differential NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1 of 1701

AUTOMATICTRANSAXLE

SECTION

AT

CONTENTS

PREPARATION ANDPRECAUTIONS

3

Special Service Tools 3

Commercial ServiceTools 6

Service Notice 7

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 7

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 7

DESCRIPTION

8

Cross-sectional View 8

Hydraulic ControlCircuit 10

Shift Mechanism 14

Control System 15

TROUBLE DIAGNOSES 17

Preliminary Check(PriortoRoad Testing) 17

Road Testing 17

Stall Tasting 24

Pressure Testing 26

Wiring Diagram -AT - 28

Electrical Components Inspection 30

ON-VEHICLE SERVICE 31

Control ValveAssembly andAccumulator 31

Throttle WireAdjustment.. 33

Control CableInstallation andAdjustment 35

Governor Valve 36

Inhibitor SwitchAdjustment 37

Differential SideOilSeal Replacement.. 37

REMOVAL ANDINSTALLATION

39

Removal 39

Installation .40MAJOR

OVERHAUL.. 42

All Models 42

Except Model34X81 .44

Model 34X81 45•

Shift Control Components 46

i

Oil Channel 47

Locations ofAdjusting Shims,Needle

Bearings, ThrustWashers andSnap Rings -

Except Model34X81 .48

Locations ofAdjusting Shims,Needle

Bearings, ThrustWashers andSnap Rings -

Model 34X81 .49

DiSASSEMBLy 50

REPAIR FORCOMPONENT PARTS 66

Manual ShaftandThrottle Lever 66

Oil Pump 70

Control ValveAssembly 74

Control ValveUpper Body 86

Control ValveLower Body 90

Reverse Clutch 93

High Clutch 97

Forward ClutchandOverrun Clutch 102

Low &Reverse Brake 108

Rear Internal Gear,Forward ClutchHuband

Overrun ClutchHub 112

Output Shaft,Output Gear,IdlerGear,

Reduction PinionGearandBearing Retainer

- Except Model34X81 116

Output Shaft,IdlerGear, Reduction Pinion

Gear andBearing Retainer -Model 34X81 121

Band Servo Piston Assembly 126

Final Drive -Except Model34X81 131

Final Drive -Model 34X81 135

Page 3 of 1701

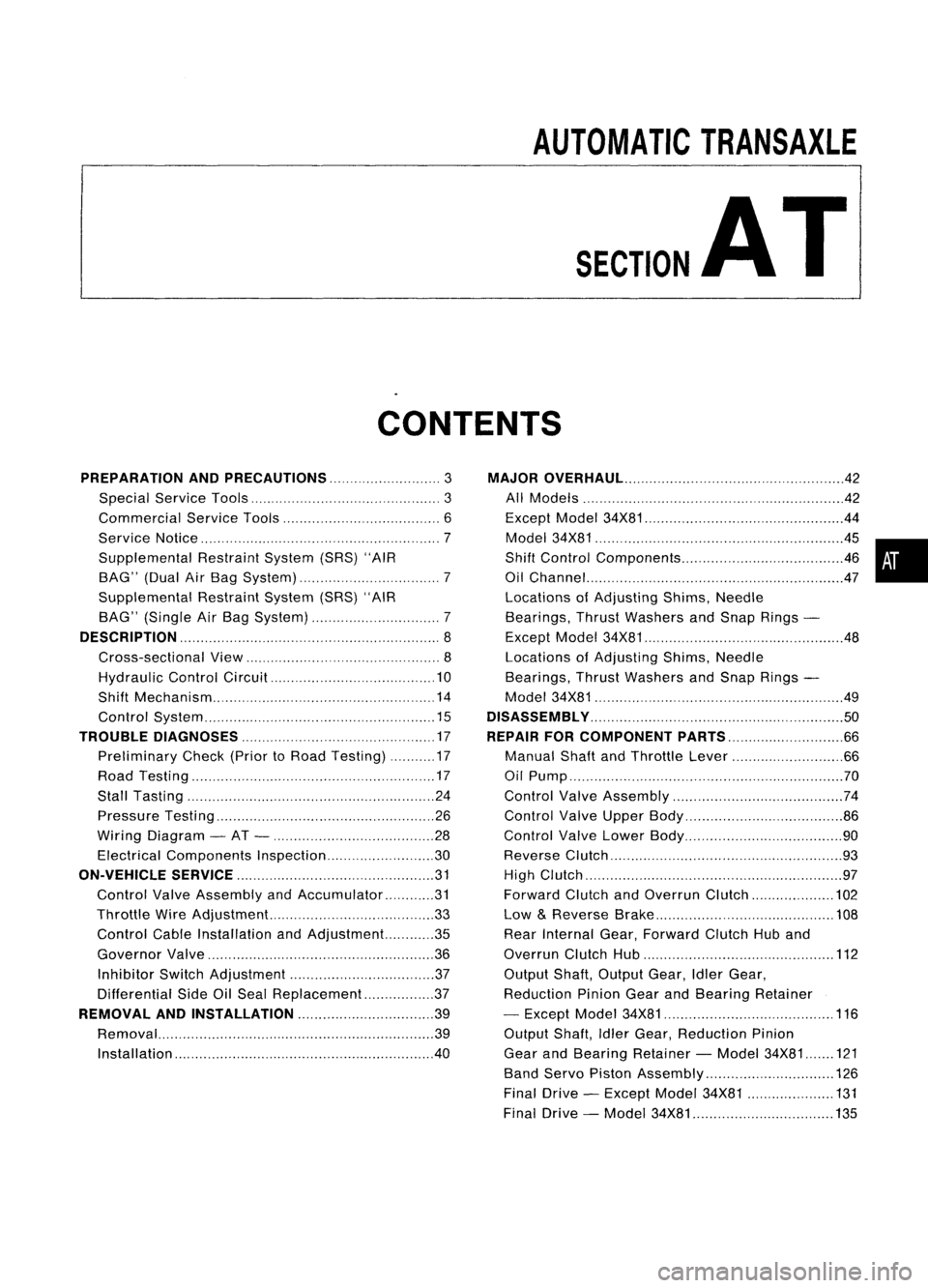

Toolnumber

Tool name

PREPARATION

ANDPRECAUTIONS

Special Service Tools

Description

8T25058001

Oil pressure gaugeset

G)

8T25051001

Oil pressure gauge

@ 8T25052000

Hose

@

8T25053000

Joint pipe

@

8T25054000

Adapter

@

8T25055000

Adapter Measuring

linepressure andgovernor

pressure

NT097

KV31103000

Drift

8T35325000 Drift

KV31103200

Clutch spring compressor

8T23540000 Pin punch

KV32101000

Pin punch

NT105

NT417

NT425

NT442

NT410

AT-3

Installing

differential sideoilseal

(Use with8T35325000)

a: 59 mm (2.32 in)dia.

b: 49 mm (1.93 in)dia.

Installing differential sideoilseal

(Use withKV31103000)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in)dia.

c: M12 x1.5P

Removing andinstalling clutchreturn

spring

a: 179 mm (7.05 in)

b: 76 mm (2.99 in)dia.

c: 174 mm (6.85 in)

Removing andinstalling parkingrodplate

and manual plate

a: 2.3 mm (0.091 in)dia.

b: 4mm (0.16 in)dia.

Installing throttleleverandmanual shaft

retaining pins

Removing andinstalling differential pinion

mate shaft lockpin.

a: 4mm (0.16 in)dia.

•

Page 4 of 1701

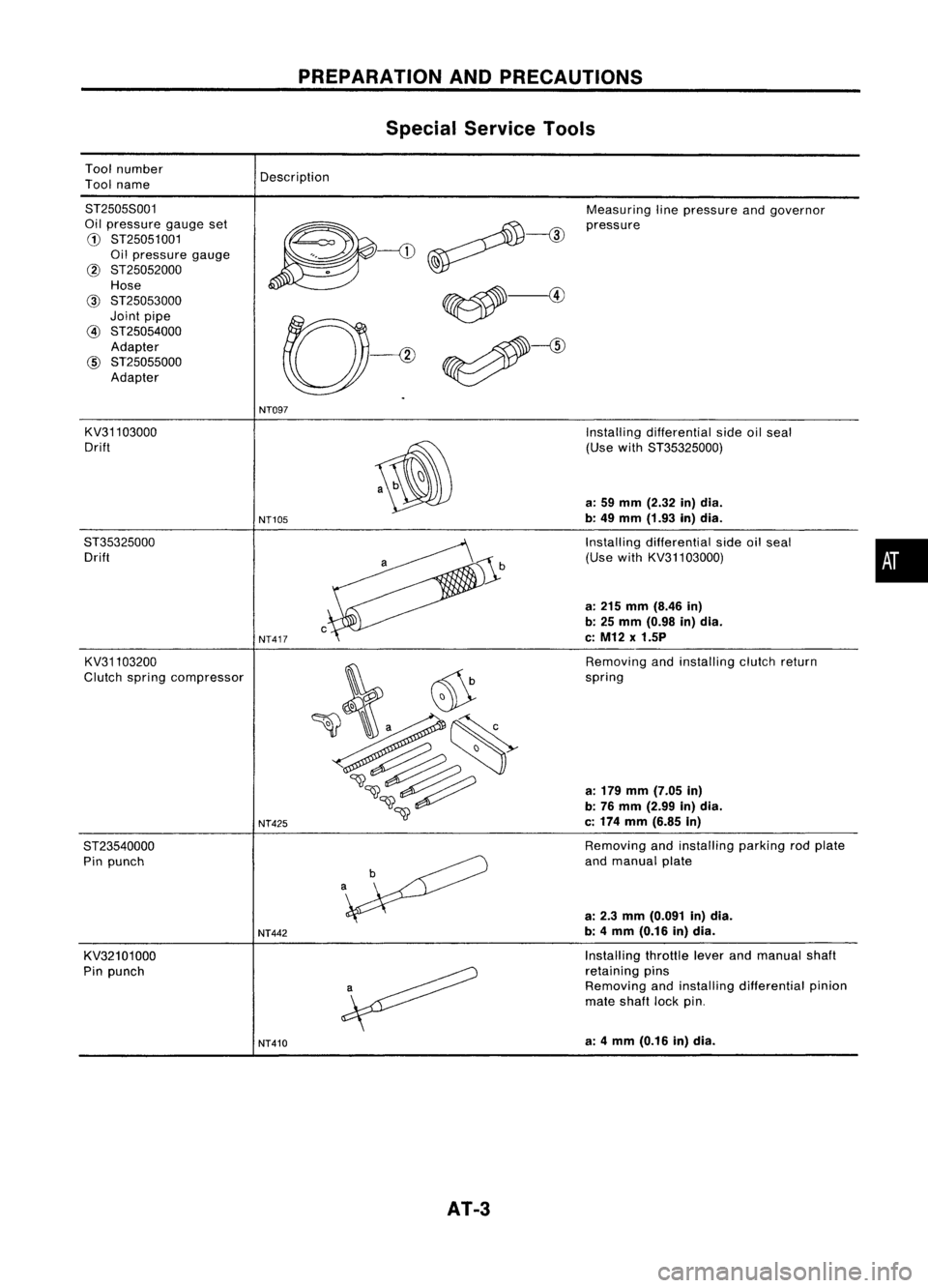

Toolnumber

Tool name

PREPARATION

ANDPRECAUTIONS

Special Service Tools(Cont'd)

Description

ST3306S001

Differential sidebearing

puller set

CD

ST33051 001

Puller

@

ST33061000

Adapter

KV381054S0

(ST33290001) Puller

NT413

NT414 ,~

a

Removing

differential sidebearing inner

race

a: 38 mm (1.50 in)dia.

b: 28.5 mm(1.122 in)dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 In)

• Removing differential sideoilseal

• Removing idlergear bearing outerrace

- EXCEPT MODEL34X81-

• Removing outputshaftbearing outer

race from bearing retainer

• Removing outputgearbearing outer

race from bearing retainer

- MODEL 34X81-

• Removing differential sidebearing outer

race

• Removing needlebearing frombearing

retainer

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST27180001 Puller

NT424

ST30031000 Puller

NT411

ST30021 000

Puller

NT411

ST35272000 Drift

~

NT426

AT-4

•

Removing idlergear

• Removing outputgear(Except model

34X81)

a: 100 mm (3.94 In)

b: 110 mm (4.33 in)

c: M8 x1.25P

Removing reductionpiniongearbearing

inner race(Except model34X81)

a: 90 mm (3.54 In)dia.

b: 50 mm (1.97 in)dia.

Removing differential sidebearing

(Except model34X81)

a: 110 mm (4.33 in)dia.

b: 68 mm (2.68 in)dia.

• Installing reduction piniongearbearing

inner race

• Installing idlergear bearing innerrace

• Installing outputgearbearing innerrace

(Except model34X81)

a: 72 mm (2.83 in)dia.

b: 35.5 mm(1.398 in)dia.

Page 5 of 1701

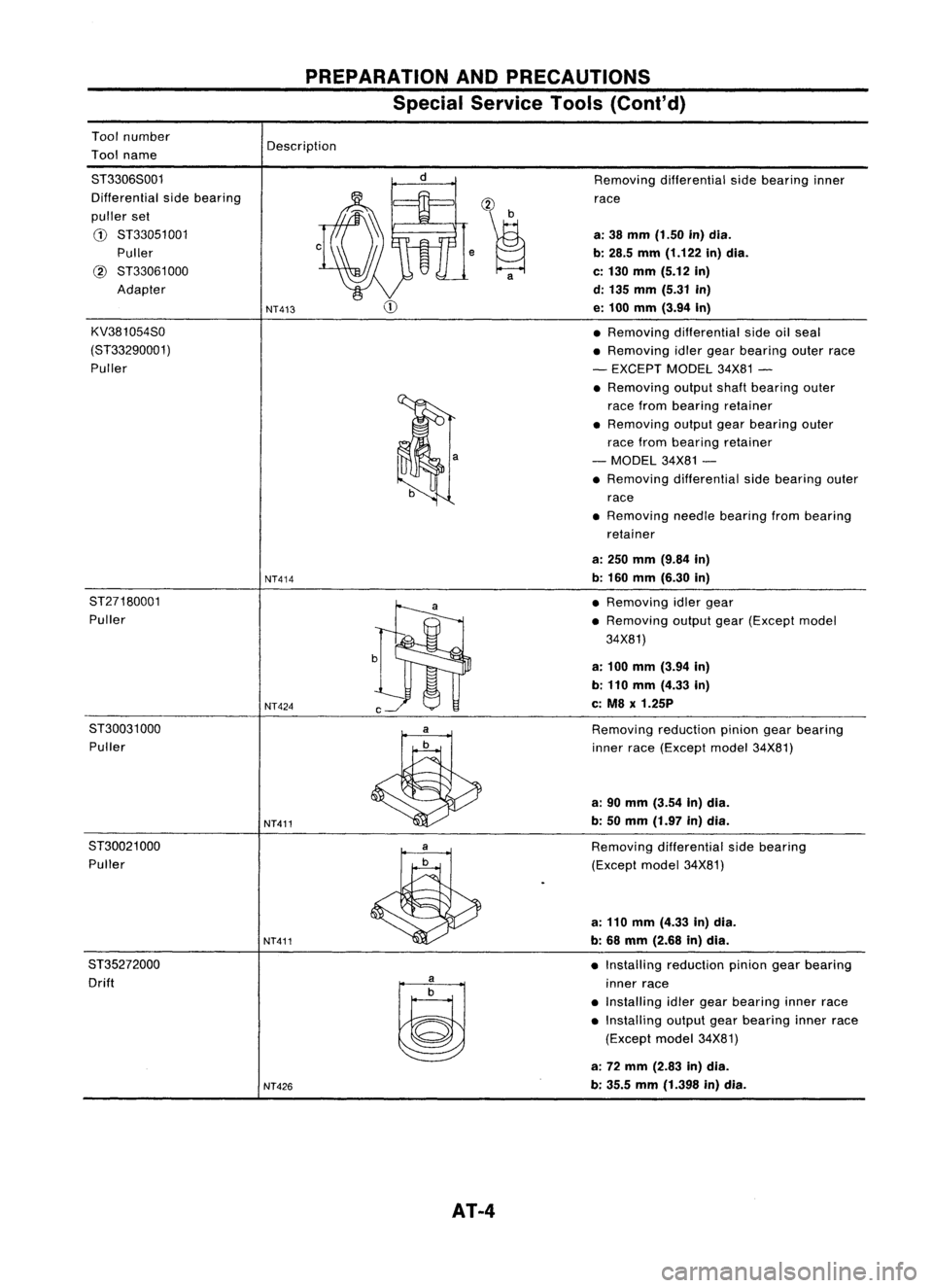

Toolnumber

Tool name

PREPARATION

ANDPRECAUTIONS

Special Service Tools(Cont'd)

Description

8T37830000 Drift

8T33200000 Drift

8T35271000 Drift

8T33400001

Drift

KV40104840

Drift

KV38105710

Preload adapter

8T35321000

Drift

ST30633000 Drift

NT427

NT091

NT115

NT086

NT108

NT087

NT073 NT073

AT-5

Installing

idlergear bearing outerrace

a: 62 mm (2.44 in)dia.

b: 39 mm (1.54 in)dia.

Installing differential sidebearing (Except

model 34X81)

a: 60 mm (2.36 in)dia.

b: 44.5 mm(1.752 in)dia.

• Installing idlergear

• Installing outputgear(Except model

34X81)

a: 72 mm (2.83 in)dia.

b: 44 mm (1.73 in)dia.

• Installing oilpump housing oilseal

• Installing outputgearbearing outerrace

onto bearing retainer (Exceptmodel •

34X81)

a: 60 mm (2.36 in)dia.

b: 47 mm (1.85 in)dia.

Installing outputshaftbearing outerrace

onto bearing retainer (Exceptmodel

34X81)

a: 49 mm (1.93 in)dia.

b: 42 mm (1.65 in)dia.

- MODEL 34X81-

• Measuring turningtorqueoffinal drive

assembly

• Measuring clearancebetweensidegear

and differential casewithwasher

• Selecting differential sidebearing

adjusting shim

Installing outputshaftbearing

(Model 34X81)

a: 49 mm (1.93 in)dia.

b: 41 mm (1.61 in)dia.

Installing differential sidebearing outer

race (Model 34X81)

a: 67 mm (2.64 in)dia.

b: 49 mm (1.93 in)dia.

Page 6 of 1701

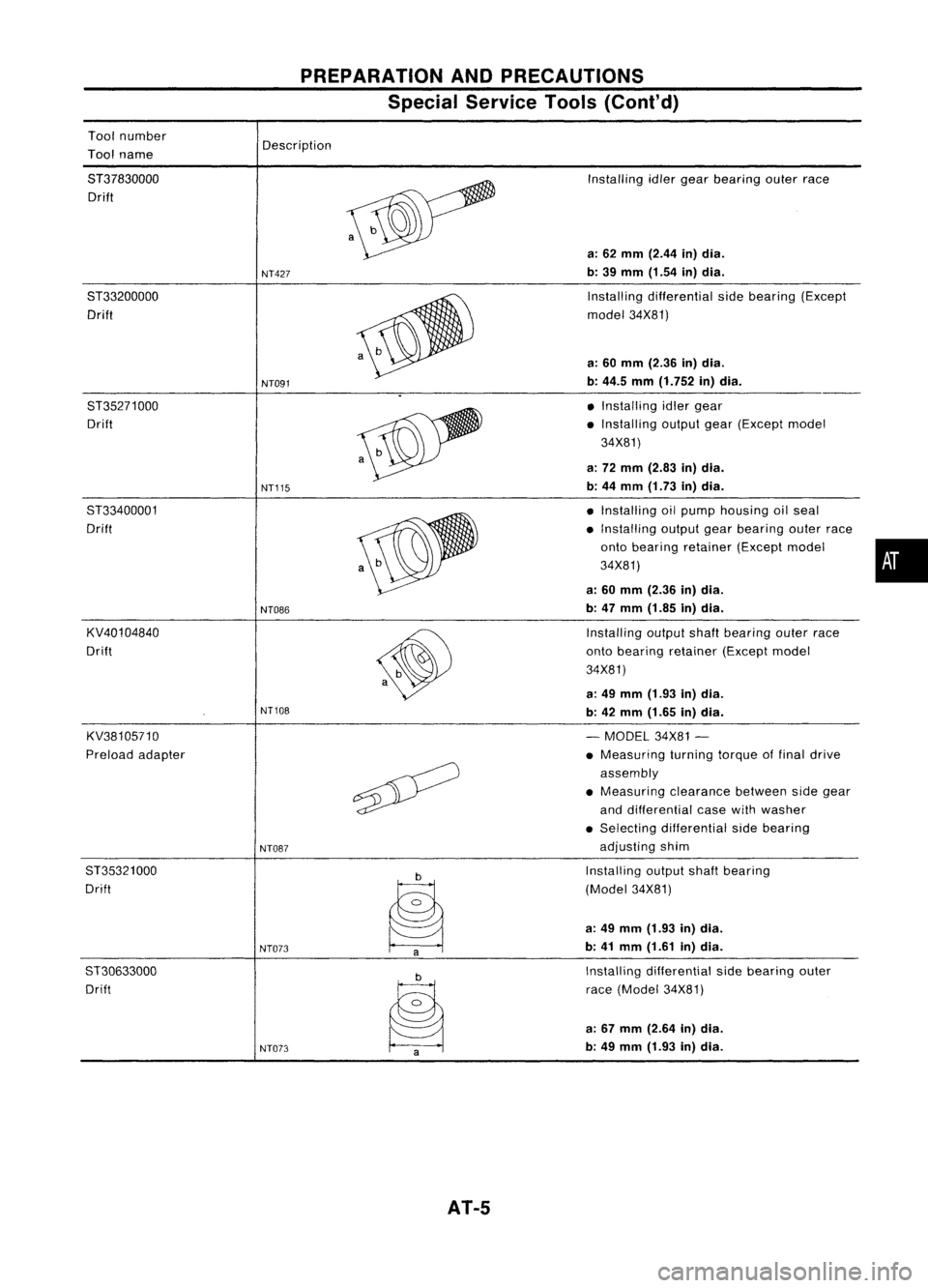

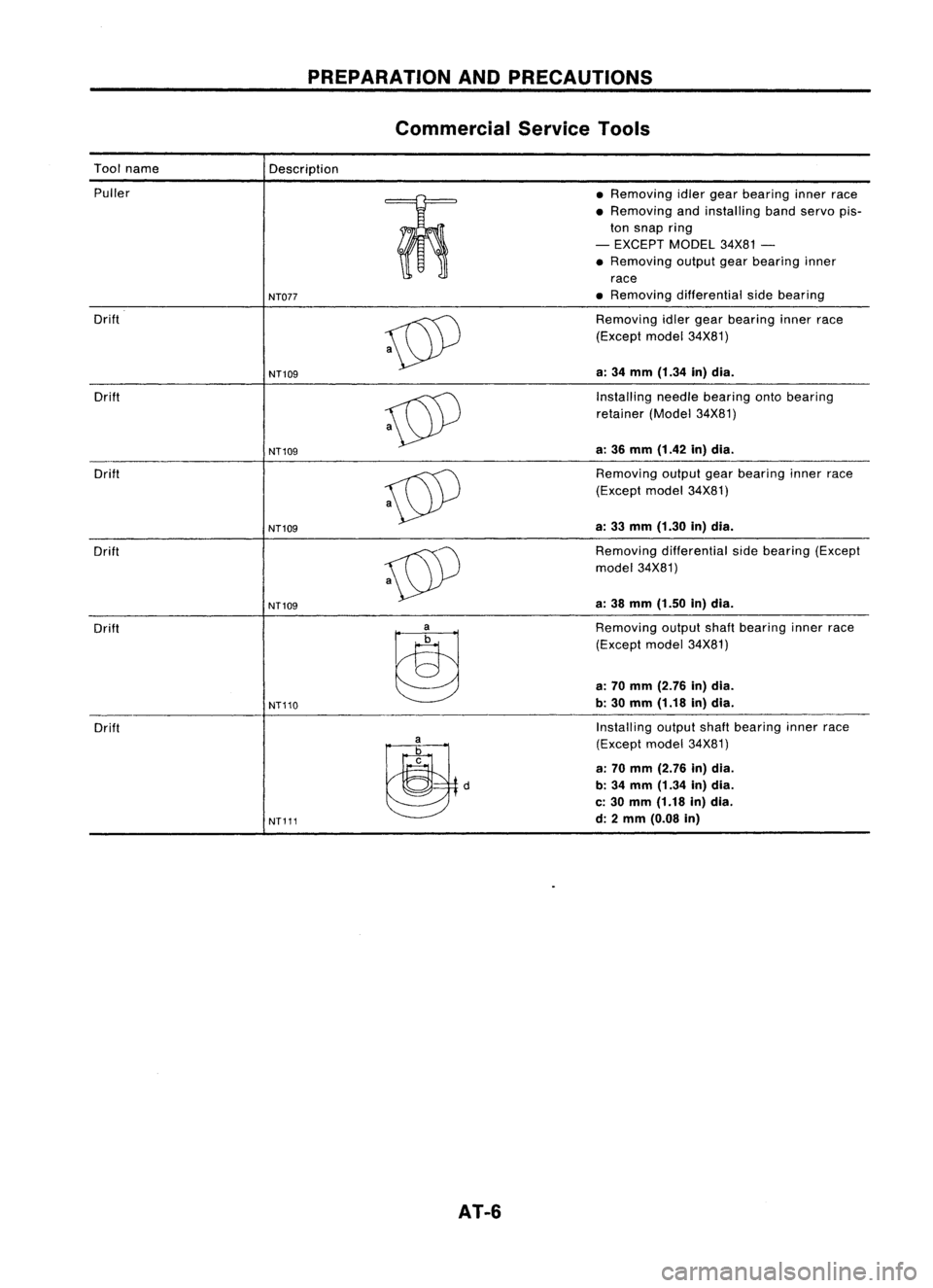

PREPARATIONANDPRECAUTIONS

Commercial ServiceTools

Tool name

Description

Puller •Removing idlergear bearing innerrace

• Removing andinstalling bandservo pis-

=m

ton

snap ring

o

0

-

EXCEPT MODEL34X81-

• Removing outputgearbearing inner

race

NT077

•

Removing differential sidebearing

Drift

~

Removing

idlergear bearing innerrace

(Except model34X81)

a: 34 mm (1.34 in)dia.

NT109

Drift

~

Installing

needlebearing ontobearing

retainer (Model34X81)

a: 36 mm (1.42 in)dia.

NT109

Drift

~

Removing

outputgearbearing innerrace

(Except model34X81)

a: 33 mm (1.30 in)dia.

NT109

Drift

~

Removing

differential sidebearing (Except

model 34X81)

a: 38 mm (1.50 in)dia.

NT109

Drift

~

Removing

outputshaftbearing innerrace

(Except model34X81)

a: 70 mm (2.76 in)dia.

NT110

b:

30 mm (1.18 in)dia.

Drift Installing

outputshaftbearing innerrace

~d

(Except

model34X81)

a: 70 mm (2.76 in)dia.

b: 34 mm (1.34 in)dia.

c: 30 mm (1.18 in)dia.

NT111

d:

2mm (0.08 in)

AT-6

Page 9 of 1701

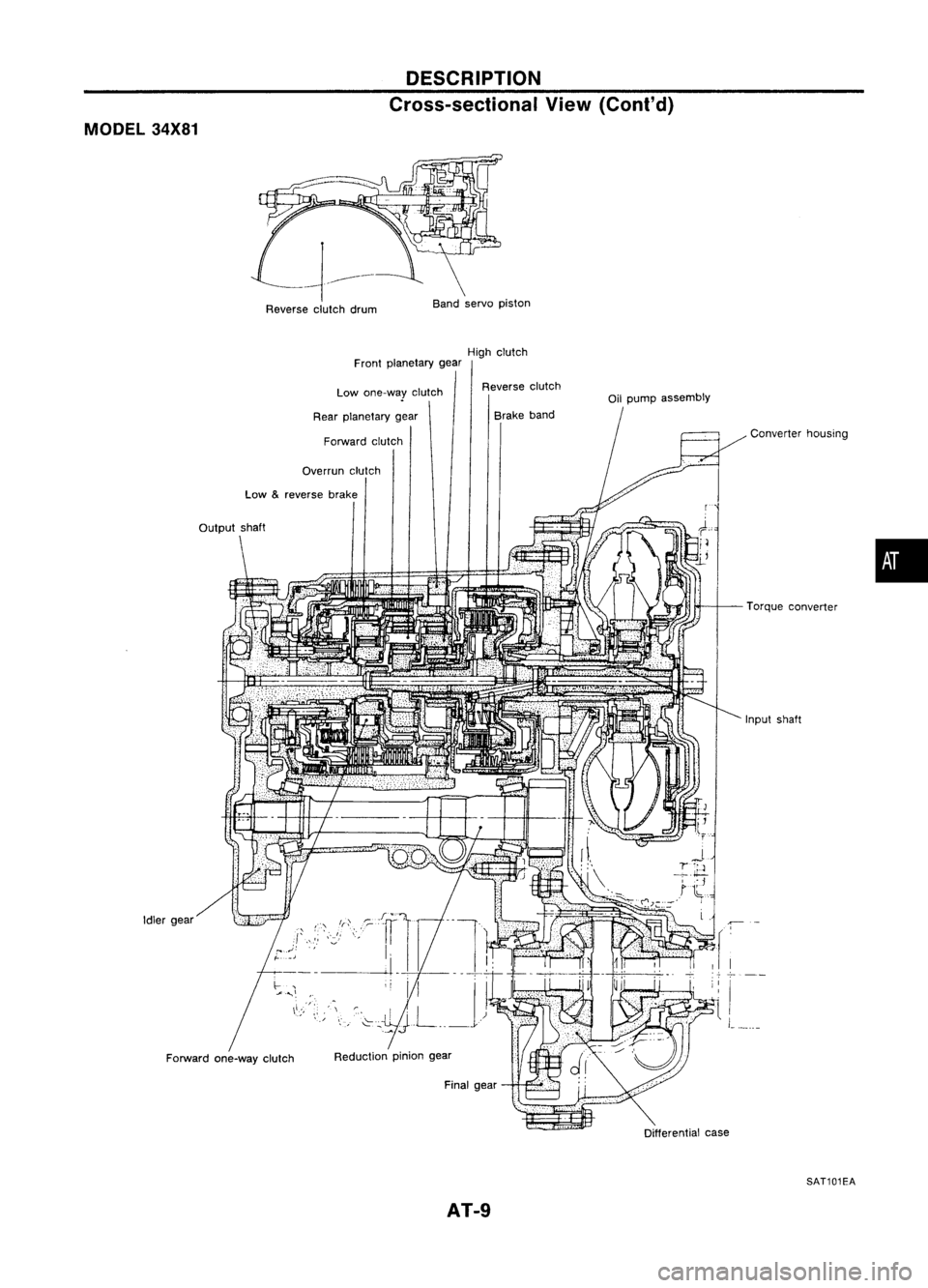

MODEL34X81 DESCRIPTION

Cross-sectional View(Cant' d)

Reverse clutchdrum Band

servo piston

High clutch

Front planetary gear

Reduction piniongear

Low

&

reverse brake

Idler gear

Forward one-way clutch Low

one-way clutch

Rear planetary gear

Forward clutch

Overrun clutch

,"'I

Reverse

clutch

Brake band

Final gear

AT-9

Oil

pump assembly

Converterhousing

Torque converter

Input shaft

c

...

-;-

I

L_

Differential case

SAT101EA

•

Page 37 of 1701

InhibitorSwitchAdjustment

1. Remove controlcableendfrom manual shaft.

2. Set manual shaftin"N" position.

3." Loosen inhibitor switchfixingbolts.

Use a4 mm (0.16 in)pin forthis adjustment. •

Insert thepinstraight intothemanual shaftadjustment hole.

Rotate inhibitor switchuntilthepincan also beinserted

straight intohole ininhibitor switch.

Tighten inhibitor switchfixingbolts.

Remove pinfrom adjustment holeafter adjusting inhibitor

switch.

Reinstall anypart removed.

Adjust control cable-Refer to"Control CableInstallation

and Adjustment", AT-35.

Check continuity ofinhibitor switch-Refer to"Electrical

Components Inspection",AT-30.

ON-VEHICLE

SERVICE

Governor Valve(Cont'd)

4. Remove governor valveassembly fromtransaxle.

5. Check governor valveassembly ifnecessary -Refer to

"DISASSEMBLY", AT-65.

4. a.b.

5.

6.

7.

8.

SAT580E 9.

Differential SideOilSeal Replacement

1. Remove driveshaftassemblies. -Refer toFA section

("Removal", "FRONTAXLE-Drive Shaft").

2. Remove oilseals.

AT-37

Page 38 of 1701

Converterhousingside(RHS)

Transmission caseside(LHS)

SAT259EA ON-VEHICLE

SERVICE

Differential SideOilSeal Replacement (Cont'd)

3. Install oilseals.

• Apply ATFtooil seal surface beforeinstalling.

Converter housing

side •

Install oilseals sothat dimensions

"A"

and

"8"

arewithin

specifications.

Transmission

case side

B

Oil

seal Oil

seal

A

SAT639D

A

5.5 -6.5 (0.217 -0.256)

4. Reinstall anypart removed.

AT-38

Unit:

mm(in)

B

0.5 (0.020)

or

less

Page 47 of 1701

MAJOROVERHAUL

Oil Channel

High clutch pressure

Oilcooler tube(OUT) hole

•

Oil

cooler tube

(IN)

Torque converter pressure

(Lock-up applied)

" Servo

4th

apply chamber pressure

Servo 2ndapply chamber pressure

• Servo 3rdrelease

chamber pressure

Torque

converter pressure

(Lock-up released)

SIR accumulator shoulderpressure

SIR accumulator backpressure

(Reverse clutchpressure)

Oil cooler tube

(IN)

hole

Torque

converter

pressure (Lock-up applied)

Torque converter

pressure (Lock-up released)

reverse

brakepressure

Overrun clutchpressure

Forward clutchpressure

High

clutch pressure

Reverse clutch

pressure

Oil pump suction hole

Differential lubricanthole

High clutch pressure

Oil pump discharge hole

Reverse clutch

pressure

Oil pump suction hole

Reverse

clutch

pressure

Low

&

Oil

pump suction hole

Oil pump discharge hole

Forward clutchpressure

Overrun clutchpressure

Low

&

reverse brake

pressure

Torque

converter pressure

(Lock-up released)

Torque converter

pressure (Lock-up applied)

Governor pressure

Linepressure

SAT586DC

AT-47

Page 54 of 1701

DISASSEMBLV

21. Remove throttlewirefrom throttle lever.

22. Remove throttlewiremounting bolt.

23. Draw outthrottle wirefrom transmission case.

- All models -

24. Remove converter housingaccording tothe following pro-

cedures.

a. Remove converter housingmounting bolts@and

CID.

b. Remove converter housing.

c. Remove O-ringfromdifferential oilport.

AT-54