wheel bolts NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 86 of 2898

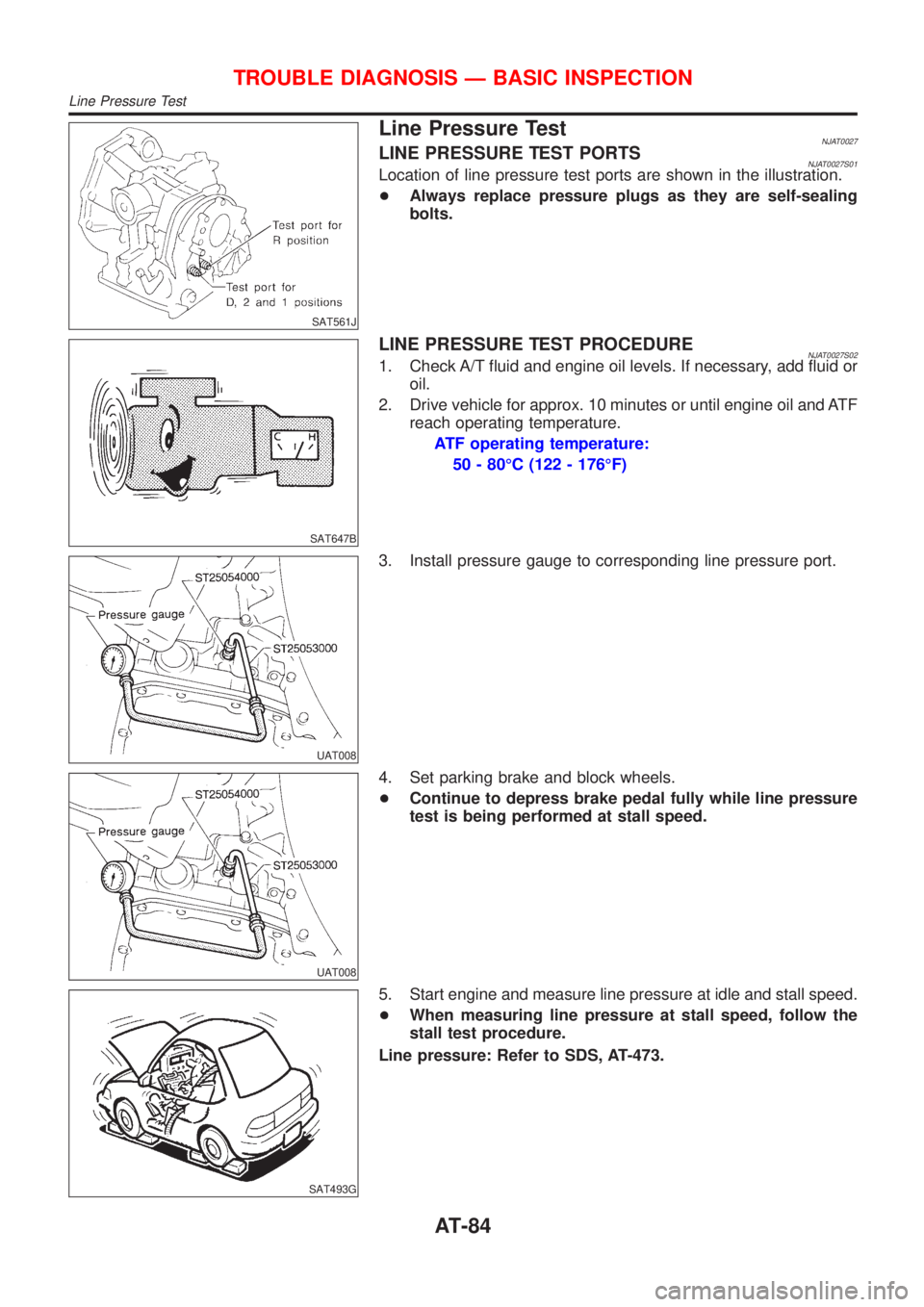

SAT561J

Line Pressure TestNJAT0027LINE PRESSURE TEST PORTSNJAT0027S01Location of line pressure test ports are shown in the illustration.

+Always replace pressure plugs as they are self-sealing

bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENJAT0027S021. Check A/T fluid and engine oil levels. If necessary, add fluid or

oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

UAT008

3. Install pressure gauge to corresponding line pressure port.

UAT008

4. Set parking brake and block wheels.

+Continue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

+When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-473.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-84

Page 357 of 2898

AAT259A

14. Remove rear plate cover.

15. Remove torque converter bolts.

Rotate crankshaft to gain access to securing bolts.

16. Remove rear transaxle to engine bracket. Refer to EM-51,

ªREMOVAL AND INSTALLATIONº.

17. Support engine with a jack.

18. Remove rear transaxle mount. Refer to EM-51, ªREMOVAL

AND INSTALLATIONº.

19. Remove lower bolts fixing transaxle to engine.

20. Lower transaxle while supporting it with a jack.

SAT977H

InstallationNJAT01161. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM-62, ªFLYWHEEL/DRIVE PLATE

RUNOUTº.

+If this runout is out of allowance, replace drive plate with ring

gear.

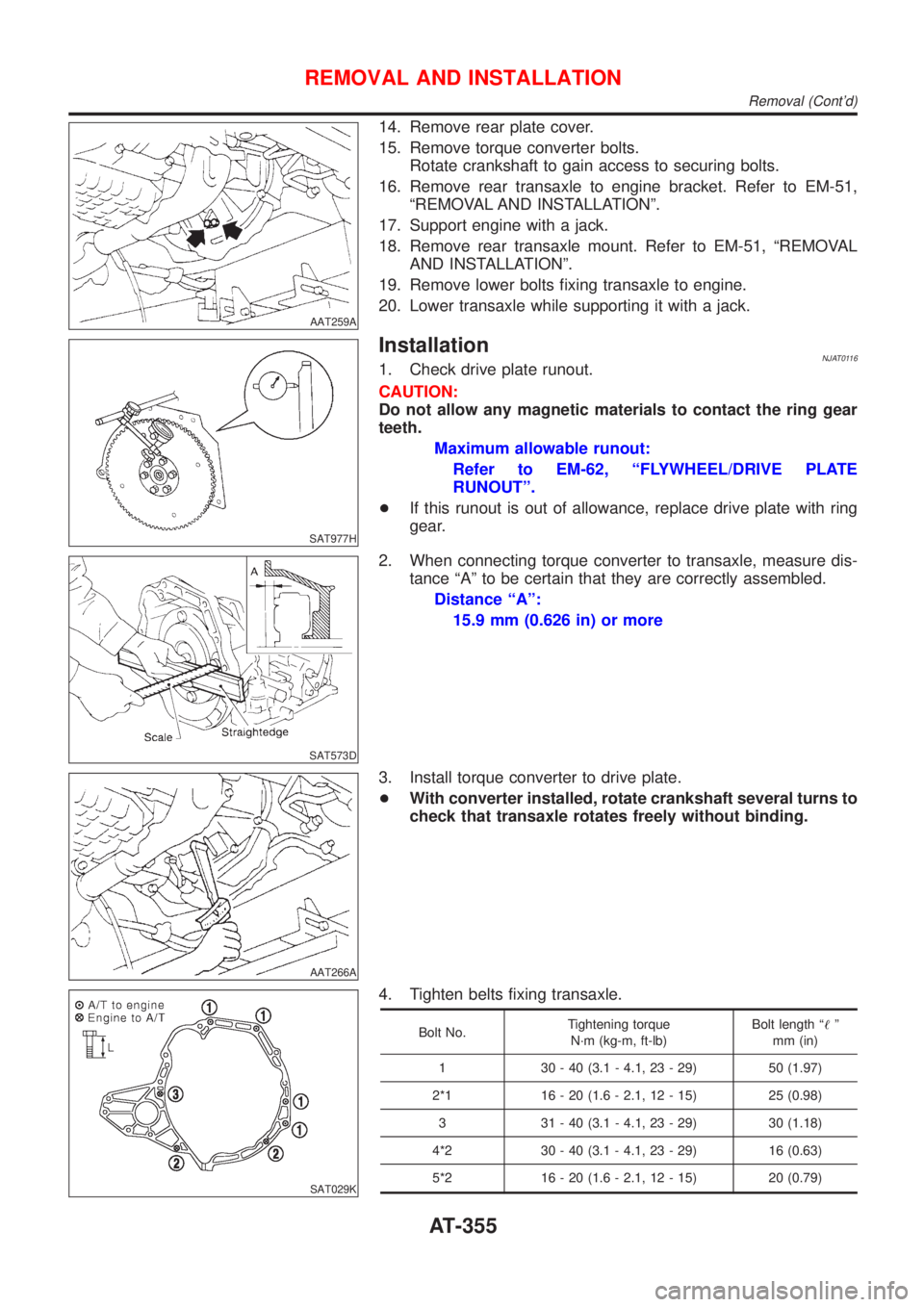

SAT573D

2. When connecting torque converter to transaxle, measure dis-

tance ªAº to be certain that they are correctly assembled.

Distance ªAº:

15.9 mm (0.626 in) or more

AAT266A

3. Install torque converter to drive plate.

+With converter installed, rotate crankshaft several turns to

check that transaxle rotates freely without binding.

SAT029K

4. Tighten belts fixing transaxle.

Bolt No.Tightening torque

N´m (kg-m, ft-lb)Bolt length ª!º

mm (in)

1 30 - 40 (3.1 - 4.1, 23 - 29) 50 (1.97)

2*1 16 - 20 (1.6 - 2.1, 12 - 15) 25 (0.98)

3 31 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

4*2 30 - 40 (3.1 - 4.1, 23 - 29) 16 (0.63)

5*2 16 - 20 (1.6 - 2.1, 12 - 15) 20 (0.79)

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-355

Page 491 of 2898

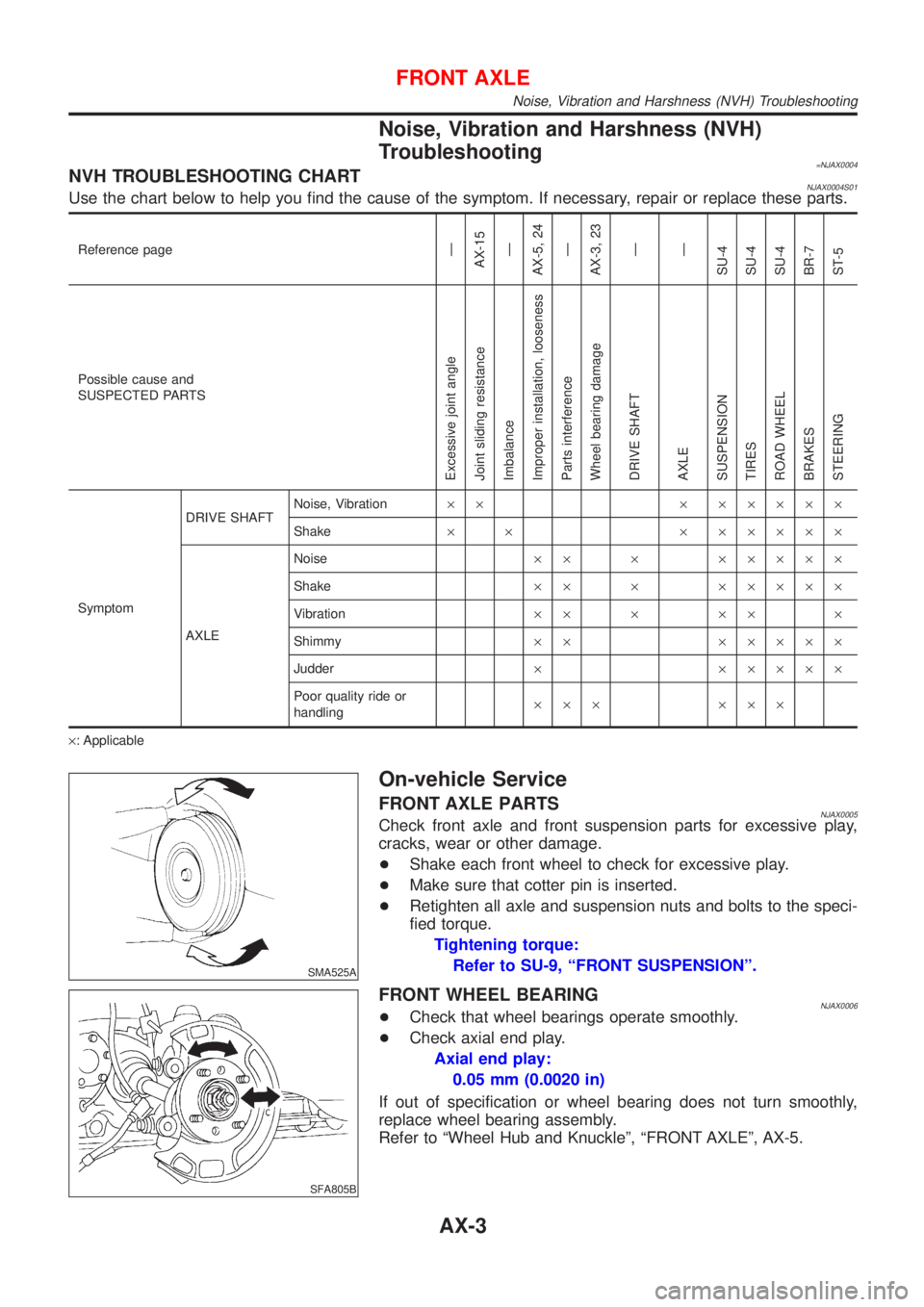

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NJAX0004NVH TROUBLESHOOTING CHARTNJAX0004S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-15

Ð

AX-5, 24

Ð

AX-3, 23

Ð

Ð

SU-4

SU-4

SU-4

BR-7

ST-5

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´ ´´´´´

Shake´ ´ ´ ´´´´´

AXLENoise´´ ´ ´´´´´

Shake´´ ´ ´´´´´

Vibration´´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNJAX0005Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

+Shake each front wheel to check for excessive play.

+Make sure that cotter pin is inserted.

+Retighten all axle and suspension nuts and bolts to the speci-

fied torque.

Tightening torque:

Refer to SU-9, ªFRONT SUSPENSIONº.

SFA805B

FRONT WHEEL BEARINGNJAX0006+Check that wheel bearings operate smoothly.

+Check axial end play.

Axial end play:

0.05 mm (0.0020 in)

If out of specification or wheel bearing does not turn smoothly,

replace wheel bearing assembly.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 494 of 2898

SFA898A

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose. Be careful not to depress brake pedal, or

piston will pop out.

Make sure brake hose is not twisted.

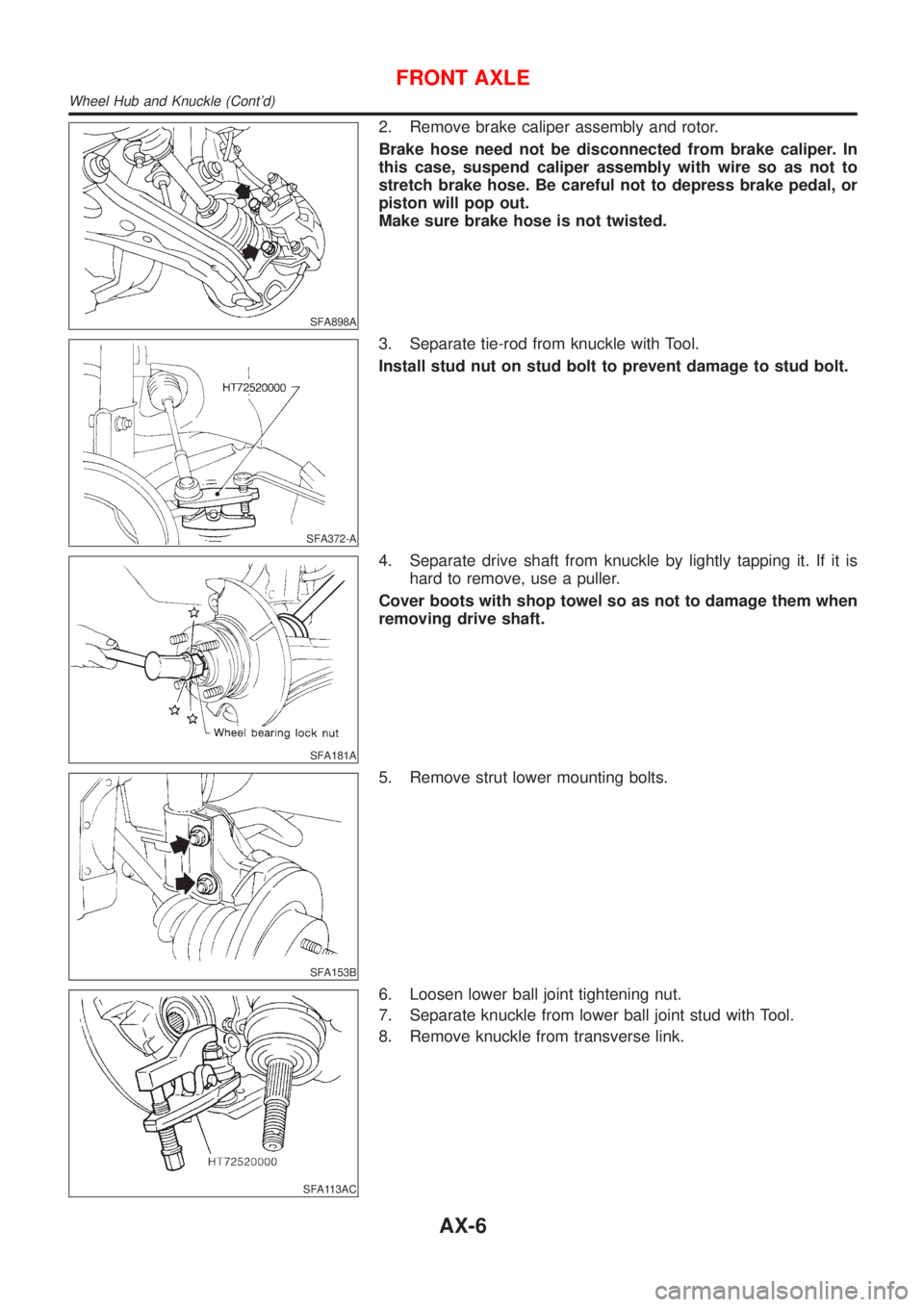

SFA372-A

3. Separate tie-rod from knuckle with Tool.

Install stud nut on stud bolt to prevent damage to stud bolt.

SFA181A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA153B

5. Remove strut lower mounting bolts.

SFA113AC

6. Loosen lower ball joint tightening nut.

7. Separate knuckle from lower ball joint stud with Tool.

8. Remove knuckle from transverse link.

FRONT AXLE

Wheel Hub and Knuckle (Cont'd)

AX-6

Page 495 of 2898

SFA114A

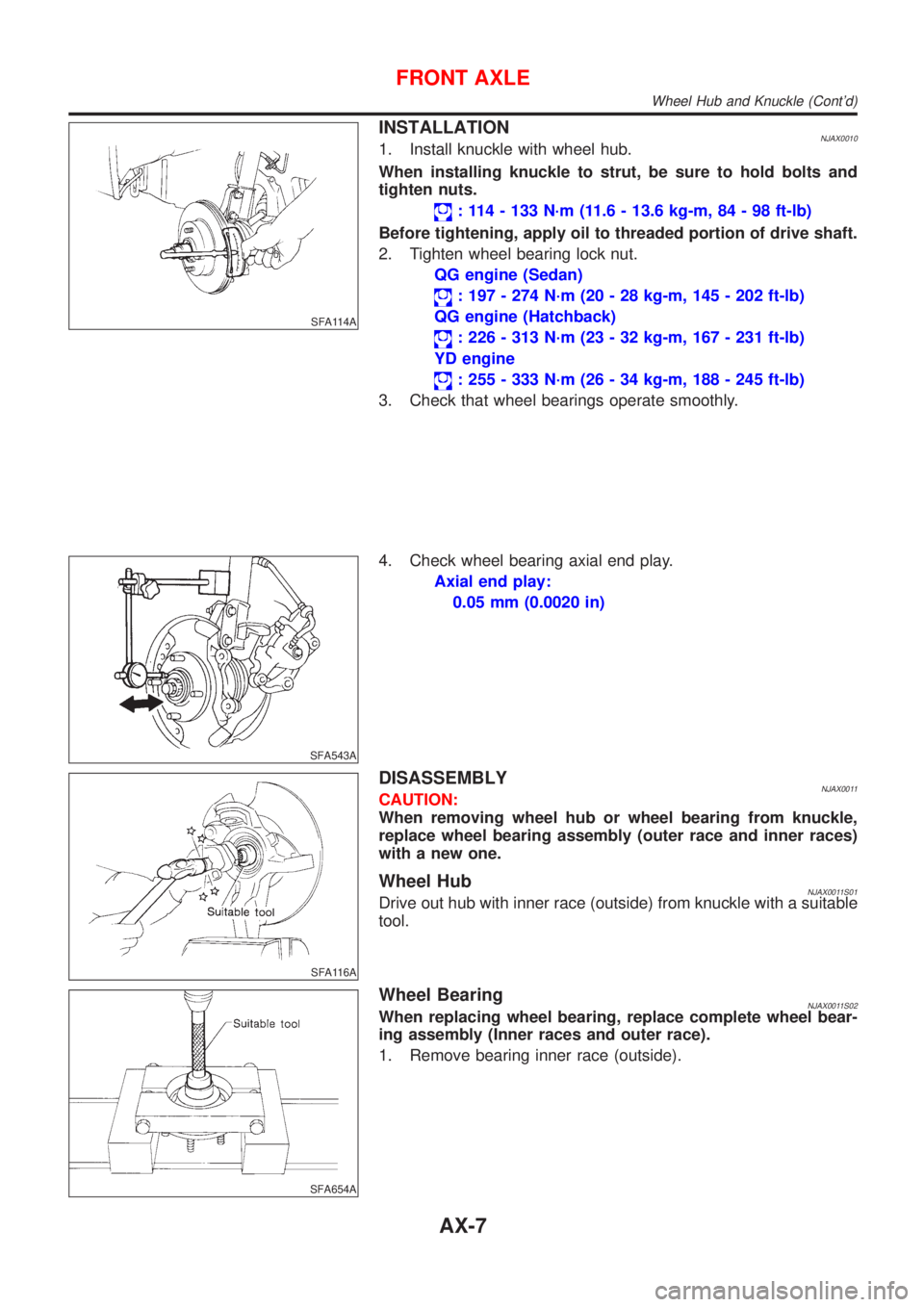

INSTALLATIONNJAX00101. Install knuckle with wheel hub.

When installing knuckle to strut, be sure to hold bolts and

tighten nuts.

: 114 - 133 N´m (11.6 - 13.6 kg-m, 84 - 98 ft-lb)

Before tightening, apply oil to threaded portion of drive shaft.

2. Tighten wheel bearing lock nut.

QG engine (Sedan)

: 197 - 274 N´m (20 - 28 kg-m, 145 - 202 ft-lb)

QG engine (Hatchback)

: 226 - 313 N´m (23 - 32 kg-m, 167 - 231 ft-lb)

YD engine

: 255 - 333 N´m (26 - 34 kg-m, 188 - 245 ft-lb)

3. Check that wheel bearings operate smoothly.

SFA543A

4. Check wheel bearing axial end play.

Axial end play:

0.05 mm (0.0020 in)

SFA116A

DISASSEMBLYNJAX0011CAUTION:

When removing wheel hub or wheel bearing from knuckle,

replace wheel bearing assembly (outer race and inner races)

with a new one.

Wheel HubNJAX0011S01Drive out hub with inner race (outside) from knuckle with a suitable

tool.

SFA654A

Wheel BearingNJAX0011S02When replacing wheel bearing, replace complete wheel bear-

ing assembly (Inner races and outer race).

1. Remove bearing inner race (outside).

FRONT AXLE

Wheel Hub and Knuckle (Cont'd)

AX-7

Page 499 of 2898

SFA090A

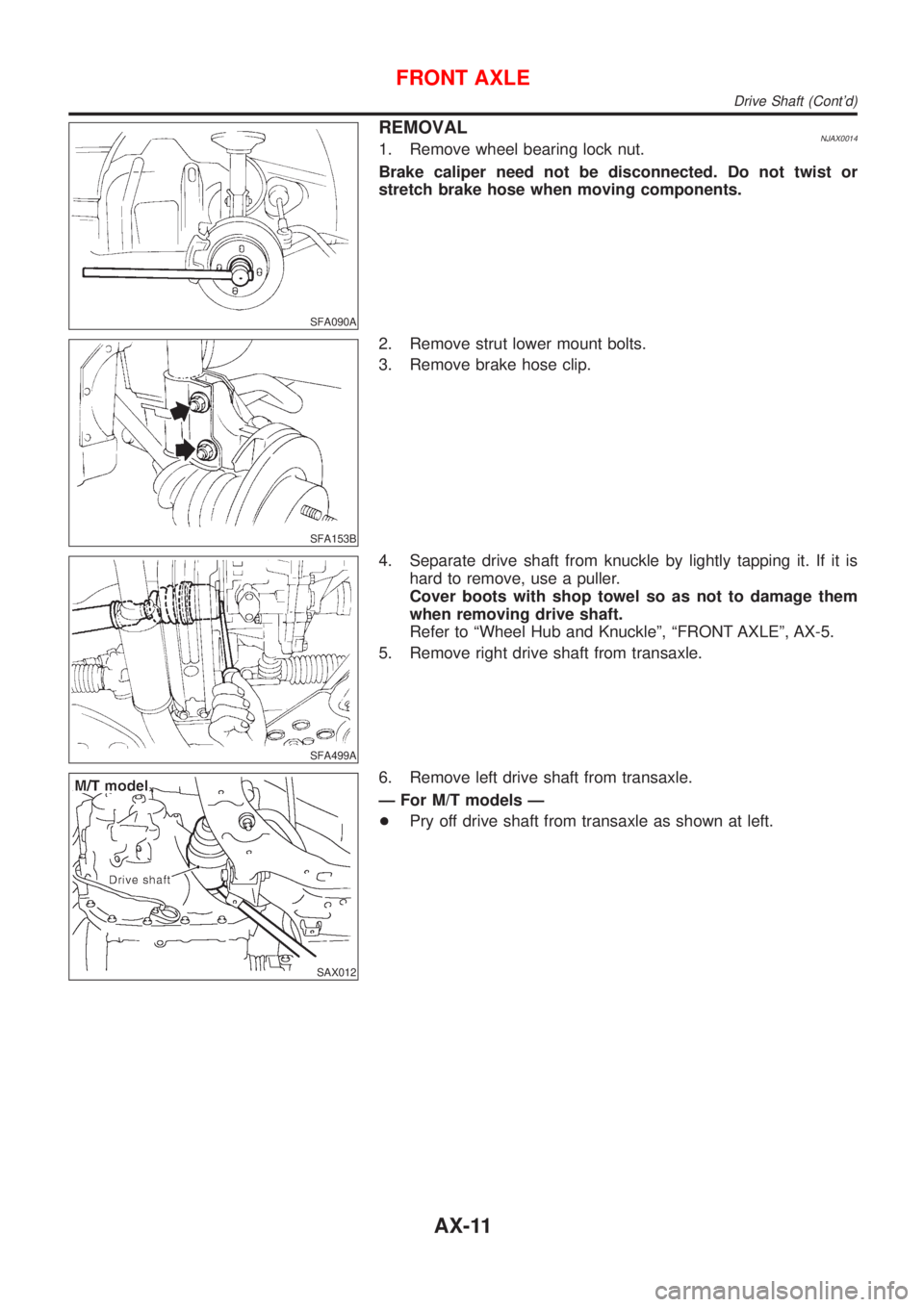

REMOVALNJAX00141. Remove wheel bearing lock nut.

Brake caliper need not be disconnected. Do not twist or

stretch brake hose when moving components.

SFA153B

2. Remove strut lower mount bolts.

3. Remove brake hose clip.

SFA499A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them

when removing drive shaft.

Refer to ªWheel Hub and Knuckleº, ªFRONT AXLEº, AX-5.

5. Remove right drive shaft from transaxle.

SAX012

6. Remove left drive shaft from transaxle.

Ð For M/T models Ð

+Pry off drive shaft from transaxle as shown at left.

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 548 of 2898

SBR617E

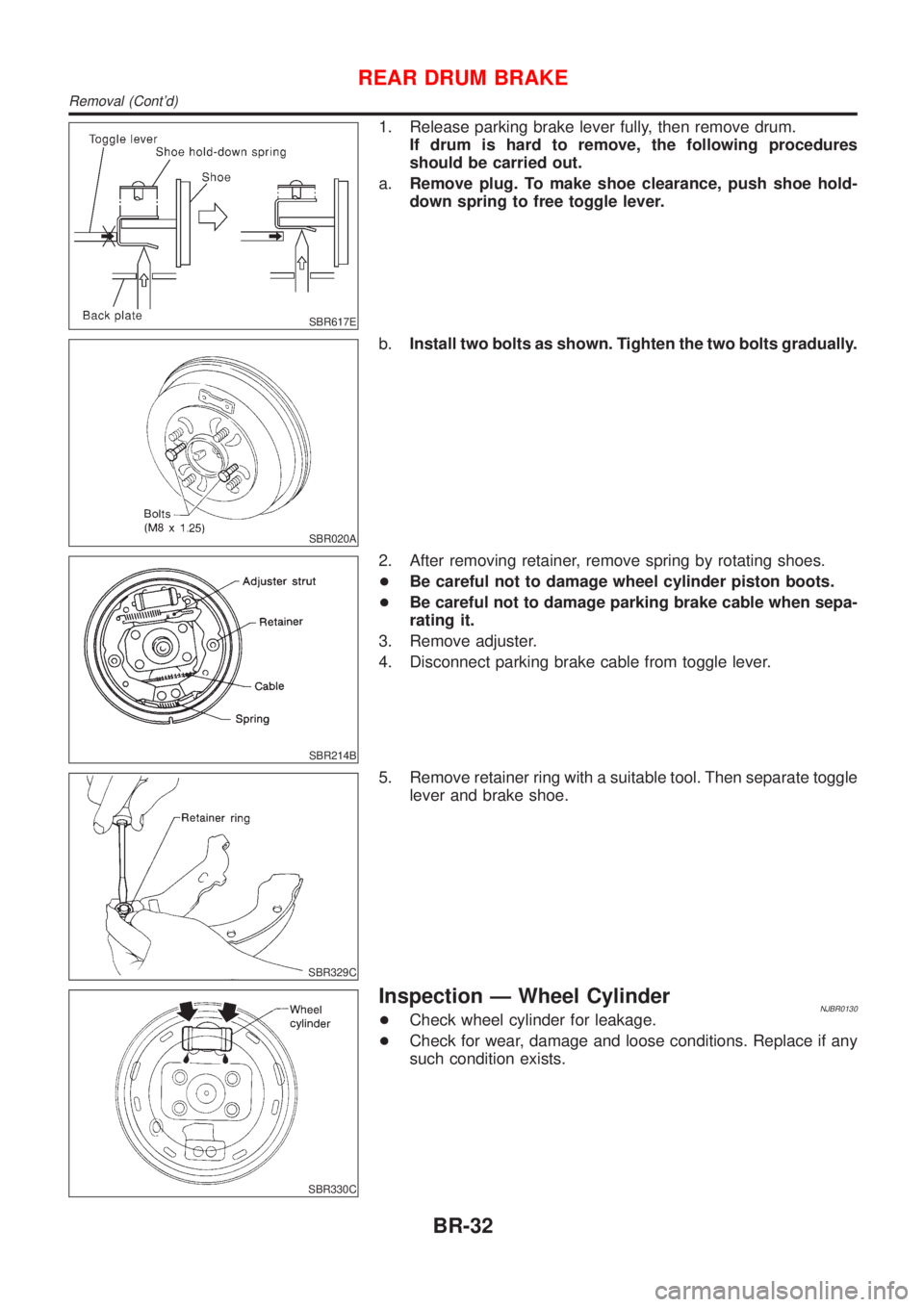

1. Release parking brake lever fully, then remove drum.

If drum is hard to remove, the following procedures

should be carried out.

a.Remove plug. To make shoe clearance, push shoe hold-

down spring to free toggle lever.

SBR020A

b.Install two bolts as shown. Tighten the two bolts gradually.

SBR214B

2. After removing retainer, remove spring by rotating shoes.

+Be careful not to damage wheel cylinder piston boots.

+Be careful not to damage parking brake cable when sepa-

rating it.

3. Remove adjuster.

4. Disconnect parking brake cable from toggle lever.

SBR329C

5. Remove retainer ring with a suitable tool. Then separate toggle

lever and brake shoe.

SBR330C

Inspection Ð Wheel CylinderNJBR0130+Check wheel cylinder for leakage.

+Check for wear, damage and loose conditions. Replace if any

such condition exists.

REAR DRUM BRAKE

Removal (Cont'd)

BR-32

Page 562 of 2898

SBR219C

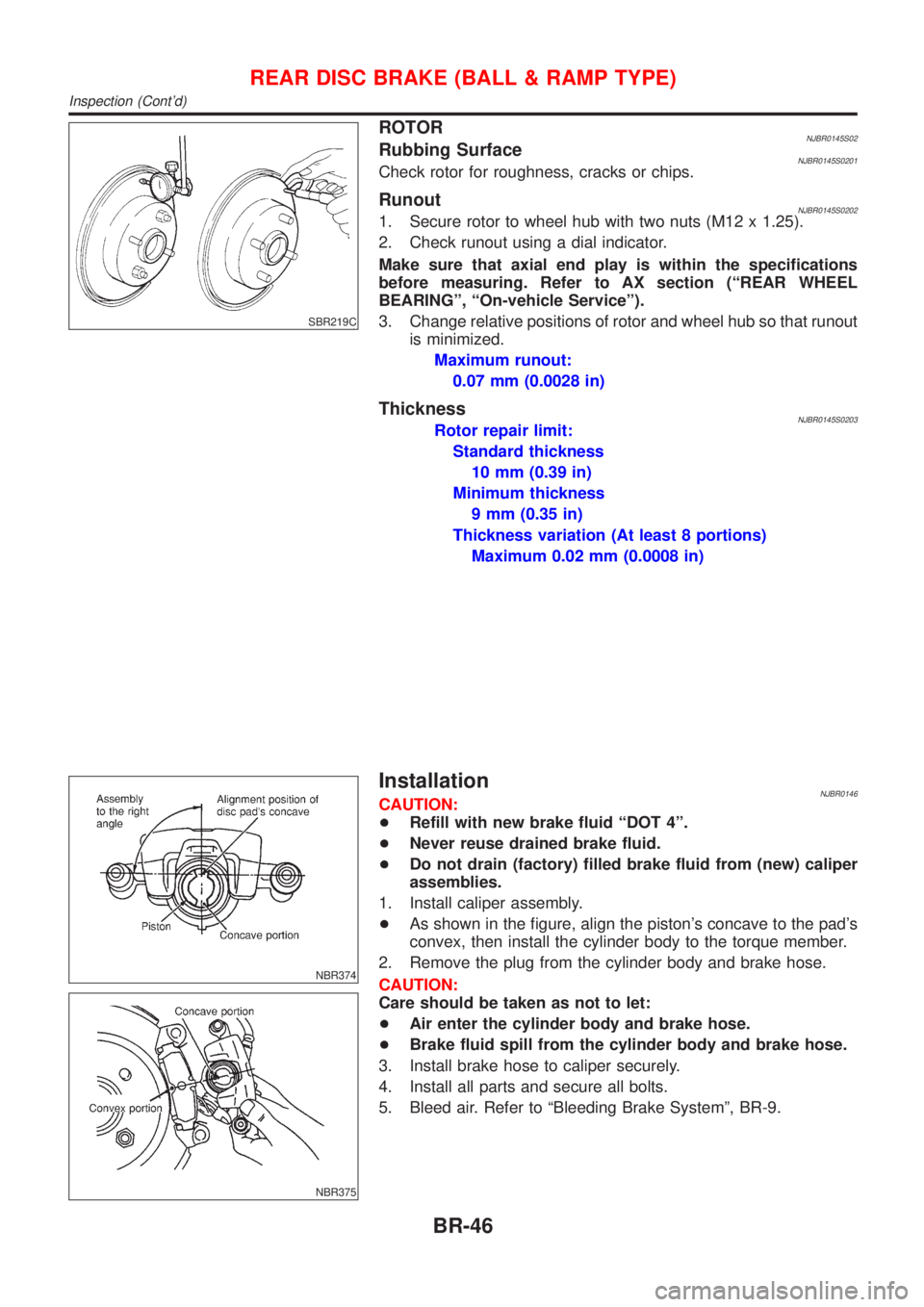

ROTORNJBR0145S02Rubbing SurfaceNJBR0145S0201Check rotor for roughness, cracks or chips.

RunoutNJBR0145S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (ªREAR WHEEL

BEARINGº, ªOn-vehicle Serviceº).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNJBR0145S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

NBR374

NBR375

InstallationNJBR0146CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

+Do not drain (factory) filled brake fluid from (new) caliper

assemblies.

1. Install caliper assembly.

+As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

2. Remove the plug from the cylinder body and brake hose.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

3. Install brake hose to caliper securely.

4. Install all parts and secure all bolts.

5. Bleed air. Refer to ªBleeding Brake Systemº, BR-9.

REAR DISC BRAKE (BALL & RAMP TYPE)

Inspection (Cont'd)

BR-46

Page 625 of 2898

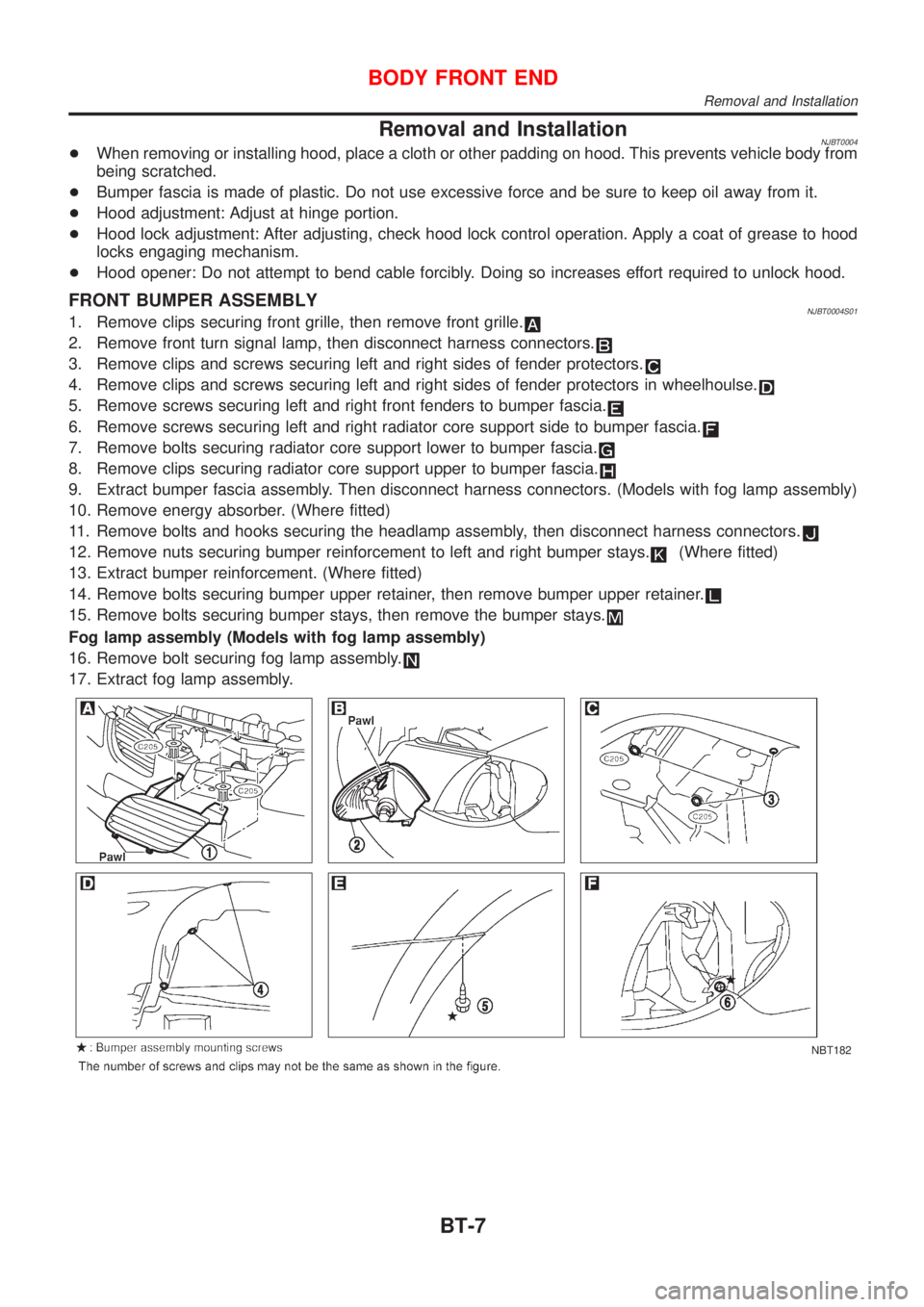

Removal and InstallationNJBT0004+When removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body from

being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

FRONT BUMPER ASSEMBLYNJBT0004S011. Remove clips securing front grille, then remove front grille.

2. Remove front turn signal lamp, then disconnect harness connectors.

3. Remove clips and screws securing left and right sides of fender protectors.

4. Remove clips and screws securing left and right sides of fender protectors in wheelhoulse.

5. Remove screws securing left and right front fenders to bumper fascia.

6. Remove screws securing left and right radiator core support side to bumper fascia.

7. Remove bolts securing radiator core support lower to bumper fascia.

8. Remove clips securing radiator core support upper to bumper fascia.

9. Extract bumper fascia assembly. Then disconnect harness connectors. (Models with fog lamp assembly)

10. Remove energy absorber. (Where fitted)

11. Remove bolts and hooks securing the headlamp assembly, then disconnect harness connectors.

12. Remove nuts securing bumper reinforcement to left and right bumper stays.(Where fitted)

13. Extract bumper reinforcement. (Where fitted)

14. Remove bolts securing bumper upper retainer, then remove bumper upper retainer.

15. Remove bolts securing bumper stays, then remove the bumper stays.

Fog lamp assembly (Models with fog lamp assembly)

16. Remove bolt securing fog lamp assembly.

17. Extract fog lamp assembly.

NBT182

BODY FRONT END

Removal and Installation

BT-7

Page 723 of 2898

SCL466-C

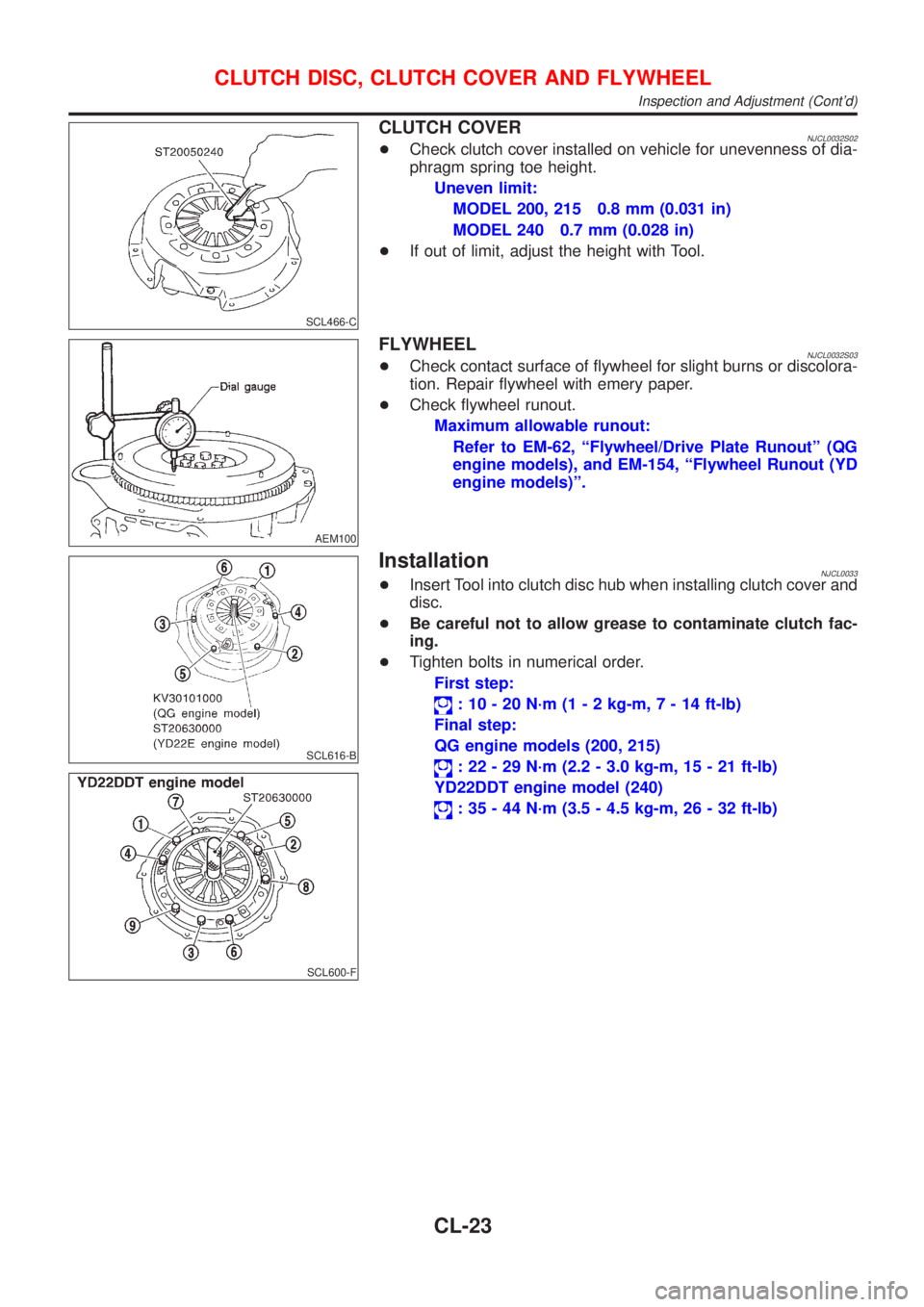

CLUTCH COVERNJCL0032S02+Check clutch cover installed on vehicle for unevenness of dia-

phragm spring toe height.

Uneven limit:

MODEL 200, 215 0.8 mm (0.031 in)

MODEL 240 0.7 mm (0.028 in)

+If out of limit, adjust the height with Tool.

AEM100

FLYWHEELNJCL0032S03+Check contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

+Check flywheel runout.

Maximum allowable runout:

Refer to EM-62, ªFlywheel/Drive Plate Runoutº (QG

engine models), and EM-154, ªFlywheel Runout (YD

engine models)º.

SCL616-B

SCL600-F

InstallationNJCL0033+Insert Tool into clutch disc hub when installing clutch cover and

disc.

+Be careful not to allow grease to contaminate clutch fac-

ing.

+Tighten bolts in numerical order.

First step:

: 10 - 20 N´m (1 - 2 kg-m,7-14ft-lb)

Final step:

QG engine models (200, 215)

: 22 - 29 N´m (2.2 - 3.0 kg-m, 15 - 21 ft-lb)

YD22DDT engine model (240)

: 35 - 44 N´m (3.5 - 4.5 kg-m, 26 - 32 ft-lb)

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Inspection and Adjustment (Cont'd)

CL-23