oil filter NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 53 of 1701

('l:,~~

o

\~A~~l

o

u~!~~:

Contact

0

9

&k .~

'"~~~~~)(?~~

SIR

accumulator piston ~./

SAT023DB

SAT129E

SAT024D DISASSEMBL

Y

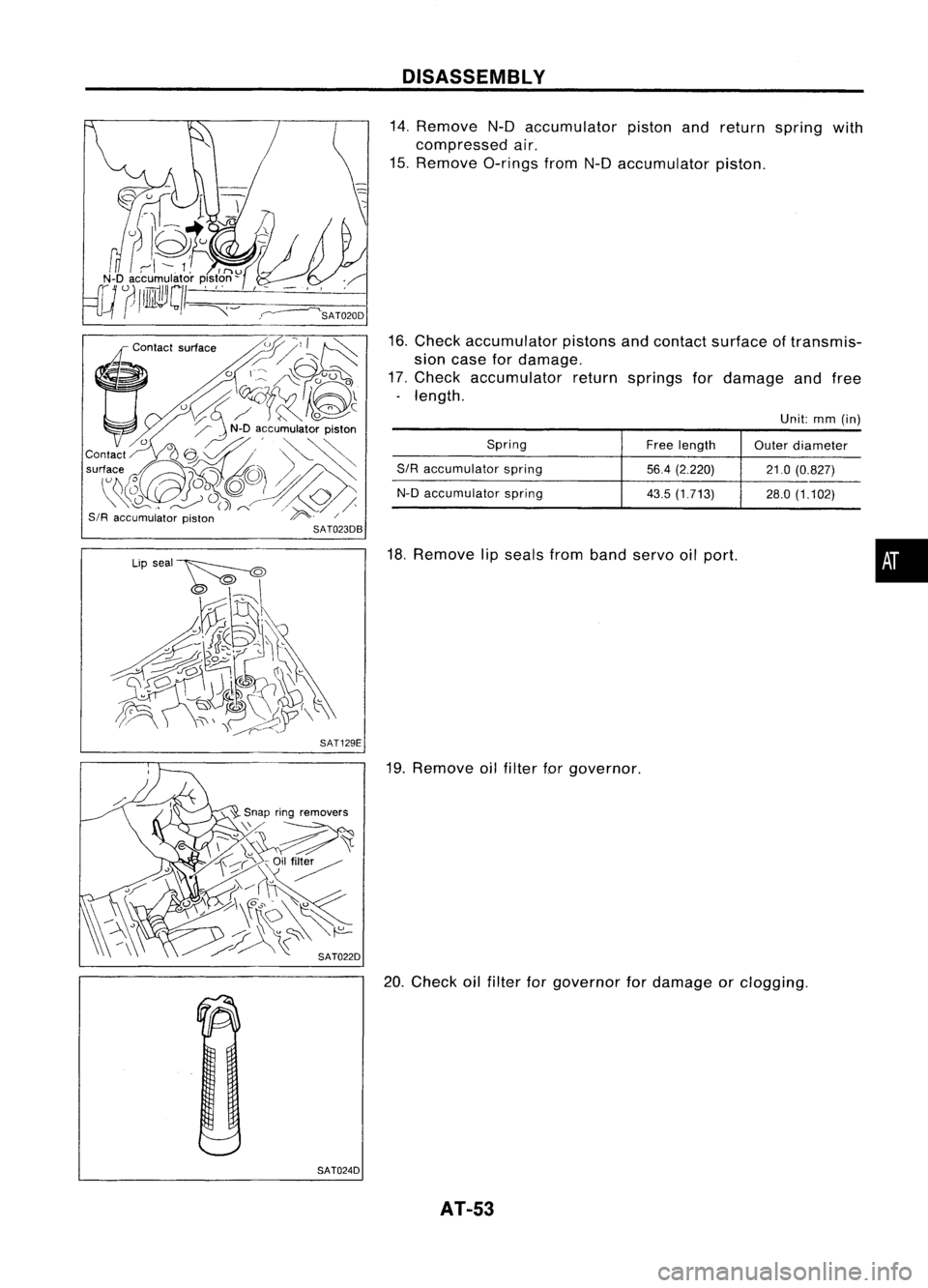

14. Remove N-Daccumulator pistonandreturn spring with

compressed air.

15. Remove O-ringsfromN-Daccumulator piston.

16. Check accumulator pistonsandcontact surface oftransmis-

sion case fordamage.

17. Check accumulator returnsprings fordamage andfree

. length.

Unit:mm(in)

Spring Freelength

Outerdiameter

SIR accumulator spring

56.4(2.220) 21.0(0.827)

N-D accumulator spring

43.5(1.713)

28.0(1.102)

18. Remove lipseals fromband servo oilport.

19. Remove oilfilter forgovernor.

20. Check oilfilter forgovernor fordamage orclogging.

AT-53

•

Page 392 of 1701

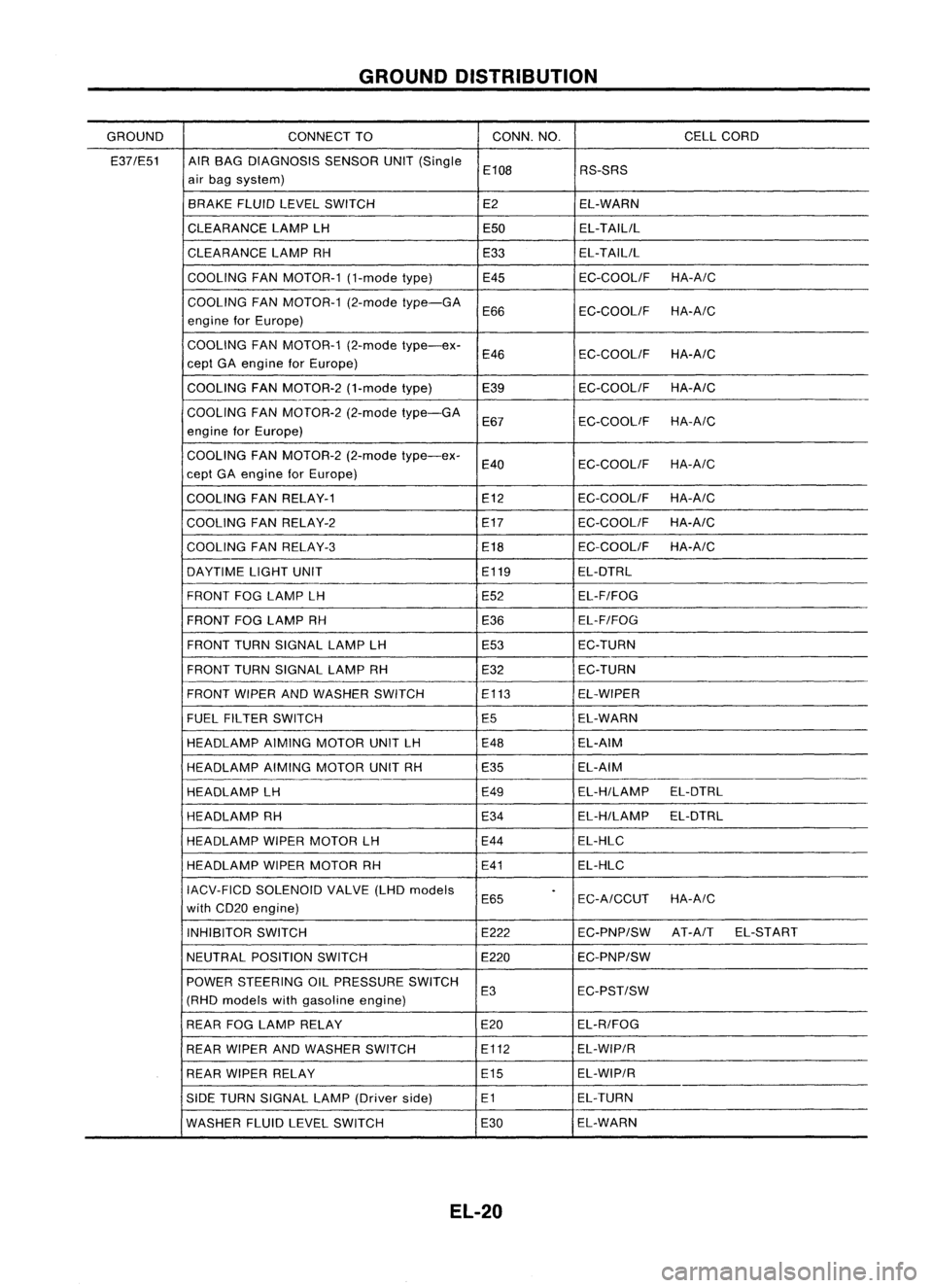

GROUNDDISTRIBUTION

GROUND CONNECTTO CONN.

NO. CELLCORD

E37/E51 AIRBAG DIAGNOSIS SENSORUNIT(Single

E108 RS-SRS

air bag system)

BRAKE FLUIDLEVEL SWITCH E2EL-WARN

CLEARANCE LAMPLH E50EL-TAILIL

CLEARANCE LAMPRH E33EL-TAILIL

COOLING FANMOTOR-1 (1-modetype) E45 EC-COOLIFHA-A/C

COOLING FANMOTOR-1 (2-modetype-GA

E66 EC-COOLIF

HA-A/C

engine forEurope)

COOLING FANMOTOR-1 (2-modetype-ex-

E46 EC-COOLIF

HA-A/C

eept GAengine forEurope)

COOLING FANMOTOR-2 (1-modetype)

E39 EC-COOLIFHA-A/C

-

COOLING FANMOTOR-2 (2-modetype-GA

E67 EC-COOLiF

HA-A/C

engine forEurope)

COOLING FANMOTOR-2 (2-modetype-ex-

E40 EC-COOLIFHA-A/C

eept GAengine forEurope)

COOLING FANRELAY-1 E12

EC-COOLIFHA-A/C

COOLING FANRELAY-2 E17

EC-COOLIFHA-A/C

COOLING FANRELAY-3 E18EC-COOLIF

HA-A/C

DAYTIME LIGHTUNIT E119EL-DTRL

FRONT FOGLAMP LH E52EL-F/FOG

FRONT FOGLAMP RH

E36EL-F/FOG

FRONT TURNSIGNAL LAMPLH E53EC-TURN

FRONT TURNSIGNAL LAMPRH E32EC-TURN

FRONT WIPERANDWASHER SWITCH E113

EL-WIPER

FUEL FILTER SWITCH

E5EL-WARN

HEADLAMP AIMINGMOTOR UNITLH E48

EL-AIM

HEADLAMP AIMINGMOTOR UNITRH E35 EL-AIM

HEADLAMP LH E49EL-H/LAMP

EL-DTRL

HEADLAMP RH E34EL-H/LAMP

EL-DTRL

HEADLAMP WIPERMOTOR LH E44

EL-HLC

HEADLAMP WIPERMOTOR RH E41EL-HLC

IACV-FICD SOLENOID VALVE(LHDmodels

.

E65 EC-A/CCUTHA-A/C

with CD20 engine)

INHIBITOR SWITCH E222EC-PNP/SWAT-A

IT EL-START

NEUTRAL POSITION SWITCH E220EC-PNP/SW

POWER STEERING OILPRESSURE SWITCH

E3 EC-PST/SW

(RHO models withgasoline engine)

REAR FOGLAMP RELAY E20EL-R/FOG

REAR WIPER ANDWASHER SWITCH E112EL-WIP/R

REAR WIPER RELAY E15EL-WIP/R

SIDE TURN SIGNAL LAMP(Driver side) E1 EL-TURN

WASHER FLUIDLEVEL SWITCH E30EL-WARN

EL-20

Page 510 of 1701

WARNINGLAMPSANDBUZZER

Warning Lamps/Schematic

>-

[[

W

f-

f-

CD

w

(f)

:J

l.L

UG

NATS

SECURITY

INDICATOR

NATSIMMU

ABS ABS

CONTROL

UNIT

OIL OILPRESSURE SWITCH

FUEL

FUELTANKGAUGE UNIT

WASHER

WASHERFLUIDLEVELSWITCH

DOOR

FRONTDOORSWITCH

(Driver's side)

FRONT DOORSWITCH

(Passenger side)

REAR ODOR SWITCH LH

ALTERNATOR PARKING

BRAKESWITCH

FUEL FILTER SWITCH

=

BRAKE

FLUIDLEVEL SWITCH

REAR

ODORSWITCH RH

=

WARNING

BUZZER

UNIT

=

ECM (ECCS

CONTROL

MODULE)

ECM

(ENGINE

CONTROL

MODULE)

I

U

f- W

H (f)

3:f-

:J

(f)[[

l.L

Zf-

O(f)

H

f-L

HO

Z

BELT

C!JZ

HO

BRAKE

Q)

(I)

D.

rl

0

Q)

L

D

::J

0

W

E

L

C

0

ro

""-

D

Q)

(I)

(f)

rl

Q)

ro

D

D

'M

C

0

rl

ro

E

ro

L

~

Q) Q)

.....

u

C C

(I)

ro

.M

Q)

.M

ro

::J

.0

OJ

C

OJ

.M

c

.M

C

rl

U

Q)

OJ

Q)

ro

L

+'

C

L

0

ro

Q) Q) Q)

.....

""-

I

C C

(I)

GLOW

.M

rl

.

M

::J

.....

L

rl

Q)

rl

0

0

(I)

0

Q)

0

(I)

Q)

(I)

L

u

D

ro

.M

ro

0

x

I

C!J

0

C!J

l.L

W

lD

MALFUNCTION

@@~@@@

INDICATOR

AIRBAG

AIRBAG

DIAGNOSIS

SENSOR

UNIT

HEL082

EL-138

Page 737 of 1701

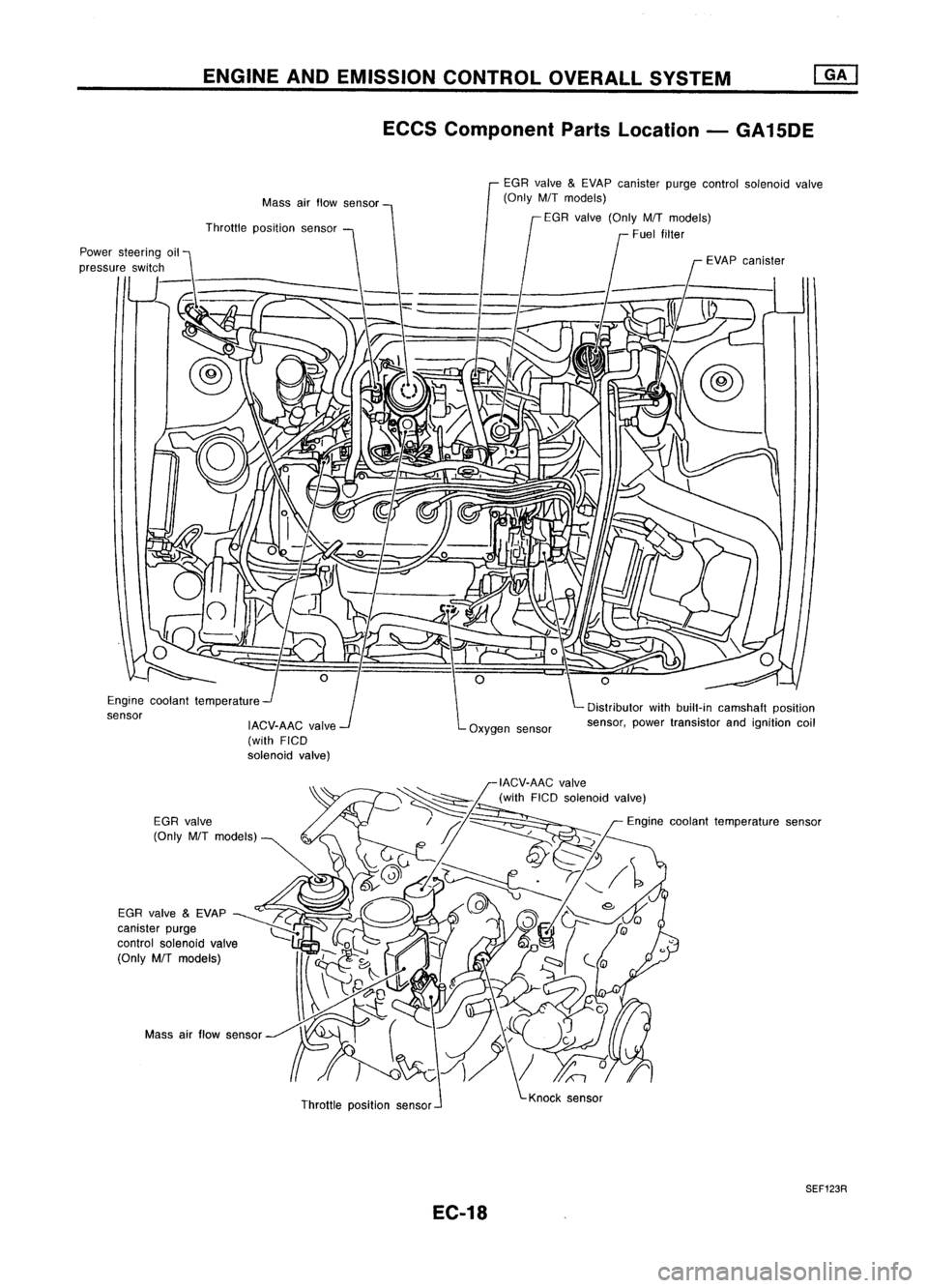

ENGINEANDEMISSION CONTROL OVERALLSYSTEM

ECCS Component PartsLocation -GA15DE

Distributor withbuilt-in camshaft position

sensor, powertransistor andignition coil

EGR

valve

&

EVAP canister purgecontrol solenoid valve

(Only M/Tmodels)

f

EGR valve (Only M/Tmodels)

Fuel filter

EVAPcanister

Oxygen sensor

Mass

airflow sensor

IACV-AAC valve

(with FICD

solenoid valve)

Throttle

position sensor

Engine coolant temperature

sensor

Massairflow sensor

Throttleposition sensor

SEF123R

EC-18

Page 792 of 1701

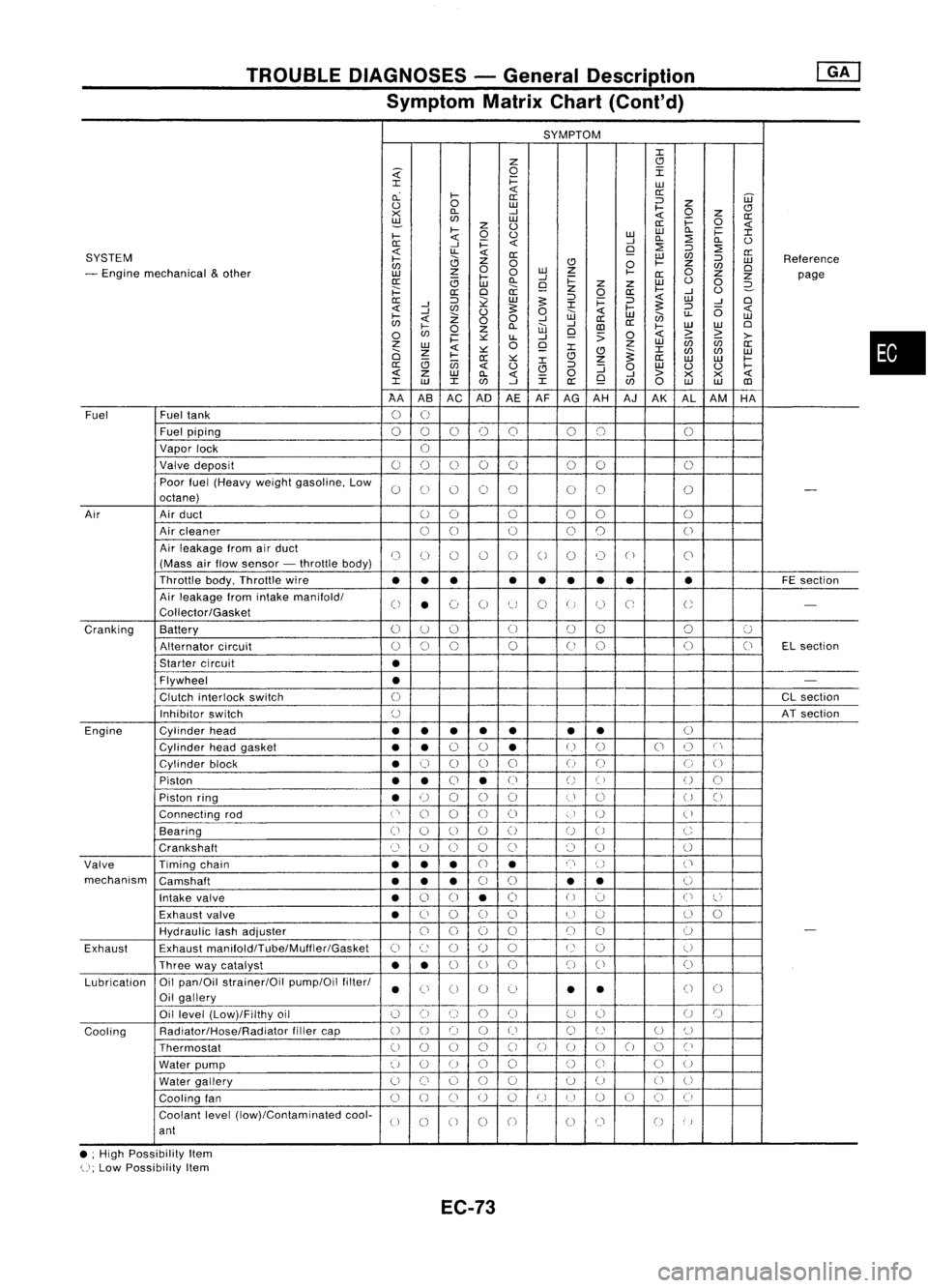

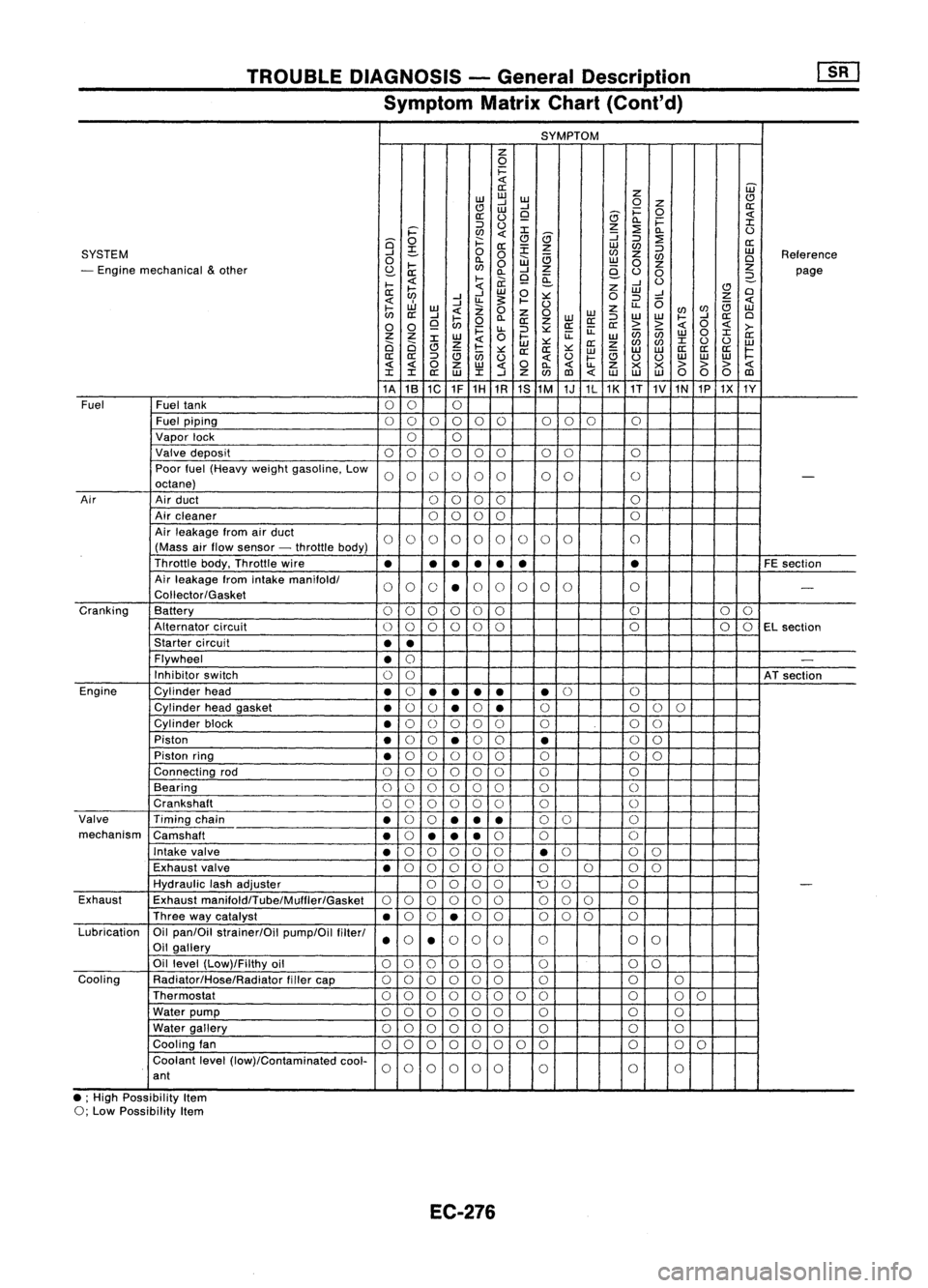

TROUBLEDIAGNOSES -General Description

Symptom MatrixChart(Cont'd)

SYMPTOM

J:

Z

CJ

~

0

I

J:

i=

LU

cL

I-

«

a:

a: ::J

UJ

0

0

LU

I-

Z

CJ

><

D..

-'

«

0

z

a:

~

LU

i=

0

z

0

a:

«

I-

0

0

LULU

D..

i=

J:

I-

«

-'

D..

:2

D..

0

0:

-'

i=

«

9

:2

::J

:2

SYSTEM

«

LL

«

0:

LU

C/J

a:

I-

0

Z

0

CJ

0

I-

Z

::J

LU

Reference

C/J

0

C/J

0

- Engine mechanical

&

other

z

0

LU

Z

I-

0

LU

I-

-'

0:

Z

Z

page

0:

(3

LU

D..

9

i=

z

Z

LU

0

0

2-

;:::

a:

0

a:

z

0

a:

I-

-'

0

0:

::J

~

LU

5:

::J

i=

::J

«

LU

-'

0

-'

J:

5:

«

-'

C/J

0

5:

0

«

I-

::J

(5

«

I-

Z

W

LU

en

LL

LU

C/J

«

00

-'

-'

a:

a:

0

I-

0

Z

D..

W

CD

I-

LU

LU

0

C/J

i=

~

LL

-'

9

:>

0

«

>

~

>-

z

0

Z

LU

(ij

C/J

a:

LU

«

~

9

J:

J:

0

Z

CJ

~

C/J

C/J

LU

I-

0:

~

CJ

Z

a:

LU LU

I-

(3

(jj

J:

a:

«

0

CJ

::J

:J

0

LU

0 0

I-

«

z

LU

D..

«

0

-'

>

><><

«

J:

LU

J:

C/J

-'

J:

a:

9

C/J

0

LU LU

CD

AA ASAC AD

AEAF

AG AH AJAK ALAM HA

Fuel Fueltank

0

U

Fuel piping

00 0

()

0 00 0

Vapor lock

U

Valve deposit

00 000 00

0

Poor fuel(Heavy weightgasoline, Low

0

C)

0 0

()

00

0

-

octane)

Air Airduct

00 0

00

0

Air cleaner

00

0

0

0

0

Air leakage fromairduct

()

(J

()

()

0

0

0 0

("

)

C'

(Mass airflow sensor -throttle body)

Throttle body,Throttle wire

••• •

••

•• •

FE

section

Air leakage fromintake manifold/

0

•

(~)

0

tJ

0

U

C;

U

-

Collector/Gasket

Cranking Battery

0

U

()

(J

00 0

':J

Alternator circuit

()

0

0

0

(J

0 0

(J

ELsection

Starter circuit

•

Flywheel

•

-

Clutch interlock switch

0

CL

section

Inhibitor switch

()

ATsection

Engine Cylinderhead

••

• •

• •

•

()

Cylinder headgasket

••

0

0

•

U

()

0

()

C'

Cylinder block

•

0

0 0

0

()

(J

0

0

Piston

••

0

•

(J

()

()

()

0

Piston ring

•

U

00

0

U

()

U

()

Connecting rod

('

0

0

00

)

U

(

)

Bearing

(i

0

()

0

()

U

0

C

Crankshaft

Cl

(~)

0 0

()

()

0

0

Valve Timingchain

•••

CJ

•

n

()

('

mechanism Camshaft

•••

0

0

•

•

0

Intake valve

•

0

0

•

0

()

':J

0

l~'

Exhaust valve

•

C)

0

()

()

U

u

()

0

HydraUlic lashadjuster

00

0

0

()

()

0

-

Exhaust Exhaust

manifoldlTube/Muffler/Gasket

C)

c:

()

()

0

U

()

U

Three waycatalyst

••

0

U

0 0

()

0

Lubrication Oil

pan/Oil strainer/Oil pump/Oilfilter/

•

Ci

0 0

0

•

•

()

0

Oil gallery

Oil level (Low)/Filthy oil

()

0

()

()()

(J

0

U

()

Cooling Radiator/Hose/Radiator

fillercap

()

0 0

()

()

C)

U

U

()

Thermostat

00

0

0

C)

0

()

00

0

Cl

Water pump

u

0

U

0

0

()

Ci

C)

U

Water gallery

U

()

0

()

0 0

U

0

U

Cooling fan

0

()

CJ

U

0

U

I)

U

()

CJ

(i

Coolant level(low)/Contaminated cool-

U

0

0 0

0

00

()

)

ant

• ;High Possibility Item

U;

Low Possibility Item

EC-73

•

Page 995 of 1701

TROUBLEDIAGNOSIS -General Descrip_tio_n

1s_R_1

Symptom MatrixChart(Cont'd)

SYMPTOM

z

0

i=

«

W

a:

z

w

w

w

CJ

CJ

....J

....J

0

Z

a:

w

i=

0

a:

(.)

9

8

«

0.. i=

:I:

::J

(.)

z

:2

i='

en

«

:I:

8

:J

0..

(.)

Q

0

f:::.

CJ

:J

:2

a:

a:

:E

z

w

en

SYSTEM

....J

~

0

0

en

z

:J

w

Reference

0

0..

W

a

w

en

Cl

- Engine mechanical

&

other

I-

en

0

z

0

z

z

S:?-

a: 0..

....J

e-

(.)

0

page

I-

«

l-

ii.

9

~

....J

(.)

2-

a:

~

«

w

0

z

w

CJ

Cl

....J ....J

:.:::

0

:J

....J

Z

«

....J

u.

~

I-

(.)

u..

0

a

«

I-

w

«

Z

0

z

enen

w

en

a:

....J

I-

0..

Z

0

WW

:J

W

W

I-

....J

a:

Cl

0 0

9

en

0

a:

z

a:a:

a:

> >

«

0

«

>-

i=

u..

:J

:.:::

ii:

enen

0

:I:

Z Z

W

0

l-

ii:

w w

a:

Ci Ci

:I:

Z

«

w

:.:::

a:

z

en

en

:I:

(.)

(.)

w

CJ

a

I-

:.:::

a:a:

:.:::

w

a

w

w

a:

a:a:

~

a:

a:

:J

en

(.)

«

(.)

I-

(.)

(.)

w

w

w

« «

0

z

w

«

0

0..

«

u..

Z

x x

>>>

«

:I: :I:

a:

w

:I:

....J

Z

en

(l)

«

w w

w

00 0

(l)

1A 1B

1C 1F1H

1R 1S

1M 1J1L1K

1T

1V

1N

1P1X 1Y

Fuel Fueltank

00 0

Fuel piping

00 0000 000

0

Vapor lock

00

Valve deposit

000 000 00 0

Poor fuel(Heavy weightgasoline. Low

0000 00 00

0

-

octane)

Air Airduct

00 00 0

Air cleaner

0

0

00 0

Air leakage fromairduct

00 00 00 0

0 0

0

(Mass airflow sensor -throttle body)

Throttle body.Throttle wire

•

•

•

•

• •

•

FE

section

Air leakage fromintake

manifoldl

00 0

•

0

0 0

00 0

-

Coliector/Gasket

Cranking Battery

0

0

00 0

0 0

0

0

Alternator circuit

00

00

0

0 0

00

EL

section

Starter circuit

••

Flywheel

•

0

-

Inhibitor switch

00

ATsection

Engine Cylinderhead

•

0

•

•

••

•

0

0

Cylinder headgasket

•

0

()

•

0

•

0

0

00

Cylinder block

•

0

()

0 00 0 00

Piston

•

0

0

•

0

0

•

0

0

Piston ring

•

0

00 0

0 0 00

Connecting rod

00 00

00 0 0

Bearing

000 000 0

0

Crankshaft

00

0 0

0

0 0

0

Valve Timingchain

•

0

0

••

•

0

0 0

mechanism Camshaft

•

0

•• •

0

0 0

Intake valve

•

0

00 0

0

•

0

0

0

Exhaust valve

•

0

00 00 0000

Hydraulic lashadjuster

0000

'0

0 0

-

Exhaust Exhaust

manifoldlTube/Mulfler/Gasket

00

00 0

0

00

0 0

Three waycatalyst

•

0

0

•

0

0 000 0

Lubrication Oilpan/Oil strainer/Oil pump/Oilfilterl

000

0

0 0

0

Oil gallery

••

Oil level (Low)/Filthy oil

00 0000

0 0

0

Cooling Radiator/Hose/Radiator fillercap

00

0 00

0 0 00

Thermostat

00

00 0

0 00 0

00

Water pump

000 000 0 0

0

Water gallery

00 00 00

0 0

0

Cooling fan

00 0

00

0 0

0 0

0

0

Coolant level(low)/Contaminated cool-

00

0000

0 0

0

ant

• ;High Possibility Item

0; Low Possibility Item

EC-276

Page 1141 of 1701

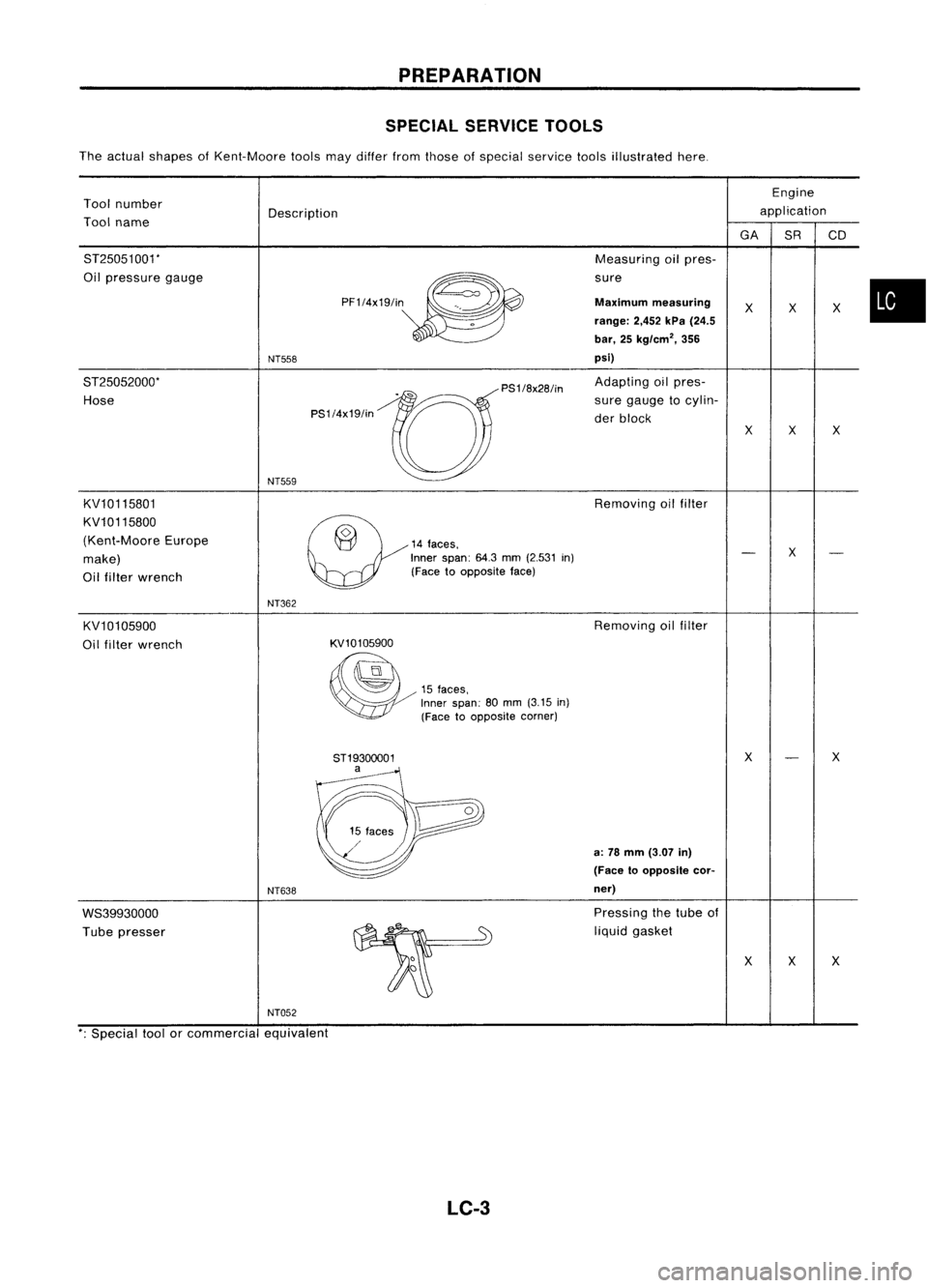

PREPARATION

SPECIAL SERVICETOOLS

The actual shapes ofKent-Moore toolsmaydiller fromthose ofspecial service toolsillustrated here.

Tool number

Tool name

ST25051001'

Oil pressure gauge

ST25052000'

Hose

KV10115801

KV10115800

(Kent-Moore Europe

make)

Oil filter wrench

KV10105900

Oil filter wrench

WS39930000

Tube presser

NT559

NT362

NT638

~o

14faces,

Inner span:

64.3

mm

(2.531

in)

(Face toopposite face)

KV101 05900

~

15

faces,

Inner span:

80

mm

(3.15

in)

(Face toopposite corner)

8T1930oo01 a

Removing

oilfilter

Removing oilfilter

a:

78

mm

(3.07

in)

(Face 10opposite cor-

ner)

Pressing thetube of

liquid gasket

x

x

x

x

x

x

NT052

'; Special toolorcommercial equivalent

LC-3

Page 1158 of 1701

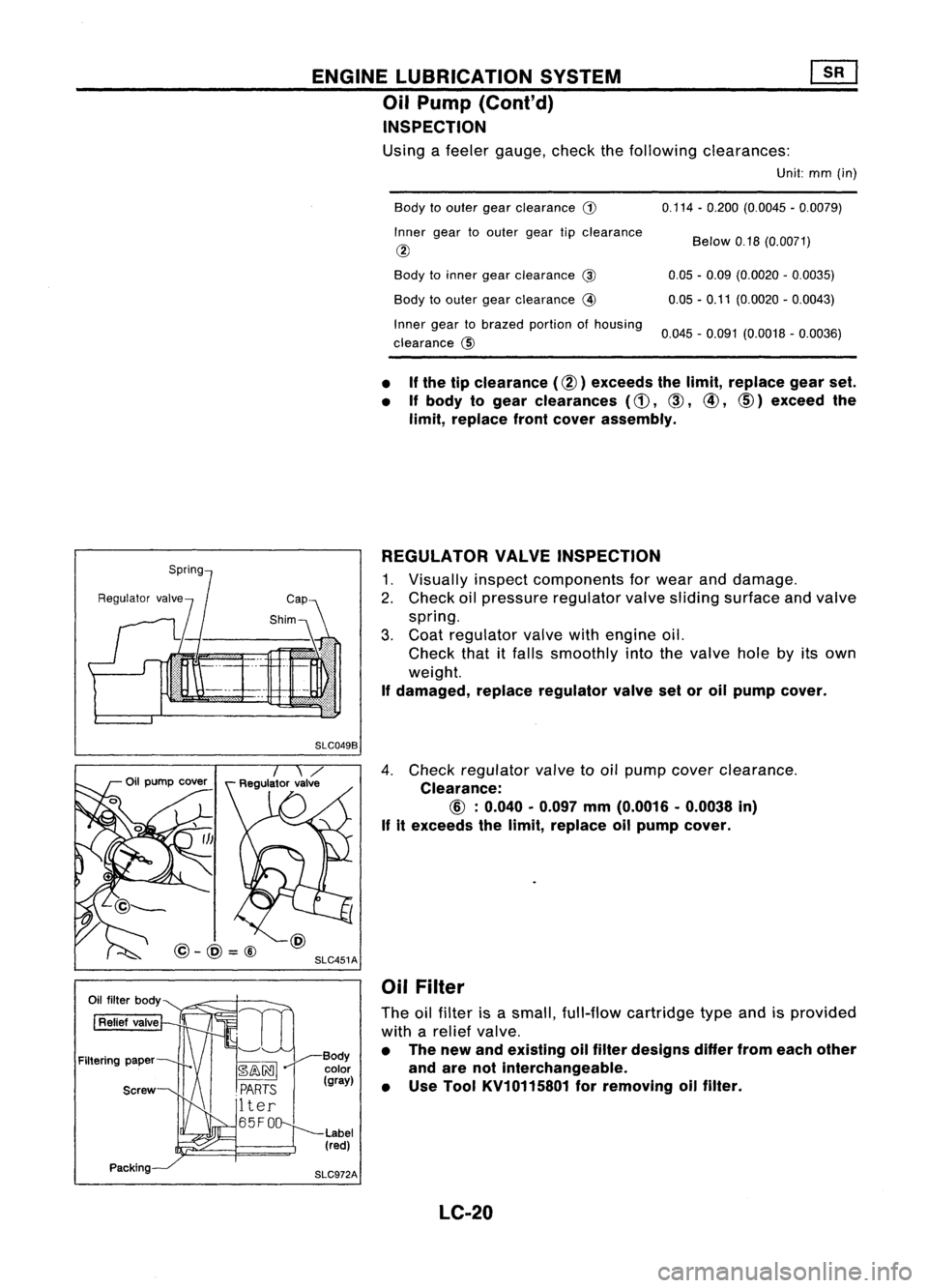

ENGINELUBRICATION SYSTEM

Oil Pump (Cont'd)

INSPECTION

Using afeeler gauge, checkthefollowing clearances:

Unit:mm(in)

Body toouter gearclearance

G)

Inner geartoouter geartipclearance

@

Body toinner gearclearance

@

Body toouter gearclearance

@

Inner geartobrazed portionofhousing

clearance @ 0.114

-0.200 (0.0045 -0.0079)

Below 0.18(0.0071)

0.05 -0.09 (0.0020 -0.0035)

0.05 -0.11 (0.0020 -0.0043)

0.045 -0.091 (0.0018 -0.0036)

• If

the tipclearance (@) exceeds thelimit, replace gearset.

• Ifbody togear clearances

(d),

CID,

@,

CID)

exceed the

limit, replace frontcover assembly.

REGULATOR VALVEINSPECTION

1. Visually inspectcomponents forwear anddamage.

2. Check oilpressure regulator valvesliding surface andvalve

spring.

3. Coat regulator valvewithengine oil.

Check thatitfalls smoothly intothevalve holebyitsown

weight.

If damaged, replaceregulator valvesetoroil pump cover.

SLC049B

SLC451A

@-@=@

4.

Check regulator valvetooil pump cover clearance.

Clearance:

If

itexceeds thelimit, replace oilpump cover.

Oil Filter

The oilfilter isasmall, full-flow cartridge typeandisprovided

with arelief valve.

• The new andeXisting oilfilter designs differfromeach other

and arenotinterchangeable.

• Use Tool KV10115801 forremoving oilfilter.

LC-20

Page 1164 of 1701

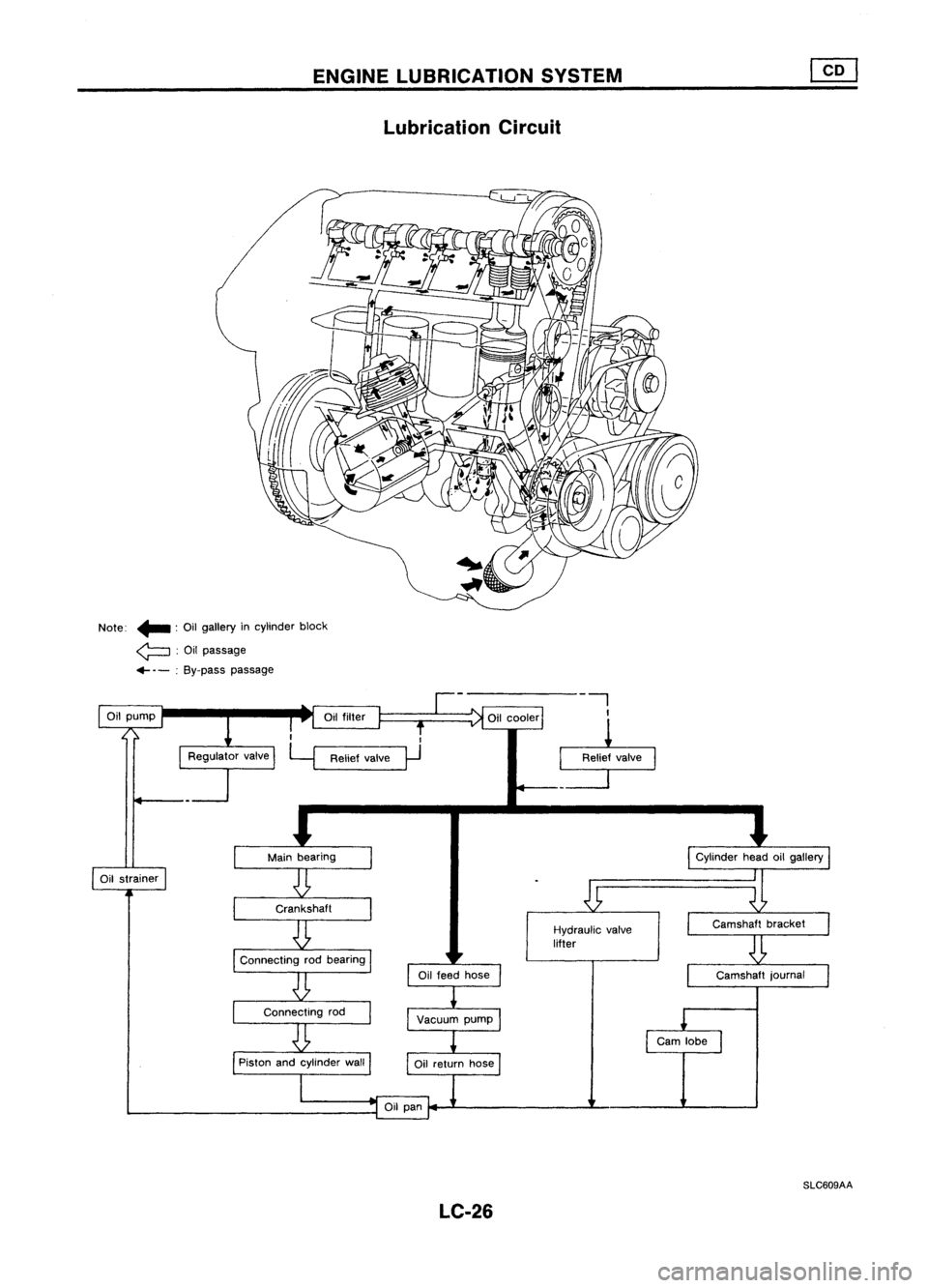

ENGINELUBRICATION SYSTEM

Lubrication Circuit

Note: .. :Oil gallery incylinder block

~ :Oil passage

.... -:By-pass passage

II

Hydraulic valve

lifter

Oil

cooler

Relief valve

0

Oil

filter

Oil

pump

SLC609AA

LC-26

Page 1168 of 1701

ENGINELUBRICATION SYSTEM

Oil Pump (Cont'd)

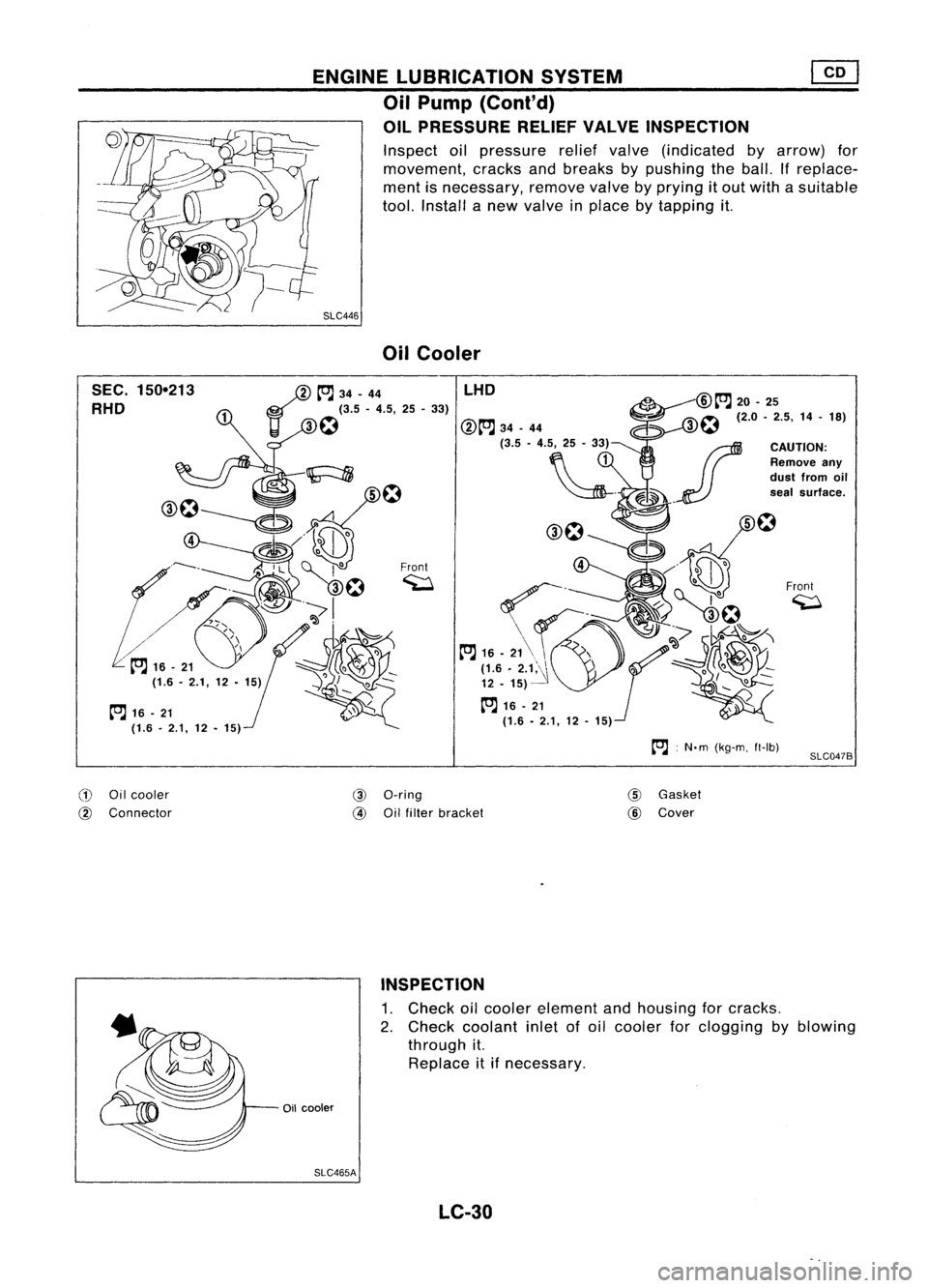

OIL PRESSURE RELIEFVALVEINSPECTION

Inspect oilpressure reliefvalve (indicated byarrow) for

movement, cracksandbreaks bypushing theball. Ifreplace-

ment isnecessary, removevalvebyprying itout with asuitable

tool. Install anew valve inplace bytapping it.

SLC446 OilCooler

SEC. 150-213

RHO

tOJ

16-21

(1.6. 2.1,12•15)

/

tOJ

34-44

11 ~

f:1

(3.5 -4.5, 25-33)

Front ~ LHO

:N.m (kg-m, ft-Ib)

Front

~

SLC047B

CD

Oilcooler

@

Connector

@

a-ring

@

Oilfilter bracket

@

Gasket

@

Cover

INSPECTION

1. Check oilcooler element andhousing forcracks.

2. Check coolant inletofoil cooler forclogging byblowing

through it.

Replace itifnecessary.

Oil cooler

SLC465A LC-30