abs NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 279 of 1701

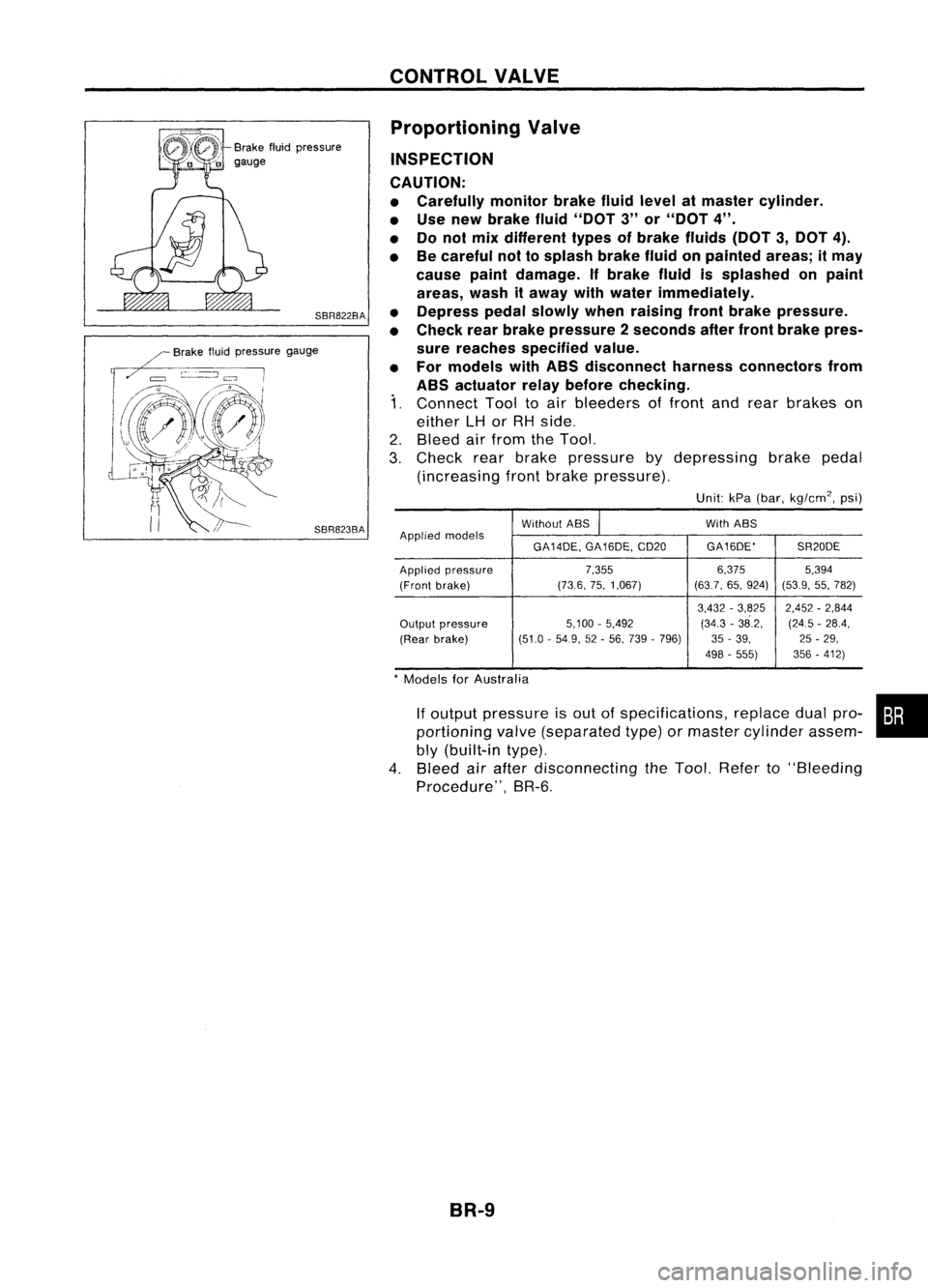

CONTROLVALVE

Proportioning Valve

INSPECTION

CAUTION:

• Carefully monitorbrakefluidlevel atmaster cylinder.

• Use new brake fluid"DOT 3"or"DOT 4".

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

• Becareful nottosplash brakefluidonpainted areas;itmay

cause paintdamage. Ifbrake fluidissplashed onpaint

areas, washitaway withwater immediately.

• Depress pedalslowly whenraising frontbrake pressure.

• Check rearbrake pressure 2seconds afterfront brake pres-

sure reaches specified value.

• For models withABS disconnect harnessconnectors from

ABS actuator relaybefore checking.

1.

Connect Tooltoair bleeders offront andrear brakes on

either

LH

or

RH

side.

2. Bleed airfrom theTool.

3. Check rearbrake pressure bydepressing brakepedal

(increasing frontbrake pressure).

Unit:kPa(bar, kg/cm

2,

psi)

Without ABS

I

With

ABS

Applied models

GA14DE,GA16DE,CD20 GA16DE'

SR20DE

Applied pressure 7.3556.375

5,394

(Front brake) (73.6,

75,1,067) (63.7,65,924)

(53.9,55,782)

3,432 -3,825 2,452-2,844

Output pressure 5,100

-5,492 (34.3-38.2, (245-28.4,

(Rear brake) (51.0

-54.9, 52-56, 739 -796) 35-39, 25-29,

498 -555) 356-412)

*

Models forAustralia

If

output pressure isout ofspecifications, replacedualpro- •••

portioning valve(separated type)ormaster cylinder assem-

bly (built-in type).

4. Bleed airafter disconnecting theTool. Refer to"Bleeding

Procedure", BR-5.

BR-9

Page 282 of 1701

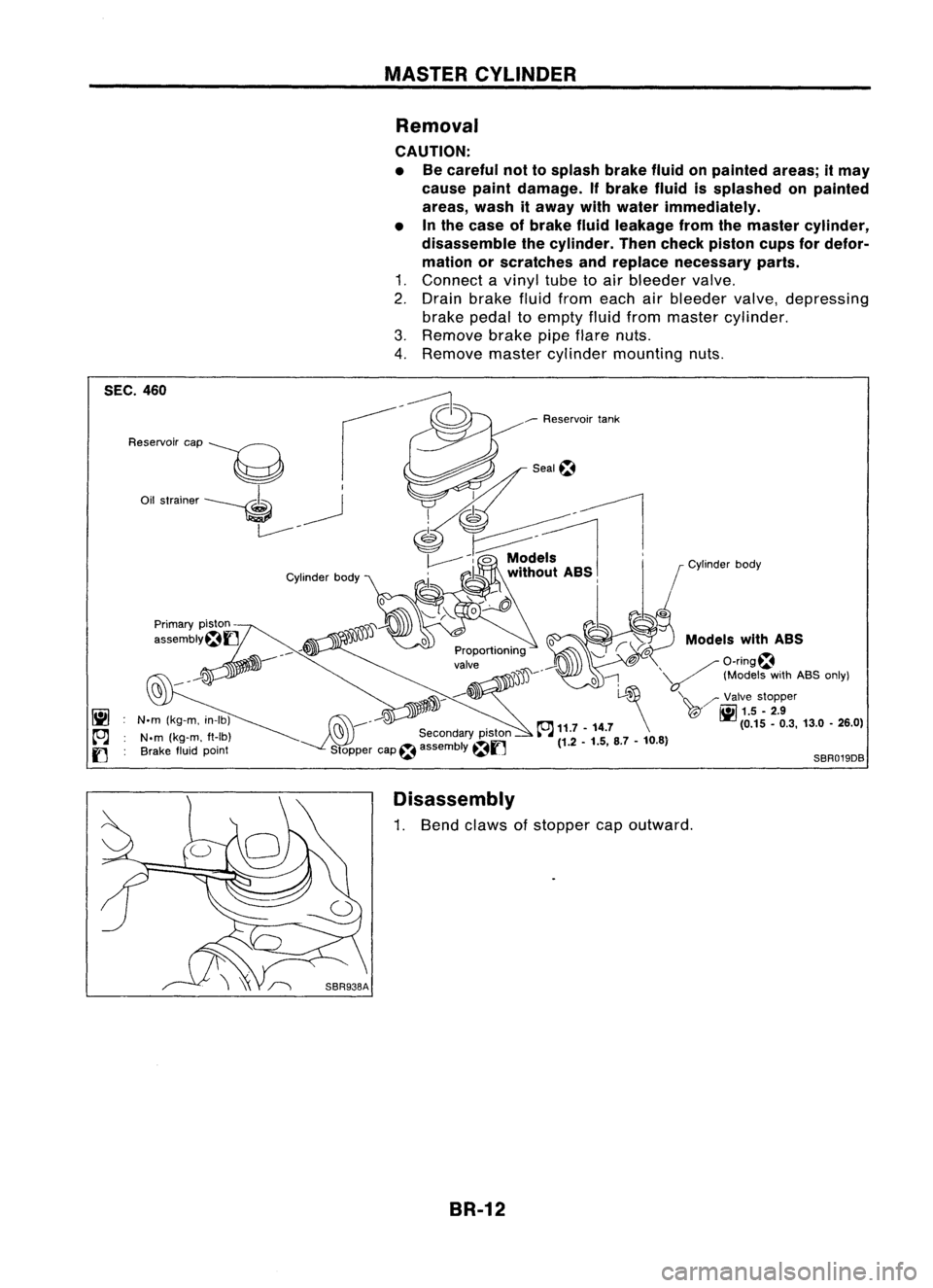

MASTERCYLINDER

Removal

CAUTION:

• Becareful nottosplash brakefluidonpainted areas;itmay

cause paintdamage. Ifbrake fluidissplashed onpainted

areas, washitaway withwater immediately.

• Inthe case ofbrake fluidleakage fromthemaster cylinder,

disassemble thecylinder. Thencheck piston cupsfordefor-

mation orscratches andreplace necessary parts.

1. Connect avinyl tubetoair bleeder valve.

2. Drain brake fluidfrom each airbleeder valve,depressing

brake pedaltoempty fluidfrom master cylinder.

3. Remove brakepipeflare nuts.

4. Remove mastercylinder mounting nuts.

Models withASS

/O-ring~

'V

(ModelswithABS only)

'\~ /'Valve stopper

T@" ~

1.5.2.9

(0.15.0.3, 13.0•26.0)

o

l-~

~ 11.7 -14.7 \

(1.2 -1.5, 8.7-10.8)

SBR019DB

Seal~

___

Reservoir tank

jJ'JD~----

~ ..-:'J

C'9 ---

Secondarypiston

Stopper cap~assembly

~f]

Cylinder

body

N.m (kg-m, in-Ib)

N.m (kg-m. ft-Ib)

Brake fluidpoint

Reservoir

cap

----g

Oil strainer ----. ~

L------- -

SEC.

460

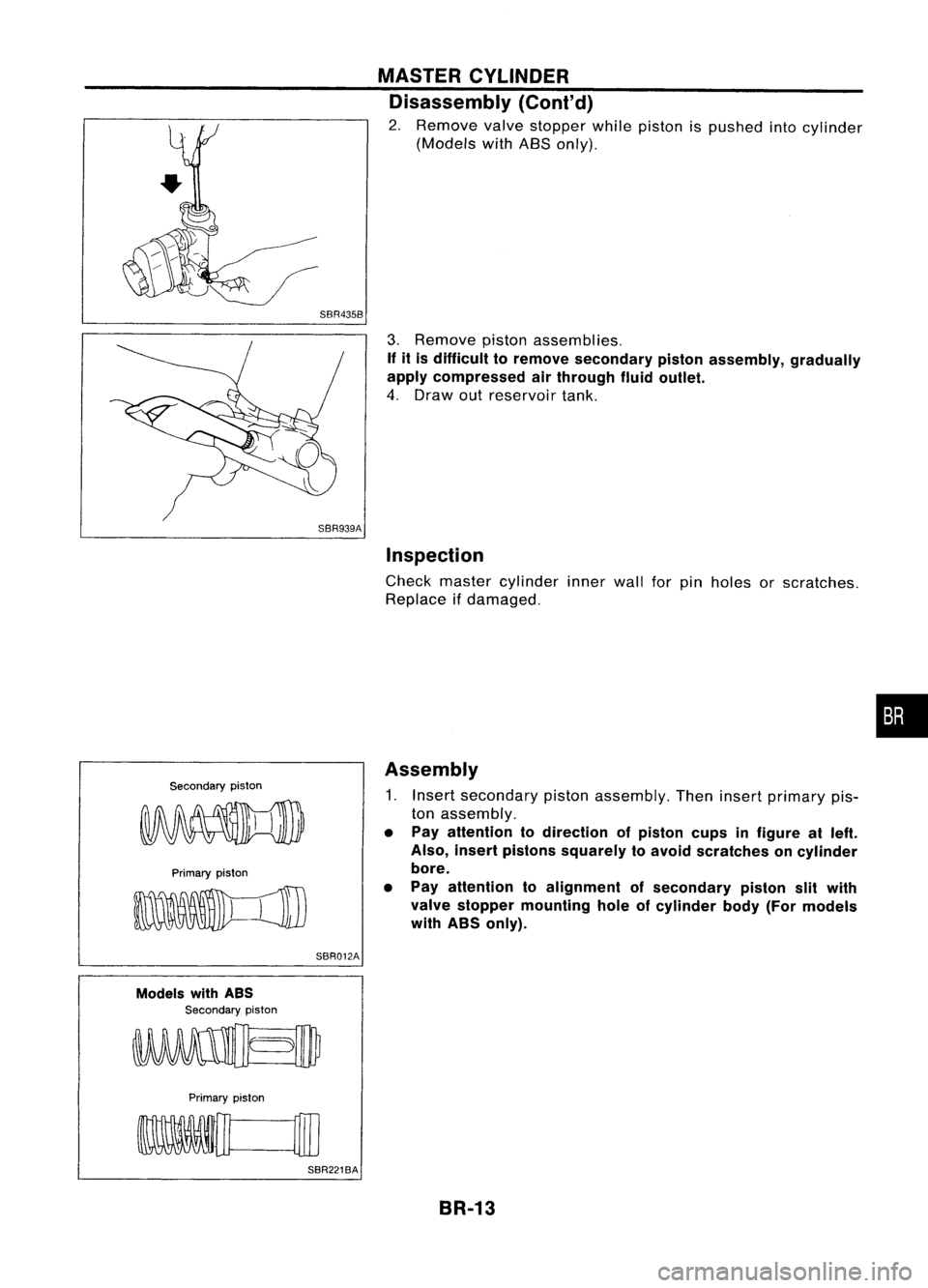

Disassembly

1. Bend claws ofstopper capoutward.

BR-12

Page 283 of 1701

SBR435B

SBR939A

Secondary piston

Primary piston

SBR012A

Models withABS

Secondary piston

Primary piston

_-rnIJ

SBR221BAMASTER

CYLINDER

Disassembly (Cont'd)

2. Remove valvestopper whilepiston ispushed intocylinder

(Models withASS only).

3. Remove pistonassemblies.

If itis difficult toremove secondary pistonassembly, gradually

apply compressed airthrough fluidoutlet.

4. Draw outreservoir tank.

Inspection

Check master cylinder innerwallforpin holes orscratches.

Replace ifdamaged.

Assembly

1. Insert secondary pistonassembly. Theninsert primary pis-

ton assembly.

• Pay attention todirection ofpiston cupsinfigure atleft.

Also, insert pistons squarely toavoid scratches oncylinder

bore.

• Pay attention toalignment ofsecondary pistonslitwith

valve stopper mounting holeofcylinder body(Formodels

with ABS only).

BR-13

•

Page 284 of 1701

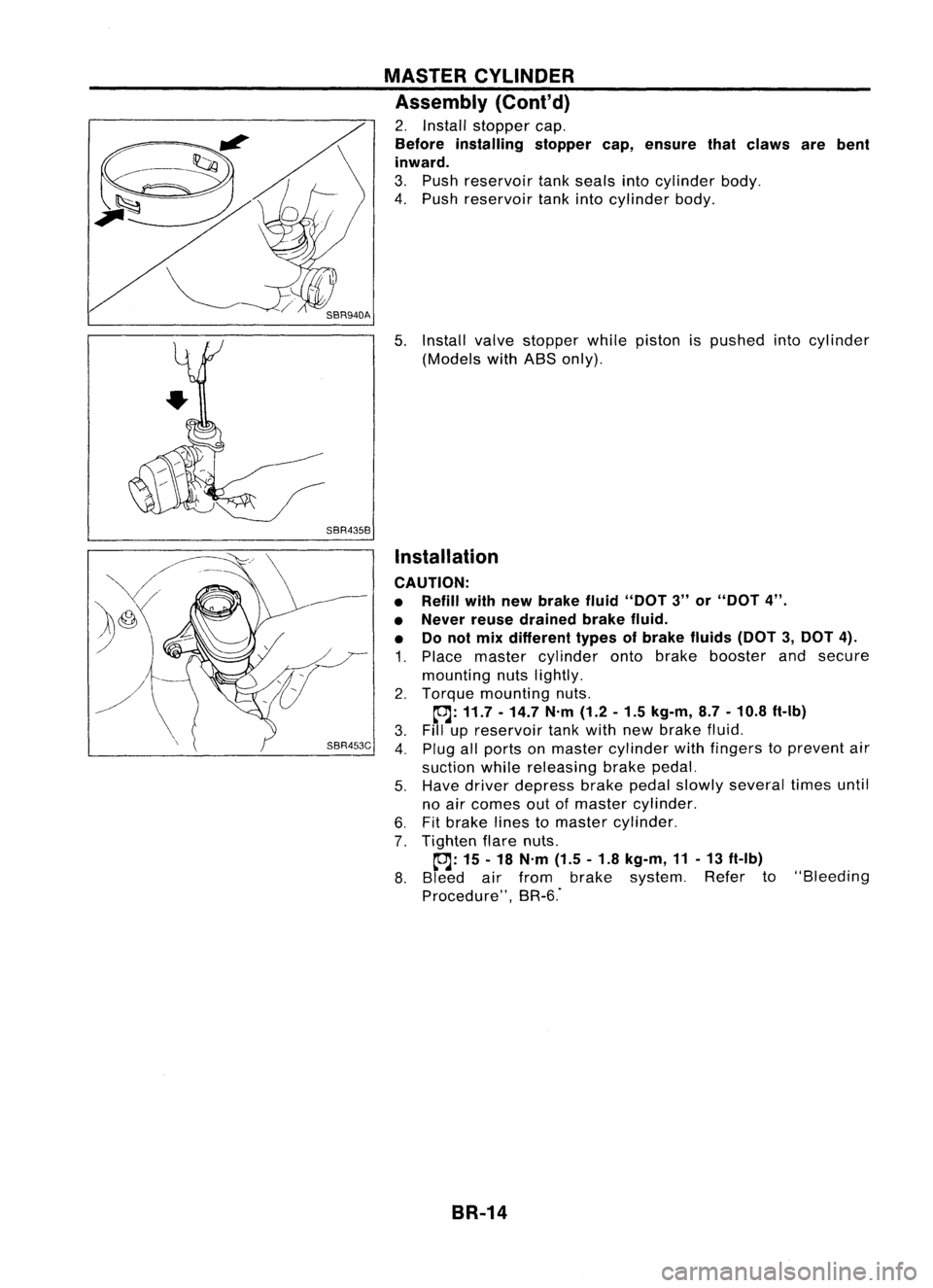

SBR435BMASTER

CYLINDER

Assembly (Cont'd)

2. Install stopper cap.

Before installing stoppercap,ensure thatclaws arebent

inward.

3. Push reservoir tankseals intocylinder body.

4. Push reservoir tankintocylinder body.

5. Install valvestopper whilepiston ispushed intocylinder

(Models withABS only).

Installation

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

1. Place master cylinder ontobrake booster andsecure

mounting nutslightly.

2. Torque mounting nuts.

~: 11.7 -14.7 N'm(1.2-1.5 kg-m, 8.7-10.8 ft-Ib)

3. Fillupreservoir tankwith newbrake fluid.

4. Plug allports onmaster cylinder withfingers toprevent air

suction whilereleasing brakepedal.

5. Have driver depress brakepedalslowly several timesuntil

no air comes outofmaster cylinder.

6. Fitbrake linestomaster cylinder.

7. Tighten flarenuts.

~: 15-18 N'm (1.5-1.8 kg-m, 11-13 ft-Ib)

8. Bleed airfrom brake system. Referto"Bleeding

Procedure", BR-6."

BR-14

Page 286 of 1701

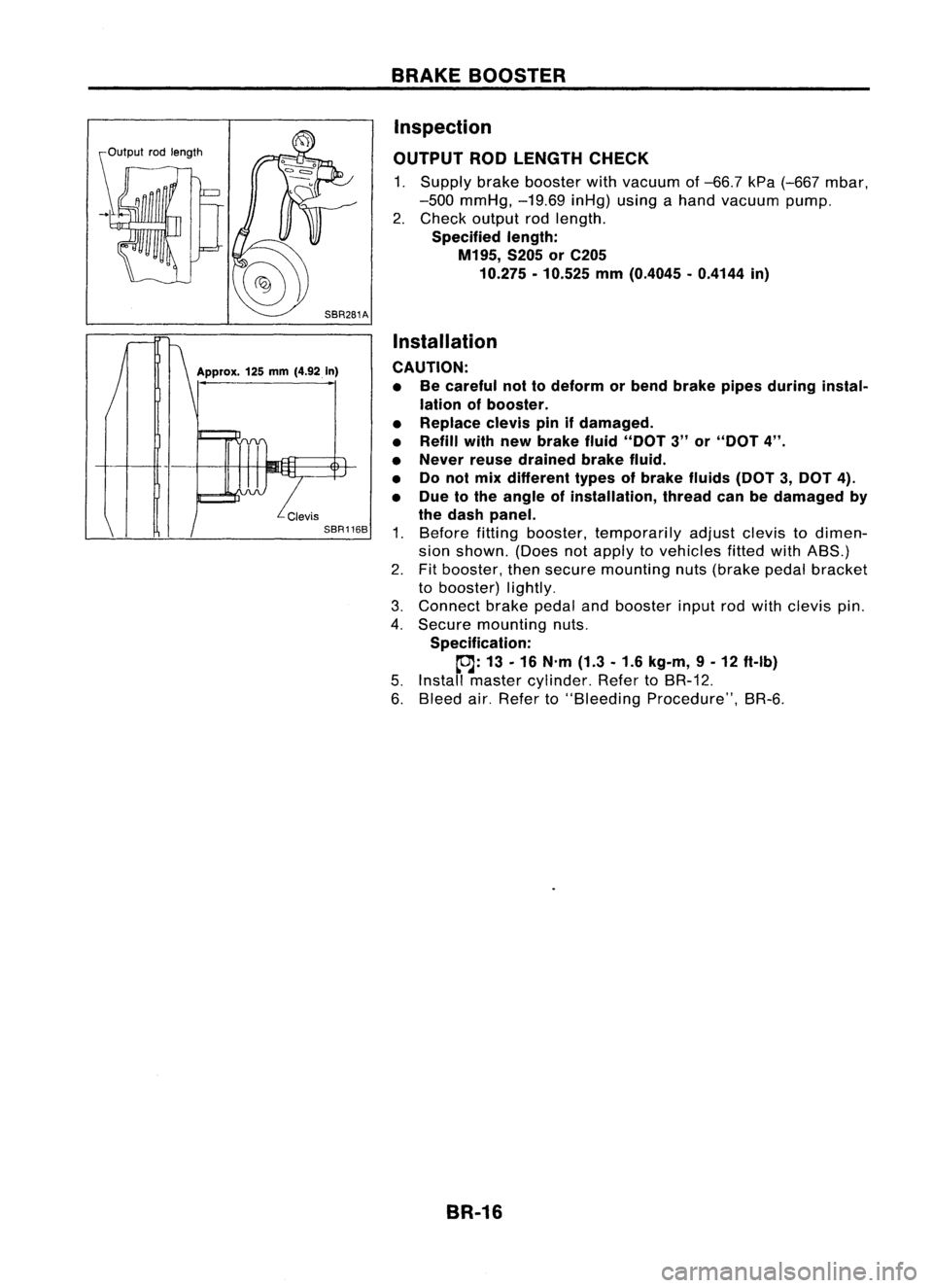

Approx.125mm (4.92 In) BRAKE

BOOSTER

Inspection

OUTPUT RODLENGTH CHECK

1. Supply brakebooster withvacuum of-66.7 kPa(-667 mbar,

-500 mmHg, -19.69inHg)usingahand vacuum pump.

2. Check output rodlength.

Specified length:

M195, S205orC205

10.275 -10.525 mm(0.4045 -0.4144 in)

Installation

CAUTION: • Becareful nottodeform orbend brake pipesduring instal-

lation ofbooster.

• Replace clevispinifdamaged.

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Never reusedrained brakefluid.

• Donol mix different typesofbrake fluids(DOT3,DOT 4).

• Due tothe angle ofinstallation, threadcanbedamaged by

the dash panel.

1. Before fittingbooster, temporarily adjustclevistodimen-

sion shown. (Doesnotapply tovehicles fittedwithABS.)

2. Fitbooster, thensecure mounting nuts(brake pedalbracket

to booster) lightly.

3. Connect brakepedalandbooster inputrodwith clevis pin.

4. Secure mounting nuts.

Specification:

~: 13-16 N'm (1.3-1.6 kg-m, 9-12 ft-Ib)

5. Install master cylinder. RefertoBR-12.

6. Bleed air.Refer to"Bleeding Procedure", BR-6.

BR-16

Page 308 of 1701

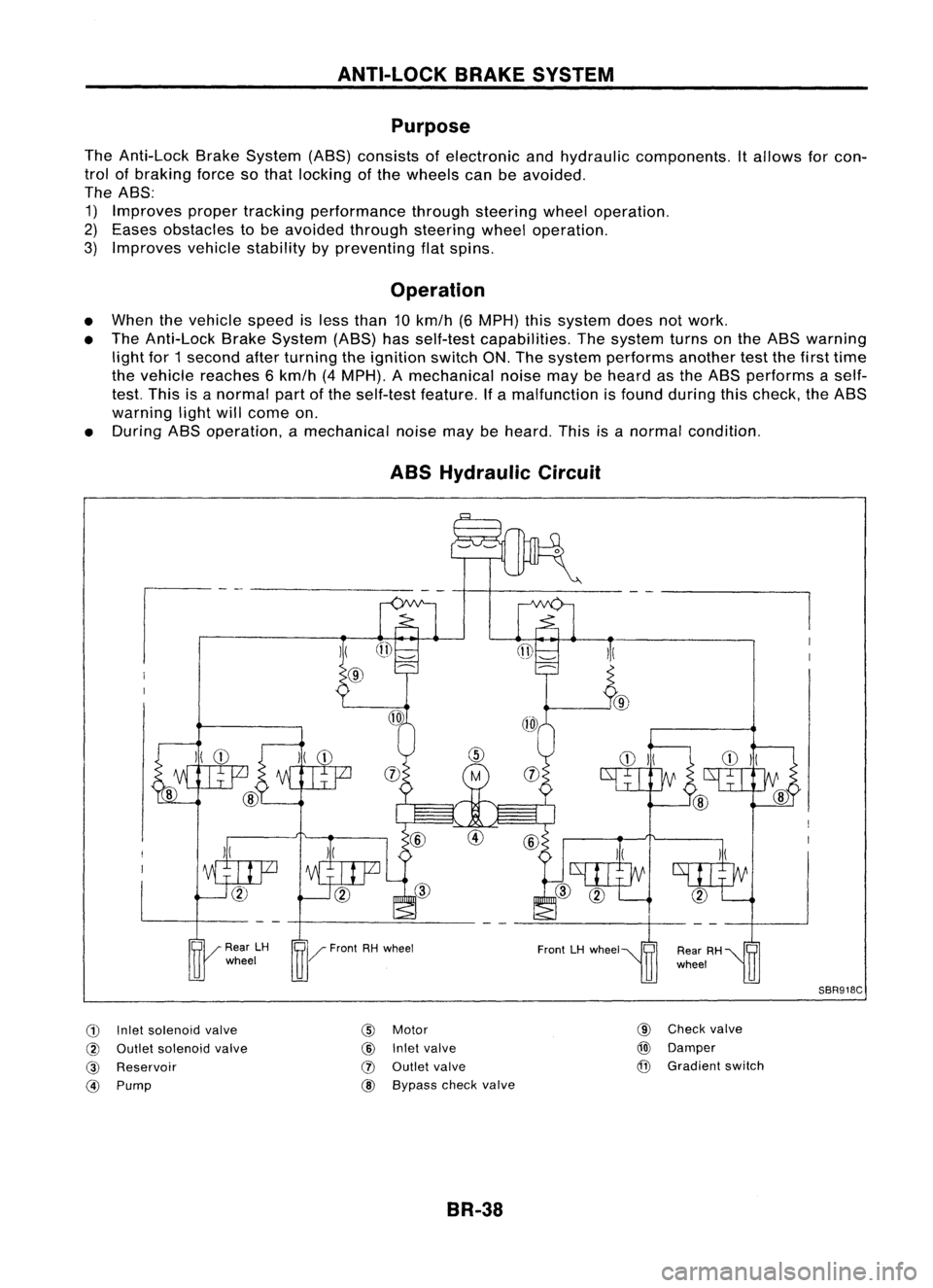

ANTI-LOCKBRAKESYSTEM

Purpose

The Anti-Lock BrakeSystem (ABS)consists ofelectronic andhydraulic components. Itallows forcon-

trol ofbraking forcesothat locking ofthe wheels canbeavoided.

The ABS:

1) Improves propertracking performance throughsteering wheeloperation.

2) Eases obstacles tobe avoided throughsteering wheeloperation.

3) Improves vehiclestability bypreventing flatspins.

Operation

• When thevehicle speedisless than 10km/h (6MPH) thissystem doesnotwork.

• The Anti-Lock BrakeSystem (ABS)hasself-test capabilities. Thesystem turnsonthe ABS warning

light for1second afterturning theignition switchON.The system performs anothertestthefirst time

the vehicle reaches 6km/h (4MPH). Amechanical noisemaybeheard asthe ABS performs aself-

test. This isanormal partofthe self-test feature.Ifa malfunction isfound during thischeck, theABS

warning lightwillcome on.

• During ABSoperation, amechanical noisemaybeheard. Thisisanormal condition.

ABS Hydraulic Circuit

G)

Inletsolenoid valve

@

Outlet solenoid valve

@

Reservoir

@)

Pump

)(

@

@

Motor

@

Inletvalve

(J)

Outlet valve

@ Bypass checkvalve

BR-38 @

Check valve

@)

Damper

@

Gradient switch

SBR918C

Page 310 of 1701

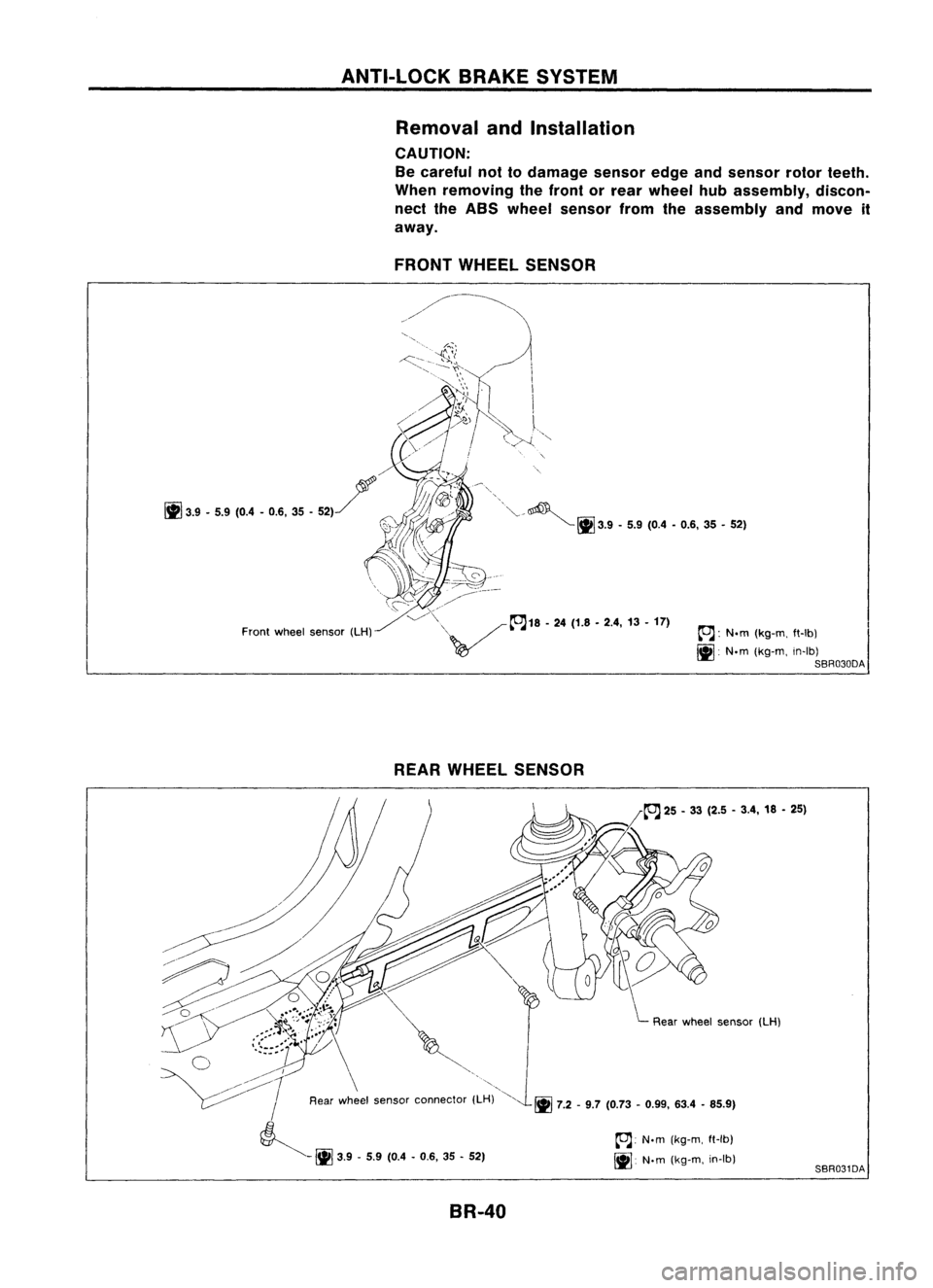

ANTI-LOCKBRAKESYSTEM

Removal andInstallation

CAUTION: Be careful nottodamage sensoredgeandsensor rotorteeth.

When removing thefront orrear wheel hubassembly, discon-

nect theABS wheel sensor fromtheassembly andmove it

away.

FRONT WHEEL SENSOR

Front wheel sensor (LH) ~!Ii

3.9-5.9 (0.4 -0.6, 35-52)

~: Nom (kg-m, ft-lb)

~: Nom(kg-m, in-Ib)

SBR030DA

REAR WHEEL SENSOR

BR-40

\

L

Rear wheel sensor (LH)

~: Nom (kg-m, ft-Ib)

~: Nom(kg-m, in-Ib)

SBR031DA

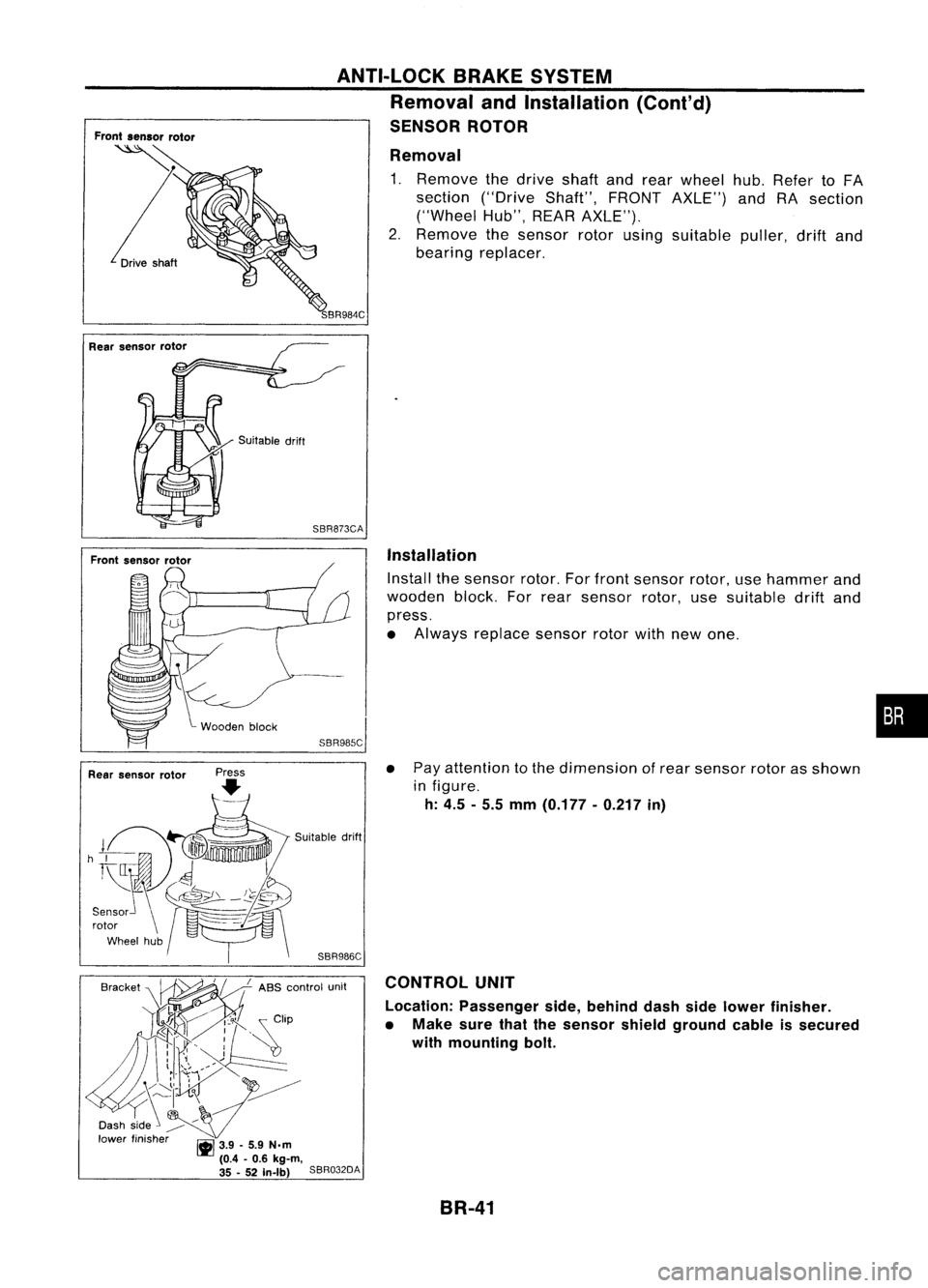

Page 311 of 1701

ANTI-LOCKBRAKESYSTEM

Removal andInstallation (Cont'd)

SENSOR ROTOR

Removal

1. Remove thedrive shaftandrear wheel hub.Refer toFA

section ("DriveShaft",FRONTAXLE") andRAsection

("Wheel Hub",REARAXLE").

2. Remove thesensor rotorusing suitable puller,driftand

bearing replacer.

Suitable drift

SBR873CA

Installation

Install thesensor rotor.Forfront sensor rotor,usehammer and

wooden block.Forrear sensor rotor,usesuitable driftand

press.

• Always replace sensorrotorwithnewone.

SBR985C

•

• Pay attention tothe dimension ofrear sensor rotorasshown

in figure.

h: 4.5 -5.5 mm (0.177 -0.217 in)

CONTROL UNIT

Location: Passenger side,behind dashsidelower finisher.

• Make surethatthesensor shieldground cableissecured

with mounting bolt.

SBR986C

Suitable

drift

B,.,k" ~ ABS

.'0"'" ","

Dash side ~

lower finisher ~3.9_5.9 N.m

(0.4 -0.6 kg-m,

35 -52 In-Ib)

SBR032DA

Rear

sensor rotor

BR-41

Page 312 of 1701

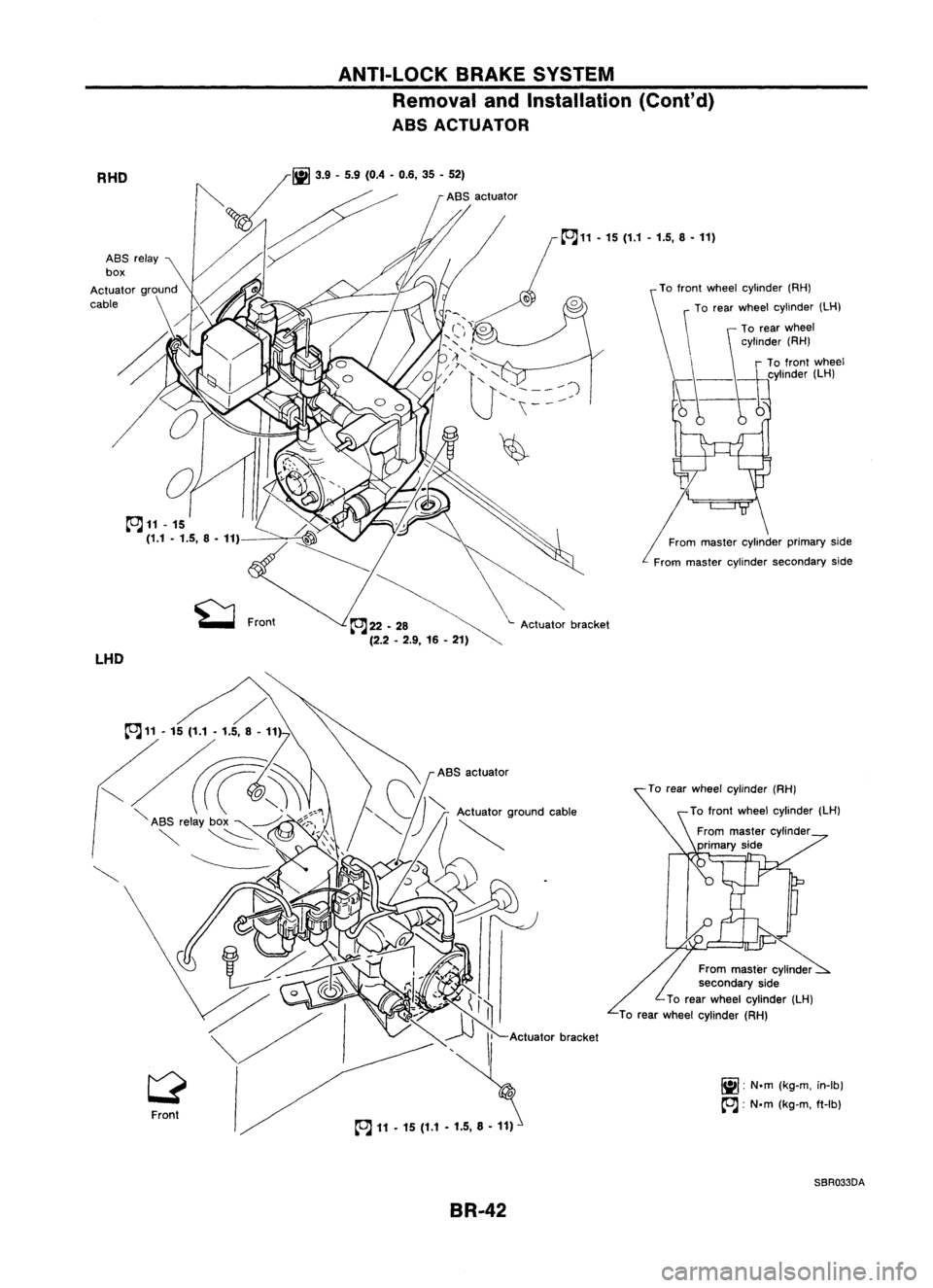

,ryside

linder prima

From master cy ndaryside

r

der seco

master cyIn

From

RHO

cc:J

11-15 .11)

(1.1 .

1.5, 8

~ Front

LHO

ASS

relay

box

ground

Actuator

cable

---------~~~~~:A~K~EirS;V~S~T~EWo.M;(c:O;;~'diij)I----

ANTI-LOCK

BRdInstallation (Cont

Removal an

ABS ACTUATOR

heelcylinder (RH)

To rear

W

clinder (LH)

f ntwheel y

To ro

aster cylinder

From m

primary side

aster cylinder

From m 'de

secondary

Sl

(LH)

Wheel cylinder

To rear

W

heel cylinder (RH)

To

rear

(kg-m.in-Ib)

r.ii1

'N.m

IX! '

(kg-m. ft-Ib)

cc:J:

N.m

SBR033DA

BR-42

Page 314 of 1701

ANTI-LOCKBRAKESYSTEM

Removal andInstallation (Cont'd)

10. Draw outASS actuator asshown.

ASS

actuator

SBR039D CAUTION:

After installation, payattention tothe following points:

• Refill brake fluidandbleed air.Refer to"CHECK AND

ADJUSTMENT", BR-5and"AIR BLEEDING", BR.6,respec-

tively.

• Charge airconditioner refrigerant.RefertoHA section,

("R-134a ServiceProcedure", "SERVICEPROCEDURES").

• The installation procedureisthe reverse ofremoval.

ASS

actuator

_-=--=--=--=--_-_-\,_~

""'~t"

b"ok.,

SBR040D

ABSRELAYS

1. Disconnect batterycable.

2. Remove ASSrelay cover.

BR-44