correct NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 790 of 1701

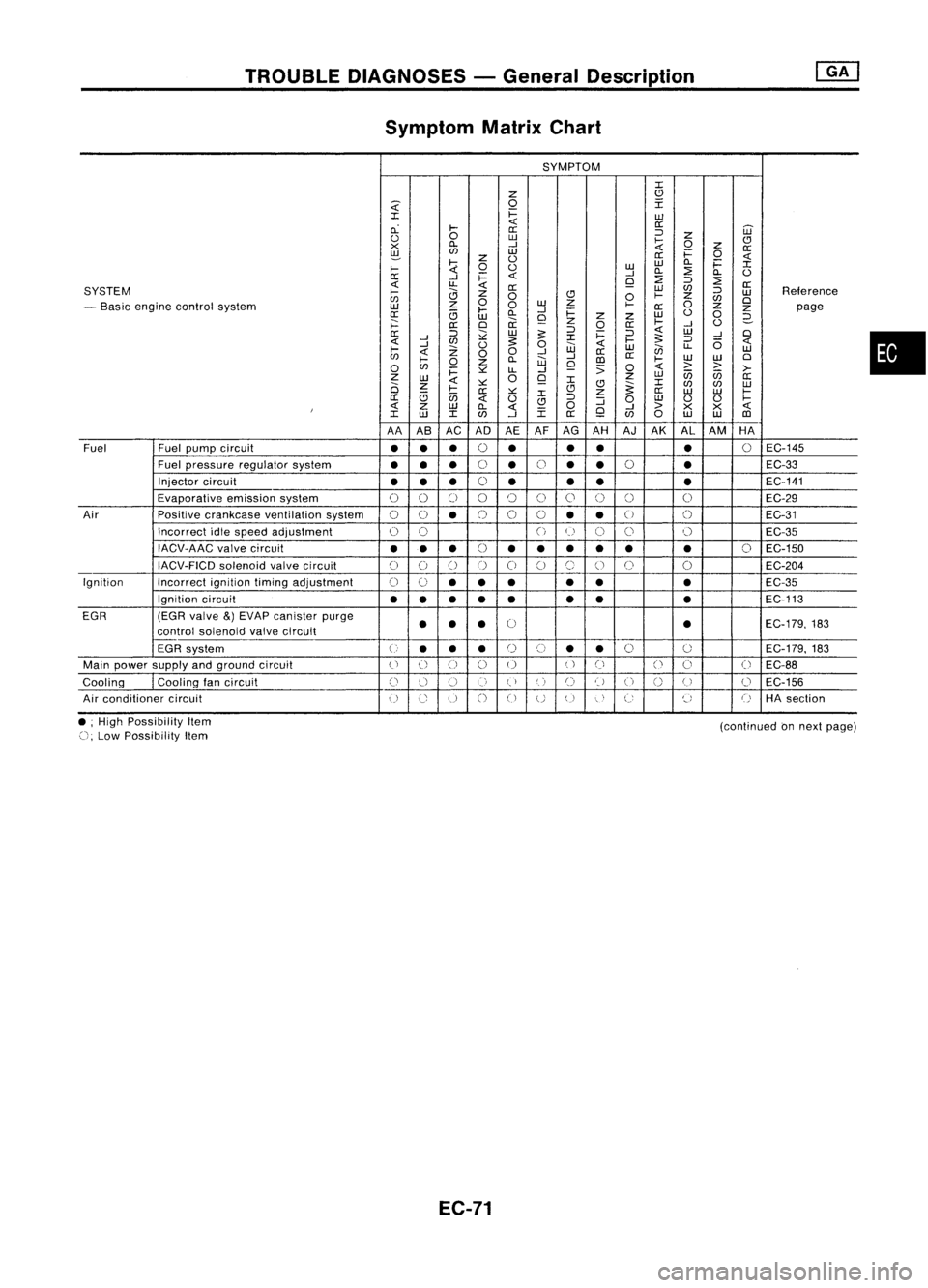

TROUBLEDIAGNOSES -General Description

Symptom MatrixChart

SYMPTOM

:c

z

(!l

~

0

I

:c

i=

w

cL

~

<{

0::

0::

='

W

<.)

0

w

~

z

CJ

x

Cl.

-I

0

Z

0::

~

en

w

i=

0

z

<.)

0::

<{

~

0

<.)

w

w

Cl.

i=

:c

~

-I

Cl.

::?

Cl.

<.)

0::

-I

i=

<{

Q

::?

=' ::?

<{

u..

<{

0::

SYSTEM

0::

W

en

='

Reterence

~

0

CJ

0

~

z

w

en

0

w

z

0

en

0

- Basic engine control system

w

z

0

~

0::

Z

Z

page

0::

<3

~

Cl.

-I

i=

w

<.)

0

w

Q

z

z

2-

j:::

0::

0

ii

z

0

0::

~

-I

<.)

0::

='

;;:

w

:s:

='

i=

='

<{

W

-I

0

<{

-I

en

:s:

:c

~

:s:

='

6

<{

-I

Z

<.)

0

w

<{

w

en

u..

w

~

<{

00

-I

0::

en

~

Cl.

W

-I

III

0::

~

W

W

0

0

en

0

z

Q

:;

0

<{

> >

i=

~

LL

-I

>-

Z

W

0

Q

z

w

U5 U5

0::

2i

z

<{

~ :c

(!l

~:c

en en

w

<3

~

0::

~

:c

CJ

z

0::

W W

~

0::

U5

<{

<.)

CJ

='

:J

0

w

<.)

<.)

~

I

<{

Z

W

Cl.

<{

0

Q

-I

>

X

X

<{

:c

w

:c

en

-I

:c

0::

en

0

w

W

III

AA AB AC ADAEAFAG

AH AJ

AK AL

AM HA

Fuel Fuel

pump circuit

••

•

0

•

•

•

•

0

EC-145

Fuel pressure regulator system

•••

0

•

0

•

•

0

•

EC-33

Injector circuit

•• •

0

• •

• •

EC-141

Evaporative emissionsystem

00

[)

00

()

0

0 0 0

EC-29

Air Positivecrankcase ventilation system

00

•

0

0

0

••

U

()

EC-31

Incorrect idlespeed adjustment

0

0

()

(~)

C)

0 0

EC-35

IACV-AAC valvecircuit

•••

(,

••• •• •

0

EC-150

~)

IACV-FICD solenoidvalvecircuit

C)

()

()

()

0

C)

(~,

()

0

0

EC-204

Ignition Incorrectignitiontimingadjustment

0

0

•• •

•

• •

EC-35

Ignition circuit

••

•

•

• •

•

•

EC-113

EGR (EGRvalve

&)

EVAP canister purge

0

EC-179,183

control soienoid valvecircuit

••

• •

EGR system

U

••

•

r)

(,)

•

•

0

0

EC-179.

183

Main power supply andground circuit

()

() ()

0 0

()

Ci

()

0

(

~

EC-88

Cooling

I

Cooling tancircuit

()

:.'-1

U

()

(,)

',)

C)

t)

U

n

(J

0

EC-156

u

Air conditioner circuit

()

Co

u

()

CJ

UU

"

,

C:

~,

()

HAsection

•

• ;High Possibility Item

(), Low Possibility Item

EC-71

(continued

onnext page)

Page 791 of 1701

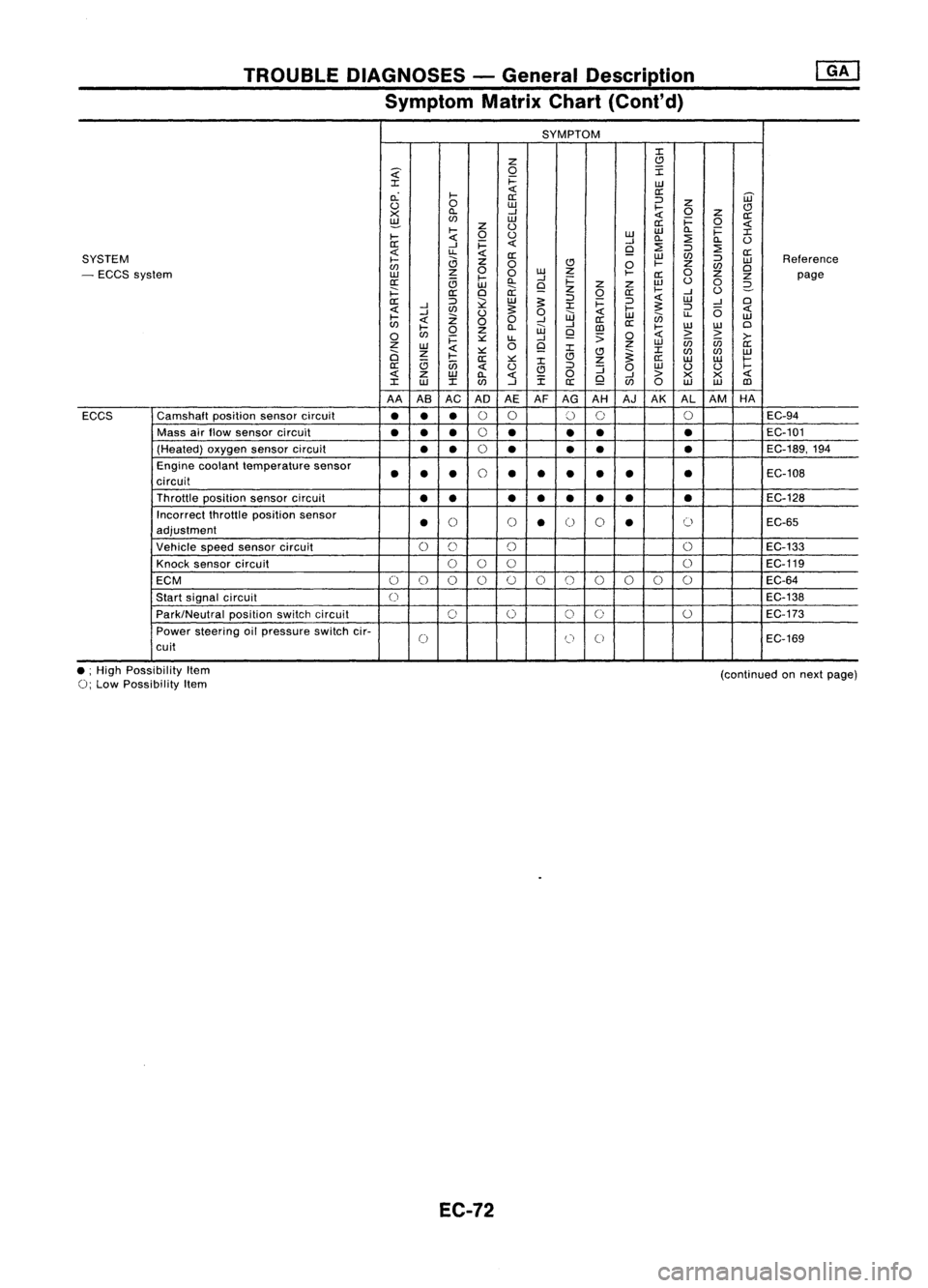

TROUBLEDIAGNOSES -General Description

Symptom MatrixChart(Cont'd)

SYMPTOM

:I:

Z

C)

~

0

I

:I:

i=

UJ

c.:

I-

«

a:

[ij'

a:

:J

u

0

UJ

I-

Z

C)

X

ll.

--l

«

0

z

a:

~

(f)

UJ

a:i=

0

«

I-

z

U

UJ

ll.

i=

:I:

I-

«

0

u

UJ

ll.

:2

ll.

U

a:

--l

i=

«

--l

:2

9

:J

:2

«

u.

«

a:

UJ

(f)

a:

SYSTEM

I-

a

z

:J

UJ

Reference

(f)

0

C)

0

I-

Z

(f)

Cl

- ECCS system

UJ

z

0

0

w

Z

I-

a:

0

z

z

page

a:

c;

l-

ll.

--l

i=

w

u

0

UJ

9

z

z

2-

i==:

a:

Cl

ii:

z

0

a:

I-

--l

U

a::

:J

l2

UJ

~

:J

i=

:J

«

UJ

--l

Cl

«

--l

(f)

~

:I:

I-

~

:J

(5

«

I-

--l

Z

U

0

UJ

«

UJ

en

u.

UJ

«

00

--l

a::

(f)

l-

ll.

W

--l

[])

a::

I-

w

W

Cl

0

(f)

0

z

9

;;

0

«

>

>

>-

i=

::.::

u.

--l

Z

0

9

z

UJ

in in

a::

UJ

«

:I:

:I:

a

z

I-

::.::

C)C)

~

(f)

(f)

UJ

a::

::.::

:I:

z

a::

UJ UJ

I-

a::

c;

in

«

u

C)

:J

:J

0

UJ

U U

I-

«

z

UJ

ll.

«

i

0

9

--l

>

X X

«

:I:

w

:I:(f)

--l

a::

(f)

0

UJ UJ

[])

AA ASAC AD AEAFAG AH AJAK ALAM HA

ECCS Camshaft

positionsensorcircuit

•••

0

0

()

0 0

EC-94

Mass airflow sensor circuit

••

•

0

•

••

•

EC-101

(Heated) oxygensensorcircuit

••

0

• •

•

•

EC-189,194

Engine coolant temperature sensor

••

•

0

••

•

•

•

•

EC-108

circuit

Throttle position sensorcircuit

•• ••• ••

•

EC-128

Incorrect throttleposition sensor

•

()

()

•

0

0

•

()

EC-65

adjustment

Vehicle speedsensor circuit

0

C)

()

0

EC-133

Knock sensor circuit

000 0

EC-119

ECM

0

()

0 0

()

0

()

()()

0 0

EC-64

Start signal circuit

0

EC-138

Park/Neutral positionswitchcircuit

0

0

0

0

0

EC-173

Power steering oilpressure switchcir-

0

(J

0

EC-169

cuit

• ;High Possibility Item

0;

Low Possibility Item

EC-72

(continued

onnext page)

Page 977 of 1701

![NISSAN ALMERA N15 1995 Owners Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

Monitored item ECM

Main

[Unit] input

signals Description

Remarks

signals

AIR COND SIG •Indicates [ON/OFF] conditionofthe

[ON/OFF]

00

air

NISSAN ALMERA N15 1995 Owners Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

Monitored item ECM

Main

[Unit] input

signals Description

Remarks

signals

AIR COND SIG •Indicates [ON/OFF] conditionofthe

[ON/OFF]

00

air](/img/5/57349/w960_57349-976.png)

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

Monitored item ECM

Main

[Unit] input

signals Description

Remarks

signals

AIR COND SIG •Indicates [ON/OFF] conditionofthe

[ON/OFF]

00

air

conditioner switchasdetermined

by the airconditioning signal.

PIN POSI SW

00

•

Indicates [ON/OFF] conditionfromthe

[ON/OFF] park/neutralpositionswitchsignal.

PW/ST SIGNAL •Indicates [ON/OFF] conditionofthe

[ON/OFF]

00

power

steering oilpressure switch

determined bythe power steering oil

pressure signal.

INJ PULSE [msec]

0

•

Indicates theactual fuelinjection •

When theengine isstopped, acertain

pulse widthcompensated byECM computedvalueisindicated.

according tothe input signals.

IGN TIMING [BTDC]

0

•

Indicates theignition timingcomputed

by ECM according tothe input sig-

nals.

IACV-AACIV

[%]

•Indicates theidle aircontrol valve

0

(AAC

valve) control valuecomputed

by ECM according tothe input sig-

nals.

A/F ALPHA [%J •Indicates themean valueofthe air- •When theengine isstopped, acertain

0

fuel

ratio feedback correction factor valueisindicated.

per cycle. •This dataalsoincludes thedata for

the air-fuel ratiolearning control.

AIR COND RLY •Indicates theairconditioner relay

[ON/OFF]

0

control

condition (determined byECM

according tothe input signal).

FUEL PUMP RLY •Indicates thefuel pump relaycontrol

[ON/OFFJ

0

condition

determined byECM accord-

ing tothe input signals.

COOLING FAN

•Indicates thecontrol condition ofthe

[HI/LOW/OFFJ coolingfans(determined byECM

0

according

tothe input signal).

HI ...High speed operation

LOW ...Low speed operation

OFF ...Stopped

EGRC SOLIV •Indicates thecontrol condition ofthe

[ON/OFFJ EGR

valve

&

EVAP canister Purge

control solenoid valve(determined by

0

ECM

according tothe input signal).

ON ...EGR andEVAP canister purge

operation cut-off

OFF ...EGR andEVAP canister purge

operation notcut-off

VOLTAGE •Voltage measured bythe voltage

[V] probe.

PULSE •Pulse width, frequency orduty cycle •Only "#"isdisplayed ifitem is

[msec] or[Hz] or

measuredbythe pulse probe. unabletobe measured.

[%]

•Figures with"#"s aretemporary

ones. Theyarethesame figures as

an actual pieceofdata which wasjust

previously measured.

EC-258

Page 993 of 1701

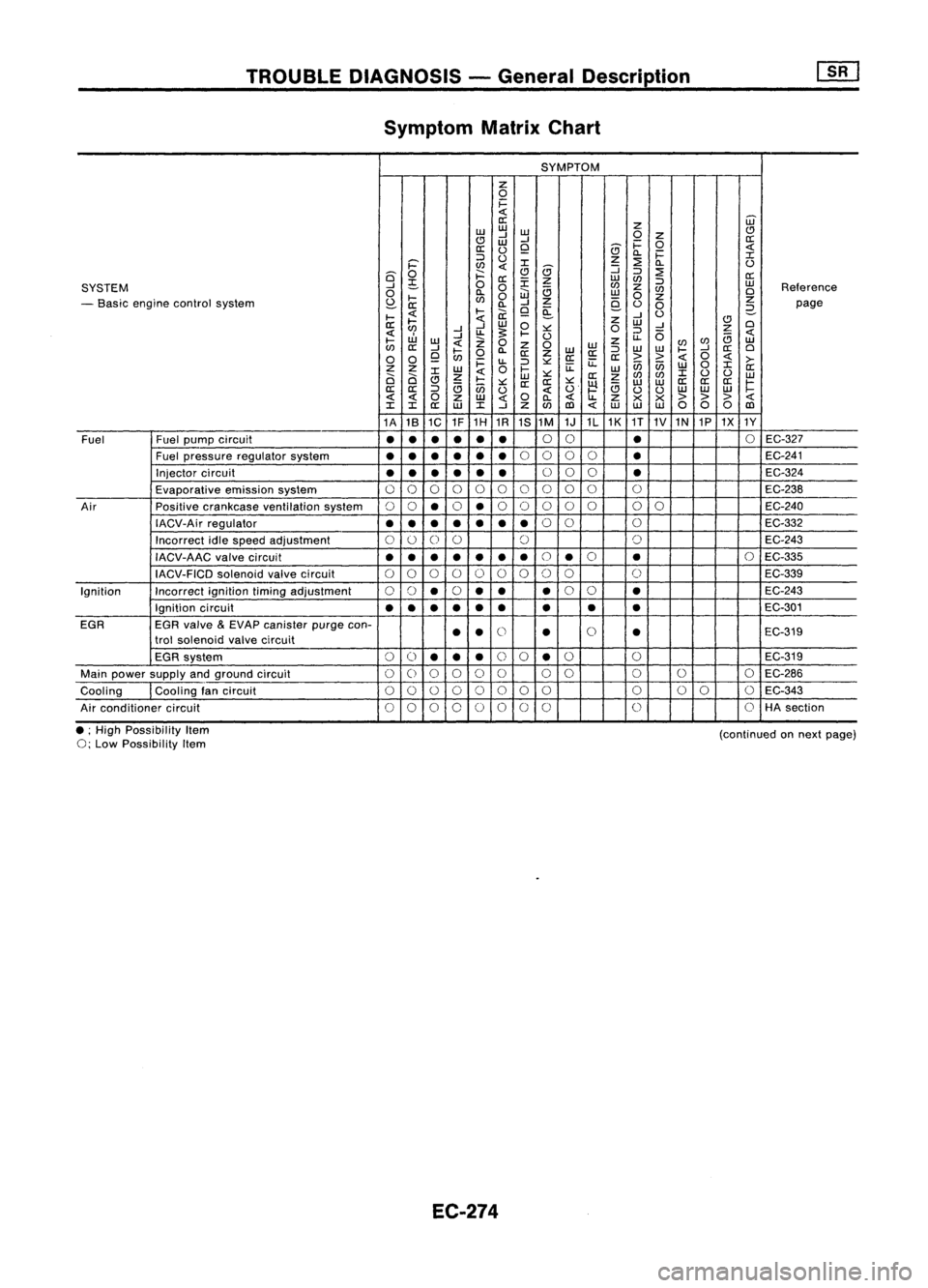

TROUBLEDIAGNOSIS -General Description

Symptom MatrixChart

SYMPTOM

z

0

i=

0::

Z

ill

w w

w

(!)

(!J

-l

-l

0

Z

0::

W

i=

0

0::

0

Q

(9

c..

i=

::>

0

z

::2:

:r:

i='

l/)

(9

:J

c..

0

6'

0

j::::

Q

::>

::2:

0::

;S

0

0::

:r:

z

w

l/)

::>

w

SYSTEM

....J

0

a

l/)

z

l/)

Reference

0

l-

e..

0

iJJ

w

0

z

0

- Basic engine control system

S?-

l/)

-l

Z

9-

z

0::

c..

Q ~

0

0

2-

page

I-

l-

ii:

....J

0

II:

I-

w

0

z

w

(!)

0

l/)

....J....J

~

:>:::

0

::>

-l

z

uJ

....J

U.

I-

0

U.

(5

B

I-

W

0

z

l/)

w

l/)

II:

....J

Z

0

W

WW

l/)

....J

II:

0

I-

0

c..

II:

Z

W

II:

::>

I-

0

0

Q

l/)

II:II:

>>

i=

u.

::>

:>:::

u::

ii5ii5

w

0

:r:

>-

z z

w

0

I-

u::

W

II:

0 0

:r:

z

w

:>:::

II:

z

l/)

l/)

:r:

0 0

w

(!J

I-

:>:::

II: II:

:>:::

~

w

W

II:

II: II:

r:

II:

II:

::>

B

ii5

0

B

00

w

w w

z

w

c..

Z

><><

>

> >

:r: :r:

II:

w

:r:

-l

z

l/)

co

WW

00 0

co

1A 181C 1F1H

1R

1S1M

1J1L1K

1T

1V1N 1P1X 1Y

Fuel Fuelpump circuit

•

•

•

•

•

•

0

0

•

0

EC-327

Fuel pressure regulatorsystem

•

••

•

••

0

0 00

•

EC-241

Injector circuit

••

•

• •

•

0

00

•

EC-324

Evaporative emissionsystem

00 0 00

0 0

0

0

0 0

EC-238

Air Positivecrankcase ventilation system

00

•

0

•

0

0 0

0

0

00

EC-240

IACV-Air regulator

•••

•

••

•

0

0

0

EC-332

Incorrect idlespeed adjustment

0

0

0

0 0 0

EC-243

IACV-AAC valvecircuit

••

•

•

•

•

•

0

•

0

•

0

EC-335

IACV-FICD solenoidvalvecircuit

0

0 0

000 00 0

C)

EC-339

Ignition Incorrectignitiontimingadjustment

00

•

0

•• •

0

0

•

EC-243

Ignition circuit

•

•

•

•

•

•

• •

•

EC-301

EGR EGRvalve

&

EVAP canister purgecon-

00

trol solenoid valvecircuit

•

•

•

•

EC-319

EGR system

0

()

•• •

0

0

•

0

0

EC-319

Main power supply andground circuit

00 0 0

C)

0 00

0

0

0

EC-286

Cooling Coolingfancircuit

0

0

0

00 00 0 000 0

EC-343

Air conditioner circuit

00 00 0

00

0 0

0

HA

section

• ;High Possibility Item

0;

Low Possibility Item

EC-274

(continued

onnext page)

Page 994 of 1701

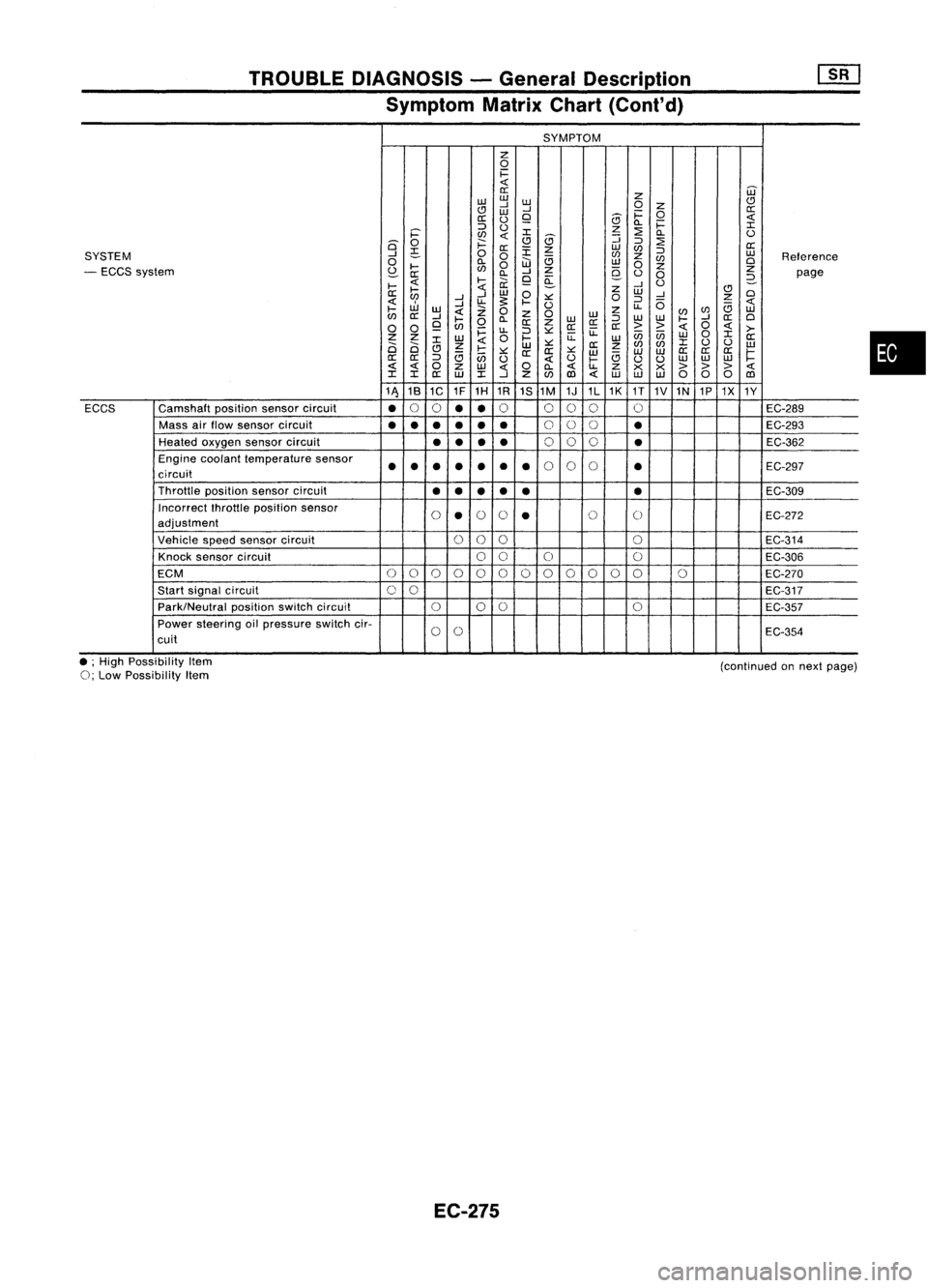

TROUBLEDIAGNOSIS -General Description

Symptom MatrixChart(Cont'd)

SYMPTOM

z

0

1=

0::

Z

W

w w

CJ

..J

W

0

Z

CJ

W

..J

1=

0

0::

0::

()

9

5

Q.

1=

::::>

()

z

:2

I

i='

en

I

5

::;

Q.

()

is'

0

;:::

CJ

::::>

:2

0::

~

0::

:r:

z

w

en

::::>

SYSTEM

..J

0

0

en

z

w

Reference

0

Q.

W

e;

w

en

0

- ECCS system

~

....

en

0

..J

Z

9-

0

z

Z

0::

Q.

9

a:

()

0

2-

page

....

....

ii:

..J

U

....

Z

CJ

0::

..J

W

0

W

..J

0

en

..J

u-

s:

.... ::.:::

0

::::>

0

z

W

..J

U

u-

e;

....

w

Z

0

z

0

w

z

(/)

en

w

en

0::

..J

....

Q.

W

::::>

w

w

....

..J

0::

0

0 0

9

en

0

0::

Z

0::0::

0::

>>

0

>-

~

u-

::::>::.:::

u:

enen

0

I

Z Z

W

0

....

u:

w

W

0::

2i 2i

I

Z

W

::.:::

0::

z

en

(/)

I

()

()

w

CJ

e;

....

::.:::

0:: 0::

::.:::

w w

W

0::

0::

0::

1=

0::

0::

::::>

en

()

()

....

e;

uu

w

w

w

0

Z

w

0

Q.

u-

Z

x x

> >>

I I

0::

W

I

..J

Z

(/)

1Il

w

w w

000

1Il

11\ 18

1C 1F

1H 1R

1S1M 1J1L1K

1T

1V1N 1P1X

1Y

ECCS Camshaft

positionsensorcircuit

•

0

0

••

0

000 0

EC-289

Mass airflow sensor circuit

•••

•••

0

00

•

EC-293

Heated oxygen sensorcircuit

••

••

0

00

•

EC-362

Engine coolant temperature sensor

••• ••

•

•

0

0

0

•

EC-297

circuit

Throttle positionsensorcircuit

••

••

• •

EC-309

Incorrect fhrottleposition sensor

0

•

0

0

•

0

0

EC-272

adjustment

Vehicle speedsensor circuit

000

0

EC-314

Knock sensor circuit

00

0 0

EC-306

ECM

0

0

0

0

00000

0

00 0

EC-270

Start signal circuit

00

EC-317

Park/Neutral positionswitchcircuit

000

0

EC-357

Power steering oilpressure switchcir-

0

0

EC-354

cuit

•

• ;High Possibility Item

0;

Low Possibility Item

EC-275

(continued

onnext page)

Page 1099 of 1701

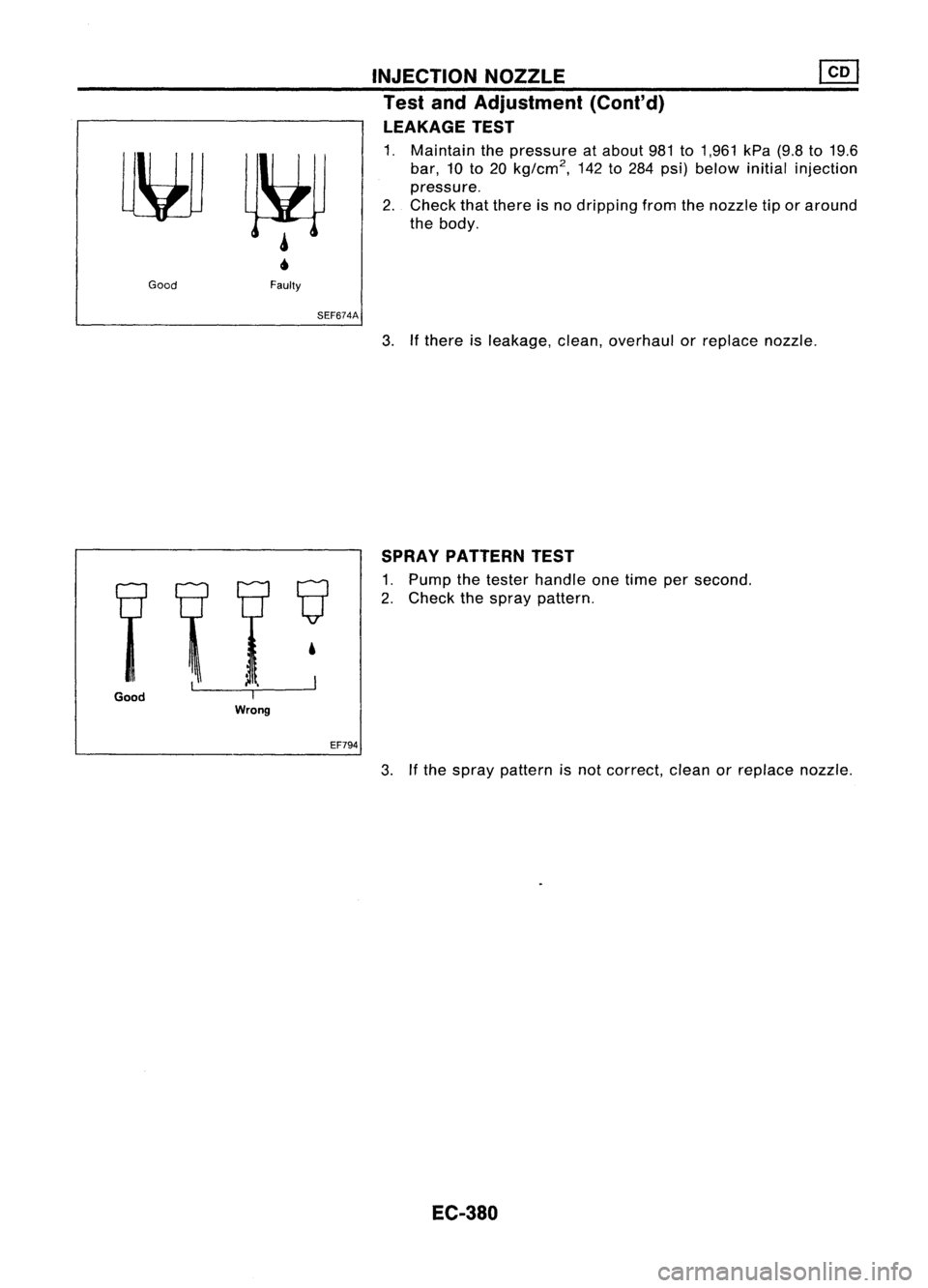

INJECTIONNOZZLE ~

Test andAdjustment (Cont'd)

LEAKAGE TEST

1. Maintain thepressure atabout 981to1,961 kPa(9.8to19.6

bar, 10to20 kg/cm

2,

142to284 psi) below initialinjection

pressure.

2. Check thatthere isno dripping fromthenozzle tiporaround

the body.

Good

Faulty

SEF674A

3.Ifthere isleakage, clean,overhaul orreplace nozzle.

Good

I

Wrong

•

EF794 SPRAY

PATTERN TEST

1. Pump thetester handle onetime persecond.

2. Check thespray pattern .

3. Ifthe spray pattern isnot correct, cleanorreplace nozzle.

EC-380

Page 1113 of 1701

![NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

~

ill]

SEF941P

Ii]

~i5

Glow

Eill~

plug

0

@]Q]

2

[ill

~SEF942P INSPECTION

START

Check fuellevel, fuelsupplying system,

~Correct.

starter motor NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

~

ill]

SEF941P

Ii]

~i5

Glow

Eill~

plug

0

@]Q]

2

[ill

~SEF942P INSPECTION

START

Check fuellevel, fuelsupplying system,

~Correct.

starter motor](/img/5/57349/w960_57349-1112.png)

TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

~

ill]

SEF941P

Ii]

~i5

Glow

Eill~

plug

0

@]Q]

2

[ill

~SEF942P INSPECTION

START

Check fuellevel, fuelsupplying system,

~Correct.

starter motor,etc.

OK

m

Check thatallglow plugconnecting

~Installproperly.

plate nutsareinstalled properly.

OK

CHECK OVERALL FUNCTION. OK

CHECK COMPONENT

Check entirequick-glow system.(Refer

---..

(Glowplug).

to "System Operation Check"onnext See

page EC-397.

page.)

NG

CHECK POWER SUPPLY ANDGROUND NG

Repair harness orcon-

CIRCUIT.

---..

nector.

(Refer to"Power Supplyandground

circuit forECM", EC-396).

OK

(!]

CHECK VOLTAGE BETWEEN GLOW NG

Check thefollowing.

RELA YAND GROUND.

---..

•7.5A fuse

1) Check voltage between terminals •

75A fusible link

G), @and ground withtester. •Harness continuity

Voltage: Batteryvoltage between

glowrelay

OK and

fuse

If NG, repair harness or

connectors.

[!1

CHECK OUTPUT SIGNALCIRCUIT. NG

Repair harness orcon-

1) Check harness continuity between

---+

nectors.

ECM terminal

@

andterminal @.

Continuity shouldexist.

OK

Ii]

CHECK HARNESS CONTINUITY NG

Repair harness orcon-

BETWEEN GLOWRELAY ANDGLOW

---+

nectors.

PLUG. 1) Disconnect ECMharness connector.

2) Disconnect glowrelay.

3) Check harness continuity between

glow relay terminal

@

and glow

plug.

Continuity shouldexist.

~OK

SEF940P

SEF939P

-"-.....

'y;-----...

Connecting platenut:J

~1.0 •1.5

N.mr-

"(0.1 •0.15 kg-m,- ""'-

8.7 -13.0 in-Ib)

~

""

.

'------

~

~

ECM

E1

CONNECTOR

II

106

II

(!]

~io

EC-394

Page 1165 of 1701

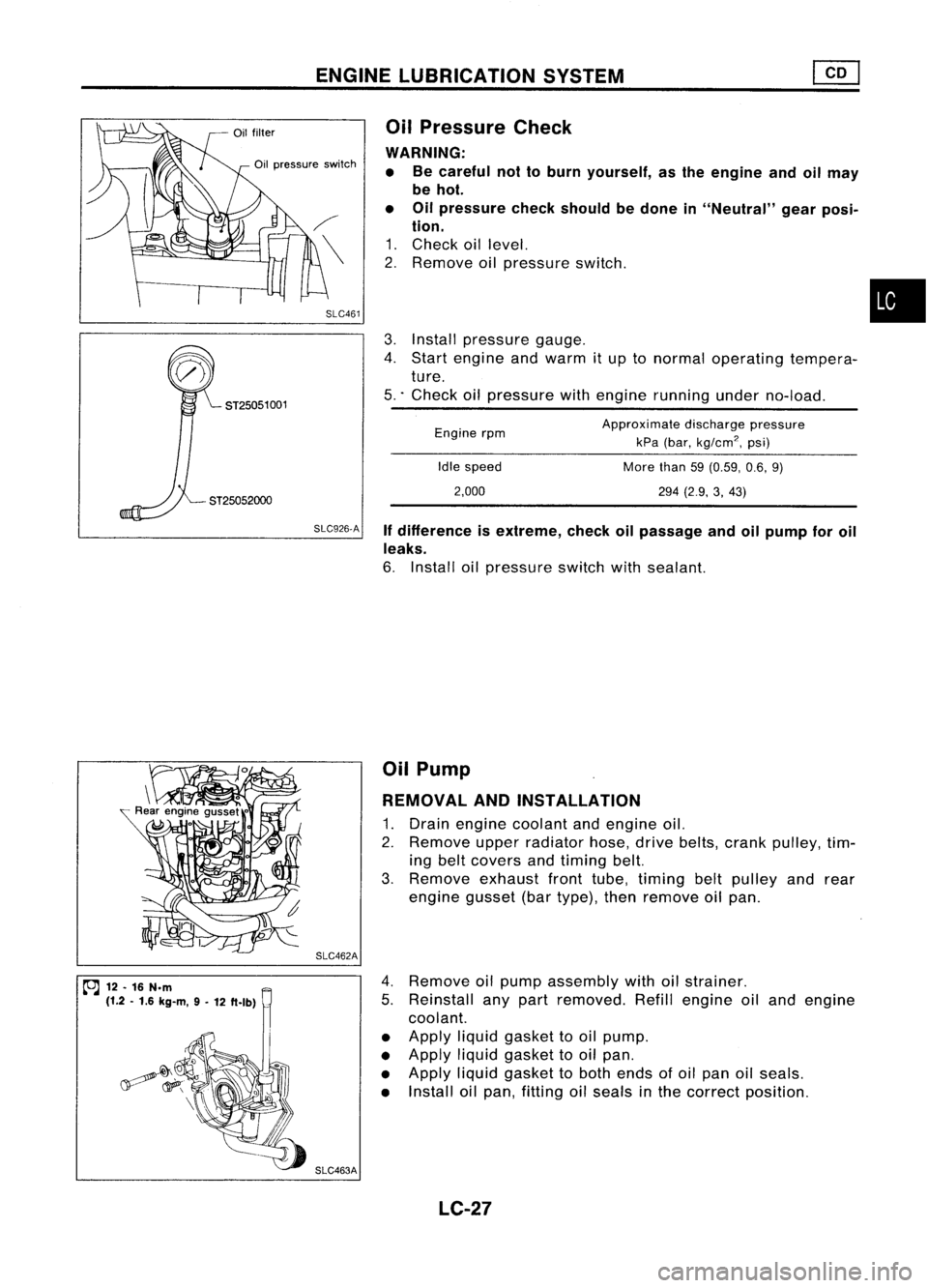

ENGINELUBRICATION SYSTEM

SLC926.A Ifdifference isextreme, checkoilpassage andoilpump foroil

leaks.

6. Install oilpressure switchwithsealant.

ST25052000

3.

Install pressure gauge.

4. Start engine andwarm itup tonormal operating tempera-

ture.

5 .. Check oilpressure withengine running underno-load.

•

Approximate dischargepressure

kPa (bar,

kg/cm

2,

psi)

More than59(0.59, 0.6,9)

294 (2.9, 3,43)

Idle

speed

2,000

Engine

rpm

Oil

Pressure Check

WARNING: • Becareful nottoburn yourself, asthe engine andoilmay

be hot.

• Oilpressure checkshould bedone in"Neutral" gearposi-

tion.

1. Check oillevel.

2. Remove oilpressure switch.

SLC461

Oil

pressure switch

ST25051 001

~ 12.16 N.m

(1.2 .1.6 kg-m, 9-

12 ft.lb) SLC462A

SLC463A Oil

Pump

REMOVAL ANDINSTAllATION

1. Drain engine coolant andengine oil.

2. Remove upperradiator hose,drivebelts, crank pulley, tim-

ing belt covers andtiming belt.

3. Remove exhaustfronttube, timing beltpulley andrear

engine gusset(bartype), thenremove oilpan.

4. Remove oilpump assembly withoilstrainer.

5. Reinstall anypart removed. Refillengine oiland engine

coolant.

• Apply liquidgasket tooil pump.

• Apply liquidgasket tooil pan.

• Apply liquidgasket toboth ends ofoil pan oilseals.

• Install oilpan, fitting oilseals inthe correct position.

LC-27

Page 1200 of 1701

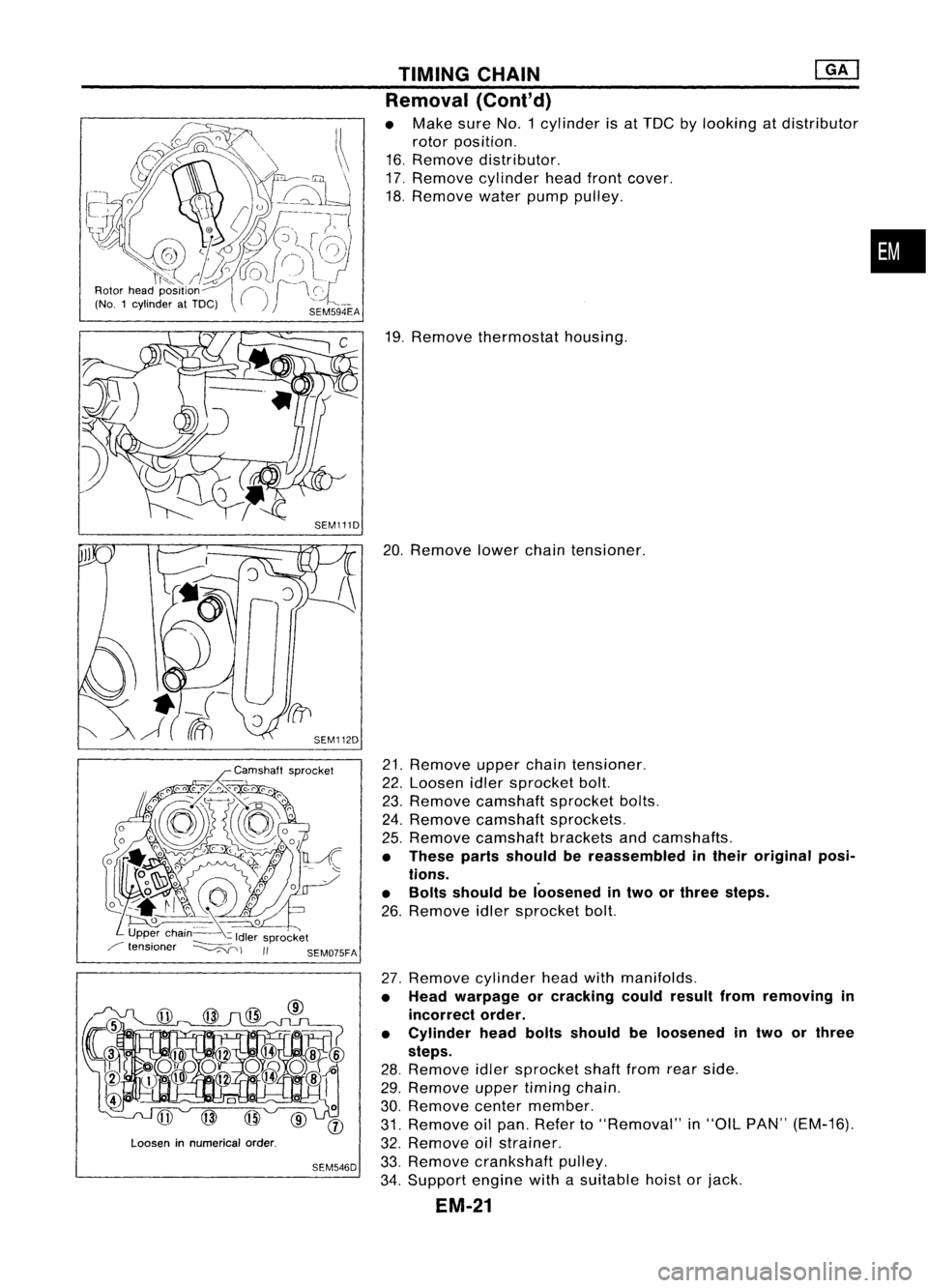

Looseninnumerical order.

SEM546D TIMING

CHAIN @KJ

Removal (Cont'd)

• Make sureNo.1 cylinder isat TDC bylooking atdistributor

rotor position.

16. Remove distributor.

17. Remove cylinder headfrontcover.

18. Remove waterpumppulley.

19. Remove thermostat housing.

20. Remove lowerchaintensioner.

21. Remove upperchaintensioner.

22. Loosen idlersprocket bolt.

23. Remove camshaft sprocketbolts.

24. Remove camshaft sprockets.

25. Remove camshaft bracketsandcamshafts.

• These partsshould bereassembled intheir original posi-

tions.

• Bolts should beloosened intwo orthree steps.

26. Remove idlersprocket bolt.

27. Remove cylinderheadwithmanifolds.

• Head warpage orcracking couldresult fromremoving in

incorrect order.

• Cylinder headboltsshould beloosened intwo orthree

steps.

28. Remove idlersprocket shaftfromrearside.

29. Remove uppertiming chain.

30. Remove centermember.

31. Remove oilpan. Refer to"Removal" in"OIL PAN" (EM-16).

32. Remove oilstrainer.

33. Remove crankshaft pulley.

34. Support enginewithasuitable hoistorjack.

EM-21

•

Page 1217 of 1701

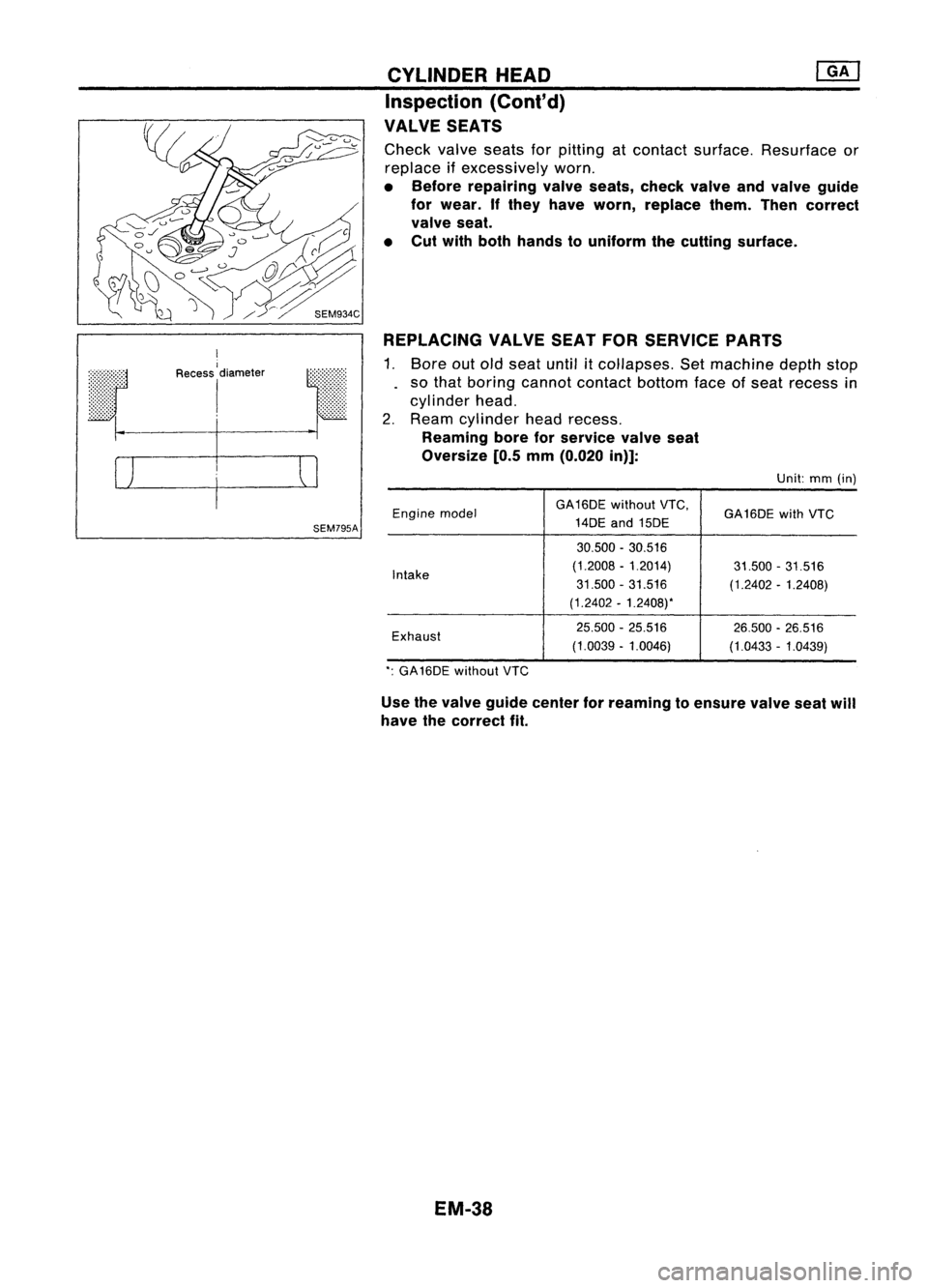

I

Recess

1

diameter

I

SEM795A CYLINDER

HEAD

Inspection (Cont'd)

VALVE SEATS

Check valveseats forpitting atcontact surface. Resurface or

replace ifexcessively worn.

• Before repairing valveseats, checkvalveandvalve guide

for wear. Ifthey have worn, replace them.Thencorrect

valve seat.

• Cut with both hands touniform thecutting surface.

REPLACING VALVESEATFORSERVICE PARTS

1. Bore outold seat until

it

collapses. Setmachine depthstop

so that boring cannot contact bottomfaceofseat recess in

cylinder head.

2. Ream cylinder headrecess.

Reaming boreforservice valveseat

Oversize [0.5mm(0.020 in)]:

Unit:mm(in)

Engine model GA16DE

withoutVTC,

GA16DE withVTC

14DE and15DE

30.500 -30.516

Intake (1.2008

-1.2014)

31.500-31.516

31.500 -31.516

(1.2402-1.2408)

(1.2402 -1.2408).

Exhaust 25.500

-25.516

26.500-26.516

(1.0039 -1.0046)

(1.0433-1.0439)

.: GA 16DE without VTC

Use thevalve guide center forreaming toensure valveseatwill

have thecorrect fit.

EM-38