fuse chart NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 325 of 1701

TROUBLEDIAGNOSES

Self-diagnosis (ForEurope) (Cont'd)

MALFUNCTION CODE/SYMPTOM CHART

Code No.

Malfunctioningpart Diagnostic

procedure

(No. ofwarning lampflashes)

45

Actuator

frontleftoutlet solenoid valve

3

46

Actuator

frontleftinlet solenoid valve

3

41

Actuator

frontrightoutlet solenoid valve

3

42

Actuator

frontrightinletsolenoid valve

3

51

Actuator

rearright outlet solenoid valve

3

52

Actuatorrearright inletsolenoid valve

3

55

Actuator

rearleftoutlet solenoid valve

3

56

Actuator

rearleftinlet solenoid valve

3

25

Frontleftsensor (open-circuit)

4

26

Front

leftsensor (short-circuit)

4

21

Frontrightsensor (open-circuit)

4

22

Front

rightsensor (short-circuit)

4

35

Rearleftsensor (open-circuit)

4

36

Rear

leftsensor (short-circuit)

4

31

Rearrightsensor (open-circuit)

4

32

Rearrightsensor (short-circuit)

4

18

Sensorrotor

4

61

Actuatormotorormotor relay

5

63

Solenoidvalverelay

6

57

Powersupply (Lowvoltage)

7

71

Controlunit

8

Control unitpower supply circuit

Warning lampstays onwhen igni-Warning

lampbulbcircuit

tion switch isturned on Control

unitorcontrol unitconnector

2

Solenoid valverelaystuck

Power supply forsolenoid valverelaycoil

Warning lampstays on,during

Controlunit

-

self-diagnosis

Warning lampdoesnotcome onFuse, warning lampbulborwarning lampcircuit

1

when ignition switchisturned onControl unit

Warning lampdoes notcome on

Control unit

during self-diagnosis

-

Pedal vibration andnoise

-

9

Long stopping distance

-

10

Unexpected pedalaction

-

11

ABS does notwork

-

12

ABS works frequently

-

13

BR-55

•

Page 373 of 1701

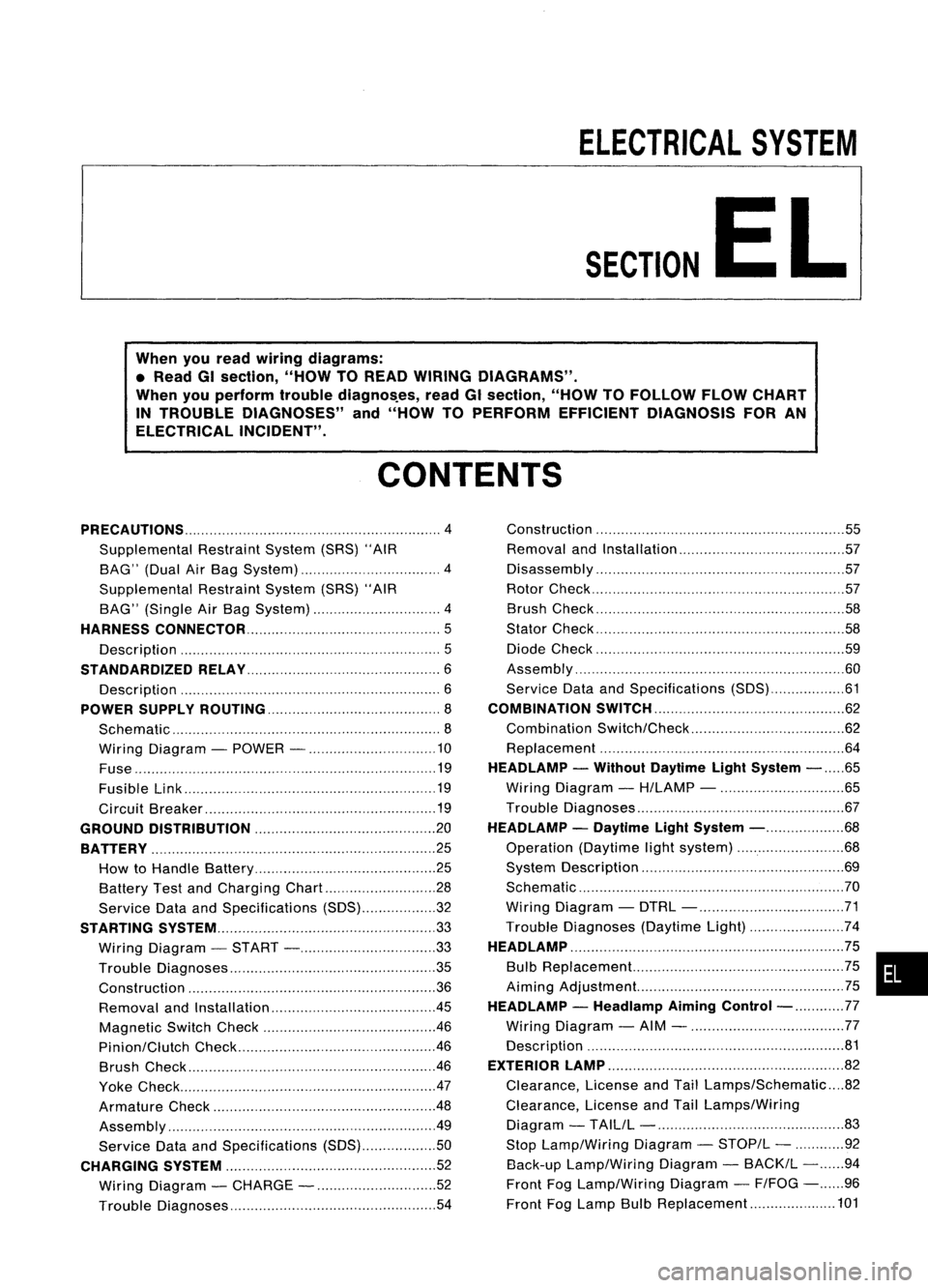

ELECTRICALSYSTEM

SECTION

EL

When youread wiring diagrams:

• Read GIsection, "HOWTOREAD WIRING DIAGRAMS".

When youperform troublediagnos.es, readGIsection, "HOWTOFOllOW FLOWCHART

IN TROUBLE DIAGNOSES" and"HOW TOPERFORM EFFICIENT DIAGNOSIS FORAN

ELECTRICAL INCIDENT".

CONTENTS

PRECAUTIONS 4

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 4

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 4

HARNESS CONNECTOR 5

Description 5

STANDARDIZED RELAy 6

Description 6

POWER SUPPLY ROUTING 8

Schematic 8

Wiring Diagram -POWER - 10

Fuse 19

Fusible Link 19

Circuit Breaker 19

GROUND DISTRIBUTION 20

BATTERy 25

How toHandle Battery 25

Battery TestandCharging Chart.. 28

Service DataandSpecifications (SOS) 32

STARTING SySTEM

33

Wiring Diagram -START - 33

Trouble Diagnoses 35

Construction 36

Removal andInstallation .45

Magnetic SwitchCheck .46

Pinion/Clutch Check 46

Brush Check 46

Yoke Check 47

Armature Check 48

Assembly .49

Service DataandSpecifications (SDS) 50

CHARGING SYSTEM 52

Wiring Diagram -CHARGE - 52

Trouble Diagnoses 54Construction

55

Removal andInstallation 57

Disassembly 57

Rotor Check 57

Brush Check 58

Stator Check 58

Diode Check 59

Assembly 60

Service DataandSpecifications (SDS) 61

COMBINATION SWITCH 62

Combination Switch/Check 62

Replacement 64

HEADLAMP -Without Daytime lightSystem -65

Wiring Diagram -H/LAMP - 65

Trouble Diagnoses 67

HEADLAMP -Daytime lightSystem - 68

Operation (Daytimelightsystem) 68

System Description 69

Schematic 70

Wiring Diagram -DTRL - 71

Trouble Diagnoses (DaytimeLight) 74

HEADLAMP 75

Bulb Replacement... 75•

Aiming Adjustment. 75

HEADLAMP -Headlamp Aiming

Control- 77

Wiring Diagram -AIM - 77

Description 81

EXTERIOR LAMP 82

Clearance, LicenseandTail Lamps/Schematic 82

Clearance, LicenseandTail Lamps/Wiring

Diagram -TAILIL - 83

Stop Lamp/Wiring Diagram-STOP/L - 92

Back-up Lamp/Wiring Diagram-BACK/L -94

Front FogLamp/Wiring Diagram-F/FOG -96

Front FogLamp BulbReplacement 101

Page 375 of 1701

CONTENTS(Cont'd.)

Component PartsLocation 248

Wiring Diagram -NATS - 249

Trouble Diagnoses 251

LOCATION OFELECTRICAL UNITS

266

Engine Compartment 266

Passenger Compartment 267

HARNESS LAyOUT

269

How toRead Harness Layout... 269

Outline 270

Engine Control Harness 271

Engine RoomHarness 274

Main Harness '" 280

Body Harness :284

Body No.2 Harness 292

Engine Harness 294Air

Bag Harness 297

Room LampHarness 298

Back DoorHarness 299

Front DoorHarness (LHside) 300

Front DoorHarness (RHside) 302

Rear Door Harness 304

SUPER MULTIPLE JUNCTION

(SMJ) Foldout

Terminal Arrangement Foldout

FUSE BLOCK -Junction Box

(JIB)

Foldout

Terminal Arrangement Foldout

ELECTRICAL UNITS

Foldout

Terminal Arrangement Foldout

JOINT CONNECTOR

(J/C)

Foldout

Terminal Arrangement Foldout

WIRING DIAGRAM REFERENCE CHART

COOLING SYSTEM

LC

SECTION

ECCS (Ignition syslem) ECSECTION

AUTOMATIC TRANSAXLECONTROLSYSTEM ATSECTION

ANTI-LOCK BRAKESYSTEM BRSECTION

SRS "AIR BAG" RSSECTION

HEATER ANDAIRCONDITIONER HASECTION

•

Page 628 of 1701

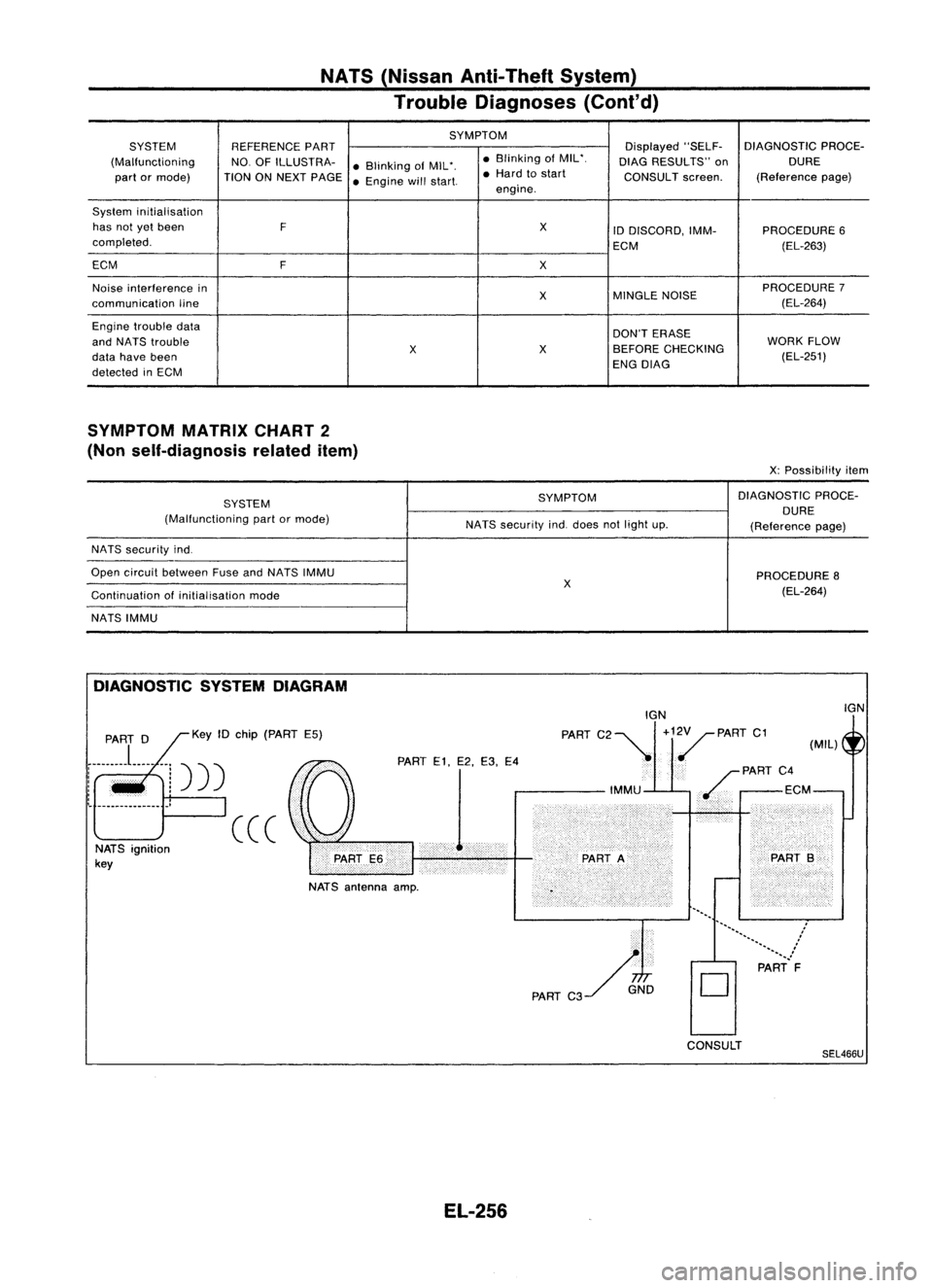

NATS(Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

SYMPTOM

SYSTEM REFERENCEPART Displayed"SELF- DIAGNOSTIC

PROCE-

(Malfunctioning NO.OFILLUSTRA-

•Blinking ofMIL*. •

Blinking ofMIL *.

DIAGRESULTS" on DURE

part ormode)

TIONONNEXT PAGE

•Engine willstart. •

Hard tostart

CONSULTscreen. (Reference

page)

engine.

System initialisation

has notyetbeen

F X

10

DISCORD, IMM- PROCEDURE 6

completed. ECM(EL-263)

ECM F X

Noise interference in

XMINGLE

NOISE PROCEDURE

7

communication line (EL-264)

Engine trouble data

DON'TERASE

and NATS trouble

BEFORECHECKING WORK

FLOW

data have been X

X

(EL-251)

detected inECM ENG

DIAG

SYMPTOM MATRIXCHART2

(Non self-diagnosis relateditem)

X:Possibility item

SYSTEM SYMPTOM

DIAGNOSTIC

PROCE-

(Malfunctioning partormode) DURE

NATS security indodoes notlight up.

(Referencepage)

NATS security indo

Open circuit between FuseandNATS IMMU

PROCEDURE8

X (EL-264)

Continuation ofinitialisation mode

NATS IMMU

DIAGNOSTIC SYSTEMDIAGRAM

NATS antenna amp.

PART

0 Key10chip (PART E5)

i-------

L---

--j)))

:

.

, ,

I~ .'

(((

NATS ignition

key

PART

E1,E2,E3, E4 IGN

PART C2~ +1./PART C1(MIL)

PART C4

ECM

..

........

................

:'

.......

PART F

D

IGN

EL-256

CONSULT

SEL466U

Page 1116 of 1701

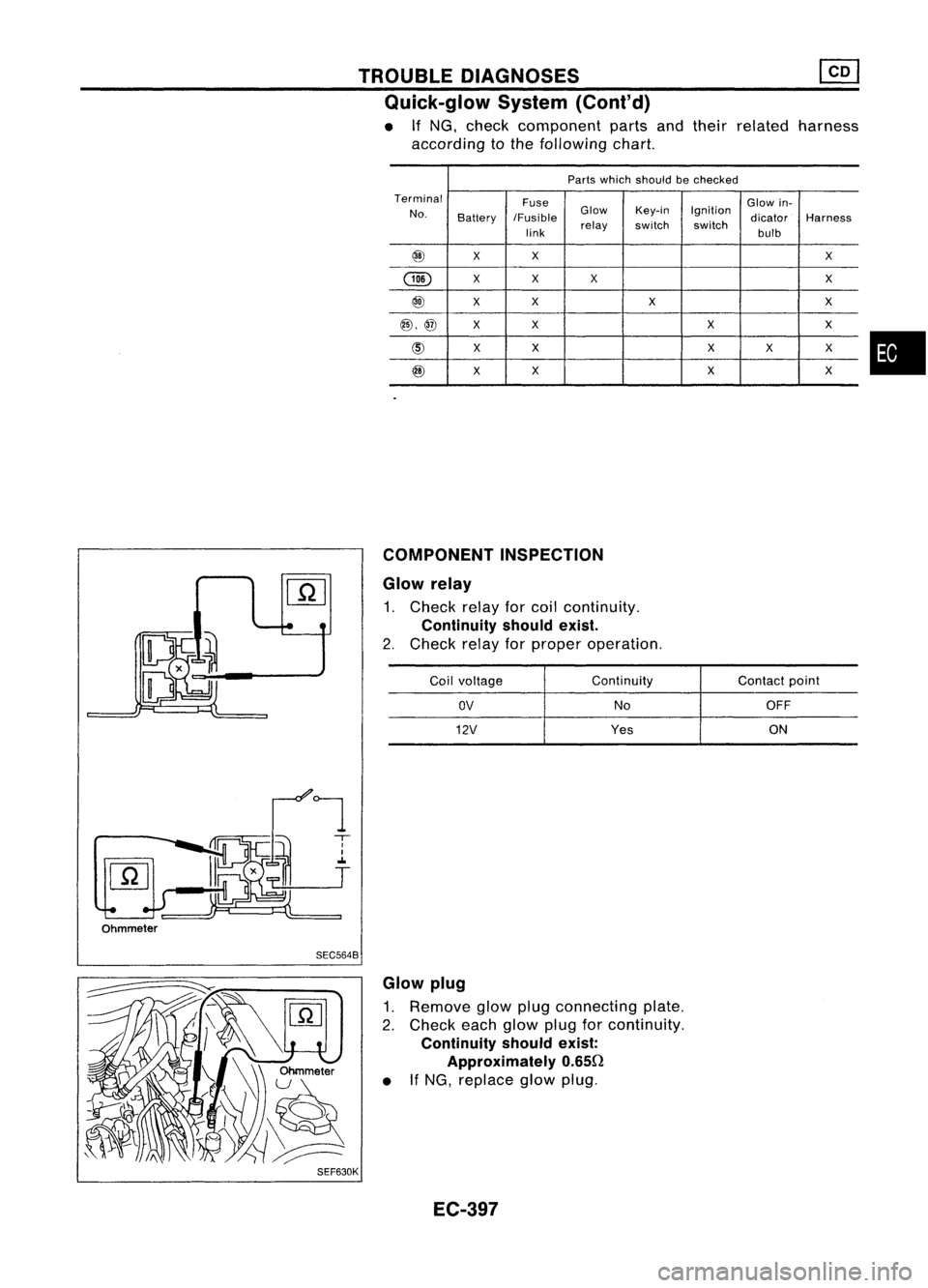

TROUBLEDIAGNOSES ~

Quick-glow System(Cont'd)

• If

NG.

check component partsandtheir related harness

according tothe following chart.

Parts which should bechecked

Terminal Fuse Glowin-

No. Battery IFusible Glow

Key-in Ignition

dicatorHarness

link relay

switch switch

bulb

@

XX

X

@

X

X X X

@

XX

X X

@,@

XX XX

@

XX X

X X

@

X

X XX

COMPONENT INSPECTION

Glow relay

1. Check relayforcoil continuity.

Continuity shouldexist.

2. Check relayforproper operation.

Coil voltage Continuity

Contactpoint

OV

NoOFF

12V

Yes ON

•

Ohmmeter SEC5648

SEF630K Glow

plug

1. Remove glowplugconnecting plate.

2. Check eachglow plugforcontinuity.

Continuity shouldexist:

Approximately 0.650

• IfNG, replace glowplug.

EC-397

Page 1366 of 1701

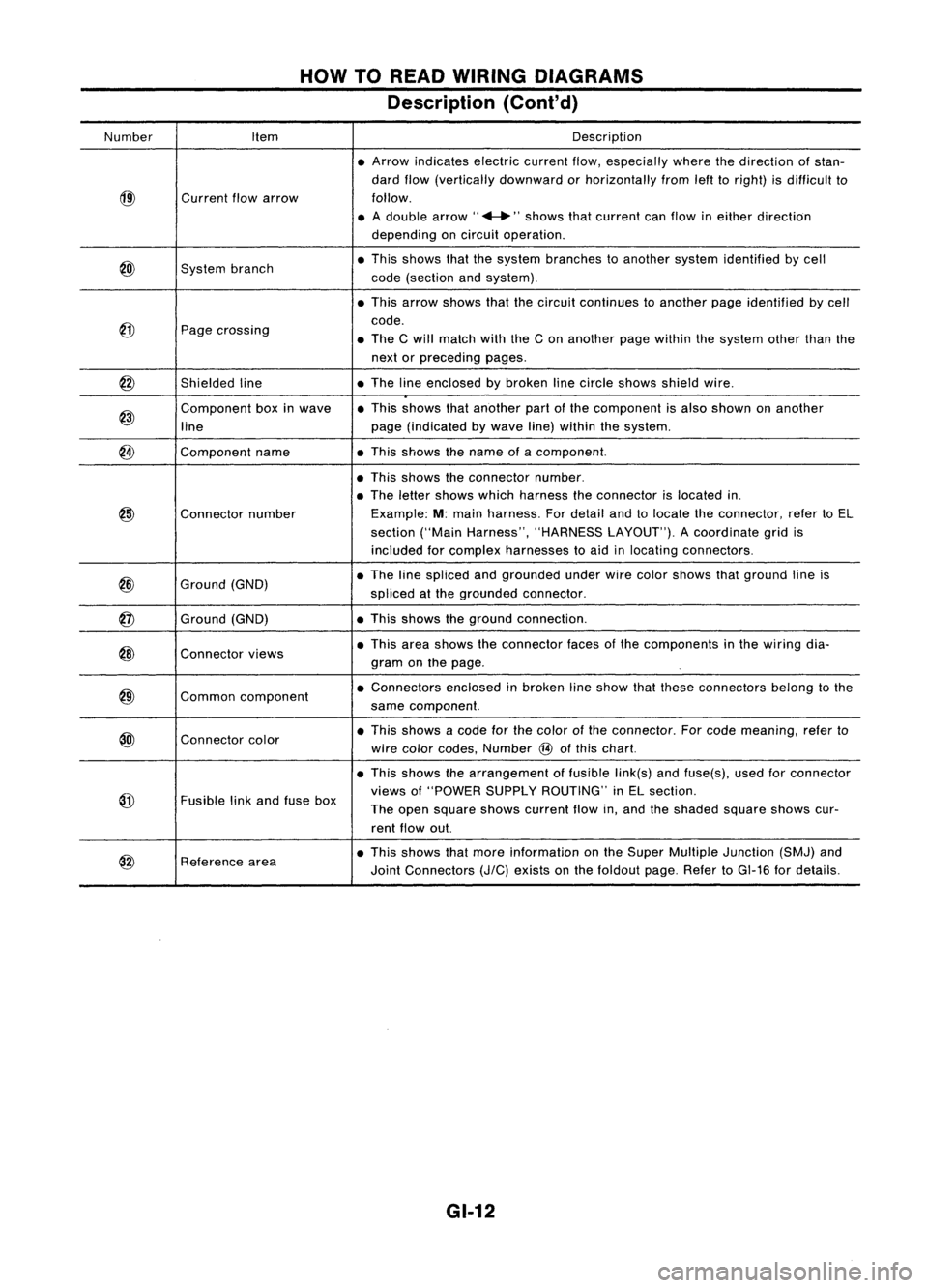

HOWTOREAD WIRING DIAGRAMS

Description (Cont'd)

Number Item Description

• Arrow indicates electriccurrentflow,especially wherethedirection ofstan-

dard flow(vertically downward orhorizontally fromlefttoright) isdifficult to

@)

Current

flowarrow follow.

• Adouble arrow" ...."shows thatcurrent canflow ineither direction

depending oncircuit operation .

@)

System

branch •

This shows thatthesystem branches toanother systemidentified bycell

code (section andsystem) .

• This arrow shows thatthecircuit continues toanother pageidentified bycell

@

code.

Page crossing

•The Cwill match withtheCon another pagewithin thesystem otherthanthe

next orpreceding pages.

@

Shieldedline •

The lineenclosed bybroken linecircle shows shieldwire.

@)

Component

boxinwave •

This shows thatanother partofthe component isalso shown onanother

line page

(indicated bywave line)within thesystem.

@

Component

name •This shows thename ofacomponent.

• This shows theconnector number.

• The letter shows whichharness theconnector islocated in.

@)

Connector

number Example:

M:main harness. Fordetail andtolocate theconnector, refertoEL

section ("MainHarness", "HARNESS LAYOUT").Acoordinate gridis

included forcomplex harnesses toaid inlocating connectors .

@

Ground

(GND) •

The linespliced andgrounded underwirecolor shows thatground lineis

spliced atthe grounded connector.

@

Ground

(GND) •

This shows theground connection.

@)

Connector

views •

This area shows theconnector facesofthe components inthe wiring dia-

gram onthe page .

@)

Common

component •

Connectors enclosedinbroken lineshow thatthese connectors belongtothe

same component.

@l

Connector

color •

This shows acode forthe color ofthe connector. Forcode meaning, referto

wire color codes, Number

@

ofthis chart.

• This shows thearrangement offusible link(s)andfuse(s), usedforconnector

@

views

of"POWER SUPPLYROUTING" inEL section.

Fusible linkand fuse box

Theopen square showscurrent flowin,and theshaded squareshowscur-

rent flow out.

@

Reference

area •

This shows thatmore information onthe Super Multiple Junction (SMJ)and

Joint Connectors

(J/C)

exists onthe foldout page.RefertoGI-16 fordetails.

GI-12

Page 1382 of 1701

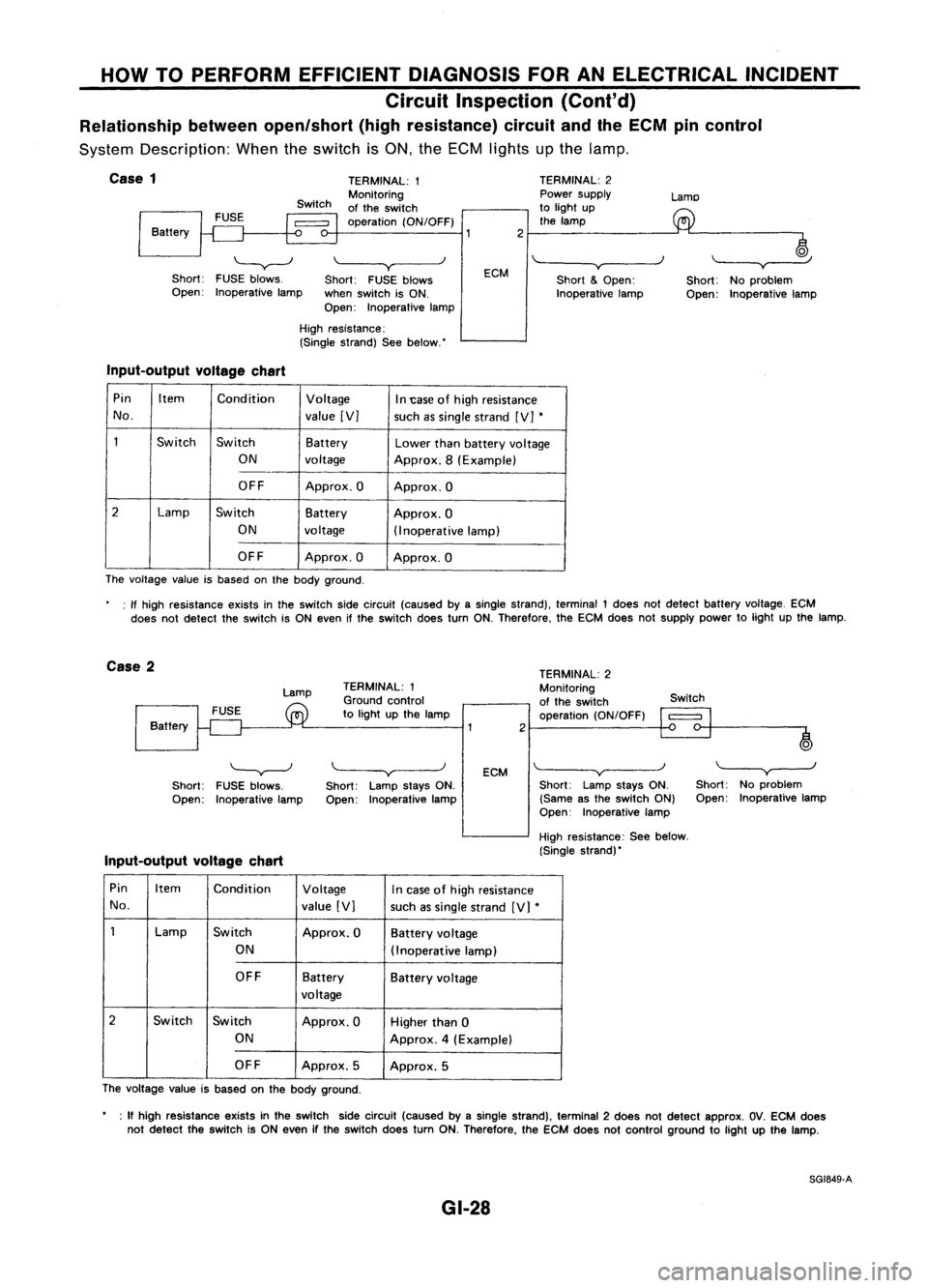

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

Relationship betweenopen/short (highresistance) circuitandtheECM pincontrol

System Description: Whentheswitch isON, theECM lights upthe lamp.

j

Case

1

Battery

'-----v--J

Short: FUSEblows.

Open: Inoperative lamp TERMINAL:

1

Monitoring

of the switch

operation (ON/OFF)

\~--~y

Short: FUSEblows

when switch isON.

Open: Inoperative lampECM

2

TERMINAL:

2

Power supply

to light up

the lamp

'"-----v~----)

Short

&

Open:

Inoperative lampLamo

~

Short: Noproblem

Open: Inoperative lamp

High resistance:

(Single strand) Seebelow.'

Input-output voltagechart

Pin Item

Condition Voltage

In1:ase ofhigh resistance

No. value[V]

suchassingle strand [V]

*

1

Switch

Switch Battery

Lowerthanbattery voltage

ON voltage Approx.8(Example)

OFF Approx.O Approx.O

2

Lamp

Switch Battery

Approx.O

ON voltage

(Inoperativelamp)

OFF Approx.O Approx.O

The voltage valueisbased onthe body ground.

: If high resistance existsinthe switch sidecircuit (caused byasingle strand), terminal 1does notdetect battery voltage. ECM

does notdetect theswitch isON even ifthe switch doesturnON.Therefore. theECM does notsupply powertolight upthe lamp.

Case 2

Lamp

Battery TERMINAL:

1

Ground control

to light upthe lamp

2TERMINAL:

2

Monitoring

of the switch

operation (ON/OFF) Switch

o

)

'---v---J

Short: FUSEblows.

Open: Inoperative lamp

Input-output voltagechart

\.----v

Short: LampstaysON.

Open: Inoperative lamp

ECM

\~--~v~--_.J

Short: LampstaysON.

(Same asthe switch ON)

Open: Inoperative lamp

High resistance: Seebelow.

(Single strand)'

"---y-----.J

Short: Noproblem

Open: Inoperative lamp

Pin Item Condition Voltage

Incase ofhigh resistance

No. value[V]

suchassingle strand [V]

*

1

Lamp

Switch

Approx.OBatteryvoltage

ON (Inoperat ivelamp)

OFF Battery

Batteryvoltage

voltage

2

Switch Switch Approx.OHigherthan0

ON Approx.4(Example)

OFF Approx.5

Approx.5

The voltage valueisbased onthe body ground.

• :If high resis1ance existsinthe switch sidecircuit (caused byasingle strand), terminal 2does notdetect approx. OV.ECM does

not detect theswitch isON even ifthe switch doesturnON.Therefore, theECM does notcontrol ground tolight upthe lamp.

SG1849-A

GI-28

Page 1385 of 1701

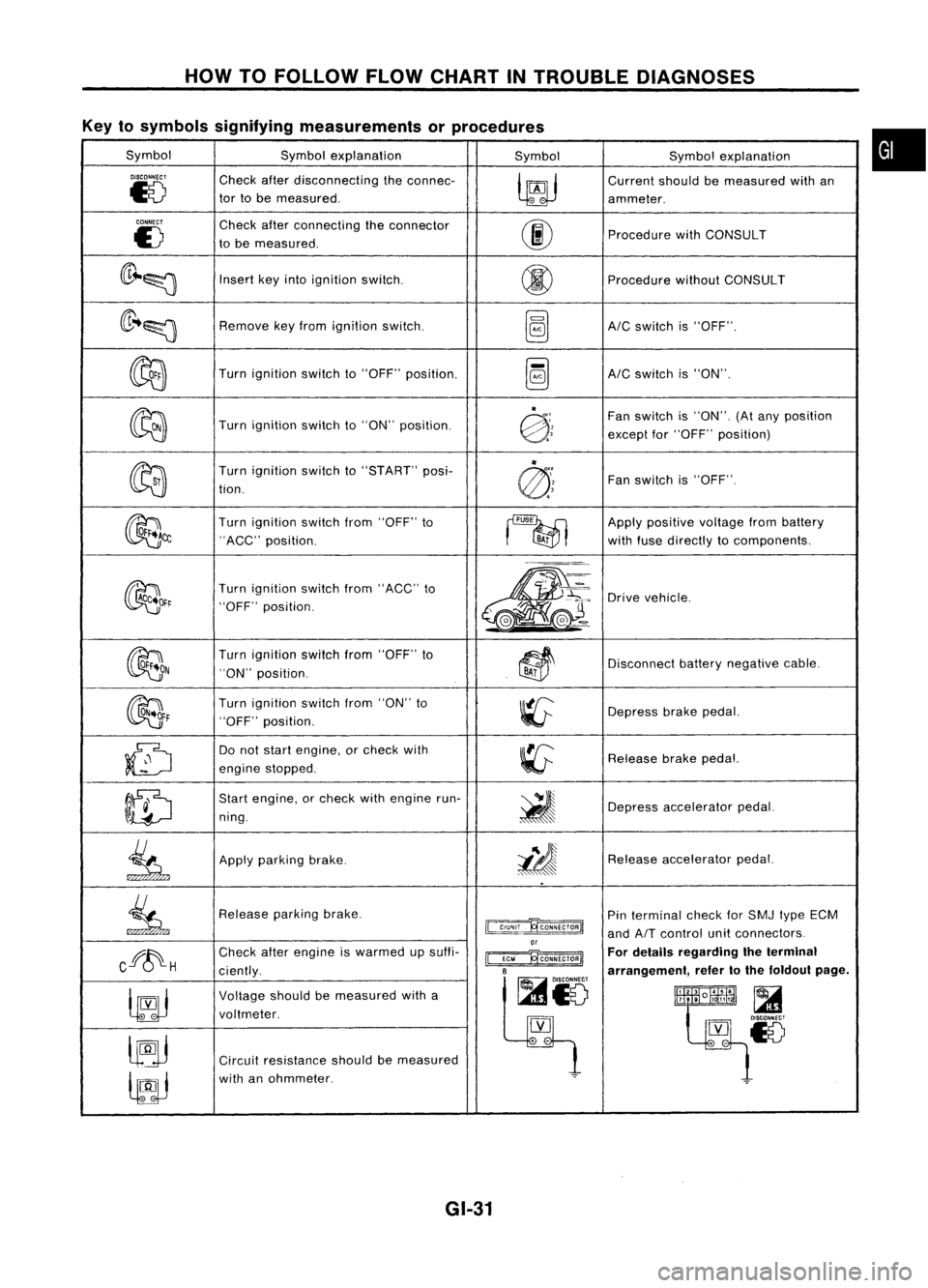

HOWTOFOLLOW FLOWCHART INTROUBLE DIAGNOSES

Key tosymbols signifying measurements orprocedures

Symbol Symbolexplanation

SymbolSymbolexplanation

DISCONNECT

Checkafterdisconnecting theconnec-

~

Current

shouldbemeasured withan

~8

tor

tobe measured.

ammeter.

CONNECT

Checkafterconnecting theconnector

00

E)

tobe measured. Procedure

withCONSULT

(lr~~

Insert

keyinto ignition switCh.

@

Procedure

withoutCONSULT

(lr ..~

Remove

keyfrom ignition switch.

~AIC

switch is"OFF".

~

Turn

ignition switchto"OFF" position.

~AIC

switch is"ON".

~

"

Fanswitch is"ON". (Atany position

Turn ignition switchto"ON" position.

@:;

exceptfor"OFF" position)

~ "

Turn ignition switchto"START" posi-

@'~

Fan

switch is"OFF".

tion.

~~

Turn

ignition switchfrom"OFF" to

~

Apply

positive voltagefrombattery

"ACC" position.

BA;

withfuse directly tocomponents.

~~r

Turn

ignition switchfrom"ACC" to

m-

~'~:

Drive

vehicle.

"OFF" position.

,.-=.

L

@J~ ..

~(e.-

OON

Turn

ignition switchfrom"OFF" to

~~

Disconnect

batterynegative cable.

"ON" position.

BAi

~F

Turn

ignition switchfrom"ON" to

~

Depress

brakepedal.

"OFF" position.

~

Do

not start engine, orcheck with

~

Release

brakepedal.

engine stopped.

ID

Start

engine, orcheck withengine run-

~

ning. Depress

accelerator pedal.

.

.

~

Apply

parking brake.

i!J

Release

accelerator pedal.

..

~

Release

parkingbrake.

~

Pin

terminal checkforSMJ typeECM

and

AIT

control unitconnectors

or

Cff~H

Check

afterengine iswarmed upsuffi-

~ For

details regarding theterminal

ciently.

B

arrangement,refertothe foldout page.

~io

~

Voltage

shouldbemeasured witha

lltlllliR~

t~~~18

voltmeter.

[YJ

lJ9j

.

-

Circuit resistance shouldbemeasured

lfJJ

with

anohmmeter.

~

GI-31

•

Page 1452 of 1701

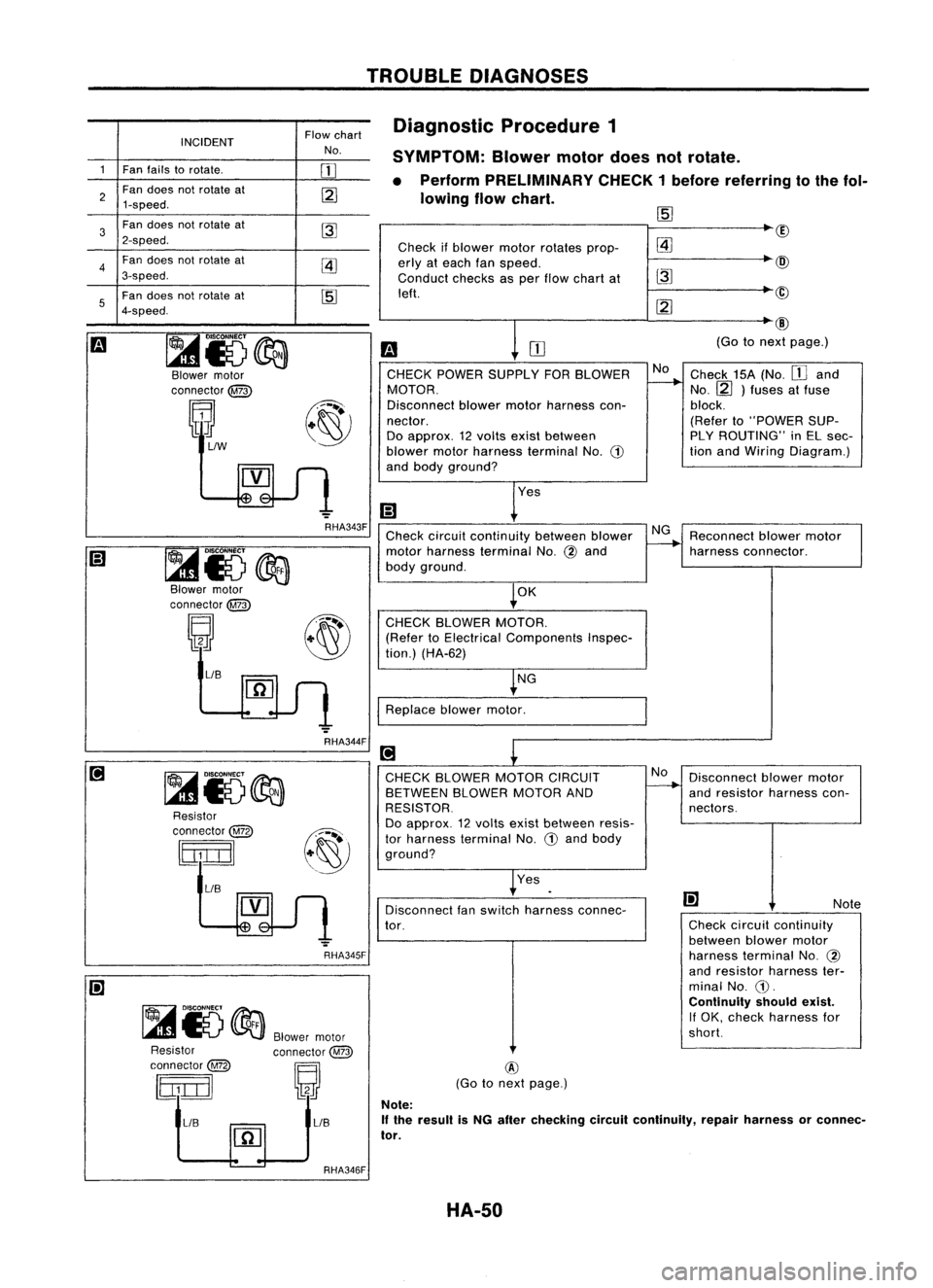

TROUBLEDIAGNOSES

INCIDENT Flow

chart

No.

1 Fan fails torotate.

rn

2 Fan

does notrotate at

[2J

1-speed.

3 Fan

does notrotate at

~

2-speed.

4 Fan

does notrotate at

[1J

3-speed.

5 Fan

does notrotate at

[2]

4-speed. Diagnostic

Procedure1

CD

@

@

@

(Go tonext page.)

Check 15A(No.

rn

and

No.

[2J)

fuses atfuse

block.

(Refer to"POWER SUP-

PLY ROUTING" inEL sec-

tion and Wiring Diagram.)

No

Ves

Check

ifblower motorrotates prop-

erly ateach fanspeed.

Conduct checksasper flow chart at

left.

rn

SYMPTOM:

Blowermotordoesnotrotate.

• Perform PRELIMINARY CHECK1before referring tothe fol-

lowing flowchart.

CHECK POWER SUPPLVFOR BLOWER

MOTOR.

Disconnect blowermotorharness con-

nector.

Do approx. 12volts existbetween

blower motorharness terminal No.

CD

and body ground?

LlW

~i5~

Blower motor

connector

@)

m

RHA343F

~ DISCONNECT

IV@a

Blower motor

connector

@)

~ ~Check

circuitcontinuity betweenblower

motor harness terminal No.@and

body ground.

~OK

CHECK BLOWER MOTOR.

(Refer toElectrical Components Inspec-

tion.) (HA-62) Reconnect

blowermotor

harness connector.

LIB

NG

I

Replace blowermotor.

RHA344F

@J

Resistor

connector@

[Qli1JJ

LIB

CHECK

BLOWER MOTORCIRCUIT

BETWEEN BLOWERMOTORAND

RESISTOR

Do approx. 12volts existbetween resis-

tor harness terminal No.

CD

and body

ground?

Ves No

Disconnect blowermotor

and resistor harness con-

nectors.

Note: If the result isNG after checking circuitcontinuity, repairharness orconnec-

tor. Note

Check circuit continuity

between blowermotor

harness terminal No.@

and resistor harness ter-

minal No.

(1).

Continuity shouldexist.

If OK, check harness for

short.

@

(Go tonext page.)

Disconnect

fanswitch harness connec-

tor.

LIB

RHA345F

Blower motor

connector@

~

LIB

Resistor

connector@

61iJ]

RHA346FHA-50

Page 1456 of 1701

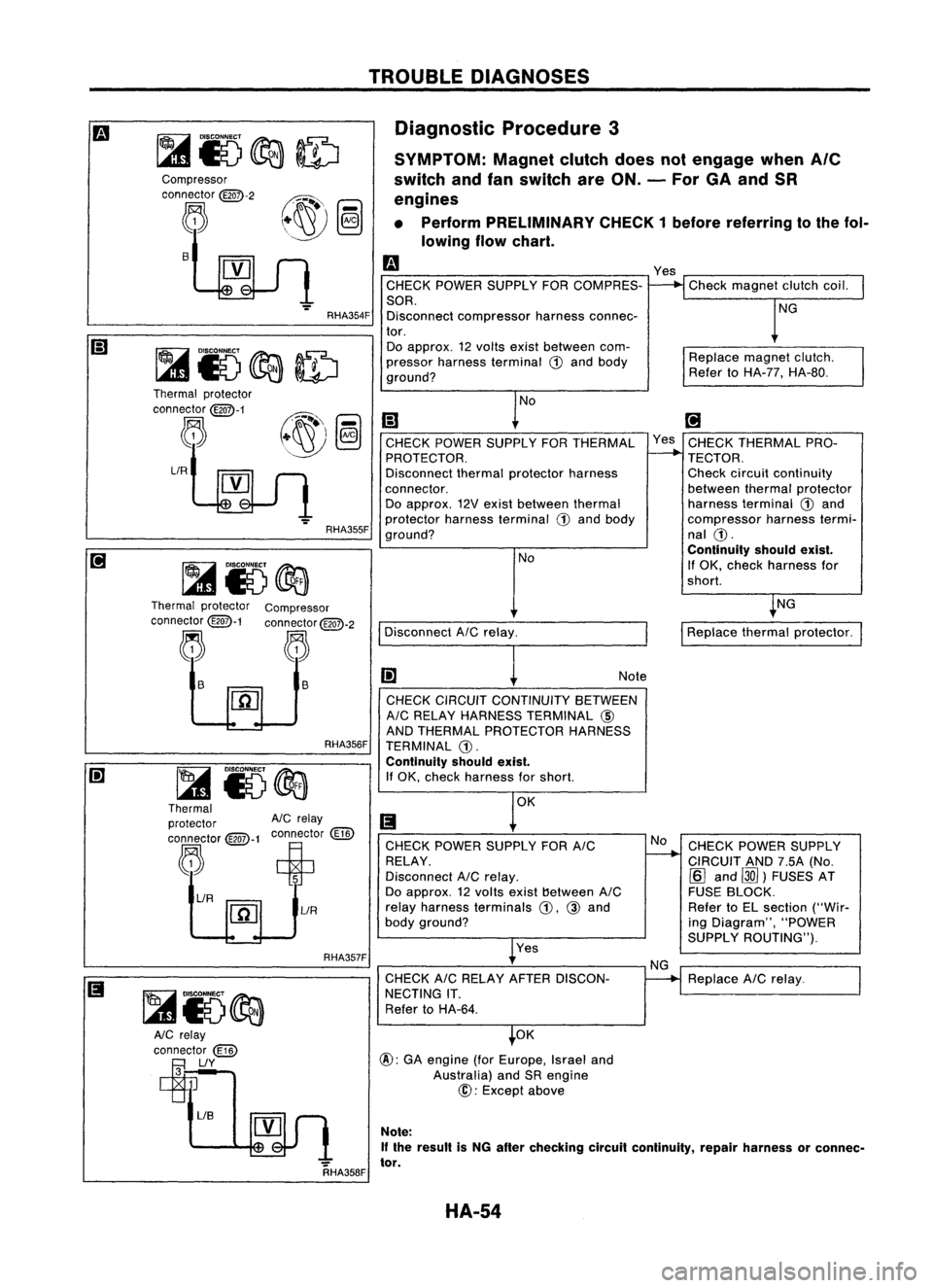

TROUBLEDIAGNOSES

Diagnostic Procedure3

SYMPTOM: Magnetclutchdoesnotengage when

Ale

switch andfanswitch areON. -For GAand SR

engines

• Perform PRELIMINARY CHECK1before referring tothe fol-

lowing flowchart.

Replacemagnetclutch.

Refer toHA-77, HA-80.

Check

magnet clutchcoil.

NG

Yes

m

CHECK POWER SUPPLY FORCOMPRES-

SOR. Disconnect compressor harnessconnec-

tor. Do approx. 12volts existbetween com-

pressor harness terminal

ill

and body

ground?

RHA354F

s

Compressor

connector

@QD-2

~

RHA357FRHA356F

NG

CHECK POWER SUPPLY

CIRCUIT AND7.5A(No.

[Q]

and ~)FUSES AT

FUSE BLOCK.

Refer toEL section ("Wir-

ing Diagram", "POWER

SUPPLY ROUTING").

Replace AICrelay.

I

Replace thermalprotector.

[;J

Yes CHECK THERMAL PRO-

TECTOR.

Check circuit continuity

between thermalprotector

harness terminal

ill

and

compressor harnesstermi-

nal

ill.

Continuity shouldexist.

If OK, check harness for

shorl.

No

NG

CHECK

CIRCUIT CONTINUITY BETWEEN

AIC RELAY HARNESS TERMINAL @

AND THERMAL PROTECTOR HARNESS

TERMINAL

ill.

Continuity shouldexist.

If OK, check harness forshorl. Note

Yes

CHECK

POWER SUPPLY FORAIC

RELAY.

Disconnect AICrelay.

Do approx. 12volts exist!)etween AIC

relay harness terminals

ill,

@

and

body ground?

CHECK AICRELAY AFTER DISCON-

NECTING IT.

Refer toHA-64.

Disconnect

AICrelay. NoNo

[;)

CHECK POWER SUPPLY FORTHERMAL

PROTECTOR.

Disconnect thermalprotector harness

connector. Do approx. 12Vexist between thermal

protector harnessterminal

ill

and body

ground?

OK

@:

GAengine (forEurope, Israeland

Australia) andSRengine

@:

Except above

RHA355F

~ i5@a

Thermal protector

AIC

relay

connector

@-1

connector

(ill)

,"R~~t

[1[]

lIR

lIR

Thermal

protector

connector

@QD-1

~

Thermal protector Compressor

connector

@QD-1

connector

@QD-2

~ ~

~ ~ ls

~

~15~

AlC relay

connector

(ill)

~lIY

RHA358FNote:

If the result isNG after checking circuitcontinuity, repairharness orconnec-

tor.

HA-54