tire pressure NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 36 of 2898

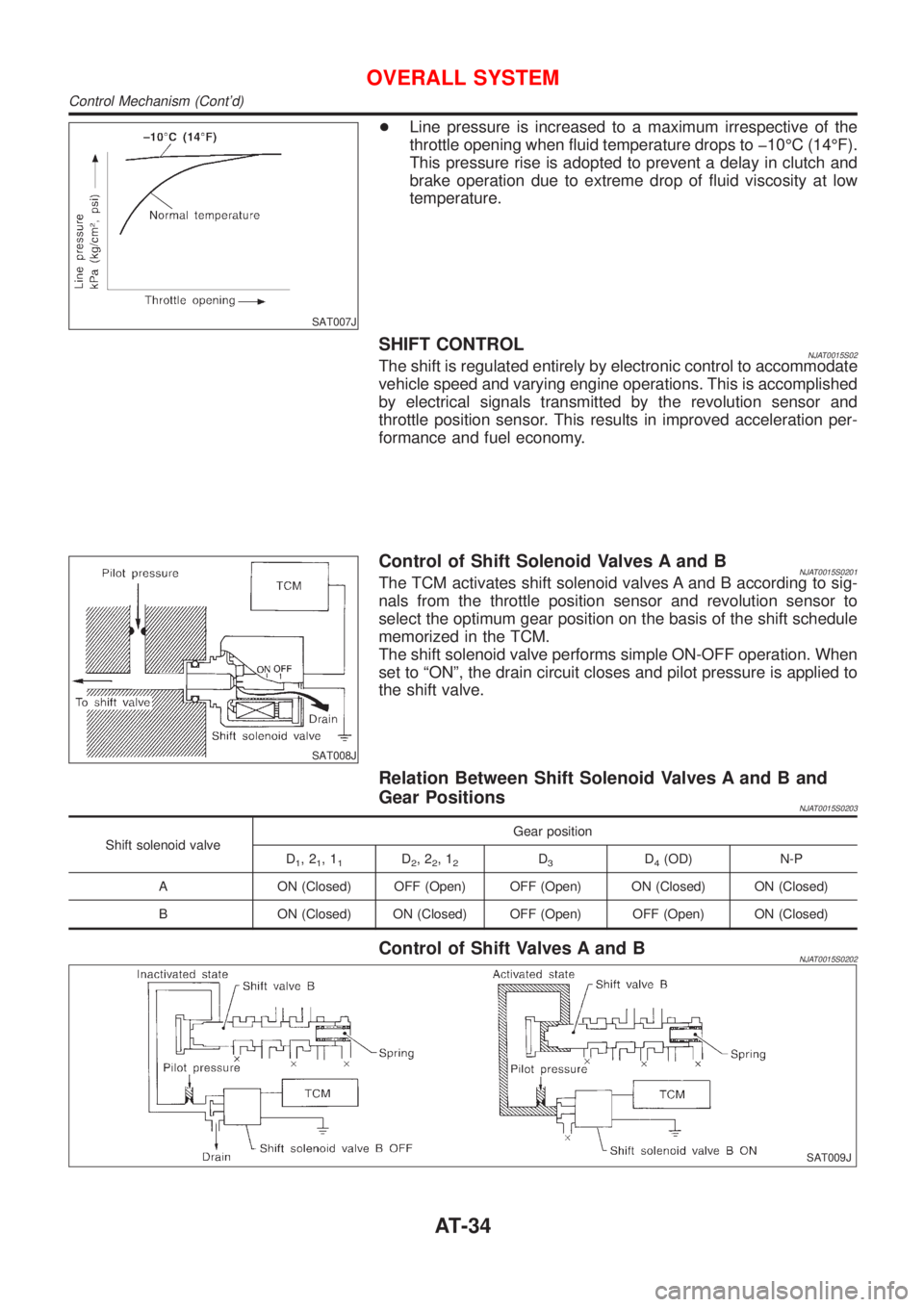

SAT007J

+Line pressure is increased to a maximum irrespective of the

throttle opening when fluid temperature drops to þ10ÉC (14ÉF).

This pressure rise is adopted to prevent a delay in clutch and

brake operation due to extreme drop of fluid viscosity at low

temperature.

SHIFT CONTROLNJAT0015S02The shift is regulated entirely by electronic control to accommodate

vehicle speed and varying engine operations. This is accomplished

by electrical signals transmitted by the revolution sensor and

throttle position sensor. This results in improved acceleration per-

formance and fuel economy.

SAT008J

Control of Shift Solenoid Valves A and BNJAT0015S0201The TCM activates shift solenoid valves A and B according to sig-

nals from the throttle position sensor and revolution sensor to

select the optimum gear position on the basis of the shift schedule

memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to ªONº, the drain circuit closes and pilot pressure is applied to

the shift valve.

Relation Between Shift Solenoid Valves A and B and

Gear Positions

NJAT0015S0203

Shift solenoid valveGear position

D

1,21,11D2,22,12D3D4(OD) N-P

A ON (Closed) OFF (Open) OFF (Open) ON (Closed) ON (Closed)

B ON (Closed) ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Control of Shift Valves A and BNJAT0015S0202

SAT009J

OVERALL SYSTEM

Control Mechanism (Cont'd)

AT-34

Page 595 of 2898

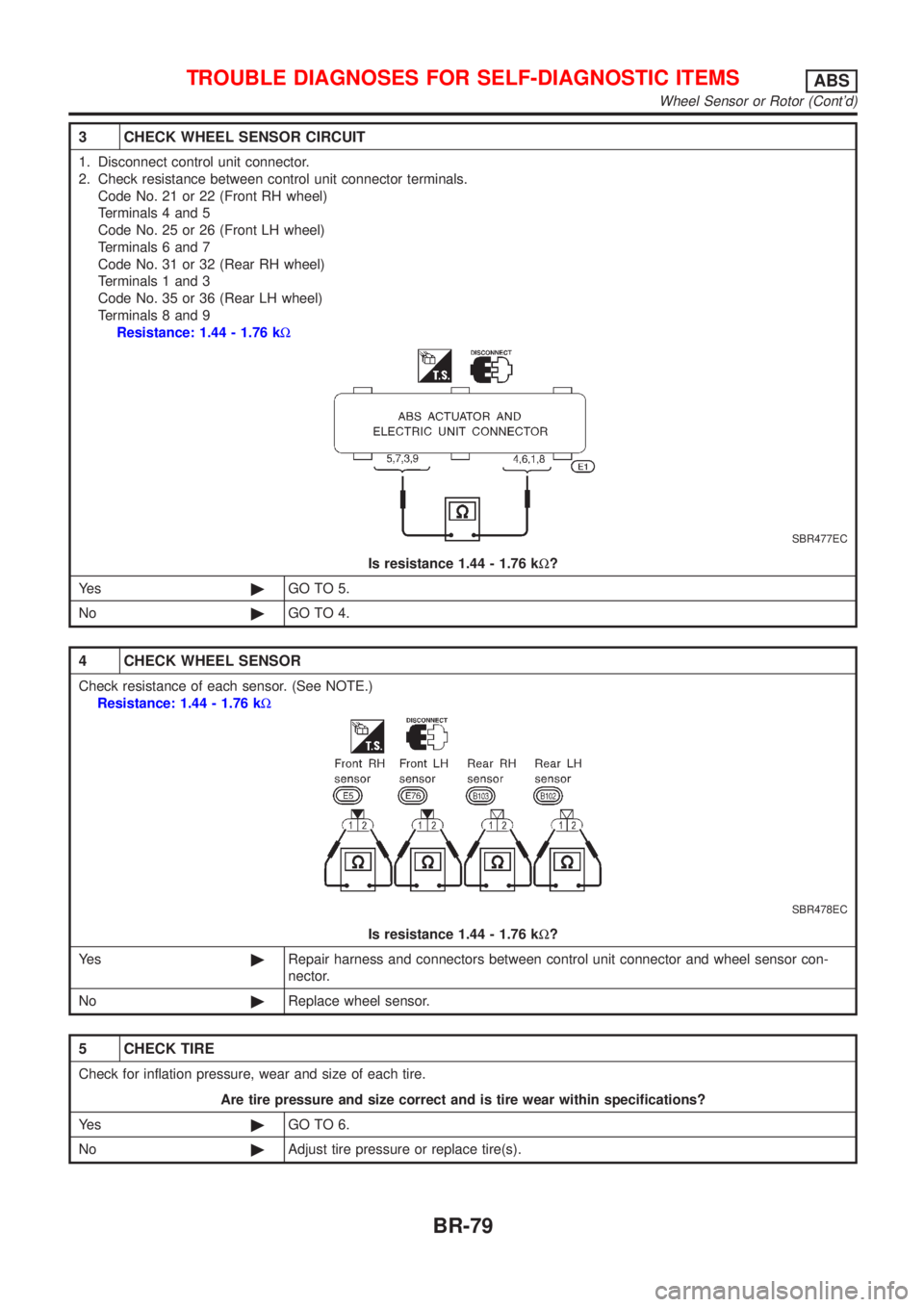

3 CHECK WHEEL SENSOR CIRCUIT

1. Disconnect control unit connector.

2. Check resistance between control unit connector terminals.

Code No. 21 or 22 (Front RH wheel)

Terminals 4 and 5

Code No. 25 or 26 (Front LH wheel)

Terminals 6 and 7

Code No. 31 or 32 (Rear RH wheel)

Terminals 1 and 3

Code No. 35 or 36 (Rear LH wheel)

Terminals 8 and 9

Resistance: 1.44 - 1.76 kW

SBR477EC

Is resistance 1.44 - 1.76 kW?

Ye s©GO TO 5.

No©GO TO 4.

4 CHECK WHEEL SENSOR

Check resistance of each sensor. (See NOTE.)

Resistance: 1.44 - 1.76 kW

SBR478EC

Is resistance 1.44 - 1.76 kW?

Ye s©Repair harness and connectors between control unit connector and wheel sensor con-

nector.

No©Replace wheel sensor.

5 CHECK TIRE

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

Ye s©GO TO 6.

No©Adjust tire pressure or replace tire(s).

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Wheel Sensor or Rotor (Cont'd)

BR-79

Page 1623 of 2898

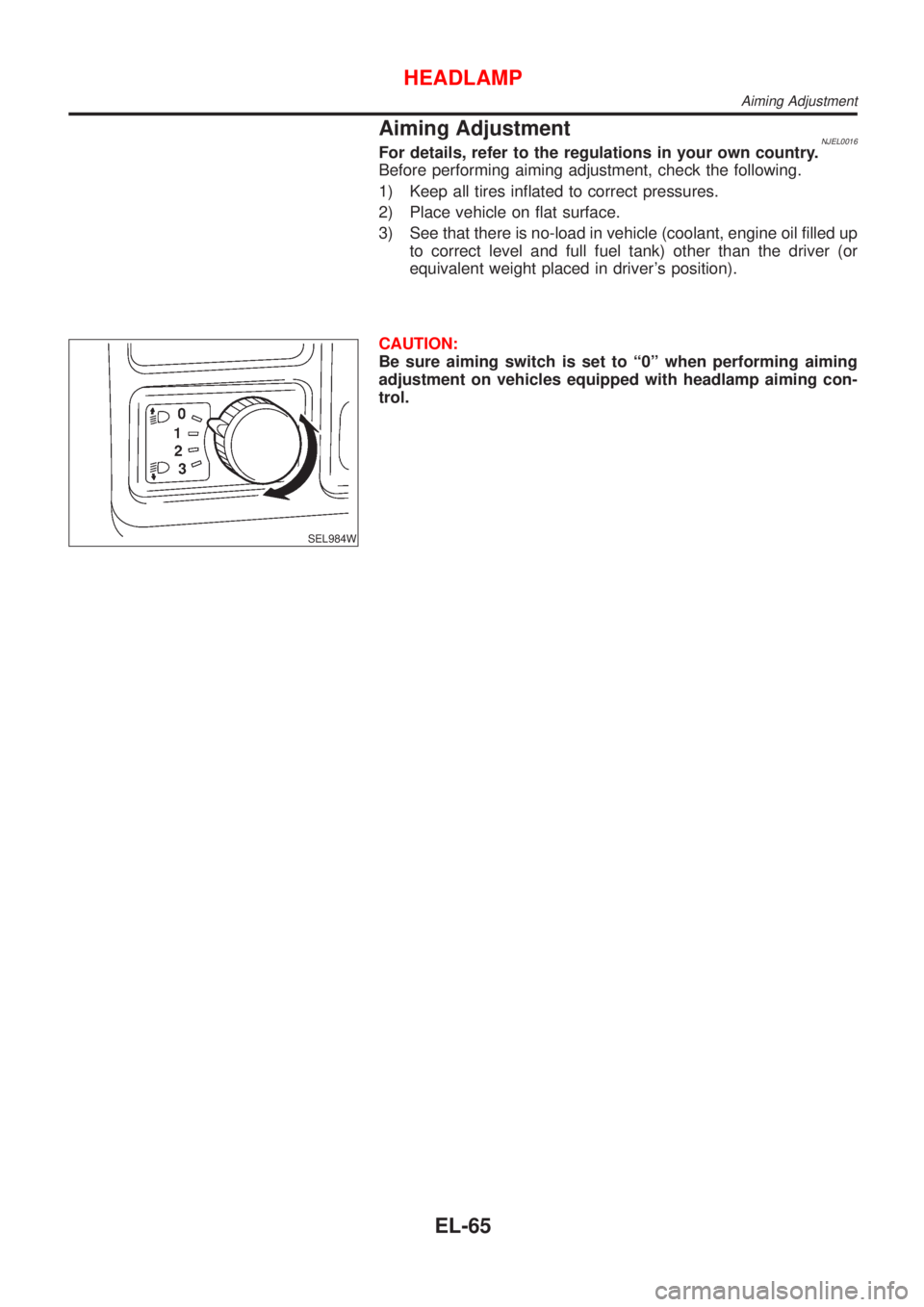

Aiming AdjustmentNJEL0016For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1) Keep all tires inflated to correct pressures.

2) Place vehicle on flat surface.

3) See that there is no-load in vehicle (coolant, engine oil filled up

to correct level and full fuel tank) other than the driver (or

equivalent weight placed in driver's position).

SEL984W

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

HEADLAMP

Aiming Adjustment

EL-65

Page 1650 of 2898

SEL976W

SEL480X

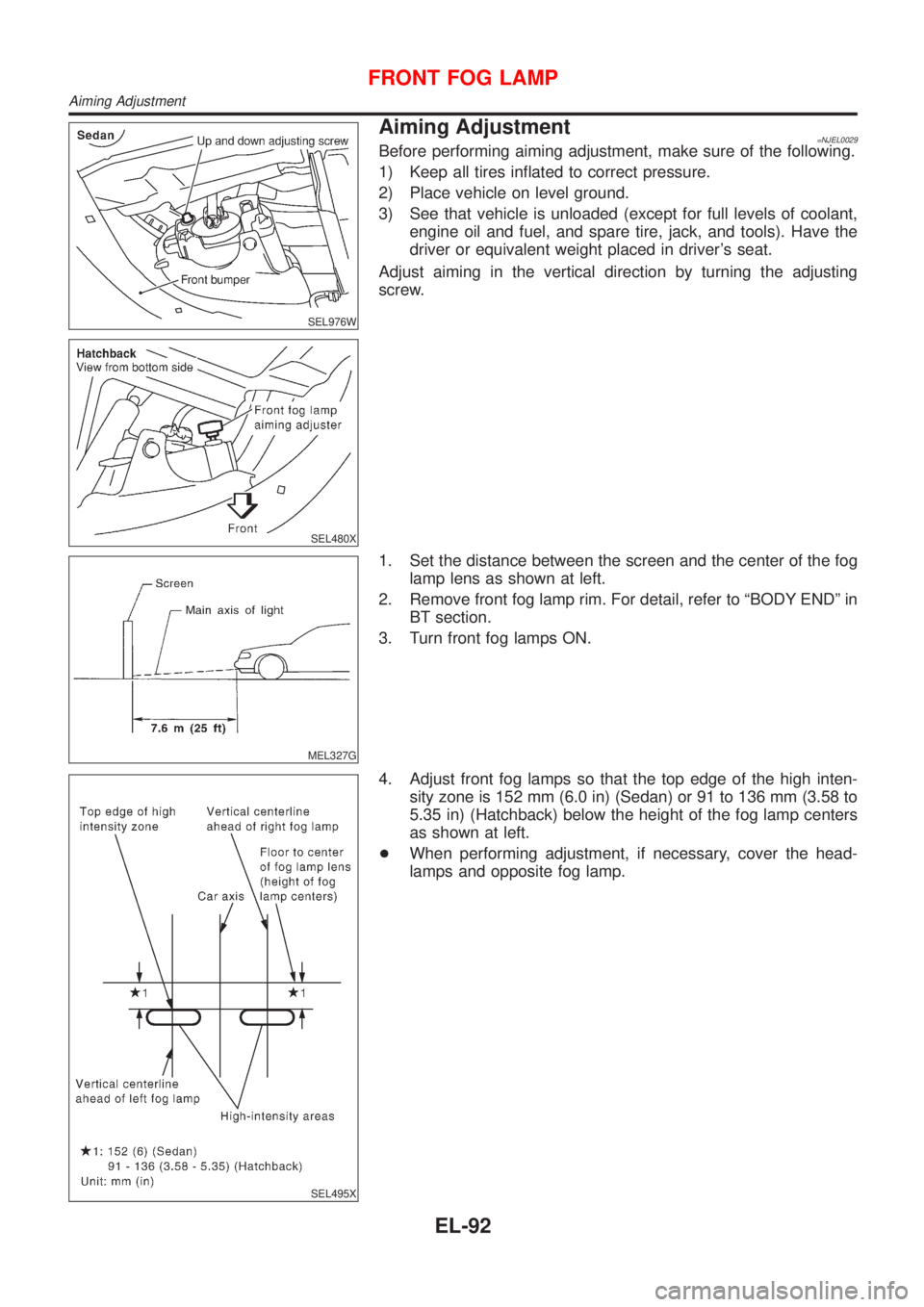

Aiming Adjustment=NJEL0029Before performing aiming adjustment, make sure of the following.

1) Keep all tires inflated to correct pressure.

2) Place vehicle on level ground.

3) See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driver's seat.

Adjust aiming in the vertical direction by turning the adjusting

screw.

MEL327G

1. Set the distance between the screen and the center of the fog

lamp lens as shown at left.

2. Remove front fog lamp rim. For detail, refer to ªBODY ENDº in

BT section.

3. Turn front fog lamps ON.

SEL495X

4. Adjust front fog lamps so that the top edge of the high inten-

sity zone is 152 mm (6.0 in) (Sedan) or 91 to 136 mm (3.58 to

5.35 in) (Hatchback) below the height of the fog lamp centers

as shown at left.

+When performing adjustment, if necessary, cover the head-

lamps and opposite fog lamp.

FRONT FOG LAMP

Aiming Adjustment

EL-92

Page 2034 of 2898

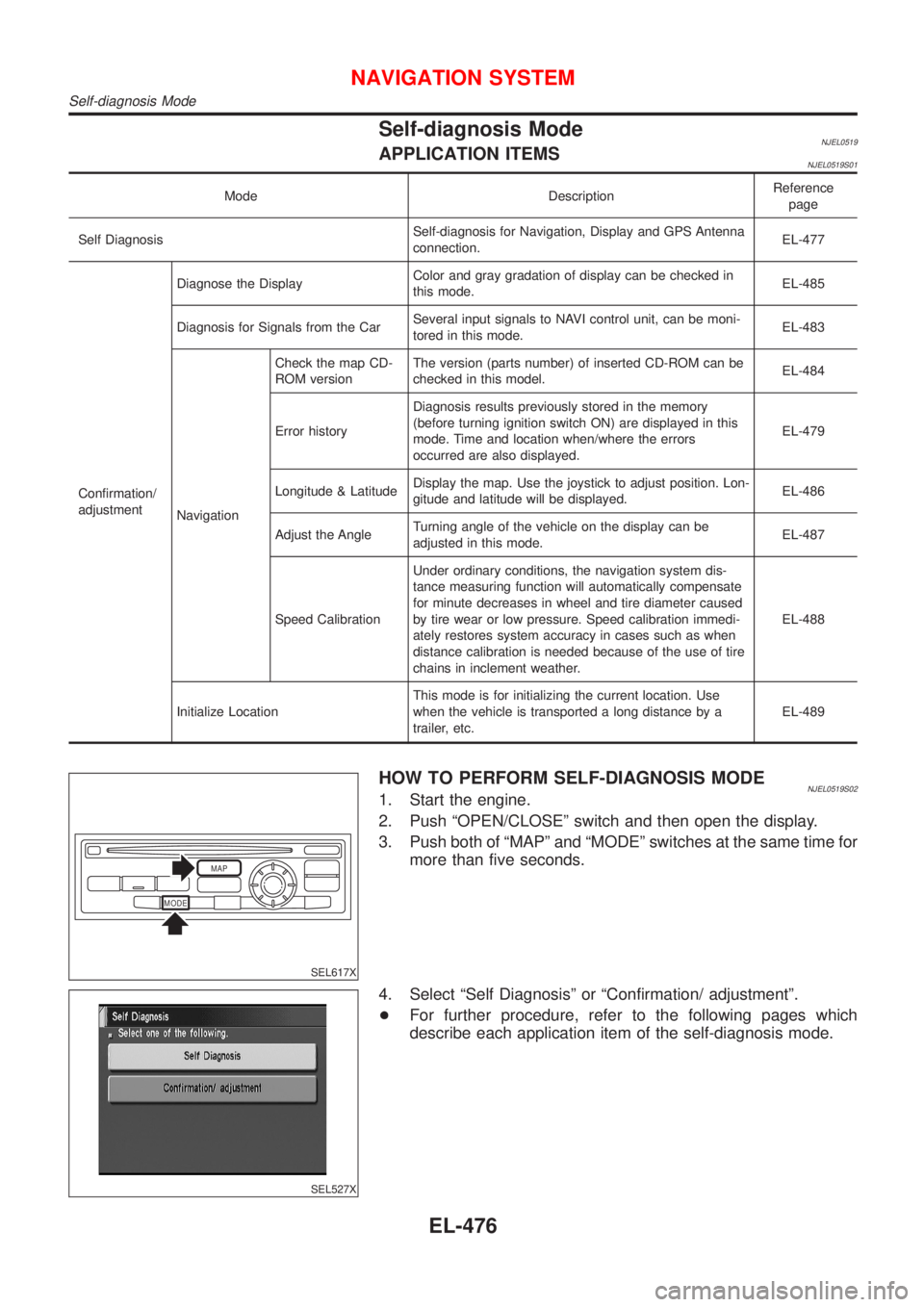

Self-diagnosis ModeNJEL0519APPLICATION ITEMSNJEL0519S01

Mode DescriptionReference

page

Self DiagnosisSelf-diagnosis for Navigation, Display and GPS Antenna

connection.EL-477

Confirmation/

adjustmentDiagnose the DisplayColor and gray gradation of display can be checked in

this mode.EL-485

Diagnosis for Signals from the CarSeveral input signals to NAVI control unit, can be moni-

tored in this mode.EL-483

NavigationCheck the map CD-

ROM versionThe version (parts number) of inserted CD-ROM can be

checked in this model.EL-484

Error historyDiagnosis results previously stored in the memory

(before turning ignition switch ON) are displayed in this

mode. Time and location when/where the errors

occurred are also displayed.EL-479

Longitude & LatitudeDisplay the map. Use the joystick to adjust position. Lon-

gitude and latitude will be displayed.EL-486

Adjust the AngleTurning angle of the vehicle on the display can be

adjusted in this mode.EL-487

Speed CalibrationUnder ordinary conditions, the navigation system dis-

tance measuring function will automatically compensate

for minute decreases in wheel and tire diameter caused

by tire wear or low pressure. Speed calibration immedi-

ately restores system accuracy in cases such as when

distance calibration is needed because of the use of tire

chains in inclement weather.EL-488

Initialize LocationThis mode is for initializing the current location. Use

when the vehicle is transported a long distance by a

trailer, etc.EL-489

MODEMAP

SEL617X

HOW TO PERFORM SELF-DIAGNOSIS MODENJEL0519S021. Start the engine.

2. Push ªOPEN/CLOSEº switch and then open the display.

3. Push both of ªMAPº and ªMODEº switches at the same time for

more than five seconds.

SEL527X

4. Select ªSelf Diagnosisº or ªConfirmation/ adjustmentº.

+For further procedure, refer to the following pages which

describe each application item of the self-diagnosis mode.

NAVIGATION SYSTEM

Self-diagnosis Mode

EL-476

Page 2531 of 2898

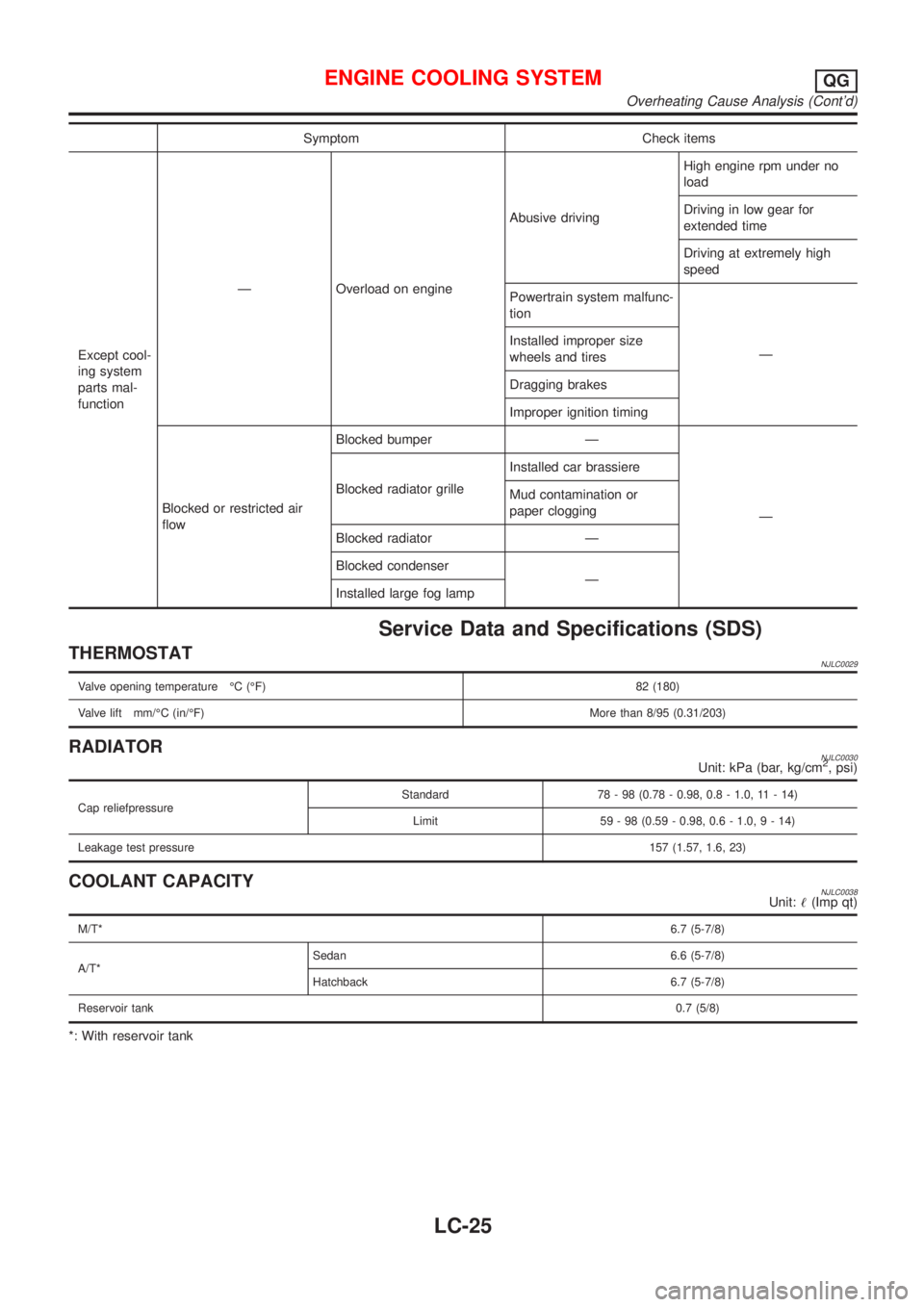

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNJLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNJLC0038Unit:!(Imp qt)

M/T*6.7 (5-7/8)

A/T*Sedan 6.6 (5-7/8)

Hatchback 6.7 (5-7/8)

Reservoir tank0.7 (5/8)

*: With reservoir tank

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-25

Page 2554 of 2898

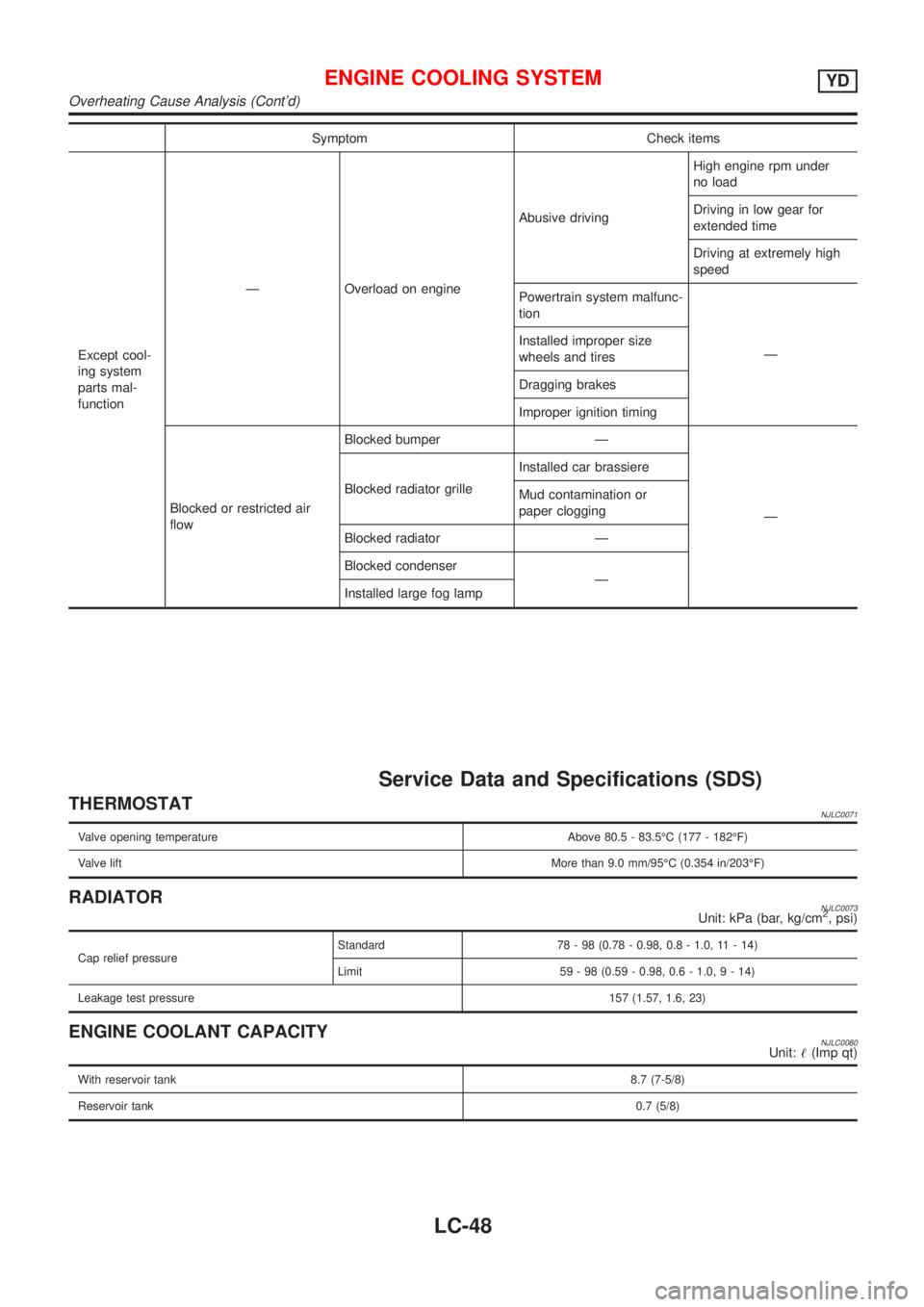

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0071

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve liftMore than 9.0 mm/95ÉC (0.354 in/203ÉF)

RADIATORNJLC0073Unit: kPa (bar, kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

ENGINE COOLANT CAPACITYNJLC0080Unit:!(Imp qt)

With reservoir tank8.7 (7-5/8)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMYD

Overheating Cause Analysis (Cont'd)

LC-48

Page 2556 of 2898

NJMA0036

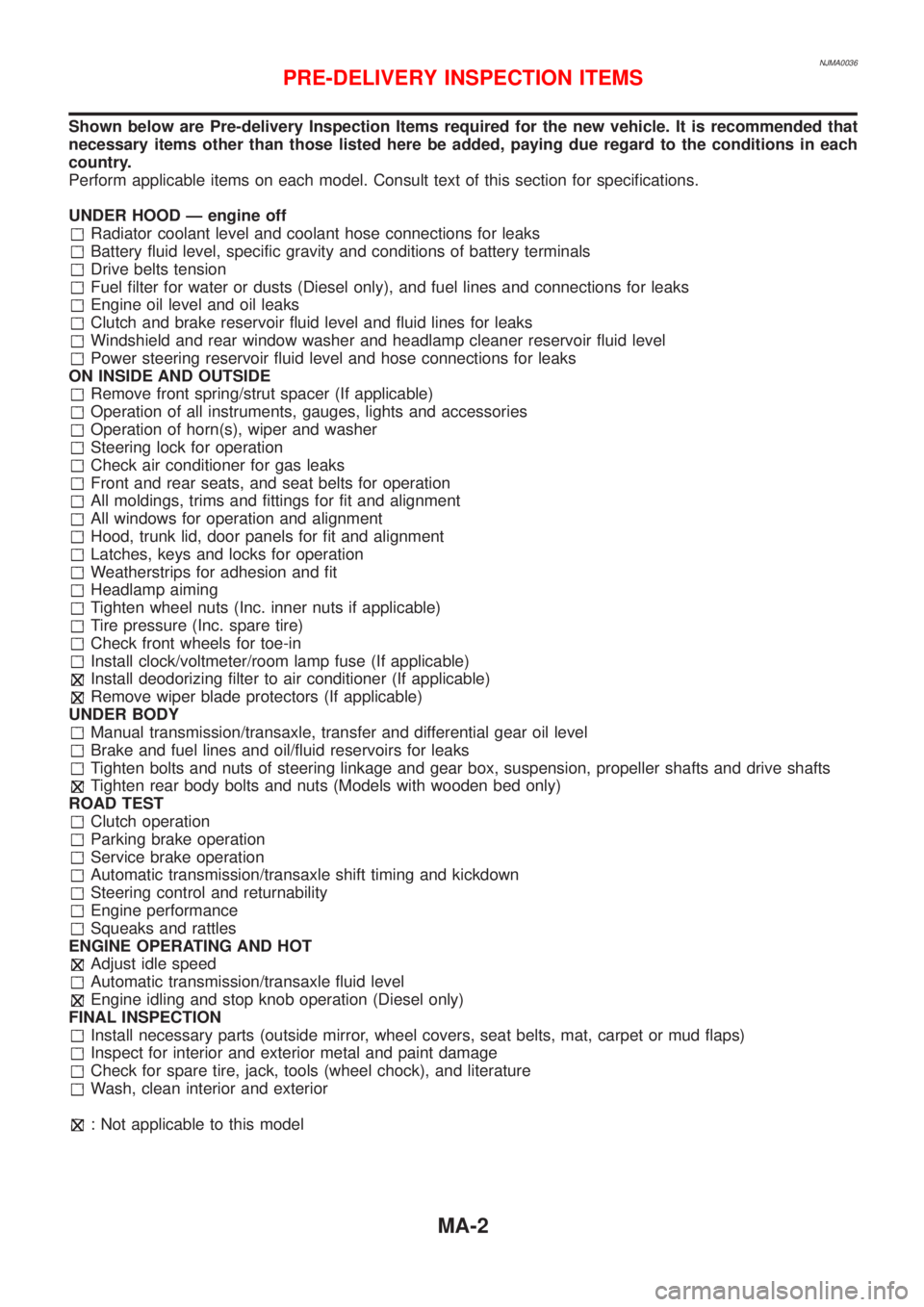

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 2557 of 2898

NJMA0004

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. Ð

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-16

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-7

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.Ð

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-4

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. LC-19, LC-45

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-31

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the ªMAXº and

ªMINº lines on the reservoir.BR-8

BatteryCheck the fluid level in each cell. It should be between the ªMAXº and ªMINº

lines.Ð

GENERAL MAINTENANCE

MA-3

Page 2844 of 2898

Bleeding Hydraulic SystemNJST00141. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then quickly turn steer-

ing wheel fully to right and left and lightly touch steering stop-

pers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2. above.

+Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning the steering wheel

slowly. This does not affect the performance or durability of the

system.

SST491B

SST090B

Checking Steering Wheel Turning ForceNJST00151. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Average rack sliding force:

Sedan

152 - 240 N (15.5 - 24.5 kg, 34 - 54 lb)

Hatchback

132 - 308 N (13.5 - 31.4 kg, 30 - 69 lb)

Maximum force deviation:

Sedan

98 N (10 kg, 22 lb)

Hatchback

176 N (17.9 kg, 39 lb)

d. Check sliding force outside the above range at rack speed of

40 mm (1.75 in)/s.

ON-VEHICLE SERVICE

Bleeding Hydraulic System

ST-8