spark plugs replace NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 777 of 1701

TROUBLEDIAGNOSIS -General Description

Sensors

~ ECMActuators

~~.~ MEF036D

SEF234G Introduction

The engine hasanECM tocontrol majorsystems suchasfuel

control, ignitioncontrol, idleaircontrol system, etc.The ECM

accepts inputsignals fromsensors andinstantly drivesactua-

tors. Itis essential thatboth input andoutput signals areproper

and stable. Atthe same time,itis important thatthere areno

problems suchasvacuum leaks,fouled sparkplugs, orother

problems withtheengine.

It is much moredifficult todiagnose aproblem thatoccurs

intermittently ratherthancontinuously. Mostintermittent prob-

lems arecaused bypoor electric connections orimproper wir-

ing. Inthis case, careful checking ofsuspected circuitsmay

help prevent thereplacement ofgood parts.

A visual checkonlymaynotfind thecause ofthe problems. A

road testwith CONSULT oracircuit testerconnected shouldbe

performed. Followthe"Work Flow"onthe next page.

Before undertaking actualchecks, takejustafew minutes to

talk with acustomer whoapproaches withadriveability com-

plaint. Thecustomer cansupply goodinformation aboutsuch

problems, especially intermittent ones.Findoutwhat symptoms

are present andunder whatconditions theyoccur. A"Diagnos-

tic Worksheet" liketheexample onEC-61 should beused.

Start yourdiagnosis bylooking for"conventional" problems

first. Thiswillhelp troubleshoot driveabilityproblemsonan

electronically controlledenginevehicle.

EC-58

Page 983 of 1701

TROUBLEDIAGNOSIS -General Description

Sensors

~ ECMActuators

~~.~ MEF036D

SEF234G Introduction

The engine hasanECM tocontrol majorsystems suchasfuel

control, ignitioncontrol, idleaircontrol system, etc.The ECM

accepts inputsignals fromsensors andinstantly drivesactua-

tors. Itis essential thatboth input andoutput signals areproper

and stable. Atthe same time,itis important thatthere areno

problems suchasvacuum leaks,fouled sparkplugs, orother

problems withtheengine.

It is much moredifficult todiagnose aproblem thatoccurs

intermittently ratherthancontinuously. Mostintermittent prob-

lems arecaused bypoor electric connections orimproper wir-

ing. Inthis case, careful checking ofsuspected circuitsmay

help prevent thereplacement ofgood parts.

A visual checkonlymaynotfind thecause ofthe problems. A

road testwith CONSULT oracircuit testerconnected shouldbe

performed. Followthe"Work Flow"onthe next page.

Before undertaking actualchecks, takejustafew minutes to

talk with acustomer whoapproaches withadriveability com-

plaint. Thecustomer cansupply goodinformation aboutsuch

problems, especially intermittent ones.Findoutwhat symptoms

are present andunder whatconditions theyoccur. A"Diagnos-

tic Worksheet" liketheexample onEC-267 shouldbeused.

Start yourdiagnosis bylooking for"conventional" problems

first. Thiswillhelp troubleshoot driveabilityproblemsonan

electronically controlledenginevehicle.

EC-264

Page 1194 of 1701

COMPRESSIONPRESSURE

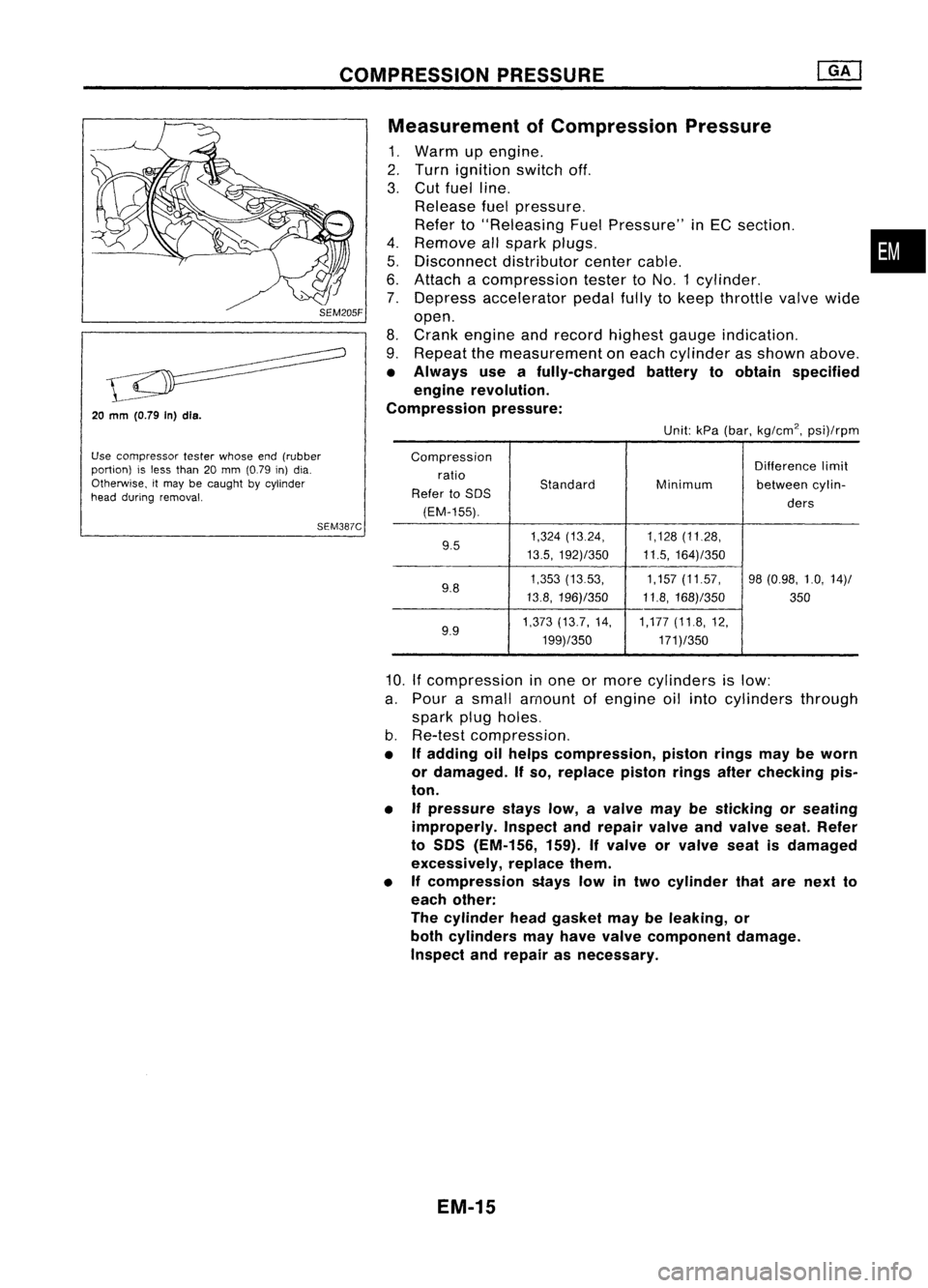

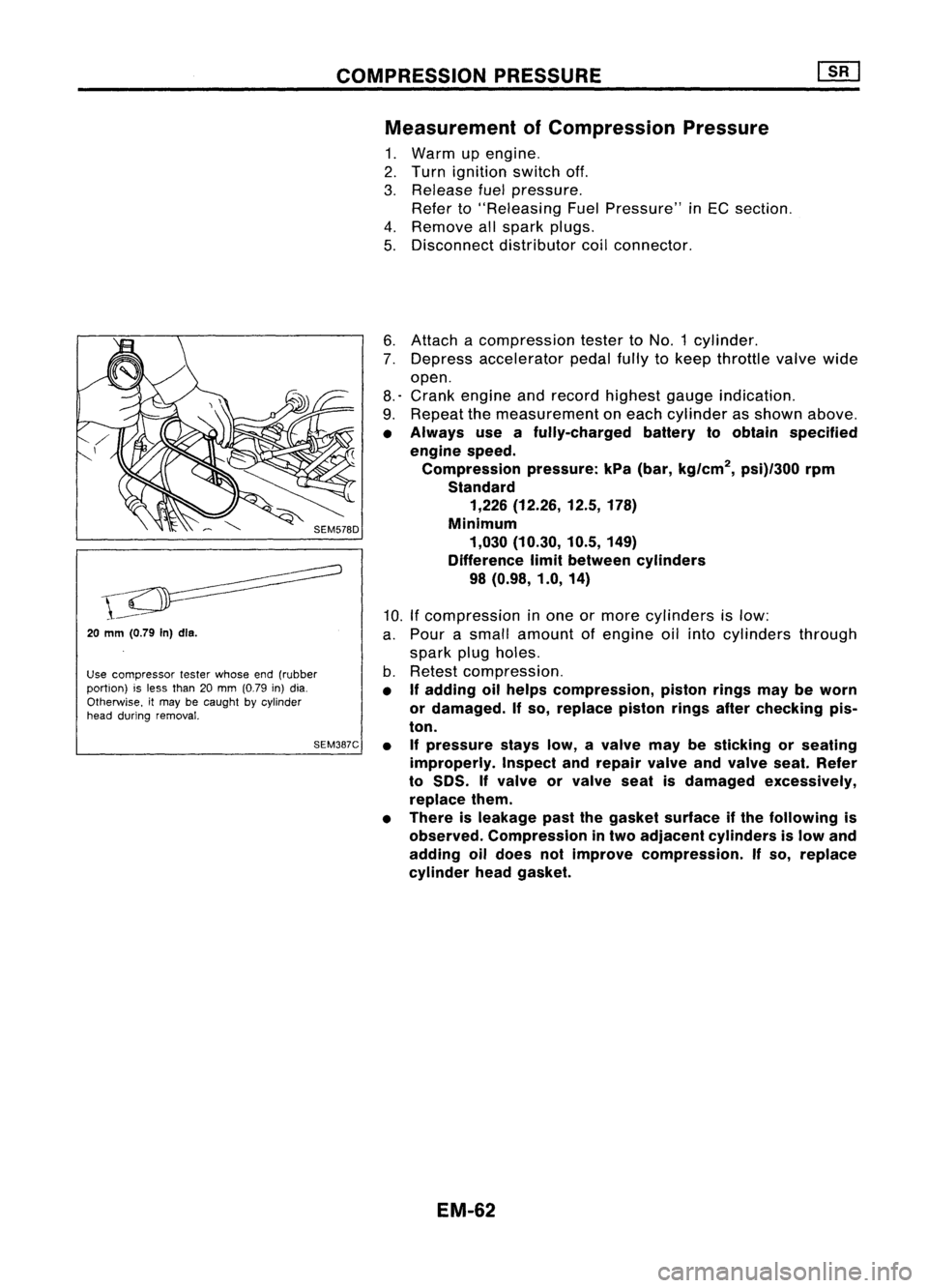

20

mm

(O.79 In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise, itmay becaught bycylinder

head during removal.

SEM387CMeasurement

ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Cut fuel line.

Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section. •

4. Remove allspark plugs.

5. Disconnect distributorcentercable.

6. Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8. Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine revolution.

Compression pressure:

Unit:kPa(bar, kg/cm

2,

psi)/rpm

Compression Differencelimit

ratio

Standard

Refer toSOS Minimum

betweencylin-

(EM-155). ders

9.5 1,324

(13.24, 1,128(11.28,

13.5, 192)/350 11.5,164)/350

9.8 1,353

(1353, 1,157(11.57, 98(0.98, 1.0,14)/

13.8, 196)/350 11.8,168)/350

350

9.9 1,373

(13.7, 14, 1,177(11.8,12,

199)/350 171)/350

10.

If

compression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Re-test compression,

• Ifadding oilhelps compression, pistonringsmaybeworn

or damaged. Ifso, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to SOS (EM-156, 159).Ifvalve orvalve seatisdamaged

excessively, replacethem.

• Ifcompression stayslowintwo cylinder thatarenext to

each other:

The cylinder headgasket maybeleaking, or

both cylinders mayhave valve component damage.

Inspect andrepair asnecessary.

EM-15

Page 1220 of 1701

VALVECLEARANCE

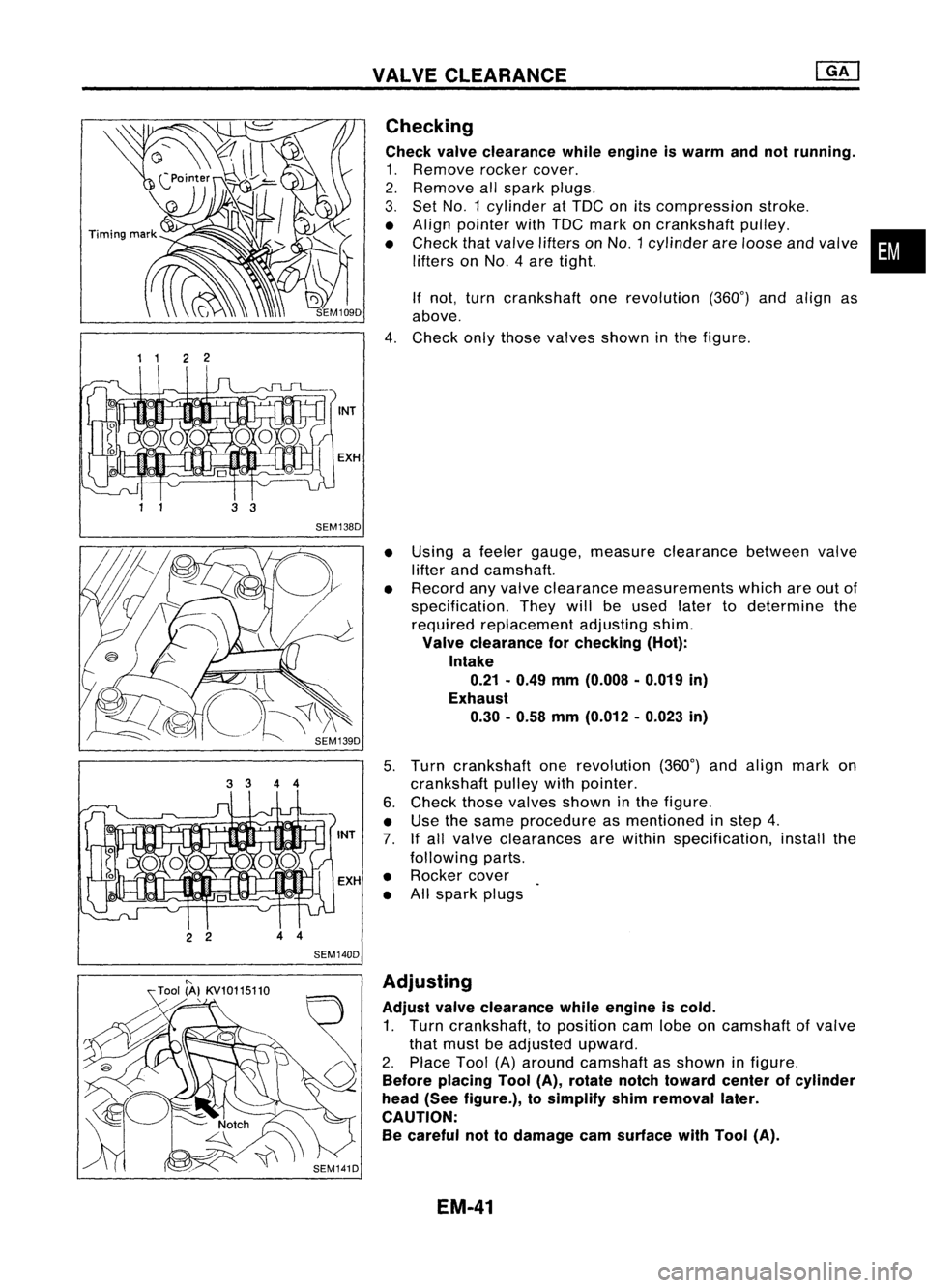

1 1 22

2 2 44

SEM140D Checking

Check valveclearance whileengine iswarm andnotrunning.

1. Remove rockercover.

2. Remove allspark plugs.

3. Set

NO.1

cylinder atTOC onitscompression stroke.

• Align pointer withTOC mark oncrankshaft pulley.

• Check thatvalve lifters on

NO.1

cylinder areloose andvalve

lifters on

NO.4

aretight.

If not, turn crankshaft onerevolution (360°)andalign as

above.

4. Check onlythose valves showninthe figure.

• Using afeeler gauge, measure clearance betweenvalve

lifter andcamshaft.

• Record anyvalve clearance measurements whichareoutof

specification. Theywillbeused latertodetermine the

required replacement adjustingshim.

Valve clearance forchecking (Hot):

Intake 0.21 -0.49 mm(0.008 .0.019 in)

Exhaust 0.30. 0.58mm(0.012 -0.023 in)

5. Turn crankshaft onerevolution (360°)andalign markon

crankshaft pulleywithpointer.

6. Check thosevalves shown inthe figure.

• Use thesame procedure asmentioned instep 4.

7. Ifall valve clearances arewithin specification, installthe

following parts.

• Rocker cover

• Allspark plugs

•

"-

Tool (A}KV10115110

,

SEM141DAdjusting

Adjust valveclearance whileengine iscold.

1. Turn crankshaft, toposition camlobeoncamshaft ofvalve

that must beadjusted upward.

2. Place Tool(A)around camshaft asshown infigure.

Before placing Tool(A),rotate notchtoward centerofcylinder

head (Seefigure.), tosimplify shimremoval later.

CAUTION: Be careful nottodamage camsurface withTool (A).

EM-41

Page 1241 of 1701

COMPRESSIONPRESSURE

Measurement ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section.

4. Remove allspark plugs.

5. Disconnect distributorcoilconnector.

20

mm (0.79

In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise. itmay becaught bycylinder

head during removal.

SEM387C6.

Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8.' Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine speed.

Compression pressure:kPa(bar, kg/cm

2,

psi)/300 rpm

Standard 1,226 (12.26, 12.5,178)

Minimum 1,030 (10.30, 10.5,149)

Difference limitbetween cylinders

98 (0.98, 1.0,14)

10. Ifcompression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Retest compression.

• If

adding oilhelps compression, pistonringsmaybeworn

or damaged.

If

so, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to

50S.

If

valve orvalve seatisdamaged excessively,

replace them.

• There isleakage pastthegasket surface ifthe following is

observed. Compression intwo adjacent cylinders islow and

adding oildoes notimprove compression.

If

so, replace

cylinder headgasket.

EM-62

Page 1261 of 1701

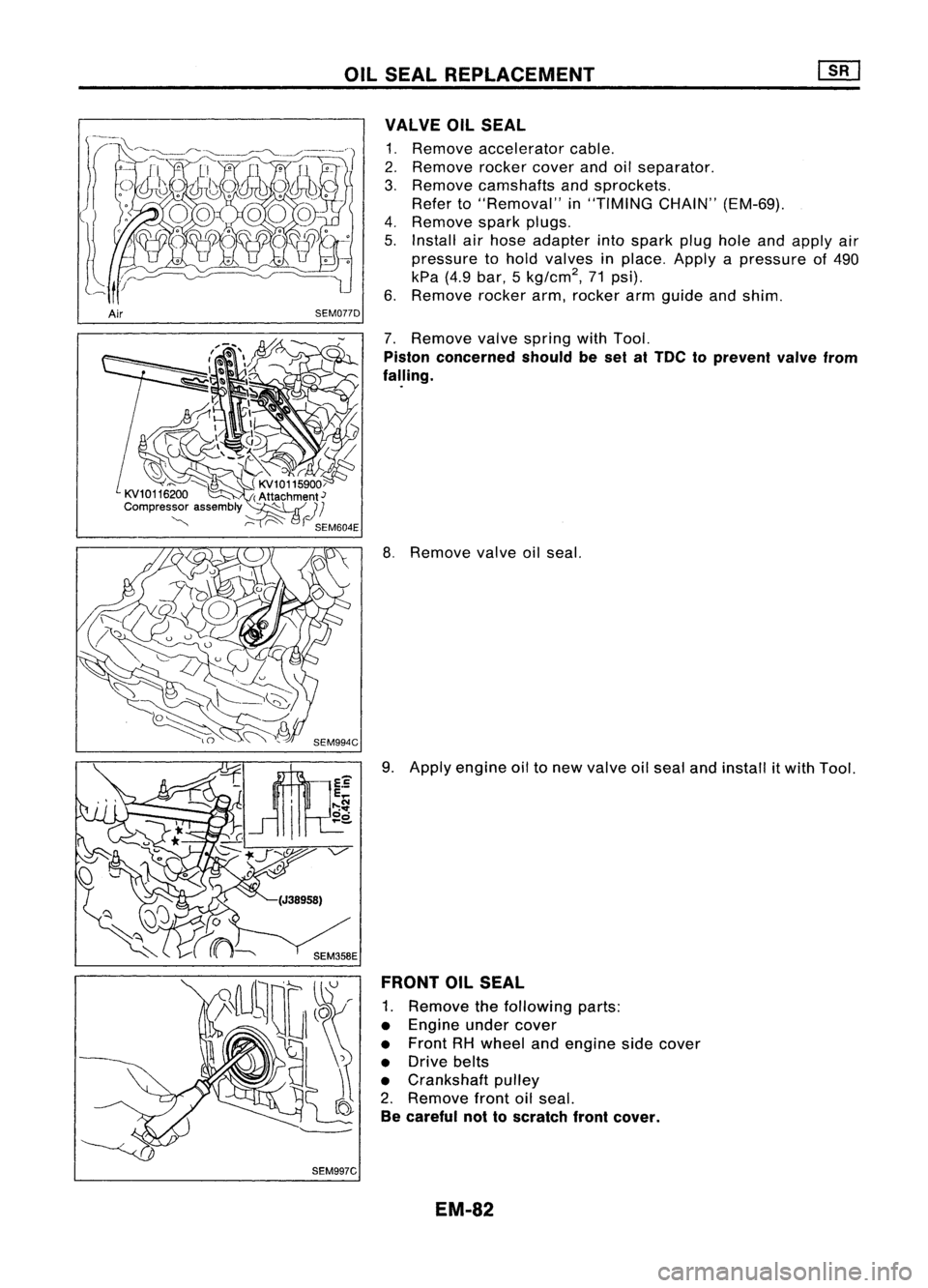

OILSEAL REPLACEMENT

VALVE OILSEAL

1. Remove accelerator cable.

2. Remove rockercoverandoilseparator.

3. Remove camshafts andsprockets.

Refer to"Removal" in"TIMING CHAIN"(EM-69).

4. Remove sparkplugs.

5. Install airhose adapter intospark plugholeandapply air

pressure tohold valves inplace. Applyapressure of490

kPa (4.9bar, 5kg/cm

2,

71psi).

6. Remove rockerarm,rocker armguide andshim.

Air SEM077D

7.Remove valvespring withTool.

Piston concerned shouldbeset atTOe toprevent valvefrom

falling.

8. Remove valveoilseal.

9. Apply engine oiltonew valve oilseal andinstall itwith Tool.

FRONT OILSEAL

1. Remove thefollowing parts:

• Engine undercover

• Front RHwheel andengine sidecover

• Drive belts

• Crankshaft pulley

2. Remove frontoilseal.

Be careful nottoscratch frontcover.

SEM997C EM-82

Page 1487 of 1701

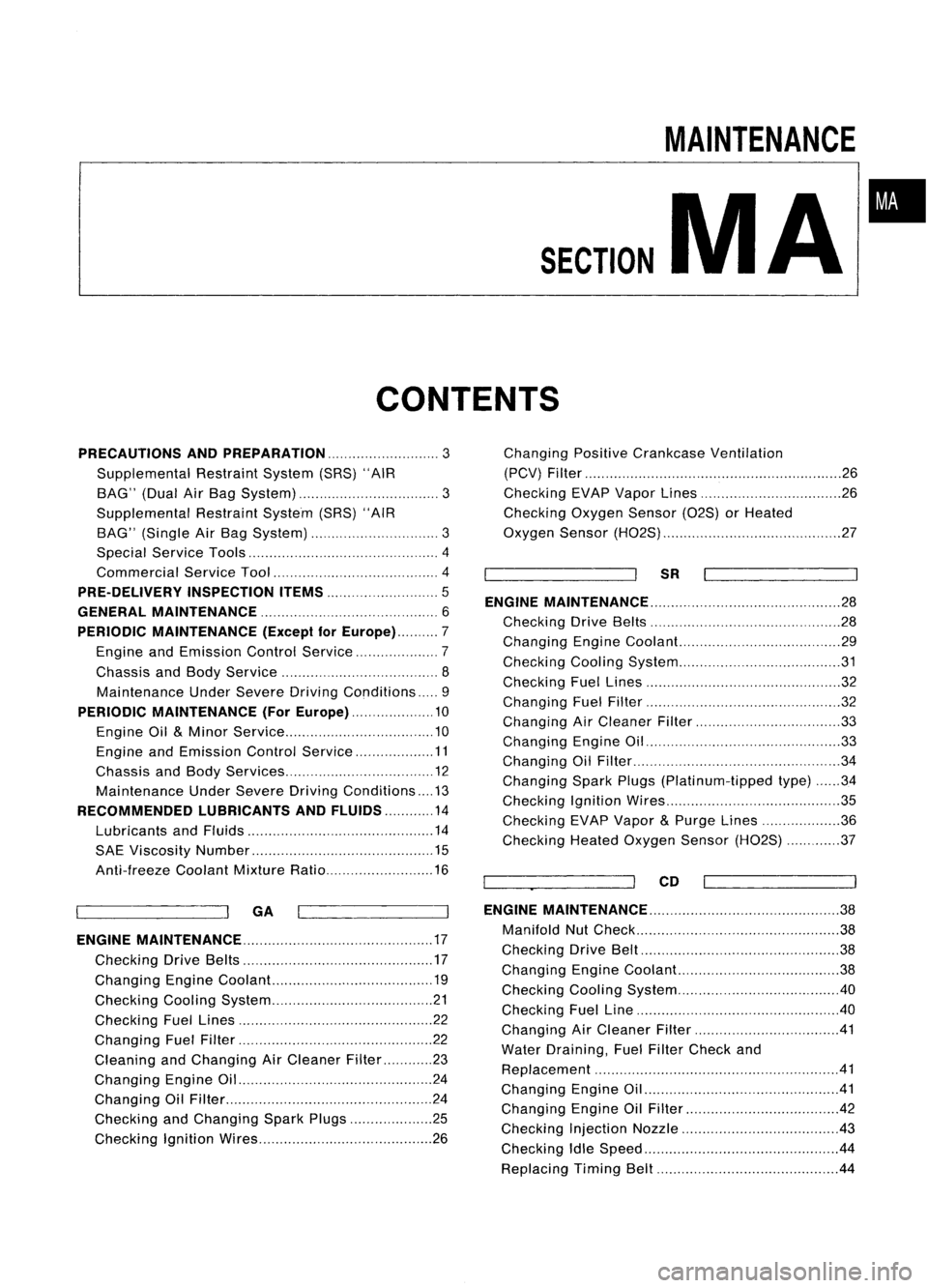

SECTION

CONTENTS

MAINTENANCE

MA

•

PRECAUTIONS ANDPREPARATION

3

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 3

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 3

Special Service Tools 4

Commercial ServiceTool 4

PRE-DELIVERY INSPECTIONITEMS

5

GENERAL MAINTENANCE 6

PERIODIC MAINTENANCE (Exceptfor

Europe) 7

Engine andEmission ControlService 7

Chassis andBody Service 8

Maintenance UnderSevere DrivingConditions 9

PERIODIC MAINTENANCE (ForEurope) 10

Engine Oil

&

Minor Service 10

Engine andEmission ControlService 11

Chassis andBody Services 12

Maintenance UnderSevere Driving Conditions 13

RECOMMENDED LUBRICANTSANDFLUIDS 14

Lubricants andFluids 14

SAE Viscosity Number 15

Anti-freeze CoolantMixtureRatio 16

~ --ll

GA

I I

ENGINE MAINTENANCE 17

Checking DriveBelts 17

Changing EngineCoolant... 19

Checking CoolingSystem 21

Checking FuelLines 22

Changing FuelFilter 22

Cleaning andChanging AirCleaner Filter 23

Changing EngineOil 24

Changing OilFilter 24

Checking andChanging SparkPlugs 25

Checking IgnitionWires 26Changing

PositiveCrankcase Ventilation

(PCV) Filter 26

Checking EVAPVapor Lines 26

Checking OxygenSensor(02S)orHeated

Oxygen Sensor(H02S) 27

~ --ll

SR

I I

ENGINE MAINTENANCE 28

Checking DriveBelts 28

Changing EngineCoolant... 29

Checking CoolingSystem 31

Checking FuelLines 32

Changing FuelFilter 32

Changing AirCleaner Filter 33

Changing EngineOil 33

Changing OilFilter 34

Changing SparkPlugs(Platinum-tipped type)34

Checking IgnitionWires 35

Checking EVAPVapor

&

Purge Lines 36

Checking HeatedOxygen Sensor(H02S) 37

~_~ ..-JI

CD

I I

ENGINE MAINTENANCE

38

Manifold NutCheck 38

Checking DriveBelt 38

Changing EngineCoolant. 38

Checking CoolingSystem .40

Checking FuelLine .40

Changing AirCleaner Filter 41

Water Draining, FuelFilter Check and

Replacement 41

Changing EngineOil .41

Changing EngineOilFilter 42

Checking InjectionNozzle 43

Checking IdleSpeed .44

Replacing TimingBelt 44

Page 1493 of 1701

PERIODICMAINTENANCE (ExceptforEurope)

The following tablesshowthenormal maintenance schedule.Depending uponweather andatmospheric

conditions, varyingroadsurfaces, individual drivinghabitsandvehicle usage,additional ormore fre-

quent maintenance mayberequired.

Periodic maintenance beyondthelast period shown onthe tables requires similarmaintenance .

Engine andEmission ControlService

•

Abbreviations: I

=

Inspect andcorrect orreplace asnecessary. R

MAINTENANCE OPERATION

Perform eitheratnumber ofkilometers (miles)

or months, whichever comestirst. km

x1,000

(Miles x1,000)

Months

Replace.

A

=

Adjust, C

=

Clean.

MAINTENANCE INTERVAL

10 20 3040

506070

80

Reference page

(6) (12) (18)

(24)(30)(36)(42)(48)

6 12 18

24

3036

42 48

Underhood andunder vehicle GA

SR

Intake

&

exhaust valveclearance (GA15DE

&

GA16DE engines) SeeNOTE (1)

EM41

-

Drive belts

II

MA 17

24

Engine anti-Ireeze coolant(Ethylene glycolbase)(LLC) RRMA 1929

Engine coolant (Softwater) RRR

R

R R

R

RMA

1929

Cooling system

I

I

I

I

MA 2131

Fuel lines

I

I

MA

22

32

Air cleaner filter(Drypaper type)*

CC

C RC CC RMA 23

-

Air cleaner filter(Viscous papertype)* R

RMA

2333

Engine oil(Use APISE,SF.SGorSH oil)*

R

RRRR R

RR

MA 24

33

Engine oilfilter* R

R R

R

R RRRMA

2433

Fuel filter* R

RMA

22

32

Spark plugs(except Platinum-tipped type) R

RMA

25

-

Spark plugs(platinum-tipped type) Replaceevery100,000 km(60.000 miles). MA

-

34

Ignition wires

I

I

MA

2635

PCV filter* R

RMA

26

-

Vapor lines

I

I

MA

26

36

(Heated) OxygenSensor

I

I

MA 2737

NOTE: (1)

If

valve noiseincreases, checkvalveclearance.

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance undersevere driv-

ing conditions".

MA-7

Page 1497 of 1701

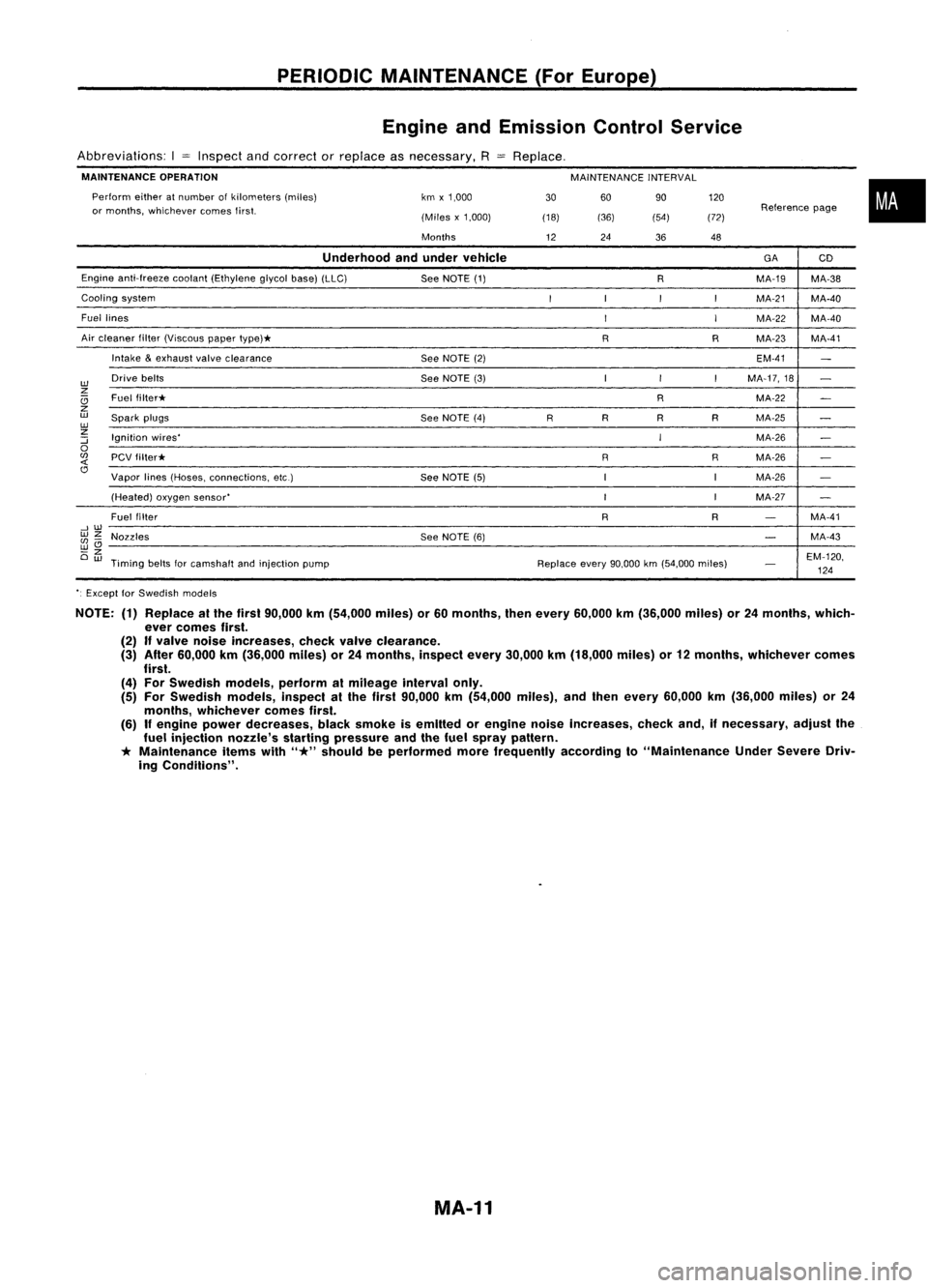

PERIODICMAINTENANCE (ForEurope)

Engine andEmission ControlService

Abbreviations: I

=

Inspect andcorrect orreplace asnecessary,

R

MAINTENANCE OPERATION

MAINTENANCEINTERVAL

60 90

(36) (54)

Perform

eitheratnumber ofkilometers (miles)

or months, whichever comesfirst. km

x1,000

(Miles x1,000)

Months

Replace,

30

(18)

12 24

36120

(72) 48

Reference

page

•

Underhood andunder vehicle

GA

CD

Engine anti-freeze cootant(Ethylene glycolbase)(LLC)

SeeNOTE (1)

RMA-19

MA-38

Cooling system

I

I

I

I

MA-21 MA-40

Fuel lines

I

I

MA-22

MA-40

Air cleaner filter(Viscous papertype)*

RRMA-23 MA-41

Intake

&

exhaust valveclearance

SeeNOTE (2) EM-41

-

w

Drive

belts

SeeNOTE (3) I

I

I

MA-17,18

-

z

Ci

Fuel

filter* RMA-22

-

z

w

Spark plugs

SeeNOTE (4)

RR

RRMA-25

-

w

z

Ignition wires'

IMA-26

:::;

-

0

(fJ

PCVfilter* RRMA-26

-

<{

Cl

Vapor lines(Hoses, connections, etc.)

SeeNOTE (5) IIMA-26

-

(Heated) oxygensensor'

I

IMA-27

-

Fuel filter

RR

-

MA-41

--,w

wz

Nozzles SeeNOTE (6)

-

MA-43

(fJ-

wCl

-z

EM-120,

Ow

Timing beltsforcamshalt andinjection pump Replaceevery90,000 km(54,000 miles)

-

124

'. Except forSwedish models

NOTE: (1)Replace atthe first 90,000 km(54,000 miles)or60 months, thenevery 60,000 km(36,000 miles)or24 months, which-

ever comes first.

(2)

If

valve noise Increases, checkvalveclearance.

(3) After 60,000 km(36,000 miles)or24 months, inspectevery30,000 km(18,000 miles)or12 months, whichever comes

first.

(4) For Swedish models,performalmileage intervalonly.

(5) For Swedish models,inspectalthe first 90,000 km(54,000 miles),andthen every 60,000 km(36,000 miles)or24

months, whichever comesfirst.

(6)

If

engine powerdecreases, blacksmoke isemitted orengine noiseincreases, checkand,ifnecessary, adjustthe

fuel injection nozzle'sstartingpressure andthefuel spray pattern.

*

Maintenance itemswith

"*"

should beperformed morefrequently accordingto"Maintenance UnderSevere Driv-

ing Conditions".

MA-11

Page 1511 of 1701

ENGINEMAINTENANCE ~

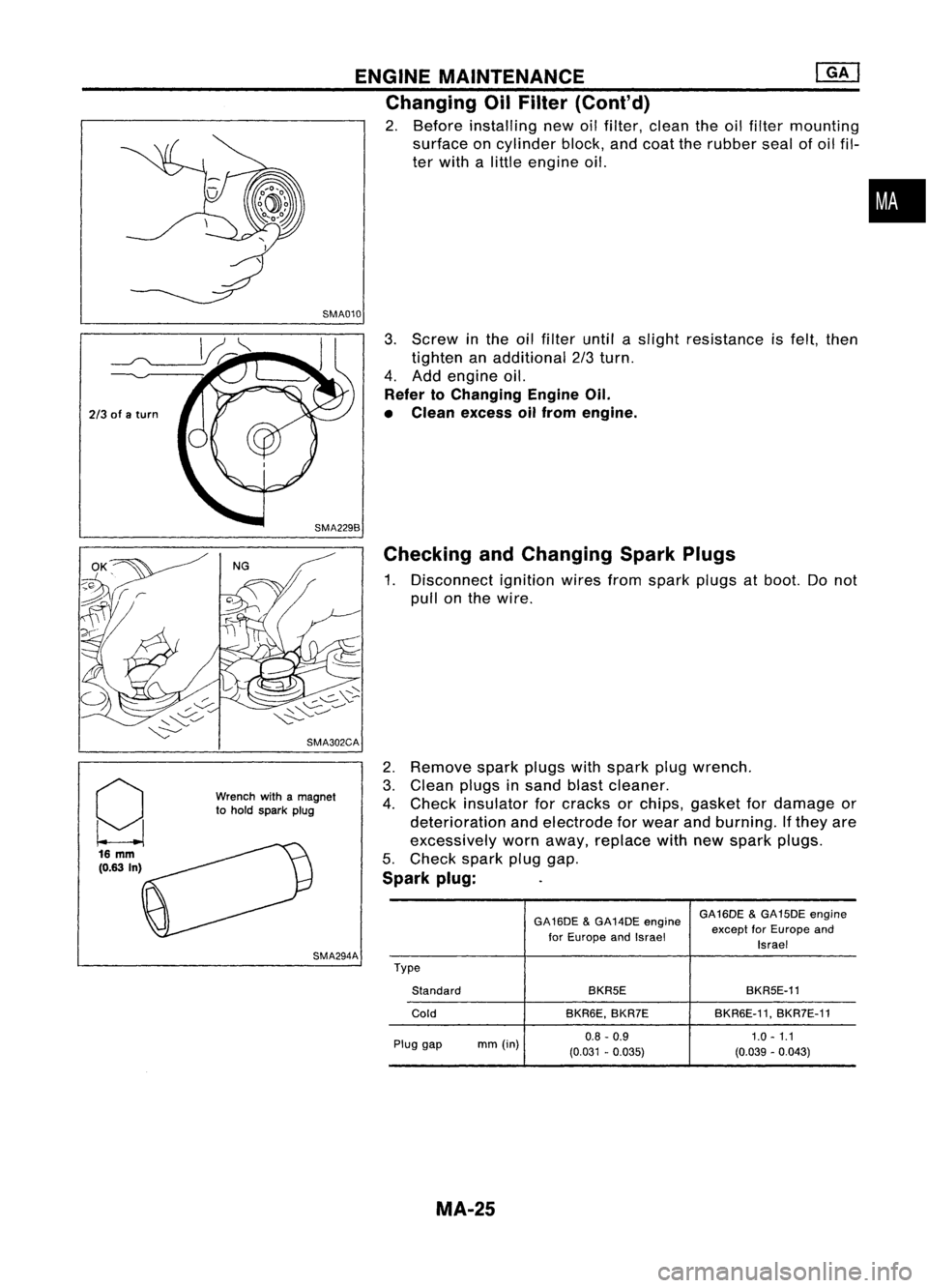

Changing OilFilter (Cont'd)

2. Before installing newoilfilter, clean theoilfilter mounting

surface oncylinder block,andcoat therubber sealofoil fil-

ter with alittle engine oil.

SMA010

•

2/3 ofaturn

g 16

mm

(0.63 In) SMA302CA

Wrench withamagnet

to hold spark plug

SMA294A

3.

Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Checking andChanging SparkPlugs

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

2. Remove sparkplugswithspark plugwrench.

3. Clean plugsinsand blastcleaner.

4. Check insulator forcracks orchips, gasket fordamage or

deterioration andelectrode forwear andburning. Ifthey are

excessively wornaway, replace withnewspark plugs.

5. Check sparkpluggap.

Spark plug:

GA16DE&GA14DE engine GA16DE

&GA15DE engine

for Europe andIsrael except

forEurope and

Israel

Type Standard BKR5E

BKR5E-11

Cold BKR6E,BKR7E BKR6E-11,

BKR7E-11

Plug gap mm(in) 0.8

-0.9 1.0-1.1

(0.031 -0.035) (0.039-0.043)

MA-25