correct NISSAN ALMERA N15 1995 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1377 of 1701

•SHORT CIRCUIT

• SHORT TOGROUND

HOW

TOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection

•

A circuit isopen when thereisno continuity throughasection ofthe circuit.

There aretwo types ofshorts.

Whenacircuit contacts anothercircuitandcauses the

normal resistance tochange.

When acircuit contacts aground sourceandgrounds the

circuit.

INTRODUCTION

In general, testingelectrical circuitsisan easy taskifitis approached inalogical andorganized method.

Before beginning itis important tohave allavailable information onthe system tobe tested. Also,get

a thorough understanding ofsystem operation. Thenyouwillbeable touse theappropriate equipment

and follow thecorrect testprocedure.

You may have tosimulate vehiclevibrations whiletesting electrical components.

Gentlyshake

thewir-

ing harness orelectrical component todo this.

OPEN

SHORT

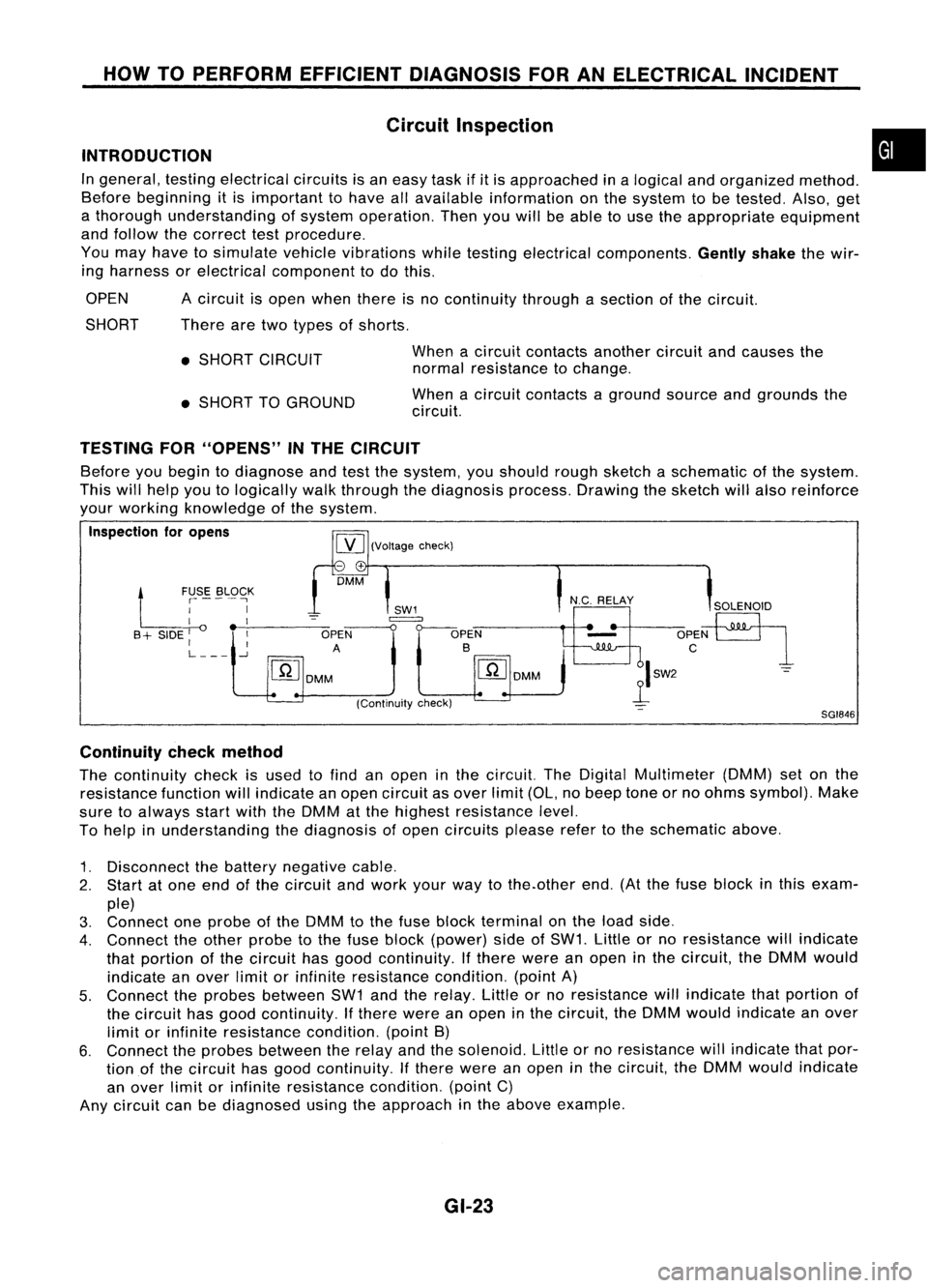

TESTING FOR"OPENS" INTHE CIRCUIT

[YJ

(Voltage check)

Before

youbegin todiagnose andtestthesystem, youshould roughsketch aschematic ofthe system.

This willhelp youtologically walkthrough thediagnosis process.Drawingthesketch willalso reinforce

your working knowledge ofthe system.

Inspection foropens

-+

DMM

Ll

~SE. ~L9~K

I

I

I __-,----

B + SIDE

I

OPEN

I I

A

L

-.J

[ill

DMM

SGI846

Continuity checkmethod

The continuity checkisused tofind anopen inthe circuit. TheDigital Multimeter (DMM)setonthe

resistance functionwillindicate anopen circuit asover limit(OL,nobeep toneorno ohms symbol). Make

sure toalways startwiththeDMM atthe highest resistance level.

To help inunderstanding thediagnosis ofopen circuits pleaserefertothe schematic above.

1. Disconnect thebattery negative cable.

2. Start atone end ofthe circuit andwork yourwaytothe.other end.(Atthe fuse block inthis exam-

ple)

3. Connect oneprobe ofthe DMM tothe fuse block terminal onthe load side.

4. Connect theother probe tothe fuse block (power) sideofSW1. Littleorno resistance willindicate

that portion ofthe circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would

indicate anover limitorinfinite resistance condition.(pointA)

5. Connect theprobes between SW1andtherelay. Littleorno resistance willindicate thatportion of

the circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would indicate anover

limit orinfinite resistance condition.(pointB)

6. Connect theprobes between therelay andthesolenoid. Littleorno resistance willindicate thatpor-

tion ofthe circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would indicate

an over limitorinfinite resistance condition.(pointC)

Any circuit canbediagnosed usingtheapproach inthe above example.

GI-23

Page 1386 of 1701

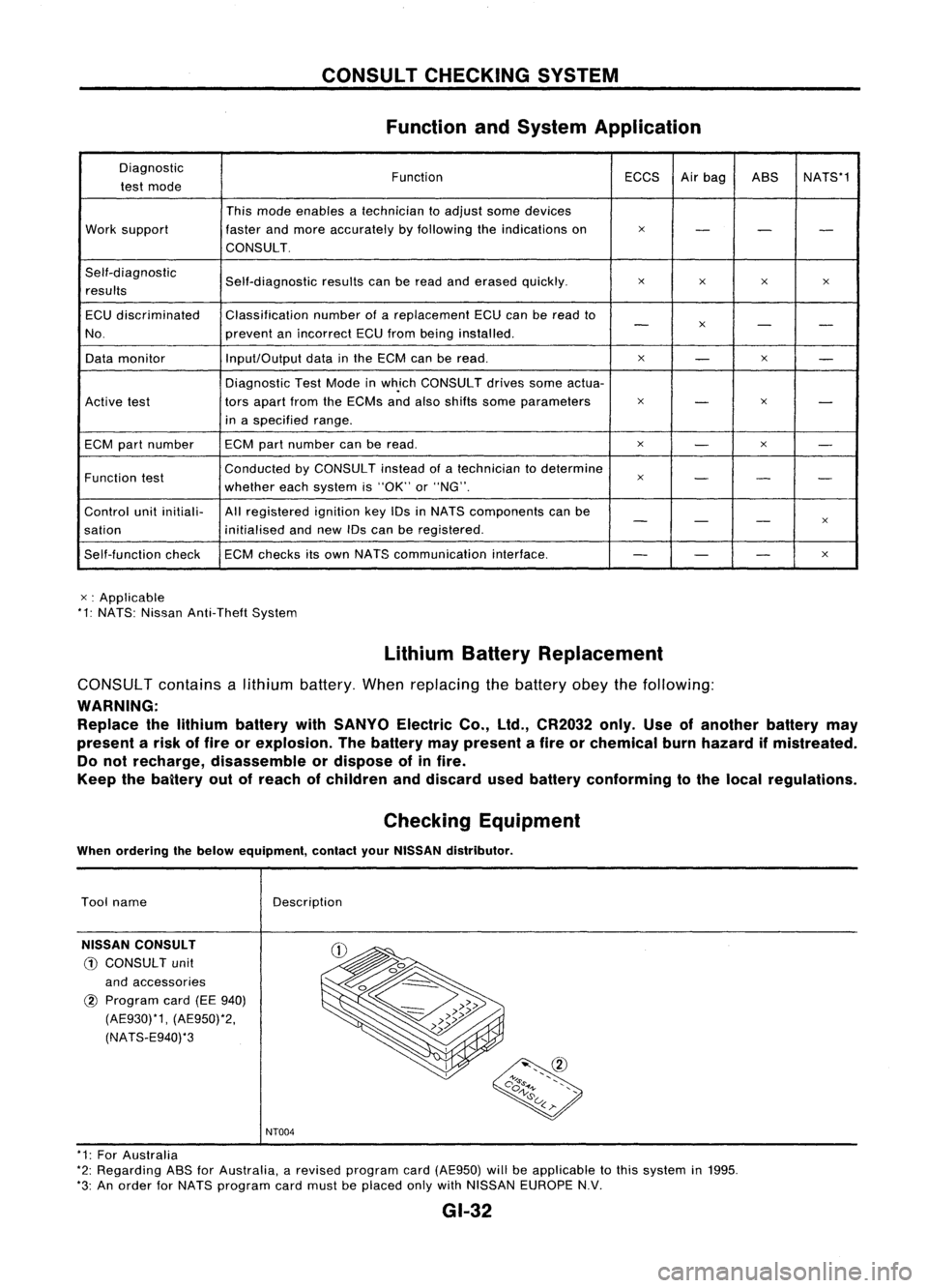

CONSULTCHECKING SYSTEM

Function andSystem Application

Diagnostic FunctionECCSAirbag ASS NATS*1

test mode

Thismode enables atechnician toadjust somedevices

Work support fasterandmore accurately byfollowing theindications on

x

- --

CONSULT.

Self-diagnostic Self-diagnosticresultscanberead anderased quickly.

x

x x

x

results

ECU discriminated Classification

numberofareplacement ECUcanberead to

-

x

- -

No. preventanincorrect ECUfrom being installed.

Data monitor Input/Output

datainthe ECM canberead.

x

-

x

-

Diagnostic TestMode inwh.ich CONSULT drivessomeactua-

Active test tors

apart fromtheECMs andalso shifts some parameters

x

-

x

-

in aspecified range.

ECM partnumber ECM

partnumber canberead.

x

-

x

-

Function test Conducted

byCONSULT insteadofatechnician todetermine

x

- --

whether eachsystem is"OK" or"NG".

Control unitinitiali- Allregistered ignitionkeyIDsinNATS components canbe

- -

-

x

sation initialisedandnew IDscan beregistered.

Self-function checkECM

checks itsown NATS communication interface.

--

-

x

x :Applicable

*1: NATS: Nissan Anti-Theft System

LithiumBatteryReplacement

CONSUL Tcontains alithium battery. Whenreplacing thebattery obeythefollowing:

WARNING: Replace thelithium battery withSANYO ElectricCo.,ltd., CR2032 only.Useofanother batterymay

present arisk offire orexplosion. Thebattery maypresent afire orchemical burnhazard ifmistreated.

Do not recharge, disassemble ordispose ofinfire.

Keep thebaitery outofreach ofchildren anddiscard usedbattery conforming tothe local regulations.

Checking Equipment

When ordering thebelow equipment, contactyourNISSAN distributor.

Tool name

NISSAN CONSULT

CD

CONSULT unit

and accessories

@

Program card(EE940)

(AE930)*1, (AE950)*2,

(NATS-E940)*3 Description

NT004

* 1: For Australia

*2: Regarding ASSforAustralia, arevised program card(AE950) willbeapplicable tothis system in1995.

*3: An order forNATS program cardmust beplaced onlywithNISSAN EUROPE N.V.

GI-32

Page 1404 of 1701

PRECAUTIONSANDPREPARATION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag" usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by anauthorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

HA-2

Page 1426 of 1701

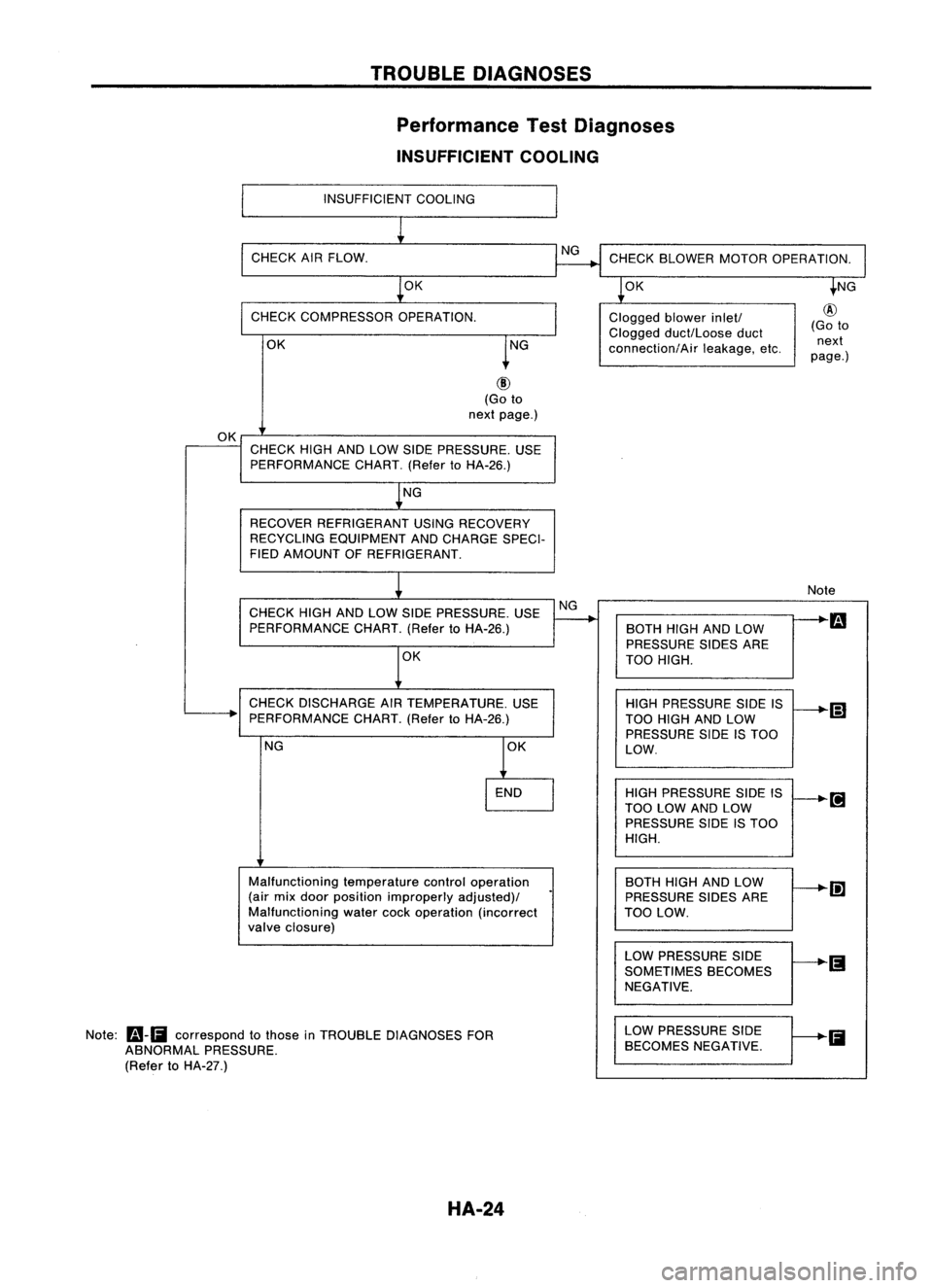

TROUBLEDIAGNOSES

Performance TestDiagnoses

INSUFFICIENT COOLING

INSUFFICIENT COOLING

CHECK AIRFLOW.

OK CHECK

BLOWER MOTOROPERATION.

OK

CHECK COMPRESSOR OPERATION.

OK Clogged

blowerinlet!

Clogged duct/Loose duct

connection/Air leakage,etc.

@

(Go to

next

page.)

(Go to

next page.)

OK CHECK HIGHANDLOW SIDE PRESSURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

NG

RECOVER REFRIGERANT USINGRECOVERY

RECYCLING EQUIPMENT ANDCHARGE SPECI-

FIED AMOUNT OFREFRIGERANT.

CHECK HIGHANDLOW SIDE PRESSURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

OK

CHECK DISCHARGE AIRTEMPERATURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

NG

Malfunctioning temperaturecontroloperation

(air mix door position improperly adjusted)/

Malfunctioning watercockoperation (incorrect

valve closure)

Note:

Fa-Ii

correspond tothose inTROUBLE DIAGNOSES FOR

ABNORMAL PRESSURE.

(Refer toHA-27.)

HA-24NG

Note

BOTH HIGHANDLOW

m

PRESSURE SIDESARE

TOO HIGH.

HIGH PRESSURE SIDEIS

(;]

TOO HIGH ANDLOW

PRESSURE SIDEISTOO

LOW.

HIGH PRESSURE SIDEIS

TOO LOW ANDLOW

PRESSURE SIDEISTOO

HIGH.

BOTH HIGHANDLOW

Ii]

PRESSURE SIDESARE

TOO LOW.

LOW PRESSURE SIDE

SOMETIMES BECOMES

NEGATIVE.

LOW PRESSURE SIDE

Ii

BECOMES NEGATIVE.

Page 1429 of 1701

TROUBLEDIAGNOSES

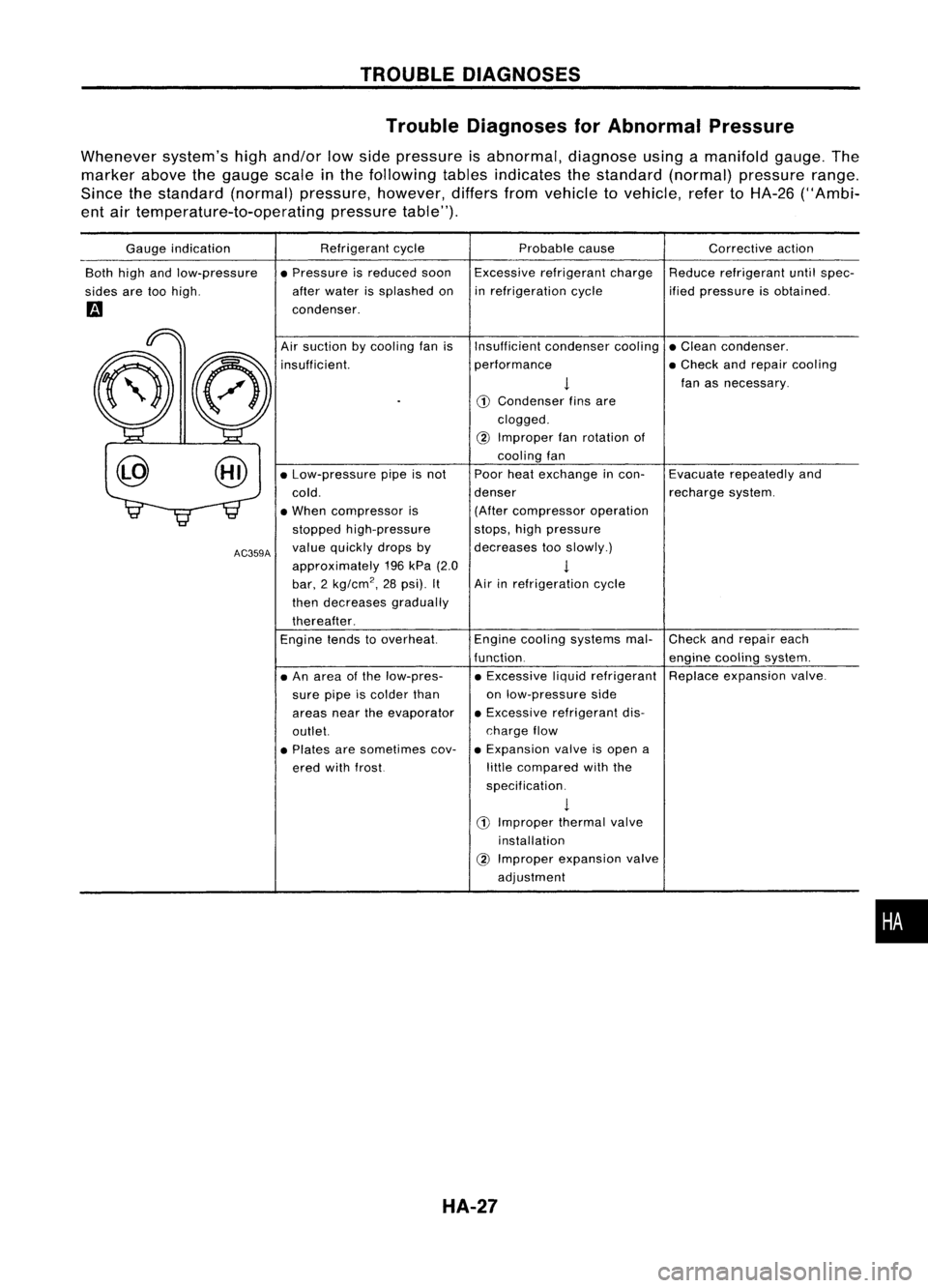

Trouble Diagnoses forAbnormal Pressure

Whenever system'shighand/or lowside pressure isabnormal, diagnoseusingamanifold gauge.The

marker abovethegauge scale

in

the following tablesindicates thestandard (normal)pressure range.

Since thestandard (normal)pressure, however,differsfromvehicle tovehicle, refertoHA-26 ("Ambi-

ent airtemperature-to-operating pressuretable").

Gauge indication

Both highandlow-pressure

sides aretoohigh.

m

Refrigerant

cycle

• Pressure isreduced soon

after water issplashed on

condenser. Probable

cause

Excessive refrigerant charge

in refrigeration cycle Corrective

action

Reduce refrigerant untilspec-

ified pressure isobtained.

•

Check

andrepair each

engine cooling system.

Replace expansion valve.

Evacuate

repeatedly and

recharge system.

Insufficient

condensercooling•Clean condenser.

performance •Check andrepair cooling

!

fanasnecessary.

CD

Condenser finsare

clogged.

@

Improper fanrotation of

cooling fan

Poor heatexchange incon-

denser (After compressor operation

stops, highpressure

decreases tooslowly.)

1

Air inrefrigeration cycle

Engine cooling systems mal-

function. • Excessive liquidrefrigerant

on low-pressure side

• Excessive refrigerant dis-

charge flow

• Expansion valveisopen a

little compared withthe

specification.

1

CD

Improper thermalvalve

installation

@

Improper expansion valve

adjustment

Air

suction bycooling fanis

insufficient.

• An area ofthe low-pres-

sure pipeiscolder than

areas neartheevaporator

outlet.

• Plates aresometimes cov-

ered withfrost.

•

Low-pressure pipeisnot

cold.

• When compressor is

stopped high-pressure

value quickly dropsby

approximately 196kPa (2.0

bar, 2

kg/cm

2,

28psi). It

then decreases gradually

thereafter.

Engine tendstooverheat.

AC359A

HA-27

Page 1430 of 1701

TROUBLEDIAGNOSES

Trouble Diagnoses forAbnormal Pressure

(Cont'd)

Compressorpressureopera-Replacecompressor.

tion isimproper.

1

Damaged insidecompressor

packings

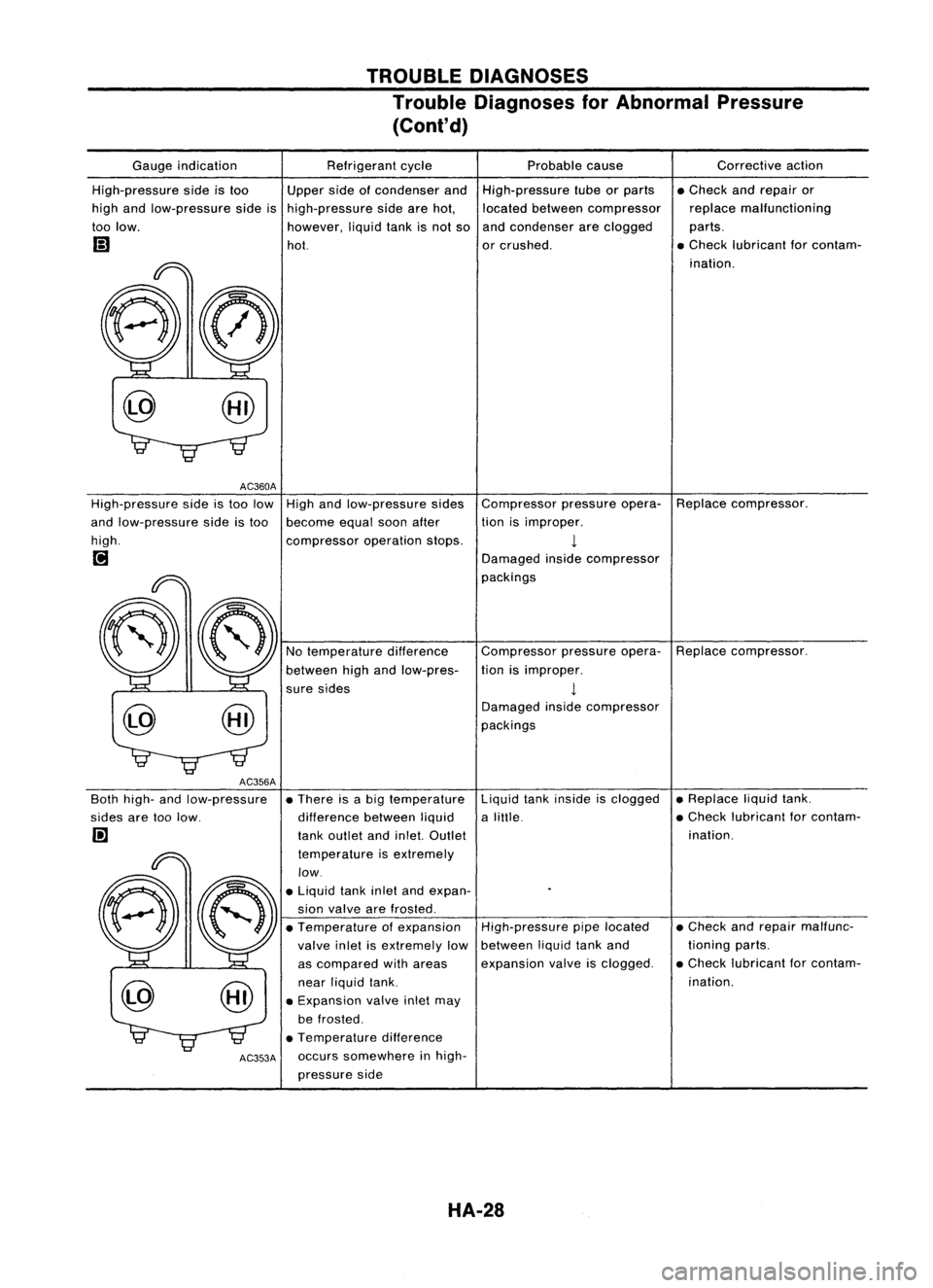

Gauge

indication

High-pressure sideistoo

high andlow-pressure sideis

too low.

AC360A

High-pressure sideistoo low

and low-pressure sideistoo

high.

[;J

AC356A

80th high- andlow-pressure

sides aretoolow.

I!]

AC353A

Refrigerant

cycle

Upper sideofcondenser and

high-pressure sidearehot,

however, liquidtankisnot so

hot.

High andlow-pressure sides

become equalsoonafter

compressor operationstops.

No temperature difference

between highandlow-pres-

sure sides

• There isabig temperature

difference betweenliquid

tank outlet andinlel. Outlet

temperature isextremely

low .

• Liquid tankinletandexpan-

sion valve arefrosted.

• Temperature ofexpansion

valve inletisextremely low

as compared withareas

near liquid tank.

• Expansion valveinletmay

be frosted .

• Temperature difference

occurs somewhere inhigh-

pressure side Probable

cause

High-pressure tubeorparts

located between compressor

and condenser areclogged

or crushed.

Compressor pressureopera-

tion isimproper.

1

Damaged insidecompressor

packings

Liquid tankinside isclogged

a lillie.

High-pressure pipelocated

between liquidtankand

expansion valveisclogged. Corrective

action

• Check andrepair or

replace malfunctioning

parts .

• Check lubricant forcontam-

ination.

Replace compressor.

• Replace liquidtank.

• Check lubricant forcontam-

ination.

• Check andrepair malfunc-

tioning parts.

• Check lubricant forcontam-

ination.

HA-28

Page 1431 of 1701

TROUBLEDIAGNOSES

Trouble Diagnoses forAbnormal Pressure

(Cont'd)

Correctiveaction

• Remove foreignparticles

by using compressed air.

• Check lubricant forcontam-

ination.

• Check andrepair malfunc-

tioning parts.

• Check lubricant forcontam-

ination.

Replace compressor.

• Drain water fromrefriger-

ant orreplace refrigerant.

• Replace liqUidtank.

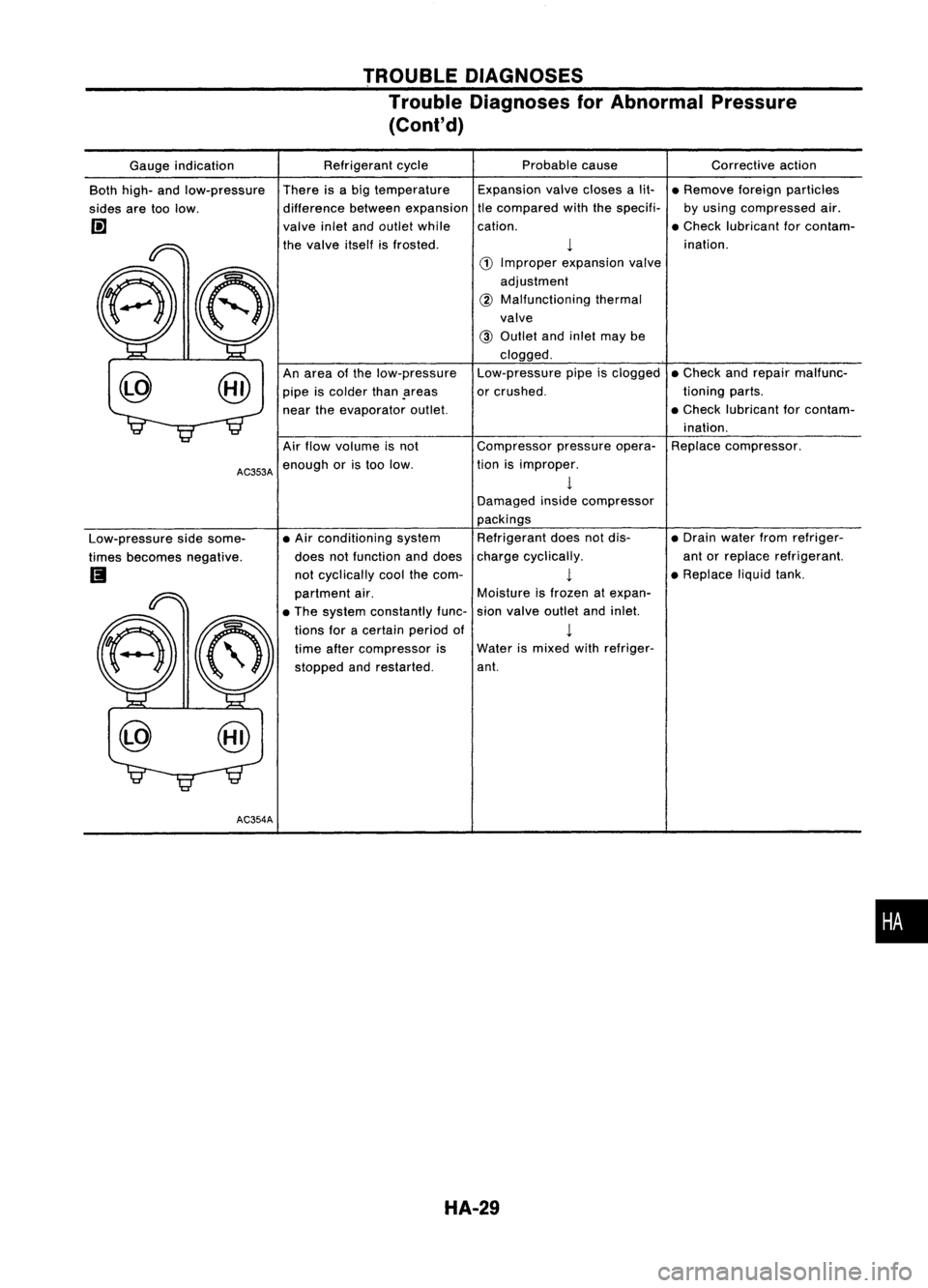

Expansion

valvecloses alit-

tle compared withthespecifi-

cation.

1

Water ismixed withrefriger-

ant. Probable

cause

1

CD

Improper expansion valve

adjustment

@

Malfunctioning thermal

valve

@

Outlet andinlet maybe

clogged.

Low-pressure pipeisclogged

or crushed.

Compressor pressureopera-

tion isimproper.

1

Damaged insidecompressor

packings Refrigerant doesnotdis-

charge cyclically.

1

Moisture isfrozen atexpan-

sion valve outlet andinlet.

Refrigerant

cycle

There isabig temperature

difference betweenexpansion

valve inletandoutlet while

the valve itselfisfrosted.

An area ofthe low-pressure

pipe iscolder thanpreas

near theevaporator outlet.

• Air conditioning system

does notfunction anddoes

not cyclically coolthecom-

partment air.

• The system constantly func-

tions foracertain periodof

time after compressor is

stopped andrestarted.

Air

flow volume isnot

AC353A

enough oristoo low.

@ Gauge

indication

Both high- andlow-pressure

sides aretoolow.

l!]

Low-pressure sidesome-

times becomes negative.

Ii

AC354A

•

HA-29

Page 1432 of 1701

TROUBLEDIAGNOSES

Trouble Diagnoses forAbnormal Pressure

(Conl'd)

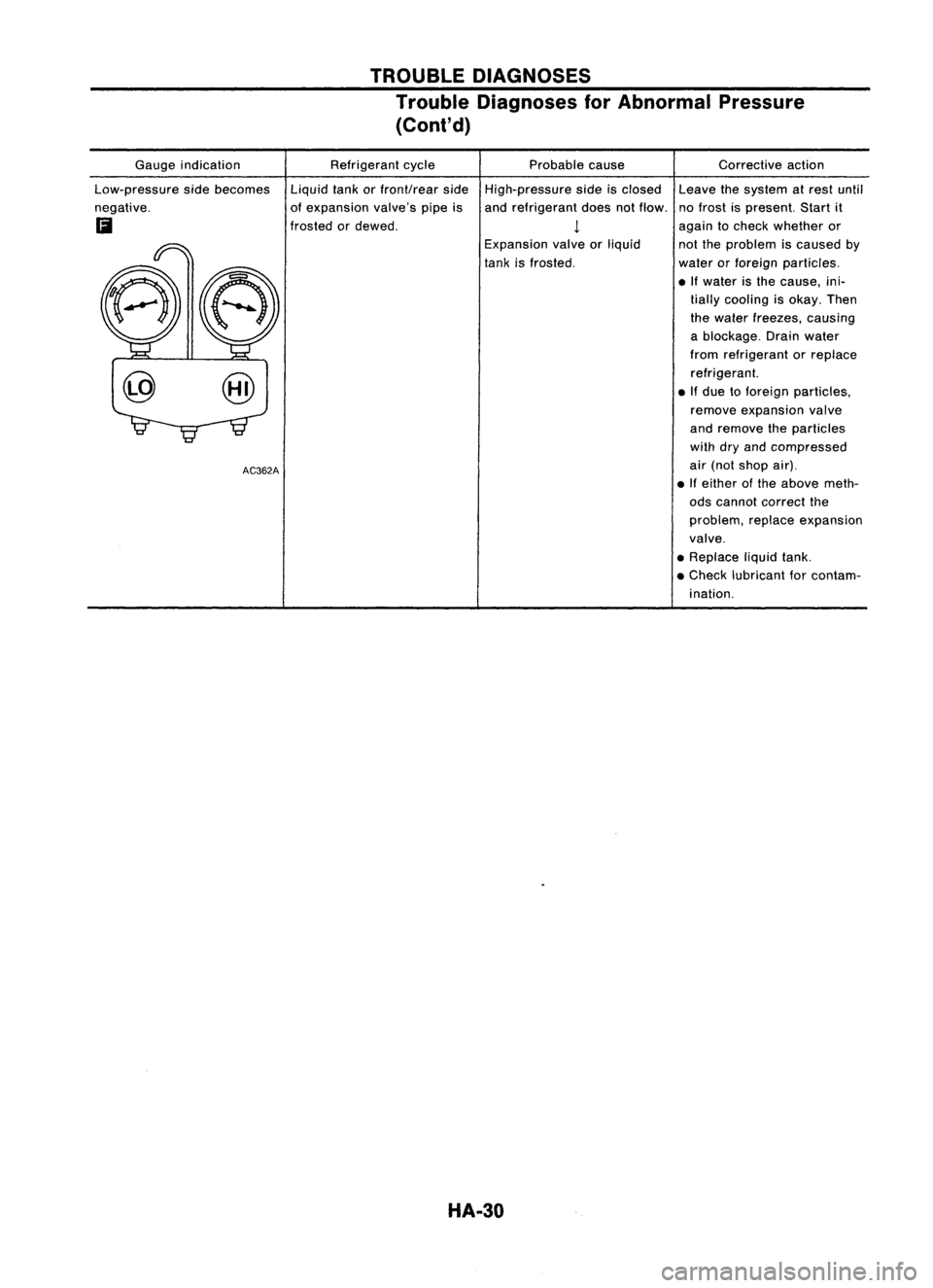

Gauge indication

Low-pressure sidebecomes

negative.

Ii

AC362A

Refrigerant

cycle

liquid tankorfront/rear side

of expansion valve'spipeis

frosted ordewed. Probable

cause

High-pressure sideisclosed

and refrigerant doesnotflow.

L

Expansion valveorliquid

tank isfrosted. Corrective

action

Leave thesystem atrest until

no frost ispresent. Startit

again tocheck whether or

not theproblem iscaused by

water orforeign particles .

• Ifwater isthe cause, ini-

tially cooling isokay. Then

the water freezes, causing

a blockage. Drainwater

from refrigerant orreplace

refrigerant.

• Ifdue toforeign particles,

remove expansion valve

and remove theparticles

with dryand compressed

air (not shop air).

• Ifeither ofthe above meth-

ods cannot correct the

problem, replaceexpansion

valve .

• Replace liquidtank.

• Check lubricant forcontam-

ination.

HA-30

Page 1489 of 1701

PRECAUTIONSANDPREPARATION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or•

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

i

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side).adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS.

MA-3

Page 1493 of 1701

PERIODICMAINTENANCE (ExceptforEurope)

The following tablesshowthenormal maintenance schedule.Depending uponweather andatmospheric

conditions, varyingroadsurfaces, individual drivinghabitsandvehicle usage,additional ormore fre-

quent maintenance mayberequired.

Periodic maintenance beyondthelast period shown onthe tables requires similarmaintenance .

Engine andEmission ControlService

•

Abbreviations: I

=

Inspect andcorrect orreplace asnecessary. R

MAINTENANCE OPERATION

Perform eitheratnumber ofkilometers (miles)

or months, whichever comestirst. km

x1,000

(Miles x1,000)

Months

Replace.

A

=

Adjust, C

=

Clean.

MAINTENANCE INTERVAL

10 20 3040

506070

80

Reference page

(6) (12) (18)

(24)(30)(36)(42)(48)

6 12 18

24

3036

42 48

Underhood andunder vehicle GA

SR

Intake

&

exhaust valveclearance (GA15DE

&

GA16DE engines) SeeNOTE (1)

EM41

-

Drive belts

II

MA 17

24

Engine anti-Ireeze coolant(Ethylene glycolbase)(LLC) RRMA 1929

Engine coolant (Softwater) RRR

R

R R

R

RMA

1929

Cooling system

I

I

I

I

MA 2131

Fuel lines

I

I

MA

22

32

Air cleaner filter(Drypaper type)*

CC

C RC CC RMA 23

-

Air cleaner filter(Viscous papertype)* R

RMA

2333

Engine oil(Use APISE,SF.SGorSH oil)*

R

RRRR R

RR

MA 24

33

Engine oilfilter* R

R R

R

R RRRMA

2433

Fuel filter* R

RMA

22

32

Spark plugs(except Platinum-tipped type) R

RMA

25

-

Spark plugs(platinum-tipped type) Replaceevery100,000 km(60.000 miles). MA

-

34

Ignition wires

I

I

MA

2635

PCV filter* R

RMA

26

-

Vapor lines

I

I

MA

26

36

(Heated) OxygenSensor

I

I

MA 2737

NOTE: (1)

If

valve noiseincreases, checkvalveclearance.

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance undersevere driv-

ing conditions".

MA-7