115 NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 5 of 1701

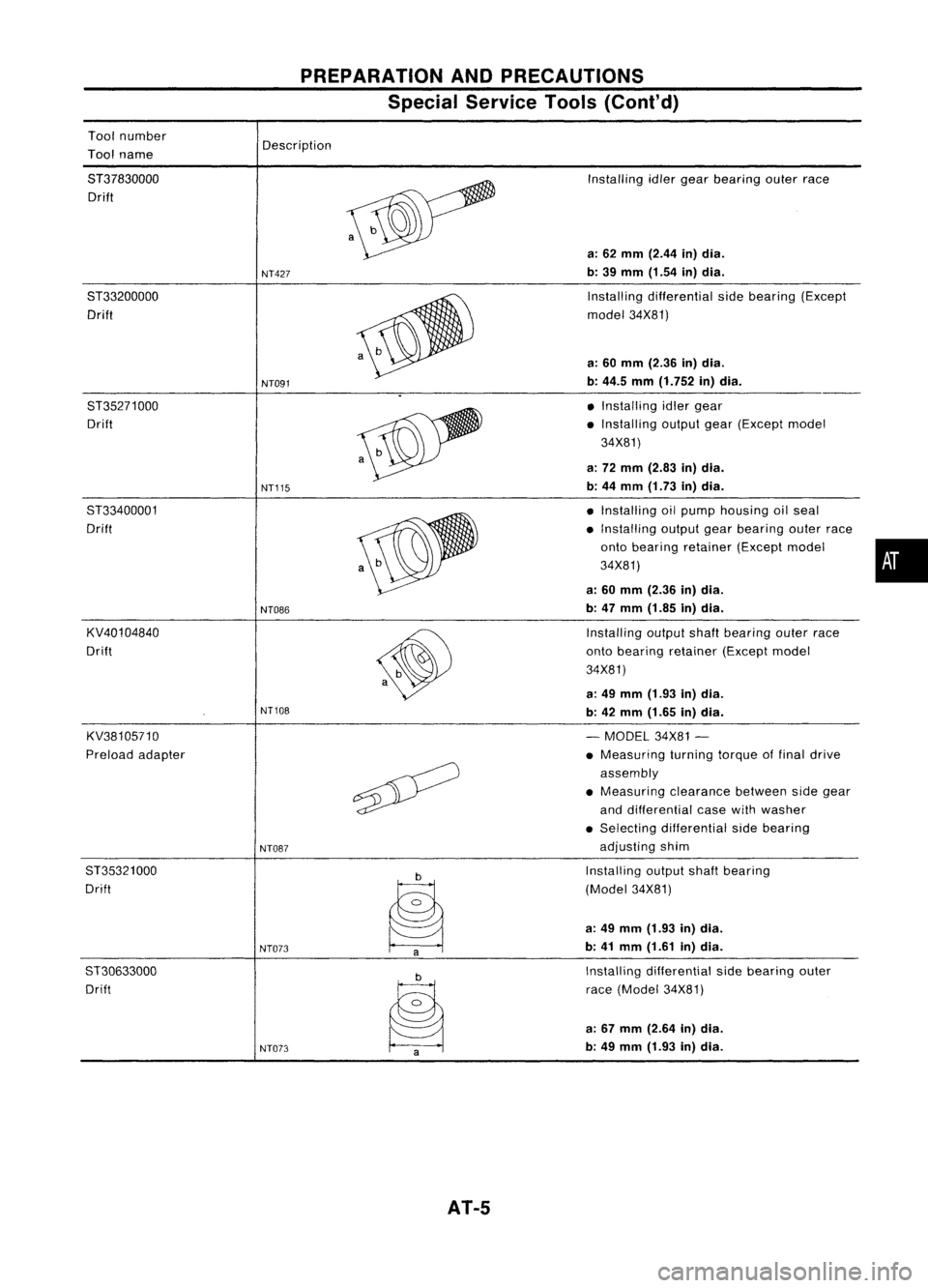

Toolnumber

Tool name

PREPARATION

ANDPRECAUTIONS

Special Service Tools(Cont'd)

Description

8T37830000 Drift

8T33200000 Drift

8T35271000 Drift

8T33400001

Drift

KV40104840

Drift

KV38105710

Preload adapter

8T35321000

Drift

ST30633000 Drift

NT427

NT091

NT115

NT086

NT108

NT087

NT073 NT073

AT-5

Installing

idlergear bearing outerrace

a: 62 mm (2.44 in)dia.

b: 39 mm (1.54 in)dia.

Installing differential sidebearing (Except

model 34X81)

a: 60 mm (2.36 in)dia.

b: 44.5 mm(1.752 in)dia.

• Installing idlergear

• Installing outputgear(Except model

34X81)

a: 72 mm (2.83 in)dia.

b: 44 mm (1.73 in)dia.

• Installing oilpump housing oilseal

• Installing outputgearbearing outerrace

onto bearing retainer (Exceptmodel •

34X81)

a: 60 mm (2.36 in)dia.

b: 47 mm (1.85 in)dia.

Installing outputshaftbearing outerrace

onto bearing retainer (Exceptmodel

34X81)

a: 49 mm (1.93 in)dia.

b: 42 mm (1.65 in)dia.

- MODEL 34X81-

• Measuring turningtorqueoffinal drive

assembly

• Measuring clearancebetweensidegear

and differential casewithwasher

• Selecting differential sidebearing

adjusting shim

Installing outputshaftbearing

(Model 34X81)

a: 49 mm (1.93 in)dia.

b: 41 mm (1.61 in)dia.

Installing differential sidebearing outer

race (Model 34X81)

a: 67 mm (2.64 in)dia.

b: 49 mm (1.93 in)dia.

Page 19 of 1701

TROUBLEDIAGNOSES

Road Testing (Cont'd)

SHIFT SCHEDULE

Drive thevehicle forapprox. 10minutes. Measuretheoiltem-

perature. Whentheoiltemperature becomesbetween50and

80°C (122and176°F), carryoutthis check.

VEHICLE SPEEDWHENSHIFTING GEARS

Model 34X68

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3

->

0

4

0

4

~

0

3

0

3

->

O

2

O

2

->

0,

1

2

~

1,

Full throttle

48

-56 88

-96 133

-141

80-88 37-45 45-53

(30 -35) (55-60)

-

(83-88)

(50-55) (23-28) (28

-33)

Half throttle

31

-39 54

-62 102-110

75-83 44

-52

7-15 45

-53

(19 -24) (34

-39)

(63-68) (47

-52)

(27-32) (4

-9)

(28-33)

Model 34X69and34X70

Throttle pas

i-

Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2~

0

3

0

3

->

0

4

0

4~

0

3

0

3

->

O

2

O

2~

0,

1

2~

1,

Full throttle

51

-60 94

-102 136-144

85-93 40

-48

48-56

(32 -37) (58-63)

-

(85-89)

(53-58) (25

-30) (30-35)

Half throttle

30

-38 52

-60 97-105 67-75 42-50 8-16

48-56

(19 -24) (32-37) (60-65) (42-47) (26-31) (5-10) (30-35)

Model 34X80

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3~

0

4

0

4

->

0

3

0

3

~

O

2

O

2

->

0,

1"

->

1,

Full throttle

52

-60 100-108 145

-153

90-98 40

-48 49-57

(32 -37) (62-67)

-

(90-95) (56-61) (25-30) (30

-35)

Half throttle

30

-38 53-61 103

-111

69-77 42

-50 8-16 49-57

(19 -24) (33-38) (64-69) (43-48) (26-31) (5-10) (30-35)

Model 34X81

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3

~

0

4

0

4

->

0

3

0

3

->

O

2

O

2

~

0,

1

2~

1,

Full throttle

58

-66 107

-115 160

-168

96-104 39

-47 48-56

(36 -41) (66

-71)

-

(99-104) (60-65) (24

-29) (30

-35)

33 -41 57-65 105

-113 69-77 45-53 8-16 48-56

Half throttle

(21-25) (35-40)

(65-70) (43

-48) (28-33) (5-10) (30

-35)

AT-19

•

Page 29 of 1701

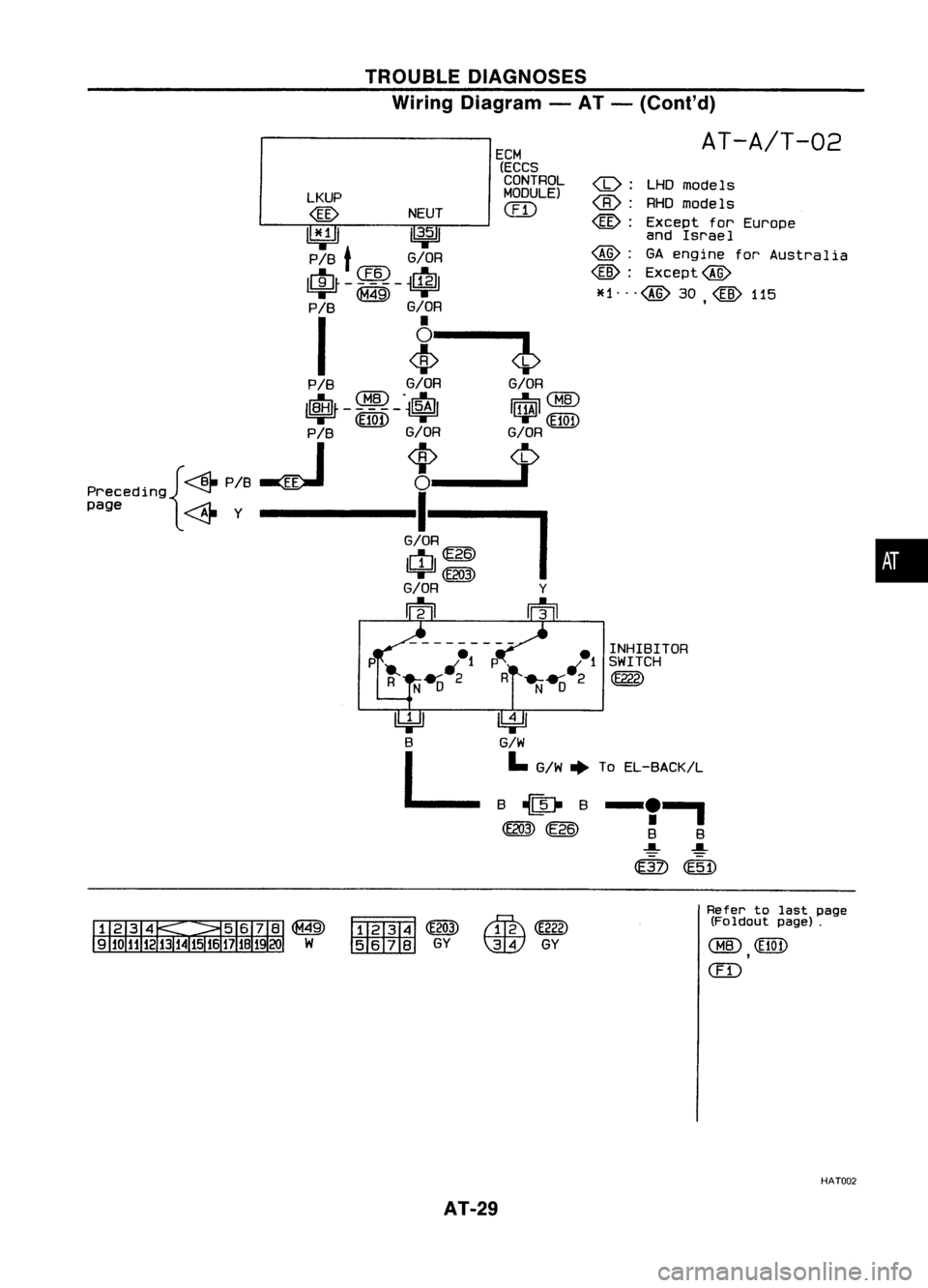

•

(b):

LHDmodels

:

RHOmodels

@:

Except forEurope

and Israel

~: GAengine forAustralia

@:

Except@

*1 ...

@

30

@

115

,

ECM

(ECCS

CONTROL

MODULE)

em

_ INHIBITOR

P .. ..1P ..

-1

SWITCH

R N-0 2 R

~-o

2

@g)

TROUBLE

DIAGNOSES

Wiring Diagram -AT -(Coni' d)

AT-A/T-02

LKUP

@

NEUT

I1¥Jl

11

3•5

1

P/B

t

G/OR

~CIID~

~-

I

i

P /B G/OR G/OR

~ CHID.

dI:-. ~

CHID

ll\tlJr -

$100 -~

I~I

P/B G/OR G/OR

. {~P/8~

*_1>

Precedlng ~

I

page ~Y-------G/O~

IUJI~

=w=

(E203)

G/OR Y

m rn

l!4='J

B

L

~

G/W

I.

G/W ~ToEL-BACK/L

-'I

B B

~ ~

@)

@j)

~

~ GY

~

(E222)

\IDY

GY Refer

tolast page

(Foldout page).

CHID

(EI0t)

,

(ill

HAT002

AT-29

Page 79 of 1701

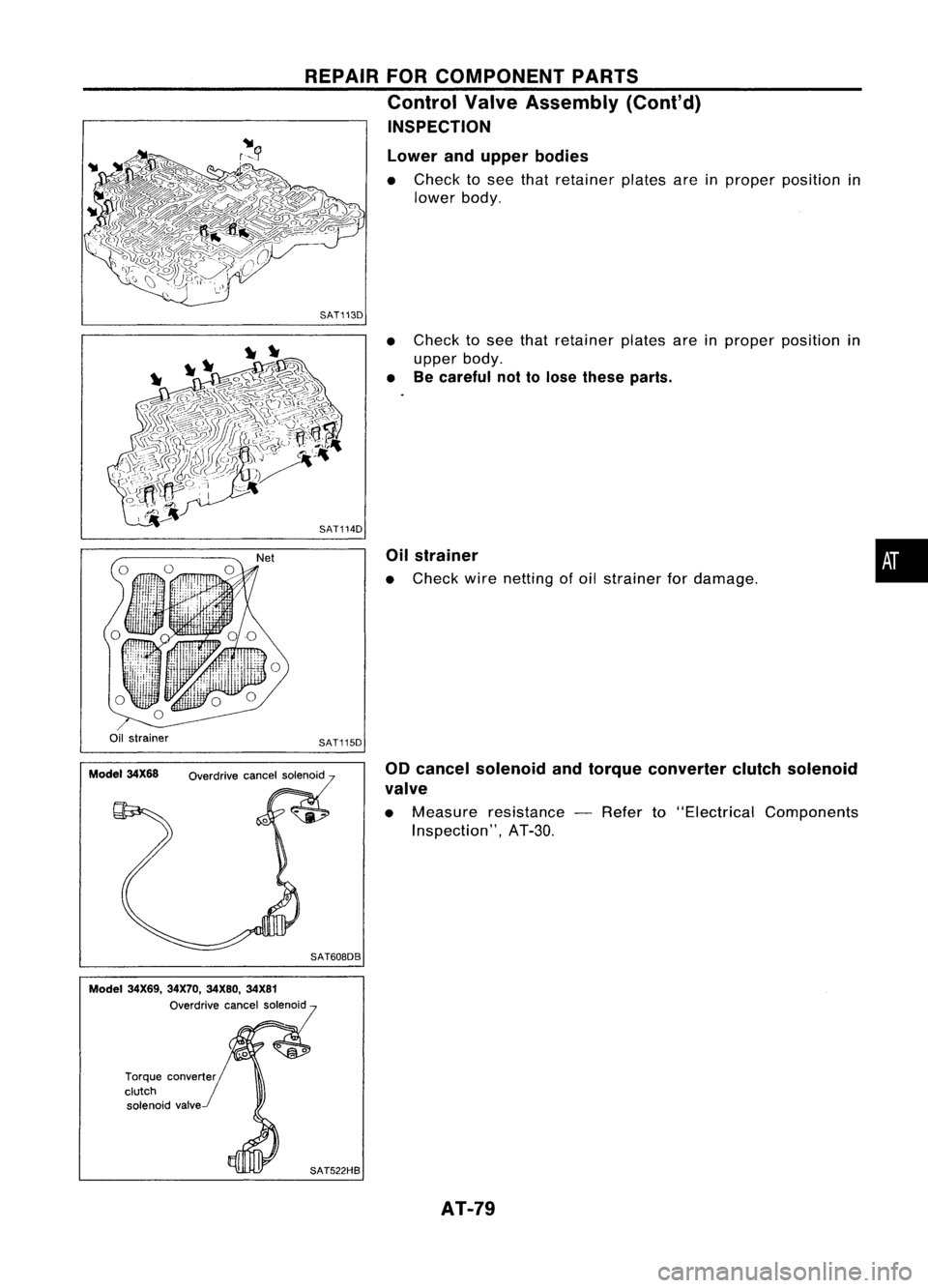

REPAIRFORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

INSPECTION

Lower andupper bodies

• Check tosee that retainer platesareinproper position in

lower body.

SAT113D

•Check tosee that retainer platesareinproper position in

upper body.

• Becareful nottolose these parts.

Oil strainer

• Check wirenetting ofoil strainer fordamage.

•

Oil strainer

Model 34X68 SAT115D

Overdrive cancelsolenoid

SAT608DB 00

cancel solenoid andtorque converter clutchsolenoid

valve

• Measure resistance -Refer to"Electrical Components

Inspection", AT-3D.

Model 34X69, 34X70,34X80, 34X81

Overdrive cancelsolenoid

Torque converter

clutch solenoid valve

SAT522HBAT-79

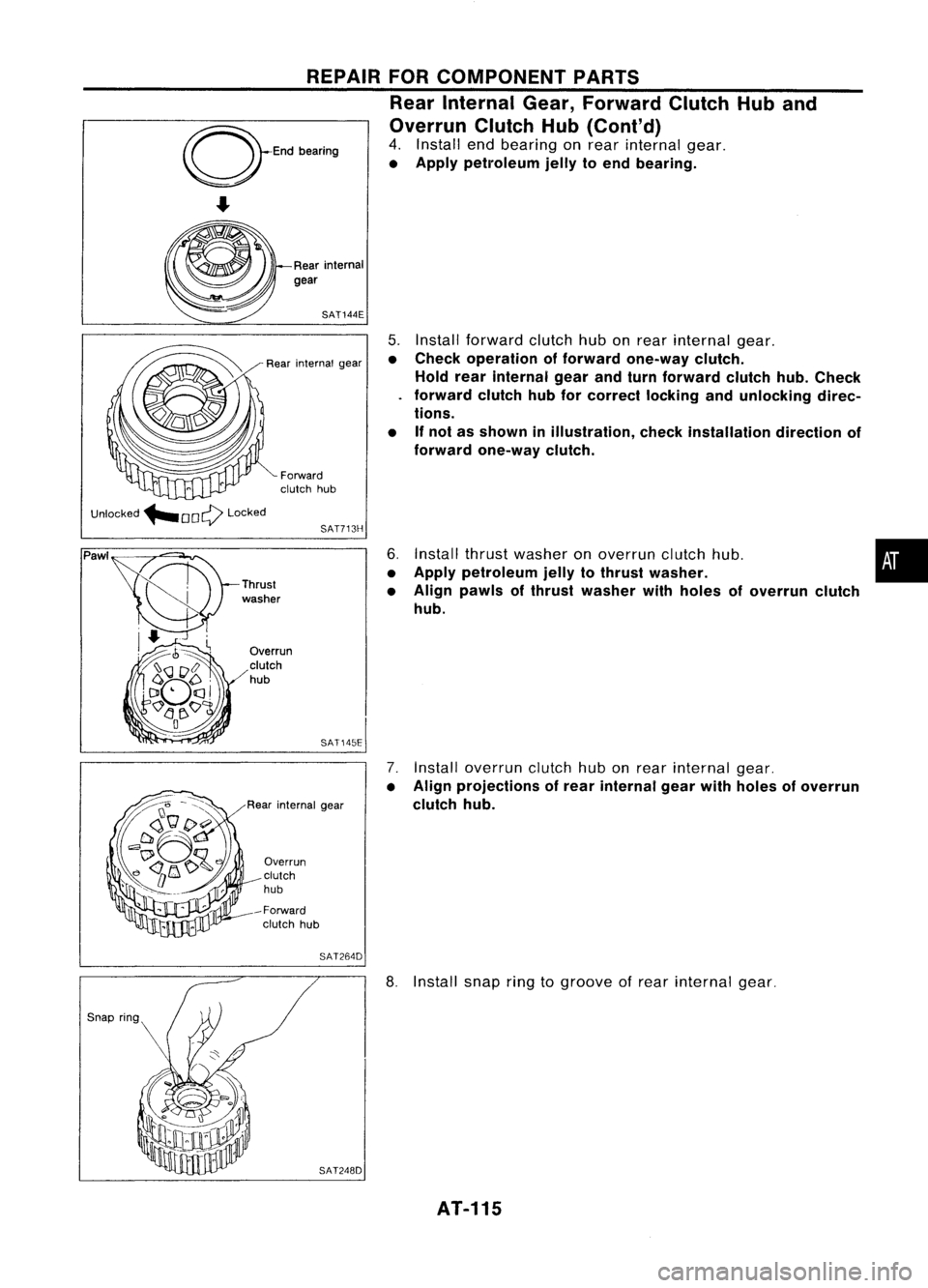

Page 115 of 1701

Rearinternal

gear

•

5.

Install forward clutchhubonrear internal gear.

• Check operation offorward one-way clutch.

Hold rearinternal gearandturn forward clutchhub.Check

forward clutchhubforcorrect lockingandunlocking direc-

tions.

• Ifnot asshown inillustration, checkinstallation directionof

forward one-way clutch.

6. Install thrustwasher onoverrun clutchhub.

• Apply petroleum jellytothrust washer.

• Align pawls ofthrust washer withholes ofoverrun clutch

hub.

7. Install overrun clutchhubonrear internal gear.

• Align projections ofrear internal gearwithholes ofoverrun

clutch hub.

SAT144E

REPAIR

FORCOMPONENT PARTS

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub(Cont'd)

4. Install endbearing onrear internal gear.

• Apply petroleum jellytoend bearing.

SAT713H

Forward

clutch hub

Rear

internal gear

SAT145E

Overrun

clutch

hub

-Forward clutch hub

Overrun

clutch

hub

Rear internal gear

Unlocked

"'OOQ Locked

Pawl

SAT264D

SAT248D

8.

Install snapringtogroove ofrear internal gear.

AT-115

Page 165 of 1701

SERVICEOATAAND SPECIFICATIONS (SOS)

General Specifications

Except Europe and

Europe Except

Europe and

Australia Australia

Australia Australia

Applied model

GA150E GA160E

SR200E

With catalyzer

Withoutcatalyzer

Automatic transaxle

RL4F03A

model

Automatic transaxle

assembly

Model codenumber 34X69 34X68 34X70

34X8034X81

Transaxle gearratio

1st 2.861

2.8611

2.861

2nd 1.5621.5622

1.562

3rd 1.0001.0000

1.000

4th 0697.0.6979

0.697

Reverse 2.3102.3103

2.310

Final drive 3.8274.0721

3.827

Recommended oil

GenuineNissanATForequivalent

Oil capacity

f

(Imp qt)

7.0(6-1/8)

Specifications andAdjustments

VEHICLE SPEEDWHENSHIFTING GEARS

Model 34X68

Throttle position Vehicle

speedkm/h(MPH)

0, -->O

2

O

2

-->0

3

0

3

-->O. O.-->0

3

0

3

-->O

2

O2-->D, 12--> 1,

Full throttle 48

-56 88-96 133-141 80-88 37-45 45-53

(30 -35) (55-60)

-

(83-88) (50-55) (23-28)

(28-33)

Half throttle 31

-39 54-62 102-110

75-83 44

-52

7-15 45-53

(19 -24) (34-39) (63-68) (47-52) (27-32) (4-9)

(28-33)

Model 34X69and34X70

Throttle position Vehicle

speedkm/h(MPH)

0, -->O

2

O

2

-->0

3

0

3

-->O. O.-->0

3

0

3

-->O

2

O

2

-->0, 1

2

--> 1,

Full throttle 51

-60

94-102 136-144 85-93 40-48 48-56

(32 -37) (58-63)

-

(85-89) (53-58) (25-30)

(30-35)

Half throttle 30

-38 52-60 97-105 67-75 42-50 8-16 48-56

(19 -24)

(32-37) (60

-65) (42-47) (26-31)

(5-10) (30

-35)

Model 34X80

Throttle position Vehicle

speedkm/h(MPH)

0, -->O

2

O

2

-->0

3

0

3

-->O. O.-->0

3

0

3

-->O

2

O2-->0, 1

2

--> 1,

Full throttle 52.60

100-108 145-153 90.98

40-48 49-57

(32 -37) (62-67)

-

(90-95) (56

-61) (25-30) (30-35)

Half throttle 30

-38 53

-61 103-111

69-77 42

-50 8-16 49-57

(19 -24)

(33-38) (64-69) (43

-48) (26-31) (5-10) (30-35)

Model 34X81

Throttle position Vehicle

speedkm/h(MPH)

0, -->O

2

O

2

-->0

3

0

3

-->O.

O.

-->0

3

0

3

-->O

2

O

2

-->0, 1

2

--> 1,

Full throttle 58.66

107.115 160.168

96-104 39-47 48-56

(36 -41) (66-71)

-

(99-104) (60-65) (24-29) (30-35)

Half throttle 33

-41 57-65 105.113

69-77 45

-53 8.

16

48-56

(21 -25) (35-40) (65.70)

(43-48) (28

-33)

(5-10) (30

-35)

AT-165

•

Page 167 of 1701

SERVICEDATAANDSPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

CONTROL VALVES

Control valvereturn springs

Unit:

mm

(in)

Parts Part

No. Freelength

Outerdiameter

Model

Pressure modi-

34X69,34X70, 34X68,

d)

liervalve 31742-31X642502(0.9850) 79(0.311)

spring 34X80,

34X81

@)

Kickdown

modulator valvespring 31742-31X03 40.5(1.594) 9.0(0.354)

34X80 31742-31X0451.14(2.0134) 17.0(0.669)

@

1-2

accumula-

tor valve spring 34X69,

34X70,34X68,

34X81 31742-31X63

50.8(2000) 17.0(0.669)

@

3-2timing valvespring 31736-21

XOO 26.3(1.035) 7.2(0.283)

~ 1st

reducing valvespring 31835-21X0822.6(0.890) 7.3(0.287)

Upper

@

Torque converter reliefvalve spring 31742-31X06 23.5(0.925) 7.4(0.291)

body Throttlemodu-

34X68,34X81

31742-31X07 29.5

(1.161)

5.5(0.217)

(J)

lator valve

spring 34X69,

34X70, 34X80 31742-31X18 29.5(1161)

5.5(0.217)

34X69, 34X70, 34X80 31736-01X02 21.7(0.854) 6.65(0.2618)

@

4th

speed cut

34X68 31756-21X0222.6(0.890)

7.3(0.287)

valve spring

34X81 31835-21X0223.2(0913) 6.2(0.244)

@

Lock-up

controlvalvespring 31742-31X08

39.5(1.555) 50(0.197)

@

4-2sequence valvespring 31742-31X0939.5(1.555) 51(0.201)

-

Oilcooler reliefvalve spring 31872-31XOO17.02(0.6701) 8.0(0.315)

Throttle valve 34X81

31802-31X06 32.0(1.260) 10.0(0.394)

d)

anddetent

34X69,34X70, 34X68,

valve spring

34X80 31802-31X07

33.0

(1.299)

10.0(0.394)

(2)

Pressure regulatorvalvespring 31742-31XOO 5224(2.0567) 15.0(0.591)

Lower 34X68

31762-31XOO

52.0(2.047)

8.0(0.315)

body

@

3-4

shift valve

34X69,34X70,34X80 31762-31X13 52.0(2.047) 7.45(0.2933)

spring

34X81 31762-31X1152.0(2.047) 80(0.315)

@

2-3shift valve spring 31762-31X0152.7(2.075) 7.0(0.276)

cID

1-2

shift valve spring 31762-31X0245.9(1.807) 5.3(0.209)

@

Overrun clutchcontrol valvespring 31742-31X60 48.9

(1.925) 7.0(0.276)

AT-167

•

Page 170 of 1701

Differential sidegear clearance

FINAL

DRIVE SERVICE

DATAANDSPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

Differential sidebearing adjusting shims

(Except model34X81)

Differential sidegear thrust washers

(Except model34X69)

Differential caseendplay (Except model

34X81) Differential

sidegear thrust washers (Model

34X69)

Clearance

betweensidegear

and differential easewith

washer mm(in)

Thickness mm(in)

0.75 -0.80 (0.0295 -0.0315)

0.80 -0.85 (0.0315 -0.0335)

0.85 -0.90 (0.0335 -0.0354)

0.90 -0.95 (0.0354 -0.0374)

0.95 -1.00 (0.0374 -0.0394)

Thickness mm(in)

0.75 -0.80 (0.0295 -0.0315)

0.80 -0.85 (0.0315 -0.0335)

0.85 -090 (0.0335 -0.0354)

090 -0.95 (0.0354 -0.0374)

0.95 -1.00 (0.0374 -0.0394)

Differential caseendplay

mm (in)

0.1

-0.2 (0.004 -0.008)

Part number

38424-31 XOO

38424-31X01

38424-31 X02

38424-31 X03

38424-31X04

Part number

38424-02111

38424-02112

38424-02113

38424-02114 38424-02115

0-015 (0-0.0059)

Thickness

mm(in) Part

number

0.48 (0.0189) 38454-M8001

0.56 (0.0220) 38454-M8003

0.64 (0.0252) 38454-M8005

0.72 (0.0283) 38454-M8007

0.80 (0.0315) 38454-M8009

0.88 (0.0346) 38454-M8011

0.96 (0.0378) 38454-M8013

1.04 (0.0409) 38454-M8015

Differential sidebearing adjusting shims

(Model 34X81)

Thickness mm(in) Partnumber

0.40 (0.0157) 31499-21X07

0.44 (0.0173) 31499-21X08

0.48 (00189) 31499-21X09

0.52 (0.0205) 31499-21X10

0.56 (0.0220) 31499-21X11

0.60 (00236) 31499-21X12

0.64 (0.0252) 31499-21X13

068 (00268) 31499-21X14

0.72 (00283) 31499-21X15

076 (0.0299) 31499-21X16

0.80 (0.0315) 31499-21X17

0.84 (0.0331) 31499-21X18

0.88 (0.0346) 31499-21X19

0.92 (0.0362) 31499-21X20

1.44 (00567) 31499-21X21

Bearing preload(Model34X81)

Oifferential sidebearing pre-

load

'T'

mm(in)

004

-009 (00016 -0.0035)

Turning torque(Model 34X81)

Turning torqueoffinal drive

049_108 ( _11 4_5)

assembly Nm(kg-em, in-Ib)' .

5.0 .0,.3 9.

AT-170

Page 179 of 1701

![NISSAN ALMERA N15 1995 Service Manual ________BODYCOMPONENT PARTS _

___________ REPLACEMENTOPERATIONS

Rear Fender

5-doorhatchback

BodyComponent Parts Sedan

5-door Hatchback

~

o

o

'"C

iD

c

co

"0

(]J

en

@

1or 111

1 NISSAN ALMERA N15 1995 Service Manual ________BODYCOMPONENT PARTS _

___________ REPLACEMENTOPERATIONS

Rear Fender

5-doorhatchback

BodyComponent Parts Sedan

5-door Hatchback

~

o

o

'"C

iD

c

co

"0

(]J

en

@

1or 111

1](/img/5/57349/w960_57349-178.png)

________BODYCOMPONENT PARTS _

___________ REPLACEMENTOPERATIONS

Rear Fender

5-doorhatchback

BodyComponent Parts Sedan

5-door Hatchback

~

o

o

'"C

iD

c

co

"0

(]J

en

@

1or 111

1IIl.

(length: 10mm)

@ 4or 113

@

1or 111

@

1

or

11 1

112

111

112

M.I. Gseam weld/

Point weld

113

111

_ 7orll5

Rear pillar inner

reinforcement

_ 200r 1115

M.1. Gplug wel(d For3panels plugweld method )

· r

.A===-= .B~

116

~

c

[IJ

co

.......

"0

:I:

(]J

[J

"en

ID

1IIl.

~~f~

@90r1l7

_50r1l4_5orll4

c

""

~

_

4orll3

co

"0

(]J

en

_ 3orll2

c

co

@ 1or 111

"0

[IJ

(]J

111

.......

en

_ 12 orll 9

:I:

0

LO

@ 5orll 4

Unit:mm

2-spot welds 3-spotwelds

Service

Joint

-41-

-4-

Page 185 of 1701

REPLACEMENTOPERATIONS

Front SideMember (PartialReplacement)

(Work afterradiator coresupport hasbeen removed.) ________

CORROSIONPROTECTION _

Stone Guard Coat

SectionB-B

Section

A-A

--r':":'

To

prevent damage causedbystones, thelower outerbodypanels (fender, door,etc.)have anadditional layer

of Stone Guard CoatovertheEDprimer coating. Thus,when replacing orrepairing thesepanels, apply

undercoat tothe same portions asbefore. Useacoat which isrust preventive, durable,shockresistant andhas

a long shelf life.

~mm1111i :

Indicates stoneguard coated portions

114

Patch

118

111

115

114

hoodledge

panel

117

111

Unit:mm

8

Patch

""

"

"

(Thickness: 1mm)

-\

Service

Joint

(This figure showrightfront sidemember)

2-spot welds 3-spotwelds M.1.

Gplug weld MIG seam weld/

(For 3panels plugweld method )P1ID.~irit

F

weld

• rr=

.A=-= .B~

G1J --- ~

Section

C-C

-35- -10-