lock NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 3 of 1701

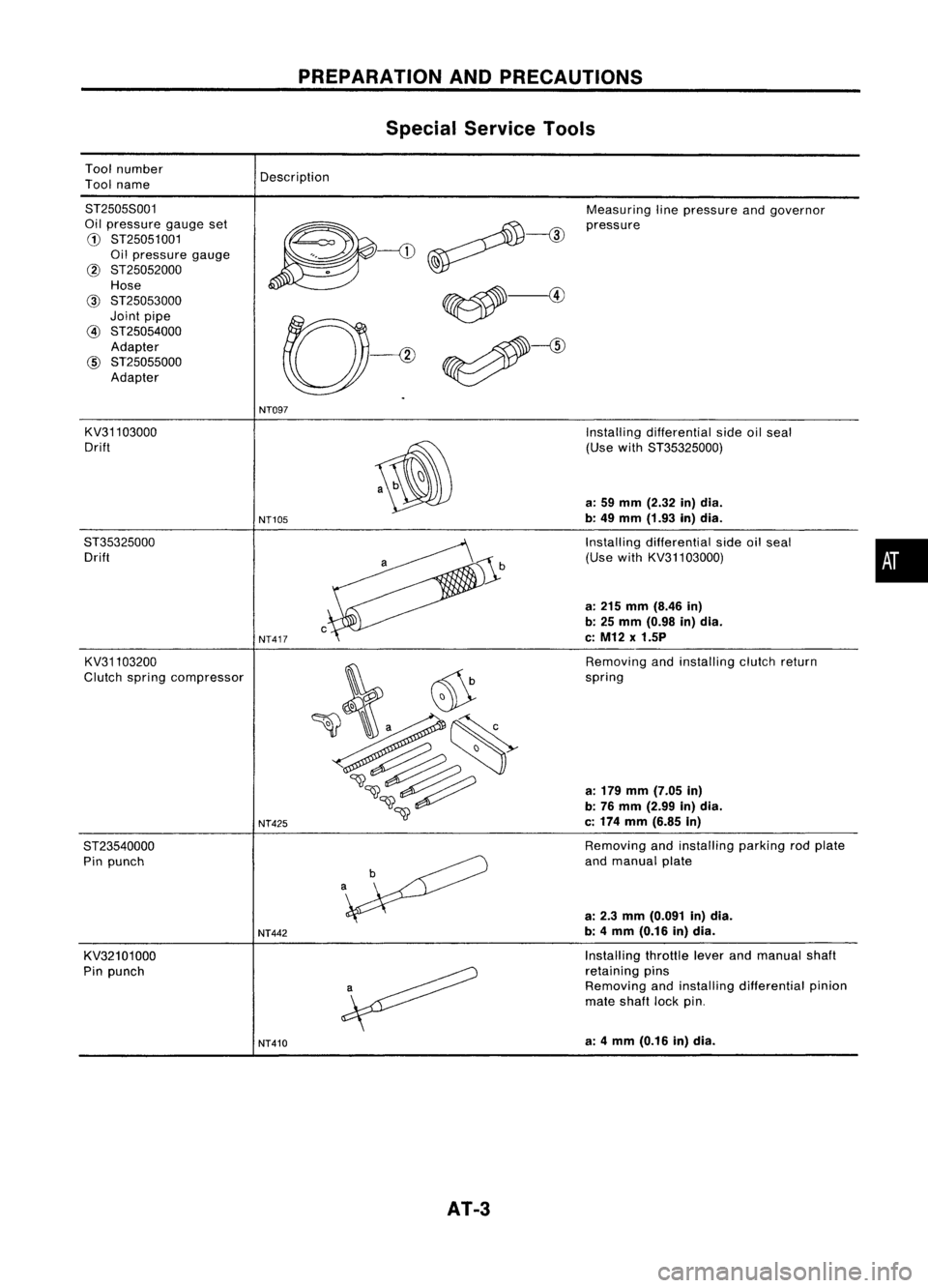

Toolnumber

Tool name

PREPARATION

ANDPRECAUTIONS

Special Service Tools

Description

8T25058001

Oil pressure gaugeset

G)

8T25051001

Oil pressure gauge

@ 8T25052000

Hose

@

8T25053000

Joint pipe

@

8T25054000

Adapter

@

8T25055000

Adapter Measuring

linepressure andgovernor

pressure

NT097

KV31103000

Drift

8T35325000 Drift

KV31103200

Clutch spring compressor

8T23540000 Pin punch

KV32101000

Pin punch

NT105

NT417

NT425

NT442

NT410

AT-3

Installing

differential sideoilseal

(Use with8T35325000)

a: 59 mm (2.32 in)dia.

b: 49 mm (1.93 in)dia.

Installing differential sideoilseal

(Use withKV31103000)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in)dia.

c: M12 x1.5P

Removing andinstalling clutchreturn

spring

a: 179 mm (7.05 in)

b: 76 mm (2.99 in)dia.

c: 174 mm (6.85 in)

Removing andinstalling parkingrodplate

and manual plate

a: 2.3 mm (0.091 in)dia.

b: 4mm (0.16 in)dia.

Installing throttleleverandmanual shaft

retaining pins

Removing andinstalling differential pinion

mate shaft lockpin.

a: 4mm (0.16 in)dia.

•

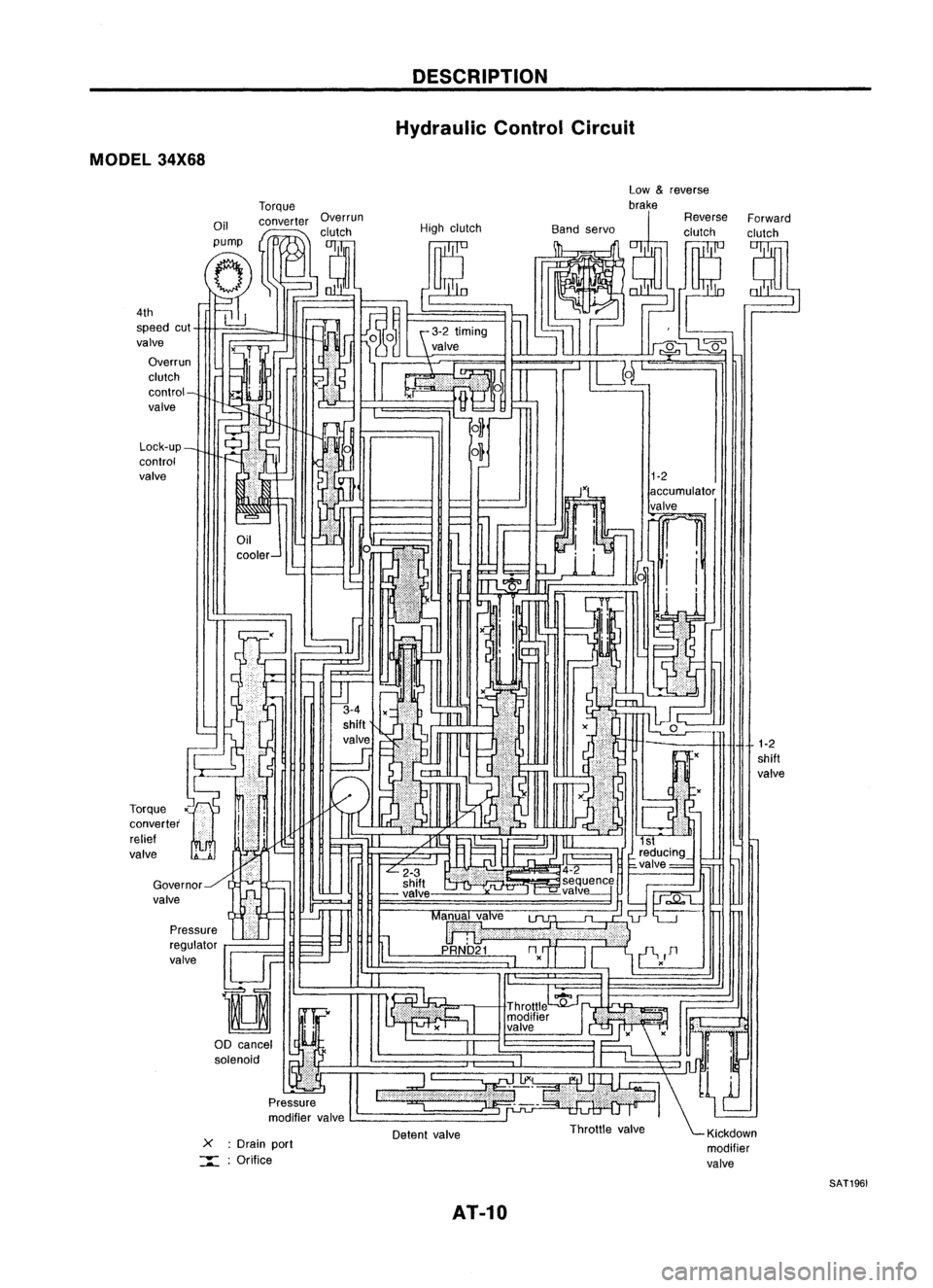

Page 10 of 1701

MODEL34X68

4th

speed cut

valve

Overrunclutch

control

valve

Lock-up

control

valve

Torque '~..•.•

converter

>..•.••••

relief ..••.....

valve ..

Governor

valve

X:Drain port

: Orifice DESCRIPTION

Hydraulic ControlCircuit

Low

&

reverse

brake

High clutch

Detent valve

AT-10 Forward

clutch

1-2

shift

valve

SAT1961

Page 11 of 1701

MODEL34X69AND34X70 DESCRIPTION

Hydraulic ControlCircuit(Cont'd)

00 cancel

solenoid

Lock-up

control

valve

X :

Drain port

•

1-2

shift valve

Forward

clutch

accumulator

valve

High

clutch

Torque

converter

Oil

pump

i

=:= :

Orifice

Overrun

clutch

II

control

valve

4th

speed

cut

valve

SAT509H

AT-11

Page 12 of 1701

DESCRIPTION

Hydraulic ControlCircuit(Cont'd)

MODEL 34X80

1-2

shift

valve

1-2

accumulator

valve

~ 1

i i

xU

::l.

x

-

Detent valve

L-

_

-

cooler- Low

&

reverse

Torque brake

Oil converter Overrun ReverseForward

I

,clutch Highclutch Bandservo clutchclutch

pump

I

tJ

(Jp::-

(T,

tf1

--;::;-;r.]O~

~J

1~

g~ (~ ~~

l]

J~ ~

~iJ -

N

~%~

UL"-'

IU4~1~~

C-1

-!

~frEJ!

1

6 ~, -~

m

~,--J

0

- ILJ

,-O...J

r

ar

r::r=< I'---,

II .(

I'

IJ

,'-

~

,,'

(

-

I -

=-

~tL ',

~H

I~

~ ~M~ ·

F=

f='l .,.11

1-

~I" ~

" ~r'

I

L...---...l

reducing_

L

2-3 .4-2

I

~valve= ~

shift ~seq!!.enc~

~ -valve ,-=-valve---j

h

1J;;;.Q"t....

=--=-.J

II

Ma~alve

lJl.

"~'L--.J

:;;; ~I 11

p

URNb'21

nn

=-.--'

I~

II

'i-V

D

I I -,

." c:

I

Throttle

':fj'~1 .

modifier

If.'

valve .

II

I

1"

";'Jnn!

l...,

:=~-' \~

Throttle valve ~Klckdown

modifier

valve

X

:Drain port

:::::: :Orifice

Pressure

regulator

valve

!lJF

D

00 cancel

I

~Y&

solenoid •

Pressure

modifier valve

Lock-up_

control

valve

4th

speed cut

valve

Overrun

clutch

control-

valve

-=~

I

r

rr=-

LL:

J~

L~

Torque

x'"~

converter

i

i

relief '

valve

2~ '-

3-4 shift valv~-HiliJI

Governor../l ..-

valve

SAT1971

AT-12

Page 13 of 1701

MODEL34X81

4th speed

cut valve

Lock-up

control valve

Overrun

clutch

control valve

3-4 shift valve

X Drainport

:::::= :

Orifice Oil

pump Torque

converter DESCRIPTION

Hydraulic ControlCircuit(Cont'd)

High clutch

AT-13 1-2

shift valve

SAT1981

•

Page 14 of 1701

DESCRIPTION

Shift Mechanism

CONSTRUCTION

18

,:-1

SAT214H

ill

Torque converter

@

Oilpump

@

Input shaft

@

Brake band

@

Reverse clutch

@

High clutch

o

Front sungear

@

Front pinion gear

@

Front internal gear

@l

Front planetary carrier

@

Rear sungear

@

Rear pinion gear

@

Rear internal gear

@

Rear planetary carrier

@

Forward clutch

@

Forward one-way clutch

@

Overrun clutch

@

Lowone-way clutch

@

Low

&

reverse brake

@

Parking pawl

@

Parking gear

@

Output shaft

@

Idlegear

@

Output gear

FUNCTION OFCLUTCH ANDBRAKE

Glutch andbrake components Abbr. Function

Reverse clutch

RIG

To

transmit inputpower tofront sungear

High clutch

HIG

To

transmit inputpower tofront planetary carrier

Forward clutch

FIG

To

connect frontplanetary carrierwithforward one-way clutch

Overrun clutch

OIG

To

connect frontplanetary carrierwithrearinternal gear

Brake band BIBTo

lock front sungear

Forward one-way clutch

F/O.G

When

forward clutchisengaged, tostop rearinternai gearfrom rotat-

ing inopposite direction againstenginespeed

Low one-way clutch LlO.GTo

stop front planetary carrierfromrotating inopposite direction

against enginespeed

Low

&

reverse brake L

&

RIB To

lock front planetary carrier

AT-14

Page 15 of 1701

DESCRIPTION

Shift Mechanism (Cont'd)

OPERATION OFCLUTCH ANDBRAKE

Bandservo

ForwardLow

Low

&

Shift posi- Reverse

HighForward

Overrun

Lock-upRemarks

tion clutch clutchclutchclutch 2nd

3rd4thone-way

one-way reverse

apply release

applyclutch

clutch brake

P PARK

POSITION

0 0REVERSE

POSI-

R TION

N NEUTRAL

POSI-

TION

1st 0'10

••

D 2nd

0'10

0

•

Automatic

shift

'4 00'10

'2@

@

•

1<-->2<-->3<-->4

3rd

4th 0@ '3@

@0

0

1st 00

••

Automatic

shift

2 1<-->2

2nd 00 0

•

1st 00

•

•

0

Locks

(heldsta-

1 tionary)

in1st

2nd 00 0

•

speed

1

<--

2

'1 Operates whenoverdrive switchissel to"OFF".

'2 Oilpressure isapplied toboth 2nd"apply" sideand3rd"release" sideofband servo piston. However, brakebanddoes notcontract

because oilpressure areaonthe "release" sideisgreater thanthatonthe "apply" side.

'3 Oilpressure isapplied to4th "apply" sideincondition '2above, andbrake bandcontracts.

'4 AIT

will notshift to4th when overdrive switchisset to"OFF" position.

o

Operates.

• Operates. During"progressive" acceleration.

@ Operates butdoes notaffect power transmission.

Control System

CONTROL SYSTEM

Engine

AIT

•

Lock-up cancel

solenoid'1

Overdrive

control switch

1:1

Governor valve

I

11

1

I

1

1

OD cancel solenoid :

; I

L

J

AT-15

'1:

Equipped onmodel

34X69, 34X70and34X80

: Electrical signal

.... :Hydraulic pressure

SAT985HA

Page 17 of 1701

Fluidleakage TROUBLE

DIAGNOSES

Preliminary Check(PriortoRoad Testing)

AIT FLUID CHECK

Fluid leakage check

1. Clean areasuspected ofleaking, -for example, mating

surface ofconverter housingandtransmission case.

2. Start engine, applyfootbrake, placeselector leverin"0"

position andwait afew minutes.

3. Stop engine.

4. Check forfresh leakage.

SAT288G

Fluidcondition check

Fluid levelcheck -Refer toMA section (CHASSIS AND

BODY MAINTENANCE).

Fluid

color

Oark orblack withburned odor

Milky pink

Varnished fluid,lighttodark brown

and tacky Suspected

problem

Wear offrictional material

Water contamination

- Road water entering through

filler tubeorbreather

Oxidation

- Over orunder filling

- Overheating

•

Road Testing

Perform roadtests using "Symptom" chart.Refertopage

AT-20.

"P"

POSITION

1. Place selector leverin"P" position andstart engine. Stop

engine andrepeat theprocedure inall positions, including

neutral position.

2. Stop vehicle onaslight upgrade andplace selector leverin

"P" position. Releaseparkingbraketomake surevehicle

remains locked.

"R"

POSITION

1. Manually moveselector leverfrom"P"to"R", andnote

shift quality.

2. Drive vehicle inreverse longenough todetect slippage or

other abnormalities.

"N"

POSITION

1. Manually moveselector leverfrom"R"and"0"to"N" and

note shift quality.

2. Release parkingbrakewithselector leverin"N" position.

Lightly depress accelerator pedaltomake surevehicle

does notmove. (When vehicle isnew orsoon afterclutches

have been replaced, vehiclemaymove slightly. Thisisnot

a problem.)

AT-17

Page 18 of 1701

SAT497GTROUBLE

DIAGNOSES

Road Testing (Cont'd)

"0"

POSITION

1. Manually moveselector leverfrom"N"to"D" position, and

note shiftquality.

2. Using theshift schedule asareference, drivevehicle in"D"

position. Record,onsymptom chart,respective vehicle

speeds atwhich up-shifting anddown-shifting occur.These

speeds aretobe read atthree different throttlepositions

(light, halfandfull), respectively. Alsodetermine thetiming

at which shocks areencountered duringshifting andwhich

clutches areengaged.

SAT612GA

3.Determine whetherlock-upproperly occurswhiledriving

vehicle inproper gearposition andatproper vehicle speed.

4. Check todetermine ifshifting tooverdrive gearcannot be

made whileODcontrol switchis"OFF".

5. Drive vehicle in"D

3"

position athalf tolight throttle posi-

tion. Keep driving at60 to70 km/h (34to43 MPH). FUlly

depress accelerator pedaltomake suretransaxle down-

shifts from3rdto2nd gear.

6. Drive vehicle in"D

2"

position athalf tolight throttle posi-

tion. Keep driving at25 to35 km/h (16to22 MPH). Fully

depress accelerator pedaltomake suretransaxle down-

shifts from2ndto1st gear.

"2"

POSITION

1. Shift to"2" position andmake surevehicle startsin1st

gear.

2. Increase vehiclespeedtomake suretransaxle upshiftsfrom

1st to2nd gear.

3. Further increase vehiclespeed.Makesuretransaxle does

not upshift to3rd gear.

4. Drive vehicle in"2

2"

position athalf tolight throttle position.

Keep driving at25 to35 km/h (16to22 MPH). Fullydepress

accelerator pedaltomake suretransaxle downshifts from

2nd to1st gear.

5. Allow vehicle torun idle while in"2" position tomake sure

that transaxle downshifts to1st gear.

6. Move selector leverto"D" position andallow vehicle to

operate at30 to40 km/h (19to25 MPH). Then,shiftto"2"

position tomake suretransaxle downshifts to2nd gear.

"1"

POSITION

1. Place selector leverin"1" position andaccelerate vehicle.

Make suretransaxle doesnotshift from 1stto2nd gear

although vehiclespeedincreases.

2. Drive vehicle in"1" position. Releaseaccelerator pedalto

make surethatengine compression actsasabrake.

3. Place selector leverin"D" or"2" position andallow vehi-

cle torun at15 to25 km/h (9to 16 MPH). Thenmove selec-

tor lever to"1" position tomake suretransaxle downshifts

to 1st gear.

AT-18

Page 22 of 1701

TROUBLEDIAGNOSES

Road Testing (Cont'd)

Numbers arearranged inorder ofprobability.

~

ONVEHICLE

..

Perform inspections startingwithnumber one

and work up.

Circled numbers indicatethatthetransaxle

must beremoved fromthevehicle.

(J)(J)

> >

01

0;

0;

. Valve expected tobe malfunctioning

c:

>

(J)

~ .;::

>>

(J)

.~

c

0;

>

0;

(J)

>

e

0;

"0 "0

Q)

C

>

::J

c:(J)

.8

rr

III

(J)

"0

0

~

0.

oil

III

<.>

'0

J::.

rtl

:;

J::.

ii

(J)

£

~(J)

(J)

(J) (J)

(J)(J)

£

"0

.~

~

01

>>

>

01

>>>

0

c: :0 c:

::J

0;0;

~

0;

0;0;

::J

E

III III

rtl

.~

rtl

0;

(3

<.>

~

rtl

>>

> >

>>

a; ~

(J) ~ (J)~

;:

'E

;t:

c:

~

>

e

.8

E (J)

0.

e

E

0;

::J

J::. J::.

:c

2

::J

~

:0

.!::

::J

rtl

rtl

C

e

(J)

c

0

c:

rtlrtl

rtlrtl

li;

rtl

J::.

01

c:

.c

III

(J)

"'f

C')

C)'

>

(J)

6

0

J::.

c:

0

a: a:

u

EO

~

UJ

::i

u

~

::E

C')

N

0

Failure tochange gearfrom 4th

to 2nd with accelerator pedal

32

6

depressed.

Failure tochange gearfrom3rd

to 2nd with accelerator pedal

32

6

depressed.

Failure tochange gearfrom 1st

32

6

to 2nd in"0" and"2"position.

Shift quality Vehicledoesnotstart from

32

6

"1st" in"0" and"2"position.

Failure tochange gearto3rd

32

6

and 4thin"0" position.

Changes gearto1st directly

when selector leverisset from

32

6

"D"

to"1" position.

Changes gearto2nd in"1"

3

2

6

position.

Lock-up pointisextremely high

32

6

or low.

Lock-up quality Torque

converter doesnotlock-

32

7

up.

Lock-up isnot released when

2

accelerator pedalisreleased.

Engine doesnotstart in"P" and "N" positions orengine starts

2

3

in positions otherthan"P"and "N" positions.

Vehicle moveswithselector leverin"P" position.

AT-22