ABS NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 182 of 1701

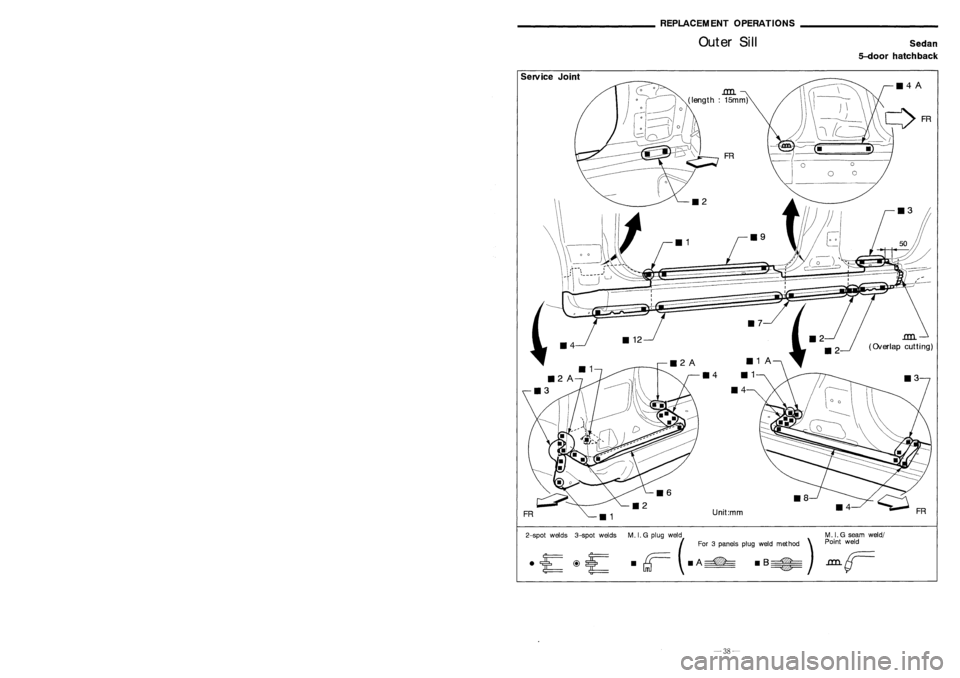

Description REPLACEMENT

OPERATIONS

Outer Sill

Sedan

5-door hatchback

FR

_4A

.cm

(OIerlap cutting)

_4

117

Unit:mm

119

112A 111A

114 111

114

M. I.G plug weld MIG seam weld/

(For 3panels plugweld method )P.an.

0int

;=::

· r .

A

=6=___

.8=:=

V

11

12

_4

111

112A

113

2-spot welds 3-spotwelds

Service

Joint

One-side precoated

Steel

sheet

~ Outside

Two-side precoated

Zn-Ni

alloy

Cationic electrodeposition primer

PHOSPHATE

COATINGTREATMENT AND

CATIONIC ELECTRODEPOSITION PRIMER

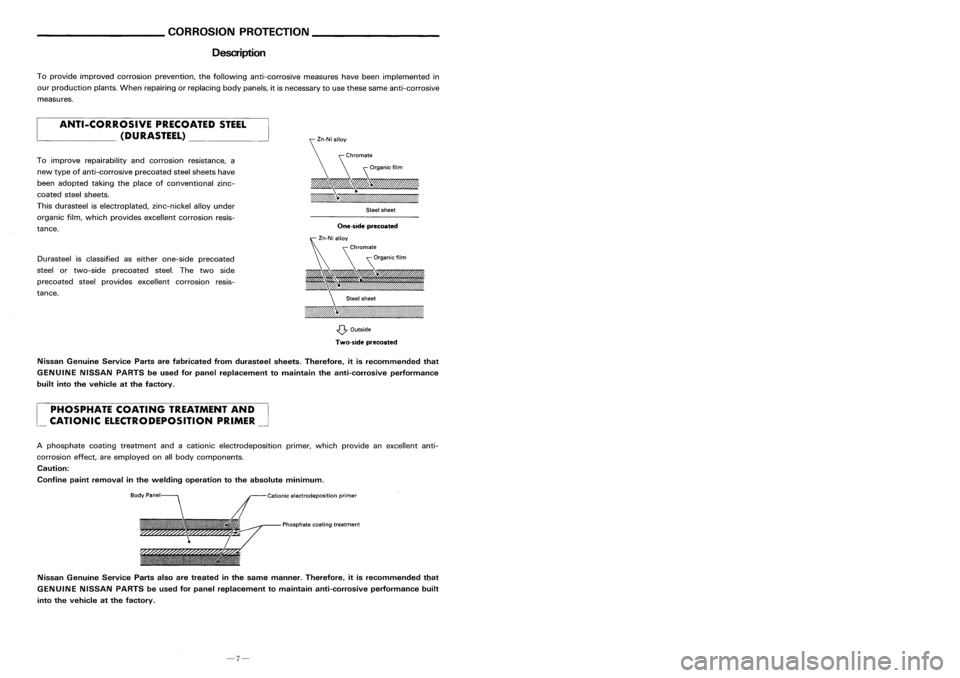

ANTI-CORROSIVE

PRECOATEDSTEEL

(DURASTEEL)

To

provide improved corrosion prevention, thefollowing anti-corrosive measureshavebeen implemented in

our production plants.Whenrepairing orreplacing bodypanels, itis necessary touse these sameanti-corrosive

measures.

Nissan Genuine ServicePartsalsoaretreated inthe same manner. Therefore, itis recommended tbat

GENUINE NISSANPARTSbeused forpanel replacement tomaintain anti-corrosive performancebuilt

into thevehicle atthe factory.

A

phosphate coatingtreatment andacationic electrodeposition primer,whichprovide anexcellent anti-

corrosion effect,areemployed onallbody components.

Caution:

Confine paintremoval inthe welding operation tothe absolute minimum.

Durasteel

isclassified aseither one-side precoated

steel ortwo-side precoated steel.Thetwo side

precoated steelprovides excellent corrosion resis-

tance. To

improve repairability andcorrosion resistance, a

new type ofanti-corrosive precoatedsteelsheets have

been adopted takingtheplace ofconventional zinc-

coated steelsheets.

This durasteel iselectroplated, zinc-nickelalloyunder

organic film,which provides excellent corrosion resis-

tance.

Nissan Genuine ServicePartsarefabricated fromdurasteel sheets.Therefore, itis recommended that

GENUINE NISSANPARTSbeused forpanel replacement tomaintain theanti-corrosive performance

built intothevehicle atthe factory.

-7-

-38-

Page 193 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __

BODYALIGNMENT _

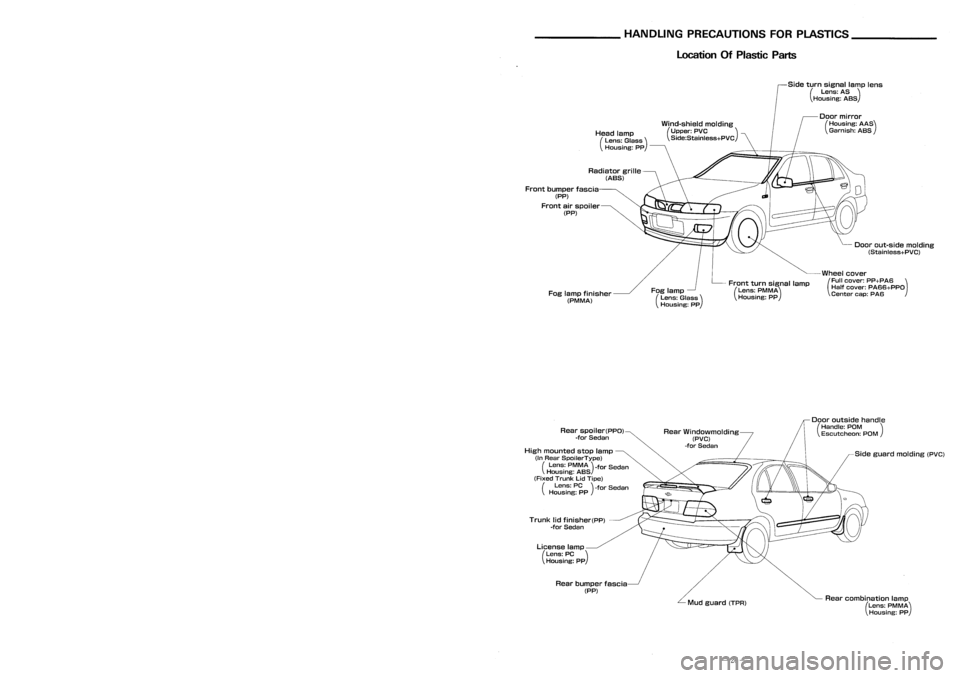

Location OfPlastic Parts

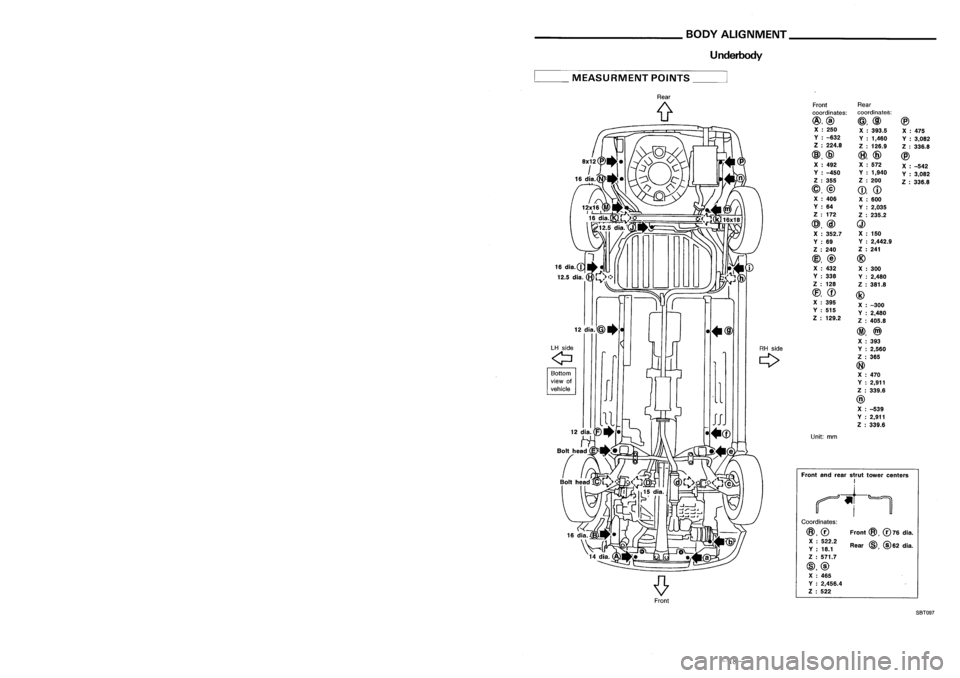

Underbody

Kicking plate(PP)

Front

@,

076

dia.

Rear

@,@

62 dia.

Front

Rear

coordinates: coordinates:

@,@ @,@@

X :250

X:393.5

X:475

V :-632

V:1,460

V:3,082

Z :224.8

Z:126.9

Z:336.8

@,@

(8),

@

@

X :492 X

:572

X:-542

V :-450 V

:1,940

V:3,082

Z :355 Z

:200

Z:336.8

@,@

CD,

CD

X :406

X:600

V :64

V:2,035

Z :172

Z:235.2

@,@

Q)

X :352.7 X

:150

V :69 V

:2,442.9

Z :240 Z

:241

@,

@

@

X :432

X:300

V :338

V:2,480

Z :128

Z:381.8

(f),

CD

@

X :395

X:-300

V :515

V:2,480

Z :129.2

Z:405.8

@,

@)

X :393

Y :2,560

Z :365

@

X :470

Y :2,911

Z :339.6

@

X :-539

Y :2,911

Z :339.6

Unit: mm

Coordinates:

@,0

X :522.2

V :18.1

Z :571.7

@,@ X :465

V :2,456.4

Z :522

Front

andrear strut tower centers

I

~t-~

Rear

(f

••@

LH side

RHside

Q

Q

Bottom

view of

,1

vehicle

__

MEASURMENT POINTS__

Glove box(PPC)

Side

wind molding(PVC)

Cluster lidC(PPC)

Instrument

panel(PPC)

Console box(PPC)

5-door

Hatchback

Cluster lidA(PPC)

~----_/

Front

pillargarnish(PPC)

Side

wind molding(PVC)

Back doorfinisher(ABS)

Roof

spoilar(FRP)

3-doorHatchback

Center pillarlower garnish(PP)

Center pillarupper garnish(PPC)

Rear pillar garnish(PPC)

High

mounted stoplamp

(Lens: PMMA )

Housing: ABS

FrontSBT097

-27-

-18-

Page 194 of 1701

__________ BODYALIGNMENT _

_HANDLINGPRECAUTIONS FORPLASTICS _

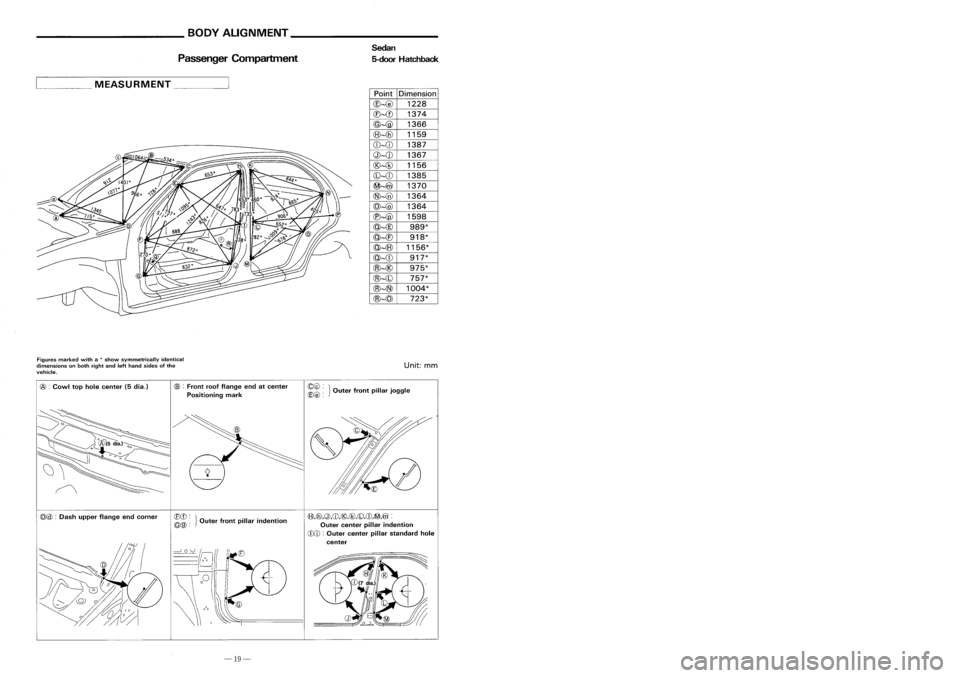

Passenger Compartment Sedan

5-door Hatchback Location

OfPlastic Parts

Side turnsignal lamplens

(Lens: AS)

Housing: ASS

Wind-shield molding

(Upper: PVC )

Side:Stainless+PVC

Doorout-side molding

(Stainless+PVC)

Wheel cover

(Full cover: PP+PA6 )

Half cover: PA66+PPO

Center cap:PA6

Door

mirror

(Housing: AAS)

Garnish: ASS

Front turnsignal lamp

(Lens: PMMA)

Housing: PP

Fog

lamp

(Lens: Glass)

Housing: PP

Head

lamp

(Lens: Glass)

Housing: pp

Radiator grille

(ABS)

Fog lamp finisher

(PM MA)

Front

bumper fascia

(PP)

Front airspoiler

(PP)

Point

Dimension

@-@

1228

CB-

@-@

1366

(8)-{6)

1159

CD--cD

1387

Q)-{J) 1367

@--@

1156

(b)--{[)

1385

~-4iV

1370

@~

1364

@~

1364

C'e)--@

1598

@--@

989*

@-{E)

918*

@~

1156*

@--{[)

917*

@~@

975*

@~(b)

757*

@~

1004*

@--@

723*

,

... ._MEASURMENT _

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

CB>

:

Front roofflange endatcenter

Positioning mark ~~

~}Outer frontpillarjoggle

Sideguard molding (PVC)

Rear combination lamp

(Lens: PMMA)

Housing: PP

Door

outside handle

(Handle: POM )

Escutcheon: POM

Mud guard (TPR)

Rear

Windowmolding

(PVC)

-for Sedan

Rear bumper fascia

(PP)

License

lamp

(Lens: PC)

Housing: PP

Trunk

lidfinisher(pp)

-for Sedan

Rear

spoiler(PPO)

-for Sedan

High mounted stoplamp

(In Rear SpoilerType)

(Lens: PMMA)-for Sedan

Housing: ASS

(Fixed Trunk LidTipe)

(Lens: PC)-for Sedan

Housing: PP

(f3),Cfi),Q),CD,@,@,CD,CD,~,@ :

Outer center pillarindention

CDCD :

Outer center pillarstandard hole

center

CBCD:

}

~@:

Outerfrontpillar indention

@@

:

Dash upper flange endcorner

-19- -26-

Page 195 of 1701

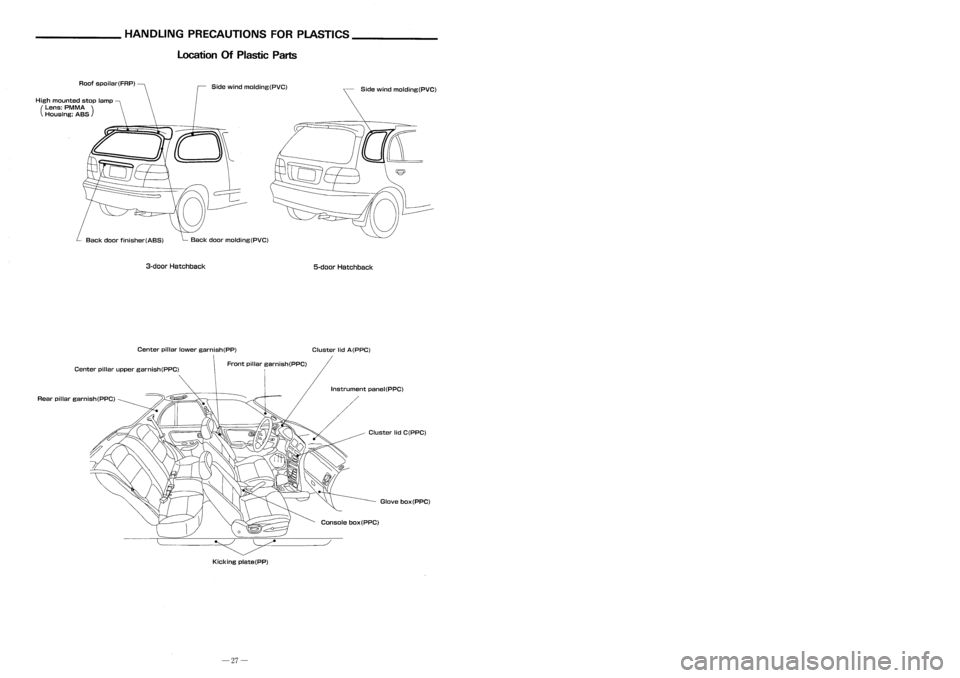

______ HANDLINGPRECAUTIONS FORPLASTICS __________

BODYALIGNMENT _

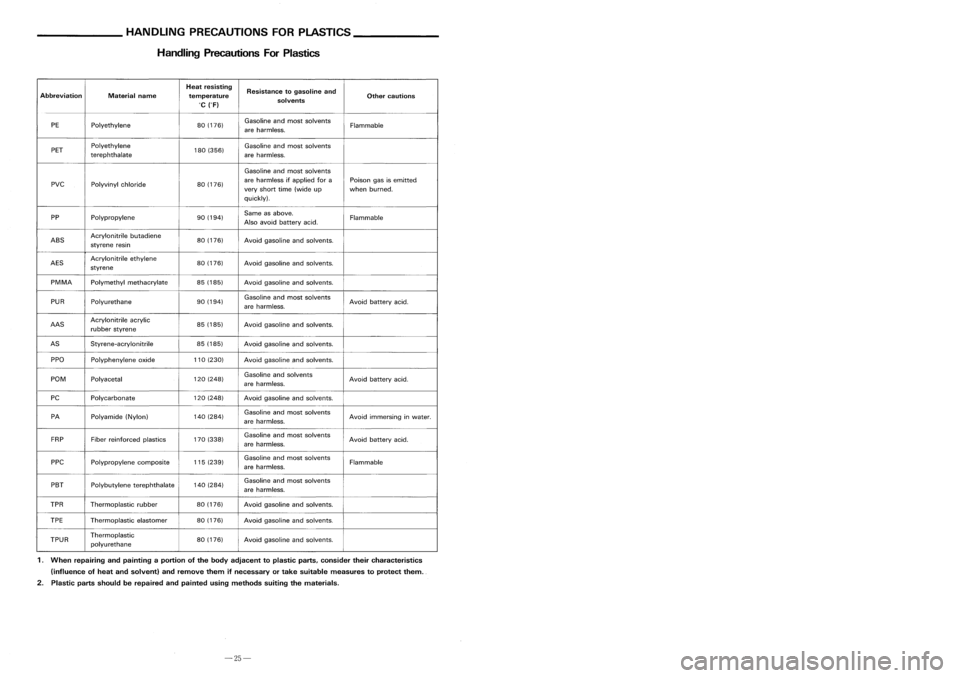

Handling Precautions ForPlastics

Heat resisting

Resistancetogasoline and

Abbreviation Materialname

temperature Othercautions

QC rF)

solvents

PE Polyethylene

80

(176)

Gasoline

andmost solvents

Flammable

are harmless.

PET Polyethylene

180(356)

Gasoline

andmost solvents

terephthalate areharmless.

Gasoline andmost solvents

PVC Polyvinylchloride

80

(176)

are

harmless ifapplied fora

Poison gasisemitted

very short time(wide up

whenburned.

quickly).

pp

Polypropylene

90

(194)

Same

asabove.

Flammable

Also avoid battery acid.

ABS Acrylonitrile

butadiene

80(176)

Avoidgasoline andsolvents.

styrene resin

AES Acrylonitrile

ethylene

80(176)

Avoidgasoline andsolvents.

styrene

PMMA Polymethylmethacrylate

85

(185)

Avoidgasoline andsolvents.

PUR Polyurethane

90

(194)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

AAS Acrylonitrile

acrylic

85(185)

Avoidgasoline andsolvents.

ru bber styrene

AS Styrene-a crylo nitri Ie

85

(185)

Avoidgasoline andsolvents.

PPO Polyphenylene oxide

110

(230)

Avoidgasoline .andsolvents.

POM Polyacetal

120

(248)

Gasoline

andsolvents

Avoidbattery acid.

are harmless.

PC Polycarbonate

120

(248)

Avoidgasoline andsolvents.

PA Polyamide(Nylon)

140

(284)

Gasoline

andmost solvents

Avoidimmersing inwater.

are harmless.

FRP Fiberreinforced plastics

170

(338)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

PPC Polypropylene composite

115

(239)

Gasoline

andmost solvents

Flammable

are harmless.

PBT Polybutylene terephthalate

140

(284)

Gasoline

andmost solvents

are harmless.

TPR Thermoplastic rubber

80

(176)

Avoidgasoline andsolvents.

TPE Thermoplastic elastomer

80

(176)

Avoidgasoline andsolvents.

TPUR Thermoplastic

80(176)

Avoidgasoline andsolvents.

polyurethane

1 . When repairing andpainting aportion ofthe body adjacent toplastic parts,consider theircharacteristics

(influence ofheat andsolvent) andremove themifnecessary ortake suitable measures toprotect them._

2. Plastic partsshould berepaired andpainted usingmethods suitingthematerials.

-25-

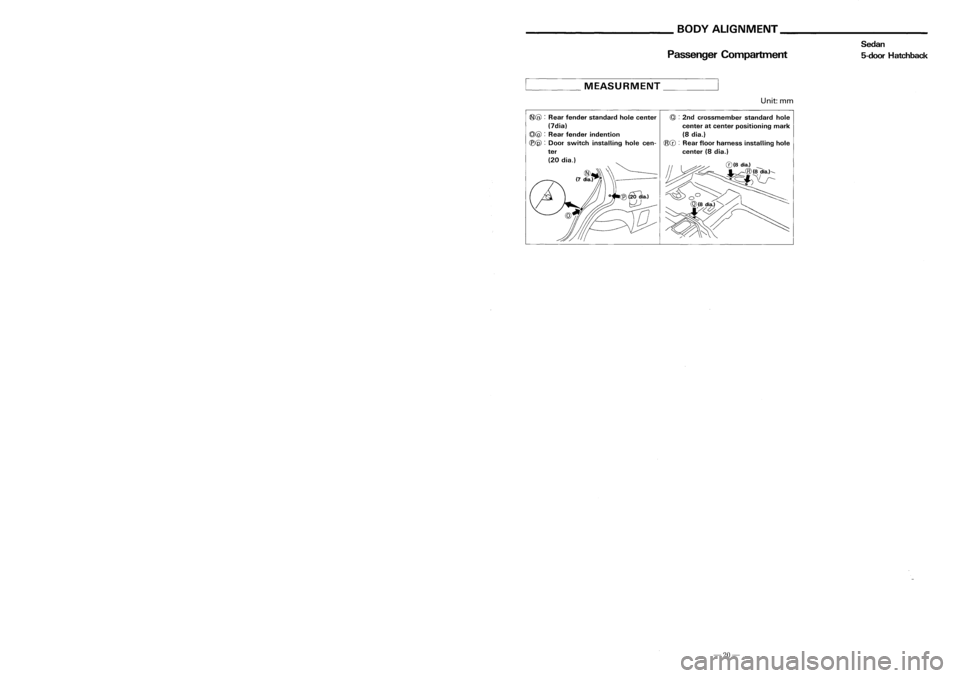

Passenger

Compartment

____ MEASURMENT _

Unit:mm

~@ :

Rear fender standard holecenter

@:

2nd crossmember standardhole

(7dia) centeratcenter positioning mark

(Q)@ :

Rear fender indention (8dia.)

(B@ :

Door switch installing holecen-

@([):

Rearfloor harness installing hole

ter center(8dia.)

(20 dia.) ~

(D<)

~~ ~~'---- ~ k@(fdiaol",

(7 diajj \\1 ~;..·

C')\U--

~ ~O"~Wiaol ~

-Z

J

D~

-20-

Sedan

5-door Hatchback

Page 200 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __________

BODYALIGNMENT _

Handling Precautions ForPlastics

Heat resisting

Resistancetogasoline and

Abbreviation Materialname

temperature Othercautions

QC rF)

solvents

PE Polyethylene

80

(176)

Gasoline

andmost solvents

Flammable

are harmless.

PET Polyethylene

180(356)

Gasoline

andmost solvents

terephthalate areharmless.

Gasoline andmost solvents

PVC Polyvinylchloride

80

(176)

are

harmless ifapplied fora

Poison gasisemitted

very short time(wide up

whenburned.

quickly).

pp

Polypropylene

90

(194)

Same

asabove.

Flammable

Also avoid battery acid.

ABS Acrylonitrile

butadiene

80(176)

Avoidgasoline andsolvents.

styrene resin

AES Acrylonitrile

ethylene

80(176)

Avoidgasoline andsolvents.

styrene

PMMA Polymethylmethacrylate

85

(185)

Avoidgasoline andsolvents.

PUR Polyurethane

90

(194)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

AAS Acrylonitrile

acrylic

85(185)

Avoidgasoline andsolvents.

ru bber styrene

AS Styrene-a crylo nitri Ie

85

(185)

Avoidgasoline andsolvents.

PPO Polyphenylene oxide

110

(230)

Avoidgasoline .andsolvents.

POM Polyacetal

120

(248)

Gasoline

andsolvents

Avoidbattery acid.

are harmless.

PC Polycarbonate

120

(248)

Avoidgasoline andsolvents.

PA Polyamide(Nylon)

140

(284)

Gasoline

andmost solvents

Avoidimmersing inwater.

are harmless.

FRP Fiberreinforced plastics

170

(338)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

PPC Polypropylene composite

115

(239)

Gasoline

andmost solvents

Flammable

are harmless.

PBT Polybutylene terephthalate

140

(284)

Gasoline

andmost solvents

are harmless.

TPR Thermoplastic rubber

80

(176)

Avoidgasoline andsolvents.

TPE Thermoplastic elastomer

80

(176)

Avoidgasoline andsolvents.

TPUR Thermoplastic

80(176)

Avoidgasoline andsolvents.

polyurethane

1 . When repairing andpainting aportion ofthe body adjacent toplastic parts,consider theircharacteristics

(influence ofheat andsolvent) andremove themifnecessary ortake suitable measures toprotect them._

2. Plastic partsshould berepaired andpainted usingmethods suitingthematerials.

-25-

Passenger

Compartment

____ MEASURMENT _

Unit:mm

~@ :

Rear fender standard holecenter

@:

2nd crossmember standardhole

(7dia) centeratcenter positioning mark

(Q)@ :

Rear fender indention (8dia.)

(B@ :

Door switch installing holecen-

@([):

Rearfloor harness installing hole

ter center(8dia.)

(20 dia.) ~

(D<)

~~ ~~'---- ~ k@(fdiaol",

(7 diajj \\1 ~;..·

C')\U--

~ ~O"~Wiaol ~

-Z

J

D~

-20-

Sedan

5-door Hatchback

Page 201 of 1701

__________ BODYALIGNMENT _

_HANDLINGPRECAUTIONS FORPLASTICS _

Passenger Compartment Sedan

5-door Hatchback Location

OfPlastic Parts

Side turnsignal lamplens

(Lens: AS)

Housing: ASS

Wind-shield molding

(Upper: PVC )

Side:Stainless+PVC

Doorout-side molding

(Stainless+PVC)

Wheel cover

(Full cover: PP+PA6 )

Half cover: PA66+PPO

Center cap:PA6

Door

mirror

(Housing: AAS)

Garnish: ASS

Front turnsignal lamp

(Lens: PMMA)

Housing: PP

Fog

lamp

(Lens: Glass)

Housing: PP

Head

lamp

(Lens: Glass)

Housing: pp

Radiator grille

(ABS)

Fog lamp finisher

(PM MA)

Front

bumper fascia

(PP)

Front airspoiler

(PP)

Point

Dimension

@-@

1228

CB-

@-@

1366

(8)-{6)

1159

CD--cD

1387

Q)-{J) 1367

@--@

1156

(b)--{[)

1385

~-4iV

1370

@~

1364

@~

1364

C'e)--@

1598

@--@

989*

@-{E)

918*

@~

1156*

@--{[)

917*

@~@

975*

@~(b)

757*

@~

1004*

@--@

723*

,

... ._MEASURMENT _

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

CB>

:

Front roofflange endatcenter

Positioning mark ~~

~}Outer frontpillarjoggle

Sideguard molding (PVC)

Rear combination lamp

(Lens: PMMA)

Housing: PP

Door

outside handle

(Handle: POM )

Escutcheon: POM

Mud guard (TPR)

Rear

Windowmolding

(PVC)

-for Sedan

Rear bumper fascia

(PP)

License

lamp

(Lens: PC)

Housing: PP

Trunk

lidfinisher(pp)

-for Sedan

Rear

spoiler(PPO)

-for Sedan

High mounted stoplamp

(In Rear SpoilerType)

(Lens: PMMA)-for Sedan

Housing: ASS

(Fixed Trunk LidTipe)

(Lens: PC)-for Sedan

Housing: PP

(f3),Cfi),Q),CD,@,@,CD,CD,~,@ :

Outer center pillarindention

CDCD :

Outer center pillarstandard hole

center

CBCD:

}

~@:

Outerfrontpillar indention

@@

:

Dash upper flange endcorner

-19- -26-

Page 202 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __

BODYALIGNMENT _

Location OfPlastic Parts

Underbody

Kicking plate(PP)

Front

@,

076

dia.

Rear

@,@

62 dia.

Front

Rear

coordinates: coordinates:

@,@ @,@@

X :250

X:393.5

X:475

V :-632

V:1,460

V:3,082

Z :224.8

Z:126.9

Z:336.8

@,@

(8),

@

@

X :492 X

:572

X:-542

V :-450 V

:1,940

V:3,082

Z :355 Z

:200

Z:336.8

@,@

CD,

CD

X :406

X:600

V :64

V:2,035

Z :172

Z:235.2

@,@

Q)

X :352.7 X

:150

V :69 V

:2,442.9

Z :240 Z

:241

@,

@

@

X :432

X:300

V :338

V:2,480

Z :128

Z:381.8

(f),

CD

@

X :395

X:-300

V :515

V:2,480

Z :129.2

Z:405.8

@,

@)

X :393

Y :2,560

Z :365

@

X :470

Y :2,911

Z :339.6

@

X :-539

Y :2,911

Z :339.6

Unit: mm

Coordinates:

@,0

X :522.2

V :18.1

Z :571.7

@,@ X :465

V :2,456.4

Z :522

Front

andrear strut tower centers

I

~t-~

Rear

(f

••@

LH side

RHside

Q

Q

Bottom

view of

,1

vehicle

__

MEASURMENT POINTS__

Glove box(PPC)

Side

wind molding(PVC)

Cluster lidC(PPC)

Instrument

panel(PPC)

Console box(PPC)

5-door

Hatchback

Cluster lidA(PPC)

~----_/

Front

pillargarnish(PPC)

Side

wind molding(PVC)

Back doorfinisher(ABS)

Roof

spoilar(FRP)

3-doorHatchback

Center pillarlower garnish(PP)

Center pillarupper garnish(PPC)

Rear pillar garnish(PPC)

High

mounted stoplamp

(Lens: PMMA )

Housing: ABS

FrontSBT097

-27-

-18-

Page 213 of 1701

Description REPLACEMENT

OPERATIONS

Outer Sill

Sedan

5-door hatchback

FR

_4A

.cm

(OIerlap cutting)

_4

117

Unit:mm

119

112A 111A

114 111

114

M. I.G plug weld MIG seam weld/

(For 3panels plugweld method )P.an.

0int

;=::

· r .

A

=6=___

.8=:=

V

11

12

_4

111

112A

113

2-spot welds 3-spotwelds

Service

Joint

One-side precoated

Steel

sheet

~ Outside

Two-side precoated

Zn-Ni

alloy

Cationic electrodeposition primer

PHOSPHATE

COATINGTREATMENT AND

CATIONIC ELECTRODEPOSITION PRIMER

ANTI-CORROSIVE

PRECOATEDSTEEL

(DURASTEEL)

To

provide improved corrosion prevention, thefollowing anti-corrosive measureshavebeen implemented in

our production plants.Whenrepairing orreplacing bodypanels, itis necessary touse these sameanti-corrosive

measures.

Nissan Genuine ServicePartsalsoaretreated inthe same manner. Therefore, itis recommended tbat

GENUINE NISSANPARTSbeused forpanel replacement tomaintain anti-corrosive performancebuilt

into thevehicle atthe factory.

A

phosphate coatingtreatment andacationic electrodeposition primer,whichprovide anexcellent anti-

corrosion effect,areemployed onallbody components.

Caution:

Confine paintremoval inthe welding operation tothe absolute minimum.

Durasteel

isclassified aseither one-side precoated

steel ortwo-side precoated steel.Thetwo side

precoated steelprovides excellent corrosion resis-

tance. To

improve repairability andcorrosion resistance, a

new type ofanti-corrosive precoatedsteelsheets have

been adopted takingtheplace ofconventional zinc-

coated steelsheets.

This durasteel iselectroplated, zinc-nickelalloyunder

organic film,which provides excellent corrosion resis-

tance.

Nissan Genuine ServicePartsarefabricated fromdurasteel sheets.Therefore, itis recommended that

GENUINE NISSANPARTSbeused forpanel replacement tomaintain theanti-corrosive performance

built intothevehicle atthe factory.

-7-

-38-

Page 271 of 1701

BRAKESYSTEM

SECTION

CONTENTS BR

PRECAUTIONS ANDPREPARATION

3

Precautions 3

Special Service Tools 4

Commercial ServiceTools 4

CHECK ANDADJUSTMENT 5

Checking BrakeFluidLevel 5

Checking BrakeLine 5

Changing BrakeFluid 5

AIR

BLEEDING 6

Bleeding Procedure 6

BRAKE HYDRAULIC LINE 7

Removal 8

Inspection 8

Installation 8

CONTROL VALVE 9

Proportioning Valve 9

BRAKE PEDALANDBRACKET 11

Removal andInstallation 11

Inspection 11

Adjustment 11

MASTER CYLINDER 12

Removal 12

Disassembly 12

Inspection 13

Assembly 13

Installation 14

BRAKE BOOSTER 15

On-vehicle Service 15

Removal 15

Inspection 16

Installation 16

VACUUM HOSE 17

Removal andInstallation 17

Inspection 17

FRONT DISCBRAKE 19

Pad Replacement.. 19

Removal 22

Disassembly 22Inspection

-Caliper 22

Inspection -Rotor 23

Assembly '".23

Installation 24

REAR DRUM BRAKE 25

Removal 25

Inspection -Wheel Cylinder 26

Wheel Cylinder Overhaul 27

Inspection -Drum 27

Inspection -Lining 27

Installation 27

REAR DISCBRAKE 29

Pad Replacement 29

~~s:~::~'~I~':::::::::::'::: ::.::::::::.::::::.::::::::::.::::::.::::::::~~ •••

Inspection -Caliper 32

Inspection -Rotor 33

Assembly 33

Installation 35

PARKING BRAKECONTROL 36

Removal andInstallation 36

Inspection 36

Adjustment ." 37

ANTI-LOCK BRAKESYSTEM 38

Purpose 38

Operation 38

ABS Hydraulic Circuit 38

System Components 39

System Description 39

Removal andInstallation .40

Wiring Diagram -ABS - .45

TROUBLE DIAGNOSES

52

Contents 52

Component PartsandHarness Connector

Location 64

SERVICE DATAANDSPECIFICATIONS (SDS)86

General Specifications 86

Inspection andAdjustment 88

Page 276 of 1701

SBR995

SBR419C AIR

BLEEDING

Bleeding Procedure

CAUTION:

• Carefully monitorbrakefluidlevel atmaster cylinder during

bleeding operation.

• Ifmaster cylinder issuspected tohave airinside, bleedair

from master cylinder first.Refer to"Installation", "MASTER

CYLINDER", BR-12.

• Fill reservoir withnewbrake fluid"DOT 3"or"DOT

4".

Make sureitis full atall times whilebleeding airout of

system.

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

• Place acontainer undermaster cylinder toavoid spillage of

brake fluid.

• For models withABS, turnignition switchOFFanddiscon-

nect ABS actuator connector orbattery cable.

• Bleed airinthe following order:

I

RHO models

I

Left rear brake-+Right frontbrake-+Right rearbrake-+Left

front brake

I

LAD models

I

Right rearbrake-+Left frontbrake-+Left rearbrake-+Right

front brake.

1. Connect atransparent vinyltubetoair bleeder valve.

2. Fully depress brakepedalseveral times.

3. With brake pedaldepressed, openairbleeder valveto

release air.

4. Close airbleeder valve.

5. Release brakepedalslowly.

6. Repeat steps2.through 5.until clear brake fluidcomes out

of air bleeder valve.

7. Tighten airbleeder valve.

~: 7-

9 N.m (0.7-0.9 kg-m, 61-78 in-Ib)

BR-6