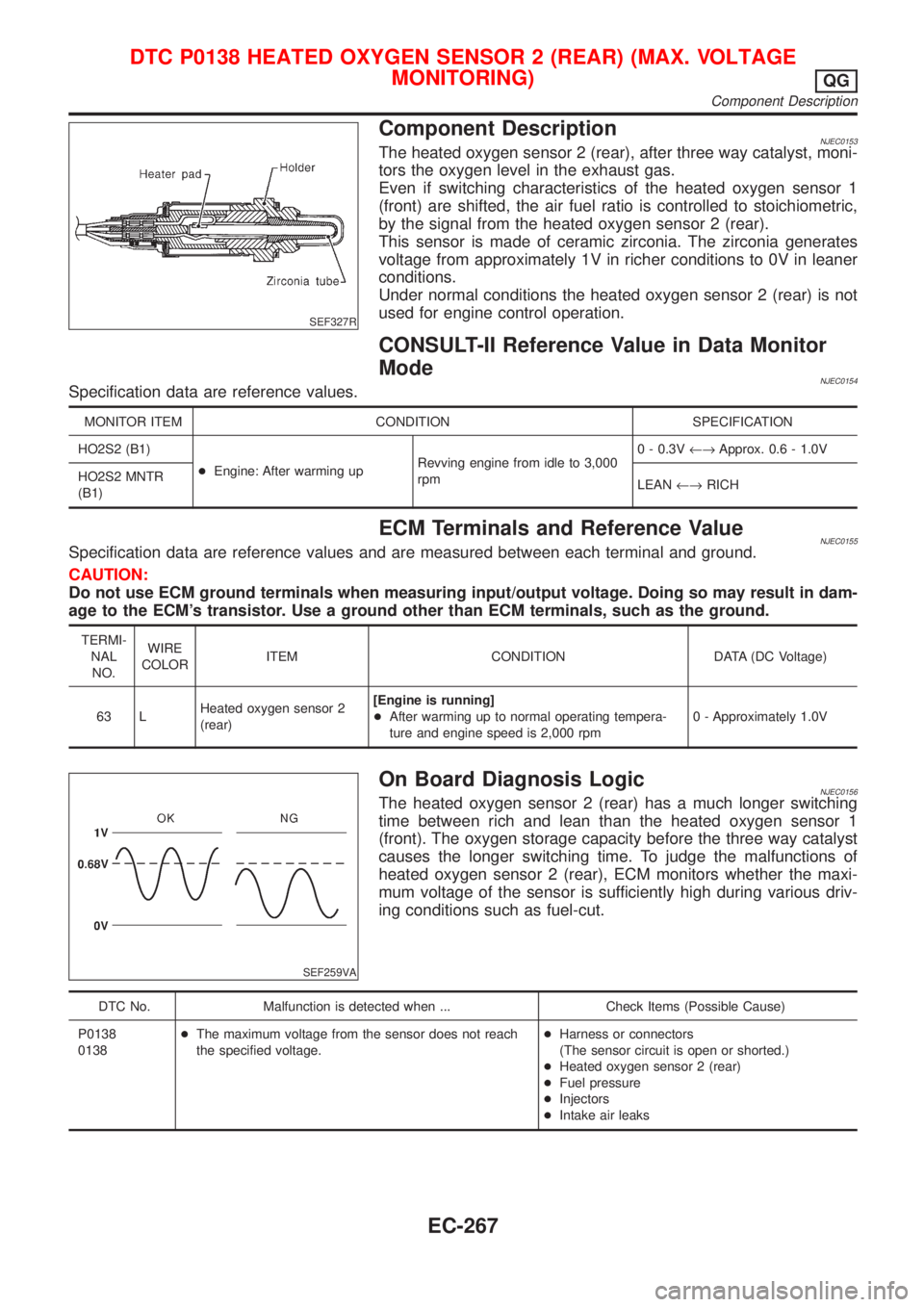

SEF258VA

On Board Diagnosis LogicNJEC0147The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether the mini-

mum voltage of the sensor is sufficiently low during various driving

conditions such as fuel-cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0137

0137+The minimum voltage from the sensor does not reach

the specified voltage.+Harness or connectors

(The sensor circuit is open or shorted.)

+Heated oxygen sensor 2 (rear)

+Fuel pressure

+Injectors

DTC P0137 HEATED OXYGEN SENSOR 2 (REAR) (MIN. VOLTAGE

MONITORING)

QG

Component Description

EC-258

Page 991 of 2898

SEF327R

Component DescriptionNJEC0153The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0154Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNJEC0155Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and engine speed is 2,000 rpm0 - Approximately 1.0V

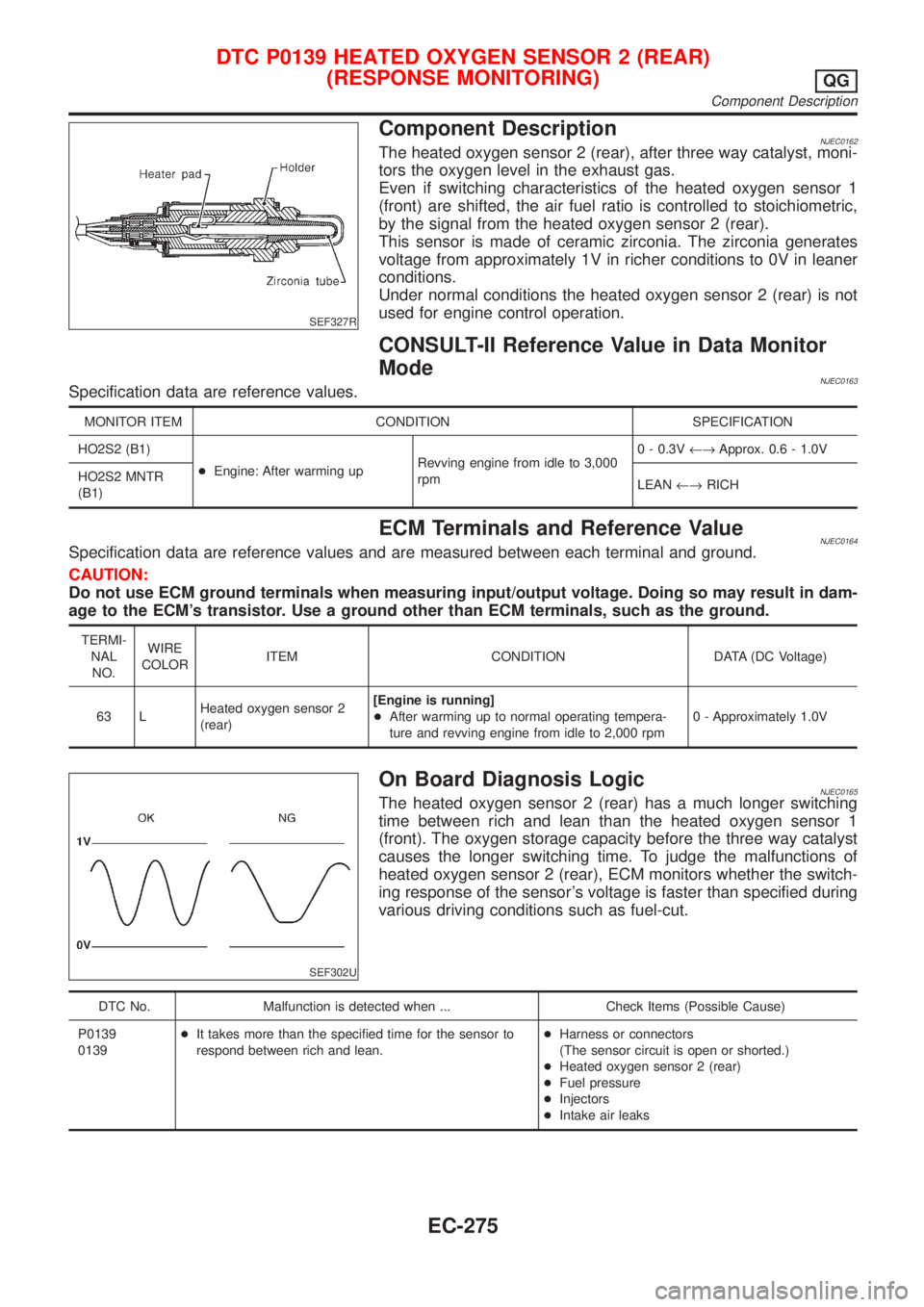

SEF259VA

On Board Diagnosis LogicNJEC0156The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether the maxi-

mum voltage of the sensor is sufficiently high during various driv-

ing conditions such as fuel-cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0138

0138+The maximum voltage from the sensor does not reach

the specified voltage.+Harness or connectors

(The sensor circuit is open or shorted.)

+Heated oxygen sensor 2 (rear)

+Fuel pressure

+Injectors

+Intake air leaks

DTC P0138 HEATED OXYGEN SENSOR 2 (REAR) (MAX. VOLTAGE

MONITORING)

QG

Component Description

EC-267

Page 999 of 2898

SEF327R

Component DescriptionNJEC0162The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0163Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNJEC0164Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and revving engine from idle to 2,000 rpm0 - Approximately 1.0V

SEF302U

On Board Diagnosis LogicNJEC0165The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether the switch-

ing response of the sensor's voltage is faster than specified during

various driving conditions such as fuel-cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0139

0139+It takes more than the specified time for the sensor to

respond between rich and lean.+Harness or connectors

(The sensor circuit is open or shorted.)

+Heated oxygen sensor 2 (rear)

+Fuel pressure

+Injectors

+Intake air leaks

DTC P0139 HEATED OXYGEN SENSOR 2 (REAR)

(RESPONSE MONITORING)

QG

Component Description

EC-275

Page 1008 of 2898

SEF327R

Component DescriptionNJEC0171The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0172Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNJEC0173Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and revving engine from idle to 2,000 rpm0 - Approximately 1.0V

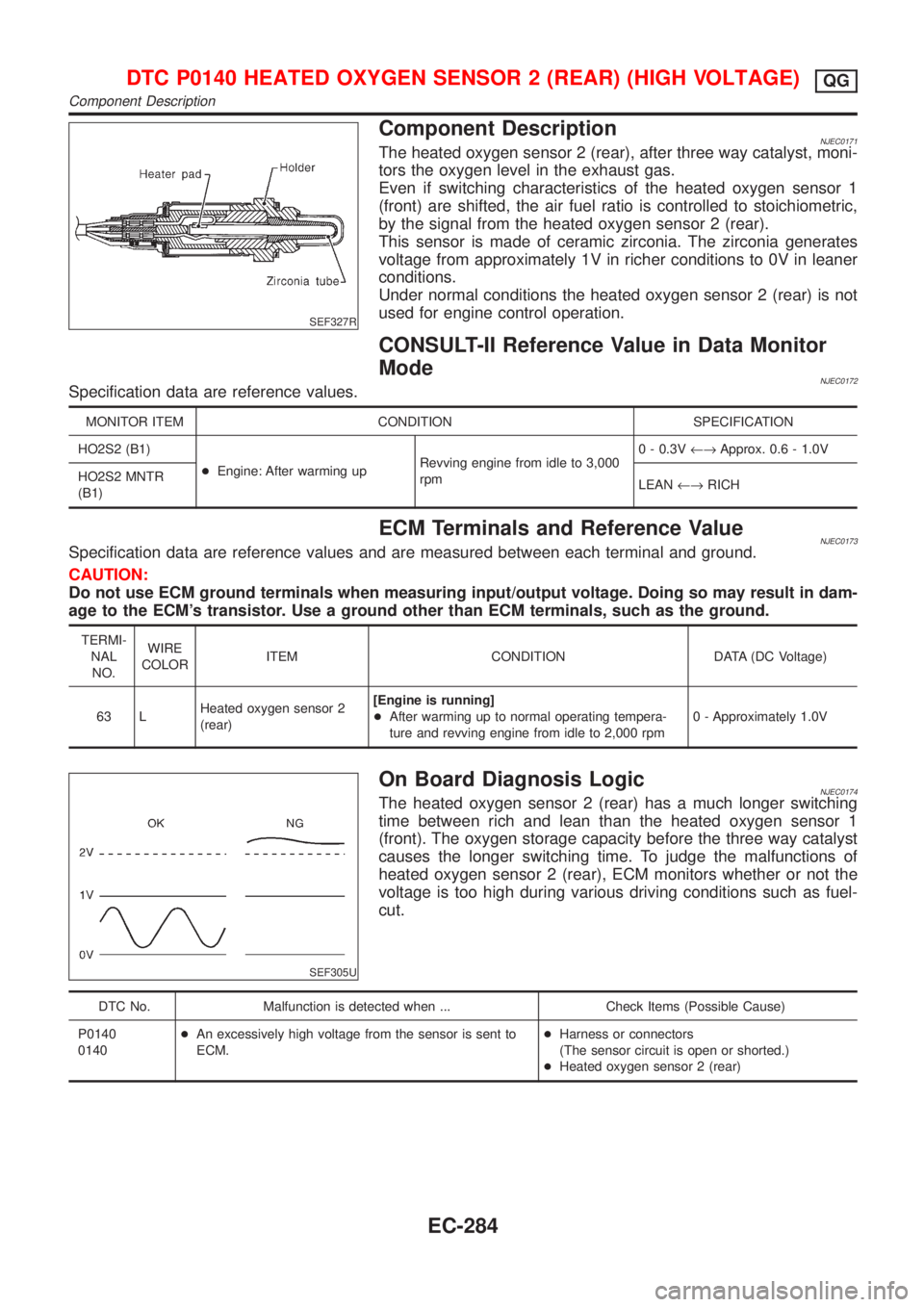

SEF305U

On Board Diagnosis LogicNJEC0174The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether or not the

voltage is too high during various driving conditions such as fuel-

cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0140

0140+An excessively high voltage from the sensor is sent to

ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Heated oxygen sensor 2 (rear)

DTC P0140 HEATED OXYGEN SENSOR 2 (REAR) (HIGH VOLTAGE)QG

Component Description

EC-284

Page 1338 of 2898

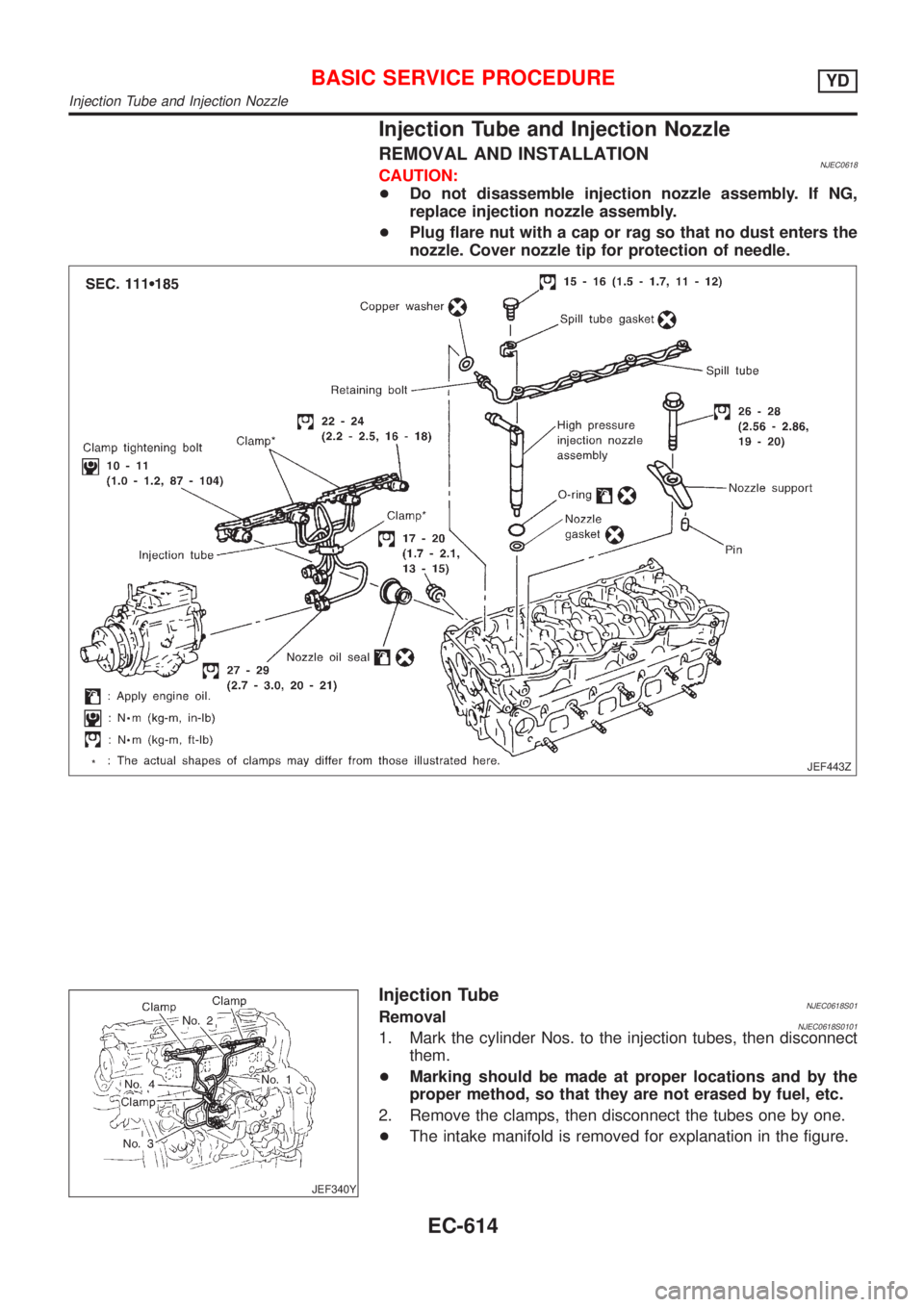

Injection Tube and Injection Nozzle

REMOVAL AND INSTALLATIONNJEC0618CAUTION:

+Do not disassemble injection nozzle assembly. If NG,

replace injection nozzle assembly.

+Plug flare nut with a cap or rag so that no dust enters the

nozzle. Cover nozzle tip for protection of needle.

JEF443Z

JEF340Y

Injection TubeNJEC0618S01RemovalNJEC0618S01011. Mark the cylinder Nos. to the injection tubes, then disconnect

them.

+Marking should be made at proper locations and by the

proper method, so that they are not erased by fuel, etc.

2. Remove the clamps, then disconnect the tubes one by one.

+The intake manifold is removed for explanation in the figure.

BASIC SERVICE PROCEDUREYD

Injection Tube and Injection Nozzle

EC-614

Page 2276 of 2898

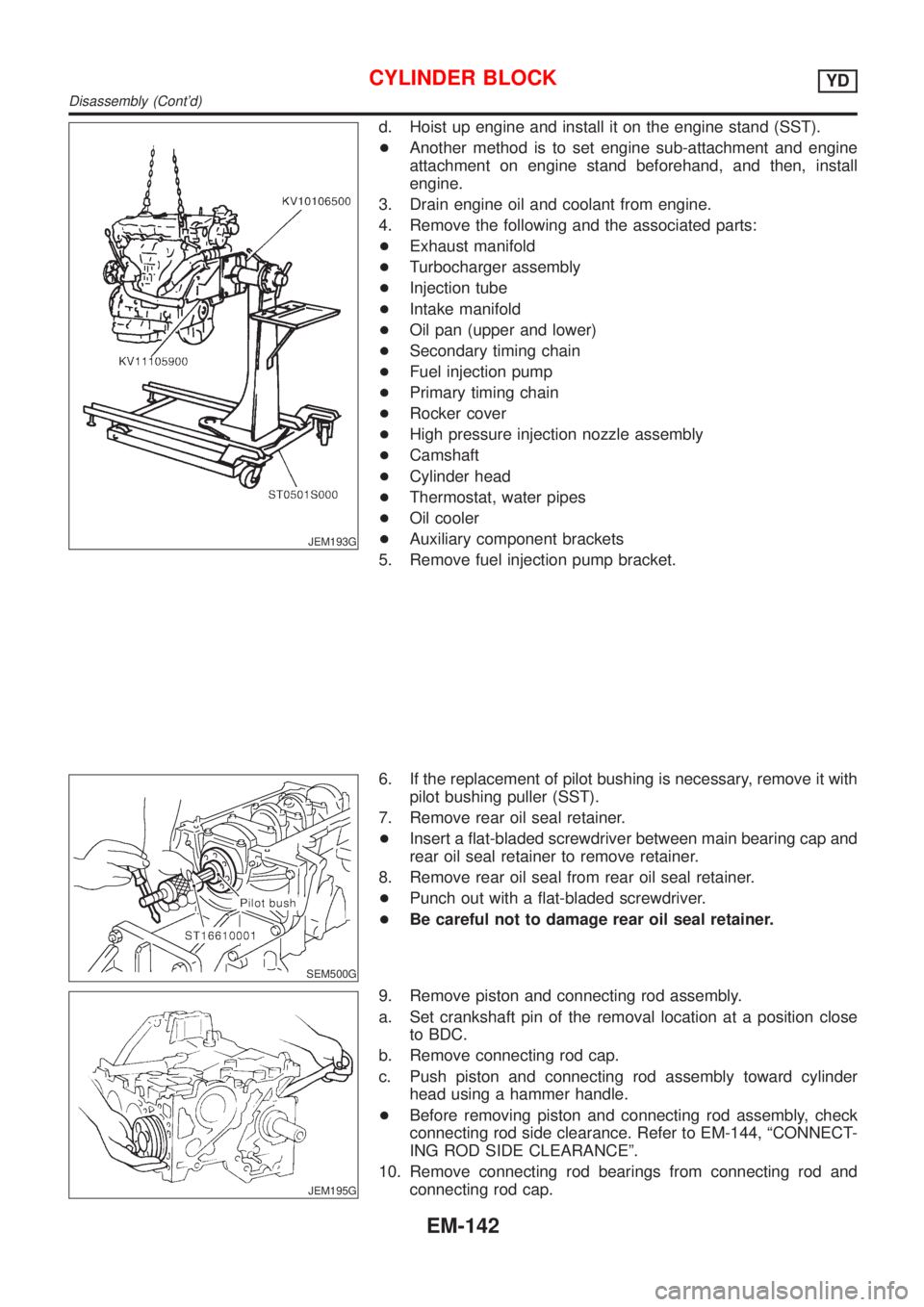

JEM193G

d. Hoist up engine and install it on the engine stand (SST).

+Another method is to set engine sub-attachment and engine

attachment on engine stand beforehand, and then, install

engine.

3. Drain engine oil and coolant from engine.

4. Remove the following and the associated parts:

+Exhaust manifold

+Turbocharger assembly

+Injection tube

+Intake manifold

+Oil pan (upper and lower)

+Secondary timing chain

+Fuel injection pump

+Primary timing chain

+Rocker cover

+High pressure injection nozzle assembly

+Camshaft

+Cylinder head

+Thermostat, water pipes

+Oil cooler

+Auxiliary component brackets

5. Remove fuel injection pump bracket.

SEM500G

6. If the replacement of pilot bushing is necessary, remove it with

pilot bushing puller (SST).

7. Remove rear oil seal retainer.

+Insert a flat-bladed screwdriver between main bearing cap and

rear oil seal retainer to remove retainer.

8. Remove rear oil seal from rear oil seal retainer.

+Punch out with a flat-bladed screwdriver.

+Be careful not to damage rear oil seal retainer.

JEM195G

9. Remove piston and connecting rod assembly.

a. Set crankshaft pin of the removal location at a position close

to BDC.

b. Remove connecting rod cap.

c. Push piston and connecting rod assembly toward cylinder

head using a hammer handle.

+Before removing piston and connecting rod assembly, check

connecting rod side clearance. Refer to EM-144, ªCONNECT-

ING ROD SIDE CLEARANCEº.

10. Remove connecting rod bearings from connecting rod and

connecting rod cap.

CYLINDER BLOCKYD

Disassembly (Cont'd)

EM-142