SMA476

Side

electrode

It, ENGINE

MAINTENANCE ~

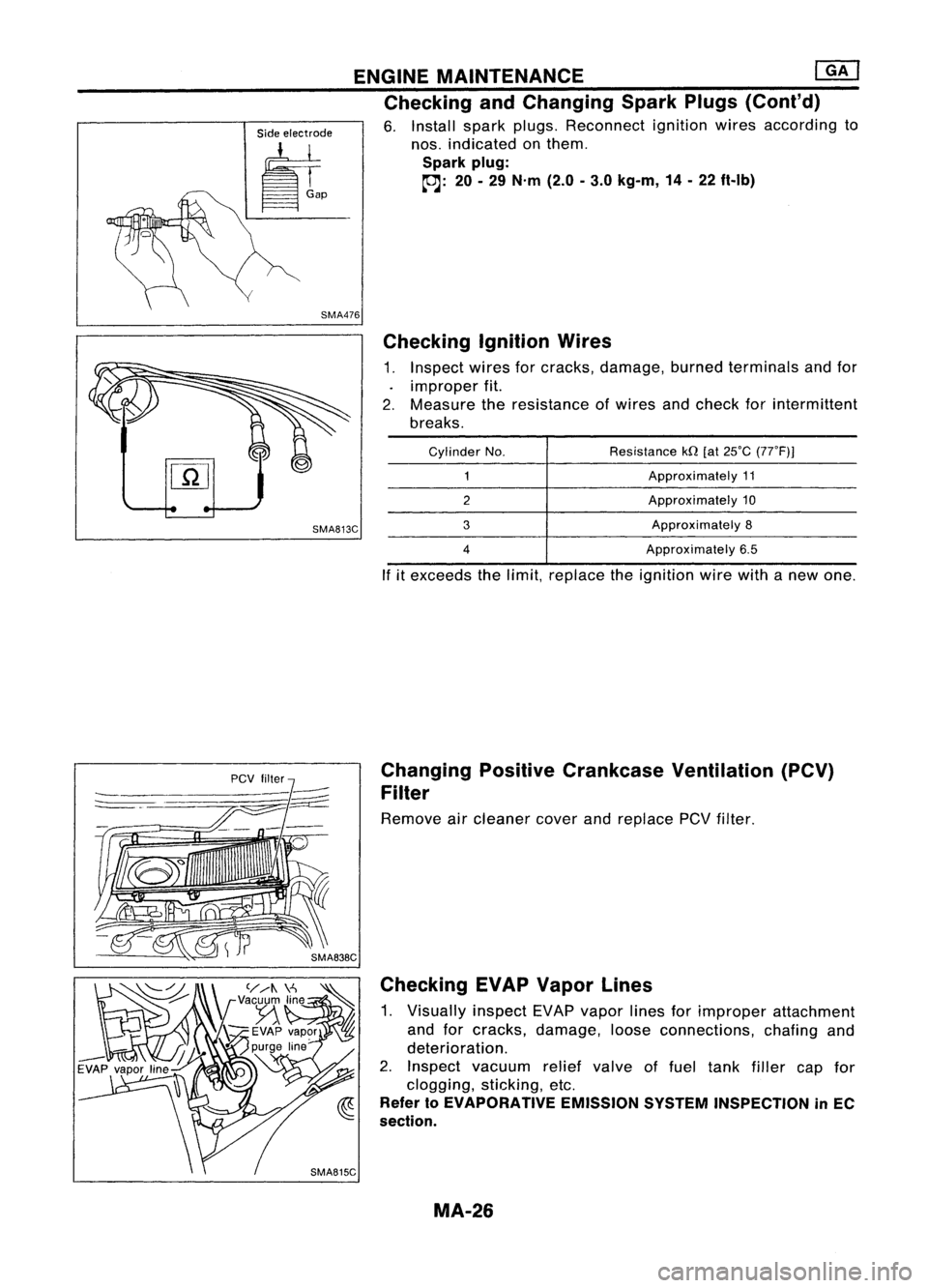

Checking andChanging SparkPlugs(Cont'd)

6. Install sparkplugs. Reconnect ignitionwiresaccording to

nos. indicated onthem.

Spark plug:

~: 20-29 N'm (2.0-3.0 kg-m, 14-22 ft-Ib)

Checking IgnitionWires

1. Inspect wiresforcracks, damage, burnedterminals andfor

improper fit.

2. Measure theresistance ofwires andcheck forintermittent

breaks.

SMA813C

Cylinder

No.

2

3

4

Resistance

kQ[at25'C (77'F)]

Approximately 11

Approximately 10

Approximately 8

Approximately 6.5

If itexceeds thelimit, replace theignition wirewithanew one.

Changing PositiveCrankcase Ventilation (PCV)

Filter

Remove aircleaner coverandreplace

pev

filter.

Checking EVAPVapor Lines

1. Visually inspectEVAPvapor linesforimproper attachment

and forcracks, damage, looseconnections, chafingand

deterioration.

2. Inspect vacuum reliefvalve offuel tank filler capfor

clogging, sticking,etc.

Refer

10

EVAPORATIVE EMISSIONSYSTEMINSPECTION inEC

section.

MA-26

g

16

mm

(0.63

In)

Wrench

withamagnet

to hold spark plug

ENGINE

MAINTENANCE

lliJ

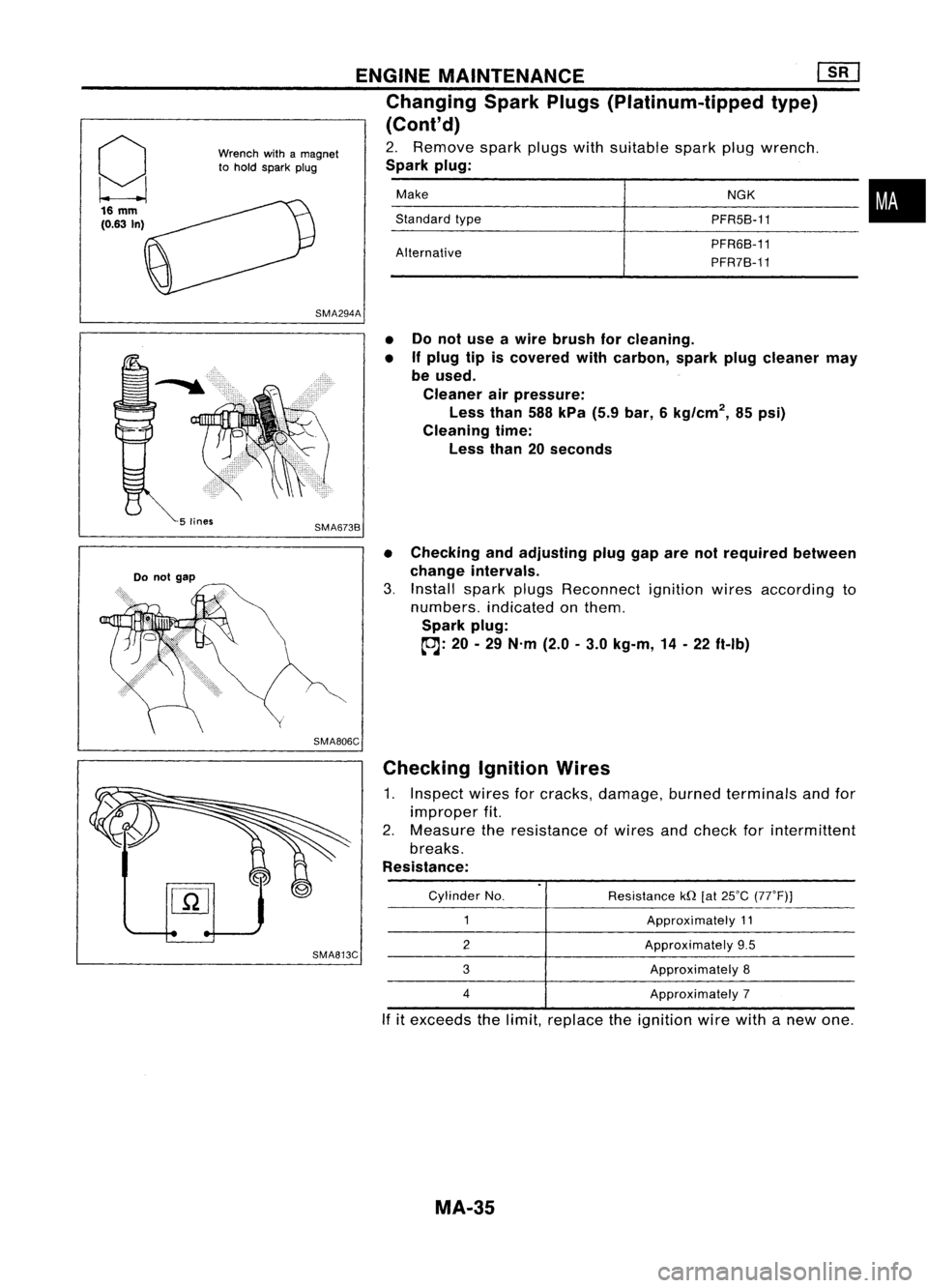

Changing SparkPlugs(Platinum-tipped type)

(Cont'd)

2. Remove sparkplugswithsuitable sparkplugwrench.

Spark plug:

Make NGK

•

Standard

type

PFR5B-11

Alternative PFR6B-11

PFR7B-11

SMA294A

Do

not

gap •

Donot use awire brush forcleaning.

• If

plug tipiscovered withcarbon, sparkplugcleaner may

be used.

Cleaner airpressure:

Less than588kPa (5.9bar, 6kg/cm

2,

85psi)

Cleaning time:

Less than20seconds

• Checking andadjusting pluggaparenotrequired between

change intervals.

3. Install sparkplugsReconnect ignitionwiresaccording to

numbers. indicatedonthem.

Spark plug:

~: 20-29 N'm (2.0-3.0 kg-m, 14-22 ft-Ib)

SMA806C Checking IgnitionWires

1. Inspect wiresforcracks, damage, burnedterminals andfor

improper fit.

2. Measure theresistance ofwires andcheck forintermittent

breaks.

Resistance:

SMA813C

Cylinder

No.

2

3

4

Resistance

kQ[at25°C (77°F)]

Approximately 11

Approximately 9.5

Approximately 8

Approximately 7

If itexceeds thelimit, replace theignition wirewithanew one.

MA-35